Page 1

MANUAL

2-D LiDAR Sensor

R2000 Measuring Sensors

FACTORY AUTOMATION

Page 2

2-D LiDAR Sensor

With regard to the supply of products, the current issue of the following document is applicable: The

General Terms of Delivery for Products and Services of the Electrical Industry, published by the

Central Association of the Electrical Industry (Zentralverband Elektrotechnik und Elektroindustrie

(ZVEI) e.V.) in its most recent version as well as the supplementary clause: "Expanded reservation

of proprietorship"

Page 3

2-D LiDAR Sensor

Contents

1 Introduction......................................................................... 5

1.1 Content of this Document .............................................................................5

1.2 Symbols Used...............................................................................................5

2 Safety................................................................................... 7

2.1 Safety Information.........................................................................................7

2.2 Laser Class 1................................................................................................8

3 Product Description ........................................................... 9

3.1 Validity ..........................................................................................................9

3.2 R2000 2-D LiDAR Sensor .............................................................................9

3.3 Functional Principle.....................................................................................10

3.4 Technical Data ............................................................................................11

3.5 Indicators and Operating Elements.............................................................11

3.6 Interfaces and Connections........................................................................12

3.7 Scope of Delivery........................................................................................13

3.8 Accessories ................................................................................................14

4 Installation ........................................................................ 15

4.1 Storage and Transport.................................................................................15

4.2 Unpacking...................................................................................................15

4.3 Mounting.....................................................................................................15

4.4 Device Connection......................................................................................17

5 Commissioning................................................................. 18

5.1 Ethernet Configuration................................................................................18

6 Operation........................................................................... 22

6.1 Menu Structure ...........................................................................................22

6.2 Operation....................................................................................................24

6.3 Description of Menu Items ..........................................................................27

6.3.1 "Ethernet Info" Menu Item.......................................................................27

6.3.2 "Ethernet Setup" Menu Item ...................................................................27

6.3.3 "Sensor Setup" Menu Item .....................................................................28

6.3.4 "Demos" Menu Item ...............................................................................29

6.3.5 "Tools" Menu Item ..................................................................................29

6.3.6 "End" Menu Item ....................................................................................29

7 Maintenance and Repair.................................................. 30

7.1 Maintenance...............................................................................................30

7.2 Repairs .......................................................................................................30

8 Troubleshooting................................................................ 31

2020-05

3

Page 4

2-D LiDAR Sensor

Contents

8.1 Potential Causes of Faults.......................................................................... 31

9 Appendix........................................................................... 32

9.1 Data Filter................................................................................................... 32

9.2 Amplitude Characteristics .......................................................................... 33

9.3 Pulse Ranging Technology (PRT) Glossary................................................ 34

9.4 Using Open Source Programs.................................................................... 36

2020-05

4

Page 5

2-D LiDAR Sensor

Introduction

1 Introduction

1.1 Content of this Document

This document contains information required to use the product in the relevant

phases of the product life cycle. This may include information on the following:

■ Product identification

■ Delivery, transport, and storage

■ Mounting and installation

■ Commissioning and operation

■ Maintenance and repair

■ Troubleshooting

■ Dismounting

■ Disposal

Note

For full information on the product, refer to the further documentation on the

Internet at www.pepperl-fuchs.com.

The documentation comprises the following parts:

■ This document

■ Datasheet

In addition, the documentation may comprise the following parts, if applicable:

■ EU-type examination certificate

■ EU declaration of conformity

■ Attestation of conformity

■ Certificates

■ Control drawings

■ Instruction manual

■ Other documents

1.2 Symbols Used

This document contains symbols for the identification of warning messages and of

informative messages.

Warning Messages

You will find warning messages, whenever dangers may arise from your actions. It

is mandatory that you observe these warning messages for your personal safety

and in order to avoid property damage.

Depending on the risk level, the warning messages are displayed in descending

order as follows:

2020-05

5

Page 6

2-D LiDAR Sensor

Introduction

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and

plants, or result in their complete failure.

Informative Symbols

Note

This symbol brings important information to your attention.

Action

This symbol indicates a paragraph with instructions. You are prompted to perform

an action or a sequence of actions.

2020-05

6

Page 7

2-D LiDAR Sensor

Safety

2 Safety

2.1 Safety Information

Read the following information carefully and follow this information when working

with the device. Failure to observe the safety notices and warning messages in

this documentation can lead to malfunctions and hazardous operating scenarios

during operation.

This can result in serious personal injury or death.

Target Group, Personnel

The personnel must be appropriately trained and qualified in order to carry out

mounting, installation, commissioning, operation, maintenance, and dismounting

of the device. The trained and qualified personnel must have read and

understood the instruction manual.

Prior to using the product make yourself familiar with it. Read the instruction

manual carefully.

Reference to Further Documentation

Observe laws, standards, and directives applicable to the intended use and the

operating location.

Intended Use

The R2000 2-D LiDAR sensor is a 360° measuring instrument with an all-round

display. It is used on automated transport systems or other movable machinery in

intralogistics. It is also used on stationary equipment in the area of factory and

building automation.

The device is only approved for appropriate and intended use. Ignoring these

instructions will void any warranty and absolve the manufacturer from any liability.

Operation, Maintenance, Repair

Do not remove the nameplate.

Do not remove the warning markings.

Do not repair, modify, or manipulate the device.

