Vision Sensor PHA600-F200A-B17-V1D

Function

The sensor has been developed for the precision positioning of high-bay racking operating

equipment. It detects circular holes in the racking structure and their positional deviation from

the nominal position. The sensor operates in two dimensions.

Indicating / Operating means

1

R

Model Number

PHA600-F200A-B17-V1D

Precision positioning on hole in the

70 mm x 70 mm housing

Features

• Detects the position of an

index hole

•Large capture range

• High operating range

• Integrated contrast compensation

•Compact design

•PROFINET interface

• Integrated illumination

Electrical connection

1

2

3

4

5

Main

6

7

8

CONFIG

BUS LINK

LED 1 2 3 4 5 6 7

n.c.

+ UB

n.c.

n.c.

n.c.

n.c.

GND

n.c.

BUSTX / RX

2

BUS ERR

RANGE

ZERO POS

PWR / ERR

DIAGNOSTIC

INTERNAL

Release date: 2018-10-17 16:40 Date of issue: 2018-10-22 291103_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

Pepperl+Fuchs Group

Pinout

Technical data

Bus

1

2

3

4

TX +

RX +

TX -

RX -

Bus

1

2

3

4

TX +

RX +

TX -

RX -

Profinet 1 & 2Main

1

8

7

2

6

53

4

1

4

2

3

1

PHA600-F200A-B17-V1DVision Sensor

General specifications

Light type Integrated LED lightning (infrared)

Object size Hole diameter 13 mm

Response delay 100 ms

Read distance 600 mm

Depth of focus ± 50 mm

Capture range max. 120 mm x 100 mm

Nominal ratings

Camera

Ty p e CMOS , Global shutter

Number of pixels 752 x 480 pixels

Gray scale 256

Functional safety related parameters

MTTFd 20 a

Mission Time (T

Diagnostic Coverage (DC) 0 %

Indicators/operating means

Operation indicator LED green: Ready for operation

Function indicator 7 LEDs (communication, alignment aid, status information)

Control elements Button for parameterization

Electrical specifications

Operating voltage UB24 V DC +/- 15 %, PELV

No-load supply current I

Power consumption P06 W

Interface

Interface type 100 BASE-TX PROFINET

Protocol PROFINET IO Real-Time (RT) Conformance class A

Tran sf er ra te 100 MBit/s

Sta nd ard confor mi ty

Noise immunity EN 61000-6-2:2005

Ambient conditions

Operating temperature 0 ... 60 °C (32 ... 140 °F) , -20 ... 60 °C (-4 ... 140 °F) (noncon-

Storage temperature -30 ... 85 °C (-22 ... 185 °F)

Relative humidity 90 % , noncondensing

Mechanical specifications

Degree of protection IP67

Material

Housing PC/ABS

Optical face Plastic pane

Installation 4 x M6 threading

Mass approx. 200 g

) 10 a

M

0

max. 400 mA

densing; prevent icing on the lens!)

