Pepperl+Fuchs PCV-F200-SSI-V19 Series Manual

FACTORY AUTOMATION

MANUAL

PCV...-F200-SSI-V19

Data Matrix Positioning System

PCV...-F200-SSI-V19

With regard to the supply of products, the current issue of the following document is ap-

plicable: The General Terms of Delivery for Products and Services of the Electrical Indus-

try, published by the Central Association of the Electrical Industry (Zentralverband

Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the

supplementary clause: "Expanded reservation of proprietorship"

PCV...-F200-SSI-V19

1 Introduction................................................................................. 5

2 Declaration of conformity .......................................................... 6

2.1 CE conformity....................................................................................... 6

3 Safety........................................................................................... 7

3.1 Symbols relevant to safety.................................................................. 7

3.2 Intended use......................................................................................... 7

3.3 General safety instructions ................................................................. 7

4 Product Description ................................................................... 8

4.1 Use and Application............................................................................. 8

4.2 USB Interface........................................................................................ 8

4.3 SSI Interface ......................................................................................... 8

4.4 LED indicators and controls ............................................................... 9

4.5 Accessories ........................................................................................ 11

5 Installation................................................................................. 12

5.1 Installing the Code Reel .................................................................... 12

5.2 Mounting the Read Head................................................................... 15

5.3 Establishing the Electrical Connections ......................................... 17

6 Commissioning......................................................................... 20

6.1 Aligning the Read Head..................................................................... 20

6.2 Parameterizing ................................................................................... 20

6.2.1 Internal Parameterization Using Parameterization Software ............. 20

6.2.2 External parameterization using code cards .................................... 21

7 Operation and communication................................................ 23

7.1 Communication via the SSI Interface............................................... 23

7.2 Operating with event markers........................................................... 24

7.3 Operation with Repair Tape............................................................... 26

3

PCV...-F200-SSI-V19

8 Appendix ................................................................................... 27

8.1 Code Cards for External Parameterization ......................................27

8.1.1 Code Cards With Special Functions................................................. 27

8.1.2 Code cards for adjusting the output code......................................... 29

8.1.3 Code Cards for Adjusting the Resolution..........................................29

8.1.4 Code Cards for Setting the Orientation............................................. 30

8.1.5 Code cards for controlling image capture......................................... 31

8.1.6 Code cards for adjusting input / output 2 ..........................................32

8.1.7 Code cards for adjusting input / output 3 ..........................................34

4

PCV...-F200-SSI-V19

Introduction

1 Introduction

Congratulations

You have chosen a device manufactured by Pepperl+Fuchs. Pepperl+Fuchs develops,

produces and distributes electronic sensors and interface modules for the market of

automation technology on a worldwide scale.

Symbols used

The following sym bols are used in this manual:

Note!

This symbol draws your attention to important information.

Handling instructions

You will find handling instructions beside this symbol

Contact

If you have any questions about the device, its functions, or accessories, please contact us at:

Pepperl+Fuchs GmbH

Lilienthalstraße 200

68307 Mannheim

Telephone: +49 621 776-4411

Fax: +49 621 776-274411

E-Mail: fa-info@pepperl-fuchs.com

2015-09

5

PCV...-F200-SSI-V19

Declaration of conformity

2 Declaration of conformity

2.1 CE conformity

This product was developed and manufactured under observance of the applicable European

standards and guidelines.

Note!

A declaration of conformity can be requested from the manufacturer.

2015-09

6

PCV...-F200-SSI-V19

Safety

3 Safety

3.1 Symbols relevant to safety

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants, or result in

their complete failure.

3.2 Intended use

Combined with a code strip with printed Data Matrix codes, this device represents a highresolution positioning system that can be used in all applications where precision positioning is

required along extremely long travel paths, irrespective of whether the travel path is straight,

curved or with inclines or declines.

Read through these instructions thoroughly. Familiarize yourself with the device before

installing, mounting, or operating.

