Pepperl+Fuchs SLCT Series, SLCT*/35 Series, SCLT14, SCLT30, SCLT60 Original Instructions Manual

...Page 1

AOPD

3AA2

FACTORY AUTOM ATION

ORIGINAL INSTRUCTIONS

SLCT* and SLCT*/35

Safety Light Curtains

Page 2

SLCT* and SLCT*/35 safety light curtains

With regard to the supply of products, the current issue of the following document is applicable: The

General Terms of Delivery for Products and Services of the Electrical Industry, published by the

Central Association of the Electrical Industry (Zentralverband Elektrotechnik und Elektroindustrie

(ZVEI) e.V.) in its most recent version as well as the supplementary clause: "Expanded reservation

of proprietorship"

Page 3

SLCT* and SLCT*/35 safety light curtains

Contents

1 Introduction......................................................................... 5

1.1 Content of this Document .............................................................................5

1.2 Symbols Used...............................................................................................5

2 Safety information .............................................................. 7

3 Product Description ........................................................... 9

3.1 Use and Application ......................................................................................9

3.2 Indicators and Operating Controls ..............................................................11

3.3 Interfaces and Connections ........................................................................11

3.4 Scope of Delivery........................................................................................13

4 Installation......................................................................... 14

4.1 Planning and Preparation............................................................................14

4.2 Mounting.....................................................................................................18

4.3 Reflection....................................................................................................21

4.4 Connection and Operating Mode Setting ....................................................22

4.4.1 Signal Outputs on the Receiver Unit .......................................................23

4.4.2 Signal Inputs on the Transmitter Unit ......................................................24

4.4.3 Signal Inputs on the Receiver Unit..........................................................25

4.4.4 Typical Circuits .......................................................................................27

5 Commissioning................................................................. 28

5.1 Functional Testing .......................................................................................28

5.2 Multiple Positions ........................................................................................29

6 Maintenance and Repair .................................................. 31

6.1 Maintenance ...............................................................................................31

6.2 Periodic Checks ..........................................................................................31

6.3 Repairs .......................................................................................................32

7 Troubleshooting................................................................ 33

7.1 Troubleshooting ..........................................................................................33

8 Appendix ........................................................................... 35

8.1 Technical Data ............................................................................................35

8.1.1 Standards and Data for Functional Safety...............................................38

8.2 Profile Lengths and Mass............................................................................39

8.3 Dimensional Drawing ..................................................................................41

8.4 Type Code...................................................................................................41

8.5 Application Checklist...................................................................................47

271695 2017-12

3

Page 4

SLCT* and SLCT*/35 safety light curtains

Contents

8.6 Accessories................................................................................................ 49

8.6.1 Mounting Aid OMH-SLCT-01 ................................................................. 55

8.6.2 Mounting Aid OMH-SLCT-02 ................................................................. 55

8.6.3 Mounting Brackets OMH-SLCT-03 and OMH-SLCT-04 ......................... 56

8.6.4 Mounting Aid OMH-SLCT-05 ................................................................ 56

8.6.5 OMH-SLCT-12 -500 Muting Arm with Round Rod.................................. 56

8.6.6 OMH-07-01 Mounting Bracket for Circular Profiles ................................ 56

8.6.7 OMH-SLCT-100-xxxx Mounting Profile for Floor Mounting .................... 57

8.6.8 OMH-SLCT-110-xxxx Mounting Profile with Decorative Cover (Front) ... 57

8.6.9 OMH-SLCT-120-xxx Lateral Protective Covers for Mounting Profile ...... 57

8.6.10 OMH-SLCT-200 Floor Mount for Soil Column/Mounting Profile ............. 57

8.6.11 SLCT-M-01-xxxx Inclined Mirror for 90° Deflection ................................ 58

8.6.12 Alignment Aid ........................................................................................ 58

8.6.13 Test Rod ................................................................................................ 59

8.6.14 Connection Cables ................................................................................ 60

4

271695 2017-12

Page 5

SLCT* and SLCT*/35 safety light curtains

Introduction

1 Introduction

1.1 Content of this Document

This document contains safety-relevant information for usage of the device. You

need this information to use your product throughout the applicable stages of the

product life cycle. These can include the following:

■

Product identification

■

Delivery, transport, and storage

■

Mounting and installation

■

Commissioning and operation

■

Maintenance and repair

■

Troubleshooting

■

Dismounting

■

Disposal

Note!

For full information on the product, refer to the further documentation on the

Internet at www.pepperl-fuchs.com.

The documentation consists of the following parts:

■

Original instructions (present document)

■

EU declaration of conformity

■

Datasheet

For more information about Pepperl+Fuchs products with functional safety, see

www.pepperl-fuchs.com/sil.

1.2 Symbols Used

This document contains symbols for the identification of warning messages and of

informative messages.

Warning Messages

You will find warning messages, whenever dangers may arise from your actions. It

is mandatory that you observe these warning messages for your personal safety

and in order to avoid property damage.

Depending on the risk level, the warning messages are displayed in descending

order as follows:

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

271695 2017-12

5

Page 6

SLCT* and SLCT*/35 safety light curtains

Introduction

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and

plants, or result in their complete failure.

Informative Symbols

Note!

This symbol brings important information to your attention.

Action

This symbol indicates a paragraph with instructions. You are prompted to perform

an action or a sequence of actions.

6

271695 2017-12

Page 7

SLCT* and SLCT*/35 safety light curtains

Safety information

2 Safety information

Read the following information carefully and follow this information when working

with the device. Failure to observe the safety information and warning messages

in this documentation can lead to malfunctions of the safety devices of the

machines or plants in which they are fitted.

This can result in serious personal injury or death.

Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation, maintenance,

and dismounting lies with the plant operator.

The personnel must be appropriately trained and qualified in order to carry out

mounting, installation, commissioning, operation, maintenance, and dismounting

of the device. The trained and qualified personnel must have read and

understood the instruction manual.

Prior to using the product make yourself familiar with it. Read the instruction

manual carefully.

Reference to Further Documentation

Observe laws, standards, and directives applicable to the intended use and the

operating location.

If you use the device in safety-related applications, observe the requirements for

functional safety. You can find these requirements in the functional safety

documentation under www.pepperl-fuchs.com.

Intended Use

The device is only approved for appropriate and intended use. Ignoring these

instructions will void any warranty and absolve the manufacturer from any liability.

If you use the device in safety-related applications, observe the information for

safety function and safe state.

The safety light curtain may only be used in accordance with its intended purpose

as noncontact electro-sensitive protective equipment (ESPE) for securing

sources of danger and hazardous areas on machines and plants.

Ensure that this device is used only in accordance with the technical specification

described in these instructions. The device must not be used outdoors or in an

explosion-hazardous area.

Plant design

Before selecting and using the product, an assessment must be made to

determine whether this product is suitable for the intended application.

Pepperl+Fuchs has no influence on the selection and use of this product. The

warranty therefore only covers the consistent quality of the product.

Mounting and installation

If you install the device in safety-related applications, observe the requirements for

functional safety.

271695 2017-12

7

Page 8

SLCT* and SLCT*/35 safety light curtains

Safety information

Operation, maintenance, repair

If you are operating the device in applications related to safety, note the

requirements for functional safety.

Do not remove the nameplate.

Do not remove the warning markings.

Record the results of inspections and maintenance carefully.

Do not repair, modify, or manipulate the device.

If there is a defect, always replace the device with an original device.

Only use accessories specified by the manufacturer.

Delivery, Transport, Disposal

Keep the original packaging. Always store and transport the device in the original

packaging.

Disposing of device, packaging, and possibly contained batteries must be in

compliance with the applicable laws and guidelines of the respective country.

8

271695 2017-12

Page 9

SLCT* and SLCT*/35 safety light curtains

Product Description

3 Product Description

3.1 Use and Application

Product description

The SLCS safety light curtain is noncontact electro-sensitive protective equipment

(ESPE) for securing danger zones and hazardous areas.

The SLCT safety light curtain consists of a transmitter unit and receiver unit. The

protection field is formed by infrared light beams sent from the transmitter unit to

the receiver unit. The offset between the individual light beams determines the

minimum obstacle size (14 mm, 30 mm, 60 mm, or 90 mm) that can be reliably

detected in the entire protection field range.

The transmitter unit contains a certain number of transmitter diodes that emit

protective beams. The number of transmitter diodes is determined by the

protection field height and the size of the obstacle. The function mode A/B

enables the use of 2 adjacent safety light curtains.

The receiver unit detects the transmission beams, controls the two OSSD (Output

Signal Switching Devices) safety outputs and carries out tests to ensure safety.

In addition to the displays behind the front panel of the receiver unit, there is also a

PNP output, which indicates operational readiness, a dirty lens, or fault states. If

an internal fault occurs in the receiver unit, this output switches on and off at a

frequency of 5 Hz. If an external fault occurs, this output switches on and off at a

frequency of 1 Hz. If the received signal is too weak (e.g., due to a dirty lens), the

output switches on and off at a frequency of 2.5 Hz.

The test input on the transmitter unit initiates a test sequence. Activate the input by

applying 24 VDC to the input for a defined time span.

The relay monitor (RM) and restart (RI) inputs allow monitoring of the switching

elements connected externally to the OSSDs and activation of the startup/restart

interlock function.

271695 2017-12

9

Page 10

SLCT* and SLCT*/35 safety light curtains

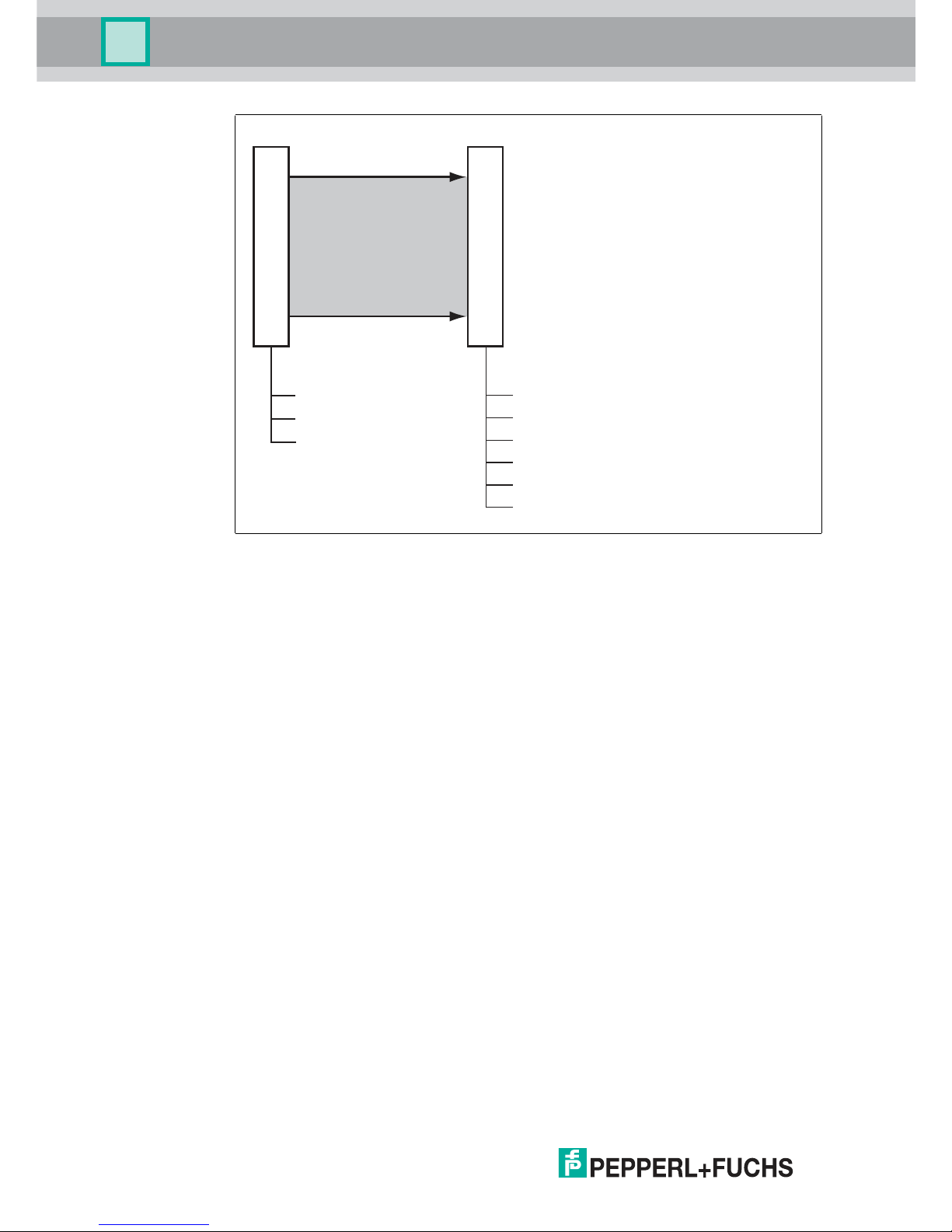

Transmitter unit

24 V supply 24 V supply

OSSDs

Status / Select RI-RM

Restart Interlock (RI)

Relay Monitor (RM)

Beam Code A/B

Protection

Receiver unit

Test

Beam Code A/B

Product Description

Figure 3.1 Schematic diagram of a detection device

Product features

■

Type 4 ESPE in accordance with IEC/EN 61496-1

■

Self-testing

■

Obstacle size, depending on type, 14 mm, 30 mm, 60 mm, 90 mm

■

Protection field heights up to 1200 mm (SCLT14)

■

Protection field heights up to 2400 mm (SLCT30, SLCT60, SLTS90)

■

Protection field grids 100 mm (SLCT14, SLCT30)

■

Protection field grids 300 mm (SLCT60, SLCT90)

■

Selectable startup/restart interlock

■

Selectable relay monitor

■

Simple layout

■

Two OSSDs

Further information about the product

The following information about the SLCT series is provided in the appendix at the

end of this document:

Technical data: .