Accessories

V19-G-5M-PUR-ABG

Female cordset, M12, 8-pin, shielded,

PUR cable

V1SD-G-2M-PUR-ABG-V1SD-G

Ethernet bus cable, M12 to M12, PUR cable 4-pin, CAT5e

V1SD-G-5M-PUR-ABG-V1SD-G

Ethernet bus cable, M12 to M12, PUR cable 4-pin, CAT5e

PCV-MB1

Mounting bracket for PCV* read head

PCV-SC12A

Grounding clip for PCV system

PCV-SC12

Grounding clip for PCV system

V19-G-10M-PUR-ABG

Female cordset, M12, 8-pin, shielded,

PUR cable

V19-G-2M-PUR-ABG

Female cordset, M12, 8-pin, shielded,

PUR cable

ries can be found at

Approvals and certificates

UL approval cULus Listed, General Purpose, Class 2 Power Source

CCC approval CCC approval / marking not required for products rated ≤36 V

Approvals CE

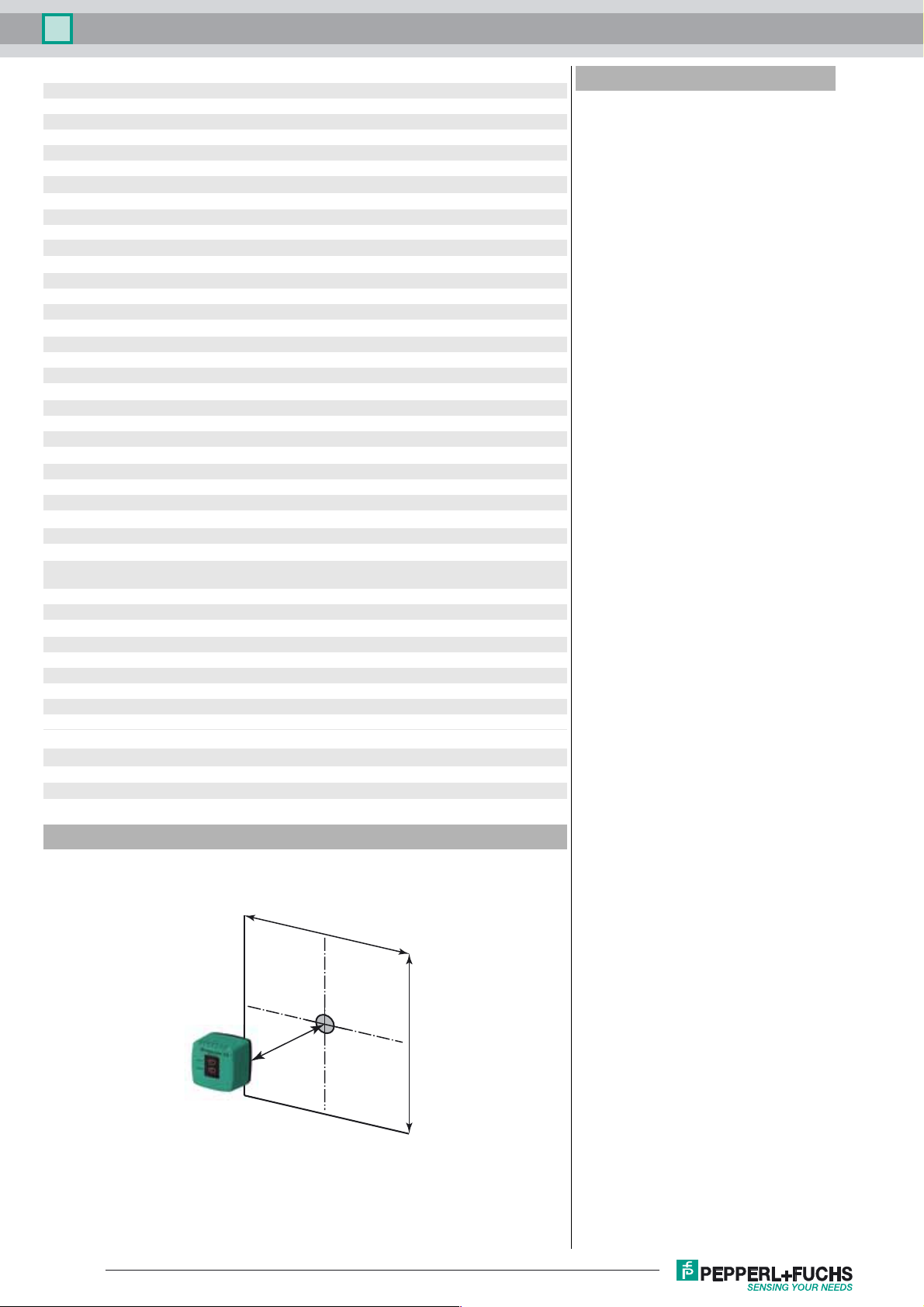

Curves / Diagrams

Capture range X (width)

reading

distance

Capture range Y (height)

Release date: 2018-10-17 16:40 Date of issue: 2018-10-22 291103_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Pepperl+Fuchs Group

Vision Sensor PHA600-F200A-B17-V1D

Dimensions

94.5

10 70 12

22

20 20

12.5

70

50

ø 25

M6 x 9 (4x)

General

The PHA... Vision Sensor has been developed for the rack fine positioning of stock feeders.

This device detects circular holes in the rack structure and determines the position deviation of

these holes in relation to the target position. The Vision Sensor operates in two dimensions.

Mounting and Commissioning

Mount the PHA... Vision Sensor in such a way that the optical surface of the device captures

the optimum distance to the carrier/hole (see "Technical Data"). The stability of the Vision Sensor mounting and the manner in which the vehicle is guided must ensure that the device is not

operated outside of its depth of focus range.

All Vision Sensors can be adapted to optimally meet specific requirements by means of parameterization.

Indicators and Controls

The PHA... Vision Sensor is equipped with seven indicator LEDs for carrying out visual function

checks and rapid diagnostics. The read head is equipped with two buttons at the back for activating the parameterization mode.

LEDs

LED Color Labeling Meaning

1 yellow BUS LINK PROFINET communication active

2 yellow BUS TX / RX Data transfer

3 red BUS ERR PROFINET communication error

4 green/red PWR/ERR Fault with power supply/general error

5 yellow ZERO POS Zero position reached

6 yellow RANGE Within detection/capture range

7 red/green/yellow INTERNAL DIAGNOSTIC Internal diagnostics

External Parameterization

In order to parameterize the device externally, the parameterization code is required in the form

of a data matrix containing the desired parameters. Data matrix code cards detailing the stepby-step process for externally parameterizing the device are printed in the operating instructions for the Vision Sensor.

• The Vision Sensor is switched over from normal operation to parameterization mode using button 2 on the back of the device. To switch the device over, button 2 must be pressed

and held for more than two seconds. LED5 then flashes.

Note: Parameterization mode is exited automatically if the device is inactive for one

minute. In this case, the Vision Sensor reverts to normal mode and operates without the

settings having been changed.

• Place the parameterization code in the field of vision of the camera module. After the parameterization code is detected, the green LED4 lights up for one second. In the event of

an invalid parameterization code, LED4 lights up red for two seconds.

• Briefly pressing button 2 will end parameterization mode. Unsaved changes will be lost.

Release date: 2018-10-17 16:40 Date of issue: 2018-10-22 291103_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

Pepperl+Fuchs Group

3

Loading...

Loading...