Page 1

VisuNet IXD

RM-IXD2100-19U*

PC-IXD2100-19U*

Manual

Page 2

With regard to the supply of products, the current issue of the following document is applicable: The

General Terms of Delivery for Products and Services of the Electrical Industry, published by the Central

Association of the Electrical Industry (Zentralverband Elektrotechnik und Elektroindustrie (ZVEI) e.V.)

in its most recent version as well as the supplementary clause: "Expanded reservation of proprietorship"

Worldwide

Pepperl+Fuchs Group

Lilienthalstr. 200

68307 Mannheim

Germany

Phone: +49 621 776 - 0

E-mail: info@de.pepperl-fuchs.com

North American Headquarters

Pepperl+Fuchs Inc.

1600 Enterprise Parkway

Twinsburg, Ohio 44087

USA

Phone: +1 330 425-3555

E-mail: sales@us.pepperl-fuchs.com

Asia Headquarters

Pepperl+Fuchs Pte. Ltd.

P+F Building

18 Ayer Rajah Crescent

Singapore 139942

Phone: +65 6779-9091

E-mail: sales@sg.pepperl-fuchs.com

https://www.pepperl-fuchs.com

Page 3

VisuNet IXD

Contents

1 Introduction................................................................................................................ 4

1.1 Content of this Document............................................................................. 4

1.2 Target Group, Personnel ............................................................................... 4

1.3 Symbols Used ................................................................................................ 4

2 Product Description ..................................................................................................6

2.1 Overview......................................................................................................... 6

2.2 Technical Specifications ............................................................................... 7

2.3 Dimensions................................................................................................... 10

2.4 Scope of Delivery......................................................................................... 12

2.5 Disposal........................................................................................................ 12

3 Mechanical Installation ........................................................................................... 13

3.1 Conditions of Safe Use................................................................................ 13

3.2 General Installation Information ................................................................13

3.3 Installation Environment............................................................................. 14

3.4 Preparing the IXD......................................................................................... 15

3.5 Yoke Mount Installation with Pedestal ....................................................... 15

3.5.1 Preparation for Floor Mounting ........................................................ 15

3.5.2 Preparing the Pedestal..................................................................... 16

3.5.3 Attaching the IXD to the Yoke and Pedestal...................................... 17

3.5.4 Installing the Keyboard Tray Kit ........................................................ 24

3.5.5 Installing the Sunshield Kit ............................................................... 26

3.6 Panel Mount Installation .............................................................................28

3.7 Wall Mount Assembly.................................................................................. 29

3.8 AG1 Assembly.............................................................................................. 31

3.8.1 Preparation for Floor Mounting with AG1 Housing ........................... 31

3.8.2 Preparing the StandardLine Pedestal .............................................. 32

3.8.3 Attaching the Pedestal to the Housing ............................................. 36

3.8.4 AG1 Housing Assembly................................................................... 39

3.8.5 Opening the AG1 Housing ............................................................... 40

3.8.6 Grounding the AG1 Housing to the Pedestal.................................... 41

3.8.7 Mounting the Keyboard.................................................................... 45

4 Appendix .................................................................................................................. 47

4.1 Accessories.................................................................................................. 47

2020-04

3

Page 4

VisuNet IXD

Introduction

1 Introduction

1.1 Content of this Document

This document contains information that you need in order to use your product throughout the

applicable stages of the product life cycle. These can include the following:

• Product identification

• Delivery, transport, and storage

• Mounting and installation

• Commissioning and operation

• Disposal

Note

This document does not substitute the instruction manual.

Note

For full information on the product, refer to the instruction manual and further documentation on

the Internet at www.pepperl-fuchs.com.

The documentation consists of the following parts:

• Present document

• Instruction manual

• Datasheet

Additionally, the following parts may belong to the documentation, if applicable:

• EU-type examination certificate

• EU declaration of conformity

• Attestation of conformity

• Certificates

• Control drawings

• Additional documents

1.2 Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation, maintenance, and dismounting lies with the plant operator.

Only appropriately trained and qualified personnel may carry out mounting, installation, commissioning, operation, maintenance, and dismounting of the product. The personnel must have

read and understood the instruction manual and the further documentation.

Prior to using the product make yourself familiar with it. Read the document carefully.

1.3 Symbols Used

This document contains symbols for the identification of warning messages and of informative

messages.

4

2020-04

Page 5

VisuNet IXD

Introduction

Warning Messages

You will find warning messages, whenever dangers may arise from your actions. It is mandatory

that you observe these warning messages for your personal safety and in order to avoid property damage.

Depending on the risk level, the warning messages are displayed in descending order as follows:

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants, or result in

their complete failure.

Informative Symbols

Note

This symbol brings important information to your attention.

Action

This symbol indicates a paragraph with instructions. You are prompted to perform an action or

a sequence of actions.