Always operate the device as described in these instructions to ensure that the device and

connected systems function correctly. The protection of operating personnel and plant is only

guaranteed if the device is operated in accordance with its intended use.

3.3 General safety instructions

Responsibility for planning, assembly, commissioning, operation, maintenance, and

dismounting lies with the plant operator.

Installation and commissioning of all devices must be performed by a trained professional only.

User modification and or repair are dangerous and will void the warranty and exclude the

manufacturer from any liability. If serious faults occur, stop using the device. Secure the device

against inadvertent operation. In the event of repairs, return the device to your local

Pepperl+Fuchs representative or sales office.

Note!

Disposal

Electronic waste is hazardous waste. When disposing of the equipment, observe the current

statutory requirements in the respective country of use, as well as local regulations.

2015-09

7

PCV...-F200-SSI-V19

Product Description

4 Product Description

4.1 Use and Application

The PCV read head is part of the positioning system in the Pepperl+Fuchs incident light

process. Its features include a cam era module and an integrated illum ination unit, enabling it to

detect position markers printed onto an adhesive code reel in the form of Data Matrix codes.

The code reel is usually mounted to a fixed part of the equipment in a stationary manner (e.g.,

elevator shaft, overhead conveyor mounting rails) and the read head is then mounted in parallel

to a moving "vehicle" (e.g., elevator car, overhead conveyor chassis).

Maximum Length of the Code Reel

Resolution of the Read Head [mm] Maximum Length of the Code Reel [km]

10 10

1 10

0.1 1.5

This positioning system can be used with an appropriate resolution in equipment with

extremely large layouts without restrictions.

The extensive yet user-friendly parameterization options as well as the freely configurable

inputs and outputs mean that the read head can easily be adapted to suit each application.

4.2 USB Interface

The user-friendly PCV Parameterization Tool can be used for extensive and optimum

configuration of the read head. This configuration software is available as a free download from

www.pepperl-fuchs.com. Follow the instructions that appear on your screen during the

installation.

You will need the parameterization cable (see Accessories) to establish a connection to the PC

(required for parameterization) and to set up an electrical power supply to the read head for

param eterization. The read head is connected to the "Service" connector.

Connecting the Service Interface

1. First connect the round plug connector to the read head.

2. Connect the plug-in power supply to the parameterization cable.

3. Plug the plug-in power supply into a socket.

The ring light of the read head and the "PWR/ADJ/ERR/NO CODE" LED2 lights up or

flashes.

4. You can now connect the USB plug-in connector to your PC.

4.3 SSI Interface

The controller and read head communicate via the SSI interface during operation. This is an

optically isolated RS422 interface. The controller sends a series of pulses via the clock+ and

clock- lines, and the read head responds synchronou sly with the 25-bit comprehensive

response telegram. You can define the structure and content of the response telegram using

the configuration software PCV Parameterization Tool.

This may include position data in an X- and Y-direction as well as speed and diagnostic data.

The read head is connected for communication via the SSI interface during live operation via

the "Main" connector.

