Page 1

MANUAL

ODT-MAC400-* /

ODT-MAC401-* /

ODT-MAC403-*

FACTORY AUTOMATION

Stationary reader for all

common 1D- and 2D-barcodes

Laser Class 2M

EN 60825-1

Page 2

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

With regard to the supply of products, the current issue of the following document is applicable: The

General Terms of Delivery for Products and Services of the Electrical Industry, published by the

Central Association of the Electrical Industry (Zentralverband Elektrotechnik und Elektroindustrie

(ZVEI) e.V.) in its most recent version as well as the supplementary clause: "Expanded reservation

of proprietorship"

Page 3

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Contents

1 Introduction......................................................................... 4

2 Declaration of conformity .................................................. 5

3 Safety................................................................................... 6

3.1 Symbols relevant to safety ............................................................................6

3.2 Intended use .................................................................................................6

3.3 General safety instructions ............................................................................6

4 Product Description ........................................................... 8

4.1 Use and application of the

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-* -....................................8

4.2 Displays and controls....................................................................................8

4.3 Interfaces and connections ...........................................................................9

4.4 Contents .....................................................................................................10

4.5 Accessories ................................................................................................11

4.5.1 Cables....................................................................................................11

4.5.2 Other accessories ..................................................................................11

5 Installation......................................................................... 12

5.1 Preparation .................................................................................................12

5.2 Mounting.....................................................................................................12

5.3 Connecting the device ................................................................................13

5.4 Assigning an IP address to a network connection using Windows XP.........14

5.5 Storage and transport .................................................................................16

6 Commissioning................................................................. 17

6.1 Connecting the stationary reader ................................................................17

7 Operation........................................................................... 18

7.1 Web-based operator interface.....................................................................18

7.1.1 Settings Tab............................................................................................20

7.1.2 Communication Tab................................................................................50

7.1.3 Tab Gallery..............................................................................................51

7.1.4 Dialog box Language .............................................................................52

8 Troubleshooting................................................................ 53

8.1 What to do in the event of an error ..............................................................53

9 Appendix ........................................................................... 54

9.1 Command format ........................................................................................54

9.2 Command overview ....................................................................................56

9.3 Input of nonprintable characters..................................................................61

216677 2012-05

3

Page 4

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Introduction

1Introduction

Congratulations

You have chosen a device manufactured by Pepperl+Fuchs. Pepperl+Fuchs

develops, produces and distributes electronic sensors and interface modules for

the market of automation technology on a worldwide scale.

Symbols used

The following symbols are used in this manual:

Note!

This symbol draws your attention to important information.

Handling instructions

You will find handling instructions beside this symbol

Contact

If you have any questions about the device, its functions, or accessories, please

contact us at:

Pepperl+Fuchs GmbH

Lilienthalstraße 200

68307 Mannheim

Telephone: +49 621 776-4411

Fax: +49 621 776-274411

E-Mail: fa-info@pepperl-fuchs.com

216677 2012-05

4

Page 5

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Declaration of conformity

2 Declaration of conformity

This product was developed and manufactured under observance of the

applicable European standards and guidelines.

Note!

A Declaration of Conformity can be requested from the manufacturer.

The product manufacturer, Pepperl+Fuchs GmbH, D-68307 Mannheim, has a

certified quality assurance system that conforms to ISO 9001.

ISO9001

216677 2012-05

5

Page 6

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Safety

3Safety

3.1 Symbols relevant to safety

Danger!

This symbol indicates a warning about an immediate possible danger.

In case of ignoring the consequences may range from personal injury to death.

Warnin g!

This symbol indicates a warning about a possible fault or danger.

In case of ignoring the consequences may cause personal injury or heaviest

property damage.

Caution!

This symbol indicates a warning about a possible fault.

In case of ignoring the devices and any connected facilities or systems may be

interrupted or fail completely.

3.2 Intended use

The ODT-MAC4**-LD-RD-MC stationary reader is intended to be used only for the

identification of objects by means of 1D- and 2D-codes.

Always operate the device as described in these instructions to ensure that the

device and connected systems function correctly. The protection of operating

personnel and plant is only guaranteed if the device is operated in accordance

with its intended use.

