Page 1

2-D Laser Scanner

OMD10M-R2000-B23,

OMD30M-R2000-B23,

OMD12M-R2000-B23

FACTORY AUTOM ATION

MANUAL

Page 2

With regard to the supply of products, the current issue of the following documen t is applicable: The

General Terms of Delivery for Products and Se rvices of the Electrical Industry, published by the

Central Asso ciation of the Electrical Indus try (Zentralverband Elektrotechnik und Elektroindustrie

(ZVEI) e.V.) in its most recent version as well as the supplementary clause: "Expanded reservation

of proprietorship"

2-D Laser Scanner

Page 3

2-D Laser Scanner

Contents

2016 -01

3

1 Introduction......................................................................... 5

1.1 Introduction ...................................................................................................5

1.2 Validity ..........................................................................................................5

2 Declaration of Conformity ................................................. 6

3 Safety................................................................................... 7

3.1 Symbols Relevant to Safety ..........................................................................7

3.2 General Safety Information ............................................................................7

3.3 Laser Class 1 ................................................................................................8

3.4 Intended Use ................................................................................................8

4 Product Description ........................................................... 9

4.1 R2000 Laser Scanner ...................................................................................9

4.2 Functional Principle.....................................................................................10

4.3 Indicators and Controls ...............................................................................10

4.4 Interfaces and Connections ........................................................................11

4.5 Scope of Delivery........................................................................................12

4.6 Accessories ................................................................................................ 12

5 Installation......................................................................... 14

5.1 Storage and Transport................................................................................. 14

5.2 Unpacking...................................................................................................14

5.3 Mounting..................................................................................................... 14

5.4 Device Connection...................................................................................... 16

6 Commissioning................................................................. 17

6.1 Ethernet Configuration ................................................................................17

7 Operation........................................................................... 19

7.1 Menu Structure ........................................................................................... 19

7.2 Operation ....................................................................................................21

7.3 Description of Menu Items ..........................................................................24

7.3.1 Ethernet Info Menu Item .........................................................................24

7.3.2 Ethernet Setup Menu Item ......................................................................24

7.3.3 Sensor Setup Menu Item ........................................................................ 25

7.3.4 Demos Menu Item .................................................................................. 26

7.3.5 Tools Menu Item .....................................................................................26

7.3.6 End Menu Item .......................................................................................26

8 Maintenance and Repair.................................................. 27

8.1 Maintenance ...............................................................................................27

8.2 Repairs .......................................................................................................27

Page 4

2016 -01

4

2-D Laser Scanner

Contents

9 Troubleshooting ............................................................... 28

9.1 Troubleshooting.......................................................................................... 28

10 Appendix........................................................................... 29

10.1 Technical Data Daten "Ultra High Density" Models ..................................... 29

10.2 Technical Data "High Density" Variants ...................................................... 32

10.3 Amplitude Characteristics .......................................................................... 35

10.4 Pulse Ranging Technology (PRT) Glossary................................................ 37

10.5 Using Open Source Programs.................................................................... 37

Page 5

2-D Laser Scanner

Introduction

2016 -01

5

1 Introduction

1.1 Introduction

Congratulations

You have chosen a device manufactured by Pepperl+Fuchs. Pepperl+Fuchs

develops, produces and distribu tes e lectronic sensors and interface modules for

the market of automation technology on a worldwide scale.

Read these instructions carefully before you install this device and put it into

operation. Instructions and hints included in this manual lead you step by step

through the installation and commissioning and provide a trouble-free use of this

product. This is for your benefit, since this helps you to:

■ ensures the safe operation of the device

■ ex ploit the full functionality of the device

■ avoid operating errors and related disturbances

■ avoid costs due to disruptions and repair work

■ increase the effectiveness and efficiency of your system.

Keep these instructions for reference for later work on the equipment.

Please check after opening the package, that the device isn 't damaged and the

completeness of the delivered goods.

Symbols used

The following symbols are used in this manual:

Handling instructions

You will find handling instructions beside this symbol

Contact

If you have any questions about the device, its functions, or accessories, please

contact us at:

Pepperl+Fuchs GmbH

Lilienthalstraße 2 00

68307 Mannheim

Telephone: +49 62 1 776-4411

Fax: +49 621 776-274411

E-Mail: fa-info@pe pperl-fuchs.com

1.2 Validity

This manual applies to devices from firmware 1.20 and hardware 1.00 o nward.

The versions can be found in the device menu; see chapter 7.3.3.

For devices with older versions, documentation is available on request.

Note!

This symbol draws your attention to important information .

Page 6

2016 -01

6

2-D Laser Scanner

Declaration of Conformity

2 Declaration of Conformity

All products were developed and manufacture d under observance of the

applicable European standards and guidelines.

The product manufacturer, Pepperl+Fuchs GmbH, 68307 Mannheim, has a

certified quality assurance system that conforms to ISO 9001.

Note!

A Declaration of Conformity can b e requested from the manufacturer.

ISO9001

Page 7

2-D Laser Scanner

Safety

2016 -01

7

3 Safety

3.1 Symbols Relevant to Safety

3.2 General Safety Information

The following basic instructions must be o bserved at all times:

■ The device must not be commissioned until the manual has been read and

understood

■ The power supply to produce the supply voltage must have a safe electrical

isolation by means of double insulation and a safety transforme r according

to DIN VDE 05 51 (corresponds to IEC 742)

■ The device must not be used outside of its specification withou t suitable

protective measures

■ Modifying the device is not permitted

■ Do not point the devices in direct sunlight and do not take meas urements in

sunlight

■ Do not remove the warnings or rating plates

Installation and commissioning of all devices mus t be performed only by

personn el specially trained for that purpose.

Protection of operating personnel and the system is not ensured if the product is

not used in accordance with its intended use.

The laws and guidelines applicable for the use or the intended purpose must be

observe d. Devices are approved only for prope r usage in accordance with

intended use. Ignoring these instructions will void any warranty and absolve the

man ufacturer from any liability.

Use only recommended original accessories.

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution !

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and

plants, or result in their complete failure.

Page 8

2016 -01

8

2-D Laser Scanner

Safety

If you are unable to resolve faults, switch the device off. Make sure that the device

cannot be switched back on accidentally. If the device needs to be repaired,

return it to Pepperl+Fuchs. If you o pen or modify the device yourself, not only are

you endang ering yourself and others but you will void any warranty and absolve

the manufacturer from any liability.

Dispos e of unusable devices in accordance with the a pplicable national statutory

regulations.

For instan ce, you can take the sensor to a designated collection point for

electronic waste.

3.3 Laser Class 1

Class 1 Laser Product

This sensor is certified according to laser protection class 1.

3.4 Intended Use

The R2000 laser scanners are measuring devices that are used on automated

transport systems or other movable machinery in intralogistics. They a re also

used on stationary equipment in the area of factory a nd building automation.

Make su re that the devices are used only for their intended purpose.

Danger!

In applications involving stock feeders a nd moving carriages, care mu st be taken

to ensu re that the applicable safety regulation s are obs erved at all times.

Failure to do so may result in serious or fatal injury!

Warning!

Class 1 lase r light

The laser light can be an irritant, especially in a dark environment. Do not point

lasers at people!

Maintenance and repairs should only be carried out by authorized service

person nel!

Install the device so that the warning is clearly visible and readable.

Caution : Use of controls, adjustments, or performance of procedures other than

those s pecified herein may result in harmful laser beam exposure.

Page 9

2-D Laser Scanner

Product Description

2016 -01

9

4 Product Description

4.1 R2000 Laser Scanner

The two-dimensional R2000 laser scan ner is made up of a static body, on which a

continuously turning me asurement module with an emitter laser and receiver

element is located. The laser scanner uses Pulse Ranging Technology (PRT).

