Pepperl+Fuchs PXV***-F200-SSI-V19 Series Manual

FACTORY AUTOMATION

MANUAL

PXV...-F200-SSI-V19

DataMatrix Positioning System

PXV...-F200-SSI-V19

With regard to the supply of products, the current issue of the following document is ap-

plicable: The General Terms of Delivery for Products and Services of the Electrical Indus-

try, published by the Central Association of the Electrical Industry (Zentralverband

Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the

supplementary clause: "Expanded reservation of proprietorship"

PXV...-F200-SSI-V19

1 Introduction................................................................................. 4

1.1 Content of this Document ................................................................... 4

1.2 Target Group, Personnel...................................................................... 4

1.3 Symbols Used ...................................................................................... 4

2 Product Description ................................................................... 6

2.1 Use and Application ............................................................................ 6

2.2 USB Interface ....................................................................................... 6

2.3 SSI Interface ......................................................................................... 7

2.4 LED Indicators and Controls............................................................... 7

2.5 Accessories.......................................................................................... 9

3 Installation................................................................................. 10

3.1 Affixing the Code Tape....................................................................... 10

3.2 Mounting the Reader ......................................................................... 12

3.3 Electrical Connection ........................................................................ 14

4 Commissioning......................................................................... 17

4.1 Aligning the Reader ........................................................................... 17

4.2 Parameterization ................................................................................ 17

4.2.1 Internal Parameterization Using Parameterization Software............. 17

4.2.2 External Parameterization Using Code Cards.................................. 18

5 Operation and Communication............................................... 20

5.1 Communication via the SSI Interface .............................................. 20

6 Appendix ................................................................................... 22

6.1 Code Cards for External Parameterization...................................... 22

6.1.1 Code Cards with Special Functions ................................................. 22

6.1.2 Code Cards for Adjusting the Resolution ......................................... 24

6.1.3 Code Cards for Setting the Orientation ............................................ 27

6.1.4 Code cards for Setting the Transfer Rate.......................................... 28

6.1.5 Code Cards for Adjusting Input/Output 3 ......................................... 30

3

PXV...-F200-SSI-V19

Introduction

1 Introduction

1.1 Content of this Document

This document contains information required to use the product in the relevant phases of the

product life cycle. This may include information on the following:

Product identification

Delivery, transport, and storage

Mounting and installation

Commissioning and operation

Maintenance and repair

Troubleshooting

Dismounting

Disposal

Note!

Visit www.pepperl-fuchs.com to access further documentation for full information about the

product.

The documentation comprises the following parts:

This document

Datasheet

In addition, the documentation may comprise the following parts, if applicable:

EU-type examination certificate

EU declaration of conformity

Attestation of conformity

Certificates

Control drawings

Instruction manual

Other documents

1.2 Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation, maintenance, and

dismounting lies with the plant operator.

Only appropriately trained and qualified personnel may carry out mounting, installation,

commissioning, operation, maintenance, and dismounting of the product. The personnel must

have read and understood the instruction manual and the further documentation.

Prior to using the product make yourself familiar with it. Read the document carefully.

2017-11

4

PXV...-F200-SSI-V19

Introduction

1.3 Symbols Used

This document contains symbols for the identification of warning messages and of informative

messages.

Warning Messages

You will find warning messages, whenever dangers may arise from your actions. It is

mandatory that you observe these warning messages for your personal safety and in order to

avoid property damage.

Depending on the risk level, the warning messages are displayed in descending order as

follows:

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants, or result in

their complete failure.

Informative Symbols

Note!

This symbol brings important information to your attention.

Action

This symbol indicates a paragraph with instructions. You are prompted to perform an action or

a sequence of actions.