3.3 General safety instructions

Class 2 laser product

This device is a class 2 laser product:

Standard s

IEC 60825-1:2007 certified. Complies with 21 CFR 1040.10 and 1040.11 except

for deviations pursuant to Laser Notice No. 50, dated 06-24-07.

216677 2012-05

6

Page 7

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Safety

Warn ing !

Visible red class 2 laser light

The irradiation can lead to irritation especially in a dark environment. Do not point

at people!

Caution: Do not look into the beam!

Maintenance and repairs should only be carried out by authorized service

personnel!

Attach the device so that the warning is clearly visible and readable.

Caution – Use of controls or adjustments or performance of procedures other

than those specified herein may result in hazardous radiation exposure..

Only use recommended original accessories.

The operating company bears responsibility for observing locally applicable

safety regulations.

Installation and commissioning of all devices must be performed by a trained

professional only.

User modification and or repair are dangerous and will void the warranty and

exclude the manufacturer from any liability. If serious faults occur, stop using the

device. Secure the device against inadvertent operation. In the event of repairs,

return the device to your local Pepperl+Fuchs representative or sales office.

216677 2012-05

7

Page 8

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

1

3

2

Product Description

4 Product Description

4.1 Use and application of the ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-* -

The stationary reader is an optical identification system for detection of up to 28

different code symbologies. With its high-performance signal processor, a partial

image capture function, and optimized decoding algorithms, the device features

extremely high reading speeds.

The stationary reading device can be configured easily and quickly using a

normal web browser, via the standard Ethernet interface or a series connection.

Support is also provided for the mechanical alignment of the reading device in the

form of an integrated laser pointer and a connected VGA monitor. The reading

device also features an integrated error image memory.