2020-04

5

Page 6

VisuNet IXD

Product Description

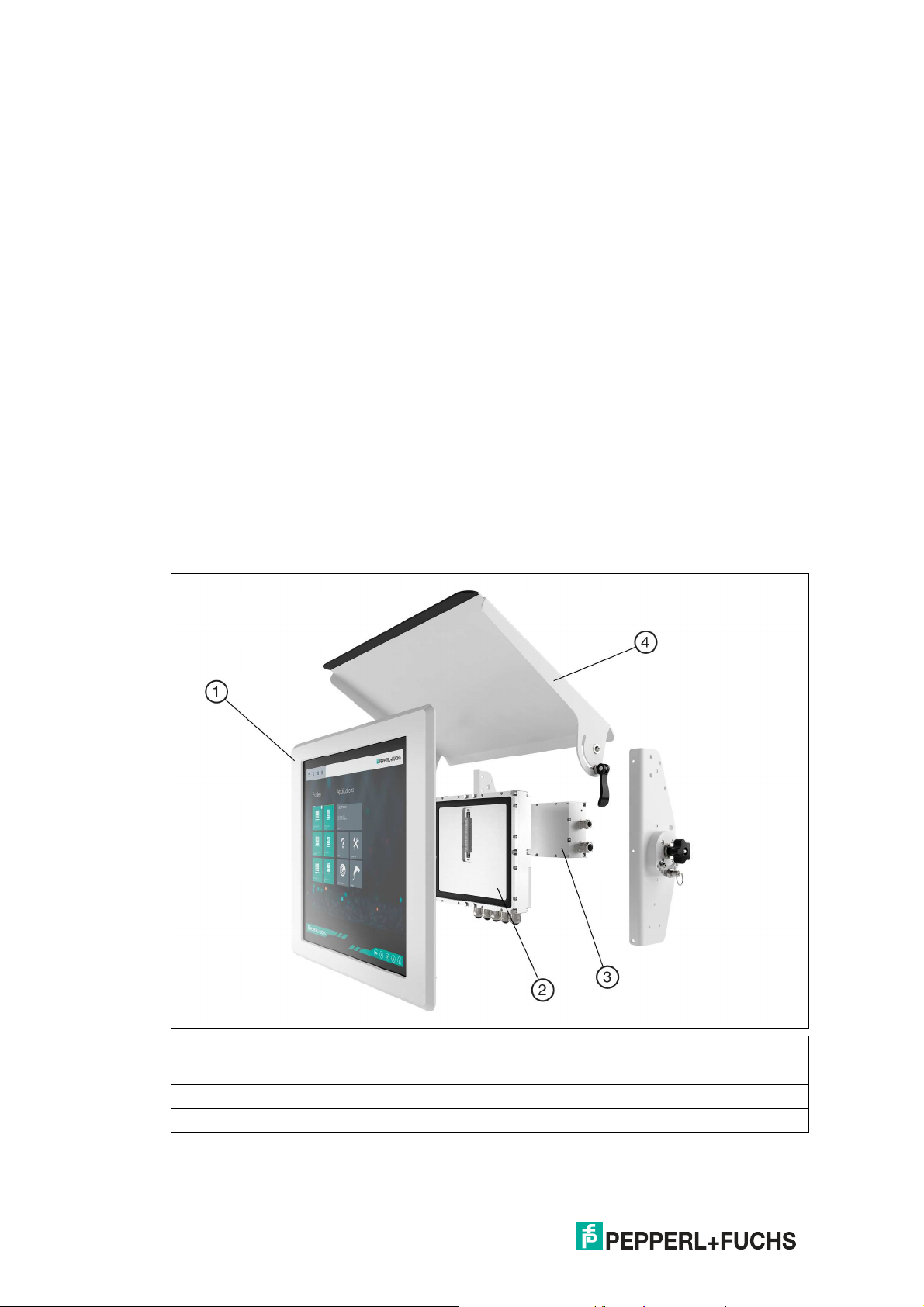

2 Product Description

2.1 Overview

The VisuNet IXD RM-IXD2100-19U* and PC-IXD-2100- 19U* are ATEX/IECEx certified

devices intended for use in potentially explosive atmospheres, such as Zones 1/21.

The VisuNet IXD serves as a thin client- or PC-based operator workstation that uses standard

Ethernet technology to transmit process information from a process control or manufacturing

execution system into hazardous areas.

The assembly consists of several core devices that can be replaced by customers:

• The display unit DPU2100-* is a display panel with optional 10-finger multi-touch sensors.

The display and touch sensors are optically bonded with the hardened front glass.

• The thin client unit TCU1100-* is a computing unit that runs the latest Pepperl+Fuchs RM

Shell 5x or RM Shell 4x firmware. TCUs allow connectivity to various host systems in the

safe area using standard Ethernet technology. For more information on RM Shell, visit

www.pepperl-fuchs.com/RM-SHELL.

• The computing unit PCU1100-* runs an open Microsoft® Windows® operating system,

allowing installation of any software, such as SCADA packages.

• The power supply unit PSU1100-* provides the above-listed devices with 24 V DC power.

It is available in DC and AC versions.

VisuNet IXD System Components

1 DPU

2 TCU/PCU

3 PSU

4 Optional sunshield

2020-04

6

Page 7

VisuNet IXD

Product Description

Several mounting options are available:

• Aluminum bezel prepared for yoke mount

• Aluminum bezel prepared for wall/VESA mount

• Aluminum bezel prepared for panel mount

• Installed into EX1 housing AG1 (SS304) front opening, for pedestal/ceiling/wall-arm

The above-listed bezel options require additional mounting kits. These kits must be ordered

separately.

Note

For a description of the product model nomenclature, view the VisuNet IXD PC or RM product

datasheet on www.pepperl-fuchs.com.

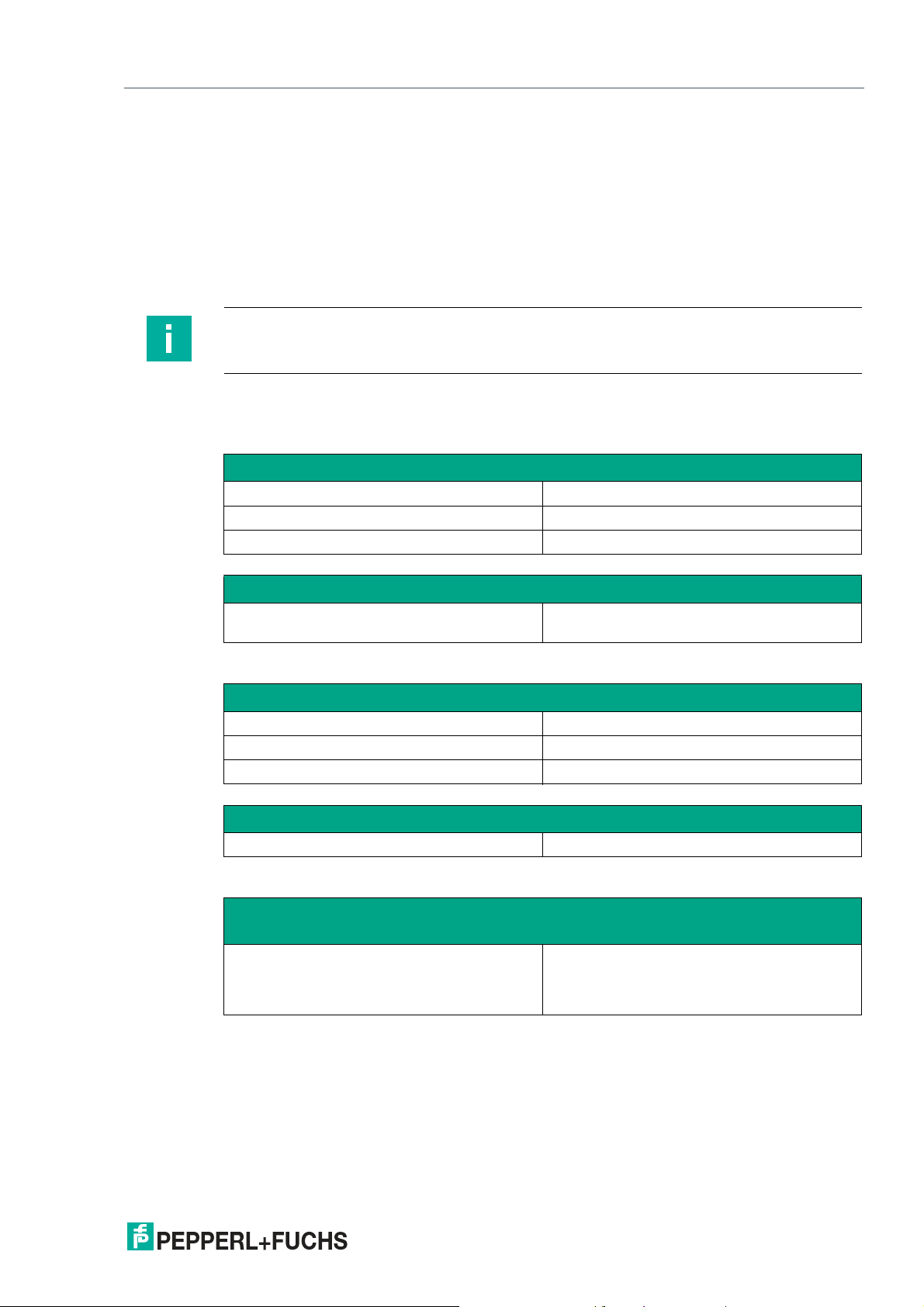

2.2 Technical Specifications

Technical Data RM-IXD*

Hardware

Processor Intel® Atom™ Bay Trail E3827 1.75 GHz

RAM 2048 MB DDR3L

Mass storage 32 GB industrial grade MLC SSD

Software

Operating system VisuNet RM Shell 5.x (based on Windows 10

Technical Data PC-IXD*

Hardware

Processor Intel® Atom™ Bay Trail E3845 1.91 GHz

RAM 4096 MB DDR3L

Mass storage 128 GB SSD

Software

Operating system Windows® 10 IoT Enterprise LTSB

Technical Data RM-IXD* and PC-IXD*

Supply

Power consumption AC:

IoT LTSB)

115/230 V AC, 1.5 A max, 50/60 Hz

DC:

18 ... 36 V DC, 5.3 A max

2020-04

7

Page 8

VisuNet IXD

Product Description

Interface

Interface type Pepperl+Fuchs interface v1.0 for display units

1 x Ethernet 100/1000BASE-TX (Ex e) or

1 x fiber optic 1000BASE-SX (Multimode) or

1 x fiber optic 1000BASE-LX (Singlemode)

