Page 1

FACTORY AUTOMATION

MANUAL

PCV...-F200-B25-V1D

Data Matrix Positioning System

Page 2

PCV...-F200-B25-V1D

With regard to the supply of products, the current issue of the following document is ap-

plicable: The General Terms of Delivery for Products and Services of the Electrical Indus-

try, published by the Central Association of the Electrical Industry (Zentralverband

Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the

supplementary clause: "Expanded reservation of proprietorship"

Page 3

PCV...-F200-B25-V1D

1 Introduction................................................................................. 5

2 Declaration of conformity .......................................................... 6

2.1 CE conformity....................................................................................... 6

3 Safety........................................................................................... 7

3.1 Symbols relevant to safety.................................................................. 7

3.2 Intended use......................................................................................... 7

3.3 General safety instructions ................................................................. 7

4 Product Description ................................................................... 8

4.1 Use and Application............................................................................. 8

4.2 USB Interface........................................................................................ 8

4.3 EtherNet/IP Interface Pin Assignment .............................................. 8

4.4 LED Indicators and Controls............................................................... 8

4.5 Accessories ........................................................................................ 11

5 Installation................................................................................. 12

5.1 Installing the Code Reel .................................................................... 12

5.2 Mounting the Read Head................................................................... 15

5.3 Electrical Connection ........................................................................ 17

5.4 EtherNet/IP Connection..................................................................... 19

6 Commissioning......................................................................... 20

6.1 Aligning the Read Head..................................................................... 20

6.2 Parameterizing ................................................................................... 20

6.2.1 Internal Programming With Vision Configurator Software................. 20

6.2.2 External Parameterization Using Code Cards .................................. 21

3

Page 4

PCV...-F200-B25-V1D

7 Operation and communication................................................ 23

7.1 Communication via EtherNet/IP........................................................23

7.1.1 General Information on Communication via EtherNet/IP ................... 23

7.1.2 Setting the IP Address......................................................................23

7.1.3 EtherNet/IP objects .......................................................................... 26

7.1.4 Attributes of the Ethernet/Read Head IP Objects.............................. 27

7.2 Operation with Repair Tape ...............................................................33

7.3 Operating with event markers ...........................................................33

8 Appendix ................................................................................... 35

8.1 Code Cards for External Parameterization ......................................35

8.1.1 Code Cards With Special Functions................................................. 35

8.1.2 Code Cards for Adjusting the Resolution.......................................... 37

8.1.3 Code Cards for Setting the Orientation.............................................38

8.1.4 Code Cards for Adjusting Output 1................................................... 39

8.1.5 Code Cards for Adjusting Output 2................................................... 41

8.1.6 Code Cards for Adjusting Output 3................................................... 43

8.2 ASCII table...........................................................................................45

4

Page 5

PCV...-F200-B25-V1D

Introduction

1 Introduction

Congratulations

You have chosen a device manufactured by Pepperl+Fuchs. Pepperl+Fuchs develops,

produces and distributes electronic sensors and interface modules for the market of

automation technology on a worldwide scale.

Symbols used

The following sym bols are used in this manual:

Note!

This symbol draws your attention to important information.

Handling instructions

You will find handling instructions beside this symbol

Contact

If you have any questions about the device, its functions, or accessories, please contact us at:

Pepperl+Fuchs GmbH

Lilienthalstraße 200

68307 Mannheim

Telephone: +49 621 776-4411

Fax: +49 621 776-274411

E-Mail: fa-info@pepperl-fuchs.com

2015-09

5

Page 6

PCV...-F200-B25-V1D

Declaration of conformity

2 Declaration of conformity

2.1 CE conformity

This product was developed and manufactured under observance of the applicable European

standards and guidelines.

Note!

A declaration of conformity can be requested from the manufacturer.

2015-09

6

Page 7

PCV...-F200-B25-V1D

Safety

3 Safety

3.1 Symbols relevant to safety

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants, or result in

their complete failure.

3.2 Intended use

Combined with a code strip with printed Data Matrix codes, this device represents a highresolution positioning system that can be used in all applications where precision positioning is

required along extremely long travel paths, irrespective of whether the travel path is straight,

curved or with inclines or declines.

Read through these instructions thoroughly. Familiarize yourself with the device before

installing, mounting, or operating.

Always operate the device as described in these instructions to ensure that the device and

connected systems function correctly. The protection of operating personnel and plant is only

guaranteed if the device is operated in accordance with its intended use.

3.3 General safety instructions

Responsibility for planning, assembly, commissioning, operation, maintenance, and

dismounting lies with the plant operator.

Installation and commissioning of all devices must be performed by a trained professional only.

User modification and or repair are dangerous and will void the warranty and exclude the

manufacturer from any liability. If serious faults occur, stop using the device. Secure the device

against inadvertent operation. In the event of repairs, return the device to your local

Pepperl+Fuchs representative or sales office.

Note!

Disposal

Electronic waste is hazardous waste. When disposing of the equipment, observe the current

statutory requirements in the respective country of use, as well as local regulations.

2015-09

7

Page 8

PCV...-F200-B25-V1D

Product Description

4 Product Description

4.1 Use and Application

The PCV read head is part of the positioning system in the Pepperl+Fuchs incident light

process. Its features include a cam era module and an integrated illum ination unit, enabling it to

detect position markers printed onto an adhesive code reel in the form of Data Matrix codes.

The code reel is usually mounted to a fixed part of the equipment in a stationary manner (e.g.,

elevator shaft, overhead conveyor mounting rails) and the read head is then mounted in parallel

to a moving "vehicle" (e.g., elevator car, overhead conveyor chassis).

Maximum Length of the Code Tape

Resolution of the read head [mm] Maximum length of the code tape [km]

10 10

1 10

0.1 10

This positioning system can be used with an appropriate resolution in equipment with

extremely large layouts without restrictions.

The extensive yet user-friendly parameterization options as well as the freely configurable

inputs and outputs mean that the read head can easily be adapted to suit each application.

4.2 USB Interface

The Vision Configurator is a useful and easy-to-use piece of software for configuring the read

head. This configuration software is available as a free download from www.pepperlfuchs.com. Follow the instructions that appear on your screen during the installation.

The PC connection required for programming and the read head power supply can be made

using a special parameterization cable. This parameterization cable can be ordered as an

accessory under the name "Cable unit for service interface with the power supply". This also

provides the electrical supply to the read head. The parameterization cable is connected to the

read head using the "Main" connector.

Connection of the Parameterization Cable

1. First connect the round plug connector to the read head.

2. Connect the plug-in power supply to the parameterization cable.

3. Plug the plug-in power supply into a socket.

The ring light of the read head and the "PWR/ADJ/ERR/NO CODE" LED2 lights up or

flashes.

4. You can now connect the USB plug-in connector to your PC.

4.3 EtherNet/IP Interface Pin Assignment

The controller and read head communicate via the EtherNet/IP interface during operation. The

interface is based on Ethernet technology and works according to the CIP protocol (Common

Industrial Protocol).

The connection of the read head in ongoing operation is carried out via the "EtherNet/IP 1 & 2"

connectors.

