Page 1

FACTORY AUTOMATION

MANUAL

PXV...-F200-B25-V1D

DataMatrix Positioning System

Page 2

PXV...-F200-B25-V1D

With regard to the supply of products, the current issue of the following document is ap-

plicable: The General Terms of Delivery for Products and Services of the Electrical Indus-

try, published by the Central Association of the Electrical Industry (Zentralverband

Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the

supplementary clause: "Expanded reservation of proprietorship"

Page 3

PXV...-F200-B25-V1D

1 Introduction................................................................................. 4

1.1 Content of this Document ................................................................... 4

1.2 Target Group, Personnel...................................................................... 4

1.3 Symbols Used ...................................................................................... 5

2 Product Description ................................................................... 6

2.1 Use and Application............................................................................. 6

2.2 USB Interface........................................................................................ 6

2.3 EtherNet/IP Interface Pin Assignment .............................................. 7

2.4 LED Indicators and Controls............................................................... 7

2.5 Accessories .......................................................................................... 9

3 Installation................................................................................. 10

3.1 Affixing the Code Tape ...................................................................... 10

3.2 Mounting of the Reader..................................................................... 12

3.3 Electrical Connection ........................................................................ 14

3.4 EtherNet/IP Connection..................................................................... 15

4 Commissioning......................................................................... 17

4.1 Aligning the Reader ........................................................................... 17

5 Operation and Communication ............................................... 18

5.1 Communication via EtherNet/IP ....................................................... 18

5.1.1 General Information on Communication via EtherNet/IP................... 18

5.1.2 Setting the IP Address ..................................................................... 18

5.1.3 EtherNet/IP Objects ......................................................................... 21

5.1.4 Attributes of the Reader's EtherNet/IP Objects ................................ 22

6 Appendix ................................................................................... 28

6.1 ASCII Table.......................................................................................... 28

3

Page 4

PXV...-F200-B25-V1D

Introduction

1Introduction

1.1 Content of this Document

This document contains information required to use the product in the relevant phases of the

product life cycle. This may include information on the following:

Product identification

Delivery, transport, and storage

Mounting and installation

Commissioning and operation

Maintenance and repair

Troubleshooting

Dismounting

Disposal

Note!

Visit www.pepperl-fuchs.com to access further documentation for full information about the

product.

The documentation comprises the following parts:

This document

Datasheet

In addition, the documentation may comprise the following parts, if applicable:

EU-type examination certificate

EU declaration of conformity

Attestation of conformity

Certificates

Control drawings

Instruction manual

Other documents

1.2 Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation, maintenance, and

dismounting lies with the plant operator.

Only appropriately trained and qualified personnel may carry out mounting, installation,

commissioning, operation, maintenance, and dismounting of the product. The personnel must

have read and understood the instruction manual and the further documentation.

Prior to using the product make yourself familiar with it. Read the document carefully.

2017-11

4

Page 5

PXV...-F200-B25-V1D

Introduction

1.3 Symbols Used

This document contains symbols for the identification of warning messages and of informative

messages.

Warning Messages

You will find warning messages, whenever dangers may arise from your actions. It is

mandatory that you observe these warning messages for your personal safety and in order to

avoid property damage.

Depending on the risk level, the warning messages are displayed in descending order as

follows:

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants, or result in

their complete failure.

Informative Symbols

Note!

This symbol brings important information to your attention.

Action

This symbol indicates a paragraph with instructions. You are prompted to perform an action or

a sequence of actions.