1 x USB 2.0 (Ex e)

2 x USB 1.1 (Ex i; intended for Pepperl+Fuchs keyboard and

mouse)

1 x DC or AC power in (via power supply unit)

Optional:

1 x barcode reader interface Pepperl+Fuchs Pscan-D/B (Ex i)

"interface 3": 1 x barcode reader interface for wired 1-D scanners

IDM-160-D*, IDM-Z1-160-D-* and base station IDMx61-B-* and

IDM-Z1-x61-B-* (Ex i)

"interface 4": 1 x barcode reader interface for wired 2-D Scanner

IDM-Z1-260-D-* (Ex i)

"interface 5": 1 x RS-232 interface with Power Supply for miscellaneous devices and peripherals (Ex i)

1 x RS-232 (Ex e)

1 x RS-485 (Ex e)

1 x Ethernet 100/1000Base-TX (Ex e)

Electromagnetic compatibility

Directive 2014/30/EU EN 61326-1:2013 (industrial locations)

RoHS

Directive 2011/65/EU (RoHS) EN 50581:2012-09

Ambient conditions

Operating temperature -20 ... 60 °C (-4 ... 140 °F)

Storage temperature -20 ... 60 °C (-4 ... 140 °F)

Relative humidity 93% at 40°C, non-condensating, according to

Altitude Operating altitude max. 2000 m

Shock resistance 3 shocks 20 g , 11 ms all axis, IEC 60068-2-27

Vibration resistance 5 ... 500 Hz, +/- 0.075 mm , 1.5 g, 10 cycles

EN 61000-6-4:2007+A1:2011

Installed in AG1 housing: -20 ... 50 °C (-4 ...

122 °F)

Installed in AG1 housing: -20 ... 50 °C (-4 ...

122 °F)

EN60068-2-78

per axis according to EN60068-2-6

Mechanical specifications

Degree of protection IP66 (individual components and entire sys-

Material Panel: anodized aluminum (TCU, PSU), pow-

tem with housing)

der coated aluminum (DPU)

Bezel: powder coated aluminum

2020-04

8

Page 9

VisuNet IXD

Product Description

Mechanical specifications

Mass panel with DC: 22 kg , panel with AC: 23 kg ,

Dimensions panel with DC: 542 mm x 460 x 132 mm

Note

For more technical information such as electrical data and connection details, refer to the

manuals and instruction manuals of the individual components:

• Display Unit DPU2100-J1*

• AC Power Supply Unit PSU1100-J1-AC-N0

• DC Power Supply Unit PSU1100-J1-DC-N0

• Thin Client Units TCU1100-J1-*

• Computing Units PCU1100-J1-*

Marking

ATEX

RM-IXD2100-J1-* / PC-IXD2100-J1-*

system housing AG1: 19 kg

panel with AC: 542 mm x 460 mm x 149 mm

panel with housing: 582 mm x 490 mm x 224

mm

II 2G Ex eb q ib [ib] IIC T4 Gb

II 2D Ex tb [ib] IIIC T85°C Db

IECEx

RM-IXD2100-J1-* / PC-IXD2100-J1-* Ex eb q ib [ib] IIC T4 Gb

Ex tb [ib] IIIC T85°C Db

DC Version Label

AC Version Label

2020-04

9

Page 10

VisuNet IXD

542

149.2

460

Product Description

Label for DC Version in AG1 Housing

Label for AC Version in AG1 Housing

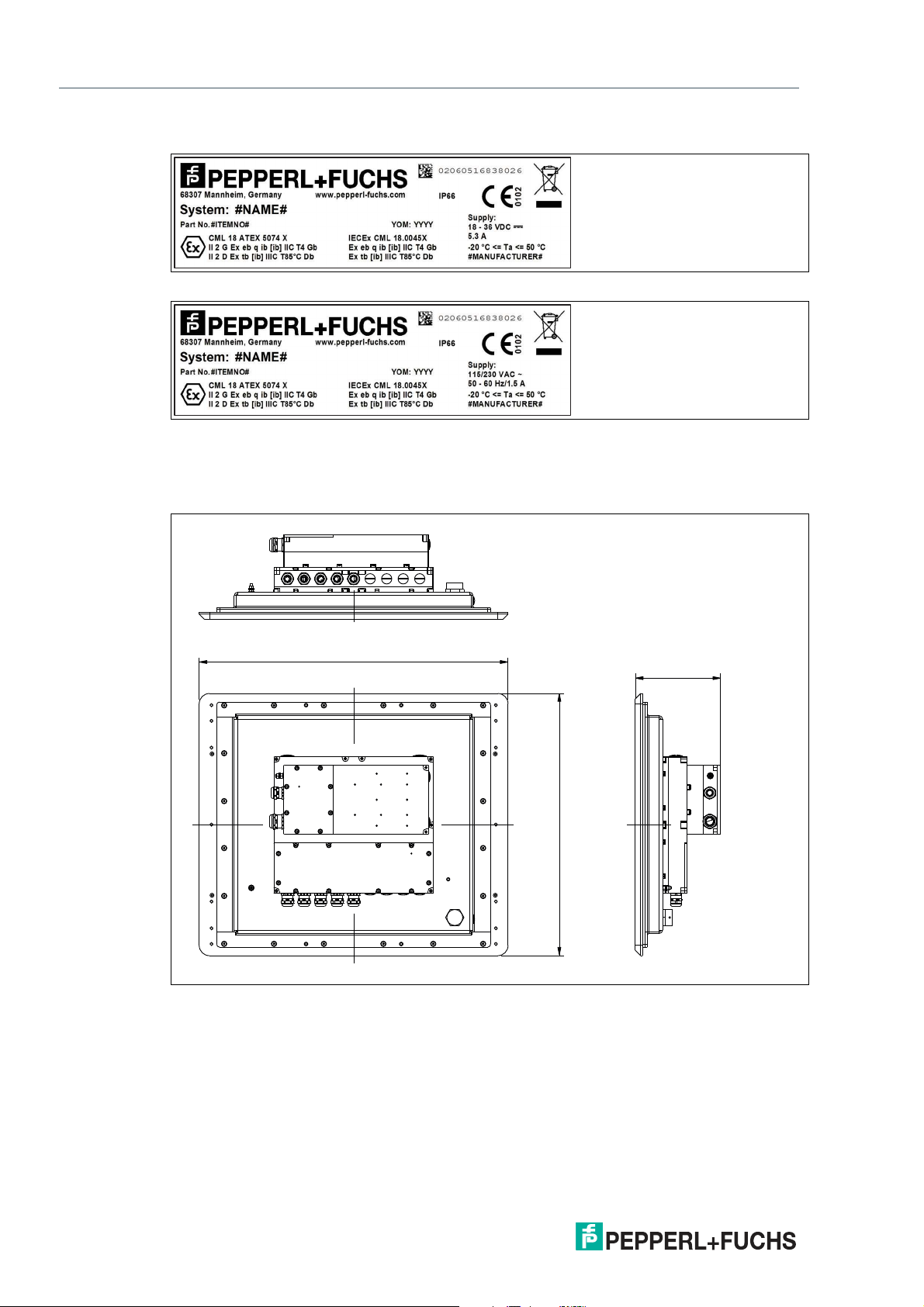

2.3 Dimensions

Panel Dimensions with Bezel

10

Figure 2.1 Panel cut-out dimensinons with bezel

2020-04

Page 11

VisuNet IXD

663

1953

404

1114

582

1703

236

472

1080

Product Description

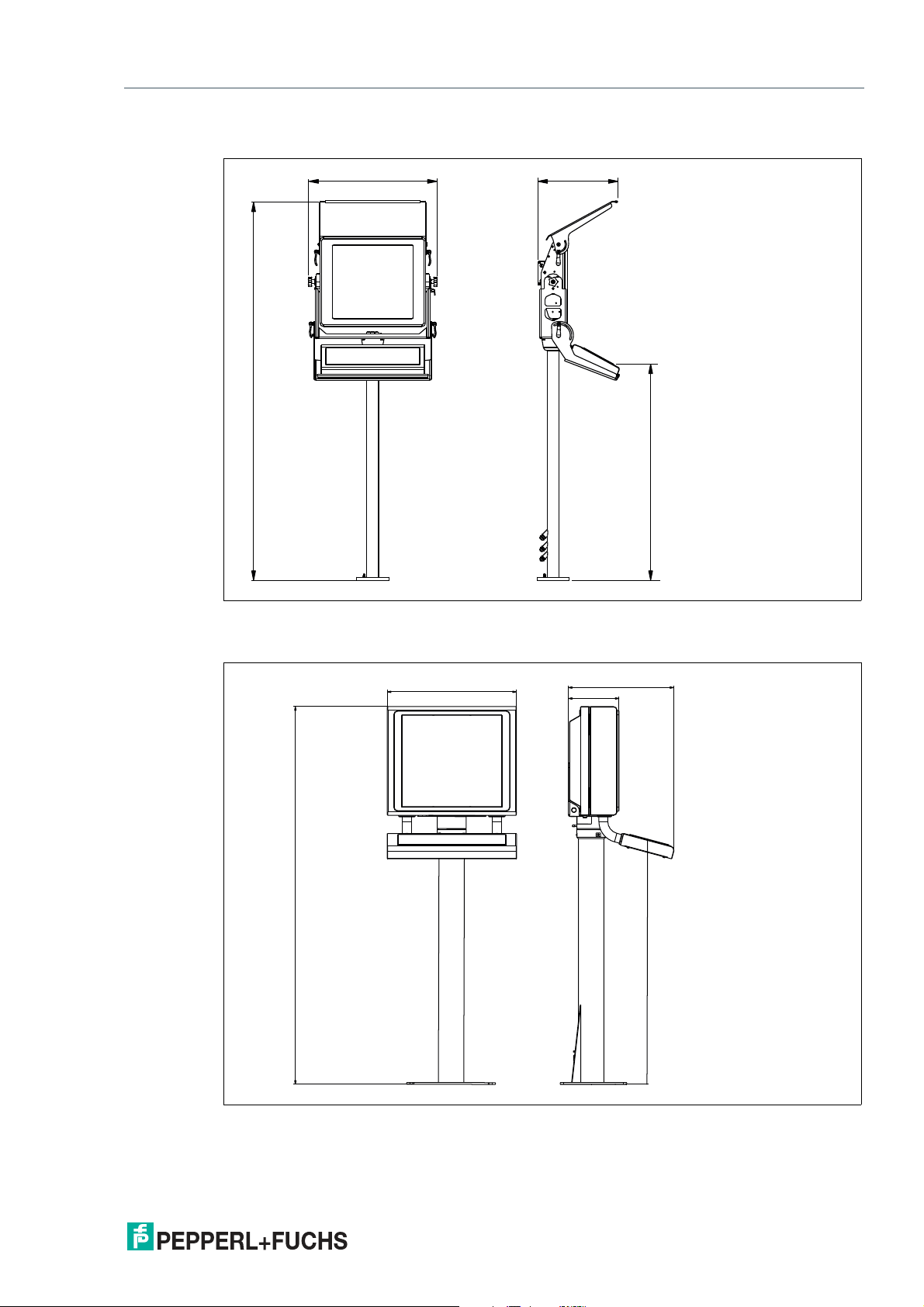

Yoke-Mount Dimensions

Figure 2.2 Yoke-mount dimensions with optional sunshield and keyboard tray

Dimensions with AG1 Housing and Pedestal

Figure 2.3 Dimensions with AG1 housing and pedestal

2020-04

11

Page 12

VisuNet IXD

Product Description

2.4 Scope of Delivery

The items included with delivery vary depending on the options selected. See the mechanical

installation chapters in this manual as well as the IXD and component datasheets on www.pepperl-fuchs.com for information about available options.

2.5 Disposal

Follow all local and any other requirements for disposing of electronic equipment. When disposing of any system component, mark VOID across all certification labels.

12

2020-04

Page 13

VisuNet IXD

Mechanical Installation

3 Mechanical Installation

3.1 Conditions of Safe Use

• The display does not pose an electrostatic discharge hazard under normal use condi-

tions. Use only water damp cloth and allow to air dry for cleaning device. Do not use or

install in high charge areas. See IEC 60079-32-1 for further information.

• In hazardous dust environment, regularly remove dust from the display unit to prevent

excessive temperature rise. See certificate for full information.

• The device shall be installed such that risk of high impact energy on display glass is con-

sidered to be low.

• The intrinsically safe circuits are connected to earth. Along the intrinsically safe circuits

potential equalization must exist.

3.2 General Installation Information

Observe the following requirements when installing the system components.

• The equipment must be installed by competent personnel in accordance with the instruc-

tions. National laws and regulations must be observed.

• The building installation must provide a 20 A overcurrent protection.

• The installer must make a readily accessible disconnect device available.

• The safety of any system incorporating the power supply unit is the responsibility of the

assembler of the system.

Warning!

Risk of injury

Lifting the device on your own may lead to injury.

Warning!

Strength of installation location and hardware

The installation location and hardware used to permanently secure the completed system to a

floor, wall, or ceiling shall be capable of supporting 4 times the total weight of the completed

system. It is the installer's responsibility to properly select the hardware and fasteners that are

appropriate for the installation location.

Note

Installation steps vary depending on the options and accessories selected. The below

instructions cover the following installation scenarios:

• Yoke mount with pedestal (including assembly of the optional sunshield and keyboard tray

accessories)