Available profile lengths/dimensions: see chapter 8.2.

Dimensional drawings: see chapter 8.3.

Product characteristics by type code: see chapter 8.4.

10

Available accessories: see chapter 8.6.

271695 2017-12

Page 11

SLCT* and SLCT*/35 safety light curtains

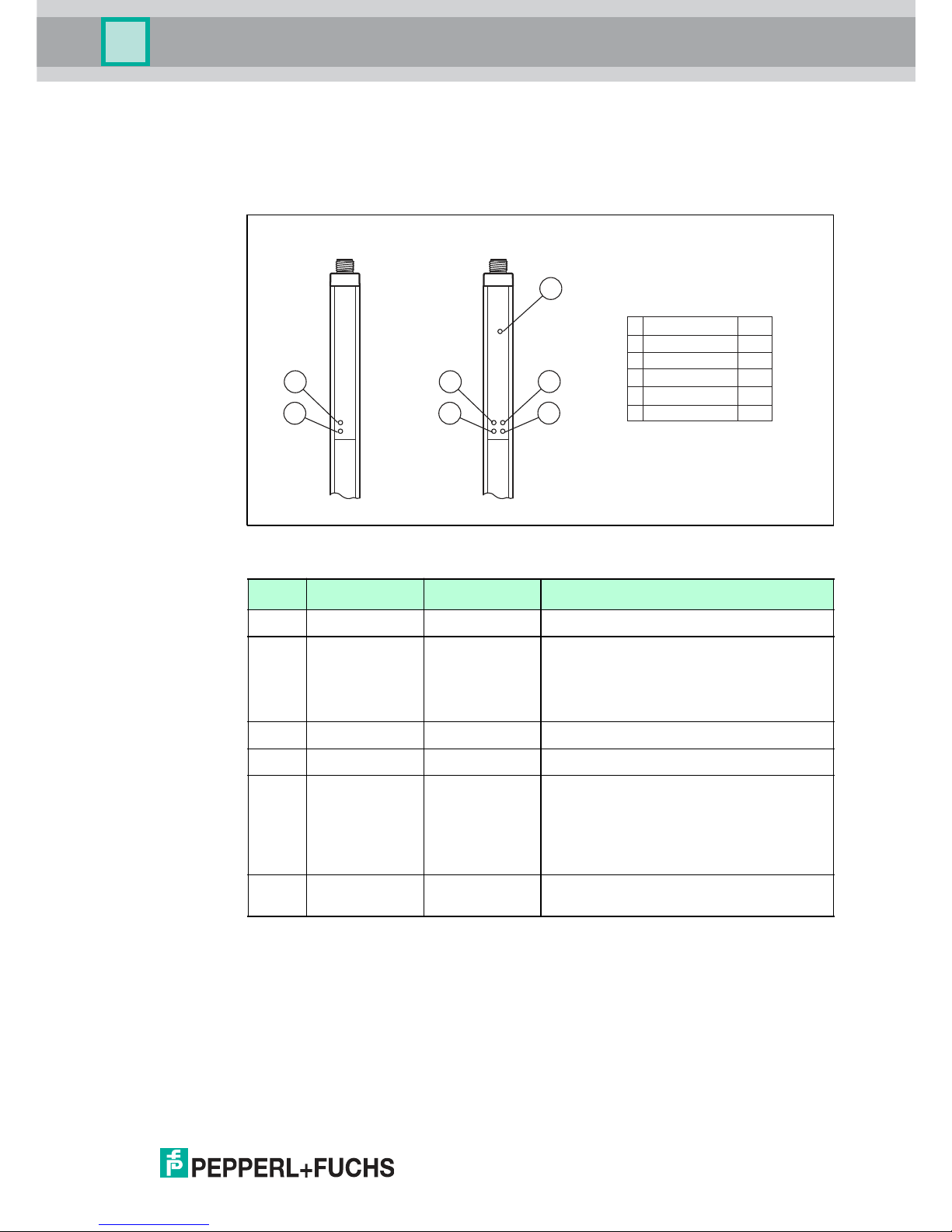

1 Power green

2 Mode A/B, Status yellow

3 OSSD OFF red

4 OSSD ON green

5 Restart/Status yellow

6 Mode A/B yellow

Transmitter

Receiver

1

2

3

5

4

6

1

Product Description

3.2 Indicators and Operating Controls

The transmitter has two LEDs to display its operating status.

The receiver has five LEDs to display its operating status.

Figure 3.2 Displays on the transmitter and receiver units

No. Designation LED Color Meaning

1 Power LED Green Transmitter and receiver units operating

2 A/B mode,

Yellow Indicator flashing at 1 Hz: testing time

status

3 OSSD OFF Red OSSDs switched off

4 OSSD ON Green OSSDs switched on

5 Restart/status Yellow On: protection field free: system ready to

6 Mode A/B Yellow Off: mode A

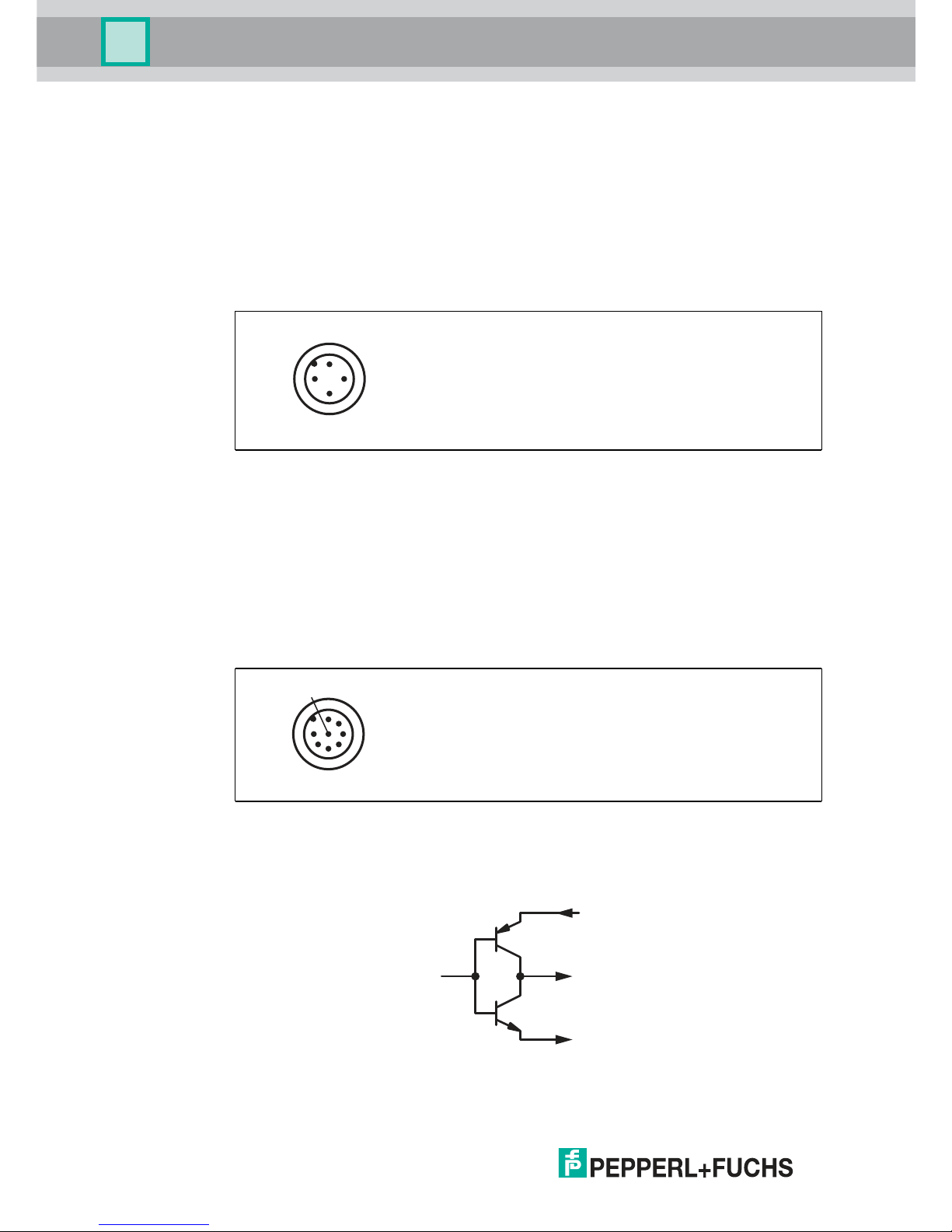

3.3 Interfaces and Connections

The electrical connections of the safety light curtain are made using M12 plug-in

connectors. The transmitter has a 4-pin connector and the receiver an 8-pin plugin connector.

Connect the power supply and, depending on the application, the test signal to

the transmitter unit. The mode can also be selected via the A/B mode input.

271695 2017-12

exceeded

or A/B mode input level change

Indicator flashing at 5 Hz: internal fault

start

Indicator flashing at 1 Hz: external fault

Indicator flashing at 2.5 Hz: insufficient

functional reserve

Indicator flashing at 5 Hz: internal fault

On: mode B

11

Page 12

SLCT* and SLCT*/35 safety light curtains

1

3

4

2

1

4

6

7

8

53

2

0 V

24 V

OSSD 1/2

Product Description

Connect the power supply, the fail-safe outputs (OSSD), the status/select output

and the inputs for the startup enable, relay monitor and A/B mode to the receiver

unit.

The housing profile is connected internally with approx. 2.3 MOhm// 33 nF each at

+24 V and 0 V. Internal varistors limit any surges that occur at approx. 85 V. A

separate grounding or connection between the housing and functional ground is

not required.

Transmitter

Figure 3.3 Pin assignment transmitter unit

1 24 V DC

2 Mode A/B

3 0 V DC

4 Test

Receiver

Figure 3.4 Pin assignment receiver unit

1 Restart Interlock (RI)

2 24 V DC

3 Relaismonitor (RM)

4 Status / Select RI-RM

5 OSSD 1

6 OSSD 2

7 0 V DC

8 Mode A/B

12

271695 2017-12

Page 13

SLCT* and SLCT*/35 safety light curtains

Product Description

3.4 Scope of Delivery

The scope of delivery includes:

Scope of delivery : transmitter

■

Transmitter

Scope of delivery : receiver

■

Receiver

■

I/O Manual

■

Test rod

Bracket and cable are not included in the scope of delivery. Visit www.pepperlfuchs.com for a selection of compatible fixing brackets and recommended cables.