2017-11

5

Page 6

PXV...-F200-B25-V1D

000 009.0 m P

XV

AA25

w

ww.pe

p

per

l

fuchs

.c

om

Y

Z

X

Product Description

2 Product Description

2.1 Use and Application

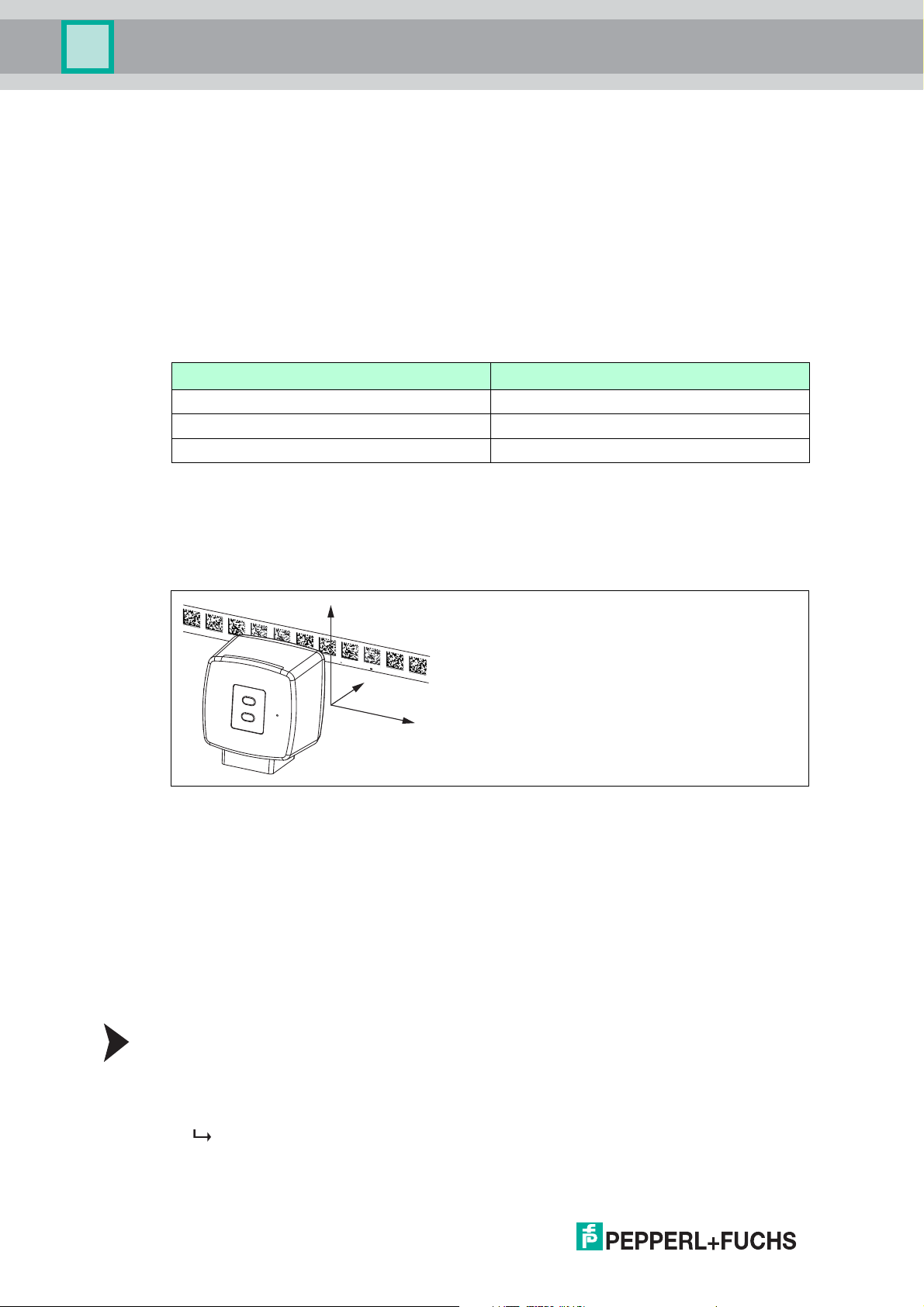

The Data Matrix Positioning System is the positioning system in the Pepperl+Fuchs incident

light process. The heart of the system is the reader, which has features including a camera

module with an integrated illumination unit. This enables the reader to detect position markers

printed onto a self-adhesive code tape in the form of 2-D Data Matrix codes.

The code tape is mounted on a fixed part of the plant (e.g. the wall of an elevator shaft or the

rail on a monorail conveyor). The reader is mounted on a moving "vehicle" positioned in parallel

with the code tape (e.g. on the elevator cab or on the chassis of a monorail conveyor).

Maximum Length of the Code Tape

Resolution of the reader [mm] Maximum length of the code tape [km]

10 10

1 10

0.1 10

The code tape length of up to 10 km is sufficient for even very large applications. It also offers

sufficient reserves for extensions or systems with several branches and parallel conveyor

routes.

The extensive yet user-friendly parameterization options as well as the freely configurable

inputs and outputs mean that the reader can easily be adapted to suit each application.

Figure 2.1 Schematic diagram of the alignment of the code tape and reader

2.2 USB Interface

The Vision Configurator is a useful and easy-to-use piece of software for configuring the read

head. This configuration software is available as a free download from www.pepperlfuchs.com. Follow the instructions that appear on your screen during the installation.

The PC connection required for programming and the read head power supply can be made

using a special parameterization cable. This parameterization cable can be ordered as an

accessory under the name "Cable unit for service interface with the power supply". This also

provides the electrical supply to the read head. The parameterization cable is connected to the

read head using the "Main" connector.

Connection of the Parameterization Cable

1. First connect the round plug connector to the read head.

2. Connect the plug-in power supply to the parameterization cable.

3. Plug the plug-in power supply into a socket.

The ring light of the read head and the "PWR/ADJ/ERR/NO CODE" LED2 lights up or

flashes.

2017-11

6

Page 7

PXV...-F200-B25-V1D

ADJUST

CONFIG

1

2

LED 1 2 3 4 5 6

Product Description

4. You can now connect the USB plug-in connector to your PC.

2.3 EtherNet/IP Interface Pin Assignment

The controller and read head communicate via the EtherNet/IP interface during operation. The

interface is based on Ethernet technology and works according to the CIP protocol (Common

Industrial Protocol).

The connection of the read head in ongoing operation is carried out via the "EtherNet/IP 1 & 2"

connectors.

