Page 1

ISO9001

3

PROCESS AUTOMATION

TECHNICAL INFORMATION

Pulscon LTC51

Guided Level Radar

Page 2

Pulscon LTC51

With regard to the supply of products, the current issue of the following document is applicable:

The General Terms of Delivery for Products and Services of the Electrical Industry,

published by the Central Association of the Electrical Industry (Zentralverband Elektrotechnik und

Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the supplementary clause:

"Expanded reservation of proprietorship"

Application

• Rod, rope or coax probe

• Process connection: Starting 3/4 in thread or flange

• Temperature: -40 ... +200 °C (-40 ... +392 °F)

• Pressure: -1 ... +40 bar (-14.5 ... +580 psi)

• Maximum measuring range: Rod 10 m (33 ft); rope 45 m (148 ft); coax 6 m (20 ft)

• Accuracy: ±2mm(0.08in)

• International explosion protection certificates; WHG; ship building approval; steam boiler approval;

EN 10204-3.1

• Linearity protocol (5-point)

Yo ur b e ne f it s

• Reliable measurement even for changing product and process conditions

• HistoROM data management for easy commissioning, maintenance and diagnostics

• Highest reliability due to Multi-Echo Tracking

• Hardware and software developed according to IEC 61508 (up to SIL3)

• Seamless integration into control or asset management systems

• Intuitive user interface in national languages

• Easy proof test for SIL and WHG

Page 3

Pulscon LTC51

Content

1 Important document information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Function and system design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Measuring principle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Life cycle of the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Measured variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 Blocking distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4 Measuring frequency spectrum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3 Linearization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.4 Galvanic isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5 Protocol-specific data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1 Terminal assignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2 HART Loop Converter KFD2-HLC-Ex1.D.** . . . . . . . . . . . . . . . . . . . . . 28

5.3 Device plug connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.4 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.5 Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.6 Current consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.7 Power supply failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.8 Potential equalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.9 Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.10 Cable entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.11 Cable specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.12 Overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2014-10

3

Page 4

Pulscon LTC51

Content

6 Performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.1 Reference operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.2 Maximum measured error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.3 Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.4 Reaction time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.5 Influence of ambient temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.6 Influence of gas layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.7 Gas phase compensation with external pressure sensor

(PROFIBUS PA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1 Mounting requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8 Operating conditions: Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.1 Ambient temperature range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.2 Ambient temperature limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.3 Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.4 Climate class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.5 Altitude according to IEC 61010-1 Ed.3 . . . . . . . . . . . . . . . . . . . . . . . . 66

8.6 Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.7 Vibration resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.8 Cleaning the probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.9 Electromagnetic compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . 67

9 Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.1 Process temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.2 Process pressure range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.3 Dielectric constant (DC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

9.4 Expansion of the rope probes through temperature . . . . . . . . . . . . . 69

4

2014-10

Page 5

Pulscon LTC51

Content

10 Mechanical construction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.1 Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.2 Tolerance of probe length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10.3 Surface roughness of Alloy C coated flanges . . . . . . . . . . . . . . . . . . . 74

10.4 Shortening probes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10.5 Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

10.6 Materials: A1 (GT19) housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

10.7 Materials: A2 (GT20) housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10.8 Materials: A3 (GT18) housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

10.9 Materials: Process connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10.10 Materials: Probe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10.11 Materials: Mounting bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

10.12 Materials: Adapter and cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

10.13 Materials: Weather protection cover . . . . . . . . . . . . . . . . . . . . . . . . . . 85

11 Operability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

11.1 Operating concept. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

11.2 Local operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

11.3 Remote operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

12 Certificates and approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

12.1 CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

12.2 C-Tick symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

12.3 Ex approval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

12.4 Dual seal according to ANSI/ISA 12.27.01 . . . . . . . . . . . . . . . . . . . . . . 90

12.5 Functional Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

12.6 Overfill prevention. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

12.7 Telecommunications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

12.8 CRN approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

12.9 Other standards and guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

2014-10

5

Page 6

Pulscon LTC51

Content

13 Ordering information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

13.1 Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

13.2 Product structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

13.3 5-point linearity protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

13.4 Customized parametrization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

14 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

14.1 Device-specific accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

14.2 Communication-specific accessories . . . . . . . . . . . . . . . . . . . . . . . . 105

14.3 Service-specific accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

14.4 System components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

15 Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

15.1 Standard documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

15.2 Safety documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

16 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

17 Patents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

2014-10

6

Page 7

Pulscon LTC51

Important document information

1 Important document information

1.1 Symbols

1.1.1 Symbols used

This document contains information that you must read for your own personal safety and to

avoid property damage. Depending on the hazard category, the warning signs are displayed in

descending order as follows:

Safety-relevant symbols

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt devices and any connected facilities or systems, or result in

their complete failure.

Informative symbols

Note!

This symbol brings important information to your attention.

Action

This symbol indicates a paragraph with instructions.

2014-10

7

Page 8

Pulscon LTC51

-

Important document information

1.1.2 Electrical symbols

Symbol Meaning

)

*

Table 1.1

Direct current

A terminal to which DC voltage is applied or through which direct

current flows.

Alternating current

A terminal to which alternating voltage is applied or through which

alternating current flows.

Direct current and alternating current

• A terminal to which alternating voltage or DC voltage is applied.

• A terminal through which alternating current or direct current

flows.

Ground connection

A grounded terminal which, as far as the operator is concerned, is

grounded via a grounding system.

Protective ground connection

A terminal which must be connected to ground prior to establishing

any other connections.

Equipotential connection

A connection that has to be connected to the plant grounding

system: This may be a potential equalization line or a star grounding

system depending on national or company codes of practice.

1.1.3 Symbols in graphics

Symbol Meaning

1, 2, 3 ... Item numbers

,…,1. 2. 3.

A, B, C, ... Views

A-A, B-B, C-C, ... Sections

.

Table 1.2

Series of steps

Hazardous area

Indicates a hazardous area.

Safe area (non-hazardous area)

Indicates a non-hazardous location.

2014-10

8

Page 9

Pulscon LTC51

F

L

D

E

20 mA

100%

4mA

0%

LN

R

Function and system design

2 Function and system design

2.1 Measuring principle

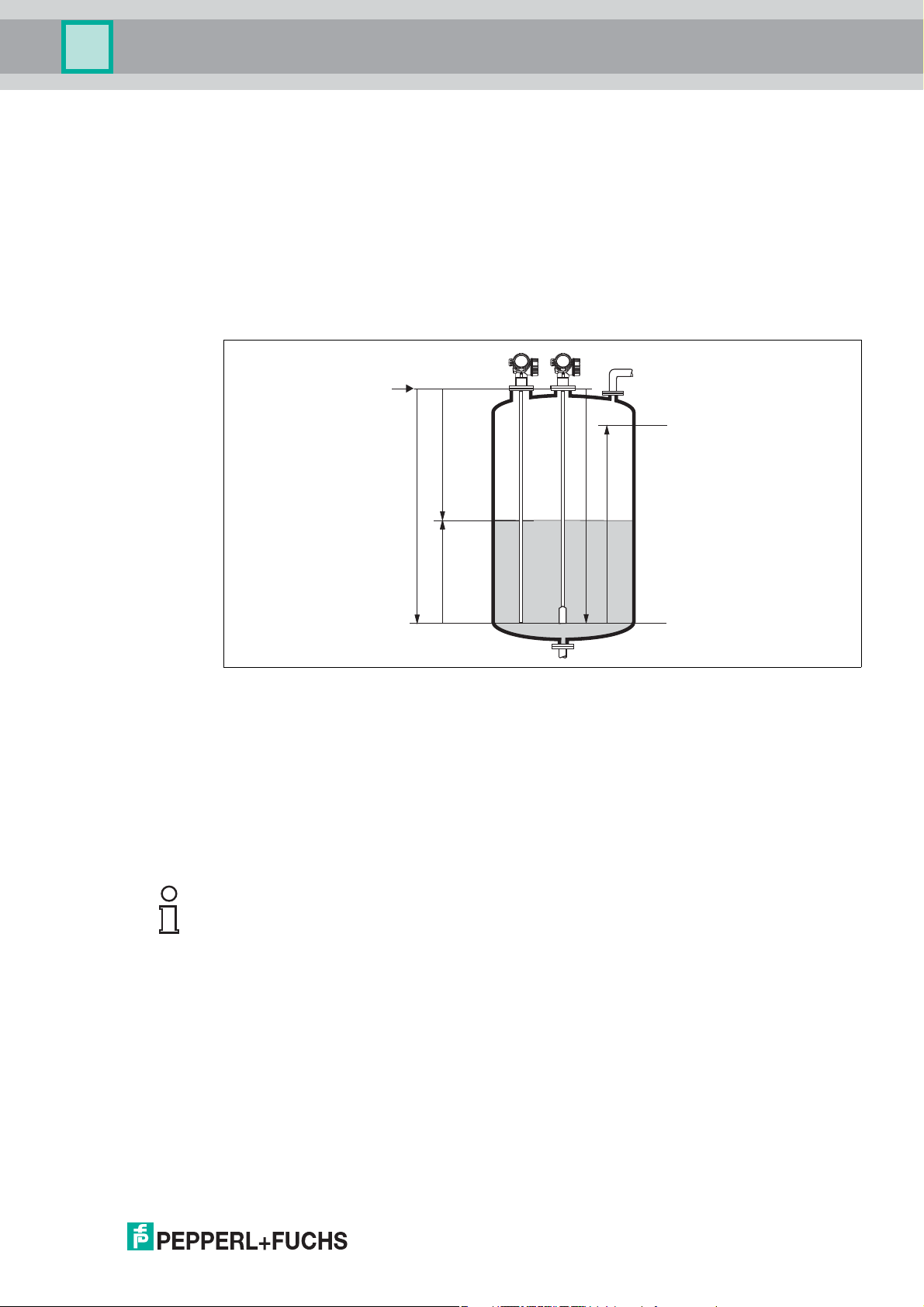

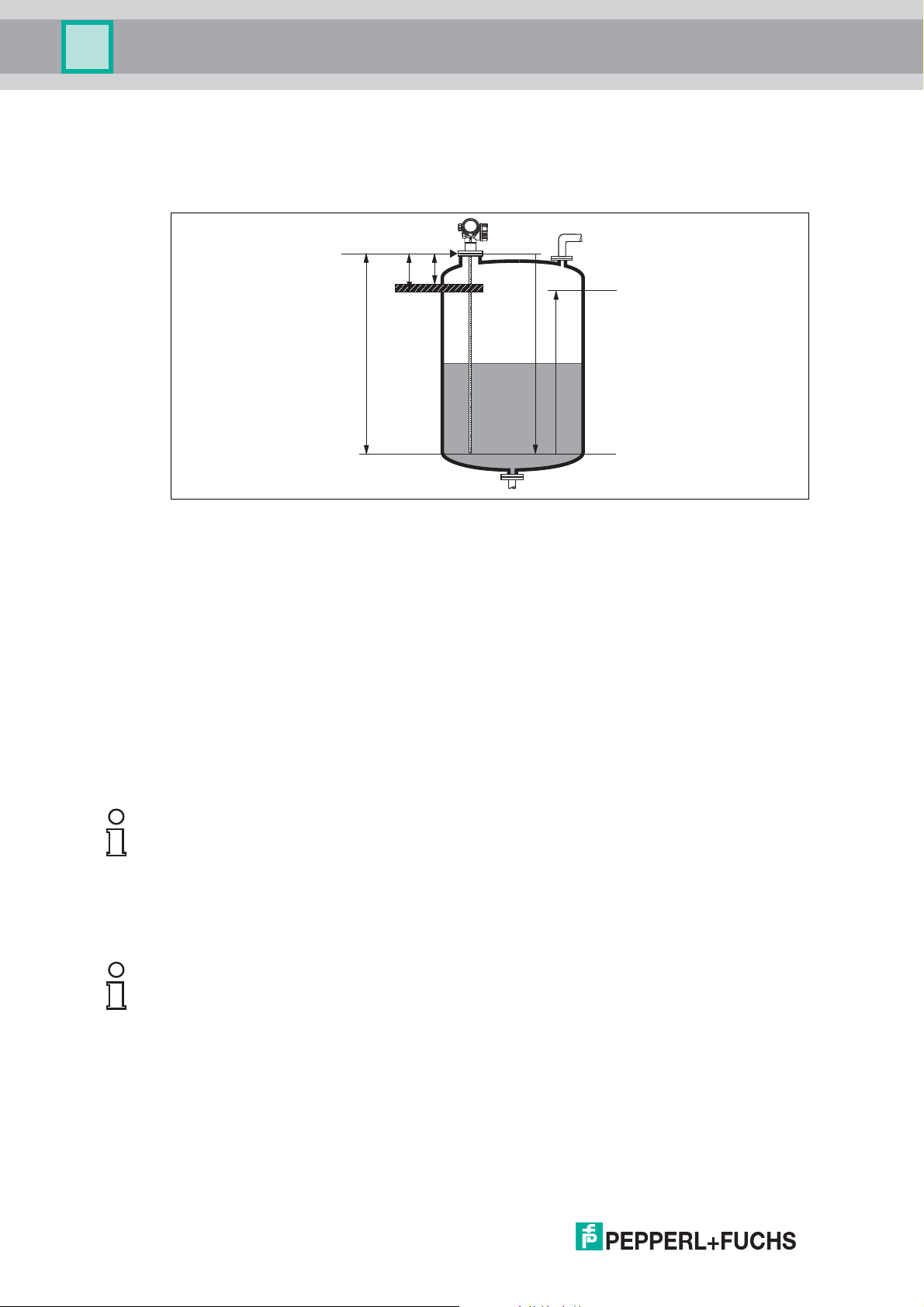

2.1.1 Basic principles

The device is a "downward-looking" measuring system that functions according to the ToF

method (ToF = Time of Flight). The distance from the reference point to the product surface is

measured. High-frequency pulses are injected to a probe and led along the probe. The pulses

are reflected by the product surface, received by the electronic evaluation unit and converted

into level information. This method is also known as TDR (Time Domain Reflectometry).