271695 2017-12

13

Page 14

SLCT* and SLCT*/35 safety light curtains

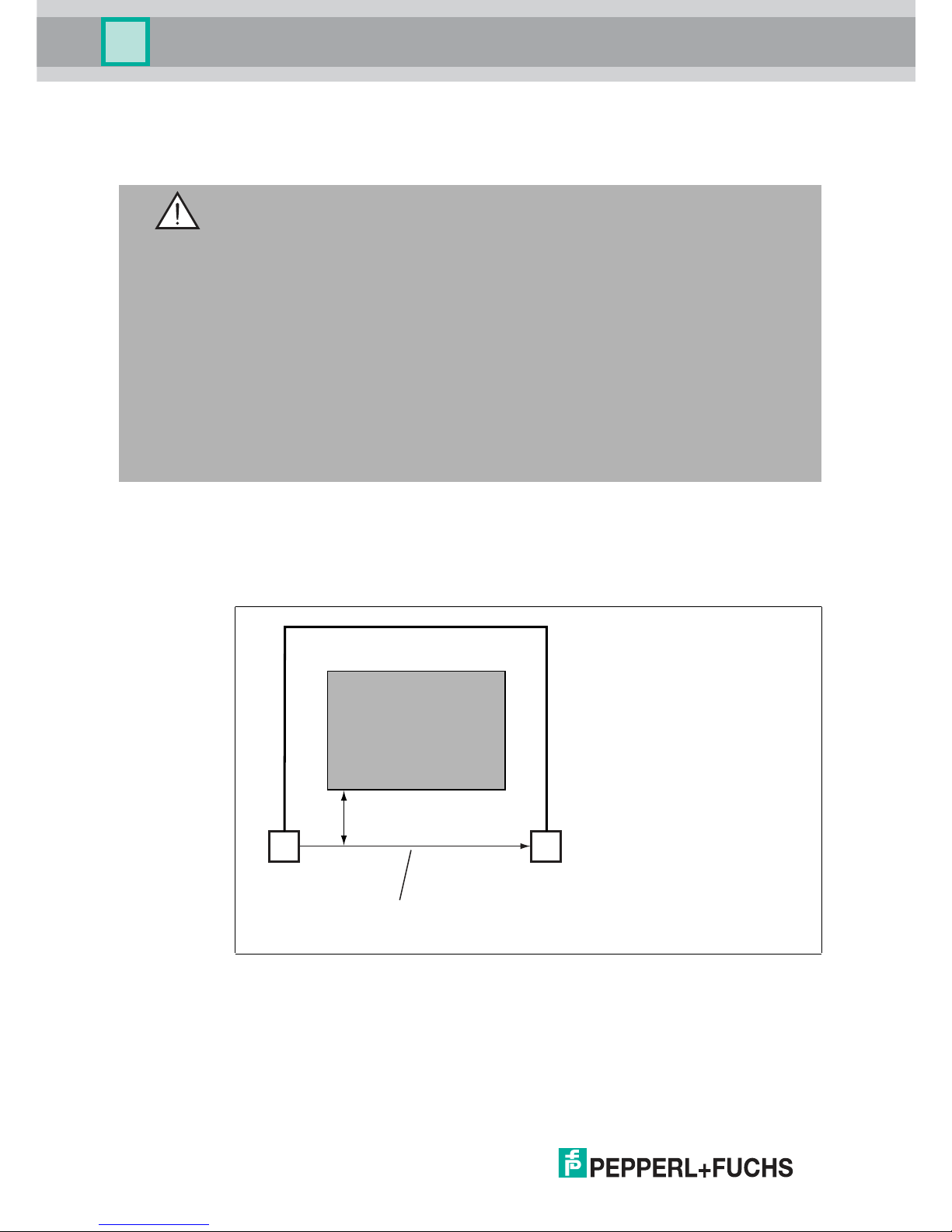

Danger zone

Minimum interval S

Sending unit

Protec

tive field

Receiving unit

Installation

4 Installation

4.1 Planning and Preparation

Warning!

Danger to life due to ineffective protective equipment

Improper or incorrect alignment, fixing, and connection to machine control can

impair the effectiveness of the protective function.

■

Note the applicable standards, guidelines, and legal regulations for the

equipment of machine and plants with protective equipment.

■

Position the protective equipment to prevent persons from being able to

reach or walk behind it, climb over or under, or otherwise bypass the

equipment in any way.

■

Use appropriate safety distances to take into account the response times

and lag times of the components in the safety chain.

■

Secure the protective equipment against manipulation or deliberate

deactivation.

Safety distance

A minimum distance must be maintained between the protection field and the

danger zone to ensure potentially dangerous movements are brought to a stop

before contact with a person is possible.

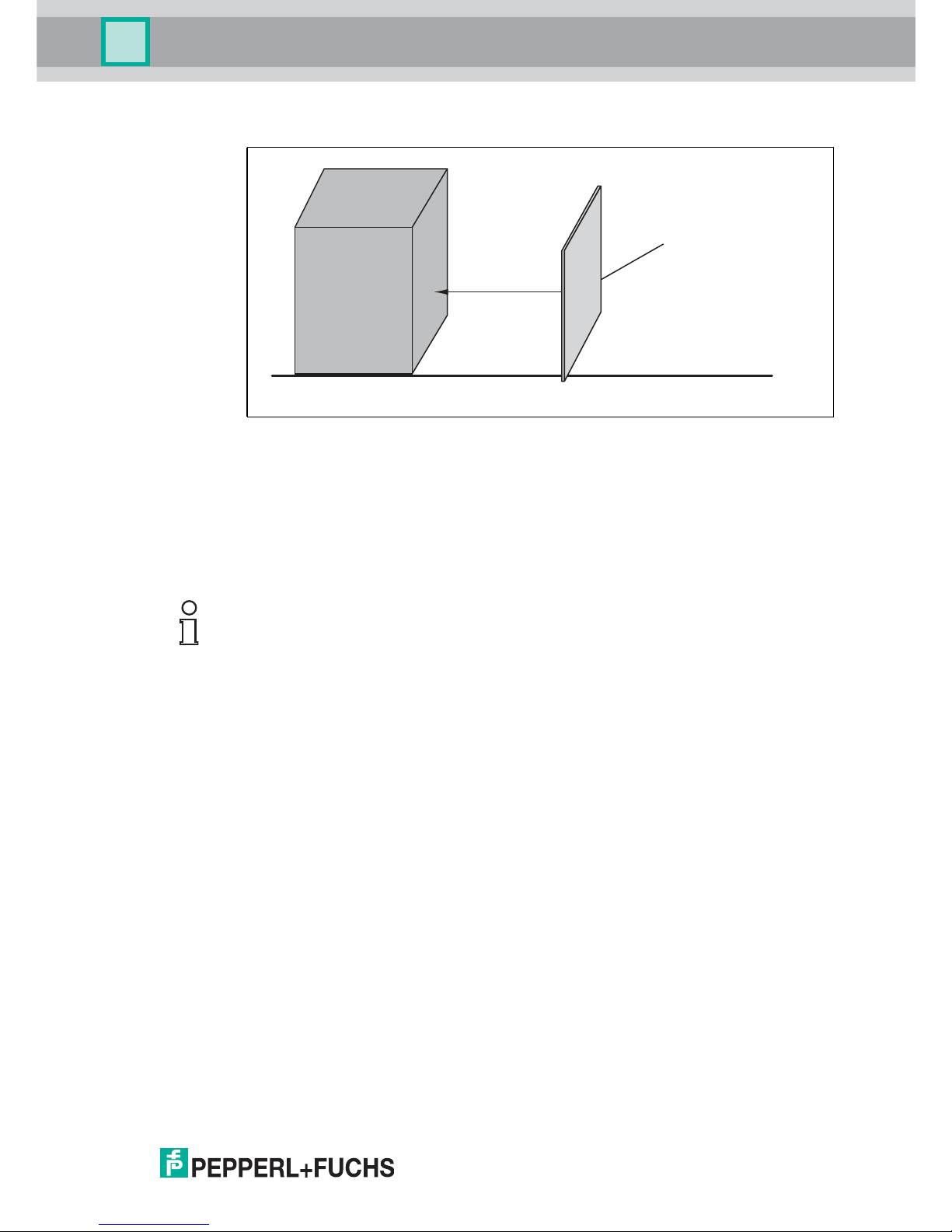

Figure 4.1 Minimum distance between protection field and hazardous area

This distance is calculated from the lag time of the machine, the response time of

the safety system, and the speed of movement of the person entering the

hazardous area (ISO/EN 13855).

14

271695 2017-12

Page 15

SLCT* and SLCT*/35 safety light curtains

Installation

To comply with the necessary distances in the event that the protection field

spreads, please refer to Table 1 of ISO/EN 13855 to check the minimum distance

for a vertically positioned protection field. If you read the value 0 from the table,

you can determine the minimum distance with the following formula:

S = K x T + C

Where, for a protection field align ed vertically to the hazardous area:

S Minimum safety distance in mm,

K Constant in mm/s for the speed of approach, bas ed on the detection

T Total response time of the protective equipment in s (T = t1 +t2)

t

1

t

2

C Additional distance in mm, see table

For any arrangements other than a vertical alignment of the protection field, see also

EN ISO 13855.

i.e. the distance between hazardous area and protection field

capacity of the sensor

Response time of the protective equipment See the table below.

