Page 1

HANDBUCH / MANUAL / MANUAL / MANUALE

HANDBUCH / MANUAL / MANUAL / MANUALE

Radar-Bewegungsmelder

Radar Motion Sensor

Avisador de movimientos radar

Rilevatori di movimento radar

RMS-FRW

FACTORY AUTOMATION

Page 2

Radar Motion Sensor RMS-FRW

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

1.1 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

2 Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

3 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

3.1 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

3.2 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

3.3 Standard-relevant safety settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

4 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

4.1 Displays and operating elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

4.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

4.3 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

5.1 Storage and transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

5.2 Unpacking the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

5.3 Mounting and connecting the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

6 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

7 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

7.1 Keypad menu operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

7.2 Remote control operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

8 Maintenance and repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

9 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

10 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

10.1 Explanation of sensor parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

10.2 Overview of sensor parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

10.3 Overview of remote control menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

10.4 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

10.5 Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

31

Page 3

Radar Motion Sensor RMS-FRW

Introduction

1 Introduction

Congratulations

You have chosen a device manufactured by Pepperl+Fuchs. Pepperl+Fuchs develops, produces and distributes

electronic sensors and interface modules for the automation technology market on a worldwide scale.

Contact

If you have any questions about the device, accessories or further functions, contact:

Pepperl+Fuchs GmbH

Lilienthalstraße 200

68307 Mannheim

Telefon: 0621 776-1111

Telefax: 0621 776-271111

E-Mail: fa-info@de.pepperl-fuchs.com

1.1 Warranty

Pepperl+Fuchs manufactures its hardware products in accordance with industry-standard practices. Pepperl+Fuchs

warrants its products will be free from defects in materials and workmanship, provided that the products are used

under normal operating conditions intended by the manufacturer. This warranty is provided to the original owner only

and is not transferable to any third party. This warranty is subject to any and all accompanying disclaimers, limitations

and other terms of this section.

Exclusion of liability

The warranty shall not apply to products that:

• have been repaired, modified or manipulated, unless carried out or expressly authorized by Pepperl+Fuchs,

• have not been maintained in accordance with the operating and handling instructions supplied by Pepperl+Fuchs,

• have been exposed to abnormal physical or electrical loads, immersed in liquids, or have been subject to one of

the following:

•breaking,

• crushing,

• incorrect use,

32

Page 4

Radar Motion Sensor RMS-FRW

Introduction

• abuse,

• power shortage,

• unsuitable voltage supply,

• incorrect polarity,

• negligence or accident

• have been used for a purpose other than that described in the operating and handling instructions.

Preventive maintenance is the responsibility of the customer and is not covered under this warranty.

General

With the exception of the above-mentioned warranties, Pepperl+Fuchs shall not accept warranties of any kind for

products supplied hereunder, neither of an explicit nor implicit nature, including, but not restricted to, implicit warranties for defects and warranties of suitability for a special purpose and non-infringement of third-party rights. The

above-named explicit warranties replace all obligations and liabilities on the part of Pepperl+Fuchs with regard to

damage, including, but not limited to, special, indirect or consequential damage in conjunction with the use or design

of the product. The liability of the seller to the buyer and other persons (irrespective of the reason for liability, whether

contract, warranty, impermissible activity, abuse and/or other causes) in conjunction with the use of a product shall,

under no circumstances, exceed the original purchase price of the product. Under no circumstances shall Pepperl+Fuchs be liable for consequential damage, special and indirect damage, collateral damage or fines or lost profits, turnover or data loss, even if Pepperl+Fuchs has been informed of this possibility in writing.

33

Page 5

Radar Motion Sensor RMS-FRW

0682

ISO9001

Declaration of conformity

2 Declaration of conformity

EC conformity:

are compliant with Directive 1999/5/EC, device class 2 and the following harmonized standards

EN 62311, EN 60950-1, EN 301 489-1, EN 301489-3, EN 300 440-2.

The products

RMS-FRW

Caution:

This device can be used in all countries within the European Union with the exception of Great Britain and France.

In other countries, all applicable national regulations must be observed.

Pepperl+Fuchs GmbH, in D-68301 Mannheim, has a certified quality assurance system in accordance with ISO

9001.

34

A complete version of the declaration of conformity is available for download at

www.pepperl-fuchs.com

.

Page 6

Radar Motion Sensor RMS-FRW

Safety

3Safety

3.1 Symbols used

Safety-relevant symbols

Danger!