The implementation of this innovative operating principle permits unbroken

scan ning of the surroundings through a full 360°.

As a compact 360° scanner with high measuring frequen cy, small angular

reso lution, precise light spot, visible measurement beam (OMD10M-R20 00-B23),

and an integrated all-round display, the system can be used in numerous

applications in factory au tomation. In addition to completing familiar tasks from

industrial areas such as logistics, transportation, and material handling, the

system can be used for innovative ap plications in buildings automation, automatic

navigation of autonomous vehicles, or for monitoring rooms.

One particular highlight of the laser scanner is the row of LEDs arranged on the

back of the measurement module. Rotating the scanner produces a cylindershaped projection surface, wh ich is su itable for displaying text-based as well as

graphical information. In this way, commissioning and operations can be carried

out without aids such as a PC or Notebook . Operating and diagnostic information

can be seen directly during ongoing o peration.

The laser scanner from the R2000 se ries fulfills the safety requirements of laser

class 1 in measurement mode. The low amount of laser light emitted guarantees

that operating personnel are neithe r injured nor harmed.

Page 10

2016 -01

10

2-D Laser Scanner

Product Description

4.2 Functional Principle

The laser scanner works according to the principle of Pulse Ranging Technology

(PRT). As part of this principle, the time between sending a light pulse and

receiving the reflected pulse from an object is measured in the device. Due to the

constan cy of the speed of light, this time is a measurement of distance.

In comparison with other distance measurement processes, run time

measurement is affected very little by any disturbances in the measu ring

environment. As a result, this measurement process can be used with a high level

of accuracy even under tough everyday industrial conditions. The light source and

light receiver are located in the rotating sensor head.

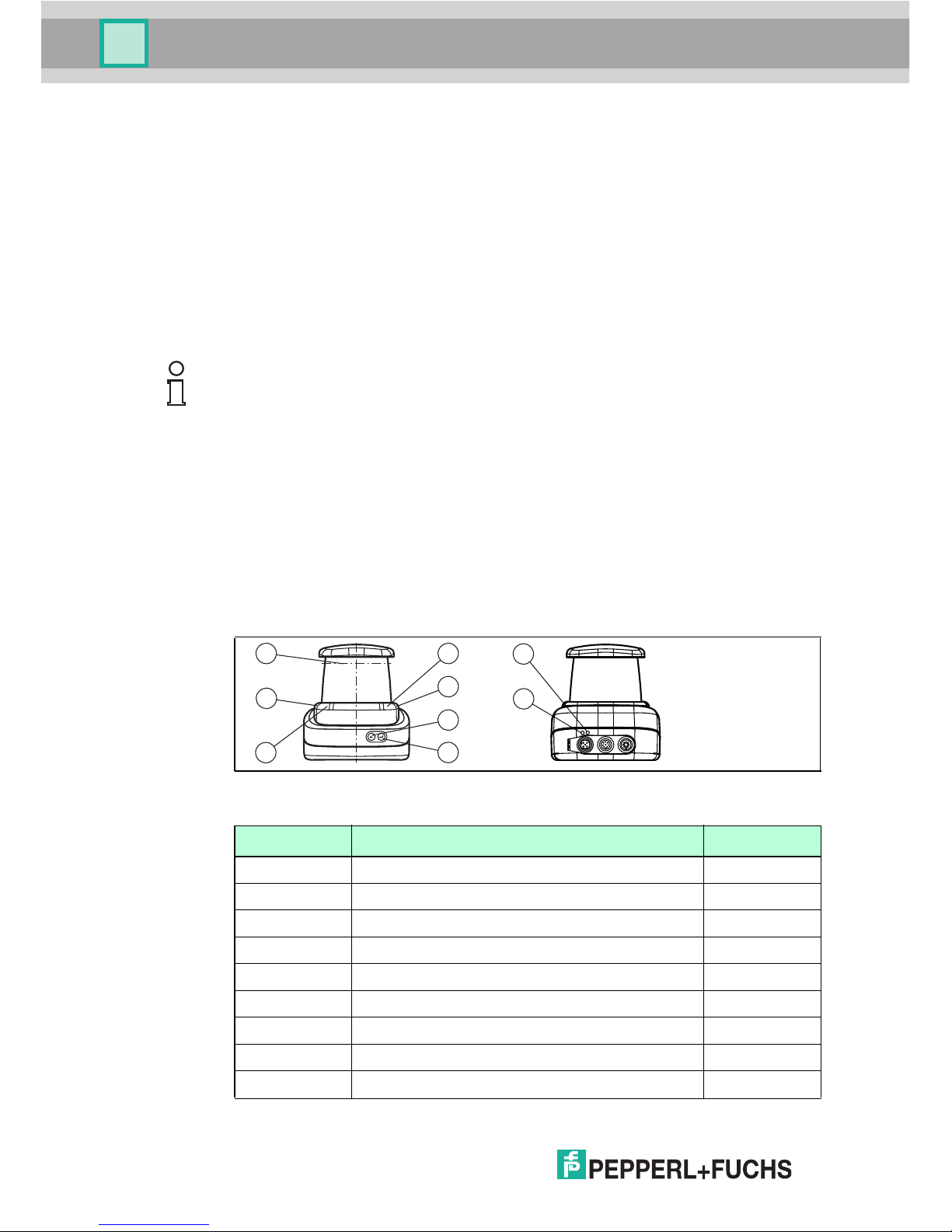

4.3 Indicators and Controls

Figure 4.1 Indicators and Controls

Note!

Influence of ambient conditions

The speed of light depends on the air temperature and barometric pressure.

The influence of the air temperature amounts to 1 pp m/K.

The influence of the barometric pressure amo unts to -0.3 ppm/hPa.

These faults must be taken into consideration b y the use r in the case of longer

distances.

In the operating range (-10 °C ... +50 °C) this fault amo unts to 0.6 mm at a

distance of 10 m.

