Page 1

R

OHV-F230-B17

PROFINET Gateway

for OHV Handheld

FACTORY AUTOMATION

MANUAL

Page 2

With regard to the supply of products, the current issue of the following document is ap-

plicable: The General Terms of Delivery for Products and Services of the Electrical Indus-

try, published by the Central Association of the Electrical Industry (Zentralverband

Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the

supplementary clause: "Expanded reservation of proprietorship"

OHV-F230-B17

Page 3

OHV-F230-B17

3

1 Introduction................................................................................. 4

1.1 Content of this Document ................................................................... 4

1.2 Target Group, Personnel...................................................................... 4

1.3 Symbols Used ...................................................................................... 5

2 Product Specifications............................................................... 6

2.1 Description ........................................................................................... 6

2.2 Dimensions........................................................................................... 6

2.3 Indicators.............................................................................................. 6

2.4 Interfaces .............................................................................................. 7

2.5 Accessories .......................................................................................... 7

3 Commissioning ........................................................................... 8

4 Operation and Communication ................................................. 9

4.1 Communication via PROFINET........................................................... 9

4.1.1 General Information on Communication via PROFINET..................... 9

4.1.2 PROFINET IO Interface ..................................................................... 9

4.1.3 Project Planning Using Device Description ...................................... 10

4.1.4 PROFINET Address and Identifying a Device.................................. 16

4.1.5 PROFINET Modules ........................................................................ 16

5 Appendix ................................................................................... 18

5.1 ASCII Table.......................................................................................... 18

Page 4

2016-12

4

OHV-F230-B17

Introduction

1 Introduction

1.1 Content of this Document

This document contains information required to use the product in the relevant phases of the

product life cycle. This may include the following:

■

Product identification

■

Delivery, transport, and storage

■

Assembly and installation

■

Commissioning and operation

■

Maintenance and repair

■

Troubleshooting

■

Dismounting

■

Disposal

The documentation comprises the following parts:

■

Present document

■

Datasheet

In addition, the documentation may comprise the following parts, if applicable:

■

EC-Type Examination Certificate

■

EC Declaration of Conformity

■

Attestation of conformity

■

Certificates

■

Control drawings

■

Other documents

1.2 Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation, maintenance, and

dismounting lies with the plant operator.

Only appropriately trained and qualified personnel may carry out mounting, installation,

commissioning, operation, maintenance, and dismounting of the product. The personnel must

have read and understood the instruction manual and the further documentation.

Prior to using the product make yourself familiar with it. Read the document carefully.

Page 5

OHV-F230-B17

Introduction

2016-12

5

1.3 Symbols Used

This document contains symbols for the identification of warning messages and of informative

messages.

Warning Messages

You will find warning messages, whenever dangers may arise from your actions. It is mandatory

that you observe these warning messages for your personal safety and in order to avoid

property damage.

Depending on the risk level, the warning messages are displayed in descending order as

follows:

Informative Symbols

Action

This symbol indicates a paragraph with instructions. You are prompted to perform an action or

a sequence of actions.

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants, or result in

their complete failure.

Note!

This symbol brings important information to your attention.

Page 6

2016-12

6

OHV-F230-B17

Product Specifications

2 Product Specifications

2.1 Description

The OHV-F230-B17 is a gateway that enables OHV100 and OHV1000 handheld readers to be

connected to a PROFINET network. An OHV handheld reader is connected to the gateway via

an RS-232 connection. The gateway communicates with a PROFINET network via a D-coded

M12 connector. The PROFINET interface has an integrated switch. The handheld reader is

supplied with power by the gateway.