This symbol indicates an imminent danger.

Failure to avoid this danger can lead to serious injury or death.

Warning!

This symbol indicates a possible fault or danger.

Failure to avoid this warning can lead to serious injury or serious property damage.

Caution!

This symbol warns of a possible fault.

Failure to observe the instructions given in this caution may result in the devices and any

connected facilities or systems developing a fault or failing completely.

Informative symbols

Note!

This symbol draws your attention to important information.

Instruction

This symbol indicates an instruction.

35

Page 7

Radar Motion Sensor RMS-FRW

Safety

3.2 General safety instructions

The operator of the system is responsible in terms of planning, mounting, set-up, operating and maintenance.

Installation and set-up of all devices must be performed by a trained professional only.

Protection of operating personnel and the system is not ensured if the module is not used in accordance with its in-

tended purpose.

Conformance to the laws and regulations applicable to the specified or intended usage should be ensured. The de-

vices are only approved for proper professional usage in accordance with the intended purposes. Improper handling

will void any claim made under the warranty and any manufacturer's liability.

Only use recommended original accessories.

If serious faults occur, stop using the device. Secure the device against inadvertent operation. In the event of repairs,

send the device to Pepperl+Fuchs. Independent interventions and separate modifications are dangerous and will

void the warranty and exclude the manufacturer from any liability.

Dispose of the defective device in accordance with country-specific legal requirements.

Correctly dispose of the sensor by handing it over to a designated collection point for the recycling of electrical and

electronic equipment waste.

In order to satisfy the safety requirements specified in EN60950-1 and UL508, the sensor must

be operated from an SELV supply where output is limited to 100 W.

The output can be limited using a T2.5 A fuse.

This device must be installed and maintained only by qualified, trained personnel.

36

Page 8

Radar Motion Sensor RMS-FRW

Safety

3.3 Standard-relevant safety settings

Some functions permit settings that are not in accordance with AutSchR: 1997 (Directive for automatic sliding doors

in escape and rescue routes):

3.3.1 Settings for doors in escape and rescue routes:

Connecting the sensor:

The two relay contacts are galvanically separated. For safety reasons, series or parallel connection is not permissible. Both contacts must be evaluated separately on the door control system. The output signal is only valid if the two

relay contacts of the movement output are in the same state.

Sensitivity of the movement detection:

The field depth must be at least 1.5 m!

Output hold time movement detector:

The setting "Off" is not permissible!

Polarity output movement detector:

The setting "Active" is not permissible!

37

Page 9

Radar Motion Sensor RMS-FRW

1

2

3

4

5

6

Product description

4 Product description

Approval for escape and rescue routes

The radar sensor RMS-FRW is certified in accordance with AutSchR and bears the TÜV seal of approval.

Typical areas of application include escape and rescue routes with airlock function. Escape and rescue routes with

windscreen function in both directions are possible in conjunction with the devices RMS-D or RMS-M from the same

family.