2017-11

5

PXV...-F200-SSI-V19

000 009.0 m PXV-AA25

www.pepperl-fuchs.com

Y

Z

X

Product Description

2 Product Description

2.1 Use and Application

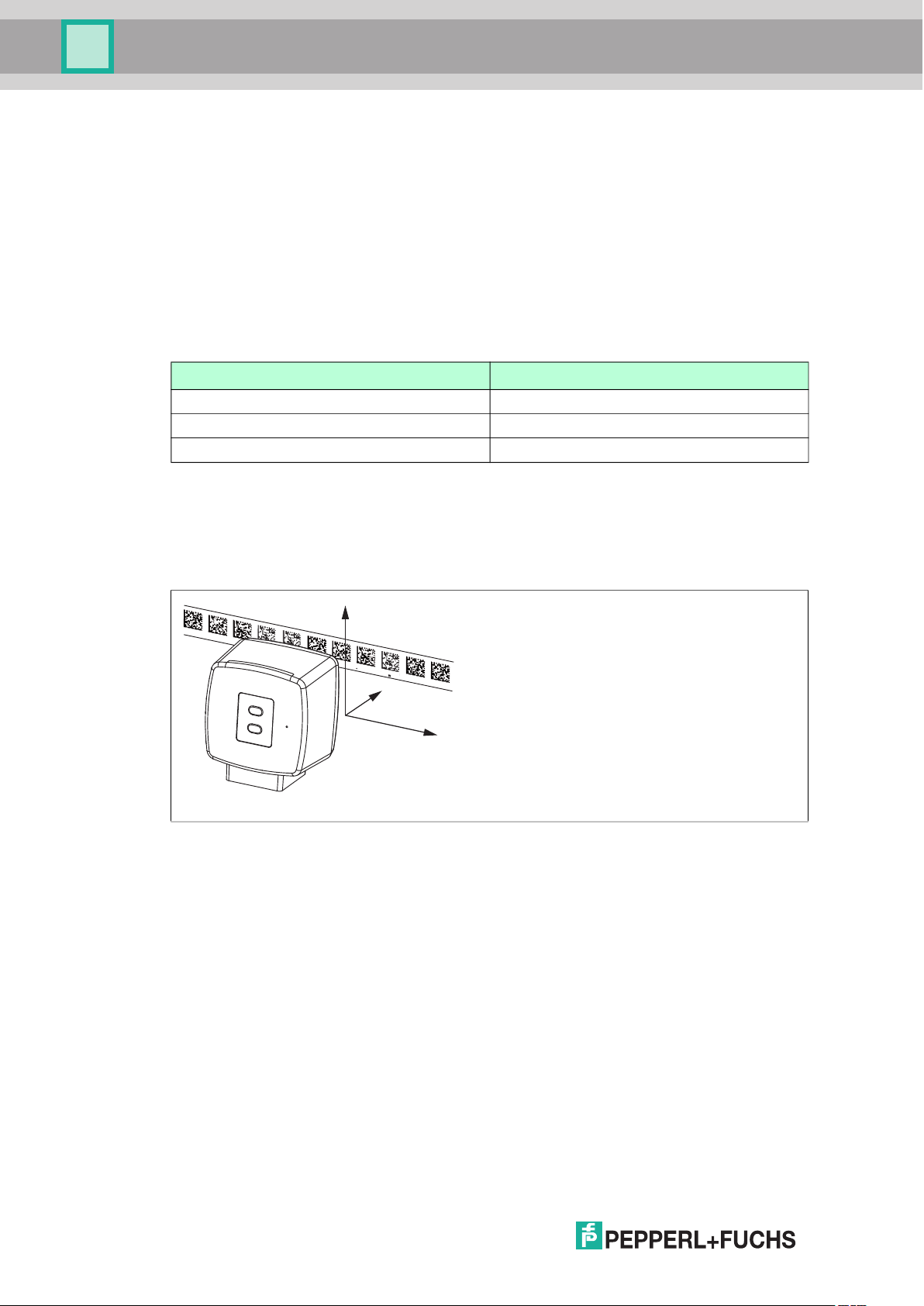

The Data Matrix Positioning System is the positioning system in the Pepperl+Fuchs incident

light process. The heart of the system is the reader, which has features including a camera

module with an integrated illumination unit. This enables the reader to detect position markers

printed onto a self-adhesive code tape in the form of 2-D Data Matrix codes.