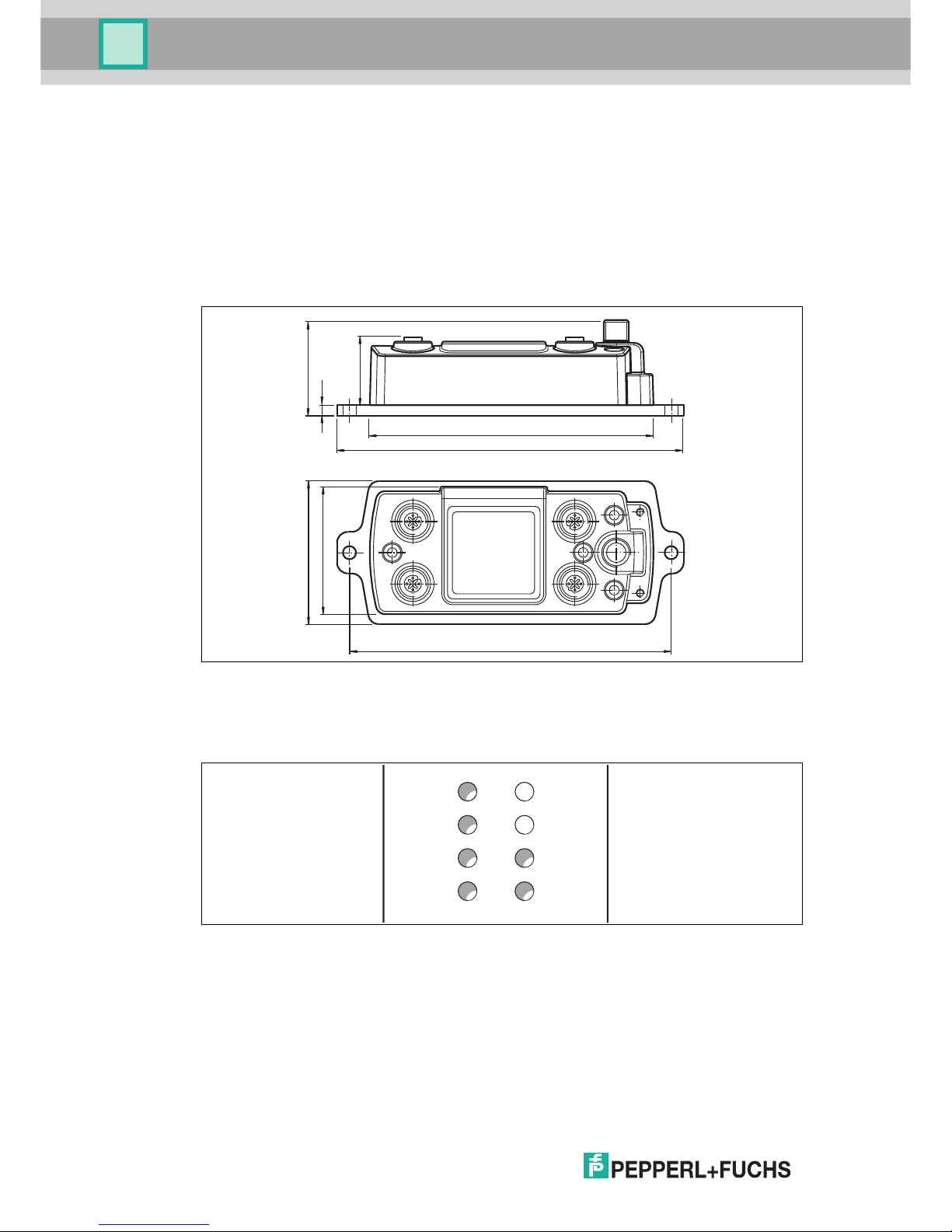

2.2 Dimensions

Figure 2.1

2.3 Indicators

The following indicators can be found on the OHV-F230-B17 gateway:

33

5

47

136.6

167

61.4

69

155

LEDs

PWR/ERR Green: gateway is switched on

Red: system error

BUS ERR Red: communication error with PROFINET network

Flashing red: configuration missing

ACTIVITY 1/ACTIVITY 2Yellow: data is being transferred to port 1 and port 2

LINK 1/LINK 2 Green: port 1 and port 2 are connected to the PROFINET network

PWR/ERR

BUS ERR

ACTIVITY 1

LINK 1

MOD STS

NET STS

ACTIVITY 2

LINK 2

Page 7

OHV-F230-B17

Product Specifications

2016-12

7

2.4 Interfaces

The following interfaces are available on the OHV-F230-B17 gateway:

Figure 2.2

2.5 Accessories

Handheld readers

Cordsets

Interface Description Connection

RS-232 RS-232, EIA/TIA-232E

Transfer rate: 115 k, 8N1

M12 socket, 8 pin, A-coded

RS-485 No function M12 socket, 8 pin, A-coded

PROFINET 2 x PROFINET IO with int. switch

Protocol: Conformance class B

Realtime class RT

Min. cycle time 1 ms

Transfer rate: 10/100 Mbit/s

M12 socket, 4 pin, D-coded

Main Power supply M12 socket, 4 pin, A-coded

2

3 1

4

3

4

2

1

1

7

4

2

6

3

5

8

Main

1 = + UB

2 = Teach In

3 = - UB/GND

4 = Trigger In

PROFINET 1 & 2

1

= Tx+

2 =

R

x+

3 = Tx4 = R

x-

RS232

1 = TX

2 = n.c.