Machine lag time

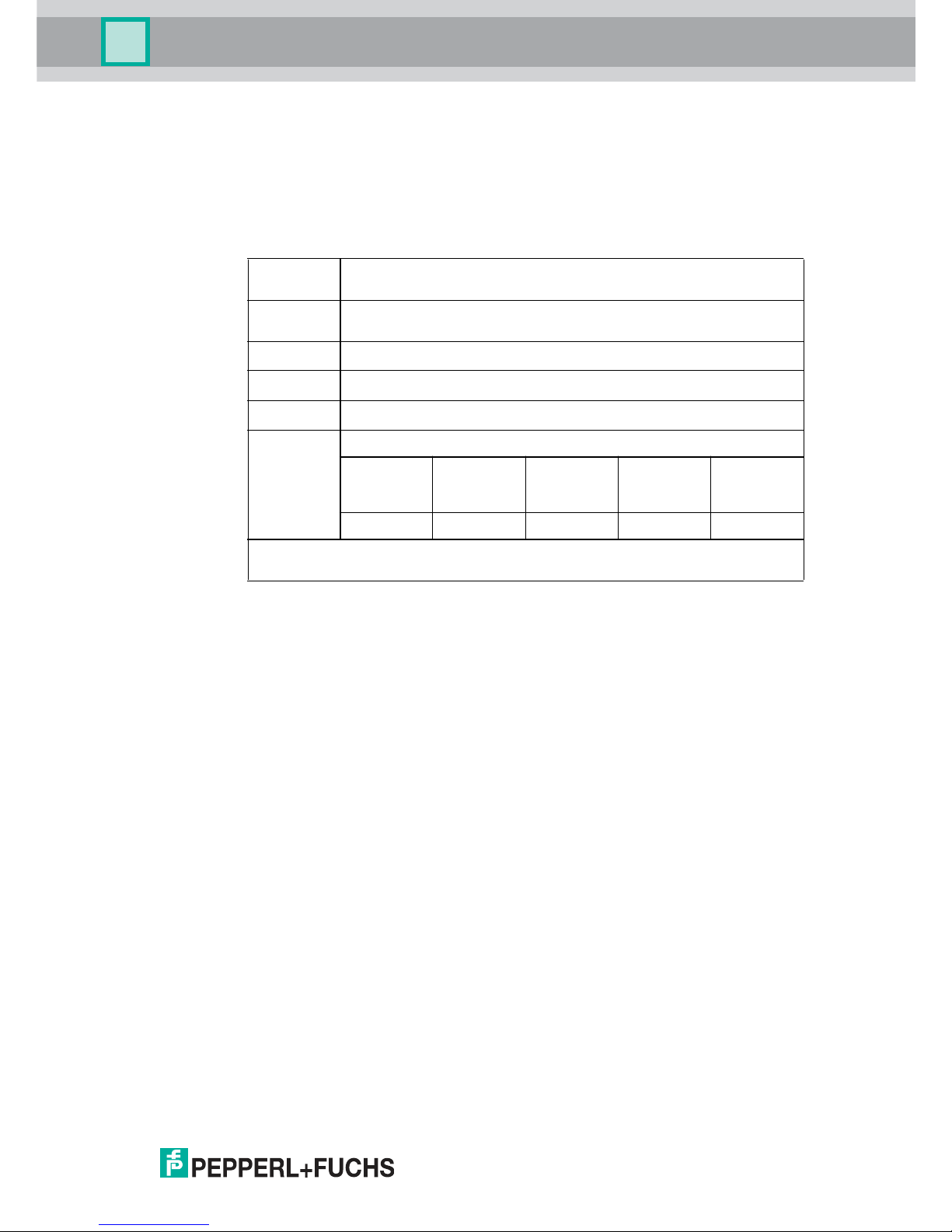

Number of

beams/res

olution

14 mm 30 mm 60 mm 90 mm

0 mm 128 mm 850 mm 850 mm

271695 2017-12

15

Page 16

SLCT* and SLCT*/35 safety light curtains

Installation

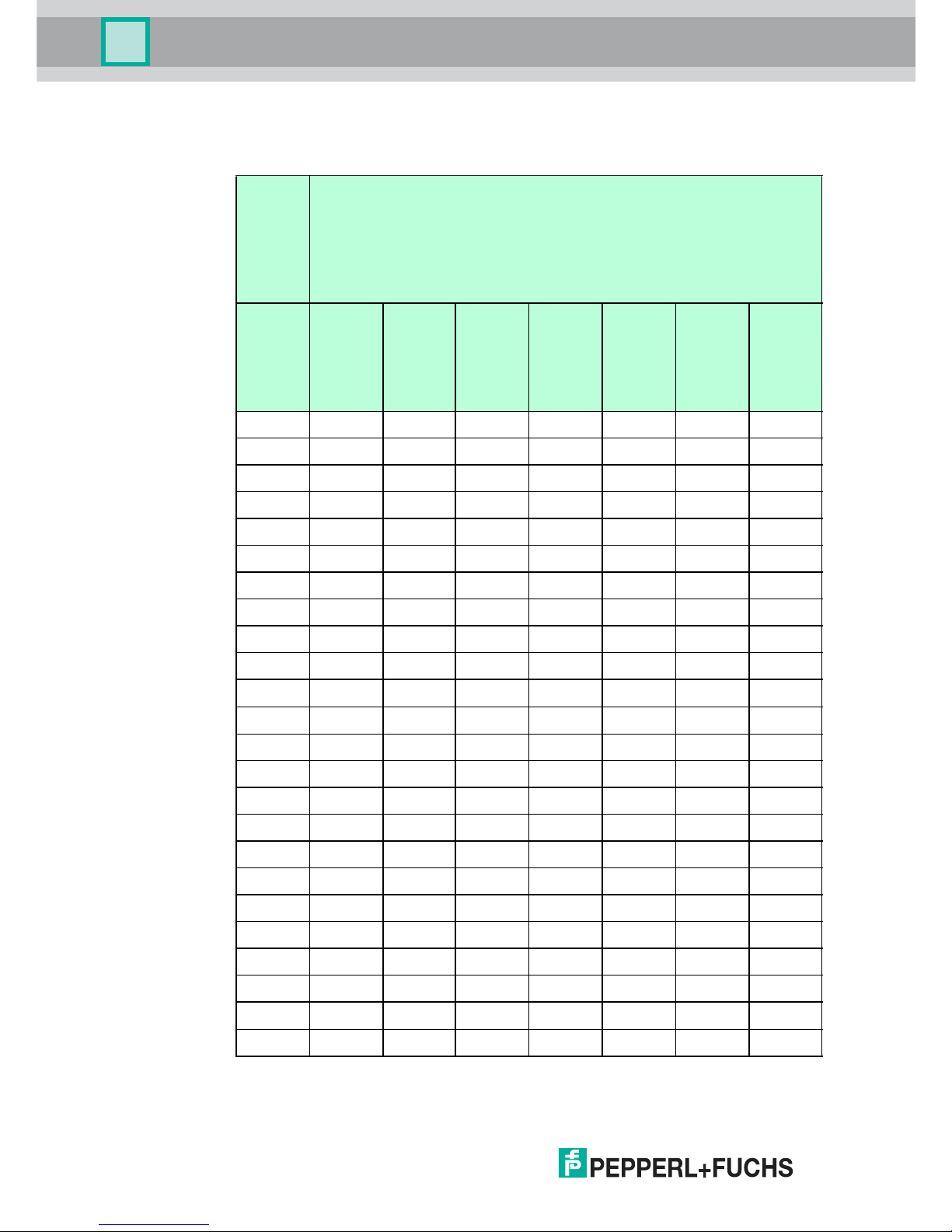

Response times of the safety light curtain

The safety light curtain response time is shown on the nameplate.

Protectio n

field height [mm]

Response

time [ms]

SLCT14-*

100 1 1 8 9 - - - -

200 1 5 10 11 - - - -

300 1 9 11 12 9 10 8 8

400 2 3 12 14 - - - -

500 2 6 14 16 - - - -

600 3 0 15 17 11 12 10 10

700 3 4 16 19 - - - -

800 3 8 17 21 - - - -

900 4 2 19 23 13 15 11 11

1000 46 20 25 - - - -

1100 50 21 26 - - - -

1200 54 23 28 15 17 12 12

1300 - 24 30 - - - -

1400 - 25 32 - - - -

1500 - 26 33 17 20 14 14

1600 - 28 35 - - - -

SLCT30-*

SLCT30-*/35

SLCT60-*

SLCT60-*/35

SLCT90-*

SLCT90-*/35

1700 - 29 37 - - - -

1800 - 30 38 19 23 15 15

1900 - 32 40 - - - -

2000 - 33 42 - - - -

2100 - 34 43 21 25 16 16

2200 - 35 45 - - - -

2300 - 37 47 - - - -

2400 - 38 48 23 28 17 17

16

271695 2017-12

Page 17

SLCT* and SLCT*/35 safety light curtains

Installation

The switch-on time after beam interruption without a restart function is between

80 ms and 200 ms. The switch-on time depends on the number of protective

beams.

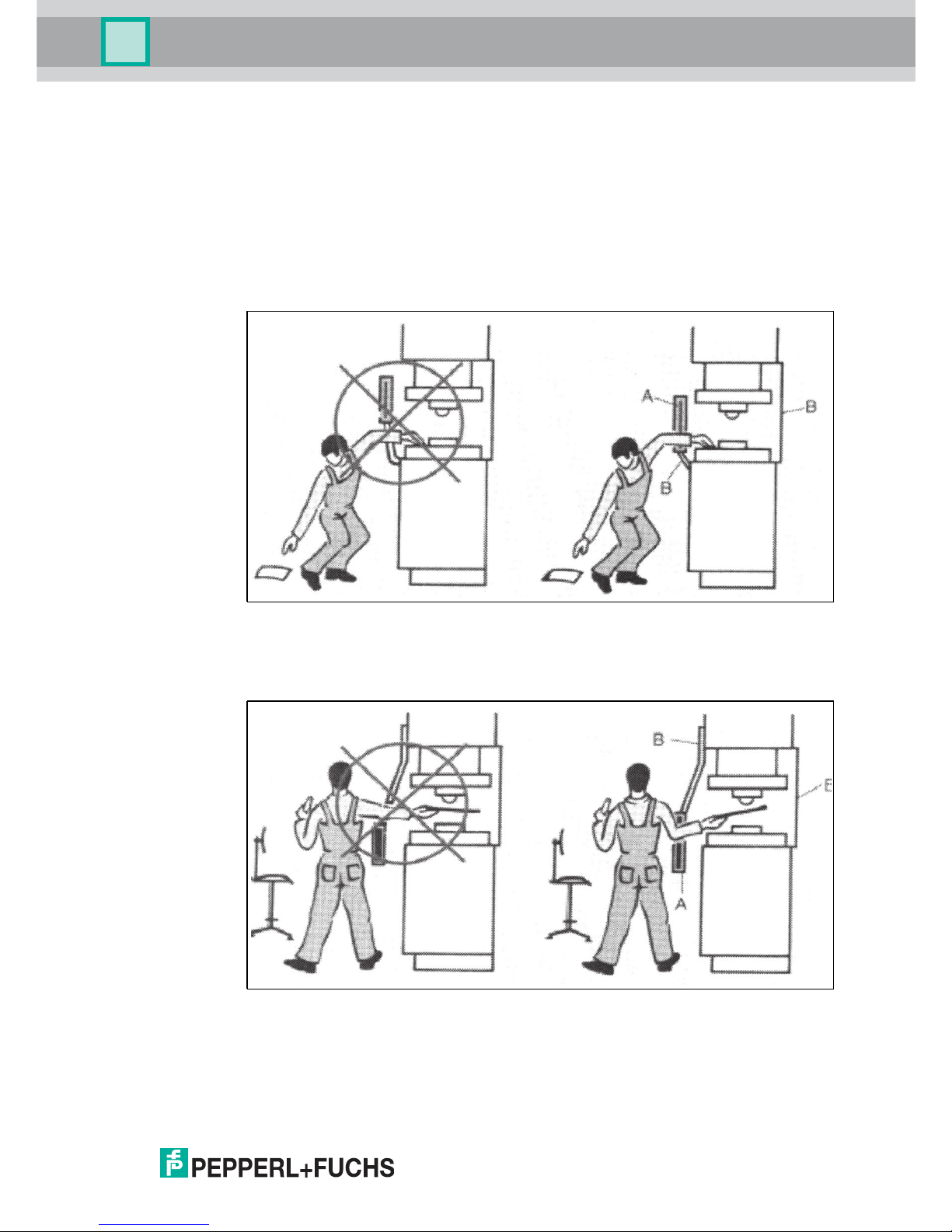

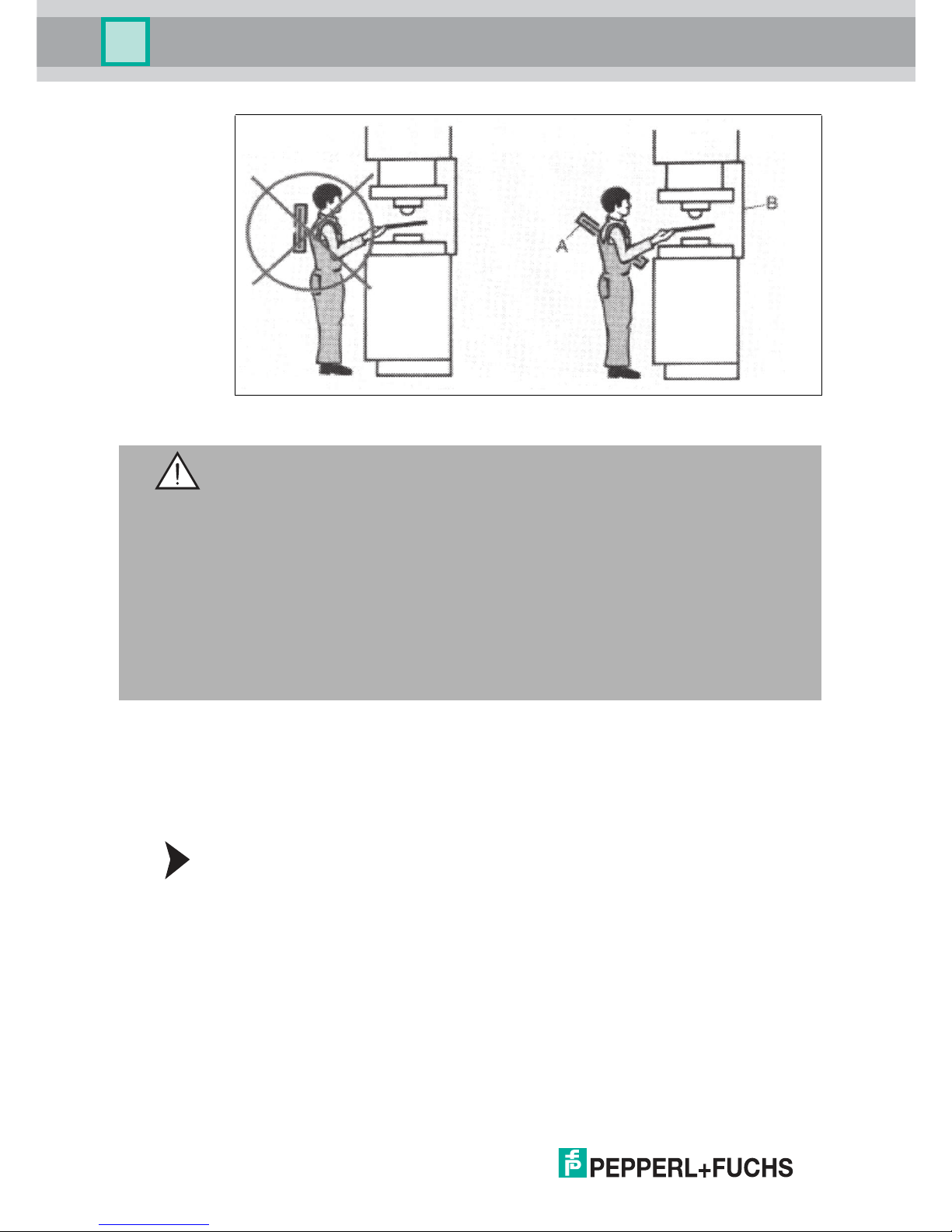

Notes on setting up safety light curtains

The protective equipment must be arranged in such a manner that it is impossible

to reach over, reach under, or walk behind the protection field. If the distance from

the protective equipment is too great, additional protective equipment must be put

in place (see illustration below).