The code tape is mounted on a fixed part of the plant (e.g., the wall of an elevator shaft or the

rail on a monorail conveyor). The reader is mounted on a moving "vehicle" positioned in

parallel with the code tape (e.g., on the elevator cab or on the chassis of a monorail conveyor).

Maximum Length of the Code Tape

Resolution of the Reader [mm] Maximum length of the Code Tape [km]

10 10

1 10

0.1 1.5

The code tape length of up to 10 km is sufficient for even very large applications. It also offers

sufficient reserves for extensions or systems with several branches and parallel conveyor

routes.

The extensive yet user-friendly parameterization options as well as the freely configurable

inputs and outputs mean that the reader can easily be adapted to suit each application.

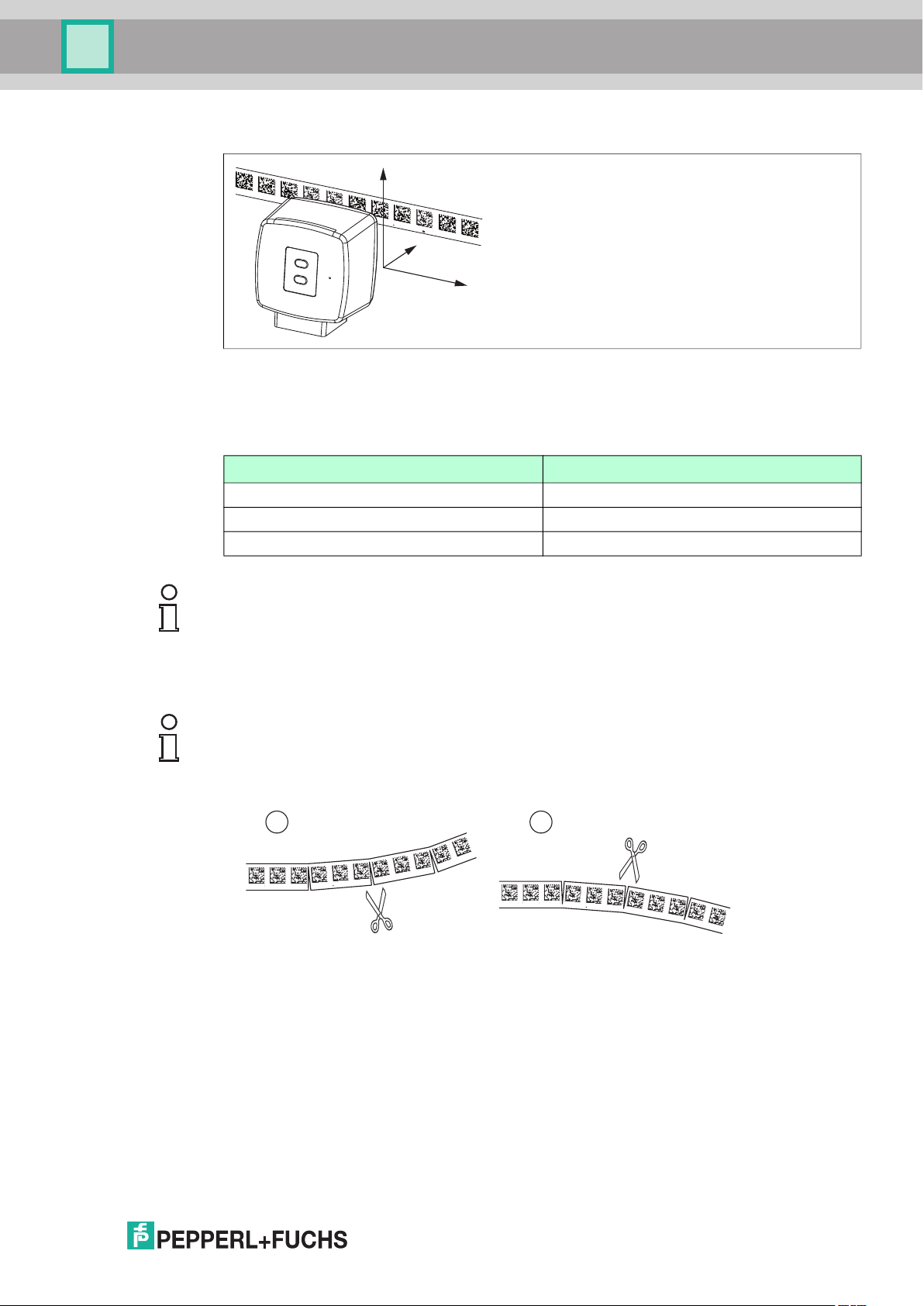

Figure 2.1 Schematic diagram of the alignment of the code tape and reader

2.2 USB Interface

The Vision Configurator is a useful and easy-to-use piece of configuration software for

configuring the reader. This configuration software is available as a free download from

www.pepperl-fuchs.com. Follow the instructions that appear on your screen during the

installation.

Use the parameterization cable (see Accessories) to establish the requisite connection to the