No. Designation Color

1 Operating status indicator Green

2 Error indicator Red

3 "Next" menu button

4 "Return" menu button

5 Q2 - no function

6 Q1 - no function

7 Laser face

8 Ethernet link ind icator Green

9 Ethernet activity indicator Yellow

Table 4.1 Indicators and Controls

2

6

1

4

3

5

7

9

8

Page 11

2-D Laser Scanner

Product Description

2016 -01

11

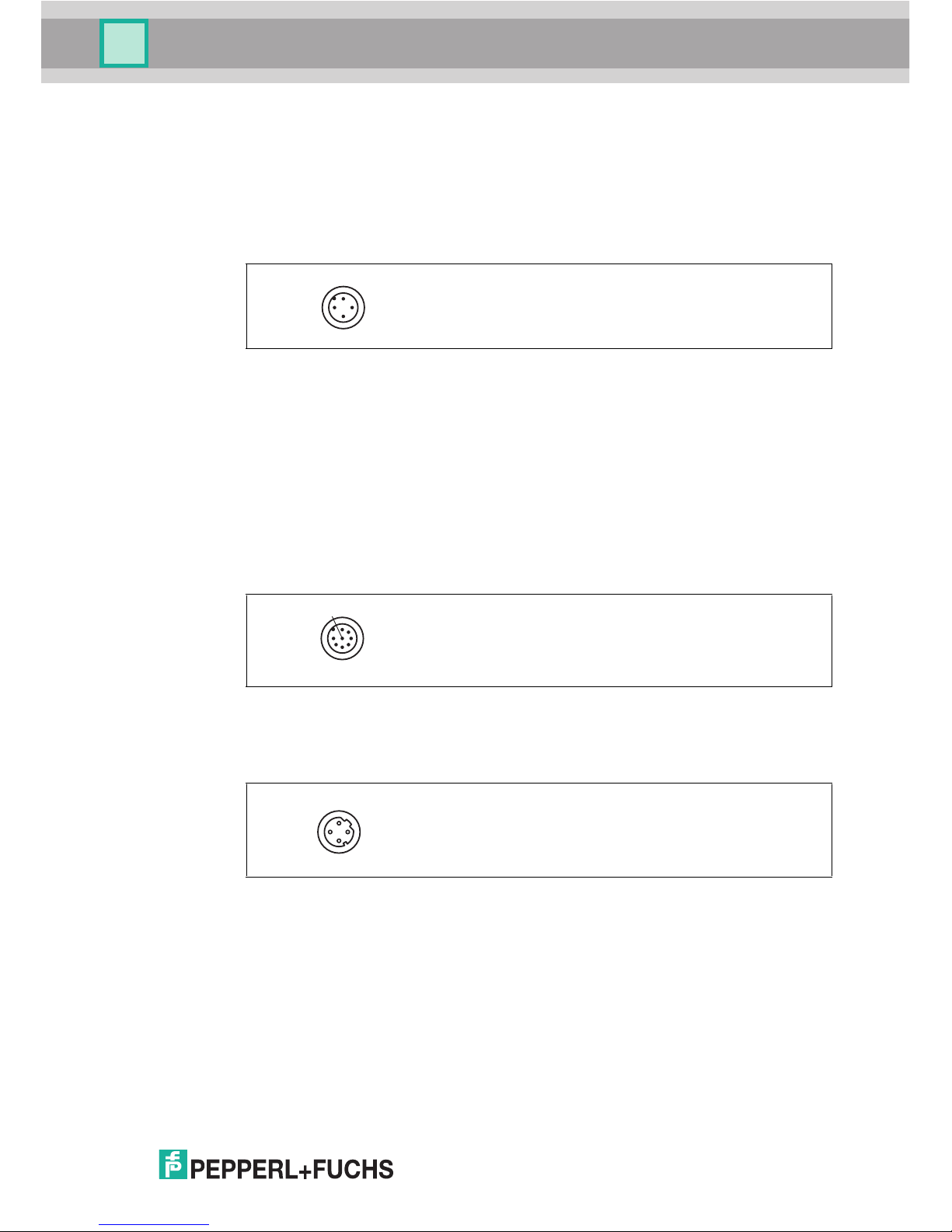

4.4 Interfaces and Connections

The following connections are found on all devices:

Power supply

There is a 4-pin M12 connector on the rear of the housing to connect the power

supply. The following diagram shows the p inning:

Figure 4.2 Power supply connectio n layout

MultiPort

The 8-pin M12 connector on the rear of the housing is for service purposes.

Interface:

There is a 4-pin M12 socket on the back of the housing to connect the Ethernet

interface. The following diagram shows the pinning:

Figure 4.3 Ethernet conne ction layout

The connector h ousing is located on the shield.

1 24 V pow er supply

2 Not used

3 Ground (GND)

4 Not used

1 TD+

2 RD+

3 TD-

4 RD-

1

3

4

2

1

4

6

7

8

53

2

1

3

4

2

Page 12

2016 -01

12

2-D Laser Scanner

Product Description

4.5 Scope of Delivery

The scope of delivery includes:

■ R2000

■ Quick start guide

■ Protective cover

■ 3 x socket cap screws, M5 x 10

■ 3 x washers, size 5

4.6 Accessories

The following products are availab le as accessories.

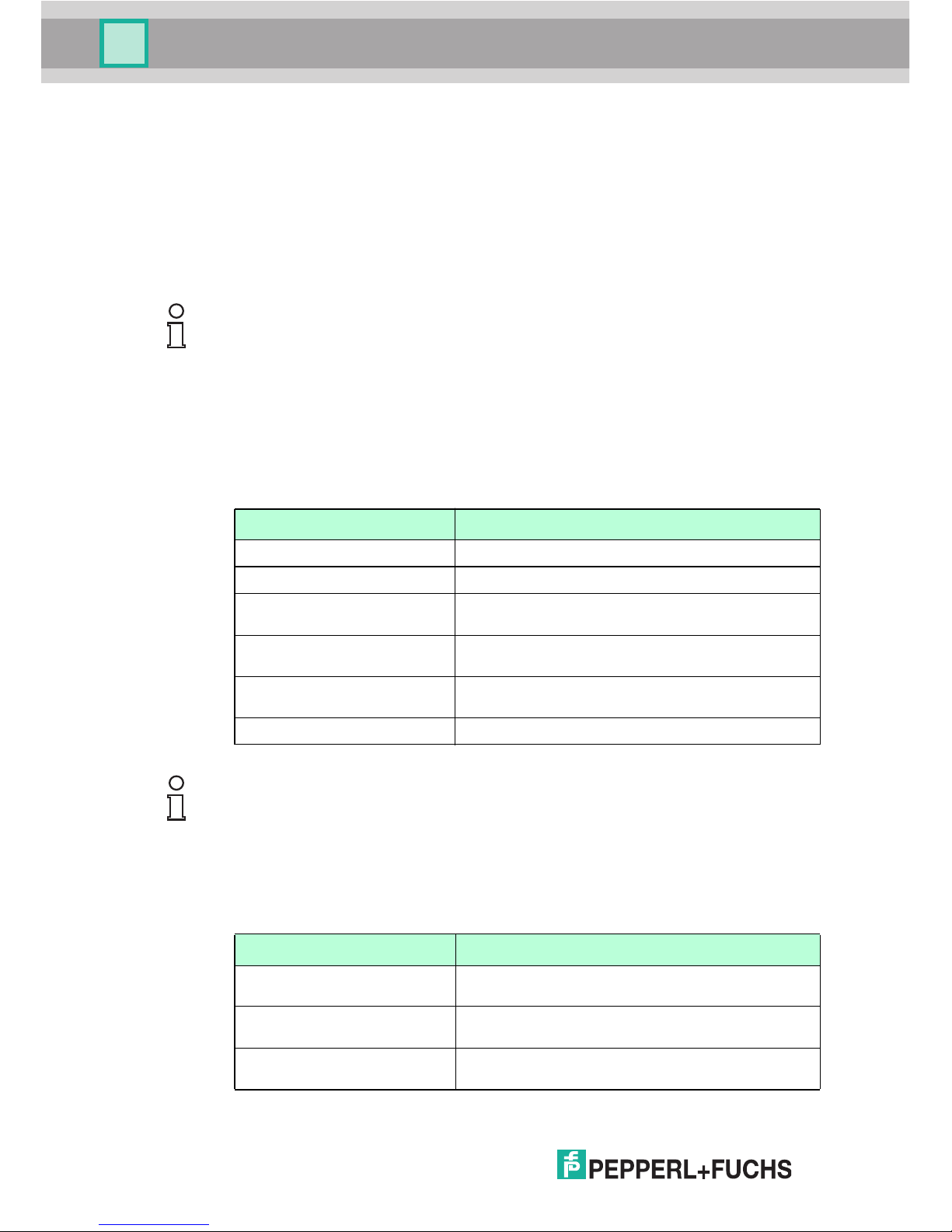

Note!

Installation Instructions for North America

If a connection is made to the M12 multi-pin connector, the product shall be use d

with a UL-listed cable/connector (CYJV) assembly rated minimum 30 VDC,

minimum 1.0 A, in the final installation for power supply.

Designation Description

V1SD-G-2M -PUR -ABG-V45-G Patch cable M12 to RJ45, len gth 2 m

V1SD-G-5M -PUR -ABG-V45-G Patch cable M12 to RJ45, len gth 5 m

V1SD-G-ABG-PG9 Single-ended male co rdset, M12 D-coded, 4-pin for

bus cable

V1-G-2M-PUR Single-ended female cordset, straight, M12 , 4-pi n,

PUR cable

V1-W-2M-P UR Single-ended female cordset, angled, M12, 4-pin,

PUR cable

MH-R2000 Mounting bracket, quick-lock and adjustment aid

Note!