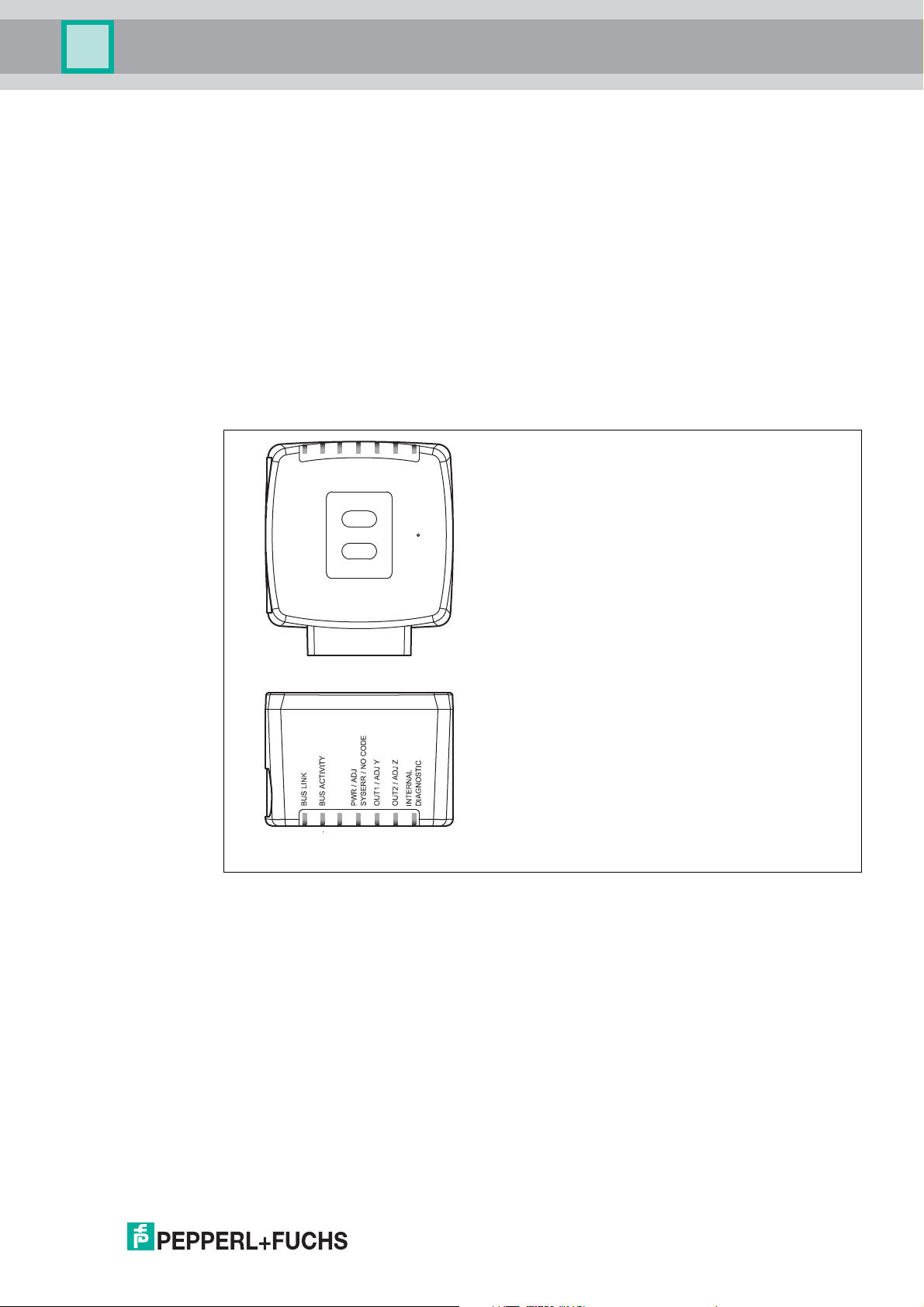

2.4 LED Indicators and Controls

The reader has six indicator LEDs for carrying out visual function checks and rapid diagnosis.

Using the two control buttons on the rear of the device, you can activate the alignment aid and

the parameterization mode.

Button 1 is labeled "ADJUST." Button 2 is labeled "CONFIG."

2017-11

Figure 2.2 Overview of LED indicators and controls

7

Page 8

PXV...-F200-B25-V1D

Product Description

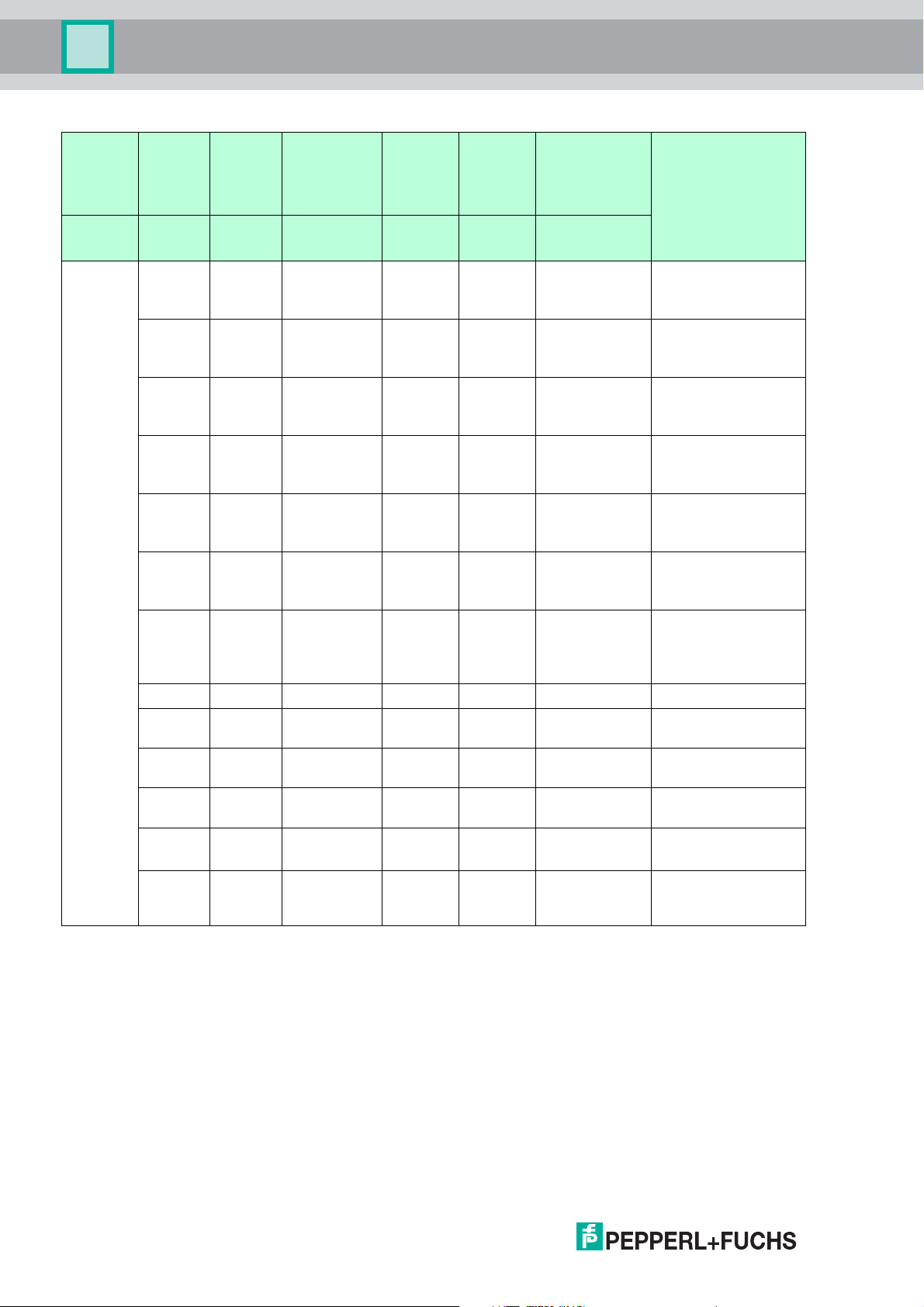

[#3]

PWR/ADJ

SYSERR/NO

CODE

green

green

green

green

green

green

green

LED

[#1]

BUS

LINK

[#2]

BUS TX /

RX

Status Off Off Flashes

Off Off Flashes

Off Off Flashes

Off Off Flashes

Off Off Flashes

Off Off Flashes

Off Off Flashes red Off Off Off Alignment

x x Lights up red x x x System error

x x Lights up

Lights up x x x x x EtherNet/IP-

x Flashes x x x x EtherNet/IP TX/RX

x x Flashes red x x x Code not recognized

x x x x Lights up Lights up Internal error

[#4]