If there is a defect, always replace the device with an original device.

Only use accessories specified by the manufacturer.

When using the device with rack feeders and moving carriages, observe the

applicable safety guidelines for these applications.

Supply the device with a power supply that meets the requirements for safety

extra-low voltage (SELV) or protective extra-low voltage (PELV).

Do not point the device directly at the sun. Do not use the device to conduct

measurements into the sun.

2020-05

7

Page 8

2-D LiDAR Sensor

Safety

Delivery, Transport, Disposal

Keep the original packaging. Always store and transport the device in the original

packaging.

The device, built-in components, packaging, and any batteries contained within

must be disposed in compliance with the applicable laws and guidelines of the

respective country.

2.2 Laser Class 1

Class 1 Laser Product

This sensor is certified according to laser protection class 1.

Warning!

Class 1 laser light

The laser light can be an irritant, especially in a dark environment. Do not point

lasers at people!

Maintenance and repairs should only be carried out by authorized service

personnel!

Install the device so that the warning is clearly visible and readable.

Caution: Use of controls, adjustments, or performance of procedures other than

those specified herein may result in harmful laser beam exposure.

2020-05

8

Page 9

2-D LiDAR Sensor

Product Description

3 Product Description

3.1 Validity

This manual applies to all R2000-series measuring devices from firmware version

1.50 and hardware version 1.50 onward. The versions can be found in the device

menu; see chapter 6.3.3.

For devices using older versions, documentation is available on request.

3.2 R2000 2-D LiDAR Sensor

The 2-D LiDAR sensor is a compact 360° sensor with an integrated all-round

display.

The sensor offers a high measurement frequency, a small angular resolution, a

precise light spot, and, depending on the version, a visible measurement beam

(OMD10M-R2000-B23), all of which make it suitable for numerous factory

automation applications. In addition to completing familiar industrial tasks such as

logistics, transportation, and material handling, the sensor can be used for

innovative applications relating to building automation, automatic navigation of

autonomous vehicles, or monitoring rooms.

Design

The device comprises a static body on which a continuously turning

measurement module with an emitter laser and a receiver element is located. The

LiDAR sensor uses Pulse Ranging Technology (PRT). This functional principle

permits continuous scanning of the surrounding area through a full 360°.

User-Friendly All-Round Display

The LiDAR sensor has a row of LEDs on the back of the measurement module

that acts as an all-round display. When the sensor is rotated, this row of LEDs

produces a cylindrical projection surface for displaying text and images. This

enables commissioning and operation without a PC or laptop. Operating and

diagnosis information can therefore be directly displayed during operation.

Safety Certification to Laser Class 1

The R2000 2-D LiDAR sensor fulfills the safety requirements of laser class 1 in

measurement mode. The low amount of laser light emitted ensures that operating

personnel are not injured or harmed.

2020-05

9

Page 10

2-D LiDAR Sensor

Product Description

3.3 Functional Principle

The LiDAR sensor uses the principle of Pulse Ranging Technology (PRT). This

means the device measures the time between the emission of a light pulse and

the receipt of the pulse reflected by an object. Due to the constancy of the speed

of light, this time is a measurement of distance.

Compared with other distance measurement processes, runtime measurement is

affected very little by disturbances in the measuring environment. As a result, this

measurement process ensures a high level of accuracy even under tough

everyday industrial conditions. The light emitter and light receiver are located in

the rotating sensor head.

10

2020-05

Page 11

2-D LiDAR Sensor

2

6

1

4

3

5

7

9

8

Product Description

Note

Influence of ambient conditions

The speed of light depends on the air temperature and barometric pressure.

The influence of the air temperature is 1 ppm/K.

The influence of the barometric pressure is -0.3 ppm/hPa.

The user must take these faults into consideration when measuring long

distances.

In the operating range of -10 °C ... +50 °C, this fault amounts to 0.6 mm at a

distance of 10 m.

3.4 Technical Data

The technical data for this product can be found in the datasheet at www.pepperlfuchs.com.

3.5 Indicators and Operating Elements

Figure 3.1 Indicators and Controls

No. Description Color

1 Operating indicator Green

2 Fault indicator Red

3 "Next" menu button

4 "Return" menu button

5 "Q2" signal indicator Yellow

6 "Q1" signal indicator Yellow

7 Laser beam outlet

8 Ethernet link indicator Green

9 Ethernet activity indicator Yellow

Table 3.1 Indicators and operating elements

2020-05

11

Page 12

2-D LiDAR Sensor

1

3

4

2

1

4

6

7

8

53

2

Product Description

3.6 Interfaces and Connections

The following connections are found on all devices:

Power Supply

There is a 4-pin M12 plug on the rear of the housing for connecting the power

supply. The following diagram shows the pinout:

Figure 3.2 Power supply connection layout

1 24 V power supply

2 Q2

3 Ground (GND)

4 Q1

12

MultiPort

There is an 8-pin M12 plug on the rear of the housing for service purposes.

2020-05

Page 13

2-D LiDAR Sensor

1

3

4

2

Product Description

Interface:

There is a 4-pin M12 socket on the rear of the housing for connecting the Ethernet

interface. The following diagram shows the pinout:

Figure 3.3 Ethernet connection layout

1 TD+

2 RD+

3 TD-

4 RD-

The connector housing is located on the shield.