Installation Information for North America

If a connection is made with the M1 2 multi-pin connector, then in the final

installation of the power supply, the product must be used with a UL-listed

cable/conn ector assembly (CYJV) that is designed for at least 30 VDC and at least

1.0 A.

Designation D escription

V1-G-BK-2M-PUR -U Single-ended female cordset, straight, M12, 4-pin,

PUR cable, leng th 2 m, "UL recognized"

V1-G-BK-5M-PUR -U Single-ended female cordset, straight, M12, 4-pin,

PUR cable, leng th 5 m, "UL recognized"

V1-G-BK-10M -PUR -U Single-end ed female cordset, straight, M12, 4-pin,

PUR cable, leng th 10 m, "UL recognized"

Page 13

2-D Laser Scanner

Product Description

2016 -01

13

To parameterize the 2-D laser scanner conveniently via a software interface, you

need the corresponding device type manager (DTM) in addition to the FDT

framework program (PACTware 4.x). Both PACTware and the DTM are available at

www.pepperl-fuchs.com.

Page 14

2016 -01

14

2-D Laser Scanner

Installation

5 Installation

5.1 Storage and Transport

Package the device for storage and transport such that it is protected from impact

and moisture. The original packaging provide s optimum protection. Also take note

of the permitted ambien t conditions.

5.2 Unpacking

Check the product for damage while unpacking. In the even t of damage to the

product, inform the post office or parcel service and notify the supplier.

Retain the original packaging in case the device mus t be stored o r shipped again

at a later date.

Should you have any questions, please direct them to Pepperl+Fuchs.

5.3 Mounting

The device can be fitted with the supplied socket head screws with washers on

the underside of the device.

Note!

If the temperature is s ubject to major fluctuations during transport, the device

must be allowed to a cclimatize for around two hours prior to installation and use.

During this acclimatization period, avoid subjecting the device to condensation at

all costs, as this could have an effect on intern al parts and cause damage.

Caution!

Safety information

Do not point the sensor into the sun.

Protect the sensor against direct and prolonge d su nlight.

Prevent condensation from forming by ensuring that the sensor is not subjected to

any major temperature fluctuations.

Do not subject the sensor to aggressive chemicals.

Keep the glass on the device clean.

For clea ning, use only water (if necessary with a little detergent) and a soft

microfiber cloth! The use of other detergents is not permitted! The glass must

never be cleaned when dry!

Caution!

Screw-in depth

The maximum screw-in depth in the base must not exceed 8 mm, otherwise the

device will be mechanically destroyed! The minimum screw-in depth is 5 mm.

Page 15

2-D Laser Scanner

Installation

2016 -01

15

Figure 5.1 Dimensional drawing R2000

70

(40)20

60

20

53

106

117.5

4658

116.5

106

16

97.1

3 x M5

20

45

Emitter range and receiver range

Complies with 21 CFR

1040.10 and 1040.11 except

for deviations pursuant to

Laser Notice No. 50,

dated June 24, 2007

CLASS 1

LASER PRODUCT

IEC 60825-1: 2007 certified.

Note!

Keep the emitting/receiving area clear

During assembly, make sure that the emitting/receiving area is kept clear. If the

emitting /receiving area is covered, this reduces the performance of the 2D laser

scan ner.

Page 16

2016 -01

16

2-D Laser Scanner

Installation

5.4 Device Connection

Electrical connection in line with IP65

Put protective cove rs on unused M12 conne ctors.

The IP65 protection class is achieved. The protective covers can be ordered

as accessories see chapter 4.6.

The device conforms to protection class III. This means that the power has to be

supplied as a low protective voltage (PELV).

The power supply of the device is 10 VDC ... 30 VDC. Due to the integrated motor,

an increase d level of startup current is required compared with no rmal op eration.

It is recommended that power sup plies with 1 A (at 24 V) or with 2 A (at 12 V) are

used.

The maximum cable length is 3 0 m.

The pin assignment is as follows:

Figure 5.2 R2000 pin assignment

PowerMultiportLAN

4

1

2

3

TD+

TD-

RD-

Shield

4

1

2

3

24 V DC

0 V

RD+

Shield

1

3

4

2

1

3

4

2

Page 17

2-D Laser Scanner

Commissioning

2016 -01

17

6 Commissioning

1. Connect the device to the power supply.

The initialization phase lasts approx. 15 seconds. This ph ase is sh own by

circles moving down the display.

2. After the initialization p hase, the Pepperl+Fuchs logo will appear.

The device is now ready for operation.

To achieve the best measure ment accuracy, allow the device to warm up for 30

minutes.

The sensor has bee n tested and calibrated before delivery. It can be put into

operation immediately.

In general, it is recommended to u se a dedicated network card for the conn ection

to the device.

6.1 Ethernet Configuration

The device has three different address modes. Select your preferred mode from

the modes described below. The setting is configured directly on the device using

the menu interface.

Auto IP

In this mode, the device independently selects a "Link-Local" IP address in the

169.25 4.0.0/16 range. It is ens ured that the selected address is not already being

used by another device.

The device is configured to Auto IP by default. The Auto IP setting is the ideal way

to establish a direct connection to a PC. Set the DHCP mode (Dynamic Host

Configuration Protocol) on the PC. To do this, select the TCP/IP protocol in the

network card properties and select the "Obtain an IP address automatically"

setting there. After approx. 30 seconds, Windows assigns an Auto IP for the PC.

Page 18

2016 -01

18

2-D Laser Scanner

Commissioning

DHCP

Set the device to DHCP under the "Address mode" menu item. The DHCP

configuration requires a DHCP server in the local network, e.g., a router. See the

"Auto IP" item for information on this.

Manual IP

Set the device to manual under the "Address mode" menu item. The IP address is

set to 10.0.10.9 and the subnet mask to 255.0.0.0 by default. To conne ct the

device to the PC, the network card must be configured as fo llows. Set the required

IP address in the network card menu. Select the TCP/IP protocol in the network

card properties and select the "Use the following IP addres s" setting there. Enter

the required IP address and subnet mask in these fields.

Note!

Device restart

Yo u must restart the device after ch anging the Ethernet configuration.

Page 19

2-D Laser Scanner

Operation

2016 -01

19

7 Operation

7.1 Menu Structure

Menu

Adress Mode

IP Address

Gateway

MAC Address

Back

Ethernet Info

Adress Mode

IP Address

Gateway

Reboot

Back

Ethernet Setup

Manuel

DHCP

Back

Auto IP

Subnet Mask

Subnet Mask

Page 20

2016 -01

20

2-D Laser Scanner

Operation

Language

Display mode

Version Info

Factory Defaults

Sensor Setup

Firmware

Hardware

PFSDP

Back

English

German

Back

Display Off

Static Logo

Bargraph distance

Bargraph reflector

Static Text

Application bitmap

Application text

Back

Bargraph echo

Load

Back

Page 21

2-D Laser Scanner

Operation

2016 -01

21

7.2 Operation

The sensor is operated using two buttons, located on the front of the sen sor, with

which you can navigate in the menu structure. You can change the parameters or

enter values u sing these buttons.

Meaning of Buttons

Sensor eyes

Tape measure

Demos

Back

Alignment aid

Tools

End

This button is used as the "Next" button. Pressing this butto n

takes you to the next menu item. You can change a value wit h

this button.

This button has a sim ilar function to the ARRO W button on

the computer keyboard.

Pressing this butto n selects the displayed menu item.

This button has a similar function to the ENTER button on the

computer keyboard.

Page 22

2016 -01

22

2-D Laser Scanner

Operation

In each menu item, the values already set are displayed with an underscore.