OUT

1/ADJ Y

[#5]

OUT

2/ADJ Z

[#6]

INTERNAL

DIAGNOSTIC

Red/green/

yellow

DescriptionColor Green Ye l l ow Red/green Ye l l o w Yellow

Off Off Off Alignment

Y > setpoint value

f

= 2 Hz

flash

Lights up Off Off Alignment

Y < setpoint value

f

= 2 Hz

flash

Flashes Off Off Alignment

Y = setpoint value

f

= 2 Hz

flash

Off Off Off Alignment

Z > setpoint value

f

= 2 Hz

flash

Off Lights up Off Alignment

Z < setpoint value

f

= 2 Hz

flash

Off Flashes Off Alignment

Z = setpoint value

f

= 2 Hz

flash

Code tape outside

read range

f

= 2 Hz

flash

x x x Normal operation,

code tape detected

connection active

data transfer

f

= 2 Hz

flash

Return to

Pepperl+Fuchs

x = LED status has no meaning

2017-11

8

Page 9

PXV...-F200-B25-V1D

Product Description

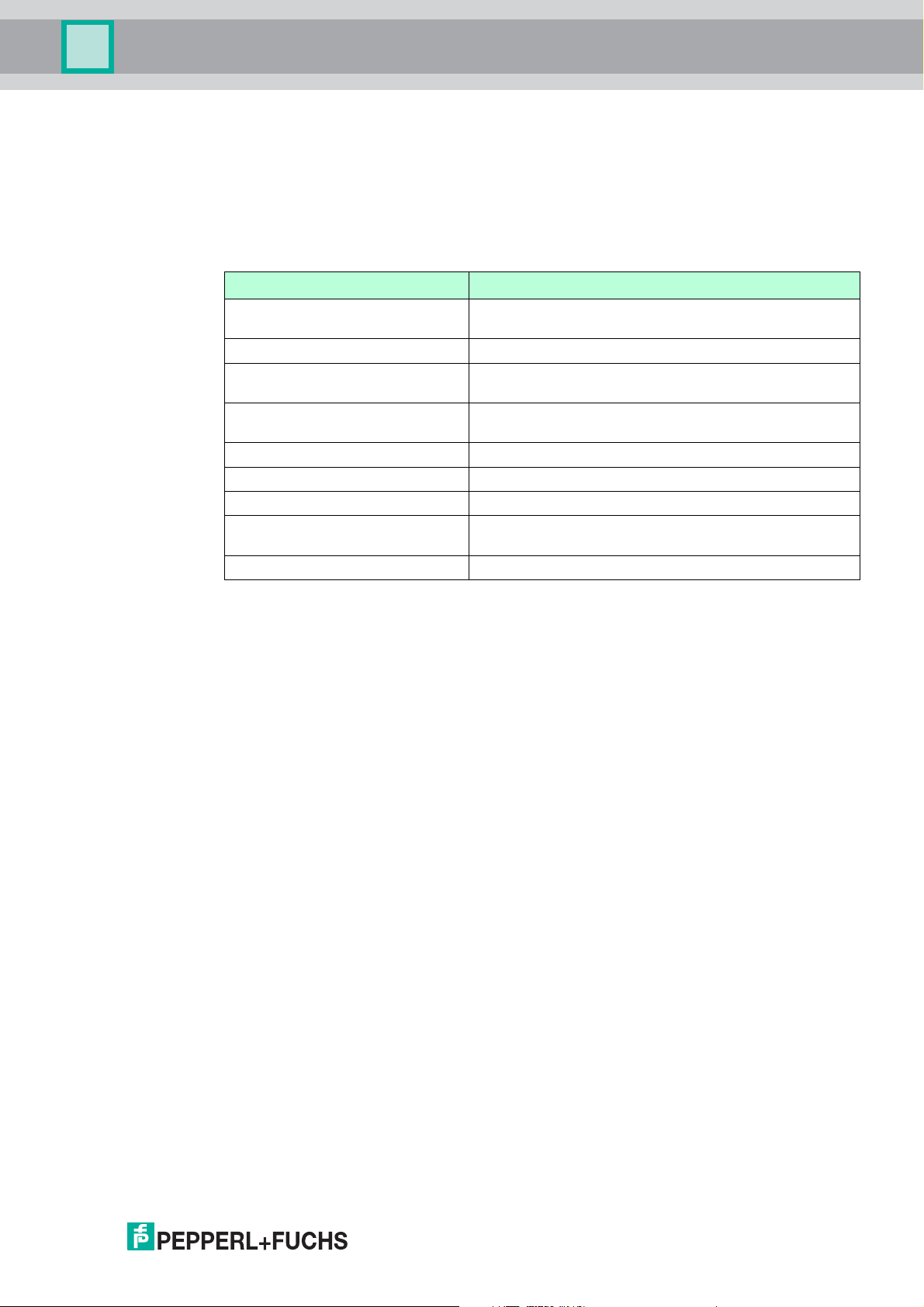

2.5 Accessories

Compatible accessories offer enormous potential for cost savings. Such accessories not only

save you a great deal of time and effort when commissioning for the first time, but also when

replacing and servicing our products.

If products are used in harsh ambient conditions, appropriate Pepperl+Fuchs accessories can

be used to extend the service life of these products.

Model number Description

V19-G-ABG-PG9 M12 single-ended female cordset, 8-pin, shielded, field-

V19-G-ABG-PG9-FE Grounding terminal and plug (set)

PCV-SC12

PCV-SC12A

V1SD-G-*M-PUR-ABG-V1SD-G Ethernet bus cable, M12 to M12, available in several

VAZ-V 1S -B Stopping plug for M12 connector

V19-G-*M-* Configurable connection cable

PCV-KBL-V19-STR-USB Cable unit for service interface with power supply

Vision Configurator Software Software for camera-based sensors that enables

PCV-MB1 Mounting bracket

attachable

Grounding clip

different lengths

convenient parameterization

Further information on accessories can be found on the reader datasheet at www.pepperlfuchs.com.