2015-09

8

PCV...-F200-SSI-V19

COM

SSI DATA / CONFIG

OUT2 / ADJ Y

OUT3 / ADJ Z

PWR / ADJ

ERR / NO CODE

INTERNAL

DIAGNOSTIC

ADJUST

CONFIG

1

2

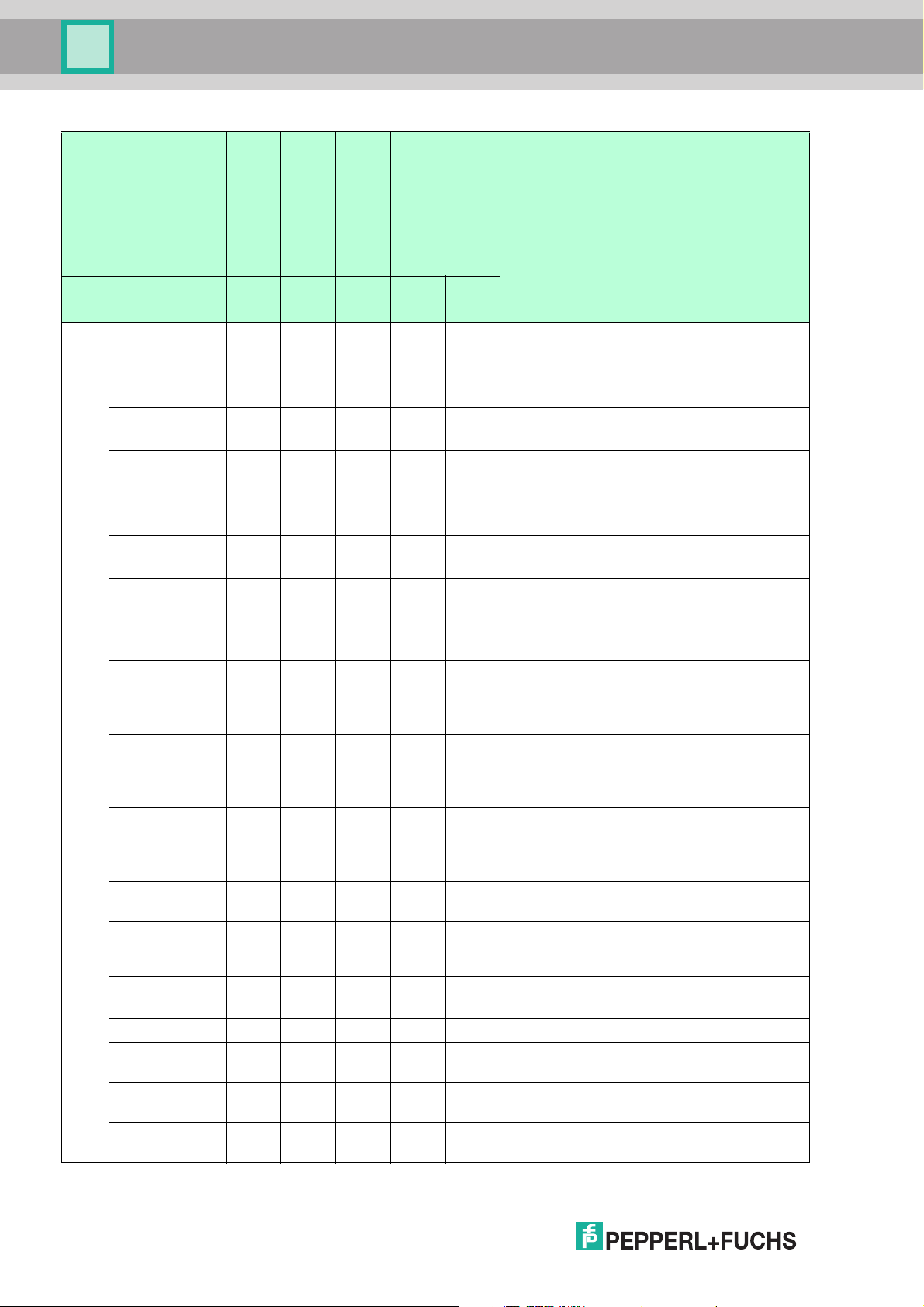

LED 1 2 3 4 5 6 7

Product Description

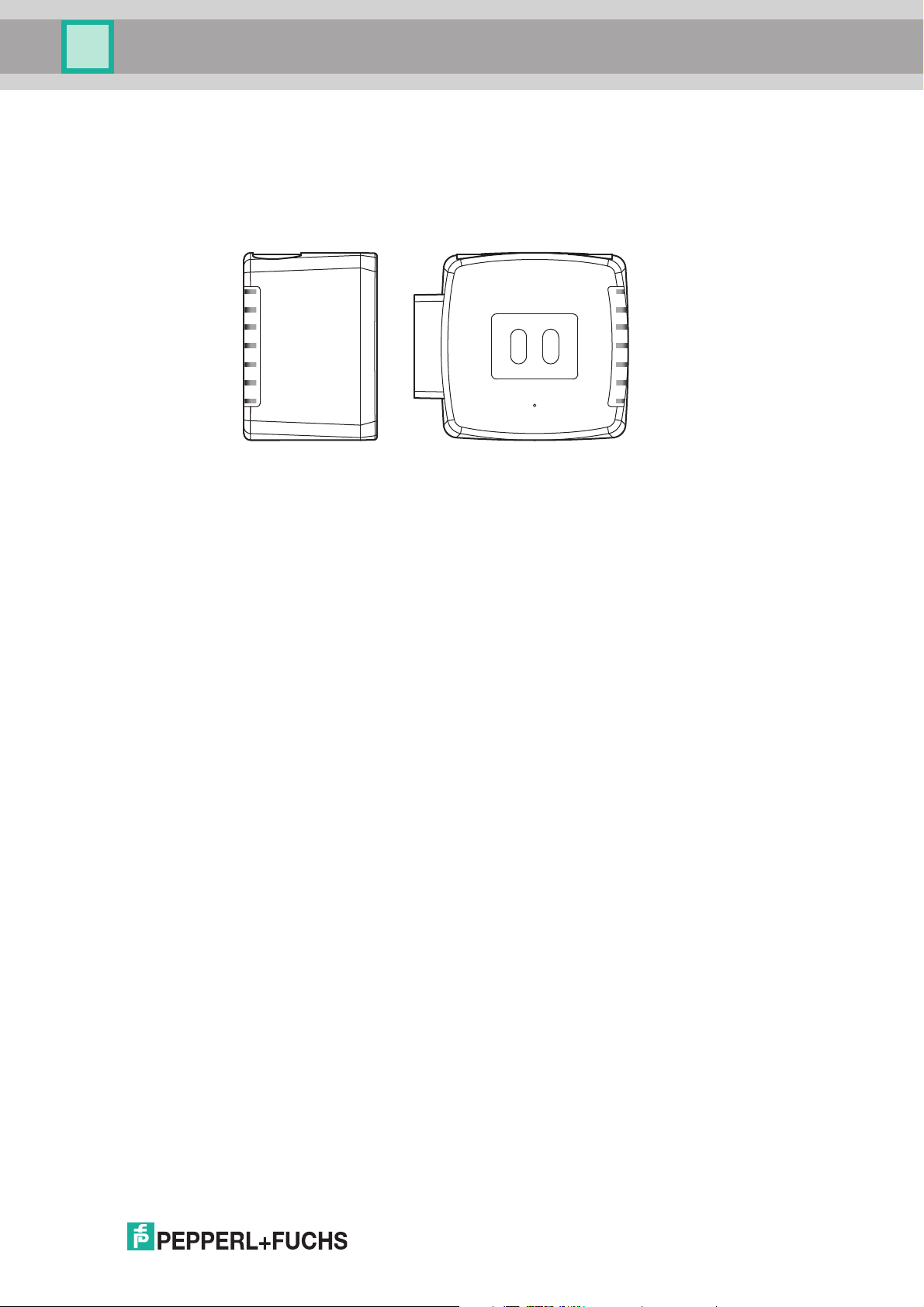

4.4 LED indicators and controls

The PCV... reading head is equipped with 7 indicator LEDs for performing visual function

checks and rapid diagnosis. For activating the alignment aid see chapter 6.1 and programming

mode, there are two buttons on the back of the reading head. ADJUST appears next to button

1 and CONFIG next to button 2.

2015-09

9

PCV...-F200-SSI-V19

Product Description

LED

[#1]

COM

[#2]

PWR / ADJ

ERR / NO CODE

[#3]

SSI DATA / CONFIG

[#4]

OUT 2 / ADJ Y

[#5]

OUT 3 / ADJ Z

green/re

d yellow yellow yellow yellow yellow

Flashes

Off

Off

Off

Off

Off

Off

Off

Off

green.

Flashes

green.

Flashes

green.

Flashes

green.

Flashes

green.

Flashes

green.

Flashes

red.