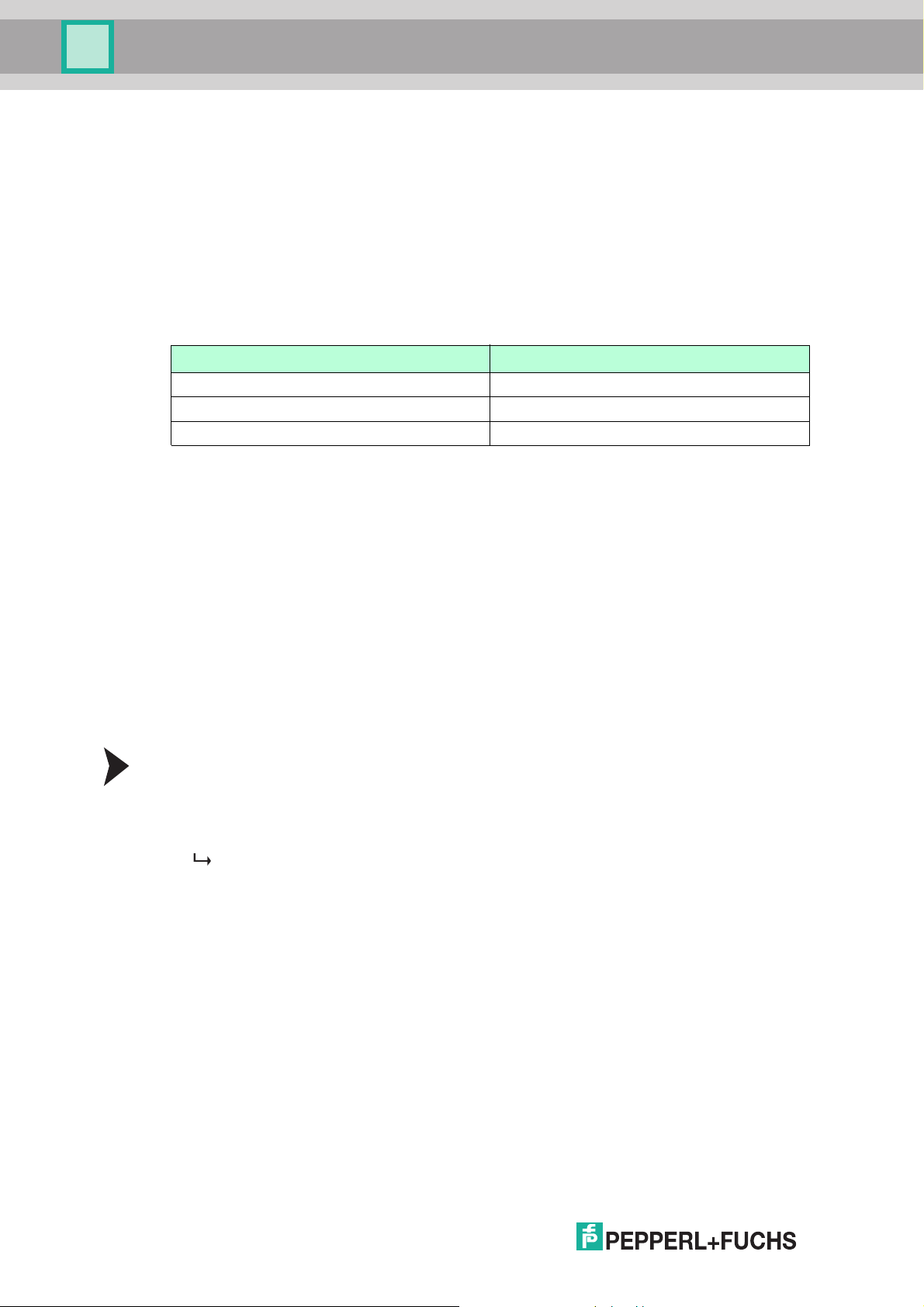

4.4 LED Indicators and Controls

The PCV... read head is equipped with 6 indicator LEDs for performing visual function checks

and rapid diagnostics. The read head is equipped with 2 buttons on the back of the device for

activating the alignment aid (see chapter 6.1) and the parameterization mode. Button 1 is

labeled ADJUST. Button 2 is labeled CONFIG.

8

2015-09

Page 9

PCV...-F200-B25-V1D

ADJUST

CONFIG

1

2

LED 1 2 3 4 5 6

Product Description

Figure 4.1

2015-09

9

Page 10

PCV...-F200-B25-V1D

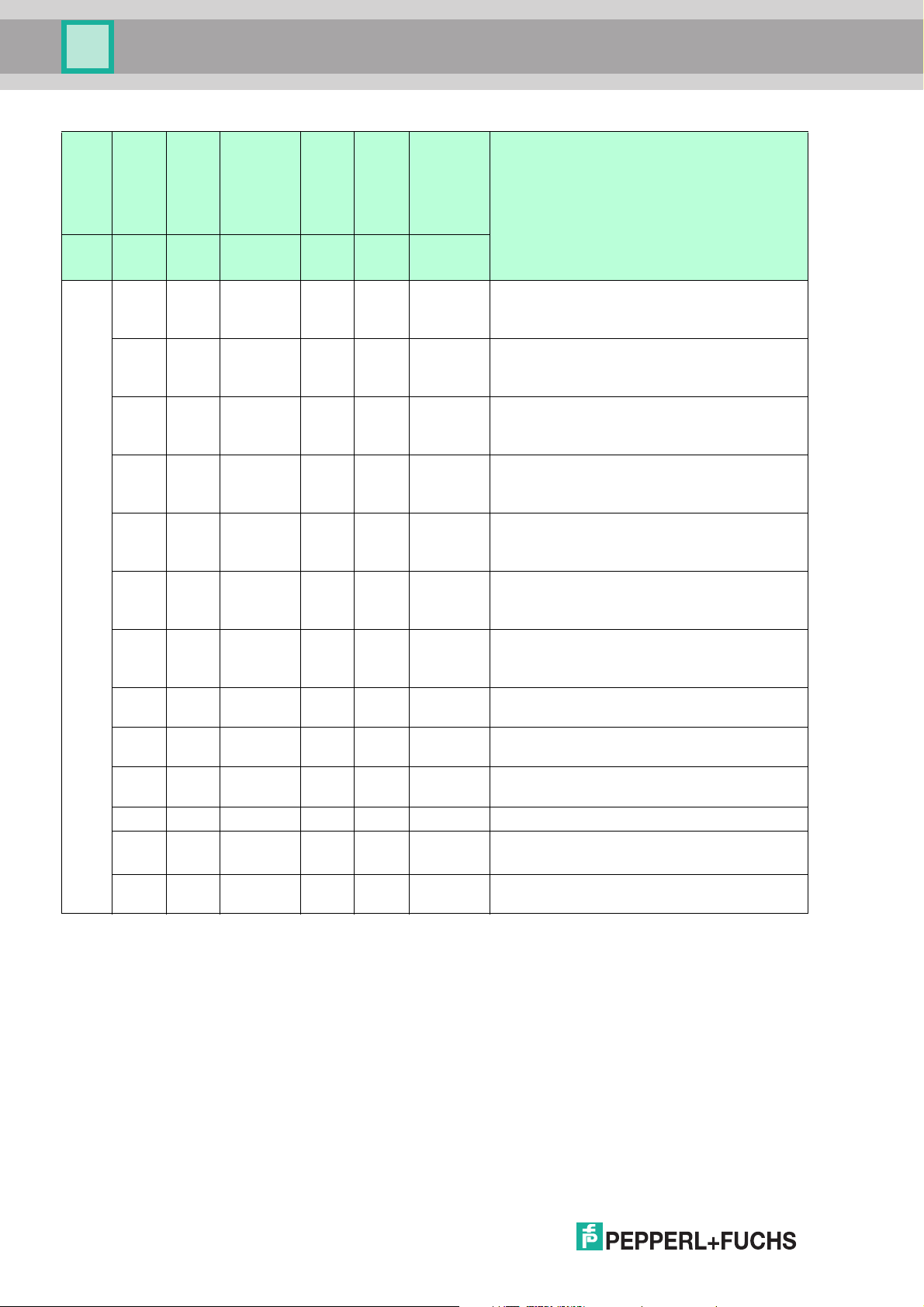

Product Description

LED

[#1]

BUS LINK

[#2]

BUS TX / RX

[#3]

PWR/ADJ

SYSERR/NO

CODE

[#4]

OUT 1/ADJ Y

[#5]

OUT 2/ADJ Z

[#6]