3.7 Scope of Delivery

The scope of delivery includes:

■ R2000

■ Quick start guide

■ Protective cover

■ 3 x socket cap screws, M5 x 10

■ 3 x washers, size 5

Note

Installation Instructions for North America

If a connection is made to the M12 multi-pin connector, the product shall be used

with a UL-listed cable/connector (CYJV) assembly rated minimum 30 VDC,

minimum 1.0 A, in the final installation for power supply.

2020-05

13

Page 14

2-D LiDAR Sensor

Product Description

3.8 Accessories

The following products are available as accessories.

Name Description

V1SD-G-2M-PURABG-V45-G

V1SD-G-5M-PURABG-V45-G

V1SD-G-ABG-PG9 Single-ended male cordset, M12 D-coded, 4-pin for bus cable

V1-G-2M-PUR Single-ended female cordset, straight, M12, 4-pin, PUR cable

V1-W-2M-PUR Single-ended female cordset, angled, M12, 4-pin, PUR cable

MH-R2000 Mounting bracket, quick-release and adjustment device

Note

Installation note for North America

If a connection is made with the M12 multi-pin connector, in the final installation of

the power supply the product must be used with a UL-listed cable/connector

assembly (CYJV) that is designed for at least 30 VDC and at least 1.0 A.

Name Description

V1-G-BK-2M-PUR-U Single-ended female cordset, straight,

V1-G-BK-5M-PUR-U Single-ended female cordset, straight,

V1-G-BK-10M-PUR-U Single-ended female cordset, straight,

Patch cable, M12 to RJ45, length 2 m

Patch cable, M12 to RJ45, length 5 m

M12, 4-pin, PUR cable, length 2 m, "UL

recognized"

M12, 4-pin, PUR cable, length 5 m, "UL

recognized"

M12, 4-pin, PUR cable, length 10 m, "UL

recognized"

14

To parameterize the R2000 conveniently via a software interface, you will need the

corresponding device type manager (DTM) in addition to the FDT framework

program (PACTware 4.x or above). PACTware and the DTM are available at

www.pepperl-fuchs.com.

2020-05

Page 15

2-D LiDAR Sensor

Installation

4 Installation

4.1 Storage and Transport

Package the device for storage and transport such that it is protected from impact

and moisture. The original packaging provides optimum protection. Also take note

of the permitted ambient conditions.

Note

If the temperature is subject to major fluctuations during transport, the device

must be allowed to acclimatize for around two hours prior to installation and use.

During this acclimatization period, avoid subjecting the device to condensation at

all costs, as this could have an effect on internal parts and cause damage.

4.2 Unpacking

Check the product for damage while unpacking. In the event of damage to the

product, inform the post office or parcel service and notify the supplier.

Retain the original packaging in case the device must be stored or shipped again

at a later date.

Should you have any questions, please contact Pepperl+Fuchs.

4.3 Mounting

Caution!

Aggressive environments may damage the sensor lens or cause it to malfunction

Using the device in aggressive environments may damage the sensor lens and

lead to impaired sensor function.

Never use the device in aggressive environments.

Caution!

Condensation may cause property damage and malfunction

Strong fluctuations in ambient temperature and humidity may damage the sensor

lens and lead to impaired sensor function.

Avoid excessive fluctuations in temperature and humidity to prevent

condensation.

Caution!

Excessive sunlight may result in property damage or malfunction

Continuous exposure to direct sunlight may damage the sensor lens and lead to

impaired sensor function. Taking measurements in direct sunlight may lead to

erroneous measurement results.

Protect the device from continuous exposure to direct sunlight.

Do not point the device's sensor at the sun.

2020-05

15

Page 16

2-D LiDAR Sensor

70

(40)20

60

20

53

106

117.5

4658

116.5

106

16

97.1

3 x M5

20

45

Emitting and receiving area

Complies with 21 CFR

1040.10 and 1040.11 except

for deviations pursuant to

Laser Notice No. 50,

dated June 24, 2007

CLASS 1

LASER PRODUCT

IEC 60825-1: 2007 certified.

Installation

Mounting the 2-D LiDAR Sensor

Only mount the sensor in locations that fulfill the following safety-relevant

requirements: no aggressive environments, no direct sunlight, no excessive

fluctuations in temperature and humidity.

1. In addition, note the following when selecting a mounting location:

■ The sensor must not be obstructed visually, e.g., behind a cover.

■ The sensor should be installed so it is protected from rain.

2. Mount the device on the underside using the supplied socket head screws

with washers.

Caution!

The wrong screw-in depth may result in property damage

If you screw the screws deeper than 8 mm into the base, the

device will be mechanically destroyed.

When mounting, make sure that the screw-in depth on the base is

≥ 5 mm ... ≤ 8 mm.

Figure 4.1 Dimensional drawing of R2000 2-D LiDAR sensor

3. Check that the sensor is securely seated.

Note

Keep the emitting/receiving area clear

When mounting, make sure the emitting area and the receiving area are kept

clear. Covering the emitting/receiving area reduces the performance of the 2-D

LiDAR sensor.

16

2020-05

Page 17

2-D LiDAR Sensor

PowerServiceLAN

4

1

2

3

TD+

TD-

RD-

Shield

4

1

2

3

24 V DC

0 V

RD+

Q2

Q1

1

3

4

2

1

3

4

2

Installation

4.4 Device Connection

Electrical connection in accordance with IP65

Put protective covers on unused M12 connectors.