• Panel mount

• Wall mount

• Installation into AG1 housing

2020-04

13

Page 14

VisuNet IXD

Mechanical Installation

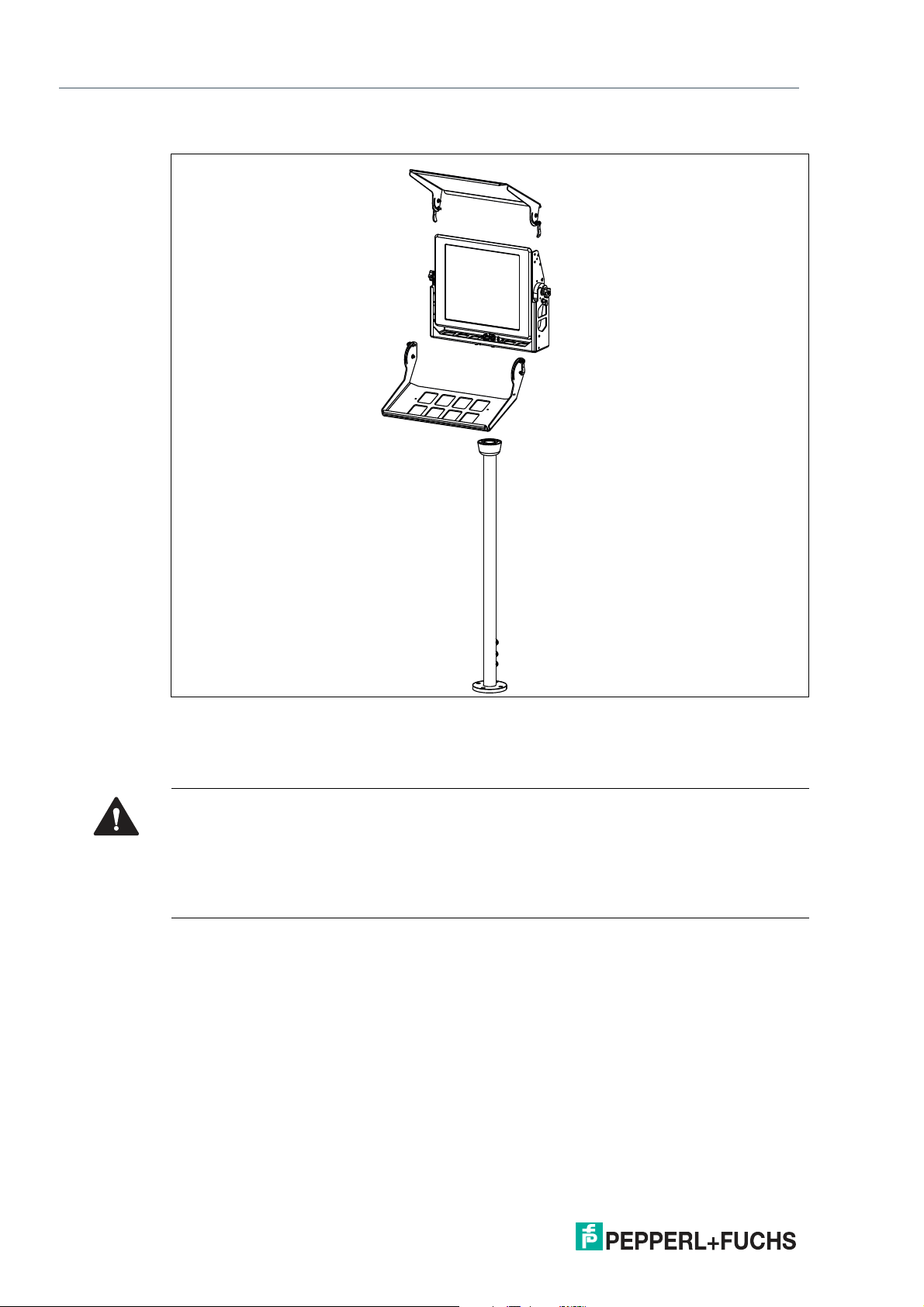

System Installation Example

Figure 3.1 Exploded view of system installation—yoke mounted with pedestal, optional keyboard tray,

and optional sunshield.

3.3 Installation Environment

Caution!

Exposure to direct sunlight and wind

Exposure to direct sunlight may heat the device beyond the maximum permitted operating temperature. Wind may cool down the device and thus impact the minimum operating temperature.

Protect the device from direct sunlight. Consider the impact of wind exposure on the specified

operating temperature range.

The VisuNet IXD product line is designed for outdoor applications. Ensure that the application

is within the specified operating temperature. Any environmental conditions that go along with

the operating temperature range and IP class 66 are suitable for the rugged workstation.

Follow the below steps to protect the device from potential failure:

• Install the device in a location that does not receive extended exposure to saltwater or

associated vapor and mist.

• To maintain the specified operating temperature, install the device in a shaded environ-

ment. Avoid direct sunlight on the IXD display, components, and housing.

• If the available shade is insufficient, the optional sunshield can provide protection. If the

sunshield is insufficient, contact Pepperl+Fuchs to find an engineered solution that provides enough mechanical protection against sunlight.

14

2020-04

Page 15

VisuNet IXD

61.1

18

125

Mechanical Installation

3.4 Preparing the IXD

The VisuNet IXD comes pre-assembled and consists of the core components display unit,

power supply unit, and thin client unit / power supply unit.

Warning!

Risk of injury

Handling the devices with bare hands may cut fingers, hands, or wrists.

Wear gloves at all times during the installation process.

Warning!

Risk of injury

Lifting the IXD housing on your own may cause injury.

Warning!

Danger resulting from scratched display unit screen

Scratches on a display unit front screen weaken the glass structure and may result in broken

glass. Explosion protection is no longer ensured if a display unit with a scratched screen is

used.

NEVER use a display unit with a scratched front screen in a hazardous area. If the surface is

damaged in any way, return the display unit to Pepperl+Fuchs at once and replace it with a new

one.

3.5 Yoke Mount Installation with Pedestal

3.5.1 Preparation for Floor Mounting

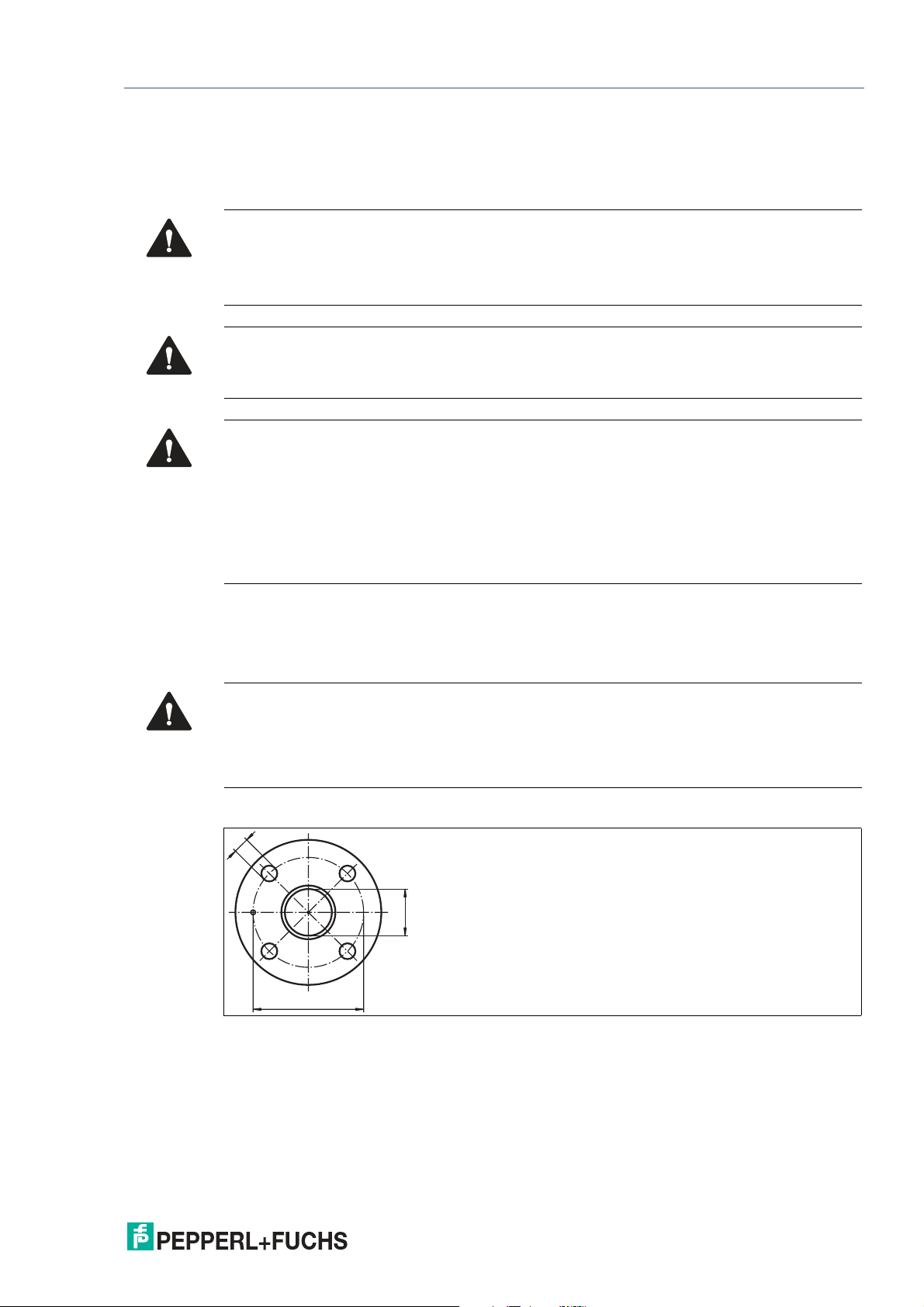

Warning!