2017-11

9

Page 10

PXV...-F200-B25-V1D

715

25

5

20

3

Installation

3Installation

3.1 Affixing the Code Tape

The code tape is made of silicone-free polyester film. A position marker appears every 100 mm

along the lower edge of the code tape (see "Code Tape Dimensions"). These position markers

are used to affix the code tape in the correct position.

The back of the code tape is covered with a modified acrylate-based adhesive designed for

permanent adhesion. Affix the self-adhesive code tape along the desired traverse distance. To

do so, proceed as follows:

Affixing the Code Tape

1. Clean the surface of any greasy or oily deposits and dust.

2. Ensure that the surface is dry, clean, and stable.

3. Pull away a few centimeters of the protective film at the beginning of the code tape. Place

the code tape at the precise point of the required starting position on the surface, and press

to attach.

4. Then affix the code tape along the desired traverse distance. Remove the protective film

gradually so that the code tape does not accidentally adhere to the surface in the incorrect

position. When affixing, ensure that the code tape does not crease or trap air bubbles.

The adhesive on the code tape hardens after 72 hours.

Note!

Thermal Expansion of the Code Tape

The heat expansion coefficient of the adhered code tape corresponds to the heat expansion

coefficient of the underside.

Dimensions of the Code Tape

2017-11

10

Page 11

PXV...-F200-B25-V1D

000 009.0 m P

XV

AA25

w

ww.pe

p

per

l

fuchs

.c

o

m

Y

Z

X

0

0

0

0

0

9.0

m

0

0

0

0

0

9

.

0

m

1 2

Installation

Alignment of the Code Tape and Reader

Position the code tape so that the PEPPERL+FUCHS logo and position markers are below the

data matrix code. The position values then increase along the X direction. The diagram shows

the orientation of a reader in the default setting of 0°. The reader can be configured in the

interface for other installation situations.

Code Tapes with a Starting Position of 0 m

Order Designation Description

PXV00001-CA25-* Code tape, 1-track, length: 1 m

... ...

PXV100000-CA25-* Code tape, 1-track, length: 100,000 m

Note!

Expansion Joints and Code Tapes

If the system covers longer distances, expansion joints are integrated in the system structure.

We recommend creating breaks along the code tape. The resulting gap must not exceed

75 mm.

Note!

Inclines and Declines

If you affix the code tape on inclines or declines, cut the code tape several times at the

transition point to the horizontal as shown.

1. Incline

2. Decline

2017-11

11

Page 12

PXV...-F200-B25-V1D

Y

0

X

Installation

Hysteresis Y-Axis

Figure 3.1 Zero line for code tapes

If the reader leaves the zero line when traversing along the X-axis, the threshold may deviate. If

the deviation exceeds the defined threshold, a warning code is issued.

Y-Axis Deviation Thresholds

Code Tape Threshold

Number of Tracks Width Exit Entry

1 15 mm ± 29 mm ±25 mm

3.2 Mounting of the Reader

Mounting the Reader

Make sure that you are able to mount the reader in a stable position. Before mounting the

reader, make sure that the travel of the moving system part is arranged so that this part does

not move outside of the reader's depth of focus range during operation.

1. Mount the reader on the moving part of the system and secure the reader in place using four

screws through the mounting adapter on the reader.

2. Mount the reader vertically so that the lens of the reader with the ring light and camera

module is aligned toward the code tape.

30°

30°

Code tape

Read distance

Figure 3.2 Vertical alignment tolerance

3. Alternatively, mount the reader horizontally so that the lens of the reader with the ring light

and camera module is aligned toward the code tape.

12

2017-11

Page 13

PXV...-F200-B25-V1D

30°

30°

1

70

80

38.5

70 14.5

1

2

22

50

ø 25

12.5

M12 x 1

9

4 x M6

20 20

Installation

Figure 3.3 Horizontal alignment tolerance

1 Read Distance

4. Check that the distance between the reader and the code tape is equal to the read distance

of the reader:

Optimum Read Distance (Z-Axis)

Order Designation Read Distance [mm] Depth of Focus [mm]

PXV100* 100 ± 50

Dimensions of the Reader

2017-11

13

Page 14

PXV...-F200-B25-V1D

Installation

Caution!

When selecting the length of the mounting screws, ensure that the maximum insertion depth of

the screws in the threaded inserts on the reader is 8 mm.

Using longer screws may damage the reader.

Caution!

The maximum torque of the mounting screws must not exceed 9 Nm.

Tightening the screws to a higher torque may damage the reader.

3.3 Electrical Connection

The reader is connected to an 8-pin M12 x 1 connector plug at the side of the housing with the

label "Main". This connection is used to provide the power supply and communicate with the

peripherals in one. The configurable inputs and outputs for the reader are also available on this

connection.

Main

1

2

3

4

5

6

7

8

OUT 2 / IN 2

+ UB

n.c.

n.c.

OUT 1

IN 1

GND

OUT 3 / IN 3

Plug Assignment

Main

1

8

7

2

6

53

4

Color Assignment

Pepperl+Fuchs single-ended female cordsets are manufactured in accordance with EN609475-2. When using a type V19-... single-ended female cordset with an open cable end on the

Main connection, the colors are assigned as follows:

Connection Pin Strand Color Color Abbreviation

1 White WH

2 Brown BN

3 Green GN

4 Yellow YE

5 Gray GY

6 Pink PK

7 Blue BU

8 Red RD

14

2017-11

Page 15

PXV...-F200-B25-V1D

Installation

Shielding Cables

The shielding of connection lines is required to suppress electromagnetic interference.

Establishing a low resistance or low impedance connection with the conductor or equipotential

bonding circuit is a particularly important factor in ensuring that these interference currents do

not become a source of interference themselves. Always use connection lines with braided

shield; never use connection lines with a film shield. The shield is integrated at both ends, i.e.,

in the switch cabinet or on the controller and on the read head. The grounding terminal

available as an accessory allows easy integration in the equipotential bonding circuit.

In exceptional cases, the shielding of a connection at one end may be more favorable if

An equipotential bonding cable is not laid or cannot be laid.

A film shield is used.

