Optical reader - safePXV PXV100A-F200-B28-V1D

Technical data

General specifications

Passage speed v ≤ 8 m/s

Measuring range max. 100000 m

Light type Integrated LED lightning (red/blue)

Read distance 100 mm

Depth of focus ± 30 mm

Field of view typ. 120 mm x 80 mm

Ambient light limit 30000 Lux

Accuracy

Non safety-related X ± 0.2 mm

Safety-related X See the original instructions

Nominal ratings

Camera

Type CMOS , Global shutter

Processor

Clock pulse frequency 600 MHz

Speed of computation 4800 MIPS

Functional safety related parameters

Safety Integrity Level (SIL) SIL 3

R

Performance level (PL) PL e

Category Cat. 4

Reaction time 165 ms

MTTF 41.66 a

MTTFd 104.74 a

Model number

PXV100A-F200-B28-V1D

Read head for incident light positioning

system

Features

• SIL 3 (EN 61508)

• Category 4 PL e (EN ISO 13849)

•PROFINET interface

• PROFIsafe interface

• Safe, non-contact positioning on Data

Matrix code tape

• Traverse distance up to 100 km

• Mechanically rugged: no wearing

parts, long operating life,

maintenance-free

Diagramms

Position Data

Y

000 009.0 m PXV-AA25

X

System components

PXV*-AA25-*

Data Matrix code tape

Mission Time (T

PFH 1.09 E-8 typ.

Indicators/operating means

LED indication 7 LEDs (communication, status messages)

Electrical specifications

Operating voltage U

No-load supply current I

Power consumption P

Interface

Interface type 100 BASE-TX

Protocol PROFINET IO Real-Time (RT) Conformance class B

Transfer rate 100 MBit/s

Conformity

Fieldbus standard PROFIsafe in accordance with IEC 61784-3-3; profile 2.4

Functional safety EN ISO 13849-1:2015 ; EN 61508:2010 part 1-7 ;

Shock resistance EN 60068-2-27:2009

Vibration resistance EN 60068-2-6:2008

Emitted interference EN 61000-6-4:2007+A1:2011

Noise immunity EN 61000-6-7:2015

Photobiological safety risk group 2 according IEC 62471

Ambient conditions

Operating temperature 0 ... 45 °C (32 ... 113 °F) , -20 ... 45 °C (-4 ... 113 °F)

Storage temperature -40 ... 85 °C (-40 ... 185 °F)

Relative humidity 90 % , noncondensing

Altitude ≤ 2000 m above MSL

Mechanical specifications

Connection type 8-pin, M12x1 connector, standard

Housing width 70 mm

Housing height 70 mm

Housing depth 50 mm

Degree of protection IP67

Material

Housing PC/ABS

Mass approx. 200 g

Approvals and certificates

CE conformity CE

CCC approval CCC approval / marking not required for products rated ≤36

TÜV approval TÜV Rheinland 01/205/5669.00/18

) 20 a

M

B

0

0

20 ... 30 V DC , PELV

max. 300 mA

6 W

EN 62061:2005 + AC:2010 + A1:2013 + A2:2015

(noncondensing; prevent icing on the lens!)

4-pin, M12x1 socket, D-coded (LAN)

4-pin, M12x1 socket, D-coded (LAN)

V

Release date: 2019-02-26 16:34 Date of issue: 2019-02-26 296169_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