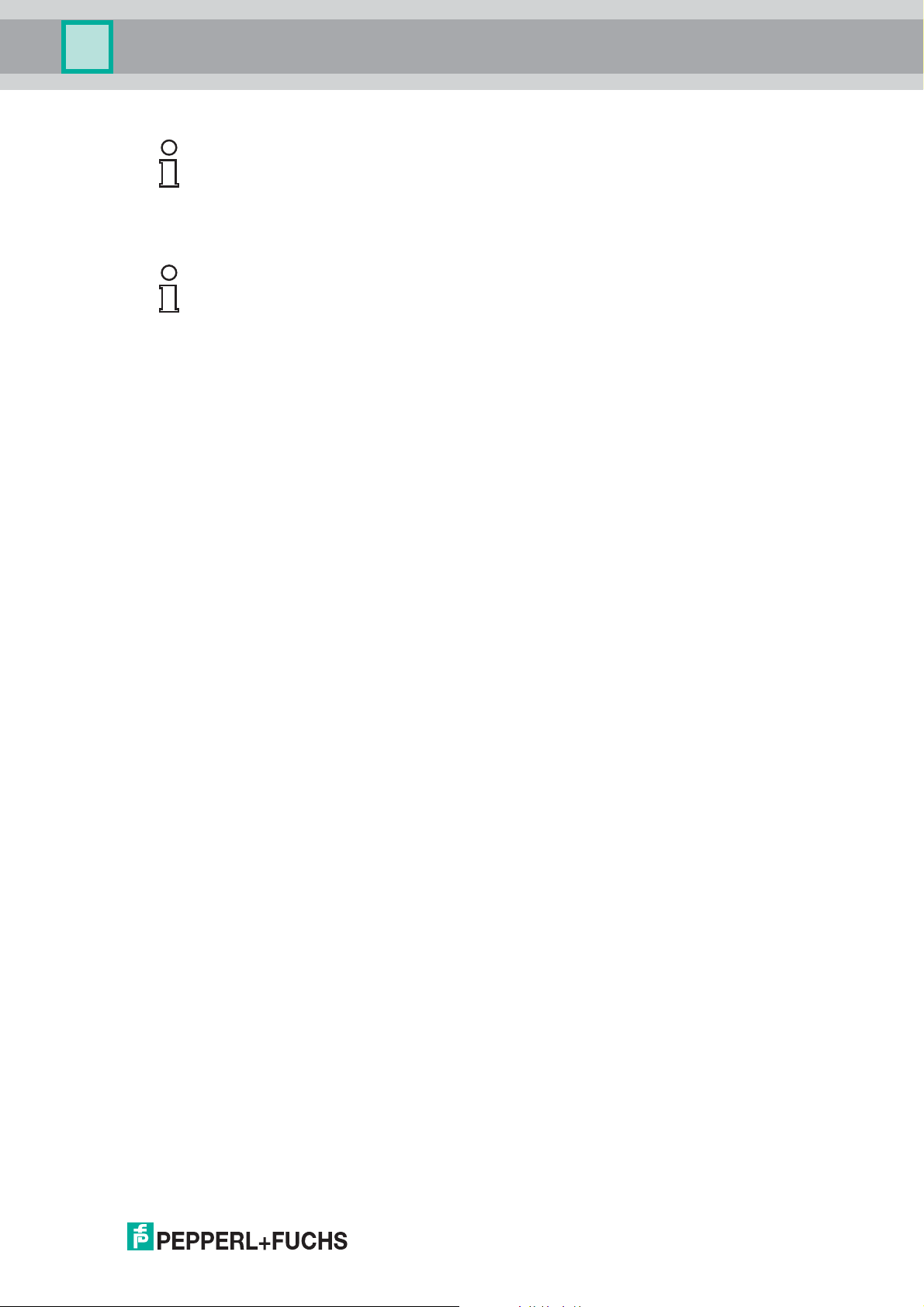

Figure 2.1 Parameters for level measurement with the guided radar

LN Probe length

D Distance

L Level

R Reference point of measurement

E Empty calibration (= zero)

F Full calibration (= span)

Note!

If, for rope probes, the DC value is less than 7, then measurement is not possible in the area of

the straining weight (0 to 250 mm from end of probe; lower blocking distance).

2.1.2 Dielectric constant

The dielectric constant (DC) of the medium has a direct impact on the degree of reflection of

the high frequency pulses. In the case of large DC values, such as for water or ammonia, there

is strong pulse reflection while, with low DC values, such as for hydrocarbons, weak pulse

reflection is experienced.

2014-10

9

Page 10

Pulscon LTC51

Function and system design

2.1.3 Input

The reflected pulses are transmitted from the probe to the electronics. There, a

microprocessor analyzes the signals and identifies the level echo which was generated by the

reflection of the high-frequency pulses at the product surface. This clear signal detection

system benefits from over 30 years' experience with pulse time-of-flight procedures.

The distance D to the product surface is proportional to the time of flight t of the impulse:

D = c x t / 2,

where c is the speed of light.

Based on the known empty distance E, the level L is calculated:

L = E – D

Note!

The reference point R of the measurement is located at the process connection.

See chapter 10.

The device possesses functions for interference echo suppression that can be activated by the

user. They guarantee that interference echoes from e. g. internals and struts are not

interpreted as level echoes.

2.1.4 Output

The device is preset at the factory to the probe length ordered so that in most cases only the

application parameters that automatically adapt the device to the measuring conditions need

to be entered. For models with a current output, the factory adjustment for zero point E and

span F is 4 mA and 20 mA, for digital outputs and the display module 0 % and 100 %. A

linearization function with max. 32 points, which is based on a table entered manually or semiautomatically, can be activated on site or via remote operation. This function allows the level to

be converted into units of volume or mass, for example.

2.2 Life cycle of the product

Engineering

• Universal measuring principle

• Measurement unaffected by medium properties

• Hardware and software developed according to SIL IEC 61508

Procurement

• Pepperl+Fuchs being the world market leader in level measurement guarantees asset

protection

• Worldwide support and service

10

Installation

• Special tools are not required

• Reverse polarity protection

• Modern, detachable terminals

• Main electronics protected by a separate connection compartment

2014-10

Page 11

Pulscon LTC51

Function and system design

Commissioning

• Fast, menu-guided commissioning in only 6 steps

• Plain text display in national languages reduces the risk of error or confusion

• Direct local access of all parameters

• Short instruction manual at the device

Operation

• Multi-echo tracking: Reliable measurement through self-learning echo-search algorithms

taking into account the short-term and long-term history in order to check the found echoes

for plausibility and to suppress interference echoes.

• Diagnostics in accordance with NAMUR NE 107

Maintenance

• HistoROM: Data backup for instrument settings and measured values

• Exact instrument and process diagnosis to assist fast decisions with clear details

concerning remedies

• Intuitive, menu-guided operating concept in national languages saves costs for training,

maintenance and operation

• Cover of the electronics compartment can be opened in hazardous areas

Retirement

• Order code translation for subsequent models

• RoHS-conforming (Restriction of certain Hazardous Substances), unleaded soldering of

electronic components

• Environmentally sound recycling concept

2014-10

11

Page 12

Pulscon LTC51

Function and system design

2.3 Measuring system

2.3.1 General notes on probe selection

• Normally use rod probes for liquids. Rope probes are used in liquids for measuring ranges

> 10 m (33 ft) and with restricted ceiling clearance which does not allow the installation of

rigid probes.

• Coax probes are suited to liquids with viscosities of up to approx. 500 cst. Coax probes

can measure most liquefied gases, as of a dielectric constant of 1.4. Moreover, installation

conditions, such as nozzles, tank internal fittings etc., have no effect on the measurement

when a coax probe is used. A coax probe offers maximum EMC safety when used in

plastic tanks.

Probe selection

The various types of probe in combination with the process connections are suitable for the

following applications

1

:

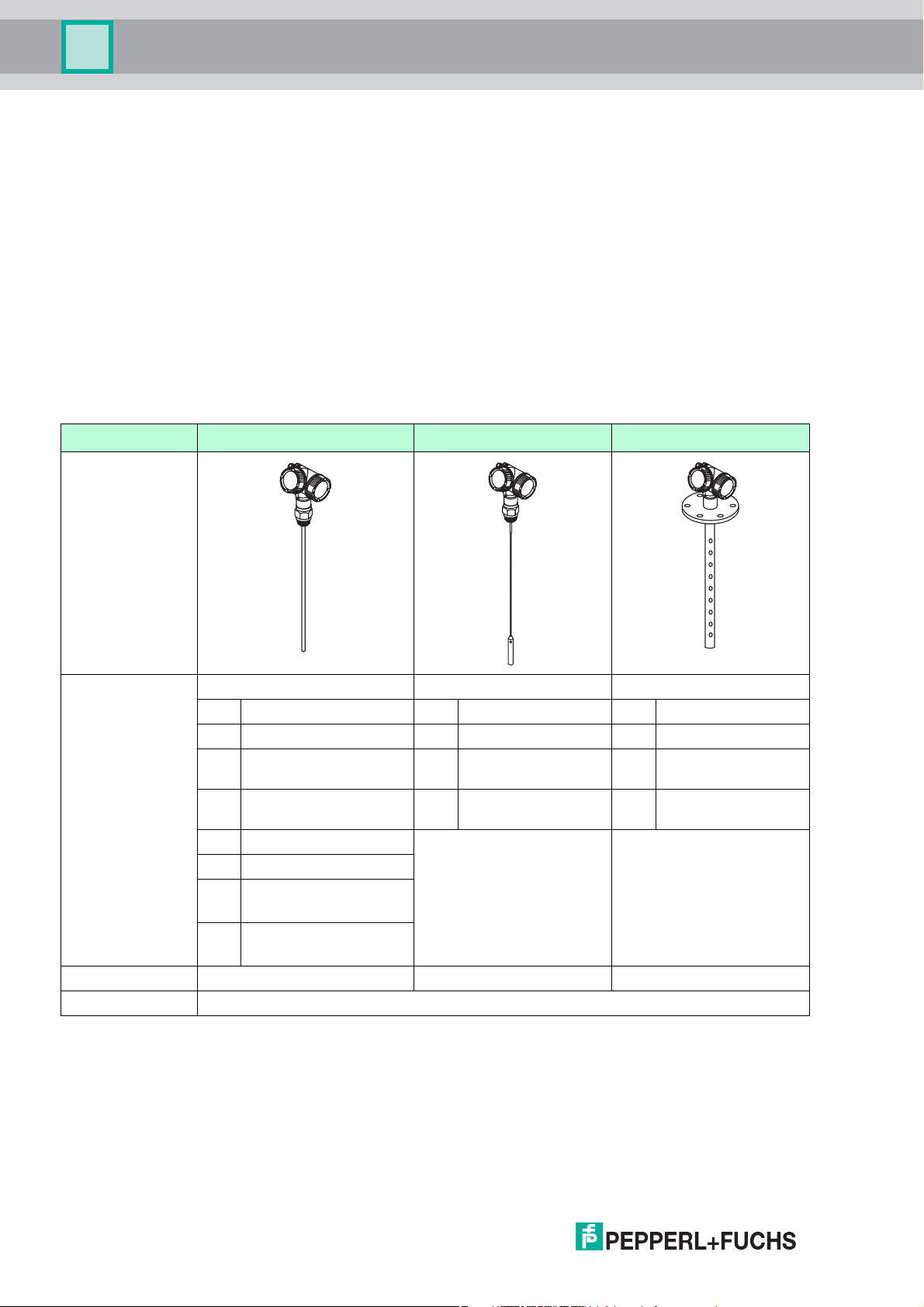

Type of probe Rod probe Rope probe Coax probe

Feature "Probe" Option Option Option

1 8 mm (316L) 2 4 mm (316) 4 ... mm (316L)

5 1/3 in (316L) 3 1/6 in (316) G ... inch (316L)

8 12 mm (316L) E 4 mm (316) with

H ... mm (Alloy C)

center rod

9 1/2 in (316L) F 1/6 in (316) with

K ... inch (Alloy C)

center rod

6 12 mm (Alloy C)

7 1/2 in (Alloy C)

A

16 mm (316L) divisible

C

B

0.63 in (316L) divisible

D

Max. probe length 10 m (33 ft)

b

45 m (148 ft) 6 m (20 ft)

For application Level measurement in liquids

Table 2.1

a

a

Multiple punched for process connections G1-1/2 in or flange

b

Maximum probe length for indivisible rod probes: 4 m (13 ft)

1

If required, rod and rope probes can be replaced. They are secured with Nord-Lock washers or a thread coating.

For further information on service and spare parts please contact the Pepperl+Fuchs service.

12

2014-10

Page 13

Pulscon LTC51

Input

3Input

3.1 Measured variable

The measured variable is the distance between the reference point and the product surface.

Subject to the empty distance entered E the level is calculated.

Alternatively, the level can be converted into other variables (volume, mass) by means of

linearization (32 points).

3.2 Measuring range

The following table describes the media groups and the possible measuring range as a

function of the media group.

Pulscon LTC51

Media

group

1 1.4 ... 1.6 condensed gases,

2 1.6 ... 1.9 • liquefied gas,

3 1.9 ... 2.5 mineral oils, fuels • one-piece: 4 m (13 ft)

4 2.5 ... 4 • benzene, styrene,

5 4 ... 7 • chlorobenzene,

6 >7 •aqueous

Table 3.1

DC (r) Typical liquids Measuring range

bare metallic

rod probes

e. g. N2, CO

e. g. propane

•solvent

•Freon

•palm oil

toluene

•furan

• naphthalene

chloroform

• cellulose spray

• isocyanate,

aniline

solutions

•alcohols

• ammonia

2

on request 6 m (20 ft)

• one-piece: 4 m (13 ft)

• divisible: 10 m (33 ft)

• divisible: 10 m (33 ft)

• one-piece: 4 m (13 ft)

• divisible: 10 m (33 ft)

• one-piece: 4 m (13 ft)

• divisible: 10 m (33 ft)

• one-piece: 4 m (13 ft)

• divisible: 10 m (33 ft)

bare metallic

rope probes

15 ... 22 m

(49 ... 72 ft)

22 ... 32 m

(72 ... 105 ft)

32 ... 42 m

(105 ... 138 ft)

42 ... 45 m

(138 ... 148 ft)

45 m (148 ft) 6 m (20 ft)

coax probes

6 m (20 ft)

6 m (20 ft)

6 m (20 ft)

6 m (20 ft)

Note!

Reduction of the max. possible measuring range through buildup, above all of moist products.

Due to the high diffusion rate of ammonia it is recommended with gas-tight bushing for

measurements in this medium.