3 = CTS

4 = RX

5 = RTS

6 = Trigger Out: 5 V; I

max

= 100 mA

7 = GND

8

=

5 V; I

max

=

500 mA

RS485

1 = Trigger Out: 24 V; I

max

= 200 mA

2 = + UB: I

max

= 1 A

3 = DATA +

4 = DATA 5 = Teach Out: 24 V; I

max

= 200 mA

6 = n.c.

7 = GND

8

=

5 V; I

max

=

500 mA

RS232

RS485

Designation Description

OHV100-F222-R2 Handheld reader for all common 1-D and 2-D codes

OHV1000-F223-R2 Handheld reader for reading lasered, punched, or printed 1-D and 2-D

codes

Designation Description

V19S-G-1.7/3M-PVC-V50 Cordset for handheld reader/gateway

V1SD-G-*M-PUR-ABG-V1SD-G

V1SD-G-*M-PUR-ABG-V45-G

PROFINET cordset; various lengths available

V1-* M12, A-coded, 4-pin, connects the gateway to the power

supply

You can find a wide range of compatible connection cables

at http://www.pepperl-fuchs.com.

Page 8

2016-12

8

OHV-F230-B17

Commissioning

3 Commissioning

Connecting the gateway to the handheld reader

1. Connect the OHV1000-F223-R2 and OHV100-F222-R2 handheld readers to the gateway

using the V19S-G-1.7/3M-PVC-V50 connection cable.

2. Connect the gateway to the power supply.

3. Scan the control code below using the handheld reader.

The handheld reader is connected to the gateway.

Page 9

OHV-F230-B17

Operation and Communication

2016-12

9

4 Operation and Communication

4.1 Communication via PROFINET

4.1.1 General Information on Communication via PROFINET

PROFINET is an open standard for industrial automation based on industrial Ethernet.

PROFINET integrates information technology with established standards such as TCP/IP and

XML in automation technology.

The communication concept for setting up decentralized applications within PROFINET is

PROFINET IO, i.e. decentralized field devices are integrated by PROFINET IO. The familiar IO

view of PROFIBUS DP is used where the usable data of the field devices is transferred to the

controller process image in cycles. PROFINET IO is a device model consisting of slots and

channels, which is based on the main features of PROFIBUS DP. The field device properties

are written in a GSDML (generic station description markup language) based on XML.

PROFINET IO is engineered in the same way as has long been the case for system integrators

of PROFIBUS DP. The decentralized field devices are assigned in the design of a controller.

PROFINET IO draws a distinction between three device types: IO controller, IO device, and IO

supervisor.

IO controller: Controller that executes the automation program.

IO device: Decentrally assigned field device that is assigned to an IO controller.

IO supervisor: Programming unit/PC with commissioning and diagnostic functions.

4.1.2 PROFINET IO Interface

OHV-F230-B17 gateways are PROFINET IO devices that communicate cyclically with the

assigned PROFINET IO controller during operation.

The PROFINET interface of the OHV-F230-B17 gateway supports:

■

A transfer rate of 100 Mbit/s

■

The real-time category RT

■

The range of functions in accordance with Conformance Class B

■

The identification and maintenance functions (I&M) IM0 – IM4

Identification & Maintenance Data

Identification and maintenance data (I&M data) is information stored in a device. I&M data

uniquely identifies a device within a system. The identification data (I data) includes information

about the device, for example the item number and device name. Identification data cannot be

changed.

Maintenance data (M data) includes information regarding the device within the system, for

example the installation location and installation date. Maintenance data is initially stored in the

device during installation; this data can be changed.

Data Input

The Step7 software from Siemens can be used to display and change the I&M data. You can

read and write I&M data 1, 2 and 3 in the "Target System" menu of the HW Config hardware

configuration using the functions "Download Module Identification" and "Download Module

Identification to PG". see Figure 4.1 on page 10.

Page 10

2016-12

10

OHV-F230-B17

Operation and Communication

I&M Data

Figure 4.1

4.1.3 Project Planning Using Device Description

As with PROFIBUS DP, a field device is integrated into the project planning tool by way of a

device description. The field device properties are described in the GSD file. The GSD file

contains the field device data (technical features and information for communication) that you

need to operate the device in a PROFINET network.