PC and to power the reader. The parameterization cable also provides the electrical supply for

the reader during the parameterization process. The reader is connected to the "Service"

connector.

2017-11

6

PXV...-F200-SSI-V19

COM

SSI DATA / CONFIG

OUT2 / ADJ Y

OUT3 / ADJ Z

PWR / ADJ

ERR / NO CODE

INTERNAL

DIAGNOSTIC

ADJUST

CONFIG

1

2

LED 1 2 3 4 5 6 7

Product Description

Connecting the Service Interface

1. First connect the round plug connector to the reader.

2. Connect the plug-in power supply to the parameterization cable.

3. Connect the plug-in power supply to a socket.

The ring light of the reader and the LED2 "PWR/ADJ/ERR/NO CODE" lights up

continuously or flashes.

4. Now connect the USB plug-in connector to your PC.

2.3 SSI Interface

The controller and reader communicate via the SSI interface during operation. This is an

optically isolated RS422 interface. The controller sends a series of pulses via the clock+ and

clock- lines, and the reader responds synchronously with the 25-bit comprehensive response

telegram. You can define the structure and content of the response telegram using the Vision

Configurator configuration software.

This may include position data in an X- and Y-direction as well as speed and diagnostic data.

During live operation, the reader is connected for communication via the SSI interface using

the "Main" connector.