The IP65 degree of protection is achieved. The protective covers can be

ordered as accessories; see chapter 3.8.

Danger!

Danger to life from electric shock

Absent or insufficient insulation can result in electric shock.

Only connect supplies that provide protection against electric shock (e. g. SELV

or PELV).

The device conforms to protection class III. This means the power supplied to the

device must be a safety extra-low protective voltage (PELV).

The power supply of the device uses a direct current of 10 VDC ... 30 VDC. Due to

the integrated motor, a higher startup current is required than with normal

operation. It is recommended that power supplies with 1 A (for 24 V) or with 2 A

(for 12 V) are used.

The maximum cable length is 30 m.

The pin assignment is as follows:

2020-05

Figure 4.2 R2000 pin assignment

17

Page 18

2-D LiDAR Sensor

Commissioning

5 Commissioning

The sensor has been tested and calibrated before delivery. It can be put into

operation immediately.

Commissioning the LiDAR sensor

Danger!

Danger to life from electric shock

Absent or insufficient insulation can result in electric shock.

Only connect supplies that provide protection against electric

shock (e. g. SELV or PELV).

1. Connect the device to the appropriate power supply.

The initialization phase lasts approx. 15 seconds. This phase is shown by

circles moving down the all-round display.

2. After the initialization phase, the Pepperl+Fuchs logo will appear on the allround display.

The device is now ready for operation.

Tip

Factoring in a warm-up phase

To achieve the best measurement accuracy, allow the device to warm up for at

least 30 minutes after switching on.

5.1 Ethernet Configuration

The sensor has 3 different addressing options that can be used as required. The

setting is configured using the menu interface on the sensor itself.

Note

Point-to-point connection

The sensor does not meet the requirement of the modern cybersecurity directives

and therefore is an unsafe component in the network structure.

We recommend establishing an isolated point-to-point connection between

sensor and the higher-level control.

Auto IP

In the Auto IP setting, the sensor independently assigns a "link-local" IP address

in the 169.254.0.0/16 range. During this process, the system ensures that the

selected address is not already being used by another device.

18

2020-05

Page 19

2-D LiDAR Sensor

Commissioning

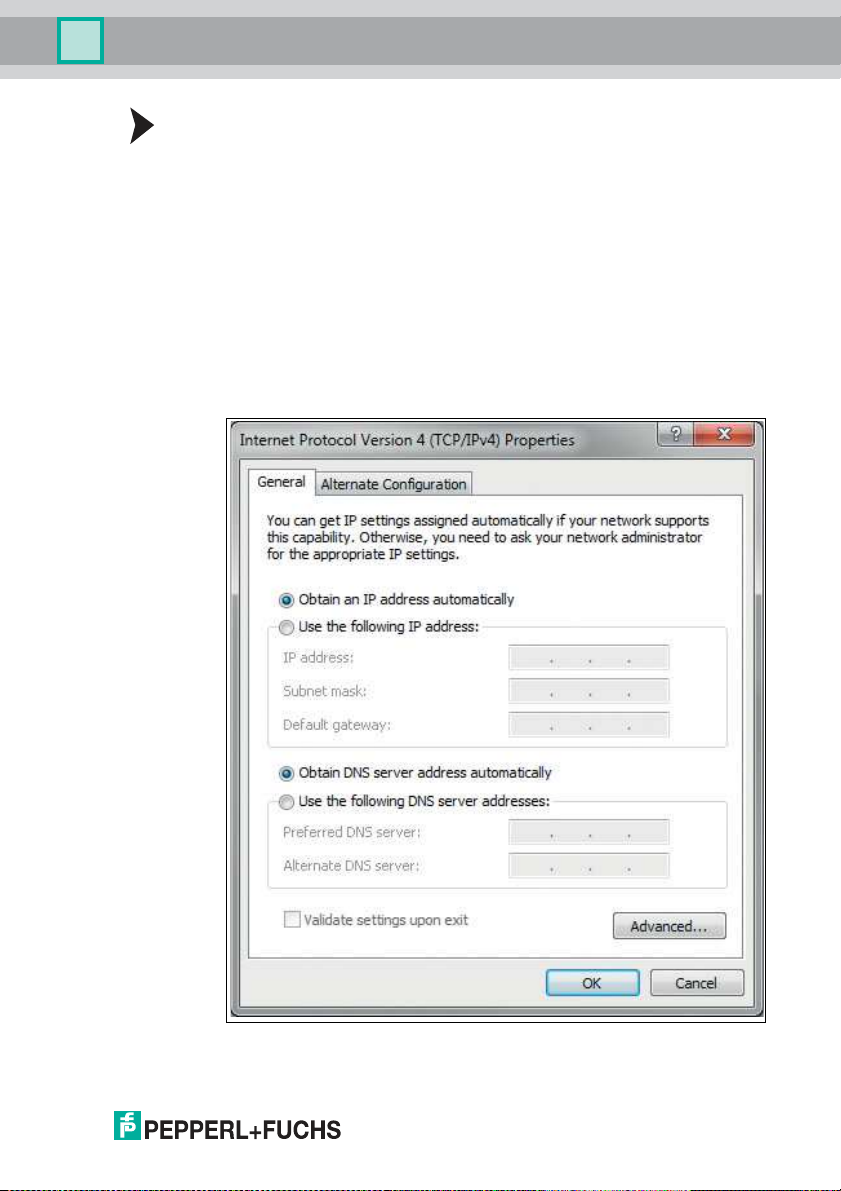

Configuring a Connection via Auto IP

The sensor is set to Auto IP by default. The Auto IP setting is the best way to

connect directly to a PC.

