Multiturn absolute encoder PVM58

Technical data

General specifications

Detection type photoelectric sampling

Device type Multiturn absolute encoder

Functional safety related parameters

MTTFd 70 a

Mission Time (TM) 20 a

L

1.9 E+11 at 6000 rpm and 20/40 N axial/radial shaft load

10h

Diagnostic Coverage (DC) 0 %

Electrical specifications

R

Model Number

PVM58

Features

• Industrial standard

housing Ø58 mm

• PROFIBUS interface

• 30 Bit multiturn

• Speed transfer

• Extended scaling functions

• Programmable limit switches

• Commissioning mode

• Servo or clamping flange

Description

This series of PROFIBUS rotary encoders is based

on the modern fast technology of singleturn sampling and the mechanical gear box of the multiturn

unit. The absolute encoder corresponds to the

PROFIBUS profile for encoders, order no. 3.062.

Operation is supported based on Class 1 and Class

2.

For operation based on Class 1, position data and

diagnostic data bytes 1 ... 16 are available. In addi-

tion, the direction of the code can be selected as

either cw ascending (clockwise rotation, code

course ascending) or cw descending (clockwise rotation, code course descending).

If the rotary encoder is operated according to Class

2, additional functions to those from Class 1 are

available. These include scaling of the resolution

per revolution and the overall resolution, as well as

the preset function. In addition, expanded diagnostic reporting is supported.

Besides, the rotary encoder offers extended functionalities such as speed transfer, extended scaling

functions, programmable limit switches and a commissioning mode.

The removable connecting hood contains a slide

switch for setting the terminating resistor and the

rotary switches for setting the address. Assign a

fixed address and bus termination to the encoder

with this switches.

The device is designed for shaft mounting and is

available in servo flange or clamping flange design.

Operating voltage U

No-load supply current I

Power consumption P

Time delay before availability t

Linearity ± 2 LSB at 16 Bit, ± 1 LSB at 13 Bit, ± 0,5 LSB at 12 Bit

Output code binary code

Code course (counting direction) programmable,

Interface

Interface type PROFIBUS

Resolution

Single turn up to 16 Bit

Multiturn 14 Bit

Overall resolution up to 30 Bit

Transfer rate 0.0096 ... 12 MBit/s

Standard conformity PNO profile 3.062, RS-485

Connection

Terminal compartment in removable housing cover

Standard conformity

Degree of protection DIN EN 60529, IP65

Climatic testing DIN EN 60068-2-30 , no moisture condensation

Emitted interference EN 61000-6-4:2007

Noise immunity EN 61000-6-2:2005

Shock resistance DIN EN 60068-2-27, 100 g, 6 ms

Vibration resistance DIN EN 60068-2-6, 20 g, 10 ... 2000 Hz

Ambient conditions

Operating temperature -40 ... 85 °C (-40 ... 185 °F)

Storage temperature -40 ... 85 °C (-40 ... 185 °F)

Mechanical specifications

Material

Combination 1 housing: powder coated aluminum

Combination 2 (Inox) housing: stainless steel

Mass approx. 600 g (combination 1)

Rotational speed max. 12000 min

Moment of inertia 30 gcm

Starting torque ≤ 3 Ncm (version without shaft seal)

Shaft load

Axial 40 N

Radial 110 N

Approvals and certificates

UL approval cULus Listed, General Purpose, Class 2 Power Source

B

0

0

v

10 ... 30 V DC

max. 230 mA at 10 V DC

max. 100 mA at 24 V DC

max. 2.5 W

< 1000 ms

cw ascending (clockwise rotation, code course ascending)

cw descending (clockwise rotation, code course

descending)

IP66, IP67 (with shaft seal)

flange: aluminum

shaft: stainless steel

flange: stainless steel

shaft: stainless steel

approx. 1200 g (combination 2)

-1

2

Release date: 2016-02-02 11:12 Date of issue: 2016-02-02 t49153_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