INTERNAL

DIAGNOSTIC

Red/green/

DescriptionColor Green Yellow Red/green Yellow Yellow

Alignment

Y > setpoint value

f

= 2 Hz

flash

Alignment

Y < setpoint value

f

= 2 Hz

flash

Alignment

Y = setpoint value

f

= 2 Hz

flash

Alignment

Z > setpoint value

f

= 2 Hz

flash

Alignment

Z < setpoint value

f

= 2 Hz

flash

Alignment

Z = setpoint value

f

= 2 Hz

flash

Status

Off Off

Off Off

Off Off

Off Off

Off Off

Off Off

Flashes

green

Flashes

green

Flashes

green

Flashes

green

Flashes

green

Flashes

green

yellow

Off Off Off

Lights

up

Off Off

Flashes Off Off

Off Off Off

Lights

Off

up

Off

Off Flashes Off

Alignment

Off Off Flashes red Off Off Off

x x

x x

Lights

up

Lights up

red

Lights up

green

x x x

x x x

x x x x x

Code tape outside read range

f

= 2 Hz

flash

System error

Normal operation, code tape detected

EtherNet/IP-connection active

x Flashes x x x x EtherNet/IP TX/RX data transfer

x x Flashes red x x x

x x x x On On

Code not recognized

f

= 2 Hz

flash

Internal error

Return to Pepperl+Fuchs

10

x = LED status has no meaning

2015-09

Page 11

PCV...-F200-B25-V1D

Product Description

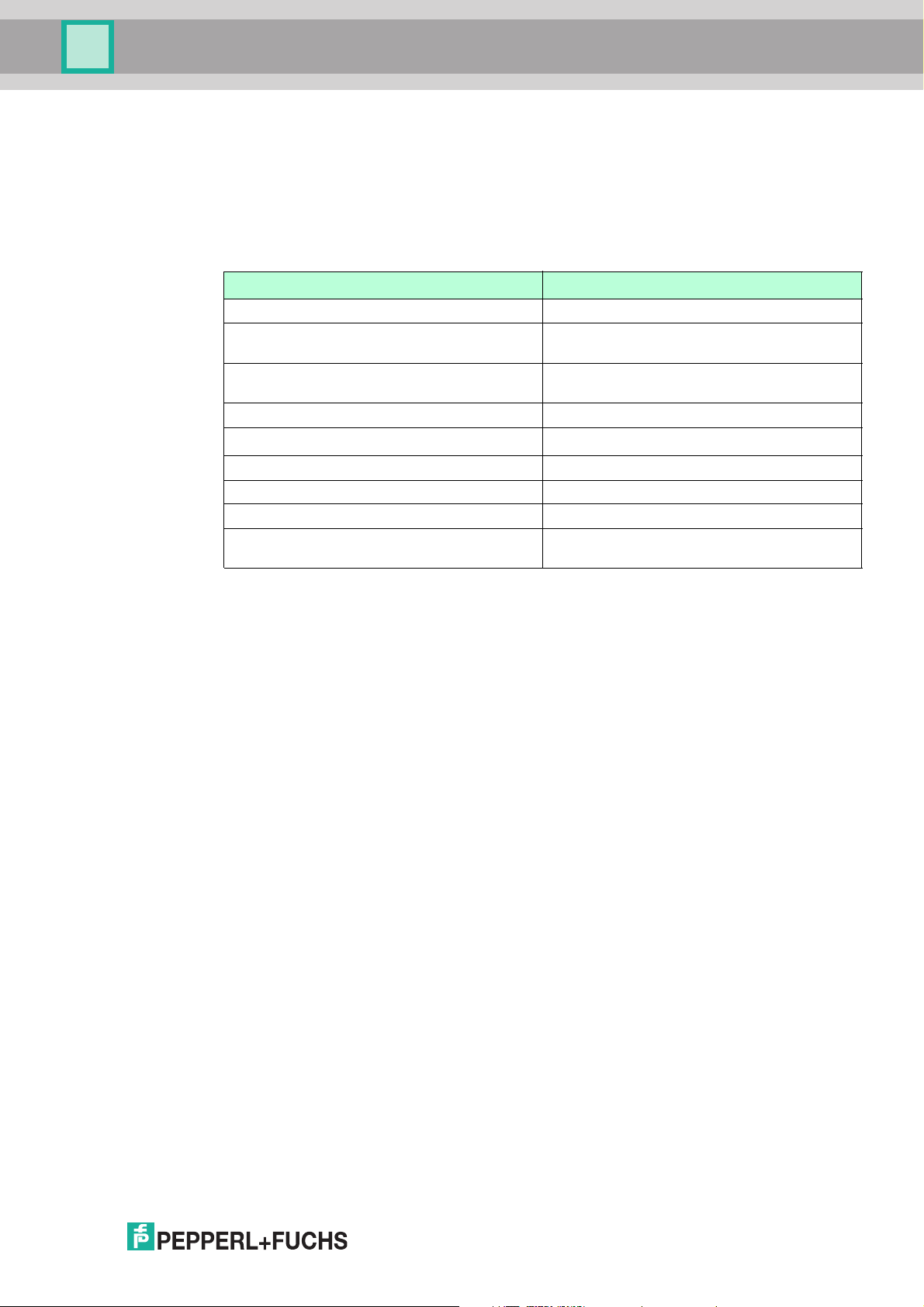

4.5 Accessories

Compatible accessories offer enormous potential for cost savings. Such accessories not only

save you a great deal of time and effort when commissioning for the first time, but also when

replacing and servicing our products.

If products are used in harsh ambient conditions, appropriate Pepperl+Fuchs accessories can

be used to extend the service life of these products.

Model number Description

V19-G-ABG-PG9-FE Grounding terminal and plug (set)

PCV-SC12

PCV-SC12A

V1SD-G-*M-PUR-ABG-V1SD-G Ethernet bus cable, M12 to M12, available in

VAZ-V1S-B Stopping plug for M12 connector

V19-G-*M-*

PCV-CM20-0* Event marker

PCV-CR20 Repair tape

PCV-KBL-V19-STR-USB Cable unit for power supply

Vision Configurator Software Software for camera-based sensors for

Grounding clip

several different lengths

Configurable connection cable

convenient programming

1)

1)

: Ask your contact person at Pepperl+Fuchs

2015-09

11

Page 12

PCV...-F200-B25-V1D

Installation

5 Installation

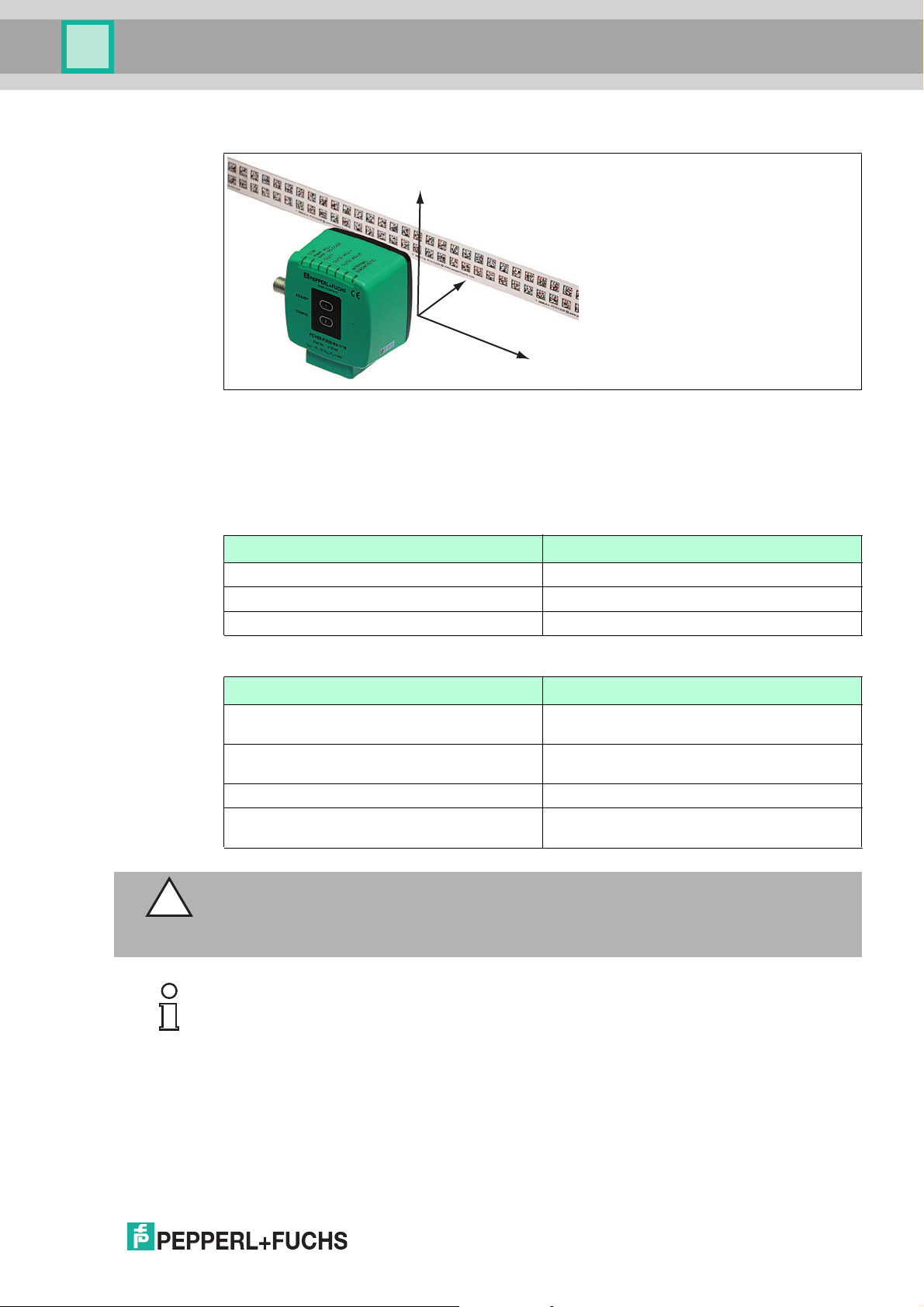

5.1 Installing the Code Reel

The code reel is made of silicone-free polyester film. A position marker appears every 100 mm

along the lower edge of the code reel (see "Dimensions, Code Reel"). This position marker is

used for various functions including precise positioning of the code reel during assembly.

The reverse side of the code reel carries a permanent modified acrylate-based adhesive. Affix

the self-adhesive code reel along the desired travel range. Proceed as follows:

Installing the Code Reel

1. Clean the surface of any greasy or oily deposits and dust.

2. Ensure that the surface is dry, clean, and stable.

3. Pull the protective foil at the beginning of the code reel a few centimeters forward. Place the

code reel at the precise point of the required starting position on the underside, and press to

attach.

4. Then affix the code reel along the desired travel range. Remove the protective film gradually

so that the code reel does not accidentally adhere to the surface in the incorrect position.