Typical areas of application are

■ Document handling

■ Printing machines

■ Identification in the packaging and warehouse sector

■ PCB identification

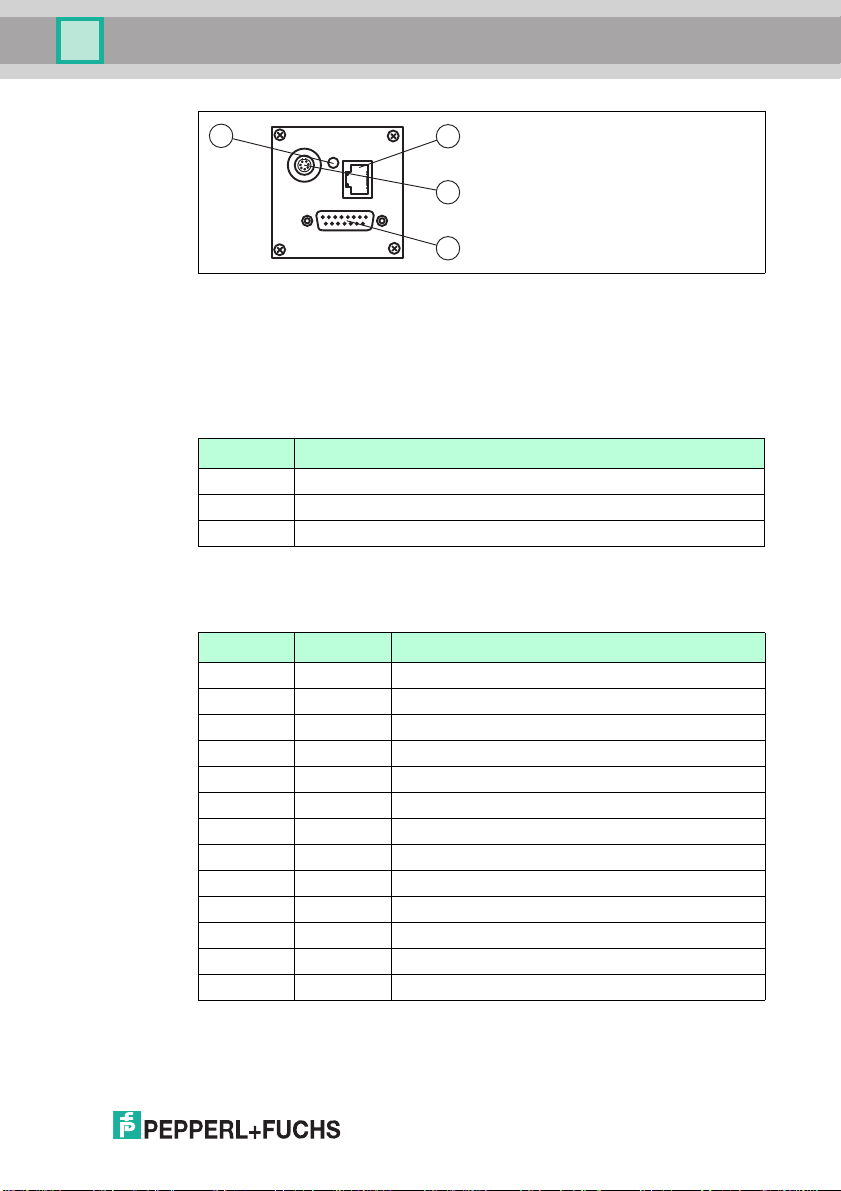

4.2 Displays and controls

1. Lightning unit

2. Laser diodes

3. CMOS camera

The stationary reader ODT-MAC403-* does not have laser diodes.

216677 2012-05

8

Page 9

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

4

1

2

3

LAN

TCP/IP

ST

VGA

VCC/I-O/RS232

Product Description

1 RJ45 Ethernet network socket

2 Video output VGA 640x480

3 15 pin D-Sub connector

4 Status LED

Stat us LE D

LED color Description

Ye l l o w The LED turns to yellow for a short time after switching on.

Green The LED flashes green after a successful read (good read).

Red The LED flashes red after an unsuccessful read (bad read).