Reaching over

The operator must not be able to reach over the protection field and into the

hazardous area (A: protection field, B: mechanical protection).

Walking behind

The machine operator must not be able to walk between the light curtain and into

the danger zone (A: protection field, B: mechanical protection).

271695 2017-12

17

Page 18

SLCT* and SLCT*/35 safety light curtains

Installation

4.2 Mounting

Warning!

Danger to life due to ineffective protective equipment

Improper or incorrect alignment, fixing, and connection to machine control can

impair the effectiveness of the protective function.

■

Check the positioning of the protective equipment and ensure that it is not

possible for persons to reach or walk behind it, climb over, under or

otherwise bypass the protective equipment.

■

Check the safety distances and the lag times of the components in the

safety chain.

■

Check that the protective equipment cannot be easily manipulated or

disabled.

Various mounting materials for mounting to machines or in the field are available

for securing the safety light curtain. See chapter 8.6.

If you are planning to install a safety light curtain with an increased detection

range, we recommend using mounting profiles for floor mounting from our

accessories range. See chapter 8.6.7.

Mounting

1. Align the transmitter and receiver units so that the two units are parallel with

one another and at the same height.

2. Align the transmitter and receiver units parallel with one another.

3. The stability alarm indicator helps with correct alignment.

When installing the safety light curtain in a hazardous area, a minimum distance

must be maintained between the protection field and the hazardous area. This

distance will ensure that movements that pose a danger to a person can be

brought to a stop before that person comes into contact with the source of danger.

The distance is calculated from the lag time of the machine, the response time of

the safety light curtain, and the speed of movement of the person entering the

hazardous area (EN ISO 13855, EN ISO 13857).

18

271695 2017-12

Page 19

SLCT* and SLCT*/35 safety light curtains

Distance S

Protective field

Danger

zone

Installation

Vertical approach

Figure 4.2 Explanation of the safety distance in a vertical arrangement of the protective

field

Where K = 2000 mm/s and C = 0 mm, e.g., for SLCT14...

or C = 128 mm, e.g., for SLCT30...

the calculation formula for a distance S of 105 mm up to and including 500 mm is:

S = 2000 mm/s * (t

+ t2) + C

1

Note!

If S is greater than 500 mm, then K = 1600 mm/s must be used for calculations:

S = 1600 mm/s * (t

+ t2) + C

1

S must be at least 500 mm. Lower results must be corrected to a minimum

distance of 500 mm.

Example: vertical arrangement

= 50 ms

t

1

t2 = 300 ms

Hand protection C = 128 mm

-3

S = 2000 mm/s * (350 * 10

s) + 128 mm

S = 700 mm + 128 mm = 828 mm

As S is > 500 mm, a smaller value can also be determined:

S = 1600 mm/s * (350 * 10-3 s) + 128 mm = 688 mm

The minimum distance between protection field and danger zone must therefore

be 688 mm. betragen.

271695 2017-12

19

Page 20

SLCT* and SLCT*/35 safety light curtains

Distance S

H (height above ground)

Protective field

Danger

zone

Installation

Parallel approach

Figure 4.3 Explanation of the safety distance in a horizontal arrangement of the

protective field

If the safety light curtain is aligned in a horizontal position, the safety distance S

will also depend on the height of the light curtain above the floor. The maximum

height H must not exceed 1000 mm.

Danger!

Risk of death due to possibility to bypass the protective function

If H is greater than 300 mm, there is a risk that access underneath the safety light

curtain will be possible.

Where height H is greater than 300 mm, the possibility of access must be factored

into the risk analysis or additional barriers must be used.

The safety distance is calculated as follows:

S = 1600 mm/s * (t

+ t2) + (1200 mm - 0.4 H)

1

Therefore (1200 mm - 0.4 H) ≥ 850 mm is required.

20

271695 2017-12

Page 21

SLCT* and SLCT*/35 safety light curtains

Reflecting object outside beam area

Obstacle

Sending unit Receiving unit

Minimum interval a

Installation

4.3 Reflection

Danger!

Danger to life due to reflection

If you do not comply with the minimum distances, objects or persons cannot be

safely detected in the beams of the protective equipment.

■

When aligning the protective equipment, ensure that the minimum distance

to reflective objects or surfaces on all sides of the protection field is

observed.

The required minimum distances are listed in the table in this

documentation.

■

Do not operate the protective equipment if diffuse dispersive media are

present.

■

Perform test rod tests throughout the whole area of the protection field. See

chapter 5. See chapter 6.2.

Ensure that there are no reflective objects within the transmitter or receiver path

that could deflect the beams around an obstruction (EN 61496-2).

Figure 4.4 Explanation to the risk of radiation protection of remirroring

Minimum distance between protection field and reflective surfaces

Protection field width [m] Minimum distance [mm]

0.2 ... 3.0 135

4.0 175

271695 2017-12

5.0 220

6.0 265

8.0 350

10 450

15 660

20 880

21

Page 22

SLCT* and SLCT*/35 safety light curtains

Installation

Danger!

Danger to life due to indirect dispersion of light during operation below the specific

minimum range

If you operate the protective equipment below its specified minimum range, this

can lead to reflection caused by reflective or dispersive objects outside the

specified minimum distances. The resulting malfunction can cause a failure to

detect persons or objects.

■

Observe the minimum range of the protective equipment that you are using.

■

Never operate the protective equipment below this specified minimum

range!

■

During mounting, also note that the conditions for light beam dispersion

may change during operation, e.g. due to moving machine parts or optically

dispersive media.

4.4 Connection and Operating Mode Setting

Both the supply voltage and the system settings can be connected to the

transmitter unit and receiver unit. The following operating mode settings are also

available:

■

Startup interlock operating mode

■

Relay monitor operating mode

■

A/B mode operating mode

Startup interlock operating mode

Note!

When the input is open, the startup/restart interlock is activated.

The startup/restart interlock ensures that after the supply voltage has been turned

on, or after an interruption in the protection field, the operational readiness state is

indicated when the protection field is free. The start-up enable must then be

actuated so that the safety light curtain turns on the OSSDs.

The function can be activated or deactivated at the 8 pin connector of the receiver

SLCT.

An NC contact between the restart and +24 VDC input is required to trigger the

startup/restart interlock. The startup/restart interlock function does not work if the

restart input is bridged with the status/select output. If the input is not connected,

the startup/restart interlock is activated (see chapter 4.4.4).

Relay monitor operating mode

The relay monitor monitors the switching positions of the downstream output

relay. If the switching position of the relay does not match the signal from the

OSSDs, the system switches to safe mode. The status LED indicates that safe

mode is active.

22

271695 2017-12

Page 23

SLCT* and SLCT*/35 safety light curtains

Installation

The function can be activated or deactivated at the 8 pin connector of the receiver

SLCT.

The two feedback contacts on the external switching elements must be placed

between 24 VDC and the relay monitor input in order to activate the relay monitor.

The relay monitor function is deactivated if the relay monitor input is bridged with

the status/select output.

Note!

An open relay monitor input results in a fault. The yellow indicator LED flashes at a

frequency of 1 Hz in case of a fault.

A/B mode operating mode

Operating mode A or operating mode B must be configured both on the

transmitter unit and on the receiver unit. The modes are used to prevent cross-talk

from adjacent SLCT safety light curtains.

4.4.1 Signal outputs on the receiver unit

Status/Select RI-RM output

The output indicates the same states as the restart/status indicator.

This signal output indicates operational readiness and is active when the

protection field is free and startup enable can be activated in order to switch on

the OSSD. Internal or external faults and a dirty lens, are also signaled at this

output.

If an external fault occurs, the output switches on and off at a frequency of 1 Hz.

The following faults may be the cause:

■

Relay monitor faulty

■

Low supply voltage

■

Short or crossed circuits at the OSSD outputs and

■

Level change at the mode input during operation

Internal faults cause the output to switch on and off at a frequency of 5 Hz.

If the safety light curtain is not adjusted correctly or the front lenses are not clean,

the output switches on and off at a frequency of 2.5 Hz.

The output is also used to define the preset operating mode during startup.

Bypassing this output to the restart and/or relay monitor inputs deactivates the

relevant operating mode.

OSSDs

The receiver has two safe outputs, which are short circuit and cross circuit proof.

The OSSDs switch off as soon as a light beam is interrupted. Switching times, .

271695 2017-12

23

Page 24

SLCT* and SLCT*/35 safety light curtains

Min. 0,4 x response time

Max. 0,8 x response time

Min. 0,4 x response time

Max. 1,2 x response time

min. 20 ms / max. 2,4 s

high

low

ON

OFF

OSSDs

Test

Installation

4.4.2 Signal Inputs on the Transmitter Unit

Test input

Connect the test input to 24 VDC via an NC contact. The test function is triggered

by opening the contact.

Note!

During operation without a startup/restart interlock, the test time must be limited to

150 ms.

The test input is used to start a complete test of the safety light curtain. During this

process, the OSSDs are switched off and all system components are checked.

Error messages from the transmitter unit are acknowledged by initiating a test.

Note!

A complete test is also carried out when the operating voltage is switched on. This

also applies to the receiver unit, which does not have a test input.

The time constraints of the test signal must be maintained for a test to be

successful ( see Figure 4.5 on page 24). On an SLCT30-600 safety light

curtain, for example, the time between the test requirement and the response to

the OSSDs is a minimum of 6 ms and a maximum of 18 ms. A test input actuation

time of fewer than 0.02 s or more than 2.4 s sw itches the transmitter unit to a fault

state.

Note!

In case of a fault, a fault reset can be triggered by activating the input between

1.2 s and 2.4 s.

Figure 4.5 Graphs of the OSSD switching states when initiating a test or reset

A/B mode input

If the input is open or connected to 0 V, the safety light curtain operates in mode A.

The inputs must be connected to the supply voltage 24 VDC to switch to mode B.

24

271695 2017-12

Page 25

SLCT* and SLCT*/35 safety light curtains

Installation

After the supply voltage is switched on, the transmitter or receiver unit selects

mode A or mode B, depending on the applied voltage.

Note!

Make sure that the transmitter unit and receiver unit are operating in the same

mode.

If the level at the input changes during operation, this is identified as a fault and

the system switches to safe mode.

4.4.3 Signal inputs on the receiver unit

Connect the restart (RI) and relay monitor inputs to the receiver unit with NC

contacts that switch 24 VDC. The function is triggered if the external control

contact is open for a defined period.

Restart (RI), startup/restart interlock input

The startup/restart interlock prevents the OSSDs from switching to ON after the

protection field is cleared or after the supply voltage is turned on when the

protection field is free. The safety function is only activated once the startup

enable button has been pressed.

An NC contact that switches the supply voltage must be connected to the input to

activate the safety function. If the start/restart interlock should be deactivated, the

input must be bridged with the status/select output. An open input also activates

the startup/restart interlock.

The input signal time is monitored and the actuation time should be active for

between 0.2 s to 1.2 s.

Note!

In the case of a fault, the fault can be reset by pressing and holding the startup

enable button for between 1.2 s and 2.4 s.

Danger!

Danger to life due to incorrectly positioned startup enable

If you install the button for the startup enable within the hazardous area or in a

position from which the hazardous area is not visible, this may result in the button

being pressed although personnel or objects are still located within the hazardous

area.

■

Mount the startup enable button in front of the hazardous area as follows:

• It must not be possible to activate the startup enable from within the

hazardous area, or to trigger a function that would mean the

protection field is interrupted by pressing the button.

• The hazardous area must be clearly visible from the location in

which the button is pressed.