These values can be cha nged. However, please note that thes e values should

only be changed by personn el with the ne ces sary expe rtise on the imp act of the

change.

If no other button is pressed within 60 seconds in the menu levels, the menu is

ended automatically.

Navigation in the Menu

Change count parameters

Menu display

Top row The current menu level is shown in the top row.

Bottom row The currently sel ected element is shown in the botto m row.

Dash One dash means that you are in the main menu.

Two dash es me an that you are in the submenu.

Operation

Pressing the ENTER butto n takes you into the menu structure.

You change to the next menu eleme nt.

If you hold down (> 1 second) the "Next" button or "ENTER"

button, you will change to the next higher menu element.

You change to the selected menu element

If you hold down (> 1 second) the "Next" button or "ENTER"

button, you will change to the next higher menu element.

Menu entry

End This menu entry e nds the main menu.

Back This menu e ntry changes to the next higher menu element

Menu display

Top row This shows the current parameter.

Bottom row This shows the currently selected parameter value.

Underli ned parameter

value

This is the currently activated value.

Operation

You change to the next available parameter value.

If you hold down the button (> 1 second), you will change to

the next highe r menu element without changing the

parameter.

You activate the parameter value currently displayed.

If you hold down the button (> 1 second), the displayed

parameter is activated and the displ ay returns to the higherlevel menu ele ment.

Page 23

2-D Laser Scanner

Operation

2016 -01

23

Changing Numerical Parameters

IP Configuration Display

Back Menu Item

You return to the higher-level menu via the "Back" men u item

Menu display

Top row Th is shows the name of the displayed p arameter.

Botto m row This shows the curren t value of the parameter.

Underline d p arameter

value

This is the parameter value currently being edited.

Operation

You increase the currently selected digit.

If you hold down the button (> 1 second), you increase the

selected digit at a faster rate

You chang e to the next editable digit.

If you hold down the button (> 1 second), you change to the

confirm menu.

Confirm menu

Top row Th is shows the changed number.

Botto m row This shows the action s that can be carried out (Save, Edit,

Cancel).

"Save" action The changed value is accep ted and saved.

"Edi t" action You change back to the edit display.

"Cancel" action The changes are rejected and you change to the higher-level

menu.

Menu display

Top row Name of the displayed parameter.

Botto m row This shows the curren t value of the parameter.

Operation

You chang e to the next menu element.

If you hold down (> 1 second) the "Next" button o r "ENTER"

button, you will change to the next higher menu element.

no function

If you hold down (> 1 second) the "Next" button o r "ENTER"

button, you will change to the next higher menu element.

Page 24

2016 -01

24

2-D Laser Scanner

Operation

7.3 Description of Menu Items

7.3.1 Ethernet Info Menu Item

This menu item provides fast access to the IP configuration currently in use. The

data can be read only in this menu item.

Address Mode

The address mode currently being used is displayed in this subitem.

IP Address

The IP address currently being used is displayed in this subitem.

Subnet Mask

The subnet mask currently being used is displayed in this subitem.

Gateway

The gateway currently being used is displayed in this subitem.

MAC Address

The MAC address currently being u sed is displayed in this subitem.

7.3.2 Ethernet Setup Menu Item

Chang e the IP configuration data in this menu item.

Address Mode

■ "Manue l": Here an IP address, the subnet mask, and the gateway can be

assign ed manually to the device

■ "DHCP": Th e device is assigned an IP address by a DHCP server (e.g.,

Windows PC)

■ "AutoIP": The device can be detected automatically by the PC

IP Address

The IP address to be used in the address mode : "Manual" can be set in this menu

item.

Subnet Mask

The subnet mask to be used in the address mode: "Manual" can be s et in this

menu item.

Gateway

The Gateway can be set in this menu item.

Note!

Changing the IP Configu ration

Chang es to the IP configuration take effect on ly after a restart! The IP

configuration currently used by the device is displayed in the "Ethernet Info" menu

item. If these settings differ from the settings made under the "Ethernet Setup"

menu item, the device must be restarted.

Page 25

2-D Laser Scanner

Operation

2016 -01

25

Reboot

The device can be restarted in this menu item.

7.3.3 Sensor Setup Menu Item

Language

The language can b e set to German or English using this menu item.

Display mod e

The display mode defines the display in normal mode w hen the menu is not

active. The display mode is set on a permanent basis. It is active following a

restart.

■ Display off: The display goes dark as soon as the menu is exited.

■ Static logo: The display shows the Pepperl+Fuchs logo. The log o can be

replaced with a custom bitmap file that will still be available after switching

the device on/off (saved in EEPROM). See the Ethernet protocol

description for details on programming .

■ Static text: The display shows the text "Pepperl+Fuchs R2000". The text

can be replaced with custom text that will still be available after switching

the device off/on (saved in EEPROM). See the Ethernet protocol

description for details on programming .

■ Bargraph distance: The display shows a bar graph indicating the

distance. The measured values in all directions are shown in the form of a

bar chart. The bars become s maller as the distance increase s.

■ Bargraph reflector : A ba r is shown on the display at the point at which a

reflector is detected.

■ Bargraph echo: The measured signal strength is shown in the form of a

graph on the display.

■ Application bitmap: A custom bitmap file (24x252 bit) is show n on the

display that is no long er available after switching off the device (saved in

RAM). See the Ethernet protocol description for details on programming.

■ Application text: Custom text is shown on the display that is no longer

available after switching off the device (saved in RAM). See the Ethernet

protocol description for details on p rogramming.

Note!

Changing the IP Configuration

Change s to the IP configuration take effect only after a restart! The IP

configuration currently used by the device is displayed in the "Ethernet Info" menu

item. If these settings differ from the settings made under the "Ethernet Setup"

men u item, the device must be restarted.

Note!

The Static logo and Static text display modes are suitable for infrequent

changes to the logo and text data.

The Application bitmap and Application text display modes are suitable for

frequent changes to the logo and text data.

Page 26

2016 -01

26

2-D Laser Scanner

Operation

Version Info

■ Firmware: The display shows the current version of the firmware.

■ Hardware: The display shows the current version of the hardware.

■ PFSDP: The display shows the current version of the Pepperl+Fuchs Scan

Data Protocol.

Factory defaults

The factory defaults for the sensor can be loaded in this menu item. To do th is, you

must select "Loa d" in the submenu an d confirm by pressing the "Enter" button.

Yo u must restart the device to accept all the changes.

7.3.4 Demos Menu Item

A demo is only active temporarily. As soon as an other option is selected in the

menu, the demo becomes inactive. This a lso applies to res tarting.

Sensor Eyes

A pair of eyes, which focuse s on moving objects, appears o n the display. If no

activity is detected within five seconds, the "eyes" close. If scanner movement is,

in fact, detected, the "eyes" open again.

Tape Measure

In this demo, the scanner measures the distance in a forward direction (x-axis).

The value is then shown in the display.

7.3.5 Tools Menu Item

Alignment aid

A bar is shown on the display at the point at which a reflector is detected. An

angular scale is shown at the bottom of the display. The "Alignment aid" tool is

automatically exited after approximately ten minutes an d the stored display mode

is activated.

7.3.6 End Menu Item

End

Pressing the "Enter" button to confirm ends the menu and the display mode set is

displayed.

Page 27

2-D Laser Scanner

Maintenance and Repair

2016 -01

27

8 Maintenance and Repair

8.1 Maintenance

Observe the applicable nation al regulations whe n maintaining the sensor.

Essentially, the sensor is maintenance free. Nonetheless, check the technical

safety of the se nsor system at regular intervals by loo king for damage to the

housing . Ch eck the sens or for dirt every now and then. To clean the sensor, wipe

it at regular intervals with a dry or damp soft cloth. This will ensure it continues to

function properly. The housing is made of plastic. For this reason, do not use

acetone or detergents containing solvents.