When affixing, ensure that the code reel does not crease or trap air bubbles.

The adhesive on the code reel hardens after 72 hours.

Note!

Thermal Expansion of the Code Reel

The heat expansion coefficient of the attached code reel corresponds to the heat expansion

coefficient of the underside.

Dimensions, Code Reel

12

Figure 5.1

2015-09

Page 13

PCV...-F200-B25-V1D

Y

Z

X

Installation

Orientation of the Code Reel and Read Head

Figure 5.2

Position the code reel so that the ww w.pepperl-fuchs.com label and the position markings

are below the data matrix code. The position values then increase along the X-direction. The

diagram shows the orientation of a read head in the default position of 0°. The read head can

be configured in the interface for other installation situations.

Code Reels with a Starting Position of 0 m

Model Number Description

PCV6M-CA20-0 Code reel, 2-track, length: 6 m

... ...

PCV100M-CA20-0 Code reel, 2-track, length: 100 m

Code Reels with Different Starting Positions

Model Number Description

PCV100M-CA20-0 Code reel, 2-track, length: 100 m, starting

position: 0 m

PCV100M-CA20-10000 Code reel, 2-track, length: 100 m, starting

position: 100 m

... ...

PCV100M-CA20-990000 Code reel, 2-track, length: 100 m, starting

position: 9,900 m

Caution!

Stop Edges

If you attach another code reel at the end of a previous code reel, the code pattern of 10 mm

must be retained.

Note!

Expansion Joints

If the system covers longer distances, expansion joints are integrated in the system structure.

We recommend creating breaks along the code reel. The resulting gaps should be 20 mm (2

code grids).

2015-09

13

Page 14

PCV...-F200-B25-V1D

Installation

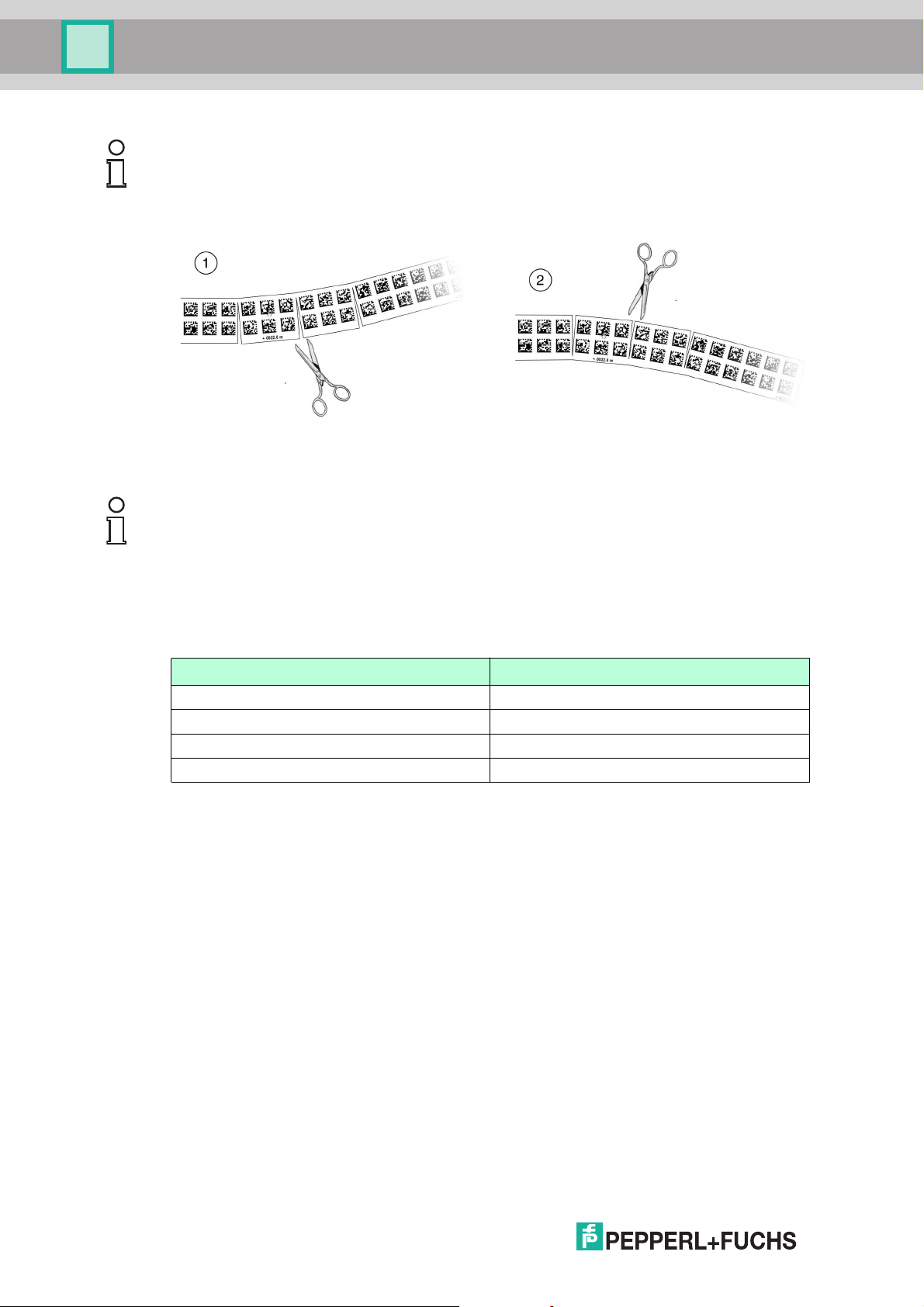

Note!

Inclines and Declines

If you mount the code reel on inclines or declines, cut the code reel several times at the

transition point to the horizontal as shown.

1. Incline

2. Decline

Note!

Code Reels with Different Row Numbers

The PCV-CA20 code reel has two rows of code to compensate for slight deviations in the travel

range in the Y-direction. The code reel is also available with other row numbers. The order code

for the code reel is PCV-CAx0, whereby x represents the number of rows of code, which can be

either 1 or 2. More rows are available on request–contact us for more information.

Code Reels with Different Numbers of Tracks

Model Number Description

PCV*M-CA10-* Code reel, 1-track

PCV*M-CA20-* Code reel, 2-track

PCV*M-CA40-* Code reel, 4-track

... ...

14

2015-09

Page 15

PCV...-F200-B25-V1D

Y

0

X

Y

0

X

Installation

Hysteresis Y-Axis

Figure 5.3 Zero line for code reels

If the read head leaves the zero line when traveling the X-axis, different threshold values will

result depending on the number of tracks. If the deviation exceeds this threshold, a warning

code is issued.

Y-Axis Deviation Thresholds

Code reel Threshold

Number of tracks Width Exit Entry

1 15 mm ± 10 mm ± 6 mm

2 25 mm ± 15 mm ± 11 mm

4 45 mm ± 25 mm ± 21 mm

6 65 mm ± 35 mm ± 31 mm

8 85 mm ± 45 mm ± 41 mm

5.2 Mounting the Read Head

Mount the PCV... read head on the moving part of your equipment using the four screws on the

mounting adapter of the read head. Mount the read head in such a way that the lens with ring

2015-09

light and camera module are aligned toward the code tape.

The stability of the mounting and the guidance of the moving system component must be such

that the field of the depth of focus of the read head is not exited during operation.

The distance between the read head and the code tape should be the same as the read

distance of the read head.

15

Page 16

PCV...-F200-B25-V1D

Read distance

Code reel

10°

10°

Read distance

10°

10°

Installation

Figure 5.4 Vertical alignment tolerance

16

Figure 5.5 Horizontal alignment tolerance

Optimum Read Distance (Z-Axis)

Model Number Read Distance [mm] Depth of Focus [mm]

PCV50* 50 ± 25

PCV80* 80 ± 15

PCV100* 100 ± 20

PCV100*-...-6011 100 ± 40

2015-09

Page 17

PCV...-F200-B25-V1D

70

80

38.5

70 14.5

1

2

22

51

ø 25

12

M12 x 1

9

4 x M6

20 20

1

2

3

4

5

6

7

8

OUT 2 / IN 2

+ UB

USB_DM

USB_DP

OUT 1

IN 1

GND

OUT 3 / IN 3

Main

Installation

Read Head Dimensions

Figure 5.6

Caution!

When selecting mounting screws, ensure that the maximum insertion depth of the screws in

the threaded inserts on the read head is 8 m m.

Using longer screws can damage the read head.

Caution!

The maximum torque of the mounting screws must not exceed 9 Nm.

Tightening the screws to a higher torque can damage the read head.

5.3 Electrical Connection

The PCV... read head is connected electrically via an 8-pin M12 x 1 connector on the side of

the housing. The power supply and communication with peripheral devices are established via

this connection. The configurable inputs and outputs on the read head are also located at this

connection.