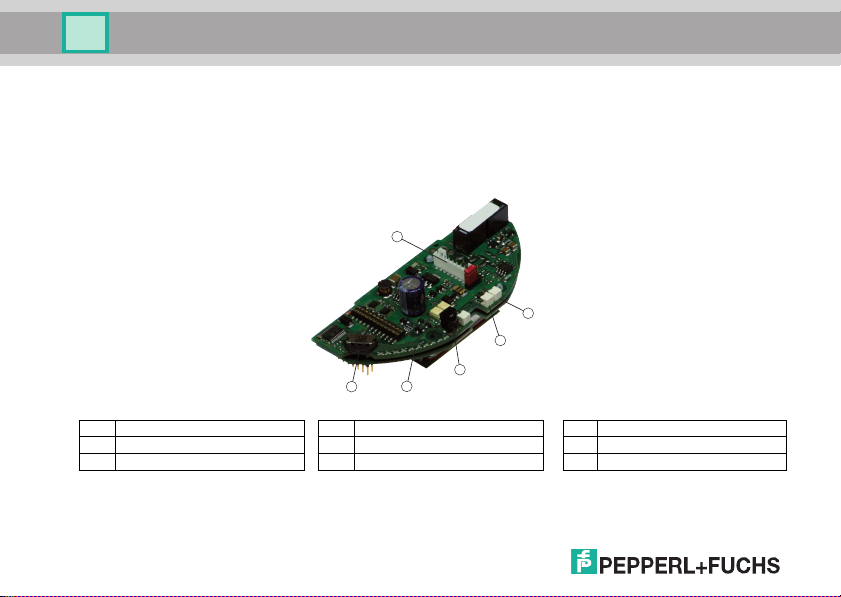

4.1 Displays and operating elements

Illustration41 Displays and operating elements

No. Designation No. Designation No. Designation

1 Bargraph with 10 LEDs 3 IR transmitter 5 Navigation key

2 LED red/green 4 IR receiver 6 Connection plug

Table 4.2 Displays and operating elements

38

Page 10

Radar Motion Sensor RMS-FRW

Product description

4.1.1 Overview of LED displays

Switch-on / initialization

LED red/green Bargraph Description

Flashes red/

green

- The sensor is being initialized.

Standard operation / detection

LED red/green Bargraph Description

Illuminates green - The sensor is ready to operate, no detection.

Illuminates red - Detection by movement detector

Operation with RMS Remote Control

LED red/green Bargraph Description

Flashes 3x green - Command received from remote control

Error

LED red/green Bargraph Description

Flashes red Error code The sensor has identified an error. The bargraph display indicates an error code.

4.2 Scope of delivery

The scope of delivery includes:

• RMS-FRW

• 3 m connection cable with 8-pin connector strip

• Self-adhesive mounting template sticker

• Screws for mounting

• Operating instructions

39

Page 11

Radar Motion Sensor RMS-FRW

Installation

4.3 Accessories

The following products are available as accessories:

No. Designation Illustration Description

1 RMS Remote Control Infrared remote control

2 RMS Weather Cap

Weather cap and mounting bracket for

ceiling mounting

5 Installation

5.1 Storage and transportation

For storage and transport purposes, package the unit using shockproof packaging material and protect it against

moisture. The best method of protection is to package the unit using the original packaging. Furthermore, ensure

that the ambient conditions are within the allowable range.

5.2 Unpacking the device

Check to see that no parts are damaged. In the case of damage, report it to the post office or carrier and notify the

supplier.

Check the scope of delivery against the original purchase order and the shipping documents.

Keep the original packing material in case the device has to be placed into storage or for possible future reshipment.

If you have any questions, contact Pepperl+Fuchs.

40

Page 12

Radar Motion Sensor RMS-FRW

Installation

5.3 Mounting and connecting the device

Positioning the sensor

Make sure that the printed circuit board is fitted horizontally (0°) in the inside of the housing.

The sensing area is 2500 mm x 3500 mm (D x W) at 2200 mm mounting height.

The printed circuit board can be adjusted by a maximum of 10°. (Max. two notches downwards)

Illustration51 Mounting the RMS-FRW

Mounting the RMS-FRW

Proceed as follows to mount the sensor:

1. Open the housing with a slotted screwdriver from below.

An indentation is located underneath the housing.

Do not open the housing from above!

2. Place the template (included with sensor) in desired location.

3. Drill mounting holes.

4. Pull the enclosed cable with the connector side through the provided opening.

5. Mount the base plate using the screws enclosed in the housing.

41

Page 13

Radar Motion Sensor RMS-FRW

Pin-out according 8-pin plug strip

Pin-out according 8-pin plug strip

(Frequency output)

(Relay output)

Pin Signal

Pin Signal

1

2

3

4

5

6

7

8

+12 ... 36 V DC

GND

Relay 1

Relay 1

Relay 2

Relay 2

No Connection

No Connection

Color

Color

white

brown

green

yellow

grey

pink

blue

red

Pin-out according 8-pin plug strip

(Voltage output)

Pin Signal

Color

1

2

3

4

5

6

7

8

+12 ... 36 V DC

GND

Uout +

Uout No Connection

No Connection

No Connection

No Connection

white

brown

green

yellow

grey

pink

blue

red

1

2

3

4

5

6

7

8

+12 ... 36 V DC

GND

Fout +

Uin Uin +

No Connection

No Connection

No Connection

white

brown

green

yellow

grey

pink

blue

red

Installation

Connecting the RMS-FRW

The sensor is supplied with power via the connection plug. It is also possible to directly connect

to the relay contact on the connection plug. Proceed as follows:

1. Connect the cable to the power supply.

2. Insert the socket on the cable into the connection plug on the printed circuit board.

3. Connect the safety sensor terminal on the controller (door control) with the relay contacts or

the corresponding voltage or frequency output of the movement detector. For this, use the

suitable wires of the cable coming from the RMS-FRW.