The following points relating to shielding must also be noted:

Use metal cable clips that cover large areas of the shield.

After installing the cable shield in the control cabinet, place it directly on the equipotential

bonding rail.

Direct the protective grounding connections to a common point in a star configuration.

The cross-section of the cables used for grounding should be as large as possible.

Additional Ground Connection

Order Designation Description

PCV-SC12 Clip for mounting an additional ground

PCV-SC12A

Caution!

Damage to the device

Connecting an alternating current or excessive supply voltage can damage the device or

cause the device to malfunction.

Electrical connections with reversed polarity can damage the device or cause the device to

malfunction.

Connect the device to direct current (DC). Ensure that the supply voltage rating is within the

specified device range. Ensure that the connecting wires on the female cordset are connected

correctly.

3.4 EtherNet/IP Connection

The reader is connected to EtherNet/IP via two 4-pin, D-coded device sockets, M12 x 1,

EtherNet/IP 1 and EtherNet/IP 2, on the side of the housing.

Bus

1

2

3

4

TX +

RX +

TX -

RX -

connection.

Figure 3.4

2017-11

15

Page 16

PXV...-F200-B25-V1D

EtherNet/IP 1 & 2

1

3

4

2

Installation

Connector Assignment

Figure 3.5

Suitable Ethernet cables can be found in the Accessories section of the reader datasheet at

www.pepperl-fuchs.com.

16

2017-11

Page 17

PXV...-F200-B25-V1D

000 009.0 m P

XV

AA25

w

ww.pe

p

per

l

f

uchs

.c

om

Y

Z

X

Commissioning

4 Commissioning

4.1 Aligning the Reader

The reader provides an integrated alignment aid to enable simple optimal alignment of the

reader relative to the code tape in the Y-coordinate and the Z-coordinate.

Note!

The alignment aid may only be activated within 10 minutes of switching on the reader.

You can also switch the reader from normal operation to parameterization mode, if necessary.

Press button 1 on the rear of the reader and hold for at least 2 seconds.

Activating the Alignment Aid

1. Press button 1 for longer than 2 seconds.

If the reader has recognized the code tape, LED2 flashes green. If the reader has not

recognized the code tape, LED2 flashes red. .

2. Align the reader in the Z and Y coordinates. The LEDs on the reader will support you.

Z coordinate:If the distance between the camera and the code tape is too small, the yellow

LED5 lights up. If the distance between the camera and the code tape is too large, the yellow

LED5 goes out. Within the target range, the yellow LED5 and the green LED2 flash

synchronously.

Set the distance between the reader and the code tape so that the yellow LED5 and the green

LED2 flash synchronously.

Y coordinate: If the optical axis of the reader is too low relative to the middle of the code tape,

the yellow LED4 lights up.

If the optical axis is too high, the yellow LED4 goes out. Within the target range, the yellow

LED4 and the green LED2 flash synchronously.

Set the optimal height of the reader relative to the code tape so that the yellow LED4 and the

green LED2 flash synchronously.

Briefly press button 1 to close the alignment aid. The reader now switches to normal operation.

2017-11

17

Page 18

PXV...-F200-B25-V1D

Operation and Communication

5 Operation and Communication

5.1 Communication via EtherNet/IP

5.1.1 General Information on Communication via EtherNet/IP

The read head communicates with the controller (e.g., PLC) via EtherNet/IP. An objectoriented fieldbus system for exchanging data between nodes based on Ethernet technology.

The management and development of the EtherNet/IP standards are subject to the Open

DeviceNet Vendor Association (ODVA). More information on EtherNet/IP will be supplied on

request by the Open DeviceNet Vendor Association (ODVA) at the following Internet address:

ODVA, Inc

4220 Varsity Drive, Suite A

Ann Arbor, MI 48108-5006 USA

http://www.odva.org e-mail: mailto:odva@odva.org

The basic properties of the interface are:

Transfer rate 10 Mbit/s or 100 Mbit/s, half or full duplex operation

Automatic negotiation of the transfer rate and the duplex method (auto-negotiation)

Automatic setting for crossed lines (auto-crossover)

EtherNet/IP protocol works according to the CIP protocol (Common Industrial Protocol) and is

used to control, configure, monitor, and collect data. Time-sensitive data exchange (implicit

messaging) takes place using the UDP/IP protocol and non-time-sensitive data exchange

(explicit messaging) using the TCP/IP protocol.

The read head supports the following features:

"Listen only", "Input only", and "Exclusive Owner" connection types

Message transmission as "Multipoint data transfer" (Multicast) and "Point-to-point data

transfer" (Unicast)

Cycle time (request packet interval) 2 ms

Dynamic Host Configuration Protocol (DHCP)

Device Level Ring (DLR)

Address Conflict Detection (ACD)

The read head is integrated in the network via a EDS file (electronic data sheet) with a

configuration tool such as RSLOGIX5000. The EDS file contains all of the information about

device-specific parameters and operating modes.

Downloading the EDS file

You can find the relevant EDS file in the Software section of the product detail page for the

device.

To access the product detail page for the device, go to http://www.pepperl-fuchs.com and type

information about the device (e.g., the product description or the item number) into the search

function.

5.1.2 Setting the IP Address

The read head is delivered in DHCP mode and waits for an address assignment from the

control system.

The following section describes the address assignment via the software BOOT/DHCP server

from Rockwell Automation as an example.

18

2017-11

Page 19

PXV...-F200-B25-V1D

Operation and Communication

1. Connect the read head with the DHCP server.

2. Start the BOOT/DHCP server software.

3. Enter the following data in the Network Settings menu:

- Subnet Mask "255.255.255.0 "

- Gateway "192.168.1.1"

- the remaining fields are not filled in.

4. Switch on the supply voltage to the read head.

The read head cyclically carries out DHCP requests. This enters the MAC address of the

read head in the Request History field to the list.

5. Enter the desired IP address in the New Entry menu.

- The software automatically adopts the MAC address of the read head.

- The "hostname" function is not supported.

- You may enter text under "Description".

2017-11

19

Page 20

PXV...-F200-B25-V1D

Operation and Communication

6. Confirm the entries of the address data using OK.

The IP address is assigned to the read head on the next DHCP request. The new

address data will be displayed in the Relation List field.