8.2 Repairs

If it appears that safe operation of the system is no longer possible, the system

mus t be taken out of operation and steps taken to prevent it being used

inadvertently. If the device needs to be repaired, return it to Pepperl+Fuchs. If you

open or modify the device yourself, not only are you endan gering yourself and

others but you will void any warranty and absolve the manufacturer from any

liability.

Page 28

2016 -01

28

2-D Laser Scanner

Troubleshooting

9 Troubleshooting

9.1 Troubleshooting

Interference

■ The sensor must be firmly mounted. It must not vibrate.

■ The sensor must not be installed behind a cover.

■ The sensor should be installed so it is protected from rain.

Note!

When carrying out the insulation measurement, be aware that suppressor diodes

have been installed for electromagnetic compatibility.

Page 29

2-D Laser Scanner

Appendix

2016 -01

29

10 Appendix

10.1 Technical Data "Ultra High Density" Models

General specifications

Functional safety related parameters

OMD10M-R2000-B23-*

Standard Range

OMD30M-R2 000-B23-*

Long Rang e

OMD30M-R2000-B23-*-T-*

Long Range, cold store

Measurement range 0.2 ... 3 m (bk 10%)

0.2 to 10 m (wh 90%)

0.2 to 60 m (reflector)

0.1 ... 10 m (bk 10%)

0,1 30 m (wh 90 %)

0,1 100 m (reflector)

0.1 ... 10 m (bk 10%)

0,1 30 m (wh 90 %)

0,1 100 m (reflector)

Light source laser diode laser diode laser diode

Light type modulated visible red

light

modulated infrared lig ht modul ated infrared light

Laser nominal

ratings

Note LASER LIGHT , DO

NOT STARE INTO

BEAM

LASER RADIATION ,

DO NOT STARE INTO

BEAM

LASER RADIATION , DO

NOT STARE INTO BEAM

Laser class 1 1 1

Wave length 660 nm 9 05 nm 905 nm

Beam divergence 1 mrad transversal 2 mrad ,

longitud inal 10 mrad

transversal 2 mrad ,

longitudinal 10 mrad

Pulse length 5 ns 5 ns 5 ns

Repetition rate 250 kHz 250 kHz 250 kHz

max . pulse energy < 4 nJ < 94 nJ < 94 nJ

Measuring method Pulse Ranging

Tec hnology (PRT)

Pulse Rangin g

Technology (PRT)

Pulse Ranging Technology

(PRT)

Scan rate

10 ... 50 s

-1

10 ... 50 s

-1

10 ... 50 s

-1

Scanning ang le 360° 360° 360°

Diameter of the light

spot

< 20 mm at 10 m 25 mm x 105 mm at 10 m25 mm x 105 mm at 10 m

Ambient light limit > 8000 0 Lux > 80000 Lux > 80000 Lux

Resolutio n 1 mm 1 mm 1 mm

OMD10M-R2000-B23

Standard Range

OMD30M-R 2000-B23

Long Range

OMD30M-R 2000-B23-*-T-*

Long Range, cold store

MTTF

d

75 a 75 a 75 a

Mission Time (TM) 20 a 20 a 20 a

Diagnostic Coverage

(DC)

0 % 0 % 0 %

Page 30

2016 -01

30

2-D Laser Scanner

Appendix

Indicators/operating means

Electrical specifications

Interface

Measurement accuracy

OMD10M-R20 00-B23

Standard Range

OMD30M-R2 000-B23

Long Rang e

OMD30M-R 2000-B23-*-T-*

Long Range, cold store

Operation indicator LED green L ED green LED green

Data flow indicator LED yellow: active

ethernet

LED green: Ethernet

link

LED yellow: active

ethernet

LED green: Ethernet

link

LED yell ow: active ethernet

LED green: Ethernet link

Function indicator LED red: fault

LED yellow: Q1 + Q2

LED red: fault

LED yellow: Q1 + Q2

LED red: fault

LED yell ow: Q1 + Q2

Control elements 2 Button 2 Button 2 Button

Parameterization

indicator

24 x 252 pixels , red 2 4 x 252 pixels , red 24 x 252 pixel s , red

OMD10M-R2 000-B23

Standard Range

OMD30M-R2000-B23

Long Range

OMD30M-R2000-B23-*-T-*

Long Range, col d store

Operating voltage 10 ... 30 V DC 10 ... 30 V 10 ... 30 V

Ripple 10 % within the supply

tolerance

10 % w ithi n the supply

tolerance

10 % within the supply

tolerance

No-load supply

current

≤ 400 mA / 24 V DC ≤ 400 mA / 24 V DC ≤ 400 mA / 24 V DC

Power consumption < 10 W < 10 W < 10 W

Time delay b efore

availability

< 40 s < 40 s < 40 s

OMD10M-R 2000-B23

Standard Range

OMD30M-R 2000-B23

Long Range

OMD30M-R2000-B23-*-T-*

Long Range, cold store

Interface type Fast Ethernet Fast Ethernet Fast Ethernet

Protocol HTTP , TCP/IP and

UDP/IP

HTTP , TCP/IP and

UDP/IP

HTTP , TCP/IP and UDP/IP

OMD10M-R 2000-B23

Standard Range

OMD30M-R2 000-B23

Long Rang e

OMD30M-R 2000-B23-*-T-*

Long Ran ge, cold store

Measuring speed 250000

measurements per

second

250000

measurements per

second

250000 measurements per

second

Measured value

noise

± 9 mm (1 sig ma, on

reflector film)

typ. ± 10 mm (1 sigm a;

max 20 mm; 0,1 m ... 8

m)

typ. ± 12 mm (1 sigm a;

max 20 mm; 8 m ...

100 m)

typ. ± 10 mm (1 sigma; max 20

mm; 0,1 m ... 8 m)

typ. ± 12 mm (1 sigma; max 20

mm; 8 m ... 100 m)

Angle resolution 0.014 ° 0.014 ° 0.014 °

Page 31

2-D Laser Scanner

Appendix

2016 -01

31

Ambien t conditions

Mechanical specifications

Compliance with standards and directives

Abs olute

accuracy

typ. ± 35 mm ty p. ± 25 mm ty p. ± 25 mm

Repeat accuracy < 12 mm < 12 mm < 12 mm

OMD10M-R20 00-B23

Standard Range

OMD30M-R2000-B23

Long Range

OMD30M-R20 00-B23-*-T-*

Long Range, co ld store

OMD10M-R20 00-B23

Standard Range

OMD30M-R 2000-B23

Long Ran ge

OMD30M-R 2000-B23-*-T-*

Long Range, cold store

Ambient tempe rature -10 ... 50 °C (14 ... 122

°F)

-10 ... 50 °C (14 ... 122

°F)

-30 ... 50 °C (-22 ... 122 °F)

Storage temperature -20 ... 70 °C (-4 ... 158

°F)

-20 ... 70 °C (-4 ... 158

°F)

-40 ... 70 °C (-40 ... 158 °F)

Relative humidity 95 % , no moisture

condensation

95 % , no moisture

condensation

95 % , no moisture

condensation

OMD10M-R20 00-B23

Standard Range

OMD30M-R2000-B23

Long Range

OMD30M-R 2000-B23-*-T-*

Long Range, cold store

Degree of

protection

IP65 IP65 IP67

Connection 4-pi n, M12x1 conn ector,

stand ard (supply) ,

8-pin, M12x1 conn ector,

A-cod ed (MultiPort) ,

4-pin, M12x1 socket, Dcoded (LAN)

4-pin, M12x1 connector,

standard (supply) ,

8-pin, M12x1 connector,

A-cod ed (MultiPort) ,

4-pin, M12x1 socket, Dcoded (LAN)