4. For all further steps, refer to Set-up (see section 6)

5. After completing all the settings for the sensor, push the cover over the base plate. Hook the

cover on to the upper end of the base plate and press the cover until it clicks into place.

The plug has the following pin assignment:

42

Page 14

Radar Motion Sensor RMS-FRW

UP

SELECT

DOWN

Set-up

6Set-up

When switching on the RMS-FRW, make sure to remove all objects in the door area that do not belong in the usual

vicinity of the door.

Set-up

To set-up the sensor, proceed as follows:

1. Switch on the power supply.

2. Set the output movement detector on the RMS-FRW or select the standard profile door

control. (see section 10.1)

3. Set the sensor address.

4. Set the mounting height on the RMS-FRW.

5. Set the movement detection on the RMS-FRW.

6. Check the settings by pacing through the dynamic field.

You can also program the sensor using the remote control with the hood placed in position.

In such a case, the sensor address needs to have been previously set.

7Operation

7.1 Keypad menu operation

7.1.1 General setting instructions

In the keypad menu the sensor can be set by means of the navigation key and the bar graph display.

The sensor function is maintained even in the keypad menu. The programming can be checked immediately.

43

Page 15

Radar Motion Sensor RMS-FRW

Group 1:

Movement detection parameters

Group 3:

General sensor parameters

LED 1: Sensitivity

LED 2: Detection mode

LED 3: Cross traffic suppression

LED 4: Immunity

LED 5: Output hold time

LED 6: Polarity output

LED 1: Sensor address

LED 2: Mounting height

Main menu

UP

SELECT > 2 s

DOWN

Operation

RMS-FRW parameters

7.1.2 Start / end keypad menu

Start the keypad menu by pressing the SELECT key for 2 s. The bar graph display begins to flash.

Exit the keypad menu by pressing the SELECT key for 2 s.

If no setting takes place over a period of 10 minutes, the keypad menu is automatically exited.

7.1.3 Setting parameters

Use the UP and DOWN keys to select and change the parameters.

Use the SELECT key to confirm the set value.

44

Page 16

Radar Motion Sensor RMS-FRW

Operation

1. Selecting the parameter group

The bar graph display shows the selected parameter group by flashing.

Use the UP and DOWN keys to select the parameter group and confirm by pressing the SELECT key.

Movement detection parameters

General sensor parameters

2. Selecting parameters

The bar graph display indicates the parameter selected by flashing.

Use the UP and DOWN keys to select the parameter group and confirm by pressing the SELECT key.

Display Movement detection Sensor general

3. Setting the parameter value

The bar graph display indicates the current value of the selected parameter.

Use the UP and DOWN keys to select the parameter group and confirm by pressing the SELECT key.

Parameter 1 Sensitivity Sensor address

Parameter 2 Detection mode Mounting height

Parameter 3 Cross traffic suppression

Parameter 4 Immunity

Parameter 5 Output hold time

Parameter 6 Polarity output

Parameter 7

Parameter 8

Parameter 9

ex. sensitivity - stage 4

ex. sensitivity - stage 7

45

Page 17

Radar Motion Sensor RMS-FRW

UP

SELECT > 10 s

DOWN

RMS-D-RC

RMS-M-RC

RMS-G-RC

RMS-FRW

Pepperl+Fuchs

RMS-S

RMS-S-FRW

find address

address 1

address 2

address 3

address 4

address 5

RMS-FRW

Operation

7.1.4 Fast entry

You can use the fast entry to change the "Sensitivity of the movement detection" directly.

To edit or display the current parameter value there is no need to change over to the keypad menu.

To do this, proceed as follows:

• The SELECT key shows the current value.

• The UP and DOWN keys immediately change the parameter value.

• The current value is shown for a period of 10 s.

7.1.5 Restoring the factory default settings (RESET)

If the navigation key is kept pressed for a period longer than 10 s, then the parameters are returned

to their default settings, followed by a reset of the sensor.

7.2 Remote control operation

Use the remote control to optimally program the sensor from the ground easily and quickly. The sensor function is

maintained even in programming mode. The programming can be checked immediately.

7.2.1 Establishing the connection

Read the remote control operating instructions before programming.

Switch on the sensor. The green LED lights.

Direct the remote control such that it is aimed directly at to the sensor.