20

7. Press the Disable BOOTP/DHCP key in the Relation List field.

In this way, the assigned IP address is saved permanently in the read head.

2017-11

Page 21

PXV...-F200-B25-V1D

Operation and Communication

5.1.3 EtherNet/IP objects

All the data and functions of the read head are defined via objects in accordance with the

EtherNet/IP standards. The read head corresponds to the "Encoder Device Type 0x22" device

profile.

The read head supports the following listed standard and product-specific classes.

Standard classes

Class ID Class description

0x01 Identity Object

0x02 Message Router Object

0x04 Assembly Object

0x06 Connection Manager Object

0xF5 TCP/IP Interface Object

0xF6 Ethernet Link Object

0X47 DLR Object

0X48 Quality of Service

Product-specific class

Class ID Class description

0x23 Position Sensor Object

The parameters are not directly addressable from the network with the "Set" or "Get" attribute

services. Access is via Assembly Objects (Class Code 0x04)

2017-11

21

Page 22

PXV...-F200-B25-V1D

Operation and Communication

Cyclic data communication with assembly objects (Class Code 0x04)

Assemblies are special CIP objects used for cyclic data communication (implicit messaging).

These are composed of one or more attributes of various objects. These objects allow you to

send or receive data from multiple objects by means of a connection. The composition of the

assemblies in the read head is fixed and cannot be modified by the user.

Input assemblies

Instance

no.

1 Position 4 Position Value Signed

100 Position + speed 8 Position Value Signed

101 Status, X-position, Y-

Description Size [byte] Attribute

position, Speed,

Warning, Event

Attribute

ID

10 DINT

(X-Position)

10 DINT

(X-Position)

Velocity Value 24 DINT

18 Status Word 100 UINT

Position Value Signed

(X-Position)

Y-position 101 DINT

Velocity Value 24 DINT

Warning flags 102 UINT

Event number 103 UINT

10 DINT

Data type

Addresses required for the various connection types

The connection type defines the connection between the control system (originator), in this

case the controls, and the target device (target), in this case the read head. The following

options are available for data traffic.

Data from the control system to the destination device

Instance no. (dec.) Size [byte] Connection type

192 0 Listen only

193 0 Input only

Data from the target device to the control system

Instance no. (dec.) Size [byte] Assemblies

1 4 Position

100 8 Position + speed

101 18 Status, X-position, Y-position,

5.1.4 Attributes of the Reader's EtherNet/IP Objects

Attributes of the Position Sensor Object (Class ID 0x23)

Speed, Warning, Event (lists

only)

22

Class attributes

ID Name Access Data type Size [byte] Description

1 Revision - UINT 2 Object

inspection

2017-11

Page 23

PXV...-F200-B25-V1D

Operation and Communication

Standard instance attributes for object 0x23

ID Attribute Access Data type Size [byte] Description

10 Position Value

Signed (X

position)

24 Velocity Value - DINT 4 Velocity

Reader-specific attributes

ID Attribute Access Data type Size [byte] Description

100 Status Word - UINT 2 Status information

101 Y position - UINT 4 Y position in two's

102 Warning Flags - UINT 2 Warnings

103 Event Number - UINT 2 Event marker number

Basic data structure

- DINT 4 X position in two's

complement

complement

1byte = 8bit value

Byte 4 Byte 3 Byte 2 Byte 1

Example: XP31 ... XP24

MSB (most significant

byte)

Example: XP23

... XP16

Example: XP15

... XP08

Example: XP07 ... XP00

LSB (least significant byte)

Position data X: Position Value Signed (ID 10)

Size Type Content

4 byte consistent Input data 32 bit X data

The following default settings apply:

The X position is output in the two's complement.

The value is output in the resolution set for the device.

The default is mm.

If the ERR bit is set in the "status word (ID 100)" attribute, the error number is transferred

to this attribute.

LSB first

LSB = least significant byte

Resolution: 0.1 mm, 1 mm, 10 mm, binary coded

At a resolution of 1 mm and 10 mm: L

10,000,000 mm

10.00 km =

max =

Data for attribute 10

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 2 Bit 0

Byte 1 XP07 XP06 XP05 XP04 XP03 XP02 XP01 XP00

Byte 2 XP15 XP14 XP13 XP12 XP11 XP10 XP09 XP08

Byte 3 XP23 XP22 XP21 XP20 XP19 XP18 XP17 XP16

Byte 4 XP31 XP30 XP29 XP28 XP27 XP26 XP25 XP24

2017-11

23

Page 24

PXV...-F200-B25-V1D

Operation and Communication

Position data Y: Y position (ID 101)

Size Type Content

4 byte consistent Input data 32 bit Y data

The following default settings apply:

The Y position is output in the two's complement.

The value is output in the resolution set for the device.

The default is mm.

Data for attribute 101

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 2 Bit 0

Byte 1 YP07 YP06 YP05 YP04 YP03 YP02 YP01 YP00

Byte 2 YP15 YP14 YP13 YP12 YP11 YP10 YP09 YP08

Byte 3 YP23 YP22 YP21 YP20 YP19 YP18 YP17 YP16

Byte 4 YP31 YP30 YP29 YP28 YP27 YP26 YP25 YP24

LSB first

Resolution: 0.1 mm, 1 mm, 10 mm, binary coded in

two's complement

Speed data: Velocity Value (ID 24)

Size Type Content

4 byte consistent Input data 32 bit speed data

Resolution: 0.1 m/s, 0.01 m/s, 0.001 m/s, binary coded

Speed of 0 ... 12.5 m/s

Example: Speed = 4.7 m/s --> speed output = 47 at a

resolution of 0.1 m/s

65535 for unknown speed

The following default settings apply:

The value is output in the resolution set for the device.

The default is dm/s.

Data for attribute 24

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 2 Bit 0

Byte 1 SP07 SP06 SP05 SP04 SP03 SP02 SP01 SP00

Byte 2 SP15 SP14 SP13 SP12 SP11 SP10 SP09 SP08

Byte 3 SP23 SP22 SP21 SP20 SP19 SP18 SP17 SP16

Byte 4 SP31 SP30 SP29 SP28 SP27 SP26 SP25 SP24

Status: Status word (ID 100)

24

Size Type Content

2 bytes Input data 16 bit status

If the ERR bit is set, there is an error. The error number is transmitted to the "Value Signed (ID

10)" attribute.

