Pepperl Fuchs RM-GXP1100-19S, RM-GXP1200-19S, PC-GXP1100-19S, PC-GXP1200-19S Instruction manual

VisuNet GXP

RM-GXP1100-19S

RM-GXP1200-19S

PC-GXP1100-19S

PC-GXP1200-19S

Manual

With regard to the supply of products, the current issue of the following document is applicable: The

General Terms of Delivery for Products and Services of the Electrical Industry, published by the Central

Association of the Electrical Industry (Zentralverband Elektrotechnik und Elektroindustrie (ZVEI) e.V.)

in its most recent version as well as the supplementary clause: "Expanded reservation of proprietorship"

Worldwide

Pepperl+Fuchs Group

Lilienthalstr. 200

68307 Mannheim

Germany

Phone: +49 621 776 - 0

E-mail: info@de.pepperl-fuchs.com

North American Headquarters

Pepperl+Fuchs Inc.

1600 Enterprise Parkway

Twinsburg, Ohio 44087

USA

Phone: +1 330 425-3555

E-mail: sales@us.pepperl-fuchs.com

Asia Headquarters

Pepperl+Fuchs Pte. Ltd.

P+F Building

18 Ayer Rajah Crescent

Singapore 139942

Phone: +65 6779-9091

E-mail: sales@sg.pepperl-fuchs.com

https://www.pepperl-fuchs.com

VisuNet GXP

Contents

1 Introduction................................................................................................................ 4

1.1 Content of this Document............................................................................. 4

1.2 Target Group, Personnel ............................................................................... 4

1.3 Symbols Used ................................................................................................ 5

2 Product Description ..................................................................................................6

2.1 Overview......................................................................................................... 6

2.2 Technical Specifications ............................................................................... 9

2.3 Dimensions................................................................................................... 12

2.4 Disposal........................................................................................................ 14

3 Mechanical Installation ........................................................................................... 15

3.1 General Installation Requirements ............................................................ 15

3.2 Installation Tools.......................................................................................... 15

3.3 System Installation ......................................................................................16

3.3.1 Preparation for System Installation................................................... 16

3.3.2 Preparing the GXP Panel/Housing................................................... 17

3.3.3 Preparing the StandardLine Pedestal .............................................. 20

3.3.4 Attaching the Pedestal to the Housing ............................................. 24

3.3.5 Opening the Housing ....................................................................... 27

3.3.6 Grounding the Housing to the Pedestal ........................................... 29

3.3.7 Mounting the Keyboard.................................................................... 31

3.3.8 Mounting the Scanner Holder to the AG1 Housing .......................... 33

3.3.9 Installing the Handheld 1-D/2-D Code Reader................................. 37

3.4 Replacing a VisuNet EX1 with the 19-Inch VisuNet GXP..........................43

3.4.1 Removing VisuNet EX1 from AG1 Housing...................................... 44

3.4.2 Installing VisuNet GXP into AG1 Housing ........................................ 46

3.5 Panel Mount Installation .............................................................................49

3.6 Wall Mount Installation................................................................................ 52

4 Appendix .................................................................................................................. 54

4.1 Accessories.................................................................................................. 54

4.2 UL Control Drawing ..................................................................................... 55

2020-04

3

VisuNet GXP

Introduction

1 Introduction

1.1 Content of this Document

This document contains information that you need in order to use your product throughout the

applicable stages of the product life cycle. These can include the following:

• Product identification

• Delivery, transport, and storage

• Mounting and installation

• Commissioning and operation

• Maintenance and repair

• Troubleshooting

• Dismounting

• Disposal

Note

This document does not substitute the instruction manual.

Note

For full information on the product, refer to the instruction manual and further documentation on

the Internet at www.pepperl-fuchs.com.

The documentation consists of the following parts:

• Present document

• Instruction manual

• Datasheet

Additionally, the following parts may belong to the documentation, if applicable:

• EU-type examination certificate

• EU declaration of conformity

• Attestation of conformity

• Certificates

• Control drawings

• Additional documents

1.2 Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation, maintenance, and dismounting lies with the plant operator.

Only appropriately trained and qualified personnel may carry out mounting, installation, commissioning, operation, maintenance, and dismounting of the product. The personnel must have

read and understood the instruction manual and the further documentation.

Prior to using the product make yourself familiar with it. Read the document carefully.

4

2020-04

VisuNet GXP

Introduction

1.3 Symbols Used

This document contains symbols for the identification of warning messages and of informative

messages.

Warning Messages

You will find warning messages, whenever dangers may arise from your actions. It is mandatory

that you observe these warning messages for your personal safety and in order to avoid property damage.

Depending on the risk level, the warning messages are displayed in descending order as follows:

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants, or result in

their complete failure.

Informative Symbols

Note

This symbol brings important information to your attention.

Action

This symbol indicates a paragraph with instructions. You are prompted to perform an action or

a sequence of actions.

2020-04

5

VisuNet GXP

Product Description

2 Product Description

2.1 Overview

The Pepperl+Fuchs VisuNet Remote Monitors GXP RM-GXP1100-19S*/RM-GXP1200-19S*

and PC-GXP-1100-19S*/PC-GXP-1200-19S* are ATEX/IECEx certified, UL listed devices

intended for use in potentially explosive atmospheres, such as Zones 1/21, 2/22 and Class I

Div. 2, Class II Div. 2, and Class III.

The VisuNet GXP serves as a thin client- or PC-based operator workstation that uses standard

Ethernet technology to transmit process information from a process control or manufacturing

execution system into hazardous areas.

The assembly consists of several core devices that can be exchanged by the customer:

• The display units DPU1100-* and DPU1200-* are display panels with optional 10-finger

multi-touch sensors. The displays and touch-sensors are optically bonded with the hardened front glass.

• The thin client units TCU1100-* and TCU1200-* are computing units running the latest

Pepperl+Fuchs RM Shell 5.x or RM Shell 4.x firmware. They allow connectivity to various

host systems in the safe area using standard Ethernet technology. The computing units

PCU1100-* and PCU1200-* run an open Microsoft® Windows® operating system, allowing installation of any software, such as SCADA packages.

• The power supply units PSU1100-* and PSU1200-* provide the above-listed devices with

24 V DC power. They are available as DC and AC versions.

As the standard mounting option, a bezel is available that allows the panel to be mounted into a

system housing or cabinet that needs to be ordered separately. The panel can also be flushmounted into a cabinet from behind.

2020-04

6

VisuNet GXP

1

2

3

4

Product Description

VisuNet GXP Panel Components

Figure 2.1 VisuNet GXP panel components

1 Bezel for housing and panel mounting

2 Computing unit (TCU or PCU): processor, SSD and memory, Ex circuits,

interface modules

3 Power supply unit: DC or AC option, backpacked (panel-mount) or stand-

alone (in system enclosure)