Import the GSD file into a project planning tool. Peripheral addresses are assigned to the

individual channels of the field devices. The peripheral input addresses incorporate the

received data. The user program evaluates and processes this data. The user program

generates the peripheral output values and sends them to the control interface.

Once project planning is complete, the IO controller receives the planning and configuration

data. The IO controller parameterizes and configures the field devices automatically.

I&M data 1 = system ID

location ID

I&M data 2 = installation date

I&M data 3 = additional

information

Page 11

OHV-F230-B17

Operation and Communication

2016-12

11

Downloading the GSD File

You can find the relevant GSD file in the Software section of the product detail page for the

device.

To access the product detail page for the device, go to http://www.pepperl-fuchs.com and type

information about the device (e.g., the product description or the item number) into the search

function.

Inserting the function block and data module

1. Unzip the zip file.

2. In the module folder, mark the OHV-F230-B17 function block and the associated iDB_OHV-

F230-B17 instance data block. Right-click on the marked entries and select Copy.

3. Right-click the destination project and select Insert.

Connecting the gateway to the S7 control panel

1. Before installing a GSD file, close all hardware configuration projects.

2. To install the GSD file, select Options > Install GSD files in the hardware configuration.

3. Connect the gateway to the PROFINET network.

4. To integrate the gateway into your PROFINET, double-click the PN-IO unit in the rack.

Figure 4.2 Assigned rack

This opens the Properties window.

5. Click Properties.

6. To create a new Ethernet subnet, click New.

7. To insert the Ethernet subnet into the hardware configuration, right-click the PN-IO unit and

select Insert PROFINET IO system.

Page 12

2016-12

12

OHV-F230-B17

Operation and Communication

Figure 4.3 Inserting PROFINET-IO system

A PROFINET IO system is now available to which you can connect new nodes.

8. Drag the PROFINET module of the gateway from the catalog into the connection window

and link it to the PROFINET IO system.

Figure 4.4 Assigned rack

Page 13

OHV-F230-B17

Operation and Communication

2016-12

13

9. To assign the gateway to the PROFINET module just inserted, select Destination system

> Ethernet > Edit Ethernet node from the menu bar. In the window that opens, click

Browse.

A list opens containing all accessible nodes.

Figure 4.5 Browsing PROFINET

10.Click OK.

11.Activate the Use IP parameters option in the Edit Ethernet node window.

Page 14

2016-12

14

OHV-F230-B17

Operation and Communication

Figure 4.6 Editing Ethernet nodes

12.If the device name of the node from the list open previously is present in the section Assign

device name (in this example ohv-f230), click Assign name.

13.Click Close.

14.Double-click the PROFINET module in the connection window and check whether the

device name has been successfully transferred. If the device name has not been

transferred, enter the device name in the field Device name.

Page 15

OHV-F230-B17

Operation and Communication

2016-12

15

Figure 4.7 PROFINET module properties

15.Click OK.

16.To assign address areas for inputs and outputs, add the following modules from the catalog

to the device:

- Result counter

- Result 64 byte

Figure 4.8 PROFINET configuration tables

Page 16

2016-12

16

OHV-F230-B17

Operation and Communication

4.1.4 PROFINET Address and Identifying a Device

Every PROFINET IO device has a unique device identification. This device identification

consists of the following:

■

A unique MAC address. This MAC address is printed on the back of the device.

■

A device name. The default device name is OHV-F230.

■

An IP address. The default IP address is 192.168.2.2.

4.1.5 PROFINET Modules

1 word = 16 bit value

1 byte = 8 bit value

Modules with response telegram

The following modules enable gateway data to be retrieved using PROFINET.

Result counter 32 bit module

The result counter increments a 32 bit value when a handheld reader has sent a result to the

gateway.

Result 64 byte module

Result message from the handheld reader

Size Type Content

2 words,

consistent

Input data 32 bit scan data

MSB first

MSB = most significant byte

Status byte 0 Status byte

Status byte 1 Message length

Data byte 0 Start of the scan result

MSB first

1

1.Example:

If the read code has a value of 123, the following data bytes are sent:

Data byte 0 = '1' (0x31)

Data byte 1 = '2' (0x32)

Data byte 2 = '3' (0x33)

All other data bytes: 0 (0x0)

Data byte 1 Scan result

... Scan result

Data byte 61 End of the scan result

Page 17

OHV-F230-B17

Operation and Communication

2016-12

17

Result 128 byte module

Result message from the handheld reader

Explanation of status bytes

Status byte 0 Status byte

Status byte 1 Message length

Data byte 0 Start of the scan result

MSB first

1

1.Example:

If the read code has a value of 123, the following data bytes are sent:

Data byte 0 = '1' (0x31)

Data byte 1 = '2' (0x32)

Data byte 2 = '3' (0x33)

All other data bytes: 0 (0x0)

Data byte 1 Scan result

... Scan result

Data byte 125 End of the scan result

Byte Content Bit no.