2017-11

Page 25

PXV...-F200-B25-V1D

Operation and Communication

Data for attribute 100

Content

Byte 1, 2

Bit no.

1 ERR Error message (error code in XP00–XP15); remaining

2 NP No position information/OUT (XP = 0, YP = 0, SP = 0)

3 WRN Warnings present, see Warning attribute

4 EV Event, see Event attribute

5 Posdetected Valid position information available

... ... -

16 0 -

Error Codes

Error code Description Priority

1 Reader tilted 180° 2

2 No clear position can be determined (difference between codes

> 1000 Internal error 1

Status

is too great, code distance incorrect, etc.)

Function

bits = 0, see Error Codes

3

Event: Event Marker No. (ID 103)

Size Type Content

2 byte consistent Input data Last event marker

The event marker no. is binary coded and unsigned.

Data for attribute 103

Bit no.

1 EV01

2 EV02

3 EV03

4 EV04

5 EV05

6 EV06

7 EV07

8 EV08

9 EV09

10 0

... ...

16 0

Last event no.

Content

Byte 1, 2

Last event marker data

2017-11

25

Page 26

PXV...-F200-B25-V1D

Operation and Communication

Warning: Warning Flags (ID 102)

Size Type Content

2 byte consistent Input data Last warnings

A set bit indicates that the corresponding warning is active.

Data for attribute 102

Bit no.

1 WRN01

2 WRN02

3 WRN03

4 WRN04

5 WRN05

6 WRN06

7 WRN07

8 WRN08

9 WRN09

10 WRN10

11 WRN11

12 WRN12

13 WRN13

14 WRN14

15 WRN15

16 WRN16

Last warning no.

Content

Byte 1, 2

Last warning data

26

Warning data set

Content

Bit no.

1 WRN01 A code with content that did not come from the reader (PXV) was

2 WRN02 Reader too close to code tape

3 WRN03 Reader too far from code tape

4 WRN04 Y position too large. The sensor is just before OUT

5 WRN05 Y position too small. The sensor is just before OUT

6 WRN06 The reader is rotated or tilted in relation to the code tape

7 WRN07 Low level of code contrast

8 WRN08 Repair tape detected

9 WRN09 Temperature too high

10 WRN10 Reserved

11 WRN11 Reserved

12 WRN12 Reserved

13 WRN13 Reserved

DescriptionByte 1, 2

found.

2017-11

Page 27

PXV...-F200-B25-V1D

Operation and Communication

Content

Bit no.

14 WRN14 Reserved

15 WRN15 Reserved

16 WRN16 Reserved

Note!

If no warnings are present, all bits in the warning data set are set to 0.

DescriptionByte 1, 2

2017-11

27

Page 28

PXV...-F200-B25-V1D

Appendix

6Appendix

6.1 ASCII Table

hex dec ASCII hex dec ASCII hex dec ASCII hex dec ASCII

00 0 NUL 20 32 Space 40 64 @ 60 96 '

01 1 SOH 21 33 ! 41 65 A 61 97 a

02 2 STX 22 34 " 42 66 B 62 98 b

03 3 ETX 23 35 # 43 67 C 63 99 c

04 4 EOT 24 36 $ 44 68 D 64 100 d

05 5 ENQ 25 37 % 45 69 E 65 101 e

06 6 ACK 26 38 & 46 70 F 66 102 f

07 7 BEL 27 39 ' 47 71 G 67 103 g

08 8 BS 28 40 ( 48 72 H 68 104 h

09 9 HT 29 41 ) 49 73 I 69 105 I

0A 10 LF 2A 42 * 4A 74 J 6A 106 j

0B 11 VT 2B 43 + 4B 75 K 6B 107 k

0C 12 FF 2C 44 , 4C 76 L 6C 108 l

0D 13 CR 2D 45 - 4D 77 M 6D 109 m

0E 14 SO 2E 46 . 4E 78 N 6E 110 n

0F 15 SI 2F 47 / 4F 79 O 6F 111 o

10 16 DLE 30 48 0 50 80 P 70 112 p

11 17 DC1 31 49 1 51 81 Q 71 113 q

12 18 DC2 32 50 2 52 82 R 72 114 r

13 19 DC3 33 51 3 53 83 S 73 115 s

14 20 DC4 34 52 4 54 84 T 74 116 t

15 21 NAK 35 53 5 55 85 U 75 117 u

16 22 SYN 36 54 6 56 86 V 76 118 v

17 23 ETB 37 55 7 57 87 W 77 119 w

18 24 CAN 38 56 8 58 88 X 78 120 x

19 25 EM 39 57 9 59 89 Y 79 121 y

1A 26 SUB 3A 58 : 5A 90 Z 7A 122 z

1B 27 ESC 3B 59 ; 5B 91 [ 7B 123 {

1C 28 FS 3C 60 < 5C 92 \ 7C 124 |

1D 29 GS 3D 61 = 5D 93 ] 7D 125 }

1E 30 RS 3E 62 > 5E 94 ^ 7E 126 ~

1F 31 US 3F 63 ? 5F 95 _ 7F 127 DEL

28

2017-11

Page 29

Subject to modifications

Copyright PEPPERL+FUCHS • Printed in Germany

www.pepperl-fuchs.com

FACTORY AUTOMATION –

SENSING YOUR NEEDS

Worldwide Headquarters

Pepperl+Fuchs GmbH

68307 Mannheim · Germany

Tel. +49 621 776-0

E-mail: info@de.pepperl-fuchs.com

USA Headquarters

Pepperl+Fuchs Inc.

Twinsburg, Ohio 44087 · USA

Tel. +1 330 4253555

E-mail: sales@us.pepperl-fuchs.com

Asia Pacific Headquarters

Pepperl+Fuchs Pte Ltd.

Company Registration No. 199003130E

Singapore 139942

Tel. +65 67799091

E-mail: sales@sg.pepperl-fuchs.com

/ DOCT-5912

11/2017

Loading...

Loading...