1

Multiturn absolute encoder PVM58

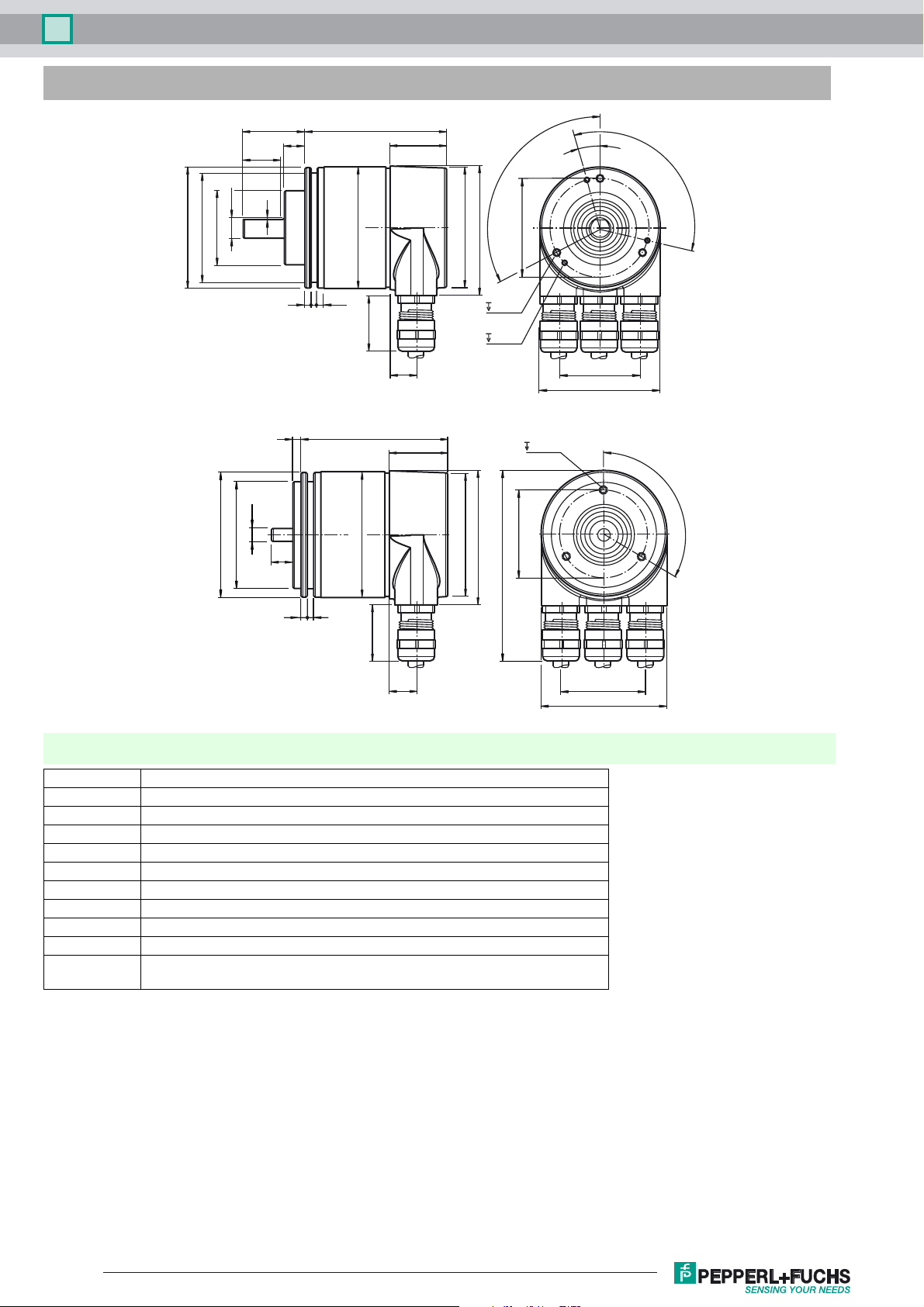

Dimensions

30 L

10

18

1

10h8

ø 58

ø 53

36f7

3 3.5

* Singleturn: L = 69, Multiturn : L = 80

** Aluminum: d = 59, stainless steel: d = 61

4

6f6

ø 58

ø 50f7

10

d**

3

25

L

d**

12.7

27.5

27.5

ø 58

ø 58

3 x 120°

63

M4 x 0.7

6

M3 x 0.5

6

63

88

TK ø 48

M4 x 0.7

6

TK ø 42

15°

3 x 120°

40

60

3 x 120°

3

3

25

* Singleturn: L = 69, Multiturn : L = 80

** Aluminum: d = 59, stainless steel: d = 61

12.7

Electrical connection

Terminal Explanation

⊥ Ground connection for power supply

B (left) Data line B (pair 1), Bus In

A (left) Data line A (pair 1), Bus In

(-) 0 V

(+) 10 V ... 30 V

B (right) Data line B (pair 2), Bus Out

A (right) Data line A (pair 2), Bus Out

(-) 0 V

(+) 10 V ... 30 V

The supply lines only have to be connected once (regardless to which terminal).

The outgoing bus is being uncoupled while the terminal resistor is on.

The arrangement of the terminals is shown in the section operating elements.

40

60

Release date: 2016-02-02 11:12 Date of issue: 2016-02-02 t49153_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Multiturn absolute encoder PVM58

x10

x1

Indicating and operating elements

Termination resistor

Supply voltage

R

T

ON

RS 485 interface

Supply voltage

Error indicator

LED red

Bus Out

Data line A

Data line B

Bus IN

+-+

A

BAB-

0

0

9 1

9 1

2

2

8

8

3

3

7

7

4

4

6

6

5

5

x1

x10

Data line A

Data line B

2

Addressing

Adjusting the participant address

The participant address can be adjusted with the rotary switches. The address can be defined between 1 and 99, and may

only be assigned once.