2014-10

13

Page 14

Pulscon LTC51

F

UB

E

100%

0%

LN

R

SD

Input

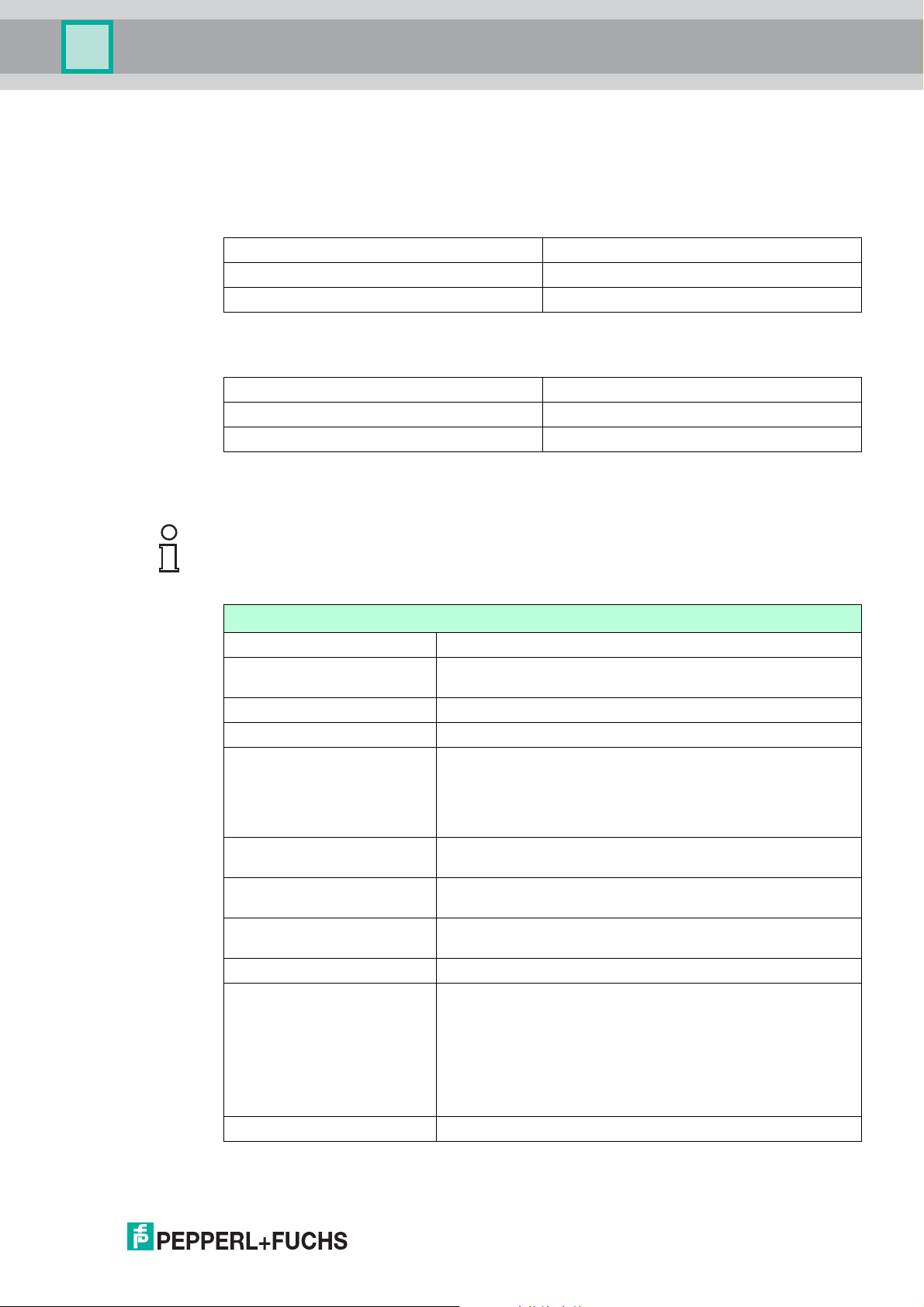

3.3 Blocking distance

The upper blocking distance (= UB) is the minimum distance from the reference point of the

measurement (mounting flange) to the maximum level.

Figure 3.1 Definition of blocking distance and safety distance

R Reference point of measurement

LN Probe length

UB Upper blocking distance

E Empty calibration (= zero)

F Full calibration (= span)

SD Safety distance

Blocking distance (factory setting):

• with coax probes: 0mm(0in)

• with rod and rope probes up to 8 m (26 ft): 200 mm (8 in)

• with rod and rope probes exceeding a length of 8 m (26 ft): 0.025 x (length of probe)

Note!

The specified blocking distances are preset on delivery. Depending on the application these

settings can be changed.

For rod and rope probes and for media with DC > 7 (or generally for stilling well/bypass

applications) the blocking distance may be reduced to 100 mm (4 in).

Within the blocking distance, a reliable measurement can not be guaranteed.

Note!

A safety distance SD can be defined in addition to the blocking distance. A warning is

generated if the level rises into this safety distance.

3.4 Measuring frequency spectrum

100 MHz to 1.5 GHz

14

2014-10

Page 15

Pulscon LTC51

Output

4Output

4.1 Output signal

HART

Signal coding FSK ±0.5 mA over currency signal

Data transmission rate 1200 Baud

Galvanic isolation Yes

Table 4.1

PROFIBUS PA

Signal coding Manchester Bus Powered (MBP)

Data transmission rate 31.25 kBit/s, voltage mode

Galvanic isolation Yes

Table 4.2

Switch output

Note!

For HART devices, the switch output is available as an option. See product structure, feature

"Electrical Output", option ID. Devices with PROFIBUS PA always have a switch output.

Switch output

Function Open collector switching output

Switching behavior Binary (conductive or non-conductive), switches when the

programmable switch point is reached

Failure mode non-conductive

Electrical connection values U = 10.4 ... 35 V DC, I = 0 ... 40 mA

Internal resistance RI < 880

The voltage drop at this internal resistance has to be taken

into account on planning the configuration. For example, the

resulting voltage at a connected relay must be sufficient to

switch the relay.

Insulation voltage floating, Insulation voltage 1350 V DC to power supply and

Switch point freely programmable, separately for switch-on and switch-off

Switching delay freely programmable from 0 to 100 s, separately for switch-

Number of switching cycles corresponds to the measuring cycle

Signal source

device variables

Number of switching cycles unlimited

Table 4.3

500 V AC to ground

point

on and switch-off point

• Level linearized

•Distance

• Terminal voltage

• Electronic temperature

• Relative echo amplitude

• Diagnostic values, Advanced diagnostics

2014-10

15

Page 16

Pulscon LTC51

Output

4.2 Signal on alarm

Depending on the interface, failure information is displayed as follows:

• Current output (for HART devices)

• Fail-safe mode selectable (in accordance with NAMUR Recommendation NE 43):

Minimum alarm: 3.6 mA

Maximum alarm (= factory setting): 22 mA

• Fail-safe mode with user-selectable value: 3.59 ... 22.5 mA

•Local display

• Status signal (in accordance with NAMUR Recommendation NE 107)

• Plain text display

• Operating tool via digital communication (HART, PROFIBUS PA) or service interface (CDI)

• Status signal (in accordance with NAMUR Recommendation NE 107)

• Plain text display

4.3 Linearization

The linearization function of the device allows the conversion of the measured value into any

unit of length or volume. Linearization tables for calculating the volume in cylindrical tanks are

pre-programmed. Other tables of up to 32 value pairs can be entered manually or semiautomatically.

4.4 Galvanic isolation

All circuits for the outputs are galvanically isolated from each other.

16

2014-10

Page 17

Pulscon LTC51

Output

4.5 Protocol-specific data

HART

Manufacturer ID 17 (0x11)

Device type ID 0x34

HART specification 6.0

Device description files

(DTM, DD)

HART load Min. 250

HART device variables The measured values can be freely assigned to the device

Supported functions •Burst mode

Table 4.4

Information and files under:

• www.pepperl-fuchs.com

• www.hartcomm.org

variables.

Measured values for PV (primary variable)

• Level linearized

•Distance

• Electronic temperature

• Relative echo amplitude

Measured values for SV, TV, FV (second, third and fourth

variable)

• Level linearized

•Distance

• Terminal voltage

• Electronic temperature

• Absolute echo amplitude

• Relative echo amplitude

• Calculated DC

• Additional transmitter status

Wireless HART data

Minimum start-up voltage 11.4 V

Start-up current 3.6 mA

Start-up time 15 s

Minimum operating voltage 11.4 V

Multidrop current 3.6 mA

Set-up time 1 s

Table 4.5

2014-10

17

Page 18

Pulscon LTC51

Output

PROFIBUS PA

Manufacturer ID 93 (5D HEX)

Ident number 0E3B HEX

Profile version 3.02

GSD file Information and files under:

GSD file version

Output values Analog Input:

Input values Analog Output:

Supported functions • Identification & Maintenance

Table 4.6

• www.pepperl-fuchs.com

•www.profibus.org

• Level linearized

•Distance

• Terminal voltage

• Electronic temperature

• Absolute echo amplitude

• Relative echo amplitude

• Calculated DC

Digital Input:

• Extended diagnostic blocks

• Status output PFS Block

• Analog value from PLC (for sensor block external

pressure and temperature)

• Analog value from PLC to be indicated on the display

Digital Output:

• Extended diagnostic block

• Level limiter

• Sensor block measurement on

• Sensor block save history on

• Status output

Simple device identification via control system and

nameplate

• Automatic Ident Number Adoption

GSD compatibility mode with respect to the previous

device

• Physical Layer Diagnostics

Installation check of the PROFIBUS segment via

terminal voltage and telegram monitoring

•PROFIBUS Up-/Download

Up to 10 times faster reading and writing of parameters

via PROFIBUS Up-/Download

•Condensed Status

Simple and self-explanatory diagnostic information due

to categorization of diagnostic messages

18

2014-10

Page 19

Pulscon LTC51

+

–

4 ... 20 mA

5412

7

8

3

+

–

1

+

2

4...20mA

HART

10

mm

2- wire

leve

l

4-20

mA

4-20

mA

HA

RT

[21]

