Inductive positioning system PMI14V-F166-U

Technical data

General specifications

Switching element function Analog voltage output

Object distance 0.5 ... 2 mm

Measurement range 0 ... 14 mm

Nominal ratings

Model Number

PMI14V-F166-U

Features

•Analog output 0...10V

• Measuring range 0 ... 14 mm

• Scaleable measurement range

programmable via cable

Operating voltage U

Reverse polarity protection reverse polarity protected

Linearity error ± 0.3 mm

Repeat accuracy R ± 0.05 mm

Resolution 33 µm

Temperature drift ± 0.3 mm (With a target distance of 0.5 mm)

No-load supply current I

Functional safety related parameters

MTTFd 830 a

Mission Time (T

Diagnostic Coverage (DC) 0 %

Analog output

Output type 1 voltage output: 0 ... 10 V

Load resistor ≥ 1000 Ω

Short-circuit protection current limit

Ambient conditions

Ambient temperature -10 ... 70 °C (14 ... 158 °F)

Storage temperature -20 ... 70 °C (-4 ... 158 °F)

Mechanical specifications

Connection type 5 x 0.14 mm2 , screened 2 m PUR cable

Degree of protection IP65

Material

Housing Zinc die-casting, nickel-plated

Target mild steel, e. g. 1.0037, SR235JR (formerly St37-2)