Adjusting the termination resistor

The terminating resistor RT (220 Ω) can be connected to the circuit by means of the switch:

LED-indicators

LED red LED green Meaning

off off No voltage supply

Encoder ready, no configuration data received.

on on

on flashing

flashing on Encoder ready, no communication with master (i.e. wrong address setting)

on off Data timeout (> 40 s). (i.e. data lines interrupted)

off on Normal operation, Data Exchange Mode

off flashing Installation Mode in Data Exchange Mode.

possible reasons:

- wrong address adjusted

- wrong bus wiring

Parameterising or configuration error. Encoder receives data of incorrect length or inconsistant data.

possible reason:

- adjusted encoder resolution exceeds

participant X last participant

R

T

ON

8

7

ON

Status indicator

LED green

0

9 1

2

3

4

6

5

x10

R

T

9 1

8

7

6

x1

0

2

3

4

5

Release date: 2016-02-02 11:12 Date of issue: 2016-02-02 t49153_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

3

Multiturn absolute encoder PVM58

Principle of data transmission

GSD file

Software

Definition of device class

enter parameter

Data base

Control

Parameter ("DDLM_Set_Prm")

onetime at start up

cyclical data interchange

(e. g. position value)

Parameter table encoder classes P+F 2.1 and P+F 2.2

Octet number (Byte) Parameter Bit number

1...8 PROFIBUS standard parameters

9 Direction of rotation 0

Class 2 functionality 1

Commissioning Diagnostics 2

Scaling function 3

Reserved 4

Reserved 5

Activate manufacturer specific parameters (Octet 26) 6

Reserved 7

10 ... 13 Desired measuring steps (reference: Octet 26, Bit 0 and 1)

14 ... 17 Overall resolution

18 ... 25 Reserved

26 Reference for desired measuring steps 0

1

Activate commissioning mode 2

Reduced diagnosis 3

Reserved 4

Activate lower software limit switch 5

Activate upper software limit switch 6

Activation of the parameters from Octet 27 7

27 ... 30 Lower limit switch

31 ... 34 Upper limit switch

35 ... 38 Physical measuring steps

39 Reserved 0

Rotary encoder type (singleturn or multiturn) 1

Reserved 2

Reserved 3

Selection of the unit for speed transfer 4

5

Reserved 6

Reserved 7

Encoder

Release date: 2016-02-02 11:12 Date of issue: 2016-02-02 t49153_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

4

Multiturn absolute encoder PVM58

Accessories

For type Accessories Name/defining feature Order code

D1: Ø10 mm, D2: Ø10 mm 9401

Couplings

Measurement wheels with circumference of 500 mm

PVM58*-011

Measurement wheels with circumference of 200 mm

Mounting aids

Couplings

PVM58*-032

Mounting aids

For additional information on the accessories, please see the "Accessories" section.

D1: Ø10 mm, D2: Ø10 mm 9404

D1: Ø10 mm, D2: Ø10 mm 9409

D1: Ø10 mm, D2: Ø10 mm KW

Plastic 9101, 10

Pimpled rubber 9102, 10

Knurled aluminium 9103, 10

Knurled plastic 9112, 10

Plastic 9108, 10

Pimpled rubber 9109, 10

Knurled aluminium 9110, 10

Knurled plastic 9113, 10

Mounting bracket 9203

Mounting bracket 9213

D1: Ø6 mm, D2: Ø6 mm 9401

D1: Ø6 mm, D2: Ø6 mm 9402

D1: Ø6 mm, D2: Ø6 mm 9404

D1: Ø6 mm, D2: Ø6 mm 9409

D1: Ø6 mm, D2: Ø6 mm KW

Mounting bracket and set 9300 and 9311-3

Eccentric clamping elements 9310-3

Order code

Release date: 2016-02-02 11:12 Date of issue: 2016-02-02 t49153_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

5

Multiturn absolute encoder PVM58

PVM58 – R0BN–

Number of bits singleturn

13 8192 (standard)

16 65536

Number of bits multiturn

12 4096 (standard)

14 16384

Option 2

N Not expanded

Output code

B Binary

Option 1

0 No option

Exit position

R Radial

Connection type

AG Removable housing cover with terminal compartment

AZ Removable housing cover with M12 connectors

Shaft dimension/flange version

011 Shaft Ø10 mm x 20 mm with clamping flange

032 Shaft Ø6 mm x 10 mm with servo flange

Housing material

N Aluminium, powder coated

I Inox

W Aluminium, powder coated with shaft seal

A Stainless steel AISI 316L

Principle of operation

M Multiturn

Shaft version

V Solid shaft

Data format

P PROFIBUS

Release date: 2016-02-02 11:12 Date of issue: 2016-02-02 t49153_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

6

Loading...

Loading...