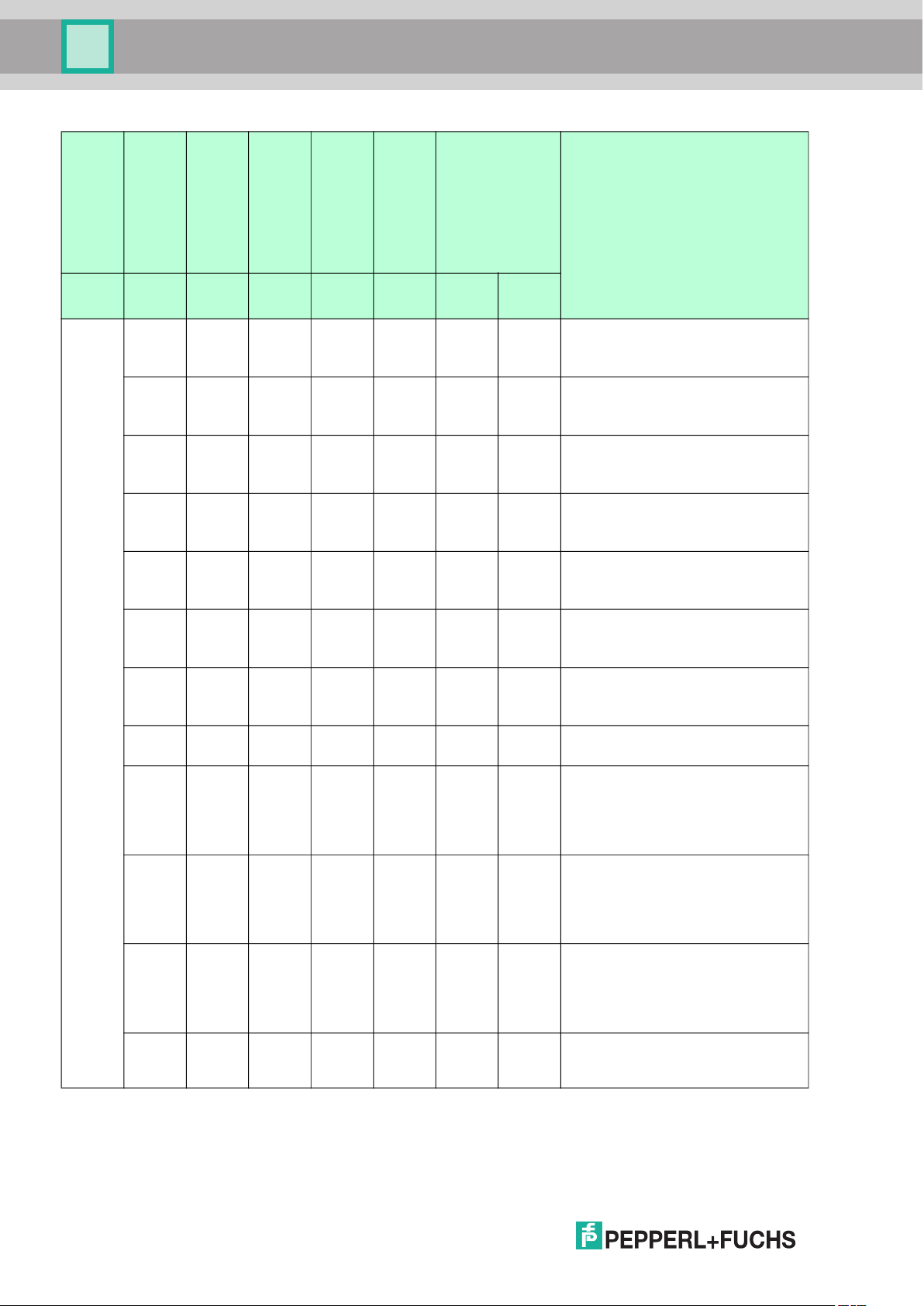

2.4 LED Indicators and Controls

The reader has seven indicator LEDs for carrying out visual function checks and rapid

diagnosis.

Using the two control buttons on the rear of the device, you can activate the alignment aid and

the parameterization mode.

Button 1 is labeled "ADJUST." Button 2 is labeled "CONFIG."

2017-11

7

PXV...-F200-SSI-V19

Product Description

LED

Status

[#1]

COM

[#2]

PWR/ADJ

(Green/

red)

Off Flashes

green

Off Flashes

green

Off Flashes

green

Off Flashes

green

Off Flashes

green

Off Flashes

green

Off Flashes

red

Off Lights

up red

Off Lights

up

green

Off Flashes

red

Off Flashes

red

Flashes Flashes

red

ERR/NO CODE

[#3]

SSI DATA/CONFIG

[#4]

OUT 2/ADJ Y

[#5]

OUT 3/ADJ Z

(yellow) (yellow) (yellow) (yellow) (yellow)

[#6] +[#7]

Internal diagnostics

DescriptionColor Yellow

Off Off Off Off Off Alignment

Y > setpoint value

f

= 2 Hz

flash

Off On Off Off Off Alignment

Y < setpoint value

= 2 Hz

f

flash

Off Flashes Off Off Off Alignment

Y = setpoint value

= 2 Hz

f

flash

Off Off Off Off Off Alignment

Z > setpoint value

= 2 Hz

f

flash

Off Off On Off Off Alignment

Z < setpoint value

= 2 Hz

f

flash

Off Off Flashes Off Off Alignment

Z = setpoint value

= 2 Hz

f

flash

Off Off Off Off Off Alignment

Code tape outside read range

= 2 Hz

f

flash

Off Off Off Off Off System error

Flashes x x Off Off Normal operation, SSI

communication active

= 2 Hz

f

flash

LEDs marked with x indicate the

status of the relevant output.

Flashes x x Off Off No code within read range,

communication active

f

= 2 Hz

flash

LEDs marked with x indicate the

status of the relevant output.