4 Display unit: display, touch screen, hardened front glass

2020-04

7

VisuNet GXP

Product Description

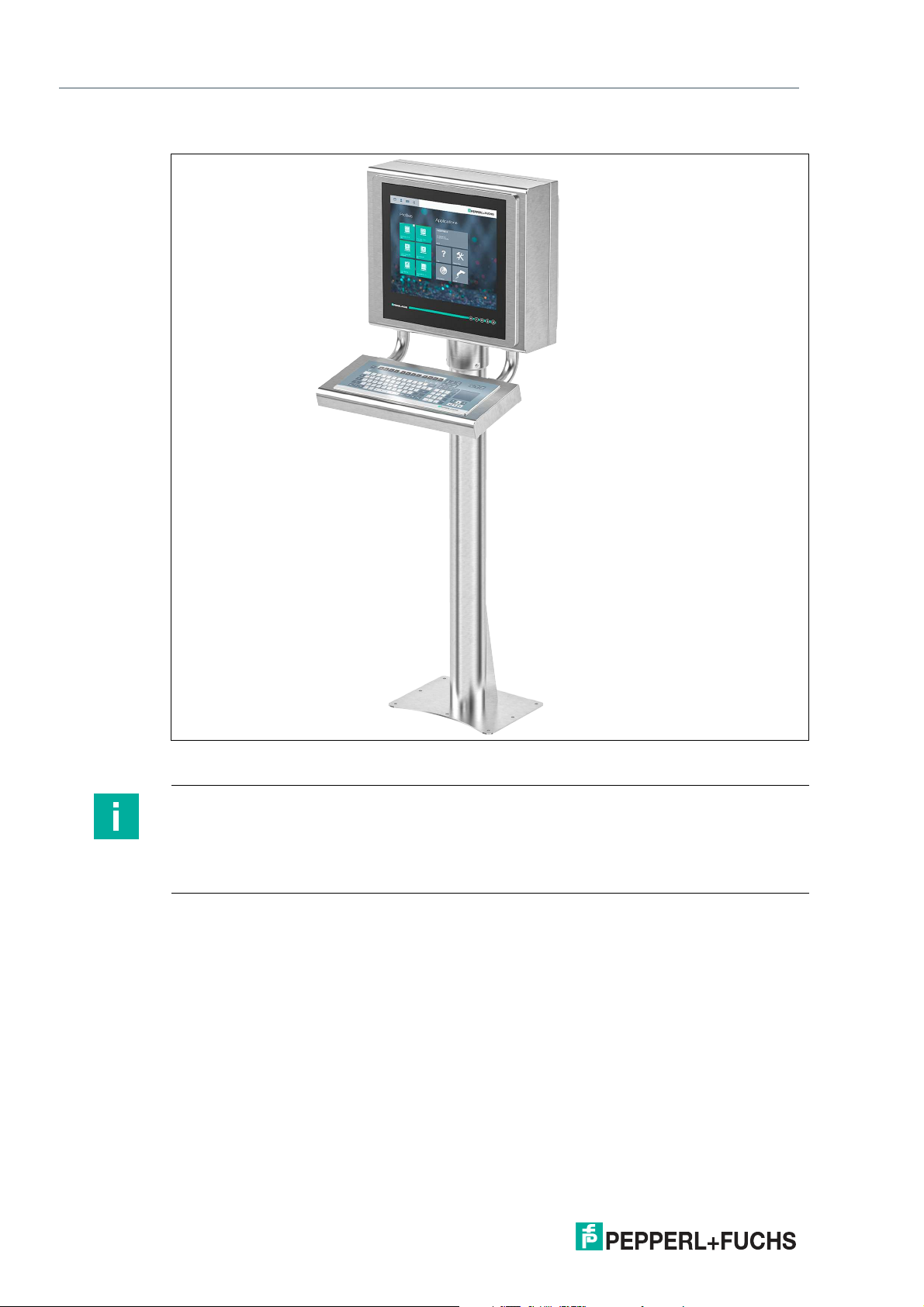

VisuNet GXP Pedestal Mounted with Keyboard/Mouse

Figure 2.2 VisuNet GXP system mounted in AG1 Housing with Pedestal5 -1458-* and EXTA2

keyboard/mouse (ordered separately)

Note

For a description of the product model nomenclature, see the VisuNet GXP PC or VisuNet GXP

RM product datasheets at www.pepperl-fuchs.com.

For more mounting options and information, see the datasheet "Mounting Options

'StandardLine' and 'BasicLine'".

2020-04

8

VisuNet GXP

Product Description

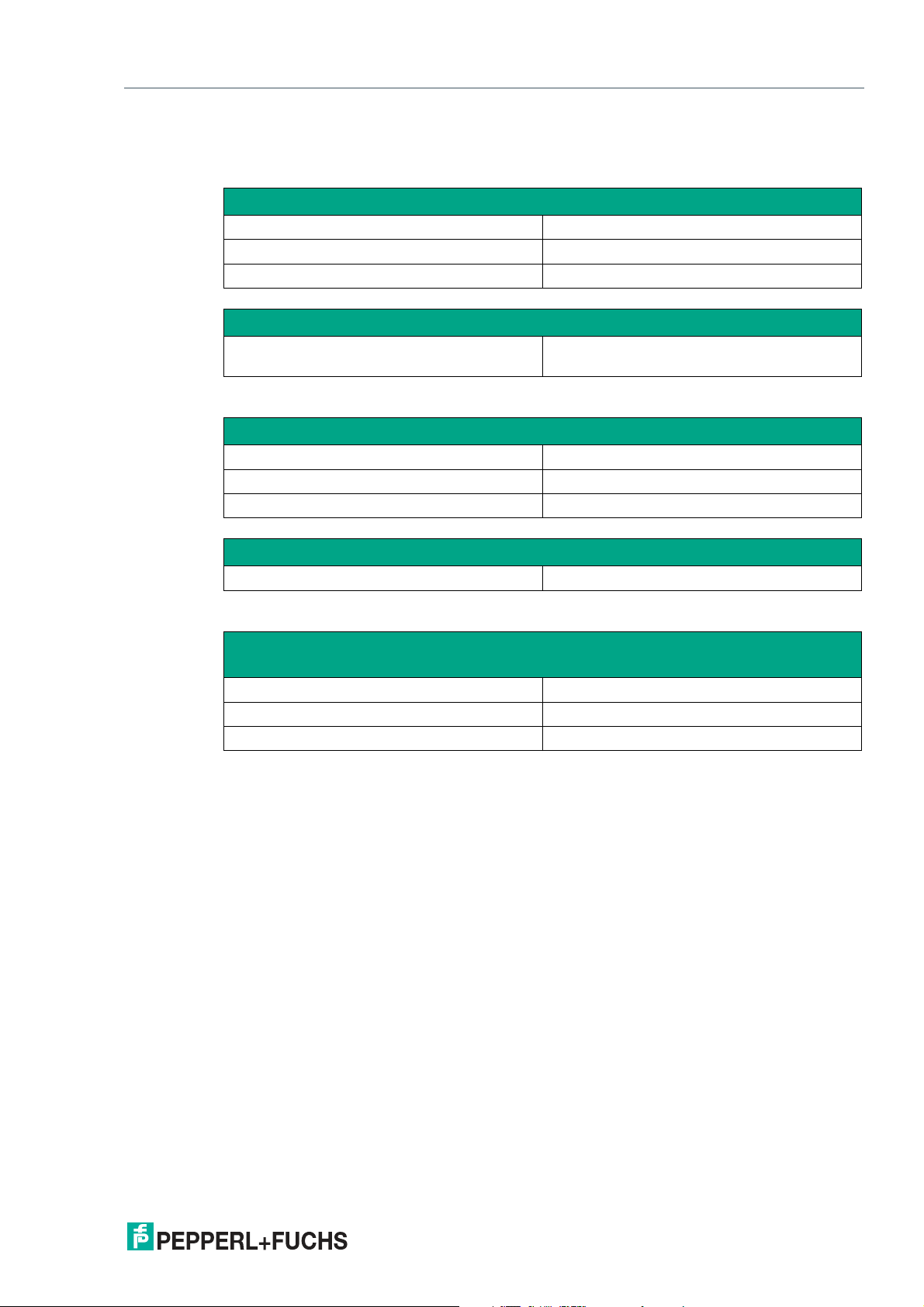

2.2 Technical Specifications

Technical Data RM-GXP*

Hardware

Processor Intel® Atom™ Bay Trail E3827 1.75 GHz

RAM 2048 MB DDR3L

Mass storage 32 GByte industrial grade MLC SSD

Software

Operating system VisuNet RM Shell 5.x (based on Microsoft®

Technical Data PC-GXP*

Hardware

Processor Intel® Atom™ Bay Trail E3845 1.91 GHz

RAM 4096 MB DDR3L

Mass storage 128 GByte industrial grade MLC SSD

Windows® 10 IoT LTSB)