4.3 Interfaces and connections

15-pin D-sub connector

PIN Signal Description

1, 2 GND GND for device

3 IO GND GND for inputs/ outputs

4, 5 +24 V Supply for device, 24 V DC PELV ±15%

6 IO +24 V Supply for inputs/ outputs, 24 V DC PELV ±15%

7 RTS Handshake signal, RS 232

8 IN1 24 V DC input

9 IO-OUT0 24 V DC "good read" output

10 IO-OUT1 24 V DC "bad read" output

11 IO-IN0 24 V DC "trigger" input

12 CTS Handshake signal, RS 232

13 TXD Transmission line, RS 232

14 RXD Receive line, RS 232

15 IN2 24 V DC input

216677 2012-05

9

Page 10

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

3

4

5

6

7

8

1

2

Product Description

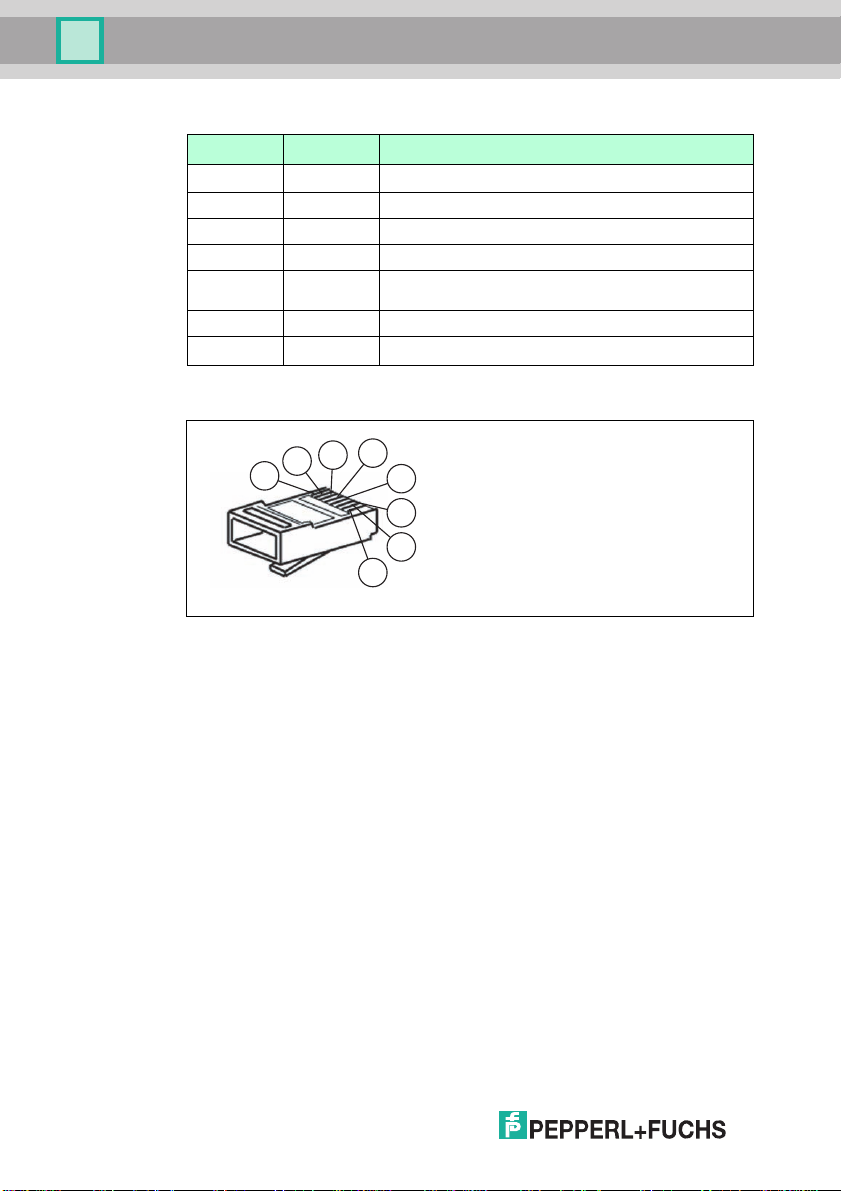

Video output VGA 640x480 (7-pin cylindrical connector)

PIN Signal Description

1 OUT V

2 GND RGB Red signal, green signal and blue signal ground

3 OUT R Red signal output

4 OUT G Green signal output

5 GND Horizontal synchronization output ground and vertical

6 OUT B Blue signal output

7 OUT H

Network connection

Vertical synchronization output

sync

synchronization output ground

Horizontal synchronization output

sync

Figure 4.1 Network connection pin assignments

1 Transmit data (+)

2 Transmit data (-)

3 Receive data (+)

4 Not assigned

5 Not assigned

6 Receive data (-)

7 Not assigned

8 Not assigned

4.4 Contents

■ ODT-MAC4**-LD-RD-MC

■ Quick start guide

10

216677 2012-05

Page 11

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Product Description

4.5 Accessories

Various accessories are available.

4.5.1 Cables

The following cables are available as accessories.

Model number Description

ODZ-MAC-CAB-VIDEO Video connection cable, cylindrical connector, 7-pin on SUB-

ODZ-MAC-CAB15POL-2,5M-FEMALE

ODZ-MAC-CAB15POL-5M-FEMALE

ODZ-MAC-CAB-24VR2-2M

V45-G-10M-V45-G Network cable RJ45, category 5, up to 100 MHz, 10 m

4.5.2 Other accessories

Other products are available as accessories.

Model number Description

ODZ-MAC-PWR-24V Desk top power supply 24 V DC, 1.88 A

D socket, 15-pin VGA, 2 meters

Connection cable, Sub-D socket, 15-pin, 2.5 meters, can be

pre-assembled

Connection cable, Sub-D socket, 15-pin, 5 meters, can be

pre-assembled

Connection cable for power supply, RS 232

216677 2012-05

11

Page 12

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Reading distance

60

60

M5

20

Code

52.7

20 ±0.1

36.85

6.5

Reading distance

11

60

60 65

M5

20 6

11

Code

52.7

20 ±0.1

72.5

Installation

5 Installation

5.1 Preparation

Unpacking the unit

1. Check that all package contents are present and undamaged.

If anything is damaged, inform the shipper and contact the supplier.

2. Check that all items are present and correct based on your order and the

shipping documents.

If you have any questions, please contact Pepperl+Fuchs.

3. Keep the original packing material in case you need to store or ship the unit at

a later time.

5.2 Mounting

Note!

Preventing reflection and glare

Reflection and glare from reflective surfaces can impair the captured image and

therefore lead to incorrect readings. To prevent reflection and glare, install the

stationary reading device at a slight angle.

Please refer to the technical data in the data sheet for the read distance.