4-pin, M12x 1 connector,

standard (supply) ,

8-pin, M12x 1 connector, Acoded (MultiPort) ,

4-pin, M12x 1 socket, Dcoded (LAN)

Material

Housing ABS + PC + aluminum ABS + PC + aluminum ABS + PC + alumi num

Optical face PMMA PMMA PMMA

Mass approx. 0.8 kg approx. 0.8 kg approx. 0.8 kg

OMD10M-R2000-B23

Standard Range

OMD30M-R2000B23

Long Range

OMD30M-R 2000-B23-*-T-*

Long Range, cold store

Directive conformity

EMC Directive

2004/108/EC

EN 60947-5-2:2007 E N 60947-5-2:2007 EN 60 947-5-2:2007

Standard conformity

Product standard EN 60947-5-2:2007 ,

IEC 60947-5-2:2007

EN 60947-5-2:2007

, IEC 60947-52:200 7

EN 60 947-5-2:2007 , IEC

60947-5-2:2007

Laser class IEC 6082 5-1:2007

EN 60825-1:2007

IEC 60825-1:2007

EN 60825-1:200 7

IEC 60825-1:2007

EN 60 825-1:2007

Page 32

2016 -01

32

2-D Laser Scanner

Appendix

Approvals and certificates

10.2 Technical Data "High Density" Models

General specifications

OMD10M-R 2000-B23

Standard Range

OMD30M-R2000-B23

Long Range

OMD30M-R2000-B23-*-T-*

Long Range, col d store

CCC approval CCC approval /

marking not required

for products rated ≤36

V

CCC approval / marking

not required for

products rated ≤ 36 V

CCC approval / marking not

required for products rated ≤36

V

UL approval cULus Listed, Class 2

Power Source, Type 1

enclosure

cULus Listed, Class 2

Power Source, Type 1

enclosure

cULus Lis ted, Class 2 Power

Source, Type 1 enclosure

OMD30M-R 2000-B23-*-HD-*

Long Range OMD12M-R2 000-B23-*-H D-*

Measurement range 0.1 ... 10 m (bk 10%)

0.1 3 0 m (wh 90 %)

0.1 3 0 m (refle ctor)

0.2 ... 10 m (bk 10%)

0.2 12 m (wh 90 %)

0.3 ... 12 m (reflecto r)

Light source laser diode laser diode

Light type modulated infrared light modulated infrared lig ht

Laser nominal ratings

Note LASER RADIATION , DO NOT

STARE INTO BEAM

LASER RADIATION , DO NOT

STARE INTO BEAM

Laser class 1 1

Wave length 905 nm 905 nm

Beam divergence transversal 2 mrad ,

longitud inal 10 mrad

transversal 2 mrad , longitudinal 10

mrad

Pulse length 5 ns 5 ns

Repetitio n rate 84 kHz 84 kHz

max. pulse energy < 94 nJ < 94 nJ

Measuring method Pulse Rangi ng Technolog y

(PRT)

Pulse Ranging Technology (PRT)

Scan rate

10 ... 50 s

-1

10 ... 50 s

-1

Scanning angle 360 ° 360°

Diameter of the light sp ot 25 mm x 105 mm at 10 m 25 mm x 105 mm at 10 m

Ambient light limit > 80000 Lux > 80000 Lux

Resoluti on 1 mm 1 mm

Page 33

2-D Laser Scanner

Appendix

2016 -01

33

Functional safety related parameters

Indicators/operating means

Electrical specifications

Interface

Measurement accuracy

OMD30M-R 2000-B23-*-HD-*

Long Ran ge OMD12M-R2000-B23-*-HD-*

MTTF

d

75 a 75 a

Mission Time (TM) 20 a 20 a

Diagnostic Coverage (DC ) 0 % 0 %

OMD30M-R2 000-B23-*-HD-*

Long Rang e OMD 12M-R2000-B23-*-HD-*

Operation indicator LED green LED green

Data flow ind icator LED yellow: active ethernet

LED green: Ethernet link

LED yell ow: active ethernet

LED green: Ethernet link

Function indicator L ED red: fault

LED yellow: Q1 + Q2

LED red: fault

LED yell ow: Q1 + Q2

Control elements 2 Button 2 Button

Parameterization ind icator 24 x 252 pixels , red 24 x 252 pixels , red

OMD30M-R 2000-B23-*-HD-*

Long Range OMD12M-R20 00-B23-*-HD-*

Operating voltage 10 .. . 30 V DC 10 ... 30 V

Ripple 10 % within the suppl y toleran ce 10 % within the supply tolerance

No-load supply current ≤ 400 mA / 24 V DC ≤ 400 mA / 24 V DC

Power consumption < 10 W < 10 W

Time delay before availability < 40 s < 40 s

OMD30M-R 2000-B23-*-HD-*

Long Range OMD12M-R2 000-B23-*-HD-*

Interface type Fast Ethernet Fas t Ethernet

Protocol HTTP , TCP/IP and UDP /IP HTTP , TCP /IP and UDP/IP

OMD30M-R2000-B23-*-HD-*

Long Range OMD12M-R2000-B23-*-HD-*

Measuring speed 84000 me asurements per

second

84000 me asurements per second

Measured value noise typ. ± 10 mm (1 sigma; max 20

mm; 0,1 m ... 8 m)

typ. ± 12 mm (1 sigma; max 20

mm; 8 m ... 30 m)

typ. ± 20 mm (1 sigma)

Page 34

2016 -01

34

2-D Laser Scanner

Appendix

Ambient conditions

Mechanical specifications

Compliance with stand ards and directives

Angle resolution 0.042 ° 0.042 °

Absolute accuracy typ. ± 25 mm typ. ± 40 mm

Repeat ac curacy < 12 mm < 12 mm

OMD30M-R2000-B23-*-HD-*

Long Range OMD12M-R2000-B23-*-HD-*

OMD30M-R2000-B23-*-HD-*

Long Range OMD12M-R2000-B23 -*-H D-*

Ambient temp erature -10 ... 50 °C (14 ... 122 °F) -10 ... 50 °C (14 ... 122 °F)

Storage temperature -20 ... 70 °C (-4 ... 158 °F) -20 ... 70 °C (-4 ... 158 °F)

Relative humidity 95 % , no moisture condensation 95 % , no moisture con densation

OMD30M-R2000-B23-*-HD-*

Long Range OM D12M -R2000-B23-*-HD-*

Degree of protection IP65 IP65

Connection 4-pin, M12x1 connec tor, standard

(supp ly) ,

8-pin, M12x1 connector, A-coded

(Mul tiPort) ,

4-pin, M12x1 socket, D-coded (LAN)

4-pin, M12x 1 connector, standard

(suppl y) ,

8-pin, M12x 1 connector, A-coded

(MultiPort) ,

4-pin, M12x 1 socket, D-coded (LAN)

Material

Housing ABS + PC + aluminum ABS + PC + aluminum

Optical face P MMA PMMA

Mass app rox. 0.8 kg approx. 0.8 kg

OMD30M-R2000-B23-*-HD-*

Long Range OMD12M-R2000-B23 -*-H D-*

Directive conformity

EMC Directi ve

2004/108/EC

EN 60947-5-2:200 7 E N 60947-5-2:2 007

Standard conformity

Product standard EN 60947-5-2:2007 , IEC 60947-5-

2:200 7

EN 60947-5-2:2007 , IEC 60947-52:2007

Laser class IEC 60825-1:2007

EN 60825-1:200 7

IEC 60825-1:2007

EN 60825-1:2007

Page 35

2-D Laser Scanner

Appendix

2016 -01

35

Approvals and certificates

10.3 Amplitude Characteristics

In addition to the measured value output for the distance, the R2000 provides an

echo amplitude for each measuring step. The measured value for the echo

amplitude is a value with no unit of measu rement in a range from 0...4095 digits.