Software

Operating system Microsoft® Windows® 10 IoT Enterprise x64

Technical Data RM-GXP* and PC-GXP*

Supply

Power consumption

AC 115/230 V AC, 0.4 ... 0.7 A, 50/60 Hz

DC 18 ... 36 V DC , 1.5 ... 3 A

2020-04

9

VisuNet GXP

Product Description

Interface

Interface type 1 x Ethernet 100/1000BASE-TX (Ex e) or

1 x fiber optic 1000BASE-SX (Multimode) or

1 x fiber optic 1000BASE-LX (Singlemode)

1 x USB 2.0 (Ex e)

2 x USB 1.1 (Ex i; intended for Pepperl+Fuchs

keyboard and mouse)

1 x DC or AC power in (via power supply unit)

Optional:

1 x barcode reader interface Pepperl+Fuchs

Pscan-D/B (Ex i)

"interface 3": 1 x barcode reader interface for

wired 1-D scanners IDM-160-D*, IDM-Z1160-D-* and base station IDMx61-B-* and

IDM-Z1-x61-B-*

"interface 4": 1 x barcode reader interface for

wired 2-D Scanner IDM-Z1-260-D-* (Ex i)

"interface 5": 1 x RS-232 interface with Power

Supply for miscellaneous devices and peripherals (Ex i)

1 x RS-232 (Ex e)

1 x RS-485 (Ex e)

1 x Ethernet 100/1000Base-TX (Ex e)

Bluetooth v4.0, communication distance up to

30 m in open terrain, transmission power +8

dBm, transmission frequency 2.402 ... 2.48

GHz

Electromagnetic compatibility

Directive 2014/30/EU EN 61326-1:2013 (industrial locations)

RoHS

Directive 2011/65/EU (RoHS) EN 50581:2012-09

Ambient conditions

Operating temperature -20 ... 50 °C (-4 ... 122 °F)

Storage temperature -20 ... 60 °C (-4 ... 140 °F)

Relative humidity 93% at 40°C, non-condensating, according to

Altitude Operating altitude max. 2000 m

Shock resistance 18 shocks 15 g , 11 ms all axis, IEC 60068-2-

Vibration resistance 10 ... 150 Hz, +/- 0.075 mm , 1g, 10 cycles per

non-Bluetooth products only

EN60068-2-78

27

axis according to EN60068-2-6

10

2020-04

VisuNet GXP

Product Description

Mechanical specifications

Degree of protection IP66 (individual components and entire sys-

Material Internal:

Mass panel with DC: 22 kg , panel with AC: 23 kg ,

Dimensions panel with DC: 524 mm x 453 mm x 120 mm

Note

For more technical information, refer to the manuals and instruction manuals of the individual

components:

• Display Units DPU1100-J1* and DPU1200-J2*

• AC Power Supply Units PSU1100-J1-AC-N0 and PSU1200-J2-AC-N0

• DC Power Supply Units PSU1100-J1-DC-N0 and PSU1200-J2-DC-N0

tem with housing)

Panel: anodized aluminum (TCU, PSU), powder coated aluminum (DPU)

External:

Bezel: stainless steel AISI 304 (1.4301)

System housing: stainless steel AISI 304

(1.4301), ground smooth, typical surface

roughness Ra = 0.8 µm

system housing AG1: 19 kg

panel with AC: 524 mm x 453 mm x 137 mm

panel with AG1 housing: 582 mm x 490 mm x

224 mm

• Thin Client Units TCU1100-J1-* and TCU1200-J2-*

• Computing Units PCU1100-J1-* and PCU1200-J2-*

Marking

ATEX

RM-GXP1100-J1-*

RM-GXP1200-J2-*

IECEx

RM-GXP1100-J1-* Ex eb q ib [ib] IIC T4 IP66 Gb

RM-GXP1200-J2-* Ex ec [ib] q IIC T4 IP66 Gc

II 2G Ex eb q ib [ib] IIC T4 IP66 Gb

II 2D Ex tb [ib] IIIC T85°C IP66 Db

II 3G Ex ec [ib] q IIC T4 IP66 Gc

II 3D Ex tc [ib] IIIC T85 °C IP66 Dc

Ex tb [ib] IIIC T85°C IP66 Db

Ex tc [ib] IIIC T85 °C IP66 Dc

UL Marking

2020-04

11

VisuNet GXP

582

490

1702

228

475

1100

Product Description

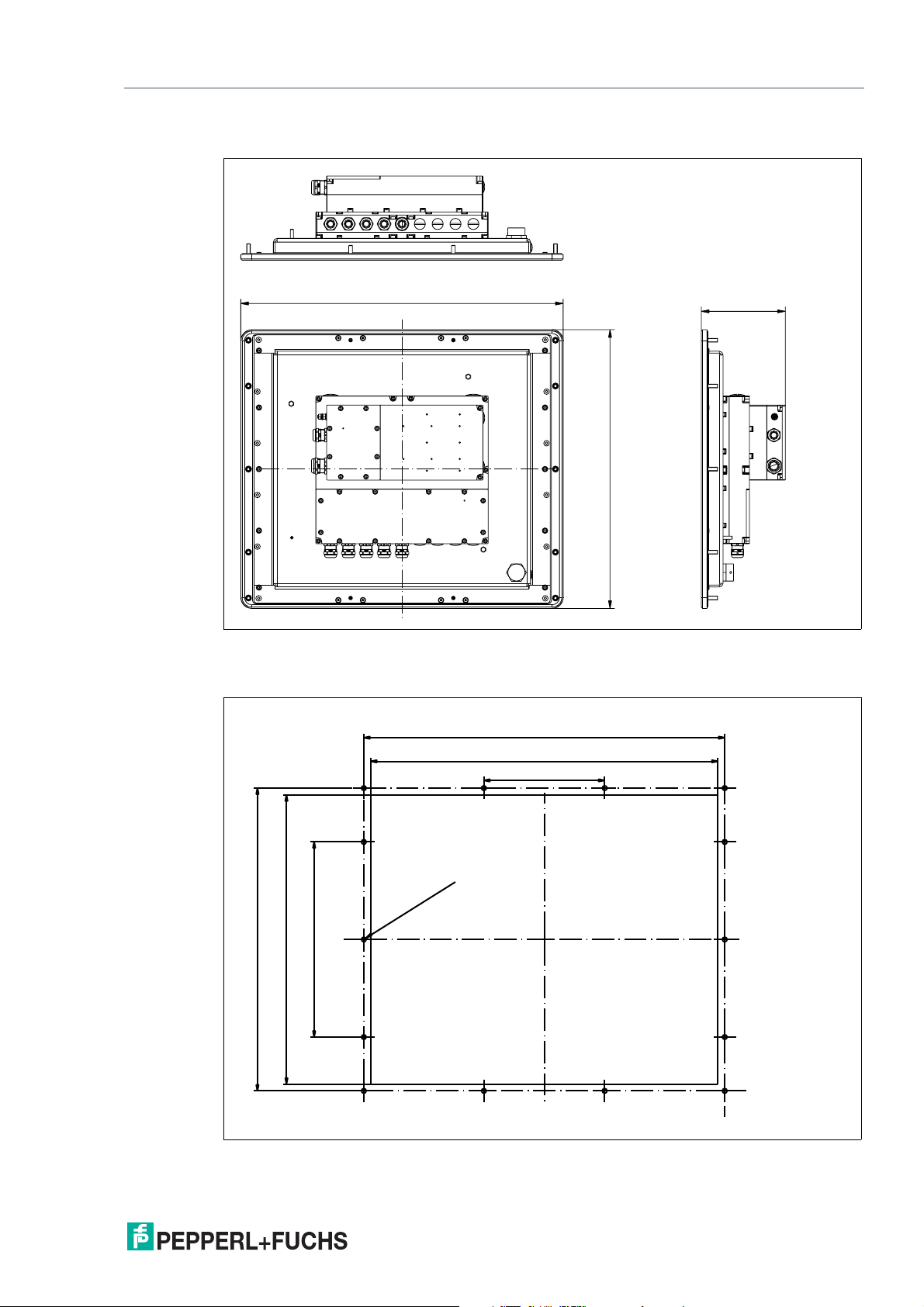

2.3 Dimensions

Dimensions with AG1 Housing and Pedestal

Figure 2.3 Dimensions with StandardLine Pedestal5-1458-Fix and EXTA2 keyboard/mouse—sample

configuration

Note

Keyboard/mouse and pedestal are ordered separately.