Proper installation on the floor

It is the installer's responsibility to select a suitable location with sufficient strength to hold the

equipment. It is the installer's responsibility to select the proper screws based on the installation conditions.

Yoke Pedestal Hole Pattern

2020-04

15

Page 16

VisuNet IXD

Mechanical Installation

3.5.2 Preparing the Pedestal

For floor mounting with a yoke bracket, the preferred pedestal option is PEDESTAL-XX00-1243-304-TRN-N0. The pedestal is shipped with a pre-installed rotating coupling and a ground

cable, which is attached to the pedestal tube.

Note

The pedestal comes with bolts attached to the coupling. Remove and discard these bolts prior

to installation.

Figure 3.2 Tool needed for removing the set screws out of the pedestal in case of IXD: hex wrench

size 3 mm

Preparing the Pedestal for Connection

1.

Bend the grounding cable and place it within the pedestal tube.

2.

Remove the cable glands at the bottom of the pedestal.

3.

Put the gland nut and ferrule of the cable gland on the cable and slide them down the cable

away from the pedestal. Keep the nut and ferrule on the cable to tighten them in a later

installation step.

2020-04

16

Page 17

VisuNet IXD

Mechanical Installation

4.

Attach the cable to the pull wire with a small cable tie and adhesive tape.

5.

Pull the cable through the cable entry and out the top of the pedestal.

6.

Repeat the preceding steps for each cable to be routed through the pedestal.

7.

Place the O-ring into the channel of the coupling.

The pedestal is now ready for connection.

Warning!

Pinched cables

Ensure that cables do not get pinched or damaged during installation.

3.5.3 Attaching the IXD to the Yoke and Pedestal

Warning!

Risk of personal injury and equipment damage

Lifting the IXD housing on your own may cause injury or damage the device.

Warning!

Risk of personal injury and equipment damage

Securing pedestal to the floor.

Ensure that the pedestal is properly secured to the floor prior to installation of the yoke and IXD.

It is the installer's responsibility to properly secure the pedestal to the floor.

2020-04

17

Page 18

VisuNet IXD

Mechanical Installation

Required Components

• Prepared pedestal. See chapter 3.5.2 for instructions on preparing the pedestal.

• IXD with yoke knobs and washers pre-assembled

• Yoke frame with loose hardware (including 2 x button head locking screws and 1 x spring

• Preassembled gland plate with loose O-ring

Required Installation Tools

• 5 mm hex key for attaching screws to coupling and gland plate

• 4 mm hex key for attaching button head lock screws to yoke

• 8 mm flat wrench for attaching ground hardware

• 19 mm flat wrench or open-ended wrench for attaching jam nut to spring plunger

• Open-ended wrench for cable glands

• Loctite 243

plunger)

18

2020-04

Page 19

VisuNet IXD

1

3

2

Mechanical Installation

Attaching Yoke Frame to Pedestal

1 2 x socket head screws inserted loosely into

2 Yoke frame orientation is correct when large

3 2 x additional socket head screws to secure

2020-04

Installation Steps

1.

Insert 2 x socket head screws (1) into the pedestal coupling. Leave the screws loose to fit them

into the yoke frame slots.

2.

Install the yoke frame and turn the frame to engage it in the slots. Ensure that the yoke frame is

installed in the correct orientation—the large treaded hole on the top portion of the yoke bracket

(2) must be on the right side.

3.

Insert 2 x additional socket head screws (3) to secure the yoke frame to the pedestal.

pedestal prior to installing yoke frame

threaded hole is on the right side.

the yoke frame to the pedestal

19

Page 20

VisuNet IXD

1

2 3

Mechanical Installation

4.

Tighten all 4 screws to 7.5 Nm. Apply a small amount of Loctite 243 to each screw prior to

installation.

Inserting IXD into Yoke Frame

1 Knobs on IXD

2 2 x button head socket screws

3 Spring plunger

Warning!

Risk of personal injury and equipment damage

Secure IXD during installation.

To prevent the top-heavy unit from falling forward, one person should hold onto the IXD while

installing the device into the yoke frame.

Installation Steps

1.

Loosen the knobs on each side of the IXD (1) until the inner thread is even with the end of the

screw.

2.

Space out the washers on each knob such that one washer is resting against the IXD and the

rest of the washers are resting against the knob.

3.

Insert the IXD onto the threads on each side.

4.

Slightly lift the IXD on each side and slide the inner washer into the yoke frame using a flathead screwdriver or similar.

5.

Tighten the knobs on each side while keeping the IXD positioned vertically.

20

6.

Insert 2 x button head screws (2) on the left side of the frame and tighten them to 7.5 Nm. Apply

a small amount of Loctite 243 to each screw prior to installation.

2020-04

Page 21

VisuNet IXD

1

2

3

Mechanical Installation

7.

Install the spring plunger into the large threaded hole on the right side of the yoke frame (3).

Thread the plunger until it stops, then back it off approximately one half turn. Tighten the hex

jam nut to 15 Nm. Apply a small amount of Loctite 243 to the threads on the end of the plunger

prior to installation.

Installing the Cable Gland Plate

1 Guide pin on cable gland plate

2 Ground hardware and location of ground bolt

3 Plunger

on bottom of cable gland plate for grounding

yoke frame to pedestal

Installation Steps

1.

Orient the gland plate assembly to match the guide pin (1) with the corresponding hole in the

yoke frame.

2.

Guide the cables that have been routed through the pedestal up through the appropriate cable

gland. See chapter 3.5.2 for instructions on routing cables through the pedestal.

Note

Install a blind plug into any unused cable entry.

2020-04

21

Page 22

VisuNet IXD

Mechanical Installation

3.

Connect the ground wire from the pedestal to the bottom of the gland plate (2). Tighten the

ground hardware to 4 Nm.

Figure 3.3 Ground hardware configuration

1 Housing

2 ground bolt (hexagon socket)

3 Contact washer

4 Nut

5 Cable lug

6 Flat washer

7 Spring washer

8 Nut

4.

Lower the gland plate assembly into place. Insert 4 x socket head screws and 4 x flat washers

(3). Tighten the screws in a diagonal pattern to 6 Nm. Apply a small amount of Loctite 243 to

the screws prior to installation.

5.

Adjust the length of the cable that has been pulled through each cable gland to ensure that

there is enough service loop to accommodate the full tilt motion of the IXD.

22

2020-04

Page 23

VisuNet IXD

Mechanical Installation

Ground Connection from PSU to DPU

The ground connection from the PSU to the DPU is assembled in the factory. If you replace the

DPU or PSU, reestablish the ground connection in the same configuration. Tighten the ground

hardware to 4 Nm.

Figure 3.4 Factory-assembled ground connection from PSU to DPU

Warning!

Connection to the ground bolts

Connection to the ground bolts is mandatory.

Warning!

Customer responsibility to verify grounding path

Check the grounding path after completing system installation.

Warning!

Risk of personal injury and equipment damage

Pinched ground wire.

Ensure that the ground wire does not get pinched between the gland plate and the yoke frame.