Pepperl+Fuchs Group

1

PXV100A-F200-B28-V1DOptical reader - safePXV

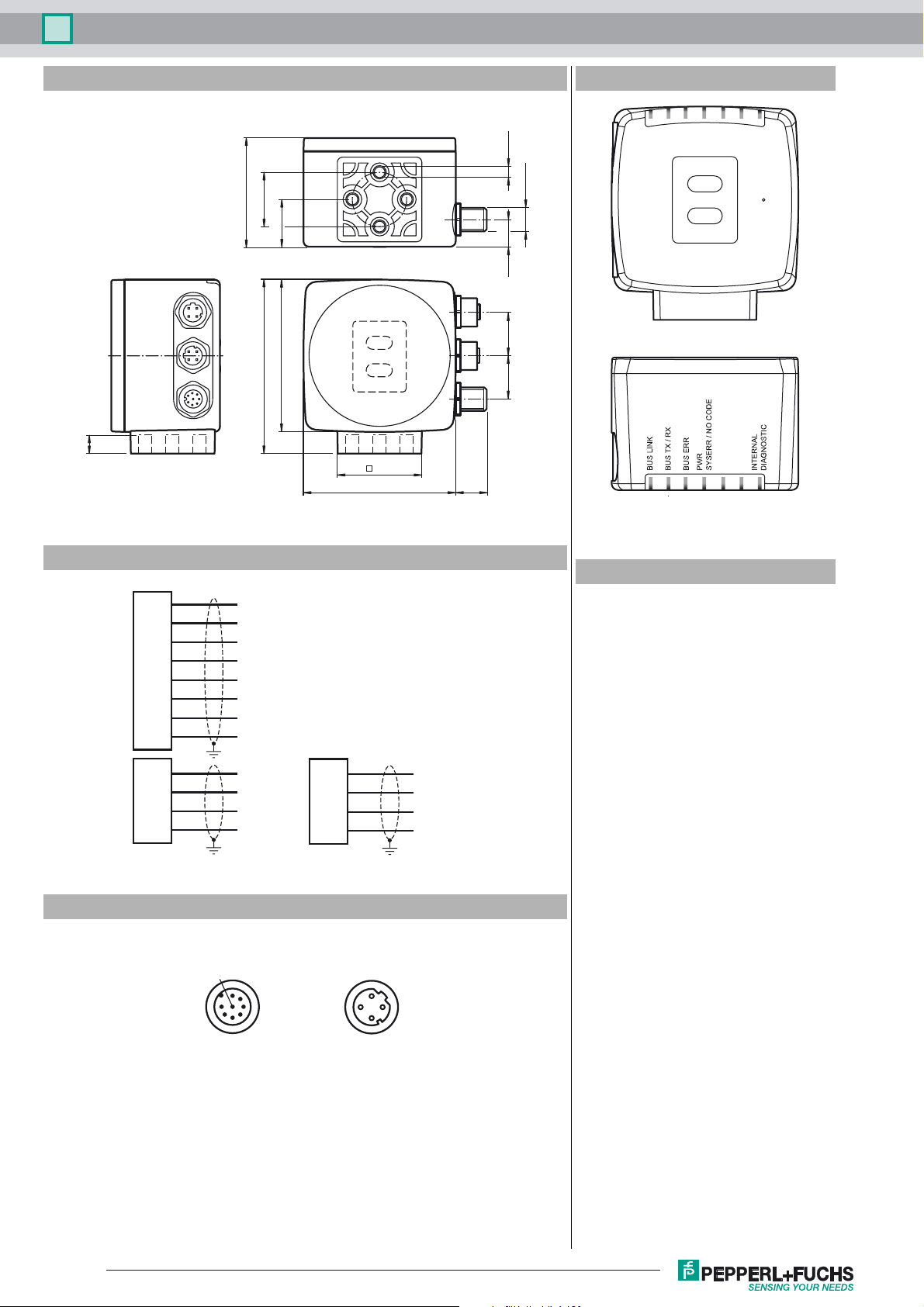

Dimensions

9

Additional information

4 x M6

50

ø 25

22

1

70

80

2

38.5

70 14.5

M12 x 1

12.5

20 20

SERVICE

NO FUNCTION

LED 1 2 3 4 5 6 7

1

2

Electrical connection

1

2

3

4

5

Main

6

7

8

1

2

3

Bus

4

Pinout

2

Accessories

n.c.

+ UB

n.c.

n.c.

n.c.

n.c.