Lights

up red

Off Off Off Off Off

Off On Off Off Off

Off Flashes Off Off Off

Off Off Off Off Off

Off Off On Off Off

Off Off

Flashes

.

Off Off Off Off Off

Off Off Off Off Off

Lights

Off

up

Flashes x x Off Off

green.

State

Flashes

Off

Off

Flashes

red

Flashes

red

Flashes

red

Flashes x x Off Off

Off x x Off Off

Flashes FlashesFlashes Off Off

Off Off Flashes Off Off Off Off

Off Red, 3 sFlashes Off Off Off Off

Green,

Off

Flashes Off Off Off Off

1 s

x Off x x x Off Off Time lock for buttons disabled

Flashes Green Off Off Off Off Off

Flashes

Flashes

red

Off Off Off Off Off

x x x x x On On

[#6] +[#7]

Internal diagnostics

Off Off

DescriptionColor yellow

Alignment

Y > setpoint value; f

flash

= 2 Hz

Alignment

Y < setpoint value; f

flash

= 2 Hz

Alignment

Y = setpoint value; f

flash

= 2 Hz

Alignment

Z > setpoint value; f

flash

= 2 Hz

Alignment

Z < setpoint value; f

flash

= 2 Hz

Alignment

Z = setpoint value; f

flash

= 2 Hz

Alignment

Code strip outside read range; f

flash

= 2 Hz

System error

Normal mode, SSI communication active

f

= 2 Hz

flash

LEDs marked with x indicate the status of the

relevant output.

No code within read range, communication active

f

= 2 Hz

flash

LEDs marked with x indicate the status of the

relevant output.

No code within read range, no SSI

communication; f

flash

= 2 Hz

LEDs marked with x indicate the status of the

relevant output.

Normal operation. Displays for 2 s if a button

is pressed when the time lock is enabled.

Configuration mode active; f

Code card faulty; f

flash

= 2 Hz

flash

= 2 Hz

Code card detected

f

= 2 Hz

flash

Position detection via USB interface, code

within read range

Position detection via USB interface, no

code within read range

Internal error

Return to Pepperl+Fuchs

10

x = LED status has no meaning.

2015-09

PCV...-F200-SSI-V19

Product Description

4.5 Accessories

Compatible accessories offer enormous savings potential. Not only do you save a great deal of

time and work when commissioning, but also when replacing and servicing our products.

If harsh external environmental conditions prevail, appropriate Pepperl+Fuchs accessories can

extend the service life of the products used.

Model Number Description

V19-G-ABG-PG9-FE Grounding terminal and plug (set)

PCV-KBL-V19-STR-USB Cable unit for power supply

VAZ-V1S-B Cap for service connector

PCV-CM20-* Event marker

You can find the right connecting cable in the Accessories section of the read head data sheet

at http://www.pepperl-fuchs.com.

2015-09

11

PCV...-F200-SSI-V19

Installation

5 Installation

5.1 Installing the Code Reel

The code reel is made of silicone-free polyester film. A position marker appears every 100 mm

along the lower edge of the code reel (see "Dimensions, Code Reel"). This position marker is

used for various functions including precise positioning of the code reel during assembly.

The reverse side of the code reel carries a permanent modified acrylate-based adhesive. Affix

the self-adhesive code reel along the desired travel range. Proceed as follows:

Installing the Code Reel

1. Clean the surface of any greasy or oily deposits and dust.

2. Ensure that the surface is dry, clean, and stable.

3. Pull the protective foil at the beginning of the code reel a few centimeters forward. Place the

code reel at the precise point of the required starting position on the underside, and press to

attach.

4. Then affix the code reel along the desired travel range. Remove the protective film gradually

so that the code reel does not accidentally adhere to the surface in the incorrect position.

When affixing, ensure that the code reel does not crease or trap air bubbles.

The adhesive on the code reel hardens after 72 hours.

Note!

Thermal Expansion of the Code Reel

The heat expansion coefficient of the attached code reel corresponds to the heat expansion

coefficient of the underside.