Off x x Off Off No code within read range, no SSI

communication

= 2 Hz

f

flash

LEDs marked with x indicate the

status of the relevant output.

Flashes Flashes Flashes Off Off Normal operation. Indication for two

seconds if a button is pressed when

the time lock is enabled.

2017-11

8

PXV...-F200-SSI-V19

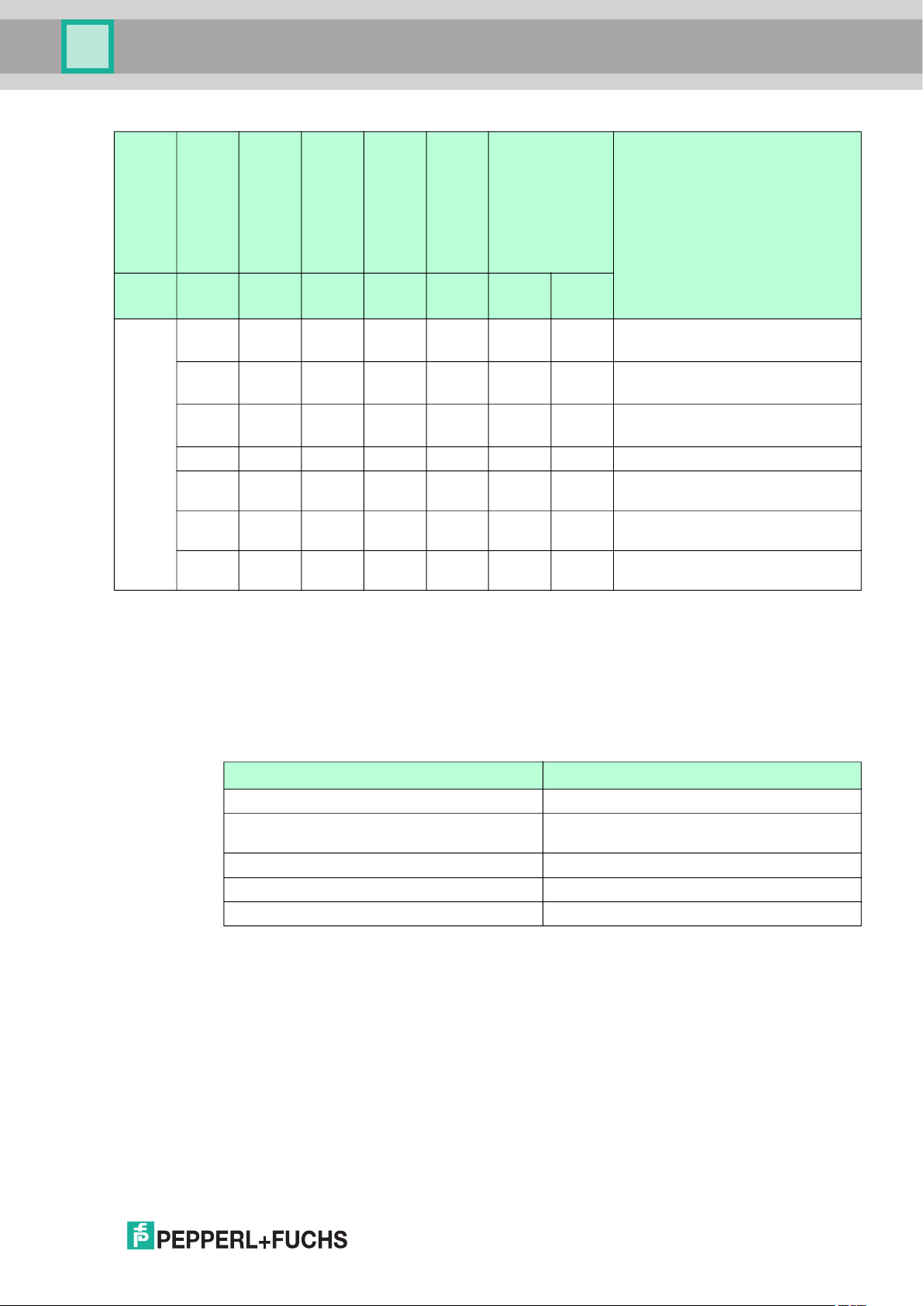

Product Description

LED

[#1]