1. If the network configuration of the sensor no longer matches the factory setting:

1. Under Ethernet Setup > Address Mode, set the sensor to "Auto IP."

2. Restart the sensor to apply the configuration.

3. To connect the sensor to the PC, set the PC to Dynamic Host Configuration

Protocol (DHCP).

4. Adjust the properties of the PC network card accordingly. To do this, select

the TCP/IP protocol in the network card properties.

5. In the Internet protocol properties, select Obtain an IP address

automatically.

6. Click OK to confirm.

2020-05

19

Page 20

2-D LiDAR Sensor

Commissioning

After approx. 30 seconds, Microsoft® Windows® assigns an auto IP for

the PC.

DHCP

Connecting via DHCP requires the availability of a DHCP server, such as a router,

on the local network; see Auto IP, PC network card settings.

If this requirement is fulfilled, you can set the sensor to DHCP.

Configuring a Connection via DHCP

1. Under Ethernet Setup > Address Mode, set the sensor to "DHCP."

2. Restart the sensor to apply the configuration.

Manual IP

You can also address the sensor via an IP address set manually. You can set the

PC network card and the sensor to an IP address of your choice.

Note

The IP address of the sensor is set to 10.0.10.9 and the subnet mask to 255.0.0.0

by default.

Configuring a Connection via a Manual IP Address

1. Configure the sensor:

1. Under Ethernet Setup > Address Mode, set the sensor to "Manual."

2. Enter the required address under Ethernet Setup > IP Address.

3. Restart the sensor to apply the configuration.

4. To connect the sensor to the PC, enter the required IP address in the menu for

the PC network card. Select the TCP/IP protocol in the PC network card

properties.

5. Select "Use the following IP address" and enter the required IP address and

subnet mask.

20

2020-05

Page 21

2-D LiDAR Sensor

Commissioning

6. Click OK to confirm.

Note

Device restart

You must restart the sensor after changing the Ethernet configuration.

2020-05

21

Page 22

2-D LiDAR Sensor

Menu

Adress Mode

IP Address

Gateway

MAC Address

Back

Ethernet Info

Adress Mode

IP Address

Gateway

Reboot

Back

Ethernet Setup

Manuel

DHCP

Back

Auto IP

Subnet Mask

Subnet Mask

Operation

6 Operation

6.1 Menu Structure

22

2020-05

Page 23

2-D LiDAR Sensor

Operation

2020-05

23

Page 24

2-D LiDAR Sensor

Operation

6.2 Operation

The sensor is operated using the two buttons on the front.

These buttons can be used to navigate within the menu structure.

You can also use the two buttons to change parameters or enter values.

The content of the all-round display will vary according to the input data.

24

2020-05

Page 25

2-D LiDAR Sensor

Operation

Meaning of Buttons

Button Explanation

In each menu item, the set values are indicated by an underscore. These values

can be changed.

Note

Device settings may only be configured by trained and qualified personnel.

ARROW button.

Press this button

■ To navigate to the next menu item,

■ To change a value.

This button has a similar function to the ARROW button on

the computer keyboard.

ENTER button.

Press this button to select a menu item from the display.

This button has a similar function to the ENTER button on the

computer keyboard.

If no buttons are pressed in the menu levels for

≥ 60 seconds, the menu is exited

automatically.

Navigation in the Menu

Menu display

Top row The current menu level is shown in the top row.

Bottom row The currently selected element is shown in the bottom row.

Dash One dash means you are in the main menu.

Two dashes mean you are in the submenu.

Operation

Pressing the ENTER button takes you into the menu structure.

Takes you to the next menu element.

Keep the ARROW button or the ENTER button pressed for

> 1 second to go to the next menu element up.

Takes you to the selected menu element.

Keep the ARROW button or the ENTER button pressed for

> 1 second to go to the next menu element up.

Menu entry

End This menu entry exits the main menu.

Back This menu entry takes you to the next menu element up.

Changing Count Parameters

Menu display

Top row This shows the current parameter.

2020-05

25

Page 26

2-D LiDAR Sensor

Operation

Bottom row This shows the currently selected parameter value.

Underlined parameter

value

Operation

Changing Numerical Parameters

Menu display

Top row This shows the name of the displayed parameter.

Bottom row This shows the current value of the parameter.

Underlined parameter

value

Operation

Confirm menu

Top row This shows the changed number.

Bottom row This shows the executable actions (Save, Edit, Cancel).

"Save" action The changed value is applied and saved.

"Edit" action Takes you back to the edit display.

"Cancel" action Rejects the changes and takes you to the higher-level menu.

This is the currently activated value.

Takes you to the next available parameter value.

Keep the button pressed for > 1 second to go to the next

menu element up without changing the parameter.

Activates the parameter value currently displayed.

Keep the button pressed for > 1 second to activate the

displayed parameter and return to the higher-level menu

element.

This is the parameter value to be edited.

Increase the currently selected digit.

Keep the button pressed for > 1 second to increase the

selected digit at a quicker rate.