open

-

6

~

Power supply

5 Power supply

5.1 Terminal assignment

2-wire: 4 ... 20 mA HART

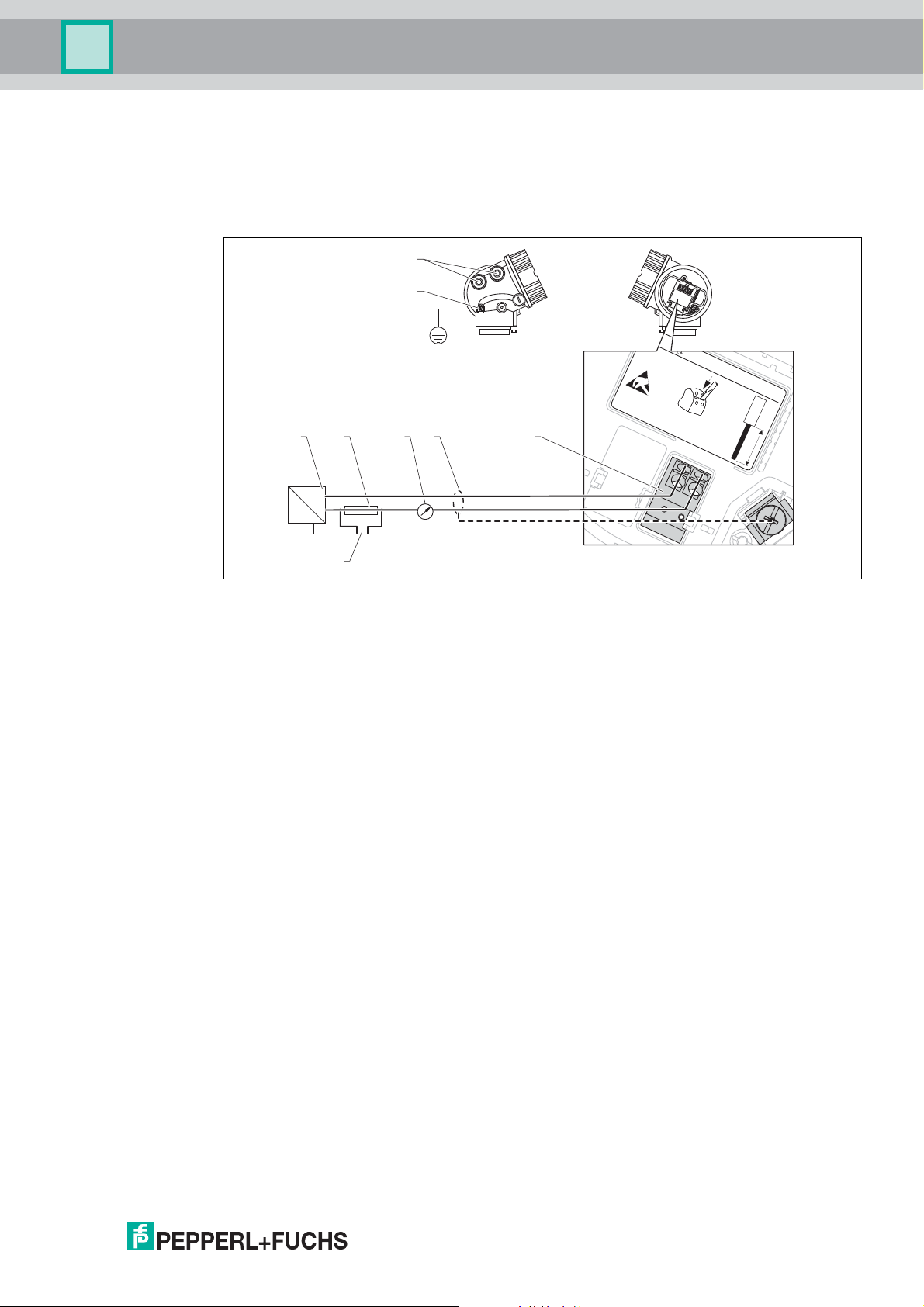

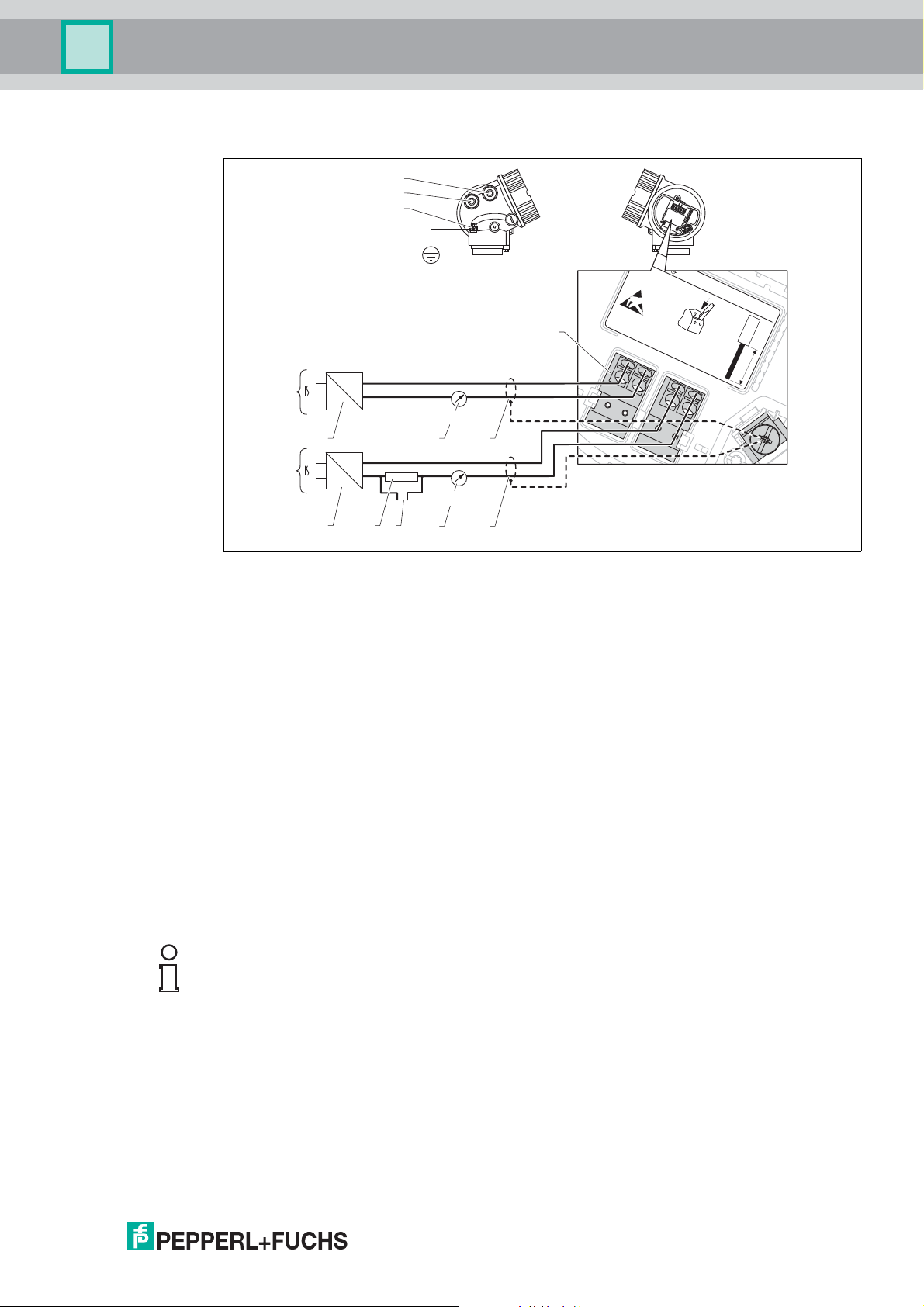

Figure 5.1 Terminal assignment 2-wire; 4 ... 20 mA HART

1 Active barrier with power supply (e. g. KCD2-STC-Ex1): observe terminal voltage

2 HART communication resistor ( 250 ): observe maximum load

3 Connection for optional field communicator

4 Analog display device: observe maximum load

5 Cable screen; observe cable specification

6 4 ... 20 mA HART (passive): terminals 1 and 2

7 Terminal for potential equalization line

8 Cable entry

2014-10

19

Page 20

Pulscon LTC51

1

+

2

4...20 mA

HART

10 mm

2- wire

4-20 mA PFS

HA

RT

[02/03

]

ope

n

-

1

+

2

-

3

+

4

-

10

9

8

7

+

-

23

4

6

5

1

4 ... 20 mA

≥ 250 Ω

3+

4-

+

–

Power supply

2-wire: 4 ... 20mA HART, switch output

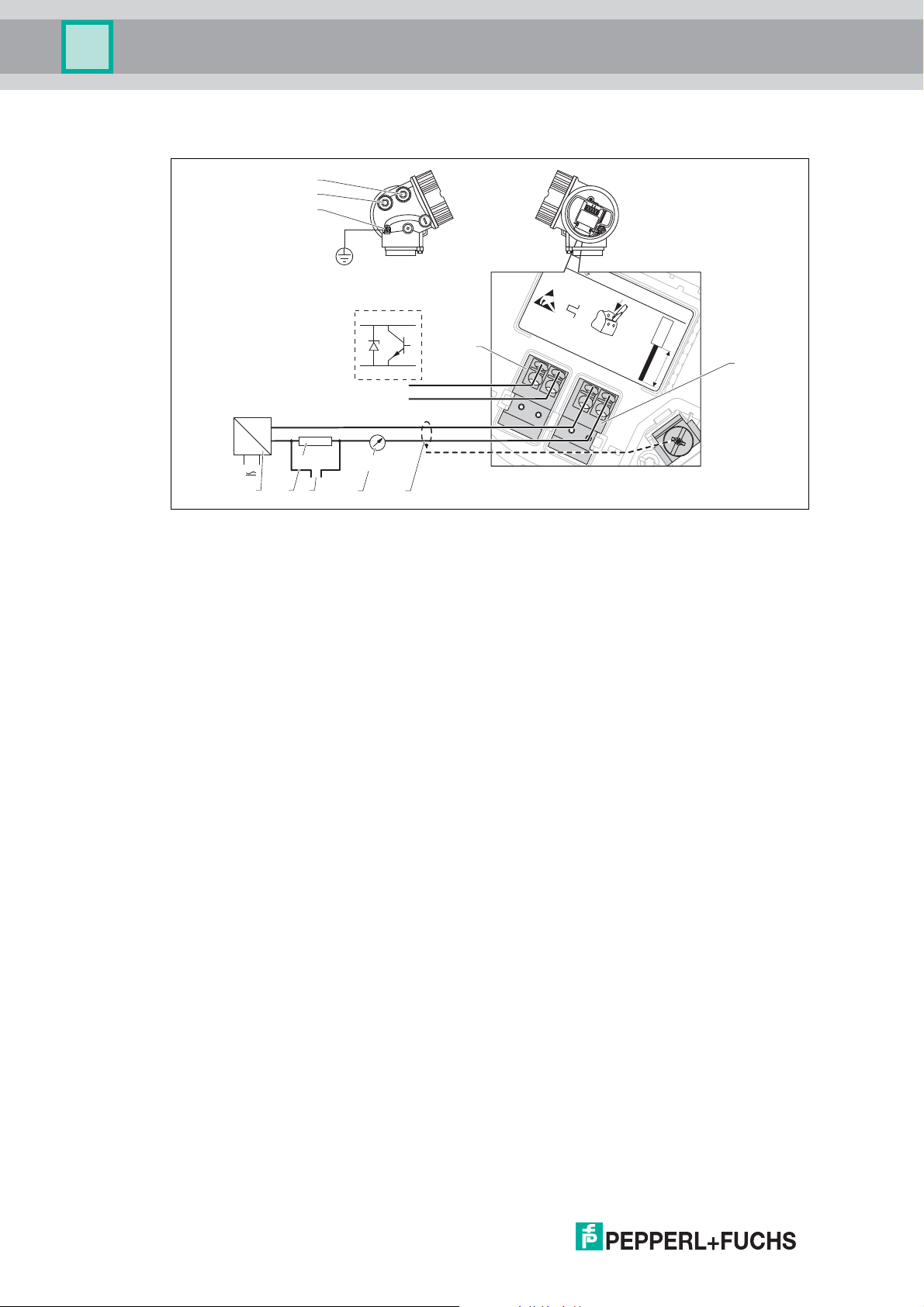

Figure 5.2 Terminal assignment 2-wire; 4 ... 20mA HART, switch output

1 Active barrier with power supply (e. g. KCD2-STC-Ex1): observe terminal voltage

2 HART communication resistor ( 250 ): observe maximum load

3 Connection for optional field communicator

4 Analog display device: observe maximum load

5 Cable screen; observe cable specification

6 4 ... 20 mA HART (passive): terminals 1 and 2

7 Switch output (open collector): terminals 3 and 4

8 Terminal for potential equalization line

9 Cable entry for 4 ... 20 mA HART line

10 Cable entry for switch output line

20

2014-10

Page 21

Pulscon LTC51

1

3

+

+

2

4

4...20mA

HART

4...20mA

10 mm

2- wire

level

4-20 mA 4-20 mA

HA

RT

[04/05]

open

-

-

10

13

12

11

+

+

-

-

1

2

3

9

586

74

4

+

–

+

–

4 ... 20 mA

4 ... 20 mA

Power supply

2-wire: 4 ... 20 mA HART, 4 ... 20 mA

Figure 5.3 Terminal assignment 2-wire, 4 ... 20 mA HART, 4 ... 20 mA

1 Connection current output 2

2 Connection current output 1

3 Supply voltage for current output 1 (e. g. KCD2-STC-Ex1); observe terminal voltage

4 Cable screen; observe cable specification

5 HART communication resistor ( 250 ): observe maximum load

6 Connection for optional field communicator

7 Analog display device; observe maximum load

8 Analog display device; observe maximum load

9 Supply voltage for current output 2 (e. g. KCD2-STC-Ex1); observe terminal voltage

10 Current output 2: terminals 3 and 4

11 Terminal for the potential equalization line

12 Cable entry for current output 1

13 Cable entry for current output 2

Note!

This version is also suited for single-channel operation. In this case, current output 1

(terminals 1 and 2) must be used.

2014-10

21

Page 22

Pulscon LTC51

3

1

+

L+

4

2

4...20 mA

HA

RT

10.4...48V=

10

mm

2- wire

4-20 mA

HA

RT

[08

]

ope

n

-

L-

13

12

11

910

+

-

23

4

6

7

8

5

1

4 ... 20 mA

250Ω

Power supply

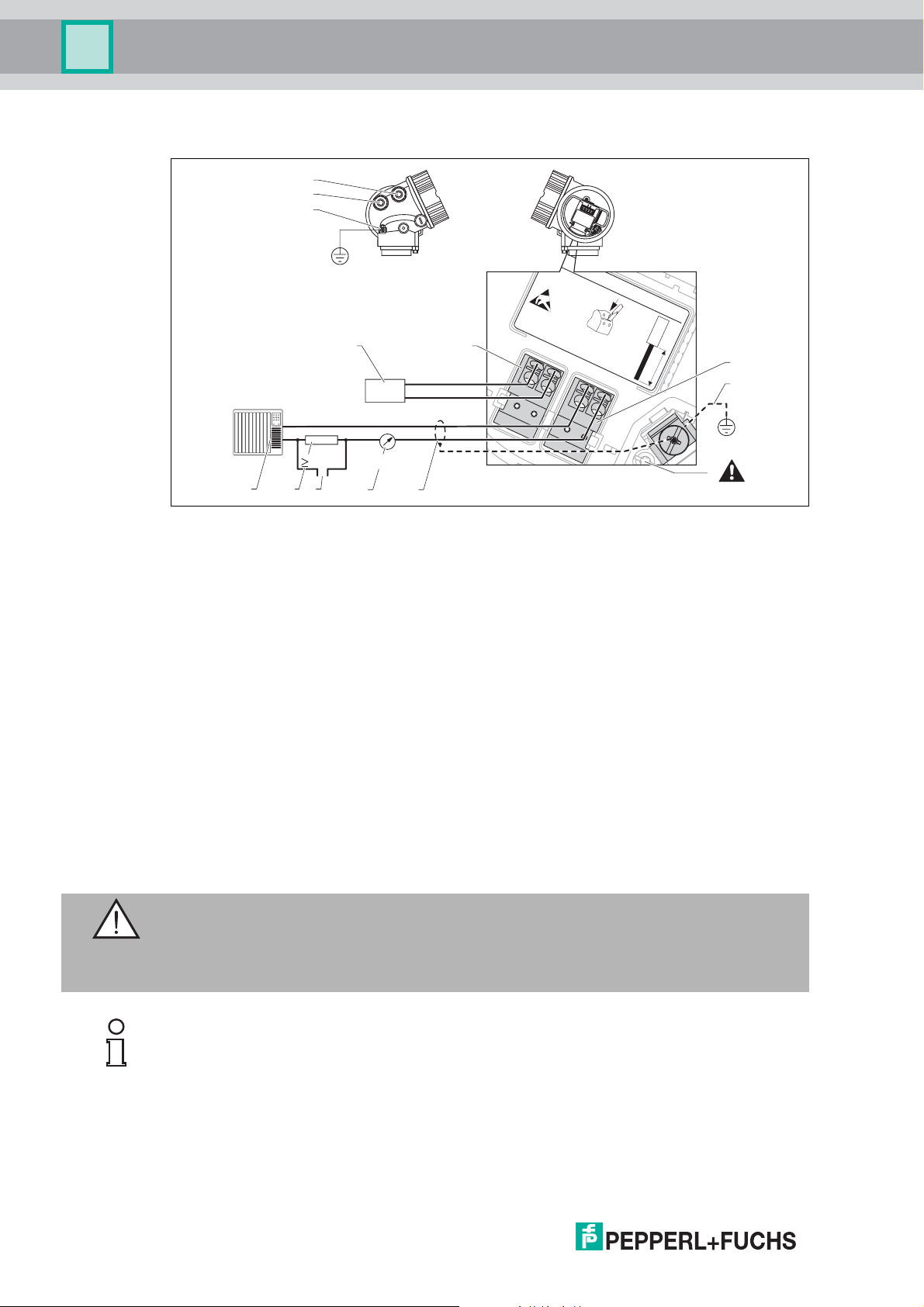

4-wire: 4 ... 20 mA HART (10.4 ... 48 V DC)

Figure 5.4 Terminal assignment 4-wire; 4 ... 20mA HART (10.4 ... 48 V DC)

1 Evaluation unit, e. g. PLC

2 HART communication resistor ( 250 ): observe maximum load

3 Connection for optional field communicator

4 Analog display device: observe maximum load

5 Signal cable including screening (if required), observe cable specification

6 Protective connection; do not disconnect!

7 Protective earth, observe cable specification

8 4 ... 20 mA HART (active): terminals 3 and 4

9 Supply voltage: terminals 1 and 2

10 Supply voltage: Observe terminal voltage, observe cable specification

11 Terminal for potential equalization

12 Cable entry for signal line

13 Cable entry for power supply

Warning!

To ensure electrical safety:

• Do not disconnect the protective connection (6).

• Disconnect the supply voltage before disconnecting the protective earth (7).

Note!

Connect protective earth to the internal ground terminal (7) before connecting the supply

voltage. If necessary, connect the potential matching line to the external ground terminal (11).

22

2014-10

Page 23

Pulscon LTC51

Power supply

Note!

In order to ensure electromagnetic compatibility (EMC): Do not only ground the device via the

protective earth conductor of the supply cable. Instead, the functional grounding must also be

connected to the process connection (flange or threaded connection) or to the external ground

terminal.

Note!

An easily accessible power switch must be installed in the proximity of the device. The power

switch must be marked as a disconnector for the device (IEC/EN 61010).