12

2020-04

VisuNet GXP

524

137

453

499

480

167

419

400

270

Ø 6.5

± 0.5 (14 x)

Product Description

Panel Dimensions with Bezel

Panel Cut-Out Dimensions

Cut-out dimensions: 480 x 400 mm. For more information, see chapter 3.5.

2020-04

13

VisuNet GXP

490

582

583

62

532

285

686

413

Product Description

Wall Mount Dimensions

Figure 2.4 Wall mount dimensions with additional wall brackets (#198768)

2.4 Disposal

Follow all local and any other requirements for disposing of electronic equipment. When disposing of any system component, mark VOID across all certification labels.

2020-04

14

VisuNet GXP

Mechanical Installation

3 Mechanical Installation

3.1 General Installation Requirements

Observe the following requirements when installing the system components.

• The equipment must be installed by competent personnel in accordance with the instruc-

tions. National laws and regulations must be observed.

• The building installation must provide a 20 A overcurrent protection.

• The installer must make a readily accessible disconnect device available.

• The safety of any system incorporating the power supply unit is the responsibility of the

assembler of the system.

3.2 Installation Tools

• 4-mm and 5-mm torque Allen keys

• Open-ended wrench for cable glands

• Screws for floor or wall mounting. Choose the appropriate screws based on the mounting

conditions.

• Small cable ties

• Side cutters

• Strong adhesive tape, such as duct tape or packing tape

• At least 1 piece of thin, 2.5-m-long wire for pulling cables through the pedestal

Warning!

Risk of injury

Lifting the device on your own may lead to injury.

Do not attempt to lift the device on your own. Use a crane or have another person help you.

2020-04

15

VisuNet GXP

Mechanical Installation

3.3 System Installation

3.3.1 Preparation for System Installation

Warning!

Proper installation on the floor

It is the installer's responsibility to select a suitable location with sufficient strength to hold the

equipment. It is the installer's responsibility to select the proper screws based on the installation conditions.

Warning!

Distance between housing and wall

Provide at least 350 mm of space between the housing/pedestal assembly and the left wall.

This is required in order to properly open the housing and connect the GXP components.

16

Figure 3.1 Distance required between housing/pedestal assembly and wall

2020-04

VisuNet GXP

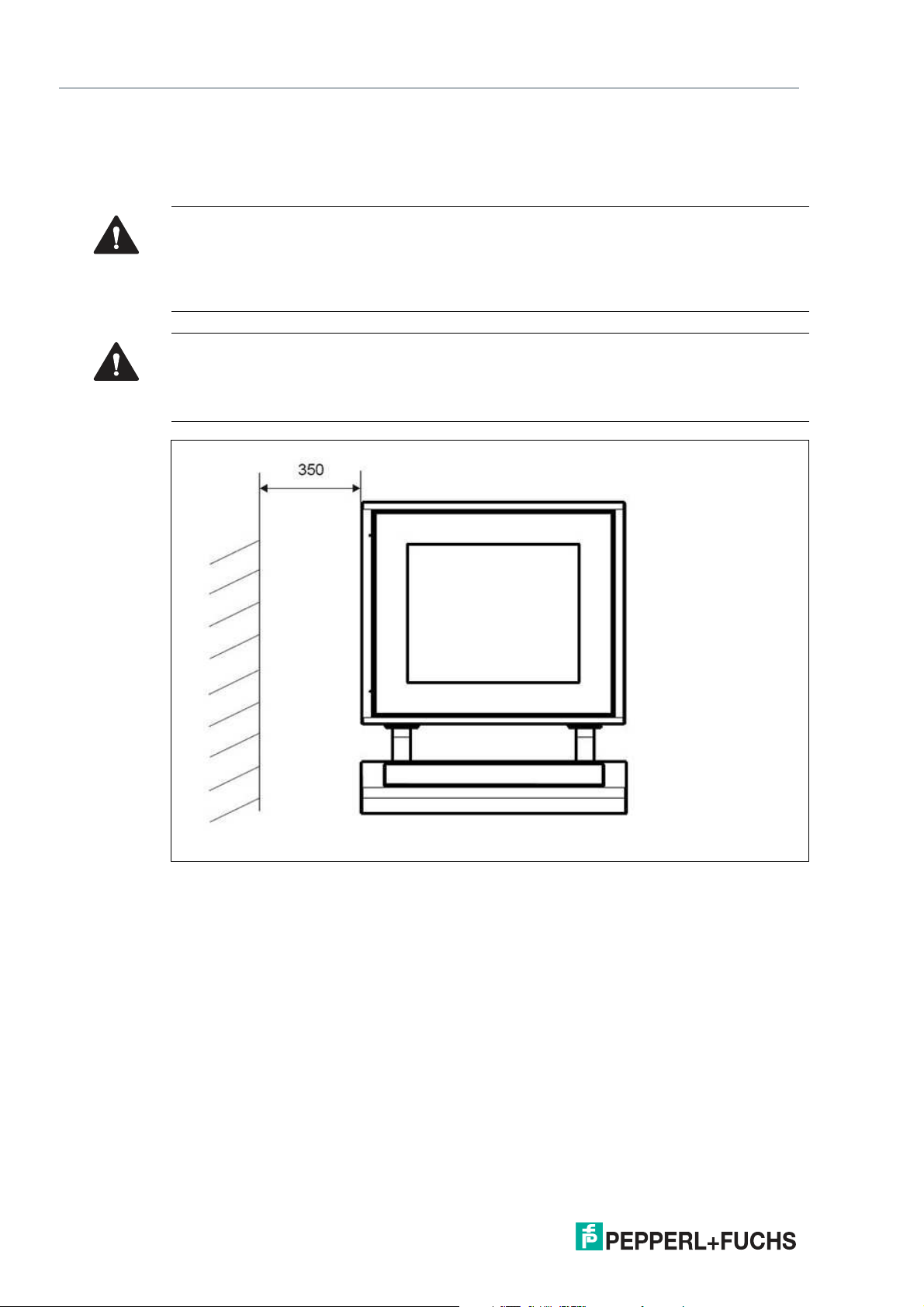

400

180 180

300

250

140

130

130

20

40

Ø 100

Ø 10

071

031

130

170

90

45°

1

0

5°

5°

184

Mechanical Installation

StandardLine Pedestal Floor-Mount Hole Pattern

BasicLine Pedestal Floor-Mount Hole Pattern

3.3.2 Preparing the GXP Panel/Housing

The VisuNet GXP comes pre-assembled and consists of the core components display unit,

power supply unit, and thin client unit / power supply unit. If the AG1 housing option is chosen,

the panel is pre-mounted in the housing.

Required Components

• 1 x pre-assembled VisuNet RM-GXP or PC-GXP panel (option: panel-mounted into AG1

housing)

2020-04

• 2 x protective tubes

• Screws for housing

• EXTA2 keyboard and PEDESTAL5-xxxx-* (ordered separately)

Warning!