The echo amplitude is a measure of the energy received by the R2000. The

mea sured value is dependent on the surface properties of the measurement

object (reflectivity, structure ), the distance from the measurement object, and the

angle of incidence of the measu rement beam. Th e measurement of the echo

amplitude is not calibrated and is used for relative distinction between different

object reflectivities.

In particular, evaluation of the echo amplitudes can be used to distinguish

between natural surfaces and reflector film.

The picture below shows the curve of the echo amplitude on reflector film

(diamon d grade 983-10). The curve represents the smallest expected measured

value in relation to the distance.

The second curve represents the largest value on white (90 % reflectivity), natura l

surfaces in relation to the distance.

OMD30M-R2000-B23-*-HD-*

Long Range OMD12M-R2000-B23-*-HD-*

CCC approval CCC app roval / marki ng not

required for products rated ≤36 V

CCC approval / m arking not required

for products rated ≤36 V

UL approval cULus Listed, Class 2 Power

Source, Ty pe 1 enc losure

cULus Lis ted, Class 2 Power Source,

Typ e 1 enclosure

Page 36

2016 -01

36

2-D Laser Scanner

Appendix

Figure 10.1 Amplitud e characteristics for OMD10M -R2000-B23-V1V1D*

Figure 10.2 Amplitud e characteristics OMD30M-R 2000-B23-V1V1D*; OMD30M-R2000-

B23-V1VD-HD-1L (ends at 30 m); OMD12M-R2000-B23* (ends at 12 m)

The measurement on reflector film is based on a vertical angle of incidence on a

reflector strip that is 4 0 mm wide an an angle resolution of 0.071 °.

700

600

500

400

300

200

100

0

0.1 0.5 1.0 10 60

Echoamplitude [digit]

Distance X [m]

Echoamplitude characteristic

Echoamplitude on Diamond Grade 983-10

Object remission 0% ... 90 %

2500

2000

1500

1000

500

0

0.1 1 10 100

Echoamplitude [digit]

Echoamplitude characteristic

Echoamplitude on Diamond Grade 983-10

Object remission 0% ... 90 %

Distance X [m]

Page 37

2-D Laser Scanner

Appendix

2016 -01

37

The measurement on a white (90 % reflectivity), natural surface is based on a

vertical angle of incidence and an emitted beam that hits the measurement object

with its full geometry.

If the emitted beam is at an entrance angle of 60°...70° on the reflector foil, the

mea sured value drops by approximately 50% compared to the value for a vertical

entrance angle.

10.4 Pulse Ranging Technology (PRT) Glossary

10.5 Using Open Source Programs

Pepperl+Fuchs uses a range of open source so ftware in the R2000 laser scanner.

This relates to the programs listed individually be low u nder 1 to 12. We have

edited programs 1 to 4:

1. U-Boot

2. Blackfin uClinux

3. Xenomai

4. Mongoose Webserver

5. Libedit

6. Giflib

7. Libncurses

8. ST Standard Peripherals Library

9. ARM CMSIS Header

10.IA R LIBC

11.AVR LIBC

12.CRC Bibliothek

You can use all programs in accordance with the respective license. The license s,

their exact scope, and the respe ctive exclusions of liability can be found in the

header of the files themselves.

Accuracy The degree to whi ch the measurement result correspo nds to th e true

value of the measurement. The accuracy is a relative deviation based on

a meas urem ent standard. For practical applications, a distinction is

drawn between different influencing factors.

Abs olute accuracy Specifies the total of all systematic measurement errors (e.g., linearity,

device offset) over a defined distance, reflec tivity range, and

temperature range that cannot be eliminated by other acti ons, such as

averaging .

Repeat accuracy (rep eatability) The meas urement is repeated under the same conditions on the same

target. The deviation is th e repeatability value. The measured value

signal noise is no t taken into account.

Measured value signal noise Randomly distributed deviation of a measured value by an average

value. The dis tribution of th e individual measurement values typicall y

follows a statistical no rmal distribution.

Measurement range The range between the smalles t and largest object distance in which the

measuring instrument supplies readings within the specification.

Page 38

2016 -01

38

2-D Laser Scanner

Appendix

In line with the provisions of the licen ses for programs 5 and 11, the respective

copyright statements— which you will also find in the relevant files, as with all other

programs—are reproduced he re:

Program no. 5: Libedit; Copyright (c) The Regents of the University of California.

Program no. 11: AVR LIBC; Portions of avr-libc are Copyright 1999 – 2005 (c)

Keith Gudger, Bjoern H aase, Steinar Haugen, Peter Jansen, Reinhard Jessich,

Magnu s Johansson, Artur Lipowski, Marek M ichalkiewicz, Colin O’Flynn, Bob

Paddock, Reiner Patommel, Michael Rickman , Theodore A . Roth, Juergen

Schilling, Philip Soeberg, Anatoly So kolov, Nils Kristian Strom, Michael Stumpf,

Stefan Swanepoel, Eric B. Wedding ton, Joerg Wu nsch, Dmitry Xmelkov, The

Regents of the University of California. Portions of avr-libc documentation

Copyright (c) 1990, 1991, 1993, 1994 The Regents of the University of California.

We have also reproduced the text of the license and exclusion of liability for

programs no. 5 and no. 11:

"Redistribution and use in source and binary forms, with or without

modification, are permitted provided that the following conditions are met:

* Redistributions of source code must retain the above copyright notice,

this list of conditions and the following disclaimer.

* Redistributions in binary form must reproduce the above copyright

notice, this list of con ditions and the following disclaimer in the

documentation and/or other materials provided with the distribution.

* Neither the name of the copyright holders nor the names of contribu tors

may be used to en dorse or promote products derived from this software

withou t specific prior written permission.

THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND

CONTRIBUTORS "AS IS" AN D ANY EXPRESS OR IMPLIED WARRANT IES,

INCLUD ING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCH ANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE

DISCLAIMED. IN NO EVENT SHALL THE COPYRIGHT OWNER OR

CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL,

SPECIAL, EXEMP LARY, OR CONSEQUENTIAL DAMAGES (INCLUDING,

BUT NOT LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR

SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS

INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY,

WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING

NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE

OF THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH

DAMAGE."

Programs 1, 2, and 3 are licensed in accordance w ith the GNU General Pub lic

License v2 , and program 3 additionally (with rega rd to the user space) in

accordance with the Lesser General Public License. Pepperl+Fuchs grants you

and any third party a free license for further proce ssing, also in accordance with

the GNU General Public License v2 and/or the Lesser General Public License.

Page 39

2-D Laser Scanner

Appendix

2016 -01

39

Pepperl+Fuchs offers to provide you and any third party with the source code for

programs 1, 2, and 3 in the form in which we have developed it for a period of

three years from distribu tion by Pepperl+Fuchs, free of charge o n a read/write tag

used as standard to exchang e software.

Pepperl+Fuchs is not liable for any changes to the open source so ftware made by

the user.

Page 40

Subject to modifications

Copyright PEPPERL+FUCHS • Printed in Germany

www.pepperl-fuchs.com

FACTORY AUTOMATION –

SENSING YOUR NEEDS

Worldwide Headquarters

Pepperl+Fuchs GmbH

68307 Mannheim · Germany

Tel. +49 621 776-0

E-mail: info@de.pepperl-fuchs.com

USA Headquarters

Pepperl+Fuchs Inc.

Twinsburg, Ohio 44087 · USA

Tel. +1 330 4253555

E-mail: sales@us.pepperl-fuchs.com

Asia Pacific Headquarters

Pepperl+Fuchs Pte Ltd.

Company Registration No. 199003130E

Singapore 139942

Tel. +65 67799091

E-mail: sales@sg.pepperl-fuchs.com

DOCT-3 124D

01/2016

Loading...

Loading...