Mass 95 g

Compliance with standards and

directives

Standard conformity

Standards EN 60947-5-2:2007

Approvals and certificates

UL approval cULus Listed, Class 2 Power Source, Type 1 enclosure

B

0

) 20 a

M

18 ... 30 V DC

≤ 20 mA

cover , PBT

IEC 60947-5-2:2007

EN 60947-5-7:2003

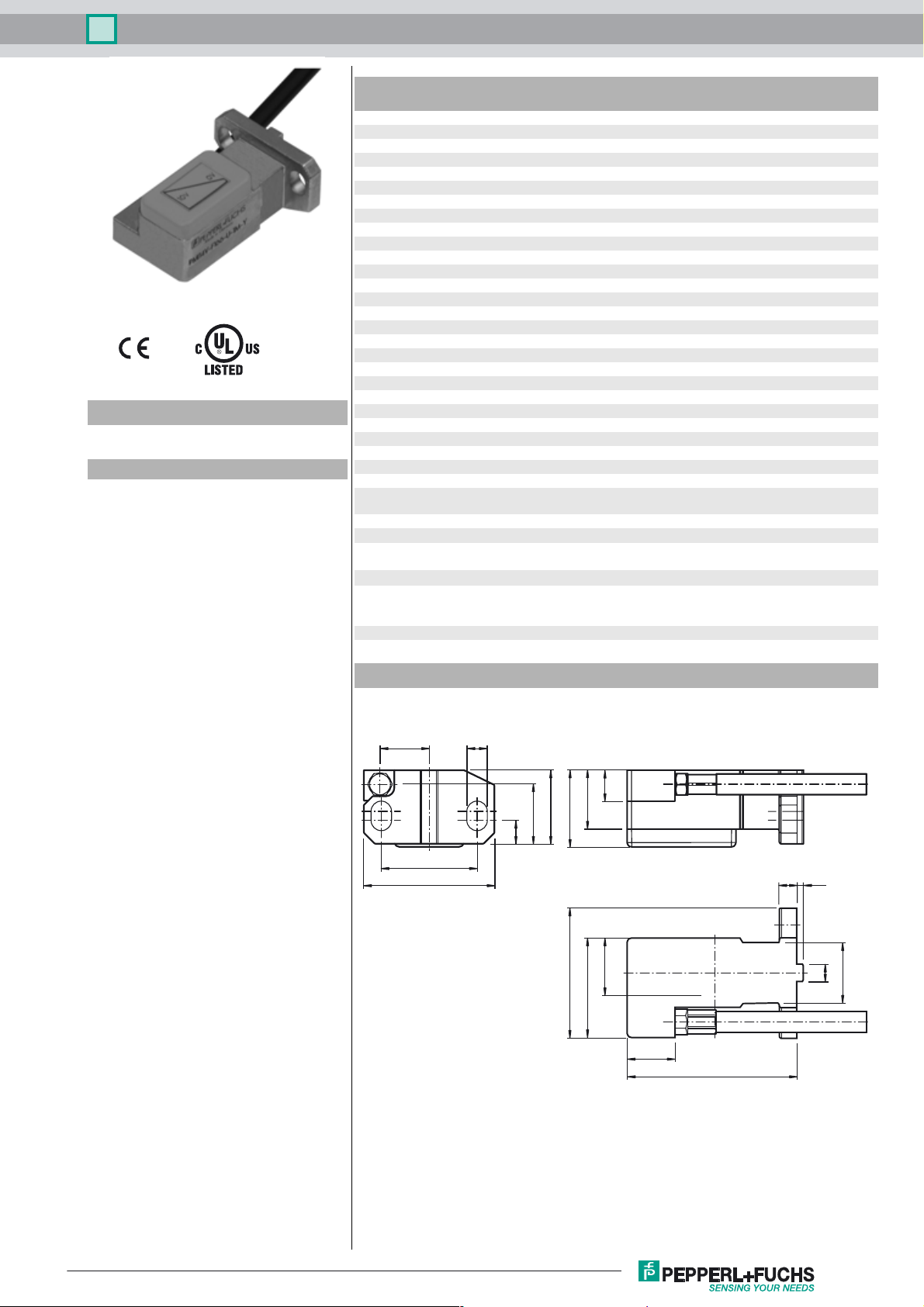

Dimensions

11.3 4.8

22

30

5.4

13.65

16.9

17.8

30

13.5

23

7

4 1.5

16

11

39

4

14

Release date: 2017-11-02 11:48 Date of issue: 2017-11-02 238619_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