Risk of injury

Handling the devices with bare hands may cut fingers, hands, or wrists.

Wear gloves at all times during the installation process.

17

VisuNet GXP

Mechanical Installation

Warning!

Risk of injury

Lifting the GXP housing on your own may cause injury.

Do not attempt to lift the device on your own. Use a crane or have another person help you.

Warning!

Danger resulting from scratched display unit screen

Scratches on a display unit front screen weaken the glass structure and may result in broken

glass. Explosion protection is no longer ensured if a display unit with a scratched screen is

used.

NEVER use a display unit with a scratched front screen in a hazardous area. If the surface is

damaged in any way, return the display unit to Pepperl+Fuchs at once and replace it with a new

one.

Preparing the Housing

1.

Remove the box and leave the protective foam blocks on the housing. Save the uncollapsed

box for further mounting steps.

2.

Wrap strong adhesive tape around the foam blocks to hold them onto the housing and protect

the components during mounting.

18

3.

Place the housing face down on a flat surface.

2020-04

VisuNet GXP

Mechanical Installation

4.

Remove and discard the screws from the bottom of the housing.

2020-04

19

VisuNet GXP

1

2

3

Mechanical Installation

3.3.3 Preparing the StandardLine Pedestal

A variety of pedestals are available for floor mounting. For a complete list of available mounting

options, see the mounting options datasheet. Pedestals are shipped with an attached protective earth (PE) wire and screws for mounting the VisuNet GXP AG1 housing to the pedestal: 6 x

M8 countersunk screws and 2 x M6 countersunk screws.

StandardLine Pedestal

1 Pre-installed PE wire

2 Top cable opening

3 Cable glands

2020-04

20

VisuNet GXP

1

2

3

4

Mechanical Installation

Bottom of Pedestal

1 PE stud

2 M25 opening

3 M20 opening

4 M20 plug

Warning!

Connection to the PE stud

Connection to the PE stud is mandatory.

Opening Size Wrench Size Cable Diameter Torque

M20 24 mm 7 ... 13 mm 12 Nm

M25 29 mm 9 ... 17 mm

Preparing the Pedestal for Connection to the GXP Housing

1.

Remove the cable glands at the bottom of the pedestal.

2.

Feed the pull wire (thin, 2.5-m-long wire for pulling cables through pedestal) through the top of

the pedestal and out the appropriate cable entry.

3.

Put the gland nut and ferrule of the cable gland on the cable and slide them a few meters down

the length of the cable away from the pedestal. Keep the nut and ferrule on the cable in order to

tighten them in a later installation step.

2020-04

21

VisuNet GXP

Mechanical Installation

4.

Attach the cable to the pull wire.

22

2020-04

VisuNet GXP

Mechanical Installation

5.

Pull the cable through the cable entry and out the top of the pedestal.

6.

Pull the cable through the pedestal so that 50 cm of cable is hanging out of the top of the

pedestal.

7.

Repeat the preceding steps for each cable that must be routed through the pedestal.

2020-04

23

VisuNet GXP

Mechanical Installation

3.3.4 Attaching the Pedestal to the Housing

Warning!

Risk of injury

Lifting the GXP housing on your own may cause injury.

Do not attempt to lift the device on your own. Use a crane or have another person help you.

Mounting the Pedestal

1.

Rest the pedestal on the box that the GXP housing was shipped in. Position the pedestal and

box behind the housing.

2.

Slide the cable ends from the top of the pedestal through the openings in the bottom of the

housing.

24

Warning!

Damage to cables

The cables may become damaged if they are pinched between the pedestal

and the housing.

Ensure that the cables do not get caught between the pedestal and housing

during the mounting process.

3.

Align the mounting holes on the top of the pedestal with the mounting holes on the back of the

housing.

2020-04

VisuNet GXP

Mechanical Installation

4.

Tighten the 6 x M8 screws in a criss-cross pattern to 20 Nm.

5.

Tighten the 2 x M6 screws to 12 Nm.

2020-04

25

VisuNet GXP

Mechanical Installation

Positioning and Floor-Mounting the GXP

1.

Remove the box from under the pedestal and carefully position the system upright on the floor

with a crane or the help of another person.

26

2.

Mount the pedestal onto the floor using suitable screws.

Warning!

Proper floor mounting

It is the installer's responsibility to select a suitable location with sufficient

strength to hold the equipment. It is the installer's responsibility to select the

proper screws based on the installation conditions.

3.

Remove the protective foam blocks.

4.

Remove the protective plastic film from the screen. This should not be present in a hazardous

location.

Note

For more information on floor mounting, including hole patterns, see see chapter 3.3.1.

Note

The StandardLine pedestal is depicted above. Follow the same steps to mount the VisuNet

GXP with the BasicLine pedestal.

2020-04

VisuNet GXP

Mechanical Installation

3.3.5 Opening the Housing

The GXP housing is hinged and opens to the left.

Opening the GXP

Warning!

Risk of Damage and Injury

Opening the GXP housing before the pedestal is mounted onto the floor may

cause the housing and pedestal to tip over.

Mount the pedestal to the floor before opening the GXP housing.

1.

Loosen the 4 screws on the back of the housing.

2.

Gently pull the front side of the housing toward you.

2020-04

27

VisuNet GXP

Mechanical Installation

3.

Pull the right side of the housing front away from the back part of the housing.

28

2020-04

VisuNet GXP

Mechanical Installation

3.3.6 Grounding the Housing to the Pedestal

Warning!

Customer responsibility to verify grounding path

Check the grounding path after completing system installation.

The AG1 housing comes with a pre-installed PE wire that is connected from the inside-top of

the housing to the inside-back of the housing. The pedestal comes with a pre-installed PE wire

that you must route from the pedestal into the housing (see see chapter 3.3.3).

Connecting the PE Wires

1.

Remove the nuts and washers from the PE stud on the inside-back of the AG1 housing.

2.

Connect the pre-installed PE wires from the the housing and pedestal to the PE stud.

2020-04

29

VisuNet GXP

Mechanical Installation

3.

Replace the nuts and washers. Fasten the nuts and washers with a torque of 7.5 Nm.

30

Figure 3.2 Grounding Concept

1 Housing

2 PE stud (hexagon socket)

3 Contact washer

4 Nut

5 Cable lug

6 Flat washer

7 Spring washer

8 Nut

2020-04

VisuNet GXP

Mechanical Installation

3.3.7 Mounting the Keyboard

1.

Remove the plug and screws from the bottom of the housing

2.

To remove the plug, open the housing (see see chapter 3.3.5). Hold the the inside nut while

removing the plug from the outside with a flat-head screwdriver.

2020-04

31

VisuNet GXP

Mechanical Installation

3.

Pull the keyboard wire through the plug and tighten the screws to 4.5 Nm.

Note

The keyboard is an intrinsically safe device. Refer to the control drawings and relevant

installation requirements.

For proper electrical termination of the keyboard, refer to the TCU/PCU and EXTA2 keyboard

manuals.

32

2020-04

VisuNet GXP

Mechanical Installation

3.3.8 Mounting the Scanner Holder to the AG1 Housing

Required Installation Tools

• Size 3 hex wrench

• Safety gloves

All tools should be torque controlled if a torque is specified.

Figure 3.3 #548268 scanner holder compatible with AG1 housing

2020-04

33

VisuNet GXP

Mechanical Installation

Mounting the Scanner Holder

1.

Open the AG1 housing. See chapter 3.3.5

2.

Remove the screws on the right side of the AG1 housing.

34

3.

Affix the barcode reader using the screw included in delivery with the barcode reader holder.

4.

Use a hex key to put the first screw (with lock washer and sealing washer) through the drilled

hole on the right side of the AG1 housing.