271695 2017-12

25

Page 26

SLCT* and SLCT*/35 safety light curtains

Installation

Relay monitor input

Auxiliary contacts on switching elements connected downstream of the OSSDs

can be connected to the relay monitor input. This allows these elements to be

monitored. Use NC contacts (see chapter 4.4.4). All monitored switching

elements must be connected in series. One end of this series connection must be

connected to the positive power supply and the other end to the relay monitor

input.

The feedback contacts on the external switching elements must guarantee a

reliable contact at a voltage of 20 VDC and a current of 5 mA.

Danger!

Danger to life due to electric shock

Insufficient separation distances can negate the safe separation of a SELV/PELV

supply of the protective equipment. This can lead to a particularly high voltage on

the device and present a danger to life.

The protection class III of the protective equipment and the necessary safe

separation distance must be taken into account when designing the insulation

coordination of the electrical installation or machine.

For more information, also see IEC 60204, IEC 60664 and IEC 61140 and the

relevant national regulations.

If the external switching element is not activated within 200 ms, this is identified as

a fault and safe mode is activated.

To disable the function, the input must be bridged with the status/select output. An

open input also activates the relay monitor function.

A/B mode input

If the input is open or connected to 0 V, the safety light curtain operates in mode A.

The inputs must be connected to the supply voltage 24 VDC to switch to mode B.

After the supply voltage is switched on, the transmitter or receiver selects mode A

or mode B, depending on the applied voltage. Make sure that the transmitter and

receiver are operating in the same mode.

If the level at the input changes during operation, this is identified as a fault and

the system switches to safe mode.

26

271695 2017-12

Page 27

SLCT* and SLCT*/35 safety light curtains

24 V

0 V

Test

Transmitter unit Receiver

unit

Restart

Relay monitor

Restart

24 V

Relay monitor

Status / Select

OSSD1

OSSD2

0 V

Mode A/B

24 V

Mode A/B

0 V

Test

K1 K2

K2.1

K1.1

1

2

3

4

5

6

7

8

1

2

3

4

Transmitter unit Receiver

unit

Restart

24 V

Relaismonitor

Status / Select

OSSD1

OSSD2

0 V

Mode A/B

24 V

Mode A/B

0 V

Test

24 V

0 V

Test

Reset

Error

optional

1

2

3

4

5

6

7

8

1

2

3

4

K1 K2

Installation

4.4.4 Typical circuits

Figure 4.6 Connection example with relay monitor and restart in Mode A

Figure 4.7 Connection example without relay monitor and without restart in Mode A

271695 2017-12

27

Page 28

SLCT* and SLCT*/35 safety light curtains

Commissioning

5 Commissioning

5.1 Functional Testing

Check the function of the transmitter and receiver

1. Check whether the transmitter and receiver are aligned parallel to one another

and are at the same height.

2. Switch on the safety light curtain when the protection field is clear.

3. Adjust the transmitter and receiver so that the reception signal exceeds the

functional reserve.

If the reception signal falls below the functional reserve, the yellow

restart/status LED on the receiver flashes.

4. Check whether the two OSSD outputs are switching on correctly. The Ready

to start message appears unless this operating mode is deactivated by an

external circuit.

5. Use the supplied test rod to test the detection capability of the safety light

curtain to identify any detection gaps caused by reflective surfaces. (see

chapter 8.6.13).

6. Check the effectiveness of the switch-off function of the safety light curtain

and the response time of the safety function when a beam is interrupted.

7. If you are using the startup/restart interlock operating mode, test whether the

lock is enabled when the power is turned on and after the protection field is

interrupted.

Warning!

Danger to life due to unexpected machine startup if the startup/restart interlock is

incorrectly set up

If the startup/restart interlock does not function correctly when the power is

switched on and after the protection field is interrupted, this can lead to an

unexpected dangerous startup of the machine.

Before commissioning the machine, check whether the startup/restart interlock is

functioning correctly when the power is connected and following interruption of

the protection field.

8. Check the function of the test input when the protection field is clear by

applying 24 V to the test input.

The OSSDs switch off and switch the OSSDs back on again after the test

has been completed successfully.

If the function "Relay monitor" is activated, the monitored switching elements

following the OSSDs accordingly.

28

271695 2017-12

Page 29

SLCT* and SLCT*/35 safety light curtains

R1 T1 T2 R2

Commissioning

5.2 Multiple Positions

Note!

If several safety light curtains/safety light grids are operating close to each other,

care must be taken to prevent any cross-talk. You can use the operating modes

"A" and "B" to prevent cross-talk.

The illustration below shows a preferred layout.

Figure 5.1 Multiple assignm ent

Warning!

Danger to life due to interference from multiple photoelectric protective devices

If you use several pieces of photoelectric protective equipment in your plant, these

may interfere with each other if positioned too close together. The resulting

malfunction may result in a failure to detect persons or objects, or in OSSDs

switching off unintentionally.

■

When using multiple items of photoelectric protective equipment, ensure

during the planning stage and before commissioning that cross-talk is

prevented.

■

Optically shield the protective equipment devices from each other, if

necessary using structural methods.

■

Prevent optically active objects such as lenses or filters from entering the

beam path.

■

Ensure that structural methods cannot subsequently become ineffective.

271695 2017-12

29

Page 30

SLCT* and SLCT*/35 safety light curtains

Mode A

Mode B

R1 T1

T2

R2

Commissioning

When operating two safety light curtains with different modes A and B, another

arrangement is possible by positioning the transmitter units and receiver units

directly on top of each other. The connector plugs extend outwards in the

opposite direction. The SLCT30 provides a continuous protection field that is

divided into 2 security areas as a special feature. Suitable devices for head-tohead mounting: standard detection range, resolution 30 mm, 60 mm, or 90 mm

and protection field height of maximum 1200 mm per strip. The height of the

continuous protection field can therefore reach a maximum of 2400 mm.

Note!

This layout is not available for the device option with increased detection range

(SLCT*/35).

Figure 5.2 Head-to-head layout

30

271695 2017-12

Page 31

SLCT* and SLCT*/35 safety light curtains

Maintenance and Repair

6 Maintenance and Repair

6.1 Maintenance

The safety light curtain is maintenance free.

The prescribed periodic checks must be carried out and documented. The

checks to determine whether the components are fitted securely and whether the

optical surfaces are clean are important.

See chapter 6.2

Note!

Use a soft, lint-free cloth to clean the surfaces and to cover the lenses. Only use

alcohol or mineral spirits as cleaning fluids. Avoid the use of any other cleaning

agents, as they may damage or impair the lens surfaces.

6.2 Periodic Checks

The test intervals and scope of the periodic checks are determined according to

requirements.

Record the results of periodic check in accordance with the applicable

regulations.

Daily Check

1. Secure the machine or plant against unintentional startup before and during

the checks.

2. Make sure the protection field is clear.

3. Activate the startup enable.

4. Interrupt the protection field inside the protection field range using the test

rod. A test rod with a suitable obstacle size must be used.

5. Check the entire protection field at several points parallel to the transmitter or

receiver, in particular in front of the transmitter and receiver and in the center

between the transmitter and receiver, to find any detection gaps caused by

reflective surfaces.

The OSSD outputs switch off.

6. Slowly move the test rod through the protection field while watching the

displays on the receiver:

If the startup/restart interlock is activated: the yellow startup readiness

display does not light up.

If the startup/restart interlock is deactivated: the green status indicator of the

OSSD display does not light up.

271695 2017-12

31

Page 32

SLCT* and SLCT*/35 safety light curtains

Maintenance and Repair

7. Remove the test rod from the protection field while watching the displays on

the receiver:

If the startup/restart indicator is activated: the yellow startup readiness

indicator lights up.

If the startup/restart interlock is deactivated: the green status display of the

OSSD display lights up.

8. When the startup/restart interlock is activated, press the startup enable.

The green OSSD display lights up.

Warning!

Danger to life due to missing safety functions

If the protective equipment is not taken into account when checking the safety

functions of the whole plant, it is possible that it may no longer function safely

together with the other components.

■

The protective equipment must be included in any general checks on

machine safety functions.

■

This includes checking for proper alignment and installation.

■

In addition, adherence to the required response times must be tested.

6.3 Repairs

The device must not be repaired, changed, or manipulated. In case of failure,

always replace the device with an original device.

Danger!

Danger to life from using damaged or repaired devices.

Using a defective or repaired device can compromise its function and its electrical

safety.

■

Do not use a damaged or polluted device.

■

The device must not be repaired, changed or manipulated.

■

If there is a defect, always replace the device with an original device from

Pepperl+Fuchs.

32

271695 2017-12

Page 33

SLCT* and SLCT*/35 safety light curtains

Troubleshooting

7 Troubleshooting

7.1 Troubleshooting

Warning!

Danger to life due to an absence of safety functions in the event of dangerous

failure

If a device has failed so dangerously that one or more safety functions can no

longer be guaranteed, the operational safety of the affected machine or plant is

impaired as a consequence.

■

Decommission the affected machine or plant and the sensor system and

secure them to prevent recommissioning.

■

Replace the defective device with an original device from Pepperl+Fuchs.

■

Send the defective device to Pepperl+Fuchs with a description of the fault.

Warning!

Danger to life as the result of an absence of functional inspections

If you resolve a fault and do not subsequently check whether the device and the

protective function it enables are functioning correctly, this can prevent the

protective equipment from working.

■

After resolving the error, carry out a functional inspection to ensure that the

protective equipment is functioning again correctly.

■

Repeat the test steps described for commissioning. See chapter 5.

If a fault occurs, press the test contact (Reset). The receiver clears the fault state

by performing a system reset.

If this process does not correct the fault, attempt to return to normal mode by

switching off the power supply for at least 1 second, then switching it back on

again.

271695 2017-12

33

Page 34

SLCT* and SLCT*/35 safety light curtains

Troubleshooting

Eliminating Interference

Source of fault Cause Action

Transmitter:

Status indicator flashes

at 1 Hz

Transmitter:

Status indicator flashes

at 5 Hz

Receiver:

Status indicator flashes

at 5 Hz

Receiver:

Status indicator flashes

at 2.5 Hz

Receiver:

Status indicator flashes

at 1 Hz

Receiver:

OSSD status LED

lights up red

Receiver:

"Ready to start" status

indicator cannot be

acknowledged

External fault:

a) Test signal faulty

b) A/B mode input error

Internal error Briefly interrupt power supply or

Internal error Briefly interrupt power supply or

insufficient functional

reserve

External error:

a) Relay monitor error

b) Low voltage

c) A/B mo de input error

d) OSSD error

Beam interrupted or

adjustment error

Faulty restart button

connection

a) Check test sequence

b) Check wiring A/B input mode

press the restart button. If the error

occurs again, send for repair.

press the restart button for

approx. 1.5 s. If the error occurs

again, send for repair.

Clean the front panels;

adjust the transmitter and receiver.

a) Check relay monitor connection

b) Check the supply voltage

c) Check A/B input mode wiring

d) Check the OSSDs for crossed

or short circuits

Remove object from protection

field or adjust transmitters and

receivers.

Check restart connection

34

271695 2017-12

Page 35

SLCT* and SLCT*/35 safety light curtains

Appendix

8 Appendix

8.1 Technical Data

General data

SLCT*

Standard detection range

SLCT*/35

Increased detection

range

Effective operating

distance

Light emitter IRED IRED

Light type Infrared, modulated light,

LED risk group

designatio n

Protection field height See chapter 8.2 See chapter 8.2

Operating mode Startup/restart interlock,

Detectable obstacle size

(resolution)

Opening angle 5 ° 5 °

Ambient light limit Immune to ambient light,

0.2 ... 8 m 5 ... 20 m

850 nm

Free group in accordance

with DIN EN 62471

can be disabled

SLCT14: 14 mm;

SLCT30: 30 mm;

SLCT60: 60 mm;

SLCT90: 90 mm

conforming to IEC 614 962

Infrared, modulated light,

850 nm

Free group in accordance

with DIN EN 6247 1

Startup/restart interlock,

can be disabled

SLCT30: 30 mm;

SLCT60: 60 mm;

SLCT90: 90 mm

Immune to ambie nt light,

conforming to IEC 614962

Indicators/operating elements

SLCT*/35

SLCT*

Standard detection range

Increased detection

range

Operating indicator Green: power on Green: power on

Function indicator Green: OSSD ON, red:

Status indicator Transmitter unit: LED

271695 2017-12

OSSD OFF

yellow: mode, test or error

Receiver unit: LED

yellow: ready to start,

functional reserve or error

Green: OSSD ON, red:

OSSD OFF

Transmitter unit: LED

yellow: mode, test or error

Receiver unit: LED

yellow: ready to start,

functional reserve or error

35

Page 36

SLCT* and SLCT*/35 safety light curtains

Appendix

Electrical data

SLCT*

Standard detection range

SLCT*/35

Increased detection

range

Operating voltage 24 VDC (-20 %, +30 %);

power supply with safe

isolation: 24 VDC

The upstream power

supply for a safety light

curtain must be capable

of withstanding power

failures of up to 20 ms.