COM

[#2]

PWR/ADJ

ERR/NO CODE

(Green/

red)

Off Off Flashes Off Off Off Off Configuration mode active

Off Red, 3

sec

Off Green,

1 sec

x Off x x x Off Off Time lock for buttons disabled

Flashes Green Off Off Off Off Off Position query via USB interface,

Flashes Flashes

red

x x x x x Lights upLights upInternal error

x = LED status has no meaning.

(yellow) (yellow) (yellow) (yellow) (yellow)

Flashes Off Off Off Off Code card faulty

Flashes Off Off Off Off Code card detected

Off Off Off Off Off Position query via USB interface,

2.5 Accessories

Compatible accessories offer you potential for cost savings when commissioning, replacing,

and servicing our products.

[#3]

SSI DATA/CONFIG

[#4]

OUT 2/ADJ Y

[#5]

OUT 3/ADJ Z

[#6] +[#7]

Internal diagnostics

DescriptionColor Yellow

f

flash

f

flash

f

flash

code within the read range

no code within read range

Return to Pepperl+Fuchs

= 2 Hz

= 2 Hz

= 2 Hz

If products are used in harsh ambient conditions, appropriate Pepperl+Fuchs accessories can

be used to extend the service life of these products.

Model number Description

V19-G-ABG-PG9-FE Grounding terminal and plug (set)

PCV-KBL-V19-STR-USB Cable unit for service interface with power

supply

VAZ-V1S-B Cap for service connector

PCV-MB1 Mounting bracket

Vision Configurator Configuration software

Suitable connection cables can be found in the Accessories section of the reader datasheet at

www.pepperl-fuchs.com.