Takes you to the next editable digit.

Keep the button pressed for > 1 second to go to the Confirm

menu.

26

IP Configuration Display

Menu display

Top row Name of the displayed parameter.

Bottom row This shows the current value of the parameter.

Operation

Takes you to the next menu element.

Keep the ARROW button or the ENTER button pressed for

> 1 second to go to the next menu element up.

2020-05

Page 27

2-D LiDAR Sensor

Operation

No function.

Keep the ARROW button or the ENTER button pressed for

> 1 second to go to the next menu element up.

Back Menu Item

The "Back" menu item returns you to the higher-level menu.

6.3 Description of Menu Items

6.3.1 "Ethernet Info" Menu Item

This menu item provides quick access to the IP configuration currently in use. The

data can be read only in this menu item.

Address Mode

The address mode currently being used is displayed in this subitem.

IP Address

The IP address currently being used is displayed in this subitem.

Subnet Mask

The subnet mask currently being used is displayed in this subitem.

Gateway

The gateway currently being used is displayed in this subitem.

MAC ID

The MAC ID currently being used is displayed in this subitem.

Note

Changing the IP configuration

Changes to the IP configuration are only applied after a restart.

The IP configuration currently used by the device is displayed in the "Ethernet

Info" menu item. If these settings differ from the configuration specified under the

"Ethernet Setup" menu item, the device must be restarted.

6.3.2 "Ethernet Setup" Menu Item

This menu item is used to change the IP configuration data.

Address Mode

■ "Manual:" Enables you to manually assign the IP address, the subnet

mask, and the gateway to the device.

■ "DHCP:" Enables you to assign an IP address to the device from a DHCP

server (e.g., a Windows® PC).

■ "AutoIP:" Enables automatic detection of the device on the network.

IP Address

The IP address to be used in the "Manual" address mode can be set in this menu

item.

2020-05

27

Page 28

2-D LiDAR Sensor

Operation

Subnet Mask

The subnet mask to be used in the "Manual" address mode can be set in this

menu item.

Gateway

The gateway can be set in this subitem.

Restart

The device can be restarted in this menu item.

Note

Changing the IP configuration

Changes to the IP configuration are only applied after a restart.

The IP configuration currently used by the device is displayed in the "Ethernet

Info" menu item. If these settings differ from the configuration specified under the

"Ethernet Setup" menu item, the device must be restarted.

6.3.3 "Sensor Setup" Menu Item

Language

This menu item can be used to set the language to German or English.

Display Mode

The display mode defines the display in normal operation when the menu is not

active. Display mode is set on a permanent basis. The display is active following a

restart.

■ Display off: The display goes dark as soon as the menu is exited.

■ Static logo: The display shows the Pepperl+Fuchs logo. The logo can be

replaced with a custom bitmap file that will still be available after the device

is switched on/off. The information is saved in the EEPROM. See the

Ethernet protocol description for details about programming.

■ Static text: The "Pepperl+Fuchs R2000" logo is shown on the display. The

text can be replaced with custom text that will still be available after the

device is switched off/on. The information is saved in the EEPROM. See

the Ethernet protocol description for details about programming.

■ Distance bar graph: The display depicts distances in the form of a bar

chart that shows data in all directions. The bars become smaller as the

distance increases.

■ Reflector bar graph: A bar is shown on the display at the point at which a

reflector is detected.

■ Echo bar graph: The measured signal strength is shown on the display in

the form of a graph.

■ Application bitmap: A custom bitmap file (24 x 252 bit) is shown on the

display. The file is saved in the RAM, so is no longer available after the

device is switched off. See the Ethernet protocol description for details

about programming.

■ Application text: Custom text is shown on the display; the text is saved in

the RAM, so is no longer available after the device is switched off. See the

Ethernet protocol description for details about programming.

28

2020-05

Page 29

2-D LiDAR Sensor

Operation

Note

The Static logo and Static text display modes are suitable for infrequent

changes to the logo and text data.

The Application bitmap and Application text display modes are suitable for

frequent changes to the logo and text data.

Product Info

■ Product name: The display shows the current product name.

■ Item number: The display shows the individual item number.

■ Serial number: The display shows the individual serial number.

Version Info

■ Firmware: The display shows the current firmware version.

■ Hardware: The display shows the current hardware version.

■ PFSDP: The display shows the current version of the Pepperl+Fuchs Scan

Data Protocol.

Factory Settings

The factory settings for the sensor can be loaded in this menu item. To do this,

select "Load" in the submenu and press the ENTER key to confirm. Restart the

device to apply all the changes.

6.3.4 "Demos" Menu Item

A demo is only active temporarily. As soon as another option is selected in the

menu, the demo becomes inactive. A restart has the same effect.

Sensor Eyes

The display shows a pair of eyes that focuses on moving objects. If no activity is

detected within approx. five seconds, the "eyes" close. The "eyes" open again if

the sensor detects movement.

Measuring Tape

In this demo, the scanner measures the distance in a forward direction (X axis).

The value is shown on the display.

6.3.5 "Tools" Menu Item

Alignment Aid

A bar is shown on the display at the point at which a reflector is detected. An

angular scale is shown at the bottom of the display. The "Alignment aid" tool is

automatically exited after approximately ten minutes and the stored display mode

is enabled.