No-load current Transmitter unit:

≤ 150 mA

Receiver unit: ≤ 150 mA

(outputs open)

Power consumption Transmitter unit: 5 W

Receiver unit: 15 W

Protectio n class III, IEC 611 40 III, IEC 61140

24 VDC (-20 %, +30 %);

power supply with safe

isolation: 24 VDC

The up stream power

supply for a safety light

curtain must be capable

of withstanding power

failures of up to 20 ms.

Transmitter unit:

≤ 150 mA

Receiver unit: ≤ 150 mA

(outputs open)

Transmitter unit: 5 W

Receiver unit: 15 W

Inputs on the transmitter unit

SLCT*/35

SLCT*

Standard detection range

Transmitter unit test

Input format NC contact NC contact

Switching voltage 24 VDC (acting on the

contact)

Increased detection

range

24 VDC (acting on the

contact)

Input current 5 mA 5 mA

Actuation time 0.02 s ... 2.4 s 0.02 s ... 2.4 s

A/B mode transmitter unit

Function Mode A: open or 0 V

Mode B: 24 VDC, 5 mA

Mode A: open or 0 V

Mode B: 24 VDC, 5 mA

Inputs on the receiver unit

SLCT*/35

SLCT*

Standard detection range

Relay monitor rec eiver unit

Input format NC contact NC contact

Switching voltage 24 VDC (acting on the

contact)

Input current 5 mA 5 mA

Actuation time < 200 ms < 200 ms

Startup enable receiver unit

Input format NC contact NC contact

Increased detection

range

24 VDC (acting on the

contact)

271695 2017-12

36

Page 37

SLCT* and SLCT*/35 safety light curtains

Appendix

SLCT*

Standard detection range

SLCT*/35

Increased detection

range

Switching voltage 24 VDC (actin g on the

contact)

Input current 5 mA 5 mA

Actuation time 0.2 ... 1.2 s 0.2 ... 1.2 s

A/B mode receiver unit (see A/B mode trans mitter unit)

Function Mode B: 24 VDC, 5 mA Mode B: 24 VDC, 5 mA

24 VDC (acting on the

contact)

Outputs on the receiver unit

SLCT*/35

SLCT*

Standard detection range

OSSD output

Output format PNP semiconductor,

monitored for short circuit

and crossed circuit

Switching voltage ON: UB - 2 V

OFF: < 1 V

Switching current (max.) ON: max. 0.1 A

OFF: < 5 µA

Load inductance (max.) 1.0 H 1.0 H

Increased detection

range

PNP semiconductor,

monitored for short circuit

and crossed circuit

ON: UB - 2 V

OFF: < 1 V

ON: max. 0.1 A

OFF: < 5 µA

Load capacitance (max.) 220 nF 220 nF

Note The outputs are

permanently monitored

by short (max. 120 µs)

sampling pulses. You

must ensure that this has

no effect on the

downstream circuit.

Signal output

Output format PNP, short-circuit proof PNP, short-circuit proof

Switching current 0.1 A 0.1 A

The outputs are

permanently monitored

by short (max. 120 µ s)

sampling pulses. You

must ensure that this has

no effect on the

downstream circuit.

Ambient conditions

SLCT*/35

SLCT*

Standard detection range

Ambient temperature -35 ... 60 °C (-31 ...

140 °F)

Storage temperature -35 ... 70 °C (-31 ... 158

°F)

Relative hum idity Max. 95 %, not

condensing

Increased detection

range

-35 ... 60 °C (-31 ...

140 °F)

-35 ... 70 °C (-31 ... 158

°F)

Max. 95 %, not

condensing

271695 2017-12

37

Page 38

SLCT* and SLCT*/35 safety light curtains

Appendix

Mechanical data

SLCT*

Standard detection range

Housing length L

SLCT*/35

Increased detection

range

Connection Transmitter unit:

Material

Housing Extruded aluminum

Optical face Plastic disk, clear

Weight See chapter 8.2 See chapter 8.2

connector plug M12 x 1,

4 pin

Receiver unit: connector

plug M12 x 1, 8 pin

Cable cross section min.

0.25 mm

Cable length max. 50 m

profile, silver anodized

polycarbonate

2

8.1.1 Standards and Data for Functional Safety

Note!

For unlisted versions, the next-largest protection field height specified in the table

applies when the resolution of the PFHd value is the same.

Functional safety data

SLCT*

Standard detection range

Transmitter unit:

connector plug M12 x 1,

4 pin

Receiver unit: connector

plug M12 x 1, 8 pin

Cable cross sectio n min.

0.25 mm

Cable length max. 50 m

Extruded aluminum

profile, silver anodized

Plastic disk, clear

polycarbonate

SLCT*/35

Increased detection

range

2

38

Safety Integrity Level

(SIL)

Performance Level (PL) PL c PL c

Category Cat. 2 Cat. 2

Useful lifetime (TM) 20 a 20 a

Type 2 2

PFH

d

SIL 1 SIL 1

271695 2017-12

Page 39

SLCT* and SLCT*/35 safety light curtains

Appendix

SLCT*

Standard detection range

SLCT14-300 1.0E-07 -

SLCT14-600 -

SLCT14-900 -

SLCT14-1200 -

SLCT30-600 1.0E-07

SLCT30-900

SLCT30-1200

SLCT30-1800

SLCT30-2400

SLCT60-1200

SLCT60-2400

SLCT90-1200

SLCT*/35

Increased detection

range

SLCT90-2400

The PFHd values specified app ly up to the maximum ambient temperature.

For unlisted versions, the next-largest protection field height specified in the table

applies when the resolution of the PFHd value is the same.

Conformity with standards

Functional safety EN ISO 13849-1; EN 61508 part1-4

Product standard EN 61496-1; IEC 61496-2

Approvals and certificates

CE conformity CE

UL approval cULus Listed

UL File Number

E21524 5

CCC approval Products with a maxim um operating voltage of ≤ 36 V are not

TÜV approval TÜV

subject to approval and are therefore not assigned a CCC

marking.

8.2 Profile lengths and mass

Protection field height [mm]

100 219 140

200 319 200

300 419 250

271695 2017-12

Overall length of the

transmitter / receiver unit

[mm]

Weight of transmitter /

receiver unit [g]

39

Page 40

SLCT* and SLCT*/35 safety light curtains

Appendix

Overall leng th of the

transmitter / rece iver unit

Protectio n field heig ht [mm]

400 519 310

500 619 370

600 719 430

700 819 480

800 919 540

900 1019 600

1000 1119 650

1100 1219 710

1200 1319 760

1300 1425 820

1400 1525 880

1500 1625 940

[mm]

Weight of transmitter /

receiver unit [g]

1600 1725 990

1700 1825 1050

1800 1925 1100

1900 2025 1160

2000 2125 1210

2100 2225 1270

2200 2325 1320

2300 2425 1380

2400 2525 1440

40

271695 2017-12

Page 41

SLCT* and SLCT*/35 safety light curtains

Protection field 111.5 8.5

L 9.5

29.5

20

Protection field 111.5 8.5

L 9.5

29.5 5.0

20

Appendix

8.3 Dimensional drawing

SLCT14* with protection field height ≤ 1200 mm and

SLCT30*/35, SLCT60*/35, SLCT90*/35 with protection field heigh ts

≤ 2400 mm

Figure 8.1 Dimensions of the safety light curtain with protection field height ≤ 1200 mm

and ≤ 2400 mm

SLCT30*, SLCT60*, SLCT90* with protection field heights ≤ 1200 mm

Figure 8.2 Dimensions of the safety light curtain with protection field height ≤ 1200 mm

SLCT30*, SLCT60*, SLCT90* with protection field heights ≥ 1300 mm

Figure 8.3 Dimensions of the safety light curtain at ≤ 1300 mm

8.4 Type Code

Safety light curtains from the SLCT series are designated a code

acc ording to the following format:

S L C T XX - YYYY - Z - AAAA /35

Here, XX represents the obstacle size, YYYY the protection field height, Z the

device type, i.e. transmitter (T) or receiver (R), and AAAA a building regulation

which applies in individual cases.

271695 2017-12

"/35" identifies the "increased detection range" option.

41

Page 42

SLCT* and SLCT*/35 safety light curtains

Appendix

Protection field

Obstacle size

XX [mm] YYYY [mm] Z AAAA

14 100, 200, 300,

30 100, 200, 300,

60 300, 600, 900,

90 300, 600, 900,

height Device type

T, R No

1200

T, R No

2400

T, R No

2400

T, R No

2400

Building

regulation

specification

specification

specification

specification

Detection

range

Standard

Standard

Increased

detection

range "/35"

Standard

Increased

detection

range "/35"

Standard

Increased

detection

range "/35"

Type code "SCLT14-* (obstacle size 14 mm)

Protectio n field

height [mm]

100 SLCt14-100 SLCT14-100-T SLCT14-100-R

200 SLCT14-200 SLCT14-200-T SLCT14-200-R

Complete Transmitter unit (-T) Receiver unit (-R)

300 SLCT14-300 SLCT14-300-T SLCT14-300-R

400 SLCT14-400 SLCT14-400-T SLCT14-400-R

500 SLCT14-500 SLCT14-500-T SLCT14-500-R

600 SLCT14-600 SLCT14-600-T SLCT14-600-R

700 SLCT14-700 SLCT14-700-T SLCT14-700-R

800 SLCT14-800 SLCT14-800-T SLCT14-800-R

900 SLCT14-900 SLCT14-900-T SLCT14-900-R

1000 SLCT14-1000 SLCT14-1000-T SLCT14-1000-R

1100 SLCT14-1100 SLCT14-1100-T SLCT14-1100-R

1200 SLCT14-1200 SLCT14-1200-T SLCT14-1200-R

42

271695 2017-12

Page 43

SLCT* and SLCT*/35 safety light curtains

Appendix

Type code "SCLT30-* (obstacle size 30 mm) - standard detection ran ge

Protection field

height [mm] Complete Transmitter unit (-T) Receiver unit (-R)

100 SLCT30-100 SLCT30 -100-T SLCT30-100-R

200 SLCT30-200 SLCT30 -200-T SLCT30-200-R

300 SLCT30-300 SLCT30 -300-T SLCT30-300-R

400 SLCT30-400 SLCT30 -400-T SLCT30-400-R

500 SLCT30-500 SLCT30 -500-T SLCT30-500-R

600 SLCT30-600 SLCT30 -600-T SLCT30-600-R

700 SLCT30-700 SLCT30 -700-T SLCT30-700-R

800 SLCT30-800 SLCT30 -800-T SLCT30-800-R

900 SLCT30-900 SLCT30 -900-T SLCT30-900-R

1000 SLCT30-1000 SLCT30 -1000-T SLCT30-1000-R

1100 SLCT30-1100 SLCT30 -1100-T SLCT30-1100-R

1200 SLCT30-1200 SLCT30 -1200-T SLCT30-1200-R

1300 SLCT30-1300 SLCT30 -1300-T SLCT30-1300-R

1400 SLCT30-1400 SLCT30 -1400-T SLCT30-1400-R

1500 SLCT30-1500 SLCT30 -1500-T SLCT30-1500-R

1600 SLCT30-1600 SLCT30 -1600-T SLCT30-1600-R

1700 SLCT30-1700 SLCT30 -1700-T SLCT30-1700-R

1800 SLCT30-1800 SLCT30 -1800-T SLCT30-1800-R

1900 SLCT30-1900 SLCT30 -1900-T SLCT30-1900-R

2000 SLCT30-2000 SLCT30 -2000-T SLCT30-2000-R

2100 SLCT30-2100 SLCT30 -2100-T SLCT30-2100-R

2200 SLCT30-2200 SLCT30 -2200-T SLCT30-2200-R

2300 SLCT30-2300 SLCT30 -2300-T SLCT30-2300-R

2400 SLCT30-2400 SLCT30 -2400-T SLCT30-2400-R

271695 2017-12

43

Page 44

SLCT* and SLCT*/35 safety light curtains

Appendix

Type code "SCLT30-* (obstacle size 30 mm) - increased detection range

Protectio n field

height [mm] Complete Transmitter unit (-T) Receiver unit (-R)