2017-11

9

PXV...-F200-SSI-V19

715

25

5

20

3

Installation

3 Installation

3.1 Affixing the Code Tape

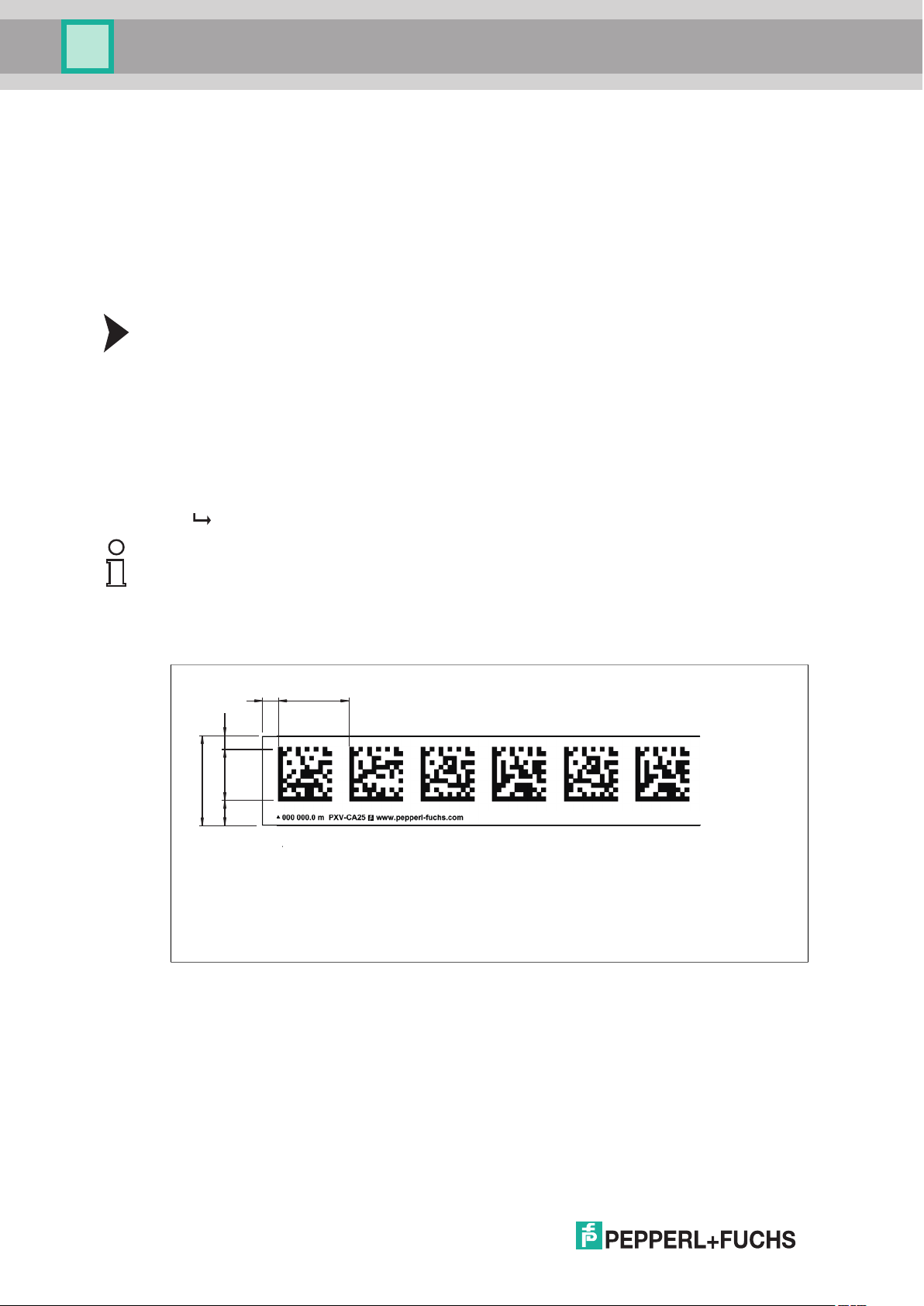

The code tape is made of silicone-free polyester film. A position marker appears every 100 mm

along the lower edge of the code tape (see "Code Tape Dimensions"). These position markers

are used to affix the code tape in the correct position.

The back of the code tape is covered with a modified acrylate-based adhesive designed for

permanent adhesion. Affix the self-adhesive code tape along the desired traverse distance. To

do so, proceed as follows:

Affixing the Code Tape

1. Clean the surface of any greasy or oily deposits and dust.

2. Ensure that the surface is dry, clean, and stable.

3. Pull away a few centimeters of the protective film at the beginning of the code tape. Place

the code tape at the precise point of the required starting position on the surface, and press

to attach.

4. Then affix the code tape along the desired traverse distance. Remove the protective film

gradually so that the code tape does not accidentally adhere to the surface in the incorrect

position. When affixing, ensure that the code tape does not crease or trap air bubbles.

The adhesive on the code tape hardens after 72 hours.

Note!

Thermal Expansion of the Code Tape

The heat expansion coefficient of the adhered code tape corresponds to the heat expansion

coefficient of the underside.

Dimensions of the Code Tape

2017-11

10

PXV...-F200-SSI-V19

000 009.0 m

0

00 009.0 m

1 2

Installation

Alignment of the Code Tape and Reader

Position the code tape so that the PEPPERL+FUCHS logo and position markers are below the

data matrix code. The position values then increase along the X direction. The diagram shows

the orientation of a reader in the default setting of 0°. The reader can be configured in the

interface for other installation situations.

Code Tapes with a Starting Position of 0 m

Order Designation Description

PXV00001-CA25-* Code tape, 1-track, length: 1 m

... ...

PXV100000-CA25-* Code tape, 1-track, length: 100,000 m

Y

000 009.0 m PXV-AA25

www.pepperl-fuchs.com

Z

X

Note!

Expansion Joints and Code Tapes

If the system covers longer distances, expansion joints are integrated in the system structure.

We recommend creating breaks along the code tape. The resulting gap must not exceed

75 mm.

Note!

Inclines and Declines

If you affix the code tape on inclines or declines, cut the code tape several times at the

transition point to the horizontal as shown.

1. Incline

2. Decline

2017-11

11

Loading...

Loading...