2020-04

23

Page 24

VisuNet IXD

1

2

Mechanical Installation

3.5.4 Installing the Keyboard Tray Kit

Required Components

• Keyboard tray kit with loose hardware to be assembled to the yoke frame by the customer.

Required Installation Tools

• 3 mm hex key for attaching screws to the yoke bracket

• Flat-head screwdriver

• Loctite 243

Attaching the Keyboard Tray

1 Cam lever assemblies

2 Shoulder screws and center holes on key-

board tray

24

2020-04

Page 25

VisuNet IXD

Mechanical Installation

Installation Steps

1.

Preassemble the cam levers (1). Place the two components on each threaded cam shaft as

shown below, with the curved side of the rubber washer fitted against the cam lever. Ensure

that the headless screw is positioned approximately even with the head of each cam lever.

2.

Bring the keyboard tray into position such that the center holes (2) are aligned with the lower

threaded holes on the sides of the yoke frame.

3.

Position the inner washers for the shoulder screws (2) between the keyboard tray and the yoke.

Start to thread the shoulder screws on each side.

4.

Apply a small amount of Loctite 243 to the shoulder screws prior to installation. Tighten the

shoulder screws to 4.5 Nm.

5.

Gently lower the keyboard tray against the pedestal.

6.

Position the inner and outer washers for the cam assemblies (1) with the upper threaded holes

on the keyboard tray.

7.

Tighten the cam levers until they can be clamped tightly against the keyboard tray to hold the

tray in position. A flat-head screwdriver can be used as needed to adjust the position of the

headless screws on the cam levers to keep the studs protruding slightly through the ends of the

cam levers.

2020-04

25

Page 26

VisuNet IXD

1

2

Mechanical Installation

3.5.5 Installing the Sunshield Kit

Required Components

• Sunshield kit with loose hardware to be assembled to the yoke frame by the customer.

Required Installation Tools

• 4 mm hex key for attaching screws to the yoke frame

• Flat-head screwdriver

Attaching the Sunshield

1 Cam lever assemblies

2 Shoulder screws and center holes on sun-

shield

2020-04

26

Page 27

VisuNet IXD

Mechanical Installation

Installation Steps

1.

Preassemble the cam levers (1). Place the two included components on each threaded cam

shaft as shown below, with the curved side of the rubber washer fitted against the cam lever.

Ensure that the headless screw is positioned approximately even with the head of each cam

lever.

2.

Bring the sunshield into position such that the center holes on the shield (2) are aligned with

the upper threaded holes on the sides of the yoke frame.

3.

Position the inner washers for the shoulder screws (2) between the sunshield and the yoke

frame. Start to thread the shoulder screws on each side.

4.

The screws are threaded into locking nuts. Tighten the screws until a slight amount of friction is

evident when lowering the sunshield.

5.

Gently lower the sunshield.

6.

Position the inner and outer washers for the cam assemblies (1) with the lower threaded holes

on the sunshield. Start to thread the cam assembly through the washers and slot them into the

adapter.

7.

Tighten the cam levers until they can be clamped tightly against the sunshield to hold it in

position. A flat-head screwdriver can be used as needed to adjust the position of the headless

screws on the cam levers to keep the studs protruding slightly through the ends of the cam

levers.

2020-04

27

Page 28

VisuNet IXD

2

3

1

Mechanical Installation

3.6 Panel Mount Installation

Required Components

• Panel mount kit with loose hardware to be assembled to the IXD by the customer

Required Installation Tools

• 4 mm hex key for clamping screws

• 5 mm hex key for attaching panel mount brackets to the IXD

• Loctite 243

Panel Mounting the IXD

1 Lower panel mount bracket

2 Upper panel mount bracket

3 Optional panel mount stiffener

28

2020-04

Page 29

VisuNet IXD

Mechanical Installation

Installation Steps

1.

Start to thread 18 x socket head screws into the threaded holes on the panel mount brackets.

2.

Attach the lower panel mount bracket (1) to the IXD using 5 x washers and 5 x socket head

screws. Apply a small amount of Loctite 243 to the 5 x screws prior to installation. Tighten the

screws to 6 Nm.

3.

From the front side of the panel, position the IXD with the opening and hang lip of the lower

panel mount bracket over the bottom edge.

4.

Slide the IXD assembly all the way to the left and attach the upper panel mount bracket (2) to

the IXD using 6 x washers and 6 x socket head screws.

5.

Apply a small amount of Loctite 243 to the 6 x screws prior to installation. Tighten the screws to

6 Nm.

Note

The clamping screws on the lower panel mount bracket can be hand-tightened

to hold the IXD in place while the upper panel mount bracket is installed.

6.

Tighten the clamping screws in a uniform criss-cross pattern until the gasket is fully

compressed. Torque will vary.

7.

If the panel is made out of thin or soft material, use the optional panel mount stiffener (3) to

avoid uneven pressure when the clamping screws are tightened. This component is ordered

separately.

3.7 Wall Mount Assembly

Warning!

Risk of personal injury and equipment damage

Lifting the IXD housing on your own may cause injury or damage the device.

Required Components

• IXD prepared for wall mounting with adapters and VESA bracket

• Wall bracket with 4 x loose screws

• Loctite 243

Required Installation Tools

• 3 mm hex key for attaching the wall bracket screws to the VESA bracket

• 4 mm hex key for attaching screws to the VESA bracket

2020-04

29

Page 30

VisuNet IXD

Mechanical Installation

Wall Mounting the IXD

Figure 3.5 Wall mount configuration

Installation Steps

1.

Lay the IXD display-side down on a flat surface.

2.

Remove the 4 x flat-head socket screws from the VESA bracket.

3.

Slide the VESA bracket over and lift it up.

4.

Position the wall mount bracket with the slots facing upward.

5.

Attach 4 x flat-head socket screws and tighten the screws to 4.5 Nm. Apply a small amount of

Loctite 243 to each screw prior to installation.

6.

Mount the two-piece assembly to the wall with 4 x or 6 x screws through the slotted holes.

7.

Lift the IXD and guide the pins through the slots in the VESA bracket.

8.

The IXD will stay in place until the 4 x flat-head socket screws are reinstalled and tightened to

7.5. Nm. Apply a small amount of Loctite 243 to each screw prior to installation.

30

2020-04

Page 31

VisuNet IXD

Mechanical Installation

3.8 AG1 Assembly

3.8.1 Preparation for Floor Mounting with AG1 Housing

Warning!

Proper installation on the floor

It is the installer's responsibility to select a suitable location with sufficient strength to hold the

equipment. It is the installer's responsibility to select the proper screws based on the installation conditions.

Warning!

Distance between housing and wall

Provide at least 350 mm of space between the housing/pedestal assembly and the left wall.

This is required in order to properly open the housing and connect the IXD components.

Note

When installed in an AG1 housing, the operating temperature of the device decreases to -20 °C

...+50 °C (-4 °F ... +122 °F).

Figure 3.6 Distance required between housing/pedestal assembly and wall

2020-04

31

Page 32

VisuNet IXD

400

180 180

300

250

140

130

130

20

40

Ø 100

Ø 10

Mechanical Installation

StandardLine Pedestal Floor-Mount Hole Pattern

3.8.2 Preparing the StandardLine Pedestal

Pedestals are shipped with an attached ground wire and screws for mounting the IXD housing

to the pedestal: 6 x M8 countersunk screws and 2 x M6 countersunk screws.

32

2020-04

Page 33

VisuNet IXD

1

2

3

Mechanical Installation

StandardLine Pedestal

1 Pre-installed ground wire

2 Top cable opening

3 Cable glands

2020-04

33

Page 34

VisuNet IXD

1

2

3

4

Mechanical Installation

Bottom of Pedestal

1 ground bolt

2 M25 opening

3 M20 opening

4 M20 plug

Warning!