100 SLCT30-100/35 SLCT30-100-T/35 SLCT30-100-R/35

200 SLCT30-200/35 SLCT30-200-T/35 SLCT30-200-R/35

300 SLCT30-300/35 SLCT30-300-T/35 SLCT30-300-R/35

400 SLCT30-400/35 SLCT30-400-T/35 SLCT30-400-R/35

500 SLCT30-500/35 SLCT30-500-T/35 SLCT30-500-R/35

600 SLCT30-600/35 SLCT30-600-T/35 SLCT30-600-R/35

700 SLCT30-700/35 SLCT30-700-T/35 SLCT30-700-R/35

800 SLCT30-800/35 SLCT30-800-T/35 SLCT30-800-R/35

900 SLCT30-900/35 SLCT30-900-T/35 SLCT30-900-R/35

1000 SLCT30-1000/35 SLCT30-1000-T/35 SLCT30-1000 -

1100 SLCT30-1100/35 SLCT30-1100-T/35 SLCT30-1100 -

1200 SLCT30-1200/35 SLCT30-1200-T/35 SLCT30-1200 -

1300 SLCT30-1300/35 SLCT30-1300-T/35 SLCT30-1300 -

1400 SLCT30-1400/35 SLCT30-1400-T/35 SLCT30-1400 -

1500 SLCT30-1500/35 SLCT30-1500-T/35 SLCT30-1500 -

1600 SLCT30-1600/35 SLCT30-1600-T/35 SLCT30-1600 -

1700 SLCT30-1700/35 SLCT30-1700-T/35 SLCT30-1700 -

1800 SLCT30-1800/35 SLCT30-1800-T/35 SLCT30-1800 -

1900 SLCT30-1900/35 SLCT30-1900-T/35 SLCT30-1900 -

2000 SLCT30-2000/35 SLCT30-2000-T/35 SLCT30-2000 -

R/35

R/35

R/35

R/35

R/35

R/35

R/35

R/35

R/35

R/35

R/35

2100 SLCT30-2100/35 SLCT30-2100-T/35 SLCT30-2100 -

2200 SLCT30-2200/35 SLCT30-2200-T/35 SLCT30-2200 -

2300 SLCT30-2300/35 SLCT30-2300-T/35 SLCT30-2300 -

2400 SLCT30-2400/35 SLCT30-2400-T/35 SLCT30-2400 -

44

R/35

R/35

R/35

R/35

271695 2017-12

Page 45

SLCT* and SLCT*/35 safety light curtains

Appendix

Type code "SCLT60-* (obstacle size 60 mm) - standard detection ran ge

Protection field

height [mm] Complete Transmitter unit (-T) Receiver unit (-R)

300 SLCT60-300 SLCT60 -300-T SLCT60-300-R

600 SLCT60-600 SLCT60 -600-T SLCT60-600-R

900 SLCT60-900 SLCT60 -900-T SLCT60-900-R

1200 SLCT60-1200 SLCT60 -1200-T SLCT60-1200-R

1500 SLCT60-1500 SLCT60 -1500-T SLCT60-1500-R

1800 SLCT60-1800 SLCT60 -1800-T SLCT60-1800-R

2100 SLCT60-2100 SLCT60 -2100-T SLCT60-2100-R

2400 SLCT60-2400 SLCT60 -2400-T SLCT60-2400-R

Type code "SCLT60-* (obstacle size 60 mm) - increased detection range

Protection field

height [mm] Complete Transmitter unit (-T) Receiver unit (-R)

300 SLCT60-300/35 SLCT60-300-T/35 SLCT60-300-R/35

600 SLCT60-600/35 SLCT60-600-T/35 SLCT60-600-R/35

900 SLCT60-900/35 SLCT60-900-T/35 SLCT60-900-R/35

1200 SLCT60-1200/35 SLCT60-1200-T/35 SLCT60-1200-

1500 SLCT60-1500/35 SLCT60-1500-T/35 SLCT60-1500-

1800 SLCT60-1800/35 SLCT60-1800-T/35 SLCT60-1800-

2100 SLCT60-2100/35 SLCT60-2100-T/35 SLCT60-2100-

2400 SLCT60-2400/35 SLCT60-2400-T/35 SLCT60-2400-

R/35

R/35

R/35

R/35

R/35

Type code "SCLT90-* (obstacle size 90 mm) - standard detection ran ge

Protection field

height [mm] Complete Transmitter unit (-T) Receiver unit (-R)

300 SLCT90-300 SLCT90 -300-T SLCT90-300-R

600 SLCT90-600 SLCT90 -600-T SLCT90-600-R

900 SLCT90-900 SLCT90 -900-T SLCT90-900-R

1200 SLCT90-1200 SLCT90 -1200-T SLCT90-1200-R

1500 SLCT90-1500 SLCT90 -1500-T SLCT90-1500-R

1800 SLCT90-1800 SLCT90 -1800-T SLCT90-1800-R

2100 SLCT90-2100 SLCT90 -2100-T SLCT90-2100-R

2400 SLCT90-2400 SLCT90 -2400-T SLCT90-2400-R

271695 2017-12

45

Page 46

SLCT* and SLCT*/35 safety light curtains

Appendix

Type code "SCLT90-* (obstacle size 90 mm) - increased detection range

Protectio n field

height [mm] Complete Transmitter unit (-T) Receiver unit (-R)

300 SLCT90-300/35 SLCT90-300-T/35 SLCT90-300-R/35

600 SLCT90-600/35 SLCT90-600-T/35 SLCT90-600-R/35

900 SLCT90-900/35 SLCT90-900-T/35 SLCT90-900-R/35

1200 SLCT90-1200/35 SLCT90-1200-T/35 SLCT90-1200 -

1500 SLCT90-1500/35 SLCT90-1500-T/35 SLCT90-1500 -

1800 SLCT90-1800/35 SLCT90-1800-T/35 SLCT90-1800 -

2100 SLCT90-2100/35 SLCT90-2100-T/35 SLCT90-2100 -

2400 SLCT90-2400/35 SLCT90-2400-T/35 SLCT90-2400 -

R/35

R/35

R/35

R/35

R/35

46

271695 2017-12

Page 47

SLCT* and SLCT*/35 safety light curtains

Appendix

8.5 Application Checklist

A list of important points should help you avoid errors when planning, setting up,

and using the protective equipment. This application checklist is not complete and

must be modified to suit each specific application.

Note!

Observing Applicable Standards and Laws

The relevant laws and standards that apply to the use of opto-electronic safety

devices must be followed. There are differences depending on the area of use.

Before installation

■

Have all the applicable standards and regulations been observed?

■

Does the technical data of the SLCT meet the requirements of the

application? This especially applies to detection capability, the protection

field height, and the operating voltage.

■

Is the overvoltage category required by EN 50178 or EN 60947-1 met at the

connections?

■

Is the electrical equipment, the wiring, and the overcurrent protection

designed in accordance with IEC 60204-1:2009?

■

Is there enough space for mounting and dismounting components?

■

Are the distances between the protection field and the hazardous area and

the surfaces to be reflected maintained as required?

■

Is the S LCT used indoors?

After installation

■

Is the startup enable input connected when the startup/restart interlock is

activated?

■

Is the ready-to-start signal lamp connected?

■

Is the test input connected?

■

Is the red/green indicator for signaling the status of the OSSD outputs in a

visible location?

■

Are all components correctly connected?

■

Has the SLCT been positioned so that the protection field cannot be

bypassed and people cannot enter the hazardous area undetected?

■

Is the S LCT aligned?

■

Have the necessary safety distances been maintained?

Commissioning

■

Has the detection capability of the SLCT been tested over the entire

protection field height using the test rod? This test should take place at

multiple locations and at least once in front of the transmitter and receiver

unit as well as at the central point between the transmitter and receiver.

■

Do the OSSD switching outputs trigger the requisite stop?

■

Has the reaction time of the protective equipment as a whole been

checked?

271695 2017-12

47

Page 48

SLCT* and SLCT*/35 safety light curtains

Appendix

Periodic check

■

Have the requisite tests and test intervals been determined?

■

Is the detection capability of the SLCT tested regularly over the entire

protection field height using the test rod?

■

Are the response times checked at regular intervals?

■

Is all machine safety equipment inspected at the required intervals?

■

Are all inspections documented?

48

271695 2017-12

Page 49

SLCT* and SLCT*/35 safety light curtains

Appendix

8.6 Accessories

The following products are available as accessories:

Matching accessories for safety light curtains

No. Designation Illustration Description

1 OMH-SLCT-01 Mounting Aid

2 OMH-SLCT-02 Mounting Aid

3 OMH-SLCT-03 Mounting Aid

4 OMH-SLCT-04 Mounting Aid

5 OMH-SLCT-05 Mounting Aid

271695 2017-12

49

Page 50

SLCT* and SLCT*/35 safety light curtains

Appendix

No. Designation Illustration Description

6 OMH-SLCT-10 Mounting Aid

7 OMH-SLCT-11 Mounting Aid

8 OMH-SLCT-

12-500

9 OMH-07-01 Light barrier holder for

Muting arm with round

rod

muting round rod

50

271695 2017-12

Page 51

SLCT* and SLCT*/35 safety light curtains

Appendix

No. Designation Illustration Description

10 OMH-SLCT-

100-1200

OMH-SLCT100-1500

OMH-SLCT100-2100

OMH-SLCT100-2500

Mounting profile for

floor mounting

271695 2017-12

51

Page 52

SLCT* and SLCT*/35 safety light curtains

Appendix

No. Designation Illustration Description

11 OMH-SLCT-

110-1200

OMH-SLCT110-1500

OMH-SLCT110-2100

OMH-SLCT110-2500

Mounting profile with

decorative cover (front)

52

271695 2017-12

Page 53

SLCT* and SLCT*/35 safety light curtains

Appendix

No. Designation Illustration Description

12 OMH-SLCT-

120-1200

OMH-SLCT120-1500

OMH-SLCT120-2100

OMH-SLCT120-2500

13 OMH-SLCT-

200

Two lateral protective

covers for mounting

profile

Floor mount for soil

column/mountin g profile

271695 2017-12

53

Page 54

SLCT* and SLCT*/35 safety light curtains

Appendix

No. Designation Illustration Description

14 SLCT-M-01-

1200

SLCT-M-011500

SLCT-M-012100

SLCT-M-012500

Inclined mirror for 90°

deflection

15 AA SLCT-01 Profile alignment aid

16 TR

14/30/50/60

54

Test rod

271695 2017-12

Page 55

SLCT* and SLCT*/35 safety light curtains

ø 4.3

8.3

16

ø 4.3

61.128

OMH-SLCT-02

OMH-SLCT-01

OMH-SLCT-02

OMH-SLCT-01

37

42.8

17.1

Appendix

Available Mounting Brackets

The mounting brackets enable light curtains and accessories to be mounted. A

complete mounting bracket is required to mount a transmitter and a receiver. The

mounting brackets are also suitable as a corner profile if two independently acting

light curtains are to be installed. For compatible mounting brackets, use the

search term SLCT-M *. on www.pepperl+fuchs.com.

8.6.1 Mounting Aid OMH-SLCT-01

Model number: OMH-SLCT-01

The transmitters/receivers can be secured using mounting aids that grip the

dovetail guide. Dovetail guides are located on three sides of the profile. When

mounting and aligning the unit, avoid subjecting the profile to mechanical tension.

A minimum of two mounting aids must be used to secure the transmitter and

receiver unit. If vibrations or shocks are expected, we recommend attaching

mounting aids at intervals of 500 mm.

8.6.2 Mounting Aid OMH-SLCT-02

Model number: OMH-SLCT-02

Figure 8.4 Dimensional drawing and assembly of the mounting aids OMH-SLCT-0 1 and

OMH-SLCT-02

The OMH-SLCT-02 mounting aid is used as a fixed bearing and secures the

position of the light curtain in the event of thermal expansion, vibration, or shock.

271695 2017-12

55

Page 56

SLCT* and SLCT*/35 safety light curtains

Appendix

8.6.3 Mounting brackets OMH-SLCT-03 and OMH-SLCT-04

Model number (fixed bearing): OMH-SLCT-03