GND

n.c.

Bus

1

2

3

4

TX +

RX +

TX -

RX -

TX +

RX +

TX -

RX -

Profinet 1 & 2Main

1

8

7

6

53

4

1

4

2

3

PGV25M-CD100-CLEAR

Protective laminate for PGV code tape

PCV-AG100

Alignment guide for PCV100-* read head

PCV-SC12

Grounding clip for PCV system

PCV-SC12A

Grounding clip for PCV system

PCV-LM25

Marker head for 25 mm code tape

PCV-MB1

Mounting bracket for PCV* read head

V1SD-G-2M-PUR-ABG-V1SD-G

Ethernet bus cable, M12 to M12, PUR

cable 4-pin, CAT5e

V1SD-G-5M-PUR-ABG-V1SD-G

Ethernet bus cable, M12 to M12, PUR

cable 4-pin, CAT5e

V1SD-G-10M-PUR-ABG-V1SD-G

Ethernet bus cable, M12 to M12, PUR

cable 4-pin, CAT5e

V1SD-G-5M-PUR-ABG-V45-G

Connection cable, M12 to RJ-45, PUR

cable 4-pin, CAT5e

V1SD-G-10M-PUR-ABG-V45-G

Connection cable, M12 to RJ-45, PUR

cable 4-pin, CAT5e

V1SD-G-30M-PUR-ABG-V45-G

Connection cable, M12 to RJ-45, PUR

cable 4-pin, CAT5e

V19-G-ABG-PG9

Release date: 2019-02-26 16:34 Date of issue: 2019-02-26 296169_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Pepperl+Fuchs Group

Optical reader - safePXV PXV100A-F200-B28-V1D

Accessories

Female connector, M12, 8-pin, shielded,

field attachable

V19-G-ABG-PG9-FE

Female connector, M12, 8-pin, shielded,

field attachable

V19-G-2M-PUR-ABG

Female cordset, M12, 8-pin, shielded,

PUR cable

V19-G-5M-PUR-ABG

Female cordset, M12, 8-pin, shielded,

PUR cable

V19-G-10M-PUR-ABG

Female cordset, M12, 8-pin, shielded,

PUR cable

Additional Information

Function

The reader forms part of the positioning system in the Pepperl+Fuchs incident light

process. The reader's features include a camera module and internal illumination

unit, enabling it to detect position markers printed onto an adhesive, colored code

tape in the form of Data Matrix codes. The code tape is generally mounted

stationary on a fixed part of the plant, e.g., elevator shaft, monorail conveyor

mounting rails, etc., and the reader is mounted parallel on the moving "vehicle," e.g.,

elevator car, monorail conveyor chassis, etc.

The positioning system issues position values that achieve the reliability required by

SIL 3 and PL e, provided that the device is properly integrated into the plant

according to the specifications given in the original instructions.

Mounting and Commissioning

Mount the reader such that the optical surface of the device captures the optimal

reading distance to the Data Matrix code tape (see "Technical Data"). The stability

of the mounting and the manner in which the vehicle is guided ensure that the reader

is not operated outside of its depth of focus range. The code tape must not leave the

maximum reading window for the reader during this process.

Displays and Operating Elements

The reader is equipped with the following indicator LEDs for carrying out visual

function checks and quick diagnostics:

LEDs

LED Color

1 Green BUS LINK PROFINET connection activated

2 Yellow BUS TX/RX Data transfer

3 Red BUS ERR PROFINET communication error

4 Red/green PWR

5 - – No function

6 - – No function

7 Red/green/

yellow

Label Meaning

SYSERR/NO

CODE

INTERNAL

DIAGNOSTIC

Code detected/not detected, error

Internal diagnostics

The SERVICE button on the back of the device is used for internal service purposes.

Release date: 2019-02-26 16:34 Date of issue: 2019-02-26 296169_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

Pepperl+Fuchs Group

3

Loading...

Loading...