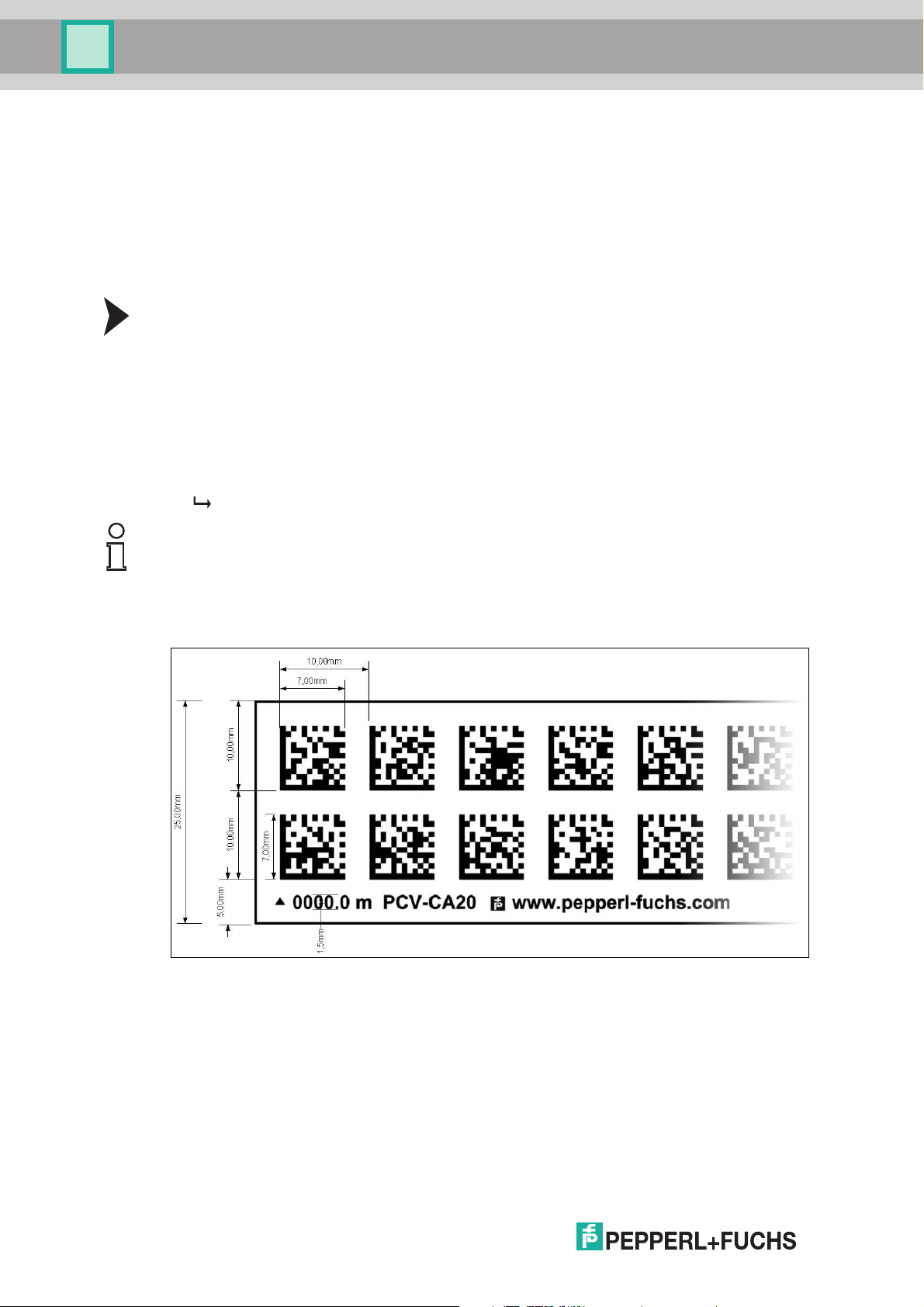

Dimensions, Code Reel

12

Figure 5.1

2015-09

Loading...

Loading...