7 6 5 4 3 2 1 0

Status

byte 0

Status byte

ND

1

1.New data flag. Changes when the gateway receives new data from the scanner and makes it available for fieldbus

transmission. Is used to recognize new data with the same value.

0

DL

2

2.Data loss flag. Flag is set to 1 if the length of the scanned code exceeds the maximum number of data bytes in the

selected module. Is also set to 1 if a transmission error between the scanner and the gateway is detected.

0 0 0 0 0

Status

byte 1

Message length

Unsigned 8 bit

Number of usable

data bytes after the

status bytes

LEN_7 LEN_6 LEN_5 LEN_4 LEN_3 LEN_2 LEN_1 LEN_0

Page 18

2016-12

18

OHV-F230-B17

Appendix

5 Appendix

5.1 ASCII table

hex dec ASCII hex dec ASCII hex dec ASCII hex dec ASCII

00 0 NUL 20 32 Space 40 64 @ 60 96 '

01 1 SOH 21 33 ! 41 65 A 61 97 a

02 2 STX 22 34 " 42 66 B 62 98 b

03 3 ETX 23 35 # 43 67 C 63 99 c

04 4 EOT 24 36 $ 44 68 D 64 100 d

05 5 ENQ 25 37 % 45 69 E 65 101 e

06 6 ACK 26 38 & 46 70 F 66 102 f

07 7 BEL 27 39 ' 47 71 G 67 103 g

08 8 BS 28 40 ( 48 72 H 68 104 h

09 9 HT 29 41 ) 49 73 I 69 105 I

0A 10 LF 2A 42 * 4A 74 J 6A 106 j

0B 11 VT 2B 43 + 4B 75 K 6B 107 k

0C 12 FF 2C 44 , 4C 76 L 6C 108 l

0D 13 CR 2D 45 - 4D 77 M 6D 109 m

0E 14 SO 2E 46 . 4E 78 N 6E 110 n

0F 15 SI 2F 47 / 4F 79 O 6F 111 o

10 16 DLE 30 48 0 50 80 P 70 112 p

11 17 DC1 31 49 1 51 81 Q 71 113 q

12 18 DC2 32 50 2 52 82 R 72 114 r

13 19 DC3 33 51 3 53 83 S 73 115 s

14 20 DC4 34 52 4 54 84 T 74 116 t

15 21 NAK 35 53 5 55 85 U 75 117 u

16 22 SYN 36 54 6 56 86 V 76 118 v

17 23 ETB 37 55 7 57 87 W 77 119 w

18 24 CAN 38 56 8 58 88 X 78 120 x

19 25 EM 39 57 9 59 89 Y 79 121 y

1A 26 SUB 3A 58 : 5A 90 Z 7A 122 z

1B 27 ESC 3B 59 ; 5B 91 [ 7B 123 {

1C 28 FS 3C 60 < 5C 92 \ 7C 124 |

1D 29 GS 3D 61 = 5D 93 ] 7D 125 }

1E 30 RS 3E 62 > 5E 94 ^ 7E 126 ~

1F 31 US 3F 63 ? 5F 95 _ 7F 127 DEL

Page 19

Sub ject to modificatio ns

Cop yright PEPPERL+FUCHS • Printed in Germa ny

www.pepperl-fuchs.com

FACTORY AUTOMATION –

SENSING YOUR NEEDS

Worldwide Headquarters

Pepperl+Fuchs GmbH

68307 Mannheim · Germany

Tel. +49 621 776-0

E-mail: info@de.pepperl-fuchs.com

USA Headquarters

Pepperl+Fuchs Inc.

Twinsburg, Ohio 44087 · USA

Tel. +1 330 4253555

E-mail: sales@us.pepperl-fuchs.com

Asia Pacific Headquarters

Pepperl+Fuchs Pte Ltd.

Company Registration No. 199003130E

Singapore 139942

Tel. +65 67799091

E-mail: sales@sg.pepperl-fuchs.com

/ DOCT-5408

12/2016

Loading...

Loading...