The port also serves as a service interface for programming the read head (see "USB

interface" in this manual).

2015-09

Figure 5.7

17

Page 18

PCV...-F200-B25-V1D

1

4

6

7

8

53

2

Main

Installation

Connector Occupancy

Figure 5.8

Color Assignment

Pepperl+Fuchs cordsets (female) are manufactured in accordance with EN60947-5-2. When

using a type V19-... () female cordset with an open cable end on the Main connection, the

colors are assigned as follows:

Connection pin Strand color Color abbreviation

1 White WH

2 Brown BN

3 Green GN

4 Yellow YE

5 Gray GY

6 Pink PK

7 Blue BU

8 Red RD

Shielding Cables

The shielding of connection lines is required to suppress electromagnetic interference.

Establishing a low resistance or low impedance connection with the conductor or equipotential

bonding circuit is a particularly important factor in ensuring that these interference currents do

not become a source of interference themselves. Always use connection lines with braided

shield; never use connection lines with a film shield. The shield is integrated at both ends, i.e.,

in the switch cabinet or on the controller and on the read head. The grounding terminal

available as an accessory allows easy integration in the equipotential bonding circuit.

In exceptional cases, the shielding of a connection at one end may be more favorable if

■

An equipotential bonding cable is not laid or cannot be laid.

■

A film shield is used.

The following points relating to shielding m ust also be noted:

■

Use metal cable clips that cover large areas of the shield.

■

After installing the cable shield in the control cabinet, place it directly on the equipotential

bonding rail.

■

Direct the protective grounding connections to a common point in a star configuration.

■

The cross-section of the cables used for grounding should be as large as possible.

Additional Ground Connection

Model number Description

PCV-SC12 Clip for mounting an additional ground

PCV-SC12A

connection.

2015-09

18

Page 19

PCV...-F200-B25-V1D

1

2

3

4

TX +

RX +

TX -

RX -

Bus

EtherNet/IP 1 & 2

1

3

4

2

Installation

Caution!

Damage to the device

Connecting an alternating current or excessive supply voltage can damage the device or cause

the device to malfunction.

Electrical connections with reversed polarity can damage the device or cause the device to

malfunction.

Connect the device to direct current (DC). Ensure that the supply voltage rating is within the

specified device range. Ensure that the connecting wires on the female cordset are connected

correctly.

5.4 EtherNet/IP Connection

The PCV... read head is connected to EtherNet/IP via two 4-pin, D-coded device sockets, M12

x 1, EtherNet/IP 1 and EtherNet/IP 2, on the side of the housing.

Figure 5.9

Connector Occupancy

Figure 5.10

For suitable Ethernet cables, see see chapter 4.5.

2015-09

19

Page 20

PCV...-F200-B25-V1D

Y

Z

X

Commissioning

6 Commissioning

6.1 Aligning the Read Head

An integrated alignment aid is available to help you align the Y and Z coordinates of the read

head easily and precisely with respect to the code reel.

Note!

The activation of the alignment aid is possible only within 10 minutes of switching on the read

head.

The switchover from normal operation to param eterization mode is via button 1 on the back of

the read head.

Activating the Alignment Aid

1. Press button 1 for longer than 2 seconds.

LED2 flashes green for a recognized code reel. LED2 flashes red for an unrecognized

code reel. .

2. Align the Z and Y coordinates of the read head. The integral LED indicators provide

assistance here.

Z coordinate: If the distance of the camera to the code reel is too small, the yellow LED5 lights

up. If the distance is too great, the yellow LED5 goes out. The yellow LED5 flashes at the same

time as the green LED2 when within the target range. .

Set the distance between the read head and the code reel so that the yellow LED5 and the

green LED2 flash synchronously.

Y coordinate: If the optical axis of the read head is too low relative to the middle of the code

reel, the yellow LED4 lights up, . If the optical axis is too high, the yellow LED4 goes out. Within

the target range, the yellow LED4 flashes at the same time as the green LED2.

Set the optimal height of the read head relative to the code reel so that the yellow LED4 flashes

in rhythm with the green LED2.

Briefly pressing button 1 ends the alignment aid, and the read head returns to normal

operation.

6.2 Parameterizing

The PCV... reading head can be adapted to specific requirements through parameterization.

The reading head can be parameterized via the service interface (internal parameterization) or

via optical parameterization codes (external parameterization).

6.2.1 Internal Programming With Vision Configurator Software

Internal parameterization of the read head via the USB interface must be started within 10

minutes of the read head being switched on. A time lock disables the read head once this time

has elapsed. The time lock remains inactive during the parameterization process. The time

lock disables the read head only if no parameterization activities take place for more than 10

minutes.

2015-09

20

Page 21

PCV...-F200-B25-V1D

Commissioning

The Vision Configurator is a useful and easy-to-use piece of software for configuring the read

head. This configuration software is available as a free download from ww w.pepperlfuchs.com. Follow the instructions that appear on your screen during the installation.

The PC connection required for programming and the read head power supply can be m ade

using a special parameterization cable. This parameterization cable can be ordered as an

accessory under the name "Cable unit for service interface with the power supply". This also

provides the electrical supply to the read head. The parameterization cable is connected to the

read head using the "Main" connector.

Connection of the Parameterization Cable

1. First connect the round plug connector to the read head.

2. Connect the plug-in power supply to the parameterization cable.

3. Plug the plug-in power supply into a socket.

The ring light of the read head and the "PWR/ADJ/ERR/NO CODE" LED2 lights up or

flashes.

4. You can now connect the USB plug-in connector to your PC.

Parameterizing the read head

1. Start the Vision Configurator software on the PC.

2. Program the read head with the help of the "Vision Configurator" m anual.

3. Transfer the parameter list to the read head.

4. Save the parameterization.

5. Unplug the plug-in power supply from the wall outlet to turn off the power supply at the head.

6. Remove the parameterization cable's USB plug-in connector from your PC

7. Remove the configuration cable from the read head.

The read head is now parameterized according to your specifications and can be used in

your application.

6.2.2 External Parameterization Using Code Cards

During external parameterization, the read head scans special code cards optically and

configures the relevant parameters. Simply hold the corresponding code cards at the correct

distance in front of the lens on the PCV...-F200- read head. The standard code cards are

contained in the appendix.

The following param eters can be configured using code cards:

■

Read head resolution [0.1 mm, 1 mm, 10 mm]

■

Read head orientation [0° ; 180°; 0° or 180°, 0°, 90°, 180° or 270°]

■

Function of output 1 [none, speed exceeded, warning, fault, contamination, event, no

position]

■

Function of output 2 [none, speed exceeded, warning, fault, contamination, event, no

position]

■

Function of output 3 [none, speed exceeded, warning, fault, contamination, event, no

position]

2015-09

21

Page 22

PCV...-F200-B25-V1D

Commissioning

Programming mode activation

Note!

External parameterization of the read head using code cards must be started within 10 minutes

of the read head switching on. A time lock disables the read head once this time has elapsed.

The time lock remains inactive during the parameterization process. The time lock disables the

read head only if no parameterization activities take place for m ore than 10 minutes.

If a button is pressed when the time lock is enabled, all LEDs flash and remain lit for 2 seconds

during each flashing cycle.

The switchover from normal mode to parameterization mode is made by pressing button 2 on

the back of the read head.

Parameterization Mode Activation

1. Press button 2 for longer than 2 s.

Yellow LED3 now flashes.

2. Hold the "ENABLE" code in front of the camera system on the read head to trigger final

activation

If the "EN ABLE" activation code is detected, the green LED2 lights up for 1 sec. If the

activation code is not detected, LED2 lights up red for 2 seconds.

Parameterization

Place the parameterization code in the field of vision of the camera module.

After the parameterization code is detected, the green LED2 lights up for 1 sec. In the event

of an invalid parameterization code, LED2 lights up red for 2 seconds.

Exiting Parameterization Mode

Hold the "STORE" code in front of the cam era system on the read head to save the

configuration

When the "STORE" memory code is detected, the green LED2 lights up for 1 sec. The

param eterization is stored in the nonvolatile memory of the read head and param eterization

mode is terminated. Parameterization of the read head is now complete. If the memory code is

not detected, LED2 lights up red for 2 seconds.

Note!

Press button 2 briefly to exit parameterization mode. Any parameter changes that are made but

have not yet been saved are discarded. The read head operates with the last valid parameters

that were saved.

The code cards "CANCEL", "USE", and "DEFAULT"

Holding one of these cards in front of the reading head exits parameterization mode with the

following consequences:

■

CANCEL:

All parameter changes that are made but have not yet been saved are discarded. The

reading head operates with the last valid parameters that were saved.

■

USE:

22

For test purposes, the reading head operates with the parameters that have just been

modified. The parameterization is not saved, however. After being switched off and on

again, the reading head operates with the last valid parameters that were saved.

■

DEFAULT:

All parameters in the reading head are overwritten with the original default settings. Reenter the configuration mode and save the default settings nonvolatile with the code card

STORE.