2014-10

23

Page 24

Pulscon LTC51

3

1

+

L

4

2

4...20 mA

HA

RT

90...2

53

V~

10

mm

2- wire

4-20 mA

HA

RT

[09

]

ope

n

-

N

13

12

11

910

+

-

23

4

6

7

8

5

1

4 ... 20 mA

≥ 250Ω

Power supply

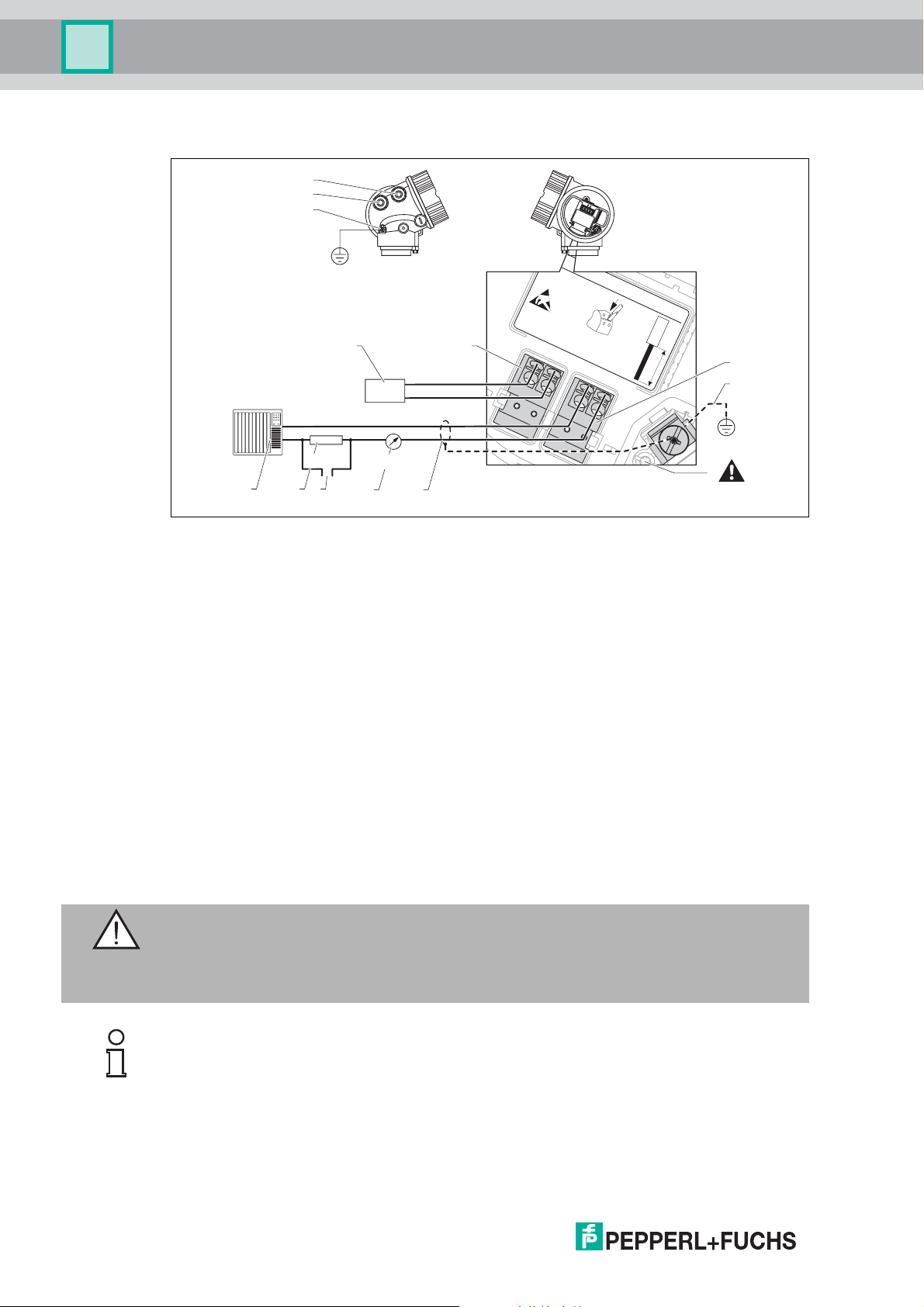

4-wire: 4 ... 20 mA HART (90 ... 253 V AC)

Figure 5.5 Terminal assignment 4-wire; 4 ... 20 mA HART (90 ... 253 V AC)

1 Evaluation unit, e. g. PLC

2 HART communication resistor ( 250 ): observe maximum load

3 Connection for optional filed communicator

4 Analog display device: observe maximum load

5 Signal cable including screening (if required), observe cable specification

6 Protective connection; do not disconnect!

7 Protective earth, observe cable specification

8 4 ... 20 mA HART (active): terminals 3 and 4

9 Supply voltage: terminals 1 and 2

10 Supply voltage: observe terminal voltage, observe cable specification

11 Terminal for potential equalization

12 Cable entry for signal line

13 Cable entry for power supply

Warning!

To ensure electrical safety:

• Do not disconnect the protective connection (6).

• Disconnect the supply voltage before disconnecting the protective earth (7).

Note!

Connect protective earth to the internal ground terminal (7) before connecting the supply

voltage. If necessary, connect the potential matching line to the external ground terminal (11).

24

2014-10

Page 25

Pulscon LTC51

Power supply

Note!

In order to ensure electromagnetic compatibility (EMC): Do not only ground the device via the

protective earth conductor of the supply cable. Instead, the functional grounding must also be

connected to the process connection (flange or threaded connection) or to the external ground

terminal.

Note!

An easily accessible power switch must be installed in the proximity of the device. The power

switch must be marked as a disconnector for the device (IEC/EN 61010).

2014-10

25

Page 26

Pulscon LTC51

1

1

+

+

2

2

PA

[06/07]

-

-

1

3

+

+

2

4

PA

10 mm

2- wire

level

4-20 mA PFS

[26/27]

open

-

-

4

1

2

3

5

3+

4-

Power supply

PROFIBUS PA

Figure 5.6 Terminal assignment PROFIBUS PA

1 Cable screen: observe cable specifications

2 Switch output (open collector): terminals 3 and 4

3 Connection PROFIBUS PA: terminals 1 and 2

4 Terminal for potential equalization line

5 Cable entries

26

2014-10

Page 27

Pulscon LTC51

Power supply

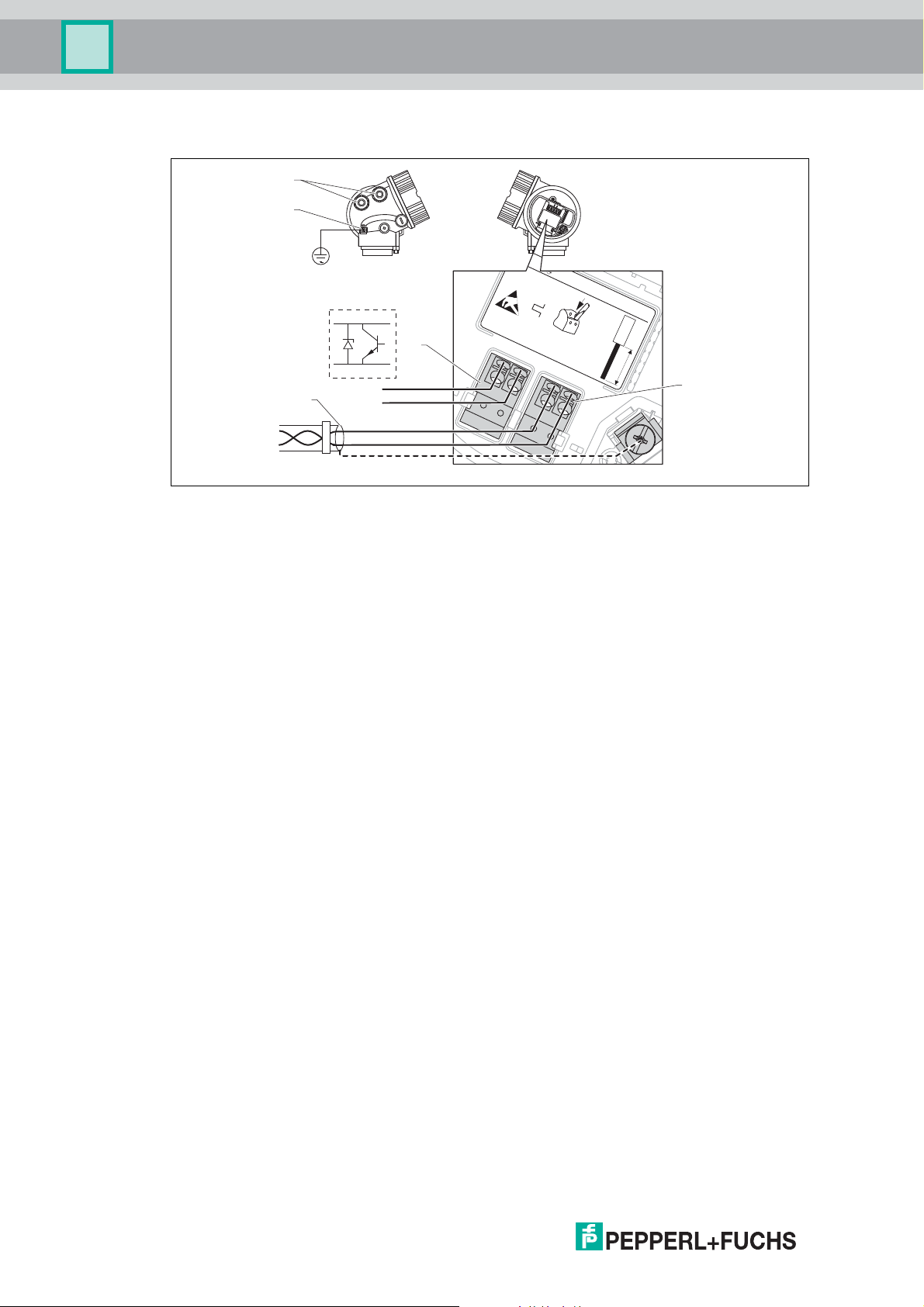

Connection examples for the switch output

Note!

For HART devices, the switch output is available as an option. See product structure, feature

"Electrical Output", option ID. Devices with PROFIBUS PA always have a switch output.

3+

4-

+

1

+

-

3+

4-

2

Connection of a relay

Suitable relays (examples):

• Solid-state relay: Phoenix Contact OV-

Connection of a digital input

1 Pull-up resistor

2 Digital input

24DC/480AC/5 with mounting rail

connector UMK-1 OM-R/AMS

• Electromechanical relay: Phoenix

Contact PLC-RSC-12DC/21

Table 5.1

Note!

For optimum interference immunity we recommend to connect an external resistor (internal

resistance of the relay or Pull-up resistor) of < 1000 .

2014-10

27

Page 28

Pulscon LTC51

Stromausgang1

Relais1

Stromausgang2

Stromausgang3

Relais2Relais2

versorgungversorgung

EingangEingang

1

2

3

4

5

6

7

8

9

11

12

13

14

15

19

20

21

16

17

18

22

23

24

24V DC

10

HART Loop Converter

HART

+

-

+

Current output 1

Relay 1

Current output 2

Current output 3

Relay 2

Power

supply

Input

Auxiliary energy

HART

ESC

OK

KFD2-HLCEx1.D.2W

RS232

PWR

ERR

1 2

OUT

19 21

15

9

13

7

20

14

8

2

2

24

18

12

16

10

23

17

11

1

3

2 4

6

5

Power supply

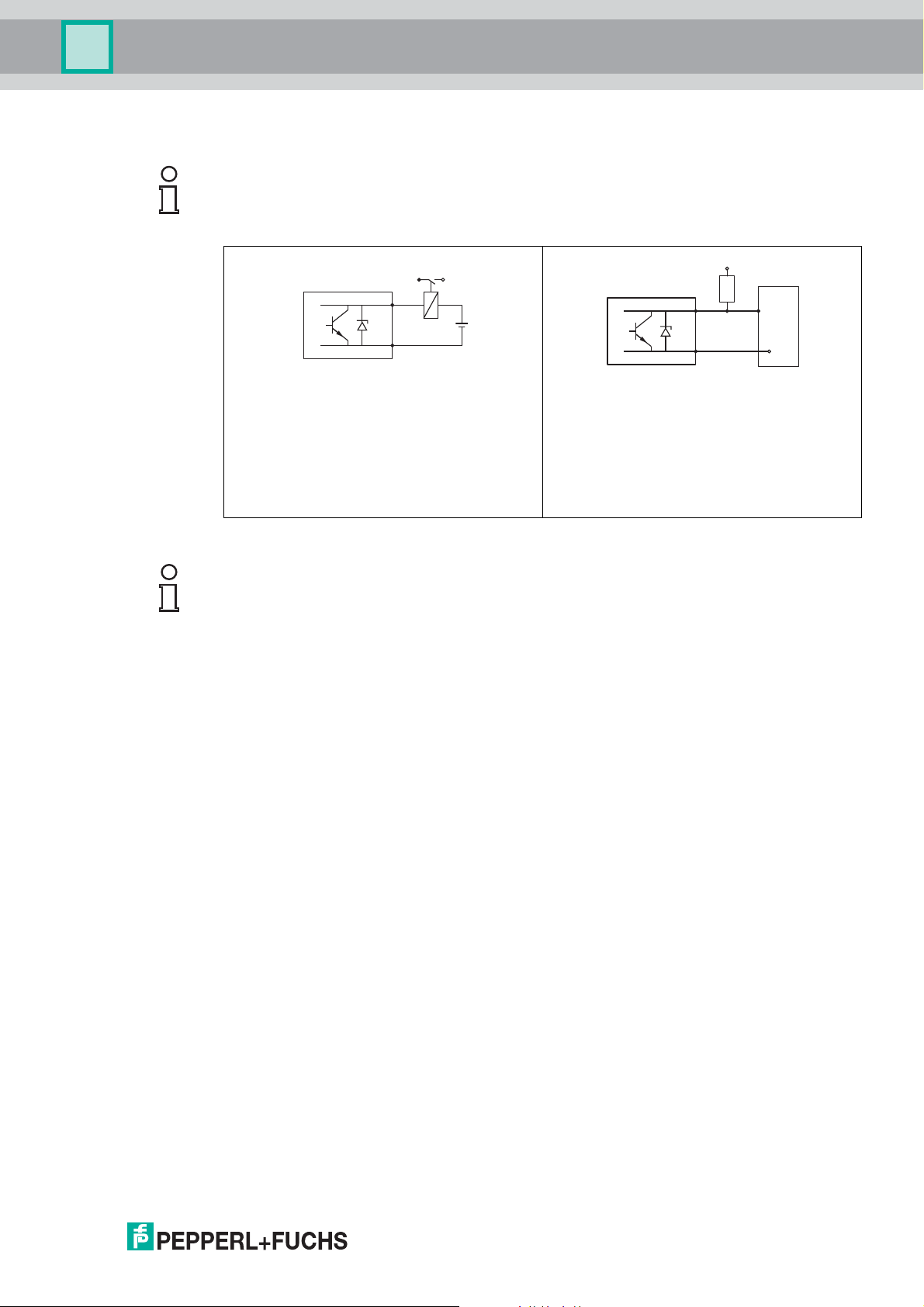

5.2 HART Loop Converter KFD2-HLC-Ex1.D.**

The dynamic variables of the HART protocol can be converted into individual 4 to 20 mA

sections using the HART loop converter KFD2-HLC-Ex1.D.**. The variables are assigned to

the current output and the measuring ranges of the individual parameters are defined in the

KFD2-HLC-Ex1.D.**.