6.3.6 "End" Menu Item

End

Pressing the ENTER button to confirm exits the menu and displays the set display

mode.

2020-05

29

Page 30

2-D LiDAR Sensor

Maintenance and Repair

7 Maintenance and Repair

7.1 Maintenance

Caution!

Failure to clean and improper cleaning may cause property damage and

malfunction

Failure to follow these instructions for cleaning the device may result in lens

damage and impaired function.

Keep the glass on the device clean.

Never clean the glass on the device when the glass is dry. Always use a soft cloth

and water, with a little detergent if necessary.

Do not use aggressive solvent-based cleaning agents such as acetone.

Observe the applicable national regulations when maintaining the device.

The sensor is largely maintenance free.

Check the technical safety of the sensor system at regular intervals by looking for

damage to the housing. Check the sensor for dirt occasionally.

To clean the sensor, wipe it with a damp soft cloth at regular intervals. This will

ensure it continues to function properly. The housing is made of plastic. For this

reason, do not use acetone or detergents containing solvents.

7.2 Repairs

If it appears that safe operation of the system is no longer possible, the system

must be taken out of operation and steps taken to prevent it being used

inadvertently. If the device needs to be repaired, return it to Pepperl+Fuchs. If you

open or modify the device yourself, not only are you endangering yourself and

others but you will void any warranty and absolve the manufacturer from any

liability.

30

2020-05

Page 31

2-D LiDAR Sensor

Troubleshooting

8 Troubleshooting

8.1 Potential Causes of Faults

If the sensor reports no data or incorrect data, check the following:

■ Is the sensor securely mounted or is it vibrating?

=> Check installation.

■ Is the sensor partially covered?

=> Check installation point for visual obstacles.

■ Is the sensor exposed to rain or condensation?

=> Check installation point for moisture and environmental fluctuations.

■ Is the sensor exposed to sunlight or positioned so that it is measuring into

the sun?

=> Check installation point for sunlight.

If none of these suggestions rectifies the fault, contact Pepperl+Fuchs.

Do not repair, modify, or manipulate the device.

If there is a defect, always replace the device with an original device.

Note

Note on insulation measurement

When conducting an insulation measurement, be aware that suppressor diodes

have been installed for EMC resistance.

2020-05

31

Page 32

2-D LiDAR Sensor

Appendix

9 Appendix

9.1 Data Filter

The R2000 allows you to preprocess data. This can be useful for suppressing

measured value noise or reducing the volume of output data, for example. The

following measured data filters are available:

■ Average value filter: All distance data and amplitude data is determined

arithmetically using an appropriate filter width.

■ Median filter: A value (median) is determined using a selectable filter

width; half of the data is greater than or equal to this value.

■ Maximum filter: Using a selectable filter width, the arithmetic mean is

determined for a subset of the data. Starting with the highest measured

value from the measurements within the filter width, the data is used that is

shorter than the maximum value by a selectable range or which has the

same measured value as the maximum value. Data outside of this range is

discarded.

■ Reflectivity filter: Using a selectable filter width, the arithmetic mean is

determined for the data. The calculation only includes data with signal

amplitudes greater than or equal to an adjustable amplitude threshold.

Note: Details about the data filters can be found in the "Ethernet Communication

Protocol" manual at www.pepperl-fuchs.com.

32

2020-05

Page 33

2-D LiDAR Sensor

700

600

500

400

300

200

100

0

0.1 0.5 1.0 10 60

Echoamplitude [digit]

Distance X [m]

Echoamplitude characteristic

Echoamplitude on Diamond Grade 983-10

Object remission 0% ... 90 %

Appendix

9.2 Amplitude Characteristics

In addition to the measured value output for the distance, the R2000 generates an

echo amplitude for each measuring step. The measured value for the echo

amplitude is a value without a unit of measurement, ranging from 0 ... 4095 digits.

The echo amplitude is a measure of the energy received by the R2000. The

measured value is dependent on the surface properties of the measurement

object (reflectivity, structure), the distance from the measurement object, and the

angle of incidence of the measurement beam. The measurement of the echo

amplitude is not calibrated and is used for relative distinction between different

object reflectivities.

In particular, evaluation of the echo amplitudes can be used to distinguish

between natural surfaces and reflective film.

The picture below shows the curve of the echo amplitude on reflective film

(diamond grade 983-10). The curve shows the smallest expected measured value

in relation to the distance.

The second curve represents the largest value on a white (90 % reflectivity),

natural surface in relation to the distance.

2020-05

Figure 9.1 Amplitude characteristics for OMD10M-R2000-B23-V1V1D*

33

Page 34

2-D LiDAR Sensor

2500

2000

1500

1000

500

0

0.1 1 10 100

Echoamplitude [digit]

Echoamplitude characteristic

Echoamplitude on Diamond Grade 983-10

Object remission 0% ... 90 %

Distance X [m]

Appendix

Figure 9.2 Amplitude characteristics OMD30M-R2000-B23-V1V1D*; OMD30M-R2000-

B23-V1VD-HD-1L (ends at 30m); OMD12M-R2000-B23* (ends at 12 m)

The measurement on reflective film is based on a vertical angle of incidence on a

40 mm-wide reflective strip and an angular resolution of 0.071°.

The measurement on a white (90 % reflectivity), natural surface is based on a

vertical angle of incidence and an emitted beam that hits the entire surface of the

measurement object.