2015-09

Page 23

PCV...-F200-B25-V1D

Operation and communication

7 Operation and communication

7.1 Communication via EtherNet/IP

7.1.1 General Information on Communication via EtherNet/IP

The read head communicates with the controller (e.g., PLC) via EtherNet/IP. An object-oriented

fieldbus system for exchanging data between nodes based on Ethernet technology.

The management and development of the EtherNet/IP standards are subject to the Open

DeviceNet Vendor Association (ODVA). More information on EtherNet/IP will be supplied on

request by the Open DeviceNet Vendor Association (ODVA) at the following Internet address:

ODVA, Inc

4220 Varsity Drive, Suite A

Ann Arbor, MI 48108-5006 USA

http://www.odva.org e-mail: mailto:odva@odva.org

The basic properties of the interface are:

■

Transfer rate 10 Mbit/s or 100 Mbit/s, half or full duplex operation

■

Automatic negotiation of the transfer rate and the duplex method (auto-negotiation)

■

Automatic setting for crossed lines (auto-crossover)

EtherNet/IP protocol works according to the CIP protocol (Common Industrial Protocol) and is

used to control, configure, monitor, and collect data. Time-sensitive data exchange (implicit

messaging) takes place using the UDP/IP protocol and non-time-sensitive data exchange

(explicit messaging) using the TCP/IP protocol.

The read head supports the following features:

■

"Listen only", "Input only", and "Exclusive Owner" connection types

■

Message transmission as "Multipoint data transfer" (Multicast) and "Point-to-point data

transfer" (Unicast)

■

Cycle time (request packet interval) ≥ 2 ms

■

Dynamic Host Configuration Protocol (DHCP)

■

Device Level Ring (DLR)

■

Address Conflict Detection (ACD)

The read head is integrated in the network via a EDS file (electronic data sheet) with a

configuration tool such as RSLOGIX5000. The EDS file contains all of the information about

device-specific parameters and operating modes.

Downloading the EDS file

You can find the relevant EDS file in the Software section of the product detail page for the

device.

To access the product detail page for the device, go to http://www.pepperl-fuchs.com and type

information about the device (e.g., the product description or the item number) into the search

function.

7.1.2 Setting the IP Address

The read head is delivered in DHCP mode and waits for an address assignment from the

control system.

The following section describes the address assignment via the software BOOT/DHCP server

from Rockwell Automation as an example.

2015-09

23

Page 24

PCV...-F200-B25-V1D

Operation and communication

1. Connect the read head with the DHCP server.

2. Start the BOOT/DHCP server software.

3. Enter the following data in the Network Settings menu:

- Subnet Mask "255.255.255.0 "

- Gateway "192.168.1.1"

- the remaining fields are not filled in.

4. Switch on the supply voltage to the read head.

24

The read head cyclically carries out DH CP requests. This enters the MAC address of the

read head in the Request History field to the list.

5. Enter the desired IP address in the New Entry menu.

- The software automatically adopts the MAC address of the read head.

- The "hostname" function is not supported.

- You may enter text under "Description".

2015-09

Page 25

PCV...-F200-B25-V1D

Operation and communication

6. Confirm the entries of the address data using OK.

The IP address is assigned to the read head on the next DHCP request. The new

address data will be displayed in the Relation List field.

7. Press the Disable BOOTP/DHCP key in the Relation List field.

In this way, the assigned IP address is saved permanently in the read head.

2015-09

25

Page 26

PCV...-F200-B25-V1D

Operation and communication

7.1.3 EtherNet/IP objects

All the data and functions of the read head are defined via objects in accordance with the

EtherNet/IP standards. The read head corresponds to the "Encoder Device Type 0x22" device

profile.

The read head supports the following listed standard and product-specific classes.

Standard classes

Class ID Class description

0x01 Identity Object

0x02 Message Router Object

0x04 Assembly Object

0x06 Connection Manager Object

0xF5 TCP/IP Interface Object

0xF6 Ethernet Link Object

0X47 DLR Object

0X48 Quality of Ser vice

Product-specific class

Class ID Class description

0x23 Position Sensor Object

26

The parameters are not directly addressable from the network with the "Set" or "Get" attribute

services. Access is via Assembly Objects (Class Code 0x04)

2015-09

Page 27

PCV...-F200-B25-V1D

Operation and communication

Cyclic data communication with assembly objects (Class Code 0x04)

Assemblies are special CIP objects used for cyclic data communication (implicit messaging).

These are composed of one or more attributes of various objects. These objects allow you to

send or receive data from multiple objects by means of a connection. The composition of the

assemblies in the read head is fixed and cannot be modified by the user.

Input assemblies

Instance

no. Description Size [byte] Attribute

1 Position 4 Position Value Signed

100 Position + speed 8 Position Value Signed

101 Status, X-position, Y-

position, Speed,

Warning, Event

Attribute

ID Data type

10 DINT

(X-Position)

10 DINT

(X-Position)

Velocity Value 24 DINT

18 Status Word 100 UINT

Position Value Signed

(X-Position)

Y-position 101 DINT

Velocity Value 24 DINT

Warning flags 102 UINT

Event number 103 UINT

10 DINT

Addresses required for the various connection types

The connection type defines the connection between the control system (originator), in this

case the controls, and the target device (target), in this case the read head. The following

options are available for data traffic.

Data from the control system to the destination device

Instance no. (dec.) Size [byte] Connection type

192 0 Listen only

193 0 Input only

Data from the target device to the control system

Instance no. (dec.) Size [byte] Assemblies

1 4 Position

100 8 Position + speed

101 18 Status, X-position, Y-position,

7.1.4 Attributes of the Ethernet/Read Head IP Objects

Position Sensor Object attributes (Class ID 0x23)

Speed, Warning, Event (lists

only)

Class attributes

ID Name Access Data type Size [byte] Description

1 Revision - UINT 2 Object

inspection

2015-09

27

Page 28

PCV...-F200-B25-V1D

Operation and communication

Standard instance attributes for object 0x23

ID Attribute Access Data type Size [byte] Description

10 Position Value

Signed (XPosition)

24 Velocity Value - DINT 4 Speed

Specific read head attributes

ID Attribute Access Data type Size [byte] Description

100 Status Word - UINT 2 Status Information

101 Y-position - UINT 4 Y-position in two's

102 Warning flags - UINT 2 Warnings

103 Event number - UINT 2 Event marker number

Basic data structure

- DINT 4 X-Position in two's

complement

complement

1 byte = 8-bit value

Byte 4 Byte 3 Byte 2 Byte 1

Example: XP31 ... XP24

MSB (Most Significant

Byte)

Example: XP23

... XP16

Example: XP15

... XP08

Exam ple: XP07 ... XP00

LSB (least significant byte)

Position data X: Position Value Signed (ID 10)

Size Type Content

4 byte consistent Input data 32-bit X data

LSB first

LSB = least significant byte

Resolution: 0.1 mm, 1 mm, 10 mm, binar y coded

At a resolution of 1 mm and 10 mm: L

10,000,000 mm

The following default settings apply:

■

The X position is output in the two's complement.

■

The value is output in the set resolution of the device.

■

The default is mm.

■

If the ERR bit is set in the "status word (ID 100)" attribute, the error number is transferred

to this attribute.

10.00 km =

max =

28

Data of the attribute 10

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 2 Bit 0

Byte 1 XP07 XP06 XP05 XP04 XP03 XP02 XP01 XP00

Byte 2 XP15 XP14 XP13 XP12 XP11 XP10 XP09 XP08

Byte 3 XP23 XP22 XP21 XP20 XP19 XP18 XP17 XP16

Byte 4 XP31 XP30 XP29 XP28 XP27 XP26 XP25 XP24

2015-09

Page 29

PCV...-F200-B25-V1D

Operation and communication

Position data Y: Y position (ID 101)

Size Type Content

4 byte consistent Input data 32-bit Y data

The following default settings apply:

■

The Y position is output in the two's complement.

■

The value is output in the set resolution of the device.

■

The default is mm.

Data of the attribute 101

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 2 Bit 0

Byte 1 YP07 YP06 YP05 YP04 YP03 YP02 YP01 YP00

Byte 2 YP15 YP14 YP13 YP12 Y P11 YP10 YP09 YP08

Byte 3 YP23 YP22 YP21 YP20 Y P19 YP18 YP17 YP16

Byte 4 YP31 YP30 YP29 YP28 Y P27 YP26 YP25 YP24

LSB first

Resolution: 0.1 mm, 1 mm, 10 mm, binar y coded in

two's com plem ent

Speed Data: Velocity Value (ID 24)

Size Type Content

4 byte consistent Input data 32-bit speed data

Resolution: 0.1 m/s, 0.01 m/s, 0.001 m/s, binary coded

Speed from 0 ... 12.5 m/s

Example: Speed = 4.7 m/s --> speed output = 47 at a

resolution of 0.1 m/s

65535 for unknown speed

The following default settings apply:

■

The value is output in the set resolution of the device.