Establishing connection without code

Select sensor "RMS-FRW" Select the address Set the sensor

46

RMS-FRW

movement detection

sensor generally

Page 18

Radar Motion Sensor RMS-FRW

RMS-D-RC

RMS-M-RC

RMS-G-RC

RMS-FRW

Pepperl+Fuchs

RMS-S

RMS-S-FRW

find address

address 1

address 2

address 3

address 4

address 5

RMS-FRW

enter code

sensitivity

detection mode

fade out cross traff.

immunity

output hold time

polarity output

movement detection

read value

1 minim.

2

3

4

5

sensitivity

read value

1 minim.

2

3

4

5

sensitivity

read value

1 minim.

2

3

4

5

sensitivity

Operation

Establishing connection with code

RMS-FRW

movement detection

sensor generally

Select sensor "RMS-FRW" Select the address Enter 4-digit code Set the sensor

When the connection has been established, a selection window with all setting options of the sensor appears.

The black bar marks the current setting.

7.2.2 Setting the sensor

Use the operating buttons to select the required setting based on the indicated values.

Example: set the sensitivity of the movement detection

Select "Sensitivity of the

movement detection"

If the connection is interrupted, a transmission error is indicated. The transmission must be repeated.

The new setting can be checked immediately after the transmission.

Select menu option "Read

value"

The current

value is displayed

Set the value

47

Page 19

Radar Motion Sensor RMS-FRW

installation height

standardprofiles

sensorstate

reset

code

close connection

sensor generally

access with code

lock access

access without code

code

enter code

repeat code

Operation

7.2.3 Address

If several sensors are within range of the remote control, the sensors must be programmed with different addresses.

This setting can only be made with the keypad menu.

7.2.4 Security

Access without code:

Access with the remote control is possible at any time.

Access with code:

The sensor can be secured against unauthorized access with a 4-digit code. The programming mode can then only

be accessed by entering the code.

48

Select "Code" Select "Access

with code"

Enter 4-digit code Repeat

4-digit code

Lock access:

If the sensor is secured with "Lock access", the device is locked. Access with the remote control is no longer possible.

The configuration mode is automatically left 30 minutes after the last transfer. cycling power the sensor is in the "Access without code" state for 30 minutes.

Page 20

Radar Motion Sensor RMS-FRW

Maintenance and repair

8 Maintenance and repair

Maintenance

Conformance to all applicable laws and regulations regarding maintenance must be ensured.

The sensor is largely maintenance-free.

However, periodically check the technical safety of the sensor system for damage to the housing.

The sensor should be checked occasionally for contamination. To clean the sensor, wipe the sensor with a dry or

damp soft cloth at regular intervals. This assures optimal functioning.

The housing is made of plastic. Therefore avoid contact with acetone and cleaning agents containing solvents.

Repairs

If safe operation is no longer possible, the sensor system must be disconnected and protected against accidental

use. In the event of repairs, send the device to Pepperl+Fuchs. Independent interventions and separate modifications are dangerous and will void the warranty and exclude the manufacturer from any liability.

9 Troubleshooting

Interfering influences

• The sensor must be mounted securely and not subject to any vibration.

• The sensor must not be installed behind a cover

• The sensing area should be free of moving objects (ex. fans, plants, trees, flags etc.)

• The sensor should be mounted with suitable rain protection. (For recommended accessories see section 4.3)

• The sensor should not be mounted close to fluorescent lighting

Eliminating interfering influences

Error source Remedy

LED red flashes

The sensor has identified an error. The bargraph display indicates an error

code.

49

Page 21

Radar Motion Sensor RMS-FRW

Appendix

10 Appendix

10.1 Explanation of sensor parameters

10.1.1Movement detection

Sensitivity

Using this sensitivity setting, the size of the sensing area can be changed.

The setting options range from 1 (smallest sensing area) to 10 (largest sensing area).

This setting can be set using the remote control or the keypad menu.

Detection mode

The direction recognition can be changed with the detection mode.

Setting Description

Mono Detects forward and backward movement

Forward Detects movement towards the sensor

Backward Detects movement away from the sensor

This setting can be set using the remote control or the keypad menu.

Suppression of cross traffic

This mode can be used to change the strength of cross traffic suppression. The setting options range from 1 (off),

2 - 5 (low) to 6 - 10 (high). High cross traffic suppression means strong suppression (fade out) of cross traffic.

This setting can be set using the remote control or the keypad menu.