Connection to the ground bolt

Connection to the ground bolt is mandatory.

Opening Size Wrench Size Cable Diameter Torque

M20 24 mm 7 ... 13 mm 12 Nm

M25 29 mm 9 ... 17 mm

Preparing the Pedestal for Connection to the IXD Housing

1.

Remove the cable glands at the bottom of the pedestal.

2.

Feed the pull wire (thin, 2.5-m-long wire for pulling cables through pedestal) through the top of

the pedestal and out the appropriate cable entry.

3.

Put the gland nut and ferrule of the cable gland on the cable and slide them down the cable

away from the pedestal. Keep the nut and ferrule on the cable to tighten them in a later

installation step.

4.

Attach the cable to the pull wire with a small cable tie and adhesive tape.

34

2020-04

Page 35

VisuNet IXD

Mechanical Installation

5.

Pull the cable through the cable entry and out the top of the pedestal.

6.

Pull the cable through the pedestal so that 50 cm of cable is hanging out of the top of the

pedestal.

7.

Repeat the preceding steps for each cable that must be routed through the pedestal.

2020-04

35

Page 36

VisuNet IXD

Mechanical Installation

3.8.3 Attaching the Pedestal to the Housing

Warning!

Risk of injury

Lifting the equipment on your own may cause injury.

Mounting the AG1 Housing to the Pedestal

1.

Rest the pedestal on the box that the AG1 housing was shipped in. Position the pedestal and

box behind the housing.

2.

Slide the cable ends from the top of the pedestal through the openings in the bottom of the

housing.

36

Warning!

Damage to cables

The cables may become damaged if they are pinched between the pedestal

and the housing.

Ensure that the cables do not get caught between the pedestal and housing

during the mounting process.

3.

Align the mounting holes on the top of the pedestal with the mounting holes on the back of the

housing.

2020-04

Page 37

VisuNet IXD

Mechanical Installation

4.

Tighten the 6 x M8 screws in a criss-cross pattern to 20 Nm.

5.

Tighten the 2 x M6 screws to 12 Nm.

2020-04

37

Page 38

VisuNet IXD

Mechanical Installation

Positioning and Floor-Mounting the IXD

1.

Remove the box from under the pedestal and carefully position the system upright on the floor

with a crane or the help of another person.

38

2.

Mount the pedestal onto the floor using suitable screws.

Warning!

Proper floor mounting

It is the installer's responsibility to select a suitable location with sufficient

strength to hold the equipment. It is the installer's responsibility to select the

proper screws based on the installation conditions.

3.

Remove the protective foam blocks.

2020-04

Page 39

VisuNet IXD

Mechanical Installation

3.8.4 AG1 Housing Assembly

Warning!

Risk of personal injury and equipment damage

Lifting the IXD housing on your own may cause injury or damage the device.

Required Components

• IXD prepared for AG1 installation with panel mount or AG1 adapter and gaskets

• Loose screws and washers

Required Installation Tools

• 5 mm hex key for attaching screws from AG1 housing into IXD

• Loctite 243

Installing the IXD into the AG1 Housing

Figure 3.7 IXD assembly into AG1 housing configuration

2020-04

39

Page 40

VisuNet IXD

Mechanical Installation

Installation Steps

1.

Guide the IXD into the AG1 housing.

2.

While holding the IXD in the housing, install a few washers and socket head screws by hand to

keep the IXD in place.

3.

Insert a total of 14 x washers and 14 x screws in a uniform criss-cross pattern.

4.

Tighten the 14 x screws to 6 Nm. Apply a small amount of Loctite 243 to each screw prior to

installation.

3.8.5 Opening the AG1 Housing

The AG1 housing is hinged and opens to the left.

Opening the Housing

Warning!

Risk of Damage and Injury

Opening the AG1 housing before the pedestal is mounted onto the floor may

cause the housing and pedestal to tip over.

Mount the pedestal to the floor before opening the AG1 housing.

1.

Loosen the 4 screws on the back of the housing.

2.

Gently pull the front side of the housing toward you.

40

2020-04

Page 41

VisuNet IXD

Mechanical Installation

3.

Pull the right side of the housing front away from the back part of the housing.

3.8.6 Grounding the AG1 Housing to the Pedestal

Warning!

Customer responsibility to verify grounding path

Check the grounding path after completing system installation.

Warning!

Connection to the ground bolts

Connection to the ground bolts is mandatory.

The AG1 housing comes with a pre-installed ground wire that is connected from the inside-top

of the housing to the inside-back of the housing. The pedestal comes with a pre-installed

ground wire that you must route from the pedestal into the housing.

2020-04

41

Page 42

VisuNet IXD

Mechanical Installation

Connecting the Ground Wires

1.

Remove the nuts and washers from the PE stud on the inside-back of the AG1 housing.

2.

Connect the pre-installed ground wires from the the housing and pedestal to the ground bolt.

3.

Replace the nuts and washers. Fasten the nuts and washers with a torque of 7.5 Nm.

42

2020-04

Page 43

VisuNet IXD

Mechanical Installation

Figure 3.8 Grounding Concept

1 Housing

2 Ground bolt (hexagon socket)

3 Contact washer

4 Nut

5 Cable lug

6 Flat washer

7 Spring washer

8 Nut

2020-04

43

Page 44

VisuNet IXD

Mechanical Installation

Ground Connection from PSU to DPU

The ground connection from the PSU to the DPU is assembled in the factory. If you replace the

DPU or PSU, reestablish the ground connection in the same configuration. Tighten the ground

hardware to 4 Nm.

44

Figure 3.9 Factory-assembled ground connection from PSU to DPU

Ground Connection between IXD System and AG1 Housing

The ground connection between the IXD system and the inside of the AG1 housing is assembled in the factory. If you install the IXD system into an AG1 housing or replace an IXD system

component, ensure that this connection is in place. Tighten the ground hardware to 4 Nm.

2020-04

Page 45

VisuNet IXD

Mechanical Installation

3.8.7 Mounting the Keyboard

1.

Remove the plug and screws from the bottom of the housing

2.

To remove the plug, open the housing (see chapter 3.8.5). Hold the inside nut while removing

the plug from the outside with a flat-head screwdriver.

2020-04

45

Page 46

VisuNet IXD

Mechanical Installation

3.

Pull the keyboard wire through the plug and tighten the screws to 4.5 Nm.

Note

The keyboard is an intrinsically safe device. Refer to the control drawings and relevant

installation requirements.

For proper electrical termination of the keyboard, refer to the TCU/PCU and EXTA2 keyboard

manuals.

46

2020-04

Page 47

VisuNet IXD

Appendix

4 Appendix

4.1 Accessories

Item Number Type Code Description

548391 PEDESTAL-YK-IXD19-4-304-

548411 KIT-IXD-WALLMOUNT-19U Wall mount kit

548327 KIT-IXD-PM-19U Panel mount kit

548266 AG1-19S-304A-NN-NN-N0 AG1 housing

548392 KIT-IXD19-KBT1 Keyboard tray for yoke mount

548393 KIT-IXD19-KBT2 Keyboard tray for wall mount

548394 KIT-IXD19-SUNSHIELD Sunshield for yoke mount

Note

For more options and accessories, contact your local Pepperl+Fuchs sales representative.

TRN-N0

Yoke mount pedestal

2020-04

47

Page 48

Pepperl+Fuchs Qua lit y

Download our latest poli cy he re:

www.pepperl-fuchs.com/quali ty

© Pepperl+Fuchs · Subject to modifications

www.pepperl-fuchs.com

Printed in Germany / DOCT-6258B

Loading...

Loading...