28

Figure 5.7 Connection example KFD2-HLC-Ex1.D.**: passive 2-wire device and current outputs

The HART loop converter KFD2-HLC-Ex1.D.** can be acquired.

Note!

Additional documentation: see data sheets.

connected as power source

2014-10

Page 29

Pulscon LTC51

21

3

4

2

1

4

3

Power supply

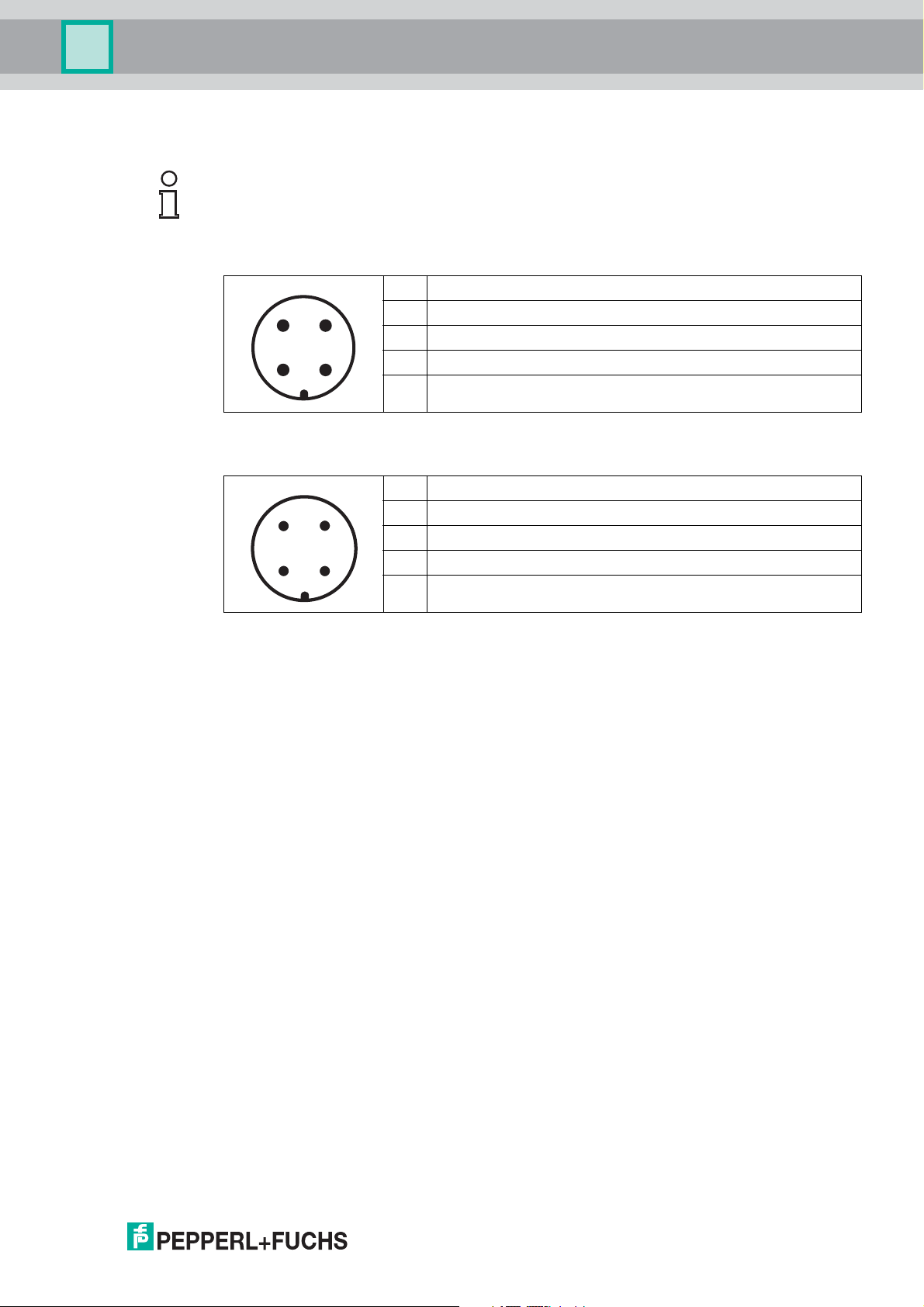

5.3 Device plug connectors

Note!

For the versions with fieldbus plug connector (M12 or 7/8 in), the signal line can be connected

without opening the housing.

Pin assignment of the M12 plug connector

Pin Meaning

1 Signal +

2 not connected

3 Signal 4 Ground

Table 5.2

Pin assignment of the 7/8 in plug connector

Table 5.3

Pin Meaning

1 Signal 2 Signal +

3 not connected

4 Screen

2014-10

29

Page 30

Pulscon LTC51

R [Ω]

[V]U

0

10

11.5 22.5

20 30 35

0

500

R [Ω]

[V]U

0

10

13.5 24.5

20 30

0

500

Power supply

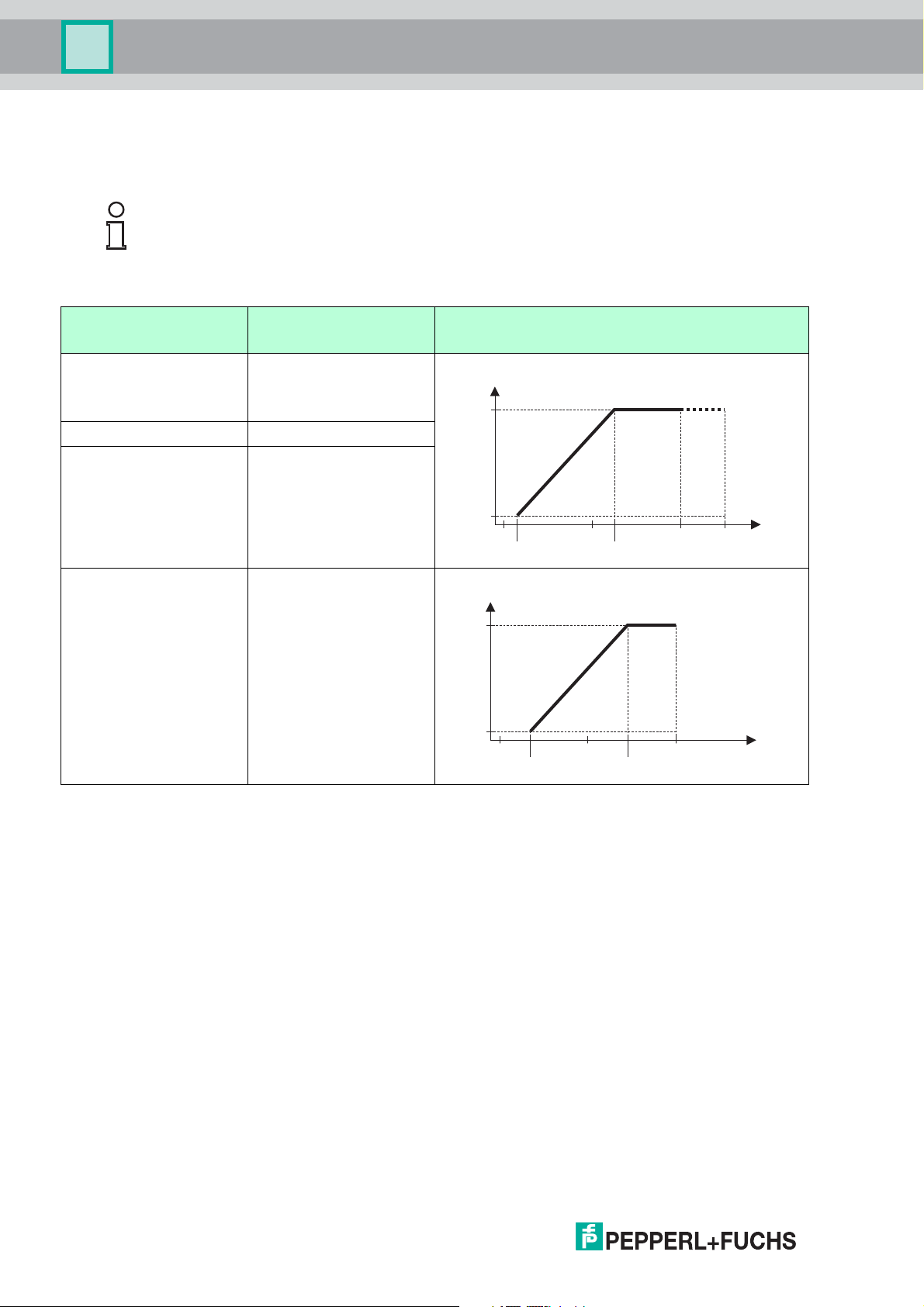

5.4 Power supply

An external power supply is required.

Note!

Various supply units can be ordered from Pepperl+Fuchs: see chapter 14.4.

2-wire, 4 ... 20 mA HART, passive

Approval

•Non-Ex

•ExnA

•CSAGP

•Exic 11.5 ... 32 V

•Exia/IS 11.5 ... 30 V

•Exd/XP

•Exic(ia)

• Ex tD/DIP

a

Terminal voltage U at the

device

11.5 ... 35 V

13.5 ... 30 V

1

Maximum load R, depending on the supply voltage

at the supply unit

U

0

b

c

d

e

Table 5.4

a

Feature "Approval" of the product structure

b

For ambient temperatures Ta -30 °C (-22 °F) a minimum voltage of 14 V is required for the startup of the device at the

MIN error current (3.6 mA). The startup current can be parametrized. If the device is operated with a fixed current I 4.5 mA

(HART multidrop mode), a voltage of U 11.5 V is sufficient throughout the entire range of ambient temperatures.

c

For ambient temperatures Ta -30 °C (-22 °F) a minimum voltage of 14 V is required for the startup of the device at the

MIN error current (3.6 mA). The startup current can be parametrized. If the device is operated with a fixed current I 4.5 mA

(HART multidrop mode), a voltage of U 11.5 V is sufficient throughout the entire range of ambient temperatures.

d

For ambient temperatures Ta -30 °C (-22 °F) a minimum voltage of 14 V is required for the startup of the device at the

MIN error current (3.6 mA). The startup current can be parametrized. If the device is operated with a fixed current I 4.5 mA

(HART multidrop mode), a voltage of U 11.5 V is sufficient throughout the entire range of ambient temperatures.

e

For ambient temperatures Ta -20 °C (-4 °F) a minimum voltage of 16 V is required for the startup of the device at the MIN error

current (3.6 mA).

1

Feature "Electrical Output" of the product structure, option IH

30

2014-10

Page 31

Pulscon LTC51

R [Ω]

U0[V]

10

12 23

20 30 35

0

500

Power supply

1

Approval

a

•Non-Ex

2-wire; 4 ... 20 mA HART, switch output

Terminal voltage U at the

device

12 ... 35 V

b

Maximum load R, depending on the supply voltage

at the supply unit

U

0

•ExnA

•ExnA(ia)

•Exic

•Exic(ia)

•Exd(ia)/XP

•Exta/DIP

•CSAGP

•Exia/IS

12 ... 30 V

c

• Ex ia + Ex d(ia)/IS + XP

Table 5.5

a

Feature "Approval" of the product structure

b

For ambient temperatures Ta -30 °C (-22 °F) a minimum voltage of 14 V is required for the startup of the device at the

MIN error current (3.6 mA).

c

For ambient temperatures Ta -30 °C (-22 °F) a minimum voltage of 14 V is required for the startup of the device at the

MIN error current (3.6 mA).

2014-10

1

Feature "Electrical Output" of the product structure, option ID

31

Page 32

Pulscon LTC51

R [Ω]

[V]U

0

10

13.5 24.5

20 30

0

500

R [Ω]

U0[V]10

12 23

20 30

0

500

Power supply

2-wire; 4 ... 20 mA HART, 4 ... 20 mA

Approval

all Channel 1:

a

Terminal voltage U at the

device

13.5 ... 30 V

Channel 2:

12 ... 30 V

1

Maximum load R, depending on the supply voltage

at the supply unit

U

0

b

Table 5.6

a

Feature "Approval" of the product structure

b

For ambient temperatures Ta -30°C (-22 °F) a minimum voltage of 16 V is required for the startup of the device at the

MIN error current (3.6 mA).

Polarity reversal protection yes

Admissible residual ripple at f = 0 to 100 Hz USS<1V

Admissible residual ripple at

USS<10mV

f = 100 to 10000 Hz

Table 5.7

1

Feature "Electrical output" of the product structure, option IE

2014-10

32

Page 33

Pulscon LTC51

Power supply

4-wire, 4 ... 20 mA HART, active

Electrical Output

AH: 4-wire 90 ... 253 V AC;

4...20mA HART

DH: 4-wire 10.4 ... 48 V DC;

4...20mAHART

Table 5.8

a

Feature "Electrical Output" the product structure

PROFIBUS PA

Electrical Output

PA: 2-wire; PROFIBUS PA,

switch output

Table 5.9

a

Terminal voltage U Maximum load R

90 ... 253 V AC (50 ... 60 Hz),

500

max

overvoltage category II

10.4 ... 48 V DC

a

Approval

•Non-Ex

b

Terminal voltage

9...32V

c

•ExnA

•ExnA(ia)

•Exic

•Exic(ia)

•Exd(ia)/XP

•Exta/DIP

•CSAGP

•Exia/IS

9...30V

d

• Ex ia + Ex d(ia)/IS + XP

a

Feature "Electrical Output" the product structure

b

Feature "Approval" of the product structure

c

Input voltages up to 35 V will not spoil the device.

d

Input voltages up to 35 V will not spoil the device.

Polarity sensitive no

FISCO/FNICO compliant according to

IEC 60079-27

Table 5.10

yes

2014-10

33

Page 34

Pulscon LTC51

Power supply

5.5 Power consumption

Electrical output

IH: 2-wire; 4 ... 20 mA HART <0.9W

ID: 2-wire; 4 ... 20 mA HART, switch output <0.9W

IE: 2-wire; 4 ... 20 mA HART, 4 ... 20 mA <2x0.7W

AH: 4-wire 90 ... 253 V AC; 4 ... 20 mA HART 6VA

DH: 4-wire 10.4 ... 48 V DC; 4 ... 20 mA HART 1.3 W

Table 5.11

a

Feature "Electrical Output" of the product structure

a

5.6 Current consumption

HART

Nominal current 3.6 ... 22 mA, the start-up current for

Breakdown signal (NAMUR NE 43) adjustable: 3.59 ... 22.5 mA

Table 5.12

PROFIBUS PA

Nominal current 14 mA

Error current FDE (Fault Disconnection Electronic) 0 mA

Table 5.13

Power consumption

multidrop mode can be parametrized (is set

to 3.6 mA on delivery)

5.7 Power supply failure

• Configuration is retained in the HistoROM (EEPROM).

• Error messages (incl. value of operated hours counter) are stored.

5.8 Potential equalization

No special measures for potential equalization are required.

Note!