Immunity

In principle, the sensor is immune against any interfering influences. However, special installation situations or major

sources of interference may sometimes cause incorrect triggering. The immunity setting can be used to minimize

various interfering influences (vibrations, reflections, fluorescence lighting etc.).

The setting options range from 1 (off), 2 - 5 (low) to 6 - 10 (high).

This setting can be set using the remote control or the keypad menu.

50

Page 22

Radar Motion Sensor RMS-FRW

Appendix

Output hold time

In the case of the setting "Off", together with the function "Polarity - output", the door could remain open or closed

indefinitely.

Setting Hold time

0 off (no output signal)

10.2s

20.5s

31s

42s

53s

64s

75s

810s

This setting can be set using the remote control or the keypad menu.

Polarity

Using this function, it can be preset whether the output of the movement detector works with active or passive switching during detection.

Output type RMS-FRW with relay RMS-FRW with voltage output RMS-FRW with frequency output

Active

Passive Relay contacts open at detection

Relay contacts closed

at detection

Output voltage = on

at detection

Output voltage = off

at detection

Output frequency = on

at detection

Output frequency = off

at detection

This setting can be set using the remote control or the keypad menu.

51

Page 23

Radar Motion Sensor RMS-FRW

Appendix

10.1.2Sensor general

Sensor address

If several sensors are within range of the remote control, the sensors must be programmed with different addresses

via the keypad menu.

16 fixed sensor addresses are available for selection.

Display Address Display Address

Sensor 1 Sensor 9

Sensor 2 Sensor 10

Sensor 3 Sensor 11

Sensor 4 Sensor 12

Sensor 5 Sensor 13

Sensor 6 Sensor 14

Sensor 7 Sensor 15

Sensor 8 Sensor 16

This setting can only be made with the keypad menu.

Mounting height

For this parameter, set the height of the sensor from the ground up to the bottom edge of the sensor.

The following setting options are possible: 200 - 220 cm / 220 - 240 cm / 240 - 260 cm / 260 - 280 cm / 280 - 300 cm

/ 300 - 320 cm / 320 - 340 cm / 340 - 360 cm / 360 - 380 cm / 380 - 400 cm

This setting can be set using the remote control or the keypad menu.

52

Page 24

Radar Motion Sensor RMS-FRW

Appendix

Standard profile door control

Following the selection of the control system, the pre-defined settings (ex. polarity outputs, test input, etc.) will be

automatically transferred to the sensor.

Please contact us directly, or consult the Internet page www.pepperl-fuchs.com for a list of the pre-defined door control systems with a listing of all settings.

This setting can only be made with the remote control.

Sensor status

The current sensor status can be read by means of this function.

Reset

Using this function, all device parameters are restored to the factory default settings, and then the sensor begins

initialization.

This setting can be set using the remote control or the keypad menu.

Code

Access to the sensor can either be set with code, without code or locked completely.

This setting can only be made with the remote control.

Disconnection

This parameter can be used to immediately disconnect the connection between remote control and sensor.

This setting can only be made with the remote control.

53

Page 25

Radar Motion Sensor RMS-FRW

Appendix

10.2 Overview of sensor parameters

Parameter Value range Default settings

Sensitivity 1- 10 10

Detection mode Mono / forward / backward Forward

Cross traffic suppression

Immunity

Output hold time Off / 0.2 s / 0.5 s / 1 s / 2 s / 3 s / 4 s / 5 s / 10 s 1 s

Movement detection

Polarity Active / passive Passive

Sensor address 1 - 16 1

Mounting height

Restore default settings - -

Sensor general

Access code Off or 4-digit code Off

1 off

2 - 5 low

6 - 10 high

1 - 2 low

2 - 5 medium

6 - 10 high

200 - 220 cm / 220 - 240 cm / 240 - 260 cm /

260 - 280 cm / 280 - 300 cm / 300 - 320 cm /

320 - 340 cm / 340 - 360 cm / 360 - 380 cm /

380 - 400 cm

Table 10.1 Overview of sensor parameters (with factory default settings)

54

1

2

200 - 220 cm

Page 26

Radar Motion Sensor RMS-FRW

Appendix

10.3 Overview of remote control menu structure

sensitivity

read value

1 minim.

2

3

4

5

detection mode

read value

mono

forwards

backwards

fade out cross traff.

read value

1 off

2 minim.

3

4 low

5

immunity

read value

1 minim.