■

The default is dm/s.

Data of attribute 24

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 2 Bit 0

Byte 1 SP07 SP06 SP05 SP04 SP03 SP02 SP01 SP00

Byte 2 SP15 SP14 SP13 SP12 SP11 SP10 SP09 SP08

Byte 3 SP23 SP22 SP21 SP20 SP19 SP18 SP17 SP16

Byte 4 SP31 SP30 SP29 SP28 SP27 SP26 SP25 SP24

2015-09

29

Page 30

PCV...-F200-B25-V1D

Operation and communication

Status: Status word (ID 100)

Size Type Content

2 bytes Input data 16-bit status

If the ERR bit is set, there is an error. The error num ber is transmitted to the "Value signed (ID

10)" attribute.

Data of attribute 100

Bit no.

1 ERR Error message (error code in

2 NP N o position information/OUT

3 WRN Warnings present; see

4 EV Event present see Event

5 0 -

... ... -

16 0 -

Content

Byte 1, 2

Status

Function

XP00–XP15); remaining bits =

0, see Error Codes

(XP = 0, YP = 0, SP = 0)

Warning Attribute

Attribute

Error codes

Error code Description Priority

1 Read head tipped 180° 2

2 No clear position can be determined (difference between codes

is too great, code distance incorrect, etc.)

> 1000 Internal error 1

3

30

2015-09

Page 31

PCV...-F200-B25-V1D

Operation and communication

Event: Event marker no. (ID 103)

Size Type Content

2 byte consistent Input data Last event marker

The event marker no. is binary coded and unsigned.

Data of attribute 103

Bit no.

1 EV00

2 EV01

3 EV02

4 EV03

5 EV04

6 EV05

7 EV06

8 EV07

9 EV08

10 EV09

11 0

... ...

16 0

Last event no.

Content

Byte 1, 2

Last event marker data

2015-09

31

Page 32

PCV...-F200-B25-V1D

Operation and communication

Warning: warning flags (ID 102)

Size Type Content

2 byte consistent Input data Last warnings

A set bit indicates that the corresponding warning is active.

Data of attribute 102

Bit no.

1 WRN00

2 WRN01

3 WRN02

4 WRN03

5 WRN04

6 WRN05

7 WRN06

8 WRN07

9 WRN08

10 WRN09

11 WRN10

12 WRN11

13 WRN12

14 WRN13

15 WRN14

16 WRN15

Last warning no.

Content

Byte 1, 2

Last warning data

32

Warning data set

Content

Bit no.

1 WRN01 A code with non-read head (PCV) content was found.

2 WRN02 Read head too close to code tape

3 WRN03 Read head too far from code tape

4 WRN04 Y position too large. The sensor is just before OUT

5 WRN05 Y position too small. The sensor is just before OUT

6 WRN06 The read head is rotated or tipped in relation to the code tape

7 WRN07 Low level of code contrast

8 WRN08 Repair tape detected

9 WRN09 Temperature too high

10 WRN10 Reser ved

11 WRN11 Reser ved

12 WRN12 Reser ved

13 WRN13 Reser ved

14 WRN14 Reser ved

15 WRN15 Reser ved

DescriptionByte 1, 2

2015-09

Page 33

PCV...-F200-B25-V1D

Operation and communication

Note!

If no warnings are present, all bits in the warning data set are set to 0.

7.2 Operation with Repair Tape

The repair tape is a short code reel with a length of one meter. The repair tape is used to bridge

defective or damaged areas of an existing code reel.

1. Cut the repair tape to the required length

2. Cover the defective area of the code reel with the repair tape

Note!

When placing a repair tape on the code reel, make sure that the repair tape represents as

accurate a continuation of the grid on the code reel as possible.

When the read head enters the range of a repair tape, it sets an event flag in the output data.

You also have the option of triggering a defined action when an event occurs by parameterizing

one of the outputs accordingly (). Actions of this type can be initiated when a certain event, all

events, or events from an event list occur.

Note!

The repair tape works incrementally. In so doing, it adds one value to the previous read position

on the code reel. If the read head starts on a repair tape, the read head reports an error. Move

the read head to a position on the code reel away from the repair tape to read the absolute

value.

Tip

If repairs are required, the Code Reel Generator at www.pepperl-fuchs.com can be used as a

short-term workaround. This allows code reel segments to be generated and printed out online.

Enter the start value in meters and the code reel length of the section to be replaced in meters.

This produces a printable PDF file with the required segment of the code reel.

Only use the printout as an emergency solution. The durability of the paper strip varies greatly

depending on the application!

Refer to the Accessories chapter for order information relating to repair tape.

7.3 Operating with event markers

In numerous position coding system applications, defined processes must be started at

specific positions so that the controller can evaluate the position data measured by the reading

head. However, this means that the exact positions for triggering events of this kind must be

defined as early as the system planning stage and can no longer be modified during the

construction phase or commissioning. If modifications are made, the position data stored in the

control software must be adapted accordingly, which involves a great deal of time and effort.

Activating a process through the detection of so-called event markers is a much more flexible

method. Only a specific event and the process linked with the event have to be programm ed

into the system controller. The position in which the corresponding event marker is placed

along the code strip can be decided immediately before final commissioning of the system.

Even if subsequent changes are made to the layout of a system, the relevant event marker is

simply moved to the new position without requiring program modifications.

Event markers are short code strips one meter in length. The event marker bears the encoded

event number and position information in incremental form. Event markers are available with

event numbers from 001 to 999. To transfer the exact position data, the reading head calculates

the last absolute position of the code strip before it entered the event range and adds the

2015-09

incremental offset from the codes of the event markers.

33

Page 34

PCV...-F200-B25-V1D

Operation and communication

When the reading head enters the range of an event m arker, it sets an event flag in the output

data. You also have the option of triggering a defined action when an event occurs by

param eterizing one of the outputs accordingly (). Actions of this type can be initiated when a

certain event, all events or events from an event list occur.

The 1 meter long event marker can be shortened. However, the minimum length should be 30

mm (3 codes). If the travel speed of the reading head increases, a longer event marker is

required. If the reading head travels at maximum speed, a full length event m arker of 1 meter

must be positioned over the code strip.

The minimum length of an event marker can be calculated according to the following formula

depending on the travel speed and the trigger period:

L

Event marker

= 30 mm + V

[m/s] * T

max

trigger

[s] x 2

With auto trigger, the trigger period is 0.025 s.

Example calculation

At a speed of 3 m/s and with a trigger period of 25 ms, the minimum length of the event marker

is therefore:

L

Event marker

= 30 mm +3 m/s * 0.025 s * 2 = 180 mm

Note!

When placing an event marker on the code strip, make sure that the event marker represents

an accurate continuation of the grid on the code strip where possible.

The printed event number and the inverted text identify event markers in contrast to the

identification on code strips (white text on a black background).

The illustration shows part of the event marker #127

Refer to the Accessories chapter for order information relating to event markers.

34

2015-09

Page 35

PCV...-F200-B25-V1D

Appendix

8 Appendix

8.1 Code Cards for External Parameterization

Here, you can find the code cards that enable you to parameterize some basic read head

functions step by step. For the exact external parameterization procedure .

Note!

When performing external parameterization with code cards, we recommend copying and

printing out the relevant pages in this manual and cutting out the code cards. This prevents the

read head from mistakenly detecting another code card on the same page. If you intend to use

this m anual directly for parameterization, cover the code cards that you do not require with a

sheet of paper, for example.

8.1.1 Code Cards With Special Functions

The following code cards have special functions:

■

ENABLE

■

STORE

■

CANCEL

■

USE

■

DEFAULT

The code card "ENABLE"

Figure 8.1 The code card "ENABLE" is used to activate external parameterization operating mode.

The code card "STORE"

Figure 8.2 The code card "STORE" stores the modified para meterization in the non-volatile

memor y of the reading head and terminates external parameterization operating mode.

2015-09

35

Page 36

PCV...-F200-B25-V1D

Appendix

The code card "CANCEL"

Figure 8.3 The code card "CANCEL" discards the modified parameterization an d term inates

external parameterization operating mode. The reading he ad switches to normal mode

and adopts the last valid config uration that was saved.

The "USE" code card

Figure 8.4 The "USE" code card takes over the set config uration volatile in the read head working

memory and terminates the external parameterization operating mode. Th e read head

then operates with this configu ration. However, if the read head is switched off an d on

again, the config uration is lost and the read head operates with the last valid

configuration that was saved. This function is used primarily for test purposes.

The "DEFAULT" code card

Figure 8.5 The "DEFAULT" code card restores the read he ad settings to default and terminates

external parameterization operating mode.