5.

Press the scanner holder against the housing from the outside. Fasten the screw using a torque

of 6 Nm.

6.

Use the hex key to put the second screw (with lock washer and sealing washer) through the

drilled hole on the right side of the AG1 housing. Fasten the screw using a torque of 6 Nm.

The scanner holder is now attached to the housing.

2020-04

VisuNet GXP

Mechanical Installation

Follow the same steps to mount the holder bracket-AG1-IDMx61-B-N0 for the IDM base station

(#548395) to the AG1 housing.

2020-04

35

VisuNet GXP

Mechanical Installation

36

Figure 3.4 Technical drawing - dimensions with scanner holder.

2020-04

VisuNet GXP

Mechanical Installation

Figure 3.5 Dimension drawing with holder bracket

3.3.9 Installing the Handheld 1-D/2-D Code Reader

Required Components

• S3 or S4 Interface (thin client / PC-unit)

• DATL-IDM-DB-S-XX00-N0

• CBL-IDMx60-D-J1-S-S18-N0 or CBL-IDMx60-D-J1-S-C38-N0

• IDM-Z1-160-D-1D-J1-*, IDM-160-D-1D-J1-*, IDM-Z1-260-D-2D-J1-S1-N-N0, or IDM-Z1-

x61-*, IDM-x61-* in combination with required Bluetooth handheld barcode reader

• Optional: SCANNER-HOLDERU1-AG1-N0 or HOLDER-BRACKET-AG1-IDMx61-B-N0

2020-04

37

VisuNet GXP

Mechanical Installation

Required Installation Tools

• Flat head screwdriver

• 19 mm socket wrench for counter nut and connector

• Size 2.5 hex wrench for cable tie screws

• Safety gloves

All tools should be torque controlled if a torque is specified.

Connector cable DATL-IDM-DB-S-XX00-N0

38

Figure 3.6 Connector cable for wired 1-D scanner IDM-Z1-160-D-1D-J1- S-* (S3-Interface required)

and 2-D scanner IDM-Z1-260-D-2D-J1-S* (S4-interface required) 4-wire with

ferrules—IDM scanner connection via M12 connector.

Note

Supports only RS-232 scanner / base station

2020-04

VisuNet GXP

Mechanical Installation

Installing the cable DATL-IDM-DB-S-XX00-N0

1.

Open the AG1 housing. See chapter 3.3.5

2.

Remove the plug at the bottom-right side of the housing by holding the screw steady from

below with a screwdriver while loosening the screw from above with a wrench.

2020-04

39

VisuNet GXP

Mechanical Installation

3.

Guide the open wire end of the cable DATL-IDM-DB-S-XX00-N0 through the hole.

40

4.

Place the M16 counter nut over the end of the cable.

2020-04

VisuNet GXP

Mechanical Installation

5.

Pull the socket into the housing and tighten it with the M16 counter nut. Tighten the nut with a

torque of 5 Nm.

6.

Protect the cable from mechanical damage by fastening it with a cable tie.

2020-04

41

VisuNet GXP

Mechanical Installation

7.

Route the cable through the cable gland on the TCU/PCU. Install the wire ends per the tables

below.

Wiring Guide

DATL-IDM-DB-S-XX00-N0 to IDM-Z1-160* and Base Station IDM-Z1-x61-B-N0* Ex i

TCU Cable

Terminal Signal

Xx.1 Vcc Supply Vcc green 1

Xx.2 GND Supply GND brown 3

Xx.3 - - - - -

Xx.4 - - - - -

Xx.5 - - - - -

Xx.6 RxD I TxD white 4

Xx.7 - - - - -

Xx.8 - - - - -

Name Direction Assignment Color coding Pin M12 con-

nector

DATL-IDM-DB-S-XX00-N0 to IDM-Z1-260*

TCU Cable

Terminal Signal

Name Direction Assignment Color coding Pin M12 con-

Xx.1 Us Supply Vcc green 1

Xx.2 RxD I TxD white 4

Xx.3 - - - - -

Xx.4 - - - - -

Xx.5 GND Supply GND brown 3

Xx.6 - - - - -

Xx.7 - - - - -

Xx.8 - - - - -

Note

For detailed information on electrical installation, refer to the TCU/PCU and IDM* barcode

reader manuals.

nector

42

2020-04

VisuNet GXP

Mechanical Installation

Connecting the IDM* Barcode Reader

Connect the plug (M12 male connector) of the barcode reader to the socket and tighten it

firmly.

Coded Plug and Socket

Figure 3.7 The plug and socket are coded. Match the coding on the plug and socket before tightening.

3.4 Replacing a VisuNet EX1 with the 19-Inch VisuNet GXP

General Requirements

• Deenergize the machine or plant.

• Ensure that there are no combustible gases in the installation area while the VisuNet sys-

tem is being dismantled.

Warning!

External equipotential bonding

The housing must be provided with external equipotential bonding. The equipotential bonding

conductor must have a minimum cross section of 4 mm 2 and be as short as possible. It must

remain connected until the device has been completely dismantled.

Warning!

Waiting period after disconnecting supply voltage

Wait three minutes after disconnecting the supply voltage before opening the Ex e terminal

compartments. Internal capacitors could otherwise still be charged, leading to an explosion in

the event of a short circuit. If the Ex e terminal compartment is open, the explosion protection is

no longer effective.

2020-04

43

VisuNet GXP

Mechanical Installation

3.4.1 Removing VisuNet EX1 from AG1 Housing

Required Installation Tools

• 3-mm wide flat head screwdriver

• Phillips head screwdriver

• Cable gland installation tool

• Ratchet strap or, preferably, a second person to help you

• Socket wrench extension with size 10 magnetic socket for EX1 nuts

• Safety gloves

• Size 5 hex wrench for housing screws

• Size 10 socket wrench for ground bolt

All tools should be torque controlled if a torque is specified.

Removing the VisuNet EX1

1.

Disconnect the supply voltage (24 V DC) for the VisuNet supply line (X1).

2.

Open the AG1 housing. See chapter 3.3.5

3.

Wait at least three minutes, then open the Ex e terminal compartment X1.

4.

Open terminals 1 and 2 in terminal compartment X1.

5.

Open the cable gland and disconnect the supply voltage cable.

6.

Loosen all other cables in terminal compartments X1 and X2, then open the cable glands and

disconnect the cables.

7.

Seal all open cable glands in terminal compartment X1 with an Ex e-compatible plug, then

tighten the glands securely.

44

8.

Close the covers of the Ex e and Ex i terminal compartments and ensure that they are tightly

sealed in accordance with regulations.

9.

Disconnect the equipotential bonding conductor between the AG1 housing and the VisuNet

EX1.

10.

To prevent the VisuNet EX1 from falling to the floor, either secure the EX1 with a ratchet strap

prior to loosening the self-locking nut, or ask a second person to help you remove the EX1.

2020-04

VisuNet GXP

Mechanical Installation

11.

Remove the VisuNet EX1 from the AG1 housing. Be sure to wear safety gloves to protect your

hands.

Warning!

Risk of damage

When setting the VisuNet EX1 down, do not rest the EX1 on the edge of the front plate.

2020-04

45

VisuNet GXP

Mechanical Installation

3.4.2 Installing VisuNet GXP into AG1 Housing

Required Components

• VisuNet GXP 19-inch prepared for panel mounting (S2 option)

• AG1 housing

Required Installation Tools

• 3-mm wide slot head screwdriver

• Phillips head screwdriver

• Cable gland installation tool

• Tools for preparing cables (wire stripper, crimp tool, and wire end ferrules

• Ratchet strap or, preferably, a second person to help you

• Socket wrench extension with size 10 magnetic socket for housing nuts

• Size 5 hex wrench for housing screws

• Size 8 socket wrench for ground bolt

• Methylated spirit or cold cleaner

• Safety gloves

All tools should be torque controlled if torque is specified.