If the device is designed for hazardous areas, observe the information in the documentation

"Safety Instructions" (SI, ZD).

5.9 Terminals

Plug-in spring terminals for wire cross-sections 0.5 ... 2.5 mm2(20 ... 14 AWG)

34

2014-10

Page 35

Pulscon LTC51

Power supply

5.10 Cable entries

Connection of power supply and signal line

To be selected in feature "Electrical Connection"

• Gland M20; material dependent on the approval:

• For Non-Ex, ATEX, IECEx, NEPSI Ex ia/ic:

plastics M20 x 1.5 for cable Ø5 ... 10 mm (0.2...0.39 in)

• For Dust-Ex, FM IS, CSA IS, CSA GP, Ex nA:

metal M20 x 1.5 for cable Ø7 ... 10 mm (0.28...0.39 in)

•For Exd:

No gland available

•Thread

•1/2 in NPT

•G1/2

• M20 × 1.5

• Plug M12/plug 7/8 in

Only available for Non-Ex, Ex ic, Ex ia

1

5.11 Cable specification

• Minimum cross-section: dependent on terminals: see chapter 5.9.

• For ambient temperature T

a

HART

• A normal device cable suffices if only the analog signal is used.

• A shielded cable is recommended if using the HART protocol. Observe grounding concept

of the plant.

• For 4-wire devices: Standard device cable is sufficient for the power line.

PROFIBUS PA

• Use a twisted, screened two-wire cable, preferably cable type A.

Note!

For further information on the cable specifications, see PNO Guideline 2.092 "PROFIBUS PA

User and Installation Guideline" and IEC 61158-2 (MBP).

5.12 Overvoltage protection

If the measuring device is used for level measurement in flammable liquids which requires the

use of overvoltage protection according to DIN EN 60079-14, standard for test procedures

60060-1 (10 kA, pulse 8/20 s), overvoltage protection has to be ensured by an external

overvoltage protection module.

60 °C(140°F): use cable for temperature T

+20K.

a

External overvoltage protection

For detailed information please refer to www.pepperl-fuchs.com

1

The material of the gland is dependent on the housing type; A3 (GT18, stainless steel housing): 316L (1.4404); A1

2014-10

(GT19, plastic housing) and A2 (GT20, aluminum housing): nickel-coated brass (CuZn).

35

Page 36

Pulscon LTC51

Performance characteristics

6 Performance characteristics

6.1 Reference operating conditions

• Temperature = + 24 °C(+75°F) ±5 °C(9°F)

• Pressure = 960 mbar abs. (14 psia) ±100 mbar (1.45 psi)

• Humidity = 60 % ±15 %

• Reflection factor 0.8 (water surface for coax probe, metal plate for rod and rope probe

with min.1 m (40 in) diameter)

• Flange for rod or rope probe 300 mm (12 in) diameter

• Distance to obstacles 1m(40in)

6.2 Maximum measured error

Typical data under reference operating conditions: DIN EN 61298-2, percentage values in

relation to the span.

Output: digital analog

Sum of non-linearity, non-

repeatability and hysteresis

Offset/Zero ±4mm(0.16in) 0.03 %

Table 6.1

a

Add error of the analogous value to the digital value.

If the reference conditions are not met, the offset/zero point arising from the mounting situation

may be up to ±12 mm (0.47 in) for rope and rod probes. This additional offset/zero point can be

compensated for by entering a correction (parameter "level correction") during commissioning.

• Measuring distance up to15 m (49 ft):

±2mm(0.08in)

• Measuring distance > 15 m (49 ft):

±10 mm (0.39 in)

0.02 %

a

36

2014-10

Page 37

Pulscon LTC51

Performance characteristics

Differing from this, the following measuring error is present in the vicinity of the lower

probe end:

80 (3.15)

60 (2.36)

40 (1.57)

20 (0.79)

0

-20 (-0.79)

-40 (-1.57)

-60 (-2.36)

-80 (-3.15)

D

0

20 (0.79)

50 (1.97)

40 (1.57)

80 (3.15)

100 (3.94)

150 (5.91)

DC = 2

DC = 80

250 (9.84)

200 (7.87)

A

300 (11.8)

Figure 6.1 Measuring error at the end-of-probe for rod and coax probes

A Distance from probe end [mm (in)]

D Measuring error: sum of non-linearity, non-repeatability and hysteresis

DC Dielectric constant

D

80 (3.15)

60 (2.36)

40 (1.57)

20 (0.79)

0

-20 (-0.79)

-40 (-1.57)

-60 (-2.36)

-80 (-3.15)

0

20 (0.79)

50 (1.97)

100 (3.94)

DC = 80

150 (5.91)

200 (7.87)

A

300 (11.8)

250 (9.84)

Figure 6.2 Measuring error at the end-of-probe for rope probes

A Distance from probe end

D Measuring error: sum of non-linearity, non-repeatability and hysteresis

DC Dielectric constant

2014-10

37

Page 38

Pulscon LTC51

Performance characteristics

120 (4.72)

100 (3.94)

80 (3.15)

60 (2.36)

40 (1.57)

20 (0.79)

0

-20 (-0.79)

-40 (-1.57)

-60 (-2.36)

-80 (-3.15)

-100 (-3.94)

-120 (-4.72)

D

DC = 2

DC = 80

0

A

50 (1.97)

30 (0.79)

150 (5.91)

100 (3.94)

200 (7.87)

250 (9.84)

300 (11.8)

Figure 6.3 Measuring error at the end-of-probe for probes with a metallic centering disk

A Distance from probe end [mm (in)]

D Measuring error: sum of non-linearity, non-repeatability and hysteresis

DC Dielectric constant

Note!

If for rope probes the DC value is less than 7, then measurement is not possible in the area of

the straining weight (0 to 250 mm from end of probe; lower blocking distance).

38

2014-10

Page 39

Pulscon LTC51

2 mm

0 mm

- 2 mm

100 mm 200 mm

10 mm

- 10 mm

20 mm

- 20 mm

30 mm

- 30 mm

40 mm

- 40 mm

R

D

DC = 2

DC = 80

Performance characteristics

In the area of the upper probe end, the measuring error is as follows (rod/rope only):

Figure 6.4 Measuring error at the upper end of the probe

D Sum of non-linearity, non-repeatability and hysteresis

R Reference point of measurement

DC Dielectric constant

6.3 Resolution

• digital: 1 mm

•analog: 1 µA

6.4 Reaction time

The reaction time can be parametrized. The following step response times (as per

DIN EN 61298-2)

Level measurement

Probe length Sampling rate Step response time

<10m(33ft) 3.6 measurements/second < 0.8 s

< 40 m (131 ft) 2.7 measurements/second < 1 s

Table 6.2

1

are valid if the damping is switched off:

1

According to DIN EN 61209-2 the response time is the time which passes after a sudden change of the input

2014-10

signal until the output signal for the first time assumes 90 % of the steady-state value.

39

Page 40

Pulscon LTC51

Performance characteristics

6.5 Influence of ambient temperature

The measurements are carried out in accordance with EN 61298-3

• digital (HART, PROFIBUS PA): average T

For devices with remote sensor

±0.3 mm/10K (0.01 in/10 K) per1 m (3.3 ft) of the remote cable.

• analog (current output):

• zero point (4 mA): average T

• span (20 mA): average T

6.6 Influence of gas layer

High pressures reduce the propagation velocity of the measuring signals in the gas/vapor

above the fluid. This effect depends on the kind of gas/vapor and of its temperature. This

results in a systematic measuring error that gets bigger as the distance increases between the

reference point of the measurement (flange) and the product surface. The following table

illustrates this measured error for a few typical gases/vapors (with regard to distance; a

positive value means that too large a distance is being measured):

1

there is an additional offset of

=0.02%/10K

K

= 0.05 %/10 K

K

= 0.6 mm/10 K

K

Gas layer Temperature Pressure

°C °F 1 bar

(14.5 psi)

10 bar

(145 psi)

50 bar

(725 psi)

100 bar

(1450 psi)

200 bar

(2900 psi)

400 bar

(5800 psi)

Air 20 68 0.00 % 0.22 % 1.2 % 2.4 % 4.9 % 9.5 %

200 392 -0.01 % 0.13 % 0.74 % 1.5 % 3.0 % 6.0 %

400 752 -0.02 % 0.08 % 0.52 % 1.1 % 2.1 % 4.2 %

Hydrogen 20 68 -0.01 % 0.10 % 0.61 % 1.2 % 2.5 % 4.9 %

200 392 -0.02 % 0.05 % 0.37 % 0.76 % 1.6 % 3.1 %

400 752 -0.02 % 0.03 % 0.25 % 0.53 % 1.1 % 2.2 %

Table 6.3

Gas layer Temperature Pressure

Water

(saturated

steam)

°C °F 1 bar

(14.5 psi)

100 212 0.26 % – – – – – – –

120 248 0.23 % 0.50 % – – – – – –

2 bar

(29 psi)

5 bar

(72.5 psi)

10 bar

(145 psi)

20 bar

(290 psi)

50 bar

(725 psi)

100 bar

(1450 psi)

152 306 0.20 % 0.42 % 1.14 % – – – – –

180 356 0.17 % 0.37 % 0.99 % 2.10 % – – – –

212 414 0.15 % 0.32 % 0.86 % 1.79 % 3.9 % – – –

264 507 0.12 % 0.26 % 0.69 % 1.44 % 3.0 % 9.2 % – –

311 592 0.09 % 0.22 % 0.58 % 1.21 % 2.5 % 7.1 % 19.3 % –

366 691 0.07 % 0.18 % 0.49 % 1.01 % 2.1 % 5.7 % 13.2 % 76 %

Table 6.4

200 bar

(2900 psi)

40

1

Product structure: Feature "Probe design", option B)

2014-10

Page 41

Pulscon LTC51

Performance characteristics

6.7 Gas phase compensation with external pressure sensor (PROFIBUS PA)

PROFIBUS devices can receive the signal of an external pressure sensor through the bus and

use it to perform a pressure dependent time-of-flight correction. In the case of saturated steam

in the temperature range from 100 ... 350 °C (212 ... 662 °F), for example, the measuring error

of the distance measurement can be reduced by this method from up to 29 % (without

compensation) to less than 3 % (with compensation).

2014-10

41

Page 42

Pulscon LTC51

A

C

1

23

4

B

Mounting

7Mounting

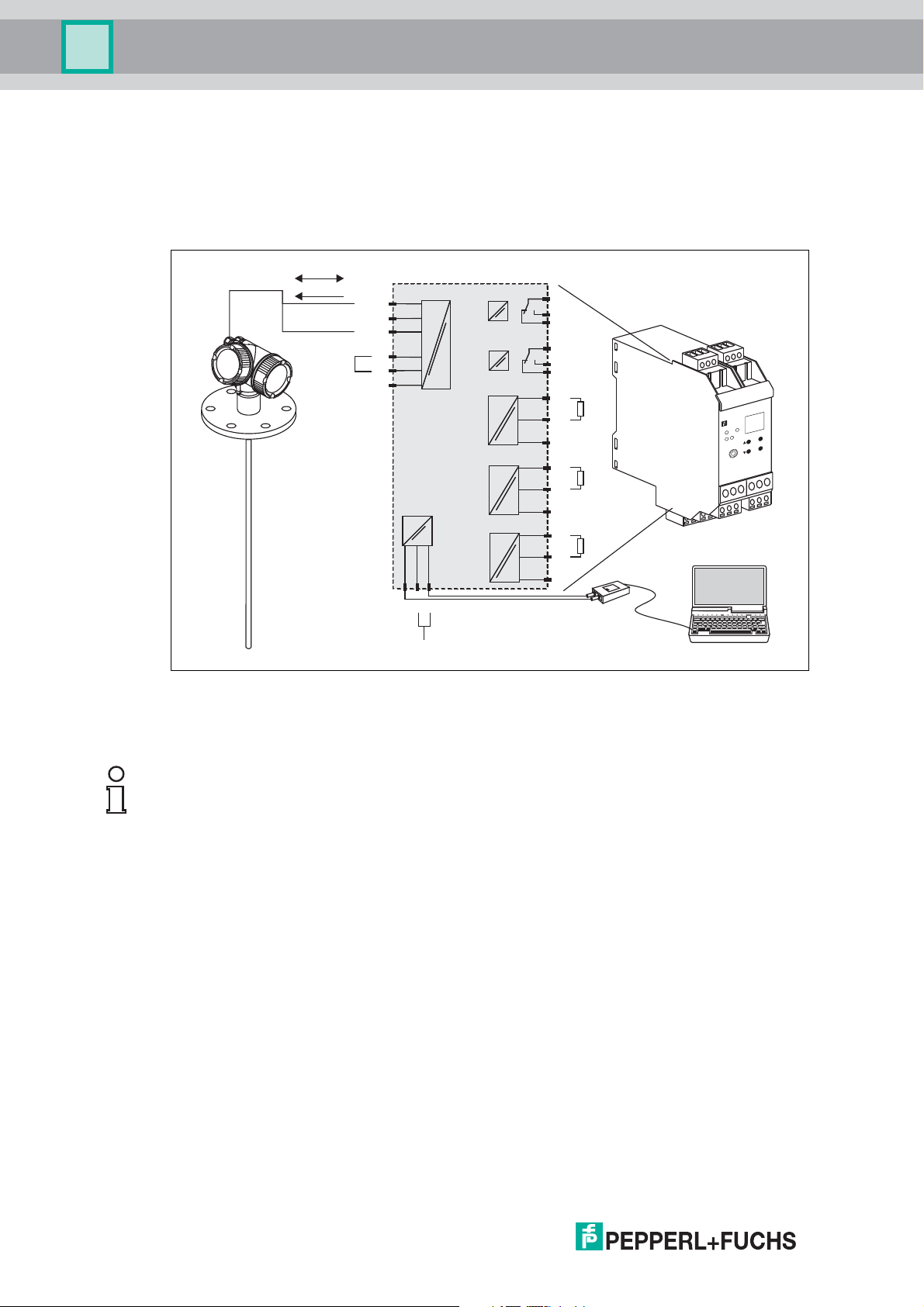

7.1 Mounting requirements

7.1.1 Suitable mounting position

Figure 7.1 Mounting requirements

Mounting distances

• Distance (A) between wall and rod or rope probe:

• for smooth metallic walls: > 50 mm (2 in)

• for plastic walls: > 300 mm (12 in) to metallic parts outside the vessel

• for concrete walls: > 500 mm (20 in), otherwise the available measuring range may

be reduced.

• Distance (B) between rod or rope probe and internal fittings in the vessel: > 300 mm (12 in)

• Distance (C) from end of probe to bottom of the vessel:

• Rope probe: > 150 mm (6 in)

• Rod probe: > 10 mm (0.4 in)

Note!

For coax probes the distance to the wall and to internal fittings is arbitrary.