36

2015-09

Page 37

PCV...-F200-B25-V1D

Appendix

8.1.2 Code Cards for Adjusting the Resolution

Parameterization enables you to assign a position data resolution of 0.1 mm / 1 mm / 10 mm to

the read head.

Resolution: 0.1 mm

Figure 8.6 The code card ass igns a position data reso lution of 0.1 mm / 1 mm / 10 mm to the

reading head.

Resolution: 1 m m

Figure 8.7 The code card ass igns a position data reso lution of 0.1 mm / 1 mm / 10 mm to the

reading head.

Resolution: 10 mm

Figure 8.8 The code card ass igns a position data reso lution of 0.1 mm / 1 mm / 10 mm to the

reading head.

Maximum Length of the Code Tape

Resolution of the read head [mm] Maximum length of the code tape [km]

10 10

1 10

0.1 10

2015-09

37

Page 38

PCV...-F200-B25-V1D

Appendix

8.1.3 Code Cards for Setting the Orientation

If the alignment of the read head to the code tape does not correspond to the default setting,

the orientation must be adjusted. The orientation can be set at an angle of 0°, 180°, or

automatic detection in 90° increments.

Orientation 0°

Figure 8.9 The code card assigns the orientation 0° to the read head.

Orientation 180°

Figure 8.10 The code card assigns the orientation 180° to the read hea d.

Orientation 0° or 180°

Figure 8.11 The code card automatically assigns the orientation 0° or 180° to the read head.

Orientation 0°, 90°, 180°, or 270°

38

Figure 8.12 The code card automatically assigns the orientation 0°, 90° , 180°, or 270° to the read

head.

2015-09

Page 39

PCV...-F200-B25-V1D

Appendix

8.1.4 Code Cards for Adjusting Output 1

Parameterization enables you to assign various functions to output 1 on the read head. The

following functions are available:

■

None

■

Speed exceeded

■

Warning

■

Fault

■

Contamination

■

Event

■

No position

Output 1: no function

Figure 8.13 Output 1 has no function.

Output 1: speed exceeded

Figure 8.14 Output 1 carries the potential +UBif the sp eed exceeds the defined maximum speed.

Output 1: Warning

Figure 8.15 Output 1 carries the potential +UB as long as a warnin g mess age is present on the read

head.

2015-09

39

Page 40

PCV...-F200-B25-V1D

Appendix

Output 1: Fault

Figure 8.16 Output 1 carries the potential +UB as long as an error message is present on the read

head.

Output 1: Pollution

Figure 8.17 Output 1 carries the potenti al +UB as long as a pollution message is present on the read

head.

Output 1: Event

Figure 8.18 Output 1 carries the potential +UB as long as an event marker is present on the read

field of the read head.

Output 1: no position

40

Figure 8.19 Output 1 carries the potential +UBwhen the reading head is not reading pos ition

information.

2015-09

Page 41

PCV...-F200-B25-V1D

Appendix

8.1.5 Code Cards for Adjusting Output 2

Parameterization enables you to assign various functions to output 2 on the read head. The

following input / output functions are available:

■

Output: none

■

Output: O verspeed message

■

Output: Warning

■

Output: Fault

■

Output: Pollution

■

Output: Event

■

Output: N o position

Output 2: no function

Figure 8.20 Input/output 2 is defined as an output but has no function.

Output 2: speed exceeded

Figure 8.21 Input/output 2 is defined as an output. This output carries the p otential +UBif the speed

exceeds the defined maximum spee d.

Output 2: Warning

Figure 8.22 Input/output 2 is defined as an output. This output carries the potential +UB as long as a

warning message is present in the read head.

2015-09

41

Page 42

PCV...-F200-B25-V1D

Appendix

Output 2: Fault

Figure 8.23 Input/output 2 is defined as an output. This output carries the potential +UB as long as

an error mess age is present on the read head.

Output 2: Pollution

Figure 8.24 Input/output 2 is defined as an output. This output carr ies the potential +UB as long as a

pollution message is pre sent in the read head.

Output 2: Event

Figure 8.25 Input/output 2 is defined as an output. This output carries the potential +UB as long as

an event marker is present in the read field of the read hea d.

Output 2: no position

42

Figure 8.26 Input/output 2 is defined as an output. This output carries the potential +UBwhen the

reading head is not reading position information.

2015-09

Page 43

PCV...-F200-B25-V1D

Appendix

8.1.6 Code Cards for Adjusting Output 3

Parameterization enables you to assign various functions to output 3 on the read head. The

following input / output functions are available:

■

Output: N one

■

Output: O verspeed message

■

Output: Warning

■

Output: Fault

■

Output: Pollution

■

Output: Event

■

Output: N o position

Output 3: no function

Figure 8.27 Input/output 3 is defined as an output but has no function.

Output 3: speed exceeded

Figure 8.28 Input/output 3 is defined as an output. This output carries the p otential +UBif the speed

exceeds the defined maximum spee d.

Output 3: Warning

Figure 8.29 Input/output 3 is defined as an output. This output carries the potential +UB as long as a

warning message is present in the read head.

2015-09

43

Page 44

PCV...-F200-B25-V1D

Appendix

Output 3: Fault

Figure 8.30 Input/output 3 is defined as an output. This output carries the potential +UB as long as

an error mess age is present on the read head.

Output 3: Pollution

Figure 8.31 Input/output 3 is defined as an output. This output carr ies the potential +UB as long as a

pollution message is pre sent in the read head.

Output 3: Event

Figure 8.32 Input/output 3 is defined as an output. This output carries the potential +UB as long as

an event marker is present in the read field of the read hea d.

Output 3: no position

44

Figure 8.33 Input/output 3 is defined as an output. This output carries the potential +UBwhen the

reading head is not reading position information.

2015-09

Page 45

PCV...-F200-B25-V1D

Appendix

8.2 ASCII table

hex dec ASCII hex dec ASCII hex dec ASCII hex dec ASCII

00 0 NUL 20 32 Space 40 64 @ 60 96 '

01 1 SOH 21 33 ! 41 65 A 61 97 a

02 2 STX 22 34 " 42 66 B 62 98 b

03 3 ETX 23 35 # 43 67 C 63 99 c

04 4 EOT 24 36 $ 44 68 D 64 100 d

05 5 ENQ 25 37 % 45 69 E 65 101 e

06 6 ACK 26 38 & 46 70 F 66 102 f

07 7 BEL 27 39 ' 47 71 G 67 103 g

08 8 BS 28 40 ( 48 72 H 68 104 h

09 9 HT 29 41 ) 49 73 I 69 105 I

0A 10 LF 2A 42 * 4A 74 J 6A 106 j

0B 11 VT 2B 43 + 4B 75 K 6B 107 k

0C 12 FF 2C 44 , 4C 76 L 6C 108 l

0D 13 CR 2D 45 - 4D 77 M 6D 109 m

0E 14 SO 2E 46 . 4E 78 N 6E 110 n

0F 15 SI 2F 47 / 4F 79 O 6F 111 o

10 16 DLE 30 48 0 50 80 P 70 112 p

11 17 DC1 31 49 1 51 81 Q 71 113 q

12 18 DC2 32 50 2 52 82 R 72 114 r

13 19 DC3 33 51 3 53 83 S 73 115 s

14 20 DC4 34 52 4 54 84 T 74 116 t

15 21 NAK 35 53 5 55 85 U 75 117 u

16 22 SYN 36 54 6 56 86 V 76 118 v

17 23 ETB 37 55 7 57 87 W 77 119 w

18 24 CAN 38 56 8 58 88 X 78 120 x

19 25 EM 39 57 9 59 89 Y 79 121 y

1A 26 SUB 3A 58 : 5A 90 Z 7A 122 z

1B 27 ESC 3B 59 ; 5B 91 [ 7B 123 {

1C 28 FS 3C 60 < 5C 92 \ 7C 124 |

1D 29 GS 3D 61 = 5D 93 ] 7D 125 }

1E 30 RS 3E 62 > 5E 94 ^ 7E 126 ~

1F 31 US 3F 63 ? 5F 95 _ 7F 127 DEL

2015-09

45

Page 46

FACTORY AUTOMATION –

SENSING YOUR NEEDS

Worldwide Headquarters

Pepperl+Fuchs GmbH

68307 Mannheim · Germany

Tel. +49 621 776-0

E-mail: info@de.pepperl-fuchs.com

USA Headquarters

Pepperl+Fuchs Inc.

Twinsburg, Ohio 44087 · USA

Tel. +1 330 4253555

E-mail: sales@us.pepperl-fuchs.com

Asia Pacific Headquarters

Pepperl+Fuchs Pte Ltd.

Company Registration No. 199003130E

Singapore 139942

Tel. +65 67799091

E-mail: sales@sg.pepperl-fuchs.com

www.pepperl-fuchs.com

Subject to modifications

Copyright PEPPERL+FUCHS • Printed in Germany

/ DOCT-4896A

09/2015

Loading...

Loading...