46

2020-04

VisuNet GXP

Mechanical Installation

Installing the VisuNet GXP

1.

Connect the AG1 housing to an external equipotential bonding conductor.

2.

Close the AG1 housing, but do not yet insert the screws to fasten the housing closed.

3.

Insert the 19-inch VisuNet GXP into the opening of the AG1 housing. Be sure to wear safety

gloves to protect your hands.

4.

Ensure that no foreign bodies are attached either to the front plate of the VisuNet GXP or to the

connection surface of the AG1 housing. If necessary, clean the surfaces with methylated spirit

or cold cleaner before installing the VisuNet GXP.

5.

While securing the VisuNet GXP housing to prevent it from falling, swing the AG1 front housing

sideways along with the GXP.

Note

Check the surrounding seal of the front plate for damage before installing the

VisuNet GXP.

6.

Tighten the self-locking nuts onto the threaded pins on the front plate using the magnetic

wrench.

7.

Connect the equipotential bonding conductor between the AG1 housing and the VisuNet GXP.

2020-04

47

VisuNet GXP

V+

V+

GND

GND

VCC

D-

D+

GND

.1TX+/D1+

.2TX-/D1-

.3D3+

.4D3-

.5RX+/D2+

.6RX-/D2-

.7D4+

.8D4-

.1

.2

.3

.4

.5

.6

.7

.8

Power Supply

+24 VDC

USB Ex e

Ethernet Ex e

X1

VCC

D-

D+

GND

VCC

D-

D+

GND

.1

.2

.3

.4

.5

.6

.7

.8

USB Ex i USB Ex i

X3

X2

.1

.2

.3

.4

.5

.6

.7

.8

.1

.2

.3

.4

.5

.6

.7

.8

Optional Modules

X4

X5

Terminal Compartment Ex e Terminal Compartment Ex i Terminal Compartment for optional modules

TTY, Ethernet, RS-232, or RS-485

TX

RX

Fiber

Optic

Mechanical Installation

8.

Wire the terminal compartments as described in the VisuNet TCU/PCU manual.

Figure 3.8 Terminal compartments

9.

Close the covers of the terminal compartments and ensure that they are tightly sealed in

accordance with regulations

10.

Close the AG1 housing.

11.

Start up the VisuNet GXP and test all connected components.

1. Switch on the power supply.

2. Check the functions of the VisuNet RM/PC, e.g., the display, external keyboard, and

mouse.

3. Switch on the machine or plant.

4. Check the functions of the machine or plant.

48

2020-04

VisuNet GXP

Mechanical Installation

3.5 Panel Mount Installation

Warning!

Proper installation

It is the installer's responsibility to select a suitable location with sufficient strength to hold the

equipment. It is the installer's responsibility to select the proper screws based on the installation conditions.

Required Components

• VisuNet GXP 19 inch bezel prepared for panel mounting or mounting into AG1 housing

(S2 option, 14 x M6 bolts included)

• No kit for panel mounting required, no panel mount bracket required

Required Installation Tools

• Safety gloves

• Loctite® Threadlocker Blue 243®

• Size 8 socket wrench for ground bolt

• Size 10 socket wrench for mounting nuts

• Appropriate tools (6.5 mm drill size) for creating the cutout

All tools should be torque controlled if a torque is specified.

If the panel mount option (S2) is chosen, no additional kit for panel mounting is required. You

will receive a pre-assembled package consisting of a display unit, a computing unit, and a

2020-04

power supply unit.

49

VisuNet GXP

499

480

167

419

400

270

Ø 6.5

± 0.5 (14 x)

Mechanical Installation

Note

If installing the device in a different housing, ensure that the operating temperature is within the

specified range or up to +50 °C.

The panel mount option is mounted from the front and placed outside the wall surface. The

monitor protrudes slightly and is exposed.

The maximum wall thickness for panel mount installation with the VisuNet GXP is 10 mm.

Use the drilling pattern below to drill holes into the surface in which the panel is to be mounted.

Use the included bolts to fasten the panel into the wall. Tighten all bolts with a torque of 4 Nm.

Drilling Pattern

Figure 3.9 The cut-out dimensions for the VisuNet GXP 19-inch are 480 x 400 mm.

2020-04

50

VisuNet GXP

Mechanical Installation

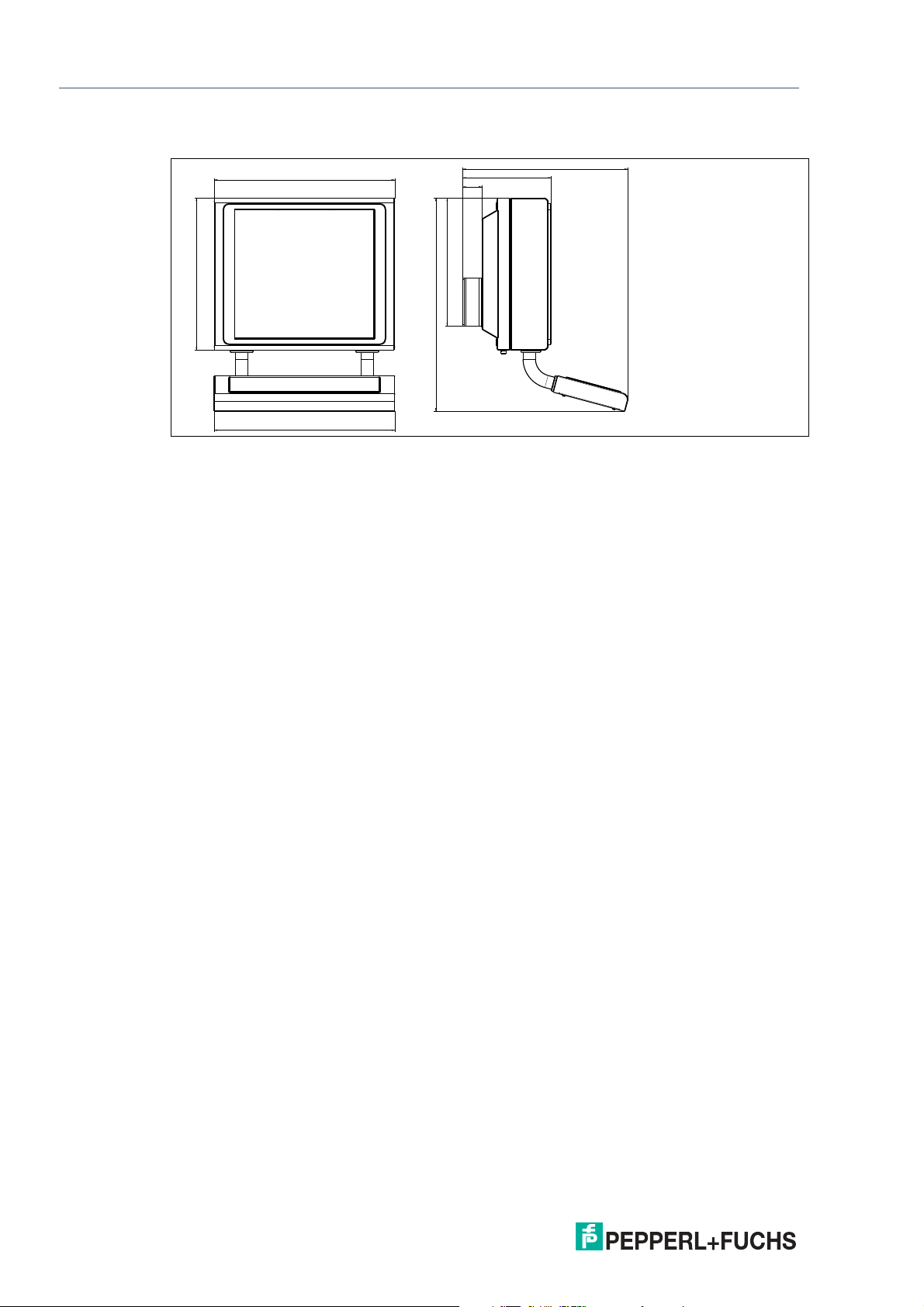

Flush Mount Installation

The 19-inch VisuNet GXP can also be flush mounted. With this mounting option (-NN), no

bezel is installed, and the monitor is recessed into the installation surface. This mounting must

be done from the back of the housing, and the fitting is kept inside the surface of the wall. The

cutout dimensions and stud location must match those on the GXP exactly.