•Coax probe: > 10mm(0.4in)

2014-10

42

Page 43

Pulscon LTC51

Mounting

Additional conditions

• When mounting in the open, a weather protection cover (1) may be installed to protect the

device against extreme weather conditions.

• In metallic vessels: Preferably do not mount the probe in the center of the vessel (2), as this

would lead to increased interference echoes.

If a central mounting position can not be avoided, it is crucial to perform an interference

echo suppression (mapping) after the commissioning of the device.

• Do not mount the probe in the filling curtain (3).

• Avoid buckling the rope probe during installation or operation (e. g. through product

movement against silo wall) by selecting a suitable mounting location.

• Check the probe regularly for defects.

Note!

With suspended rope probes (probe end not fixed at the bottom) the distance between the

probe rope and internal fittings in the tank must not fall below 300 mm (12 in) during the entire

process. A sporadic contact between the probe weight and the cone of the vessel, however,

does not influence the measurement as long as the dielectric constant of the medium is at least

DC = 1.8.

Note!

When mounting the electronics housing into a recess (e. g. in a concrete ceiling), observe a

minimum distance of 100 mm (4 in) between the cover of the terminal compartment/electronics

compartment and the wall. Otherwise the connection compartment/electronics compartment is

not accessible after installation.

2014-10

43

Page 44

Pulscon LTC51

Mounting

7.1.2 Applications with restricted mounting space

Mounting with remote sensor

The device version with a remote sensor is suited for applications with restricted mounting

space. In this case the electronics housing is mounted at a separate position from which it is

easier accessible.

A

6 Nm

(4.42 lbf ft)

C

Figure 7.2

r = 100 (4)

min

6 Nm

(4.42 lbf ft)

A Angled plug at the probe

B Angled plug at the electronics housing

C Length of the remote cable as ordered

B

(4.42 lbf ft)

r = 100 (4)

min

6 Nm

C

6 Nm

(4.42 lbf ft)

44

• Product structure, feature "Probe Design": option B "Sensor remote, 3 m/9 ft cable"

• The remote cable is supplied with these device versions, minimum bending radius:

100 mm (4 in)

• A mounting bracket for the electronics housing is supplied with these device versions.

Mounting options:

•Wall mounting

• Pipe mounting; diameter: 42 to 60 mm (1-1/4 to 2 in)

• The connection cable has got one straight and one angled plug (90°). Depending on the

local conditions the angled plug can be connected at the probe or at the electronics

housing.

Note!

Probe, electronics and connection cable are adjusted to match each other. They are marked

by a common serial number. Only components with the same serial number shall be

connected to each other.

2014-10

Page 45

Pulscon LTC51

14 mm

14 mm

Mounting

Divisible probes

Figure 7.3

If there is little mounting space (distance to the ceiling), it is advisable to use divisible rod

probes (Ø16 mm).

• max. probe length 10 m (394 in)

• max. sideways capacity 30 Nm

• probes are separable several times with the following lengths of the individual parts:

•torque: 15Nm

•500mm(20in)

• 1000 mm (40 in)

2014-10

45

Page 46

Pulscon LTC51

v

L

N

L

d

Mounting

7.1.3 Notes on the mechanical load of the probe

Tensile load limit of rope probes

Feature "Probe" Probe Tensile load limit [kN]

Option 2, 3, E, F Rope 4 mm (1/6 in) 316 5

Table 7.1

Bending strength of rod probes

Feature "Probe" Probe Bending strength [Nm]

Option 1, 5 Rod 8 mm (1/3 in) 316L 10

Option 8, 9 Rod 12 mm (1/2 in) 316L 30

Option 6, 7 Rod 12 mm (1/2 in) AlloyC 30

Option A, B, C, D Rod 16 mm (0.63 in) 316L

divisible

Table 7.2

30

Bending load (torque) through fluid flow

The formula for calculating the bending torque M impacting on the probe:

M = cw × / 2 × v2 × d × L × (LN - 0.5 × L)

with:

c

: friction factor

w

[kg/m

v [m/s]: Velocity of the medium perpendicular to the probe rod

d [m]: Diameter of the probe rod

L [m]: Level

LN [m]: Probe length

Calculation example

3

]: Density of the medium

Friction factor c

w

0.9 (on the assumption of a turbulent

current - high Reynolds number)

Density [kg/m3] 1000 (e. g. water)

Probe diameter d [m] 0.008

L = L

N

(worst case)

Table 7.3

2014-10

46

Page 47

Pulscon LTC51

Bending torque [M] on rod probes, diameter 8 mm (1/3”)

Probe length [ ] in meters

L

N

v = 0.5 m/s

v = 0.7 m/s

v = 1.0 m/s

max. bending torque

0.4 0.8 1.2 1.6 2 2.4 2.8 3.2 3.6 4

0.0

2.0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

18.0

20.0

Bending [Nm]

torque

Mounting

Figure 7.4

Bending strength of coax probes

Feature "Probe" Process connection Probe Bending strength

[Nm]

Option 4, G Thread G3/4 or NPT3/4 Coax 316L,

60

Ø21.3 mm

•Thread G1-1/2 or

NPT1-1/2

Coax 316L,

Ø42.4 mm

300

•Flange

Option H, K Flange Coax Alloy C,

300

Ø42.4 mm

Table 7.4

2014-10

47

Page 48

Pulscon LTC51

Mounting

7.1.4 Notes on the process connection

Probes are mounted to the process connection with threaded connections or flanges. If during

this installation there is the danger that the probe end moves so much that it touches the tank

floor or cone at times, the probe must, if necessary, be shortened and fixed down.

Threaded connection

Figure 7.5 Mounting with threaded connection; flush with the container ceiling

Seal

The thread as well as the type of seal comply to DIN 3852 Part 1, screwed plug form A.

They can be sealed with the following types of sealing rings:

• Thread G1-1/2: according to DIN 7603 with the dimensions 48 x 55 mm

Please use a sealing ring according to this standard in the form A, C or D and of a material that

is resistant to the application.

Note!

For the length of the screwed plug refer to the dimensional drawing: see chapter 10.

48

2014-10

Page 49

Pulscon LTC51

≤150 (6)

H

mm (in)

ø ≤150 (6)

Mounting

Nozzle mounting

Figure 7.6

• Permissible nozzle diameter: 150 mm (6 in).

For larger diameters the near range measuring capability may be reduced.

For nozzles DN300: see next section.

• Permissible nozzle height

For a larger height the near range measuring capability may be reduced.

1

: 150 mm (6 in).

Note!

With thermally insulated vessels the nozzle should also be insulated in order to prevent

condensate formation.

Center rod

For rope probes it may be necessary to use a version with center rod in order to prevent the

probe rod from coming into contact with the nozzle wall. Probes with center rod are available

for the device.

Max. nozzle height (= length of the center

rod)

150 mm 2

6 in 3

300 mm E

12 in F

Table 7.5

Option to be selected in feature "Probe"

1

2014-10

Larger nozzle heights on request

49

Page 50

Pulscon LTC51

1

2

3

4

Mounting

Installation in nozzles DN300

If installation in 300mm/12 in nozzles is unavoidable, installation must be carried out in

accordance with the following sketch.

Figure 7.7

1 Lower edge of the nozzle

2 Approx. flush with the lower edge of the nozzle (±50 mm/2 in)

3 Plate

4 Pipe diameter 150 to 180 mm (6 to 7 in)

Nozzle diameter Plate diameter

300 mm (12 in) 280 mm (11 in)

400 mm (16 in) 350 mm (14 in)

Table 7.6

50

2014-10

Page 51

Pulscon LTC51

Mounting

Mounting cladded flanges

For usage of cladded flanges, observe the following:

• Use flange screws according to the number of flange holes.

• Tighten the screws with the required torque (see table).

• Retighten the screws after 24 hours or after the first temperature cycle.

• Depending on process pressure and process temperature check and retighten the screws

at regular intervals.

Flange size Number of screws Recommended torque [Nm]

EN

DN40/PN40 4 35 55

DN50/PN16 4 45 65

DN50/PN40 4 45 65

DN80/PN16 8 40 55

DN80/PN40 8 40 55

DN100/PN16 8 40 60

DN100/PN40 8 55 80

DN150/PN16 8 75 115

DN150/PN40 8 95 145

ASME

1-1/2 in/150 lbs 4 20 30

1-1/2 in/300 lbs 4 30 40

2 in/150 lbs 4 40 55

2 in/300 lbs 8 20 30

3 in/150 lbs 4 65 95

3 in/300 lbs 8 40 55

4 in/150 lbs 8 45 70

4 in/300 lbs 8 55 80

6 in/150 lbs 8 85 125

6 in/300 lbs 12 60 90

JIS

10K 40A 4 30 45

10K 50A 4 40 60

10K 80A 8 25 35

10K 100A 8 35 55

10K 100A 8 75 115

Table 7.7

minimum maximum

2014-10

51

Page 52

Pulscon LTC51

Mounting

7.1.5 Securing the probe

Securing rope probes

C

2

Figure 7.8

B

A

1

A Sag of the rope: 1 cm per 1 m of the probe length (0.12 in per 1 ft of the probe length)

B Reliably grounded end of probe

C Reliably isolated end of probe

1 Mounting and contact with a bolt

2 Mounting kit isolated

• The end of the probe needs to be secured under the following conditions:

if otherwise the probe sporadically comes into contact with the wall of the vessel, the outlet

cone, internal fittings or other parts of the installation.

• The end of probe can be secured at its internal thread: rope 4 mm (1/6 in), 316: M14

• The fixing must be either reliably grounded or reliably insulated. If it is not possible to

mount the probe weight with a reliably insulated connection, it can be secured using an

isolated eyelet, which is available as an accessory.

• In order to prevent an extremely high tensile load (e. g. due to thermal expansion) and the

risk of rope crack, the rope has to be slack. Make the rope longer than the required

measuring range such that there is a sag in the middle of the rope that is 1cm/(1 m rope

length) [0.12 in/(1 ft rope length)].

Tensile load limit of rope probes: see chapter 7.

52

2014-10

Page 53

Pulscon LTC51

Mounting

Securing rod probes

• For Ex-approvals: For probe lengths 3 m (10 ft) a support is required.

• In general, rod probes must be supported if there is a horizontal flow (e. g. from an agitator)

or in the case of strong vibrations.

• Rod probes may only be supported at the end of the probe.

∅ a

∅ b

1

2

3

≈50 (1.97)

∅ < 25 (1.0)

≈3 (0.12)

4

5

6

≈50 (1.97)

mm (in)

Figure 7.9

1 Probe rod, uncoated

2 Sleeve bored tight to ensure electrical contact between the rod and sleeve!

3 Short metal pipe, e. g. welded in place

4 Probe rod, coated

5 Plastic sleeve, e. g. PTFE, PEEK or PPS

6 Short metal pipe, e. g. welded in place

Ø probe Øa [mm (in)] Øb [mm (in)]

8 mm (1/3 in) < 14 (0.55) 8.5 (0.34)

12 mm (1/2 in) < 20 (0.78) 12.5 (0.52)

16 mm (0.63 in) < 26 (1.02) 16.5 (0.65)

Table 7.8

2014-10

53

Page 54

Pulscon LTC51

Mounting

Warning!

Poor grounding of the end of probe may cause measuring errors.

• Apply a narrow sleeve which has good electrical contact to the probe.

Warning!

Welding may damage the main electronics module.

• Before welding: Ground the probe and dismount electronics.

Securing coax probes

For WHG-approvals: For probe lengths 3 m (10 ft) a support is required.

Figure 7.10

Coax probes can be supported at any point of the outer tube.

54

2014-10

Page 55

Pulscon LTC51

AB

≥100

(3.94)

øD

ød

ød

1

2

2

3

C

≥100

(3.94)

4

Mounting

Special mounting conditions

Bypasses and stilling wells

Figure 7.11

A Mounting in a stilling well

B Mounting in a bypass

C Center washer or centering star (on request)

1 Metallic center washer (316L) for level measurement (on request)

2 Fixing screw; torque: 25 Nm ±5Nm

3 Non-metallic centering star (PEEK, PFA) for interface measurement (on request)

4 Minimum distance between end of probe and lower edge of the bypass; see table below

Allocation of probe type and center washer or centering star to pipe diameter

Type of probe Center washer or centering star Pipe

Ød [mm (in)] Material ØD [mm (in)]

Rod probe 75 (2.95) 316L DN80/3 to DN100/4 in

Rod probe 45 (1.77) 316L DN50/2 to DN65/2-1/2 in

Rope probe 75 (2.95) 316L DN80/3 to DN100/4 in

Table 7.9

Minimum distance between end of probe and lower edge of the bypass

2014-10

Type of probe Minimum distance

Rope 150 mm (6 in)

Rod 10 mm (0.4 in)

Coax 10 mm (0.4 in)

Table 7.10

55

Page 56

Pulscon LTC51

Mounting

• Pipe diameter: > 40 mm (1.6 in) for rod probes

• Rod probe installation can take place up to a diameter size of 150 mm (6 in). In the event of

larger diameters, a coax probe is recommended.

• Side disposals, holes or slits and welded joints that protrude up to approx. 5 mm (0.2 in)

inwards do not influence the measurement.

• The pipe may not exhibit any steps in diameter.

• The probe must be 100 mm (4 in) longer than the lower disposal.

• Within the measuring range, the probe must not get into contact with the pipe wall. If

necessary, use a center washer or centering star.

• If the center washer or centering star is mounted at the end of the probe, it enables a

reliable recognition of the end-of-probe signal.

• Coax probes can always be applied if there is enough mounting space.

Note!

For bypasses with condensate formation (water) and a medium with low dielectric constant

(e. g. hydrocarbons):

In the course of time the bypass is filled with condensate up to the lower disposal and for low

levels the level echo is superimposed by the condensate echo. Thus in this range the

condensate level is measured instead of the correct level. Only higher levels are measured

correctly. To prevent this, position the lower disposal 100 mm (4 in) below the lowest level to

be measured and apply a metallic centering disk at the height of the lower edge of the lower

disposal.

Note!

With heat insulated tanks the bypass should also be insulated in order to prevent condensate

formation.

Note!

For rope probes with a length exceeding 2 m (6.7 ft) an additional weight or a spring should be

mounted in addition to the center a washer in order to tighten the rope.

Note!

For information on bypass solutions from Pepperl+Fuchs please contact your Pepperl+Fuchs

sales representative.

56

2014-10

Page 57

Pulscon LTC51

1

2

Mounting

Installation in horizontal and upright cylindrical tanks

Figure 7.12

• Any distance from wall, as long as occasional contact is prevented.

• When installing in tanks with a lot of internals or internals situated close to the probe: use a

coax probe (1), (2).

Underground tanks

Figure 7.13

Use a coax probe for nozzles with large diameters in order to avoid reflections at the nozzle

wall.

2014-10

57

Page 58

Pulscon LTC51

LN

α

Mounting

Installation at an angle

Figure 7.14

• For mechanical reasons, the probe should be installed as vertically as possible.