2

3

4

5

ut hold time

outp

read value

off

0.2s

0.5s

1.0s

2.0s

polarity output

read value

active

passiv

movement detection

sensitivity

detection mode

fade out cross traff.

immunity

output hold time

polarity output

Illustration102 Remote control menu structure

Pepperl+Fuchs

RMS-D-RC

RMS-M-RC

RMS-G-RC

RMS-FRW

RMS-S

RMS-S-FRW

RMS-FRW

find address

address 1

address 2

address 3

address 4

address 5

RMS-FRW

movement detection

sensor generally

sensor generally

installation height

standardprofiles

sensorstate

reset

code

close connection

installation height

read value

200 - 220cm

220 - 240cm

240 - 260cm

260 - 280cm

280 - 300cm

standardprofiles

profile 1

profile 2

profile 3

profile 4

profile 5

profile 6

sensorstate

transmission

reset

transmission

code

access with code

lock access

access without code

close connection

transmission

55

Page 27

Radar Motion Sensor RMS-FRW

Appendix

10.4 Technical Data

General specifications

Function principle Microwave module

Detection speed min. 0.1 m/s

Marking CE

Mounting angle 0 ... 10° in steps of 5°

Sensing area 2500 x 3500 mm (D x W) at 2200 mm mounting height and of 0° tilt angle

Operating frequency 24.05 ... 24.25 GHz K-Band

Operating mode Radar Motion Sensor

Transmission power (EIRP) < 20 dBm

Functional safety related parameters

Performance level (PL) PL d

Category Cat. 3

MTTF

d

PFH

d

Diagnostic Coverage (DC) low

Displays/operating elements

Operation indicator LED red/green & LED row green

Operating elements Navigation key

Electrical data

Operating voltage 12 ... 36 V DC

Current Consumption

Power consumption

Switching current 900 mA

FRW/31 output

Output type Relay output

Switching type Active / passive

Signal output 2 relay outputs for dynamic output

Switching voltage 48 V DC / AC

Switching current max. 1 A DC, 0.5 A AC

850 a

6.46 E-8

200 mA at 24 V DC

I0

< 3 W

P0

56

Page 28

Radar Motion Sensor RMS-FRW

Appendix

Switching capacity 30 W DC / 60 VA AC

FRW/163 output

Output type Voltage output

Switching type Active / passive

Signal output Potential-free voltage source

Max. open circuit voltage No movement detection: 10 V DC / movement detection: 500 mV DC

Switching current No movement detection: max. 10 mA at 3.2 V DC / movement detection: < 100 µA

FRW/164 output

Output type Frequency output

Switching type Transistor output (Open Collector)

Signal output Short-circuit proof

Feeding the terminating stage External: 10 V DC ... 36 V DC

Max. residual voltage 2 V DC

Max. output current 50 mA

Pulse/pause ratio 1:1 (deviation max. 10%)

Output frequency 100 Hz

Compliance with standards

Standards

Ambient conditions

Ambient temperature -20 ... 60 °C (253 ... 333 K)

Operating temperature -25 ... 60°C (248 ... 333K)

Storage temperature -30 ... 70°C (243 ... 343K)

Relative humidity max. 90 % non-condensing

Mechanical data

Mounting height max. 4000 mm

Protection category IP54

Connection 8-pin connector strip with 3 m cable

Material

Housing ABS, anthracite

Mass 6.0 oz (140 grams)

EN 60950:2000; EN 60335-1:1994; EN 301489-3 V1.4.1; EN 61000-6-1:2001, EN 610006-2:2001; EN 61000-6-3:2001; EN 61000-6-4:2001 ; EN 300440-2 V1.1.1; AutSchR: 1997

57

Page 29

10.5 Note

58

Radar Motion Sensor RMS-FRW

Appendix

Page 30

FACTORY AUTOMATION – SENSING YOUR NEEDS

Worldwide Headquarters

Pepperl+Fuchs GmbH · Mannheim · Germany

E-mail: info@de.pepperl-fuchs.com

USA Headquarters

Pepperl+Fuchs Inc. · Twinsburg · USA

E-mail: sales@us.pepperl-fuchs.com

Asia Pacific Headquarters

Pepperl+Fuchs Pte Ltd · Singapore

E-mail: sales@sg.pepperl-fuchs.com

www.pepperl-fuchs.com

Subject to reasonable modifications due to technical advances • Copyright PEPPERL+FUCHS • Printed in Germany

DOCT-1507B Part No. 206908

11/2013

Loading...

Loading...