If the emitted beam is at an entrance angle of 60° ... 70° on the reflective film, the

measured value drops by approximately 50 % compared to the value for a vertical

entrance angle.

9.3 Pulse Ranging Technology (PRT) Glossary

34

Term Explanation

Accuracy The degree to which the measurement

Absolute accuracy The total of all systematic measurement

result corresponds to the true value of the

measurement. The accuracy is a relative

error based on a measurement standard.

For practical applications, a distinction is

made between different influencing

factors.

errors (e.g., linearity, device offset) over a

defined distance range, reflectivity range,

and temperature range that cannot be

eliminated by other actions such as

average determination.

2020-05

Page 35

2-D LiDAR Sensor

Appendix

Term Explanation

Repeat accuracy (repeatability) The measurement is repeated on the same

Measured value noise Randomly distributed deviation of a

Measuring range The range between the smallest and

target and under the same conditions. The

error is the repeatability value. The

measured value noise is not taken into

account.

measured value by an average value. The

distribution of the individual measurement

values typically follows a statistical normal

distribution.

largest object distance in which the

measuring instrument supplies readings

within the specification.

2020-05

35

Page 36

2-D LiDAR Sensor

Appendix

9.4 Using Open Source Programs

Pepperl+Fuchs uses a range of open source software in the R2000. These are the

programs listed individually below from 1 to 12. We have edited programs 1 to 4:

1. U-Boot

2. Blackfin uClinux

3. Xenomai

4. Mongoose web server

5. Libedit

6. Giflib

7. Libncurses

8. ST standard peripherals library

9. ARM CMSIS header

10.IAR LIBC

11.AVR LIBC

12.CRC library

You may use all programs in accordance with the respective license. The

licenses, their exact scope, and their exclusions of liability can be found in the

header of the files themselves.

In accordance with the provisions of the licenses for programs 5 and 11, the

respective copyright statements are reproduced here. The copyright statements

can also be found in the relevant files.

Program no. 5: Libedit: Copyright (c) The Regents of the University of California.

Program no. 11: AVR LIBC: Portions of avr-libc are Copyright 1999 – 2005 (c)

Keith Gudger, Bjoern Haase, Steinar Haugen, Peter Jansen, Reinhard Jessich,

Magnus Johansson, Artur Lipowski, Marek Michalkiewicz, Colin O’Flynn, Bob

Paddock, Reiner Patommel, Michael Rickman, Theodore A. Roth, Juergen

Schilling, Philip Soeberg, Anatoly Sokolov, Nils Kristian Strom, Michael Stumpf,

Stefan Swanepoel, Eric B. Weddington, Joerg Wunsch, Dmitry Xmelkov, The

Regents of the University of California. Portions of avr-libc documentation

Copyright (c) 1990, 1991, 1993, 1994 The Regents of the University of California.

We have reproduced the text of the license and exclusion of liability for programs

no. 5 and no. 11:

"Redistribution and use in source and binary forms, with or without

modification, are permitted provided that the following conditions are met:

* Redistributions of source code must retain the above copyright notice, this list of

conditions, and the following disclaimer.

* Redistributions in binary form must reproduce the above copyright notice, this

list of conditions, and the following disclaimer in the documentation and/or other

materials provided with the distribution.

* Neither the name of the copyright holders nor the names of contributors may be

used to endorse or promote products derived from this software without specific

prior written permission.

36

2020-05

Page 37

2-D LiDAR Sensor

Appendix

THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND

CONTRIBUTORS "AS IS" AND ANY EXPRESS OR IMPLIED WARRANTIES,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE

DISCLAIMED. IN NO EVENT SHALL THE COPYRIGHT OWNER OR

CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL,

SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING,

BUT NOT LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR

SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS

INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY,

WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING

NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE

OF THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH

DAMAGE."

Programs 1, 2, and 3 are licensed in accordance with the GNU General Public

License v2. Program 3 is additionally licensed for the user spacein accordance

with the Lesser General Public License. Pepperl+Fuchs grants you and any third

party a free license for further processing in accordance with the GNU General

Public License v2 and/or the Lesser General Public License.

Pepperl+Fuchs offers to provide you and any third party with the source code for

programs 1, 2, and 3 in the form in which we developed it for a period of three

years from distribution by Pepperl+Fuchs, free of charge on a read/write tag

commonly used for exchanging software.

Pepperl+Fuchs is not liable for any changes made to the open source software by

the user.

2020-05

37

Page 38

Sub ject to mo dific ation s

Cop yrigh t PEP PERL+ FUCHS • Printed in Ger many

www.pepperl-fuchs.com

FACTORY AUTOMATION –

SENSING YOUR NEEDS

Worldwide Headquarters

Pepperl+Fuchs Group

68307 Mannheim · Germany

Tel. +49 621 776-0

E-mail: info@de.pepperl-fuchs.com

USA Headquarters

Pepperl+Fuchs Inc.

Twinsburg, Ohio 44087 · USA

Tel. +1 330 4253555

E-mail: sales@us.pepperl-fuchs.com

Asia Pacific Headquarters

Pepperl+Fuchs Pte Ltd.

Company Registration No. 199003130E

Singapore 139942

Tel. +65 67799091

E-mail: sales@sg.pepperl-fuchs.com

DOCT-6019A

05/2020

Loading...

Loading...