1

Inductive positioning system PMI14V-F166-U

Electrical Connection

BN

WH

GY

I

BK

BU

+UB

Service

Service

Analogue output

-UB

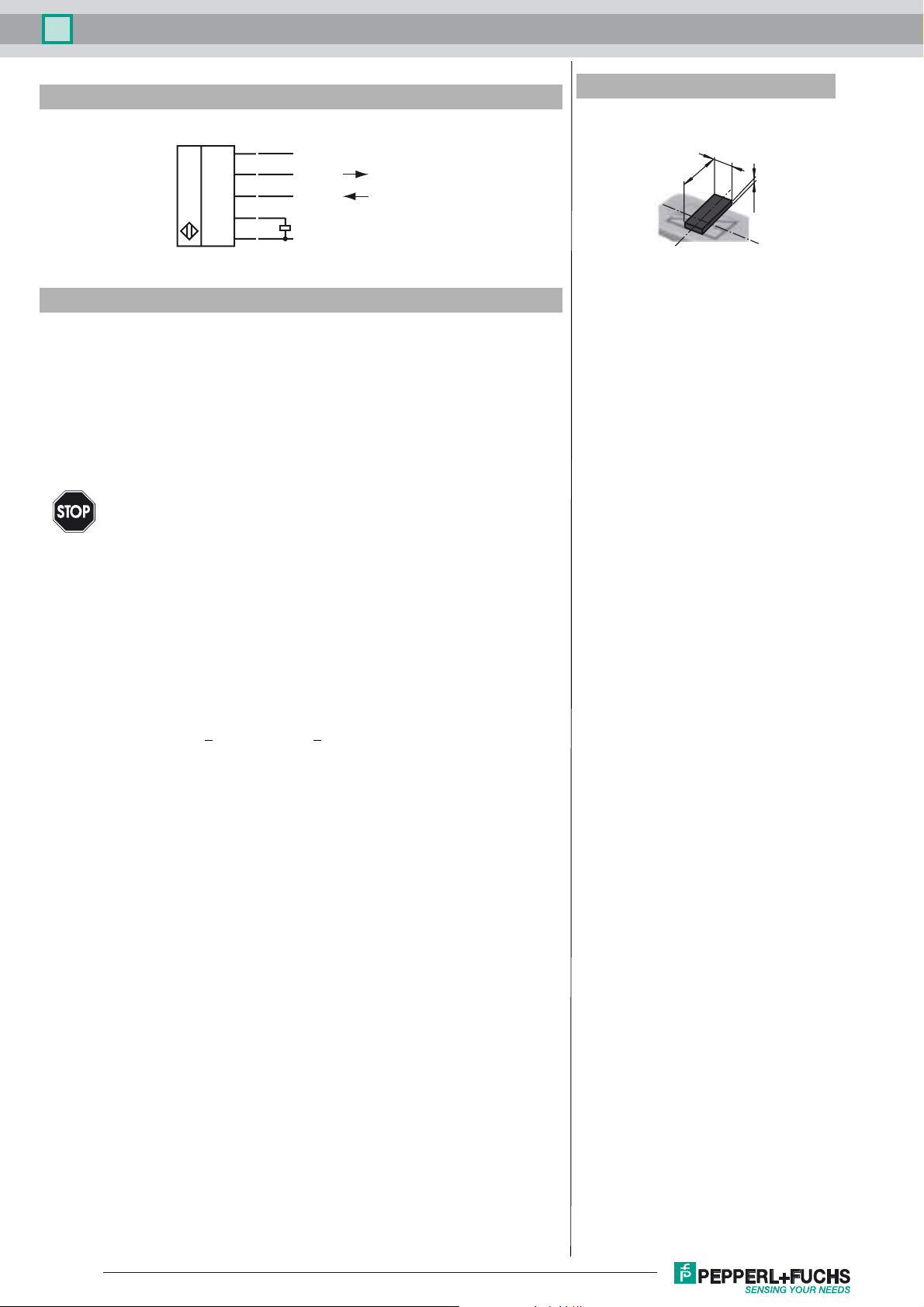

Accessories

BT-F90-W

Damping element for sensors of type F90, F112, and F166; side hole

BT-F90-G

Damping element for sensors of type F90, F112, and F166; front hole

PMI14V-Teach

Programming unit

Information on Operation

Safety Information

This product must not be used in applications in which the safety of persons

depends on the function of the device.

Warn un g

This product is not a safety component as specified in the EU Machinery Directive.

Additional Information

dimensions for the target object:

8

≥ 18

≥ 2

Actuator

The linear position measurement system is optimally aligned to the geometry of Pepperl+Fuchs actuators.

Using Your Own Actuators

Generally speaking, it is possible for you to use your own actuators. The specified measurement accuracy of the sensor will be achieved only if the actuator has the following properties:

• Material: construction steel such as S235JR+AR (previously St37)

• Dimensions (L x W x H): >

18 mm x 8 mm x > 2 mm

• The active surface of the actuator must protrude across the entire sensor width.

Note:

The width of the actuator must be precisely 8 mm. If the width of the actuator deviates from

this value, the position values will differ.

Programming the 2 Scaling Positions

You can teach 2 scaling positions using the PMI14V-Teach programming unit. The programming unit is connected directly between the sensor and the power supply. The teach-in process

is generally only possible in the first 6 minutes of the sensor being switched on. After that point,

programming is blocked and is only possible again once the power supply has been interrupted.

The sensor linearizes the voltage path characteristic curve between the 2 taught scaling positions. The first scaling position is always taught as 0 V and the second scaling position as 10 V.

If the measurement flag leaves the measuring range of the sensor, the sensor always emits 10

V. Each taught scaling position is based on half of the width (center) of the damping element.

During the teach-in, the sensor always emits the default values: 0 V for 0 mm and 10 V for 14

mm.

Teach-in Process

Switching the Sensor to Programming Mode

1. Connect the programming unit between the sensor and the power supply.

2. Press and hold the key on the programming unit for approx. 1.5 seconds.

>> The LED S2 on the programming unit flashes (2 Hz).

Scaling Position 1

Prerequisite: LED S2 is flashing.

1. Position the damping element in the required first teach-in position.

2. Press the button again.

>> The sensor teaches in scaling position 1. If the teach-in process was successful, LED S2

lights up for approx. 2 seconds and flashes for teach-in of scaling position 2.

Scaling Position 2

Prerequisite: LED S2 is flashing.

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Release date: 2017-11-02 11:48 Date of issue: 2017-11-02 238619_eng.xml

Inductive positioning system PMI14V-F166-U

1. Position the damping element in the required second teach-in position.

2. Press the button again.

>> The sensor teaches in scaling position 2. If the teach-in process was successful, LED S2 lights up for approx. 2 seconds. The sensor then

returns to its normal operating state.

Reset to Default Settings

1. Press and hold the button for approx. 6.5 seconds.

>> The sensor is reset to its default settings. The programming unit confirms this by flashing quickly (8 Hz).

Faults during Teach-in

If a teach-in process fails for any reason, LED S2 flashes quickly (16 Hz) for approx. 1.5 seconds. The cause for this may be that the teach-in

attempt was conducted outside the measuring range.

The teach-in process is canceled when the power supply is interrupted or if no button is pressed for 410 seconds.

In both cases, the existing positions remain saved.

Release date: 2017-11-02 11:48 Date of issue: 2017-11-02 238619_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

3

Loading...

Loading...