Figure 3.10 VisuNet GXP flush mounted

Note

For more options and accessories, contact your local Pepperl+Fuchs sales representative.

2020-04

51

VisuNet GXP

490

582

583

62

532

285

686

413

Mechanical Installation

3.6 Wall Mount Installation

Warning!

Proper installation

It is the installer's responsibility to select a suitable location with sufficient strength to hold the

equipment. It is the installer's responsibility to select the proper screws based on the installation conditions.

Required Components

• 19-inch VisuNet GXP prepared for wall mounting (front opening of the AG1 housing H2

option)

• Wall bracket adapter for wall mounting installation compatible with AG1 housing

• Optional EXTA2-J-F-****-U02CF-F-10-N keyboard/mouse (ordered separately)

Required Installation Tools

• 5 mm hex wrench for attaching the wall bracket screws to the AG-XX00-* housing

• Loctite® Threadlocker Blue 243®

• Cable gland installation tool

• Size 8 socket wrench for ground bolt

All tools should be torque controlled if a torque is specified.

2020-04

52

VisuNet GXP

Mechanical Installation

Installation Steps

1.

Open the AG1 housing. See chapter 3.3.5

2.

Install cable glands with counter nuts and the two ground studs into the AG1 back wall where

indicated in the image below.

3.

Close the AG1 housing.

4.

Install the wall bracket to the AG1 housing with the included M8 screws and lock washers.

5.

Install the assembled unit to the wall with the appropriate mounting material.

Note

Secure the cable gland counter nut with a medium-strength bolt adhesive (e.g., Loctite®

Threadlocker Blue 243®).

2020-04

53

VisuNet GXP

Appendix

4 Appendix

4.1 Accessories

Mounting and Installation

Item Number Type Code Description

Contact sales for model number selection

198768 WALL-BRACKET5 Direct wall mount bracket for

Peripherals

Item Number Type Code Description

Contact sales for individual

configuration

Contact sales for model selection

Contact sales for model selection

548333 CBL-IDMx60-D-J1-S-S18-N0 Cable for connecting IDMx-

548334 CBL-IDMx60-D-J1-S-C38-N0 Cable for connecting IDM-Z1-

548268 SCANNER-HOLDER-U1-

548395 HOLDER-BRACKET-AG1-

PEDESTAL5-XXXX-* StandardLine or BasicLine

EXTA2 product family Keyboard and mouse system

IDM-Z1-x60-D* Corded 1-D and 2-D handheld

IDM-Z1-x61-M* Bluetooth 1-D and 2-D hand-

AG1-N0

IDMx61-B-N0

pedestal

VisuNet GXP AG1 housing,

stainless steel (1.4301/304

Mounting options for Zone

1/21 hazardous locations

reader for Zone 1/21

held reader for Zone 1/21

Z1-60-D-* barcode readers to

the VisuNet GXP

Length: 1.8 m

x60-D-* barcode readers to

the VisuNet GXP

Length: 3.8 m

Scanner holder compatible

with AG1 housing

Material: stainless steel AISI

316L (1.4404)

Compatible with IDM-Z1-6x,

IDM-6x, ecom Ident-Ex 01,

and PSCAN

Prepared for mounting to right

side of housing

Bracket to mount IDM-Z1-61*, IDM-x61-* base station to

AG1 housing

Material: stainless steel AISI

304 (1.4301)

Assembly: right side of AG1

housing

Includes bracket and installation materials

Note: base station and cables

not included!

54

Note

For more options and accessories, contact your local Pepperl+Fuchs sales representative.

2020-04

VisuNet GXP

This document contains safety-relevant information. It must not be altered without the authorization of a NE EX

Only valid as long as released in EDM

date: 2017-AUG-28

Control Drawing for GXP Sysytem and TCU or PCU No n-incendive Outputs

116-B034A

Global

sheet 1 of 1

Connections

X3.1 / X3.5 – VCC

X3.2 / X3.6 – DX3.3 / X3.7 – D+

X3.4 / X3.8 – GND

X4.1 / X5.1 - Us

X4.4 / X5.4 - TxD

X4.6 / X5.6 - RxD

X4.2 / X5.2 – GND

X4.4 / X5.4 - TxD

X4.6 / X5.6 - RxD

X4.2 / X5.2 - GND

NI Apparatus

NI Apparatus

NI Apparatus

GXP TCU or PCU NI Outputs

Hazardous Location

Class I, Division 2, Groups A, B, C, D; T4

Class II, Division 2, Groups F, G; T4

Class III

Class I Zone 2, Group IIC; T4

Class II Zone 22, Group IIIB; T85°C

Class III Zone 22, Group IIIA; T85°C

Hazardous Location

Class I, Division 2, Groups A, B, C, D; T4

Class II, Division 2, Groups F, G; T4

Class III

Class I Zone 2, Group IIC; T4

Class II Zone 22, Group IIIB; T85°C

Class III Zone 22, Group IIIA; T85°C

Type 1

Type 2

Type 3

Notes

1. The Entity Concept allows interconnection of non-incendive apparatus with associated apparatus not specifically

examined in combination as a system when the approved values of Voc (or Uo) and Isc (or Io) for the associated

apparatus are less than or equal to Vmax (Ui) and Imax(Ii) for the non-incendive apparatus and the approved values of

Ca(Co) and La(Lo) for the associated apparatus are greater than Ci + Ccable and Li + Lcable, respectively, for the nonincendive apparatus,

Where Ccable= 60pF/ft if unknown

Where Lcable= 0.20uH/ft if unknown

2. Simple apparatus: an electrical component or combination of components of simple construction with well-defined

electrical parameters that does not generate more than 1.5 V, 100mA, 25mW, or is a passive component that does not

disipate more than 1.3W and is compatible with the intrinsic safety of the circuit in which it is used.

3. Wiring methods must be in accordance with all applicable installation requirements of the county in use. For US, this is

NFPA 70 (NEC) article 504 with additional information in ANSI-ISA –RP12.06.01. For Canada this is CSA 22.1-12 (CEC)

section 18 and appendix F.

Entity Parameters

Parameter

Type 1

Type 2

Type 3

Maximum Output Voltage Uo (Voc)

4.92 V

8.95 V

8.95 V

Maximum Output Current Io (Isc)

182 mA

150 mA

58 mA

Maximum Output Power Po

570 mW

1.4 W

128 mW

Maximum external capacitance Co (Ca)

11.5 μF

19.5 μF

26.5 μF

36.5 μF

57.5 μF

400 nF

1.9 μF

Maximum external inductance Lo (La)

9 μH

4 μH

3 μH

2 μH

1 μH

199 μH

199 μH

Appendix

4.2 UL Control Drawing

2020-04

55

Pepperl+Fuchs Qua lit y

Download our latest poli cy he re:

www.pepperl-fuchs.com/quali ty

© Pepperl+Fuchs · Subject to modifications

www.pepperl-fuchs.com

Printed in Germany / DOCT-5945C

Loading...

Loading...