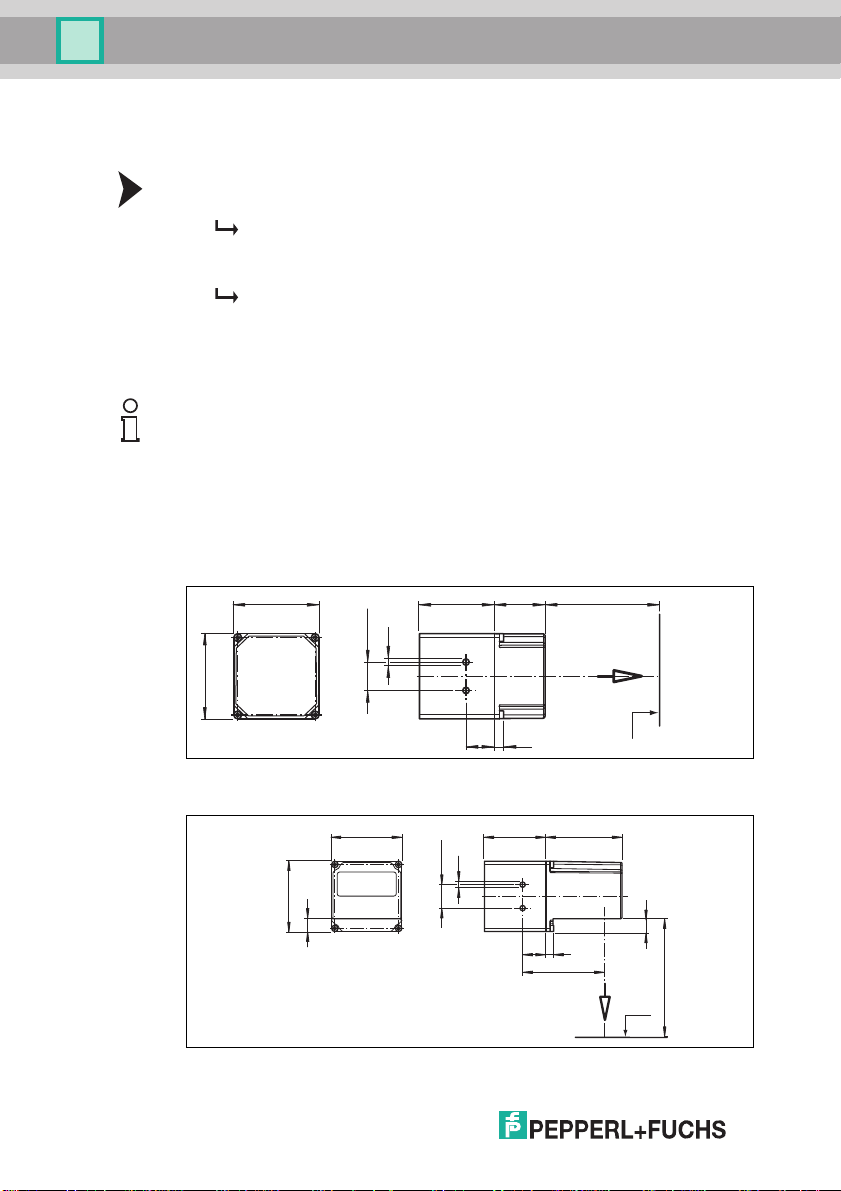

ODT-MAC400-*

Figure 5.1 Dimensions of the straight housing

ODT-MAC401-*

12

Figure 5.2 Dimensions of the angle housing

216677 2012-05

Page 13

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Reading distance

11

60

60 65

M5

20 6

11

Code

52.7

20 ±0.1

54.5

Installation

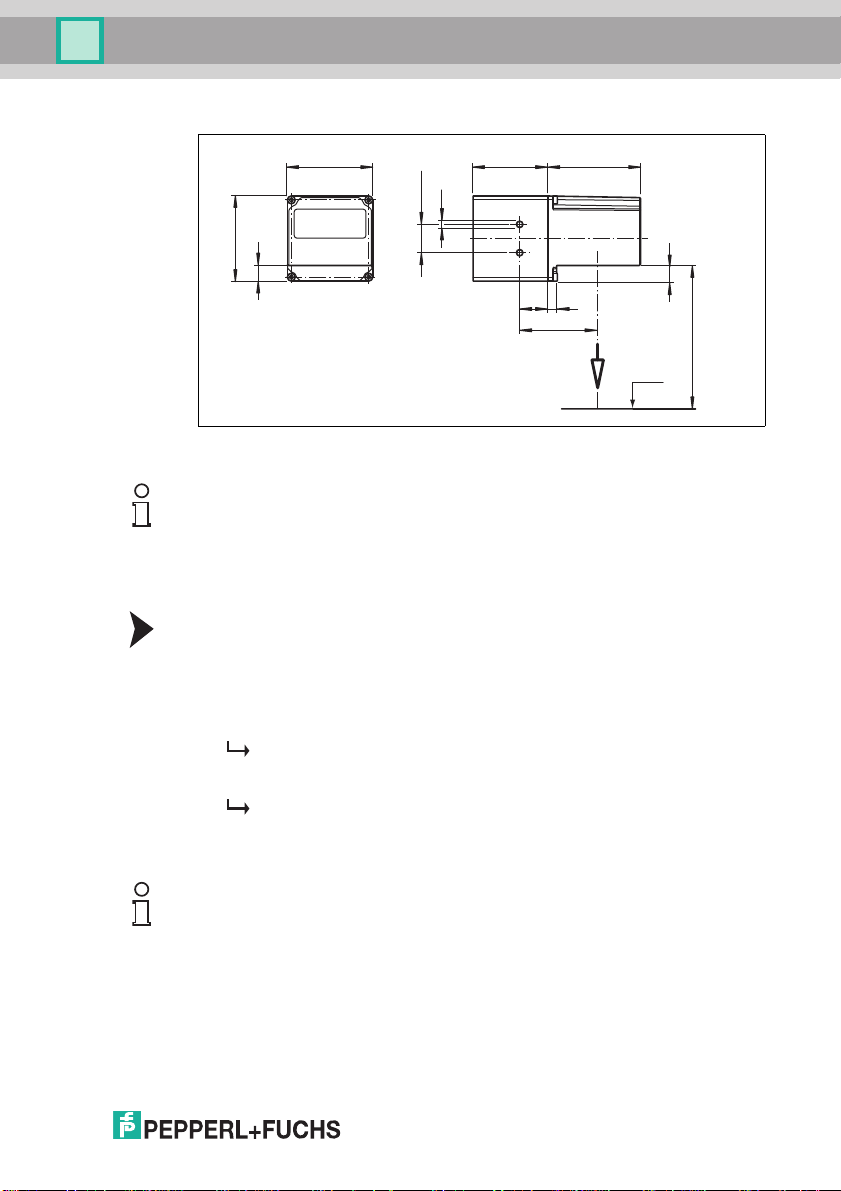

ODT-MAC403-*

Figure 5.3 Dimensions of the angle housing

Note!

Connection to ground

When installing the device, ensure that it is has a ground connection.

5.3 Connecting the device

Connecting the power supply

To connect a power supply to the device, proceed as follows.

1. Plug the 15-pin Sub-D socket into the connector provided for this purpose on

the back of the housing.

2. Screw in the two mounting screws as far as possible.

This ensures that the cable cannot be inadvertently pulled out.

3. Next connect the power supply to the appropriate pins on the Sub-D socket.

The power supply has now been connected.

To connect the power supply to the device quicker, the pre-configured connection

cable can also be used. Information can be found in the Accessories section.

Note!

216677 2012-05

Record the network configuration

The device communicates with the connected machine control system using the

TCP/IP protocol. To ensure communication works correctly, you must note down

all the changes you make to the network configuration.

13

Page 14

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Installation

Note!

Network cabling

Use a crossover network cable to connect the device directly to a PC. If the device

is being operated within a network, use a twisted-pair network cable to connect it

to the network.

Establishing a network connection

In order to establish a network connection, proceed as follows.

When delivered, the device has a fixed IP address (192.168.2.2). To facilitate

communication within the network, you must configure your network. The

configuration data can be found in the network configuration overview.

Connecting a trigger sensor

To connect a trigger sensor, proceed as follows.

Connect the trigger sensor to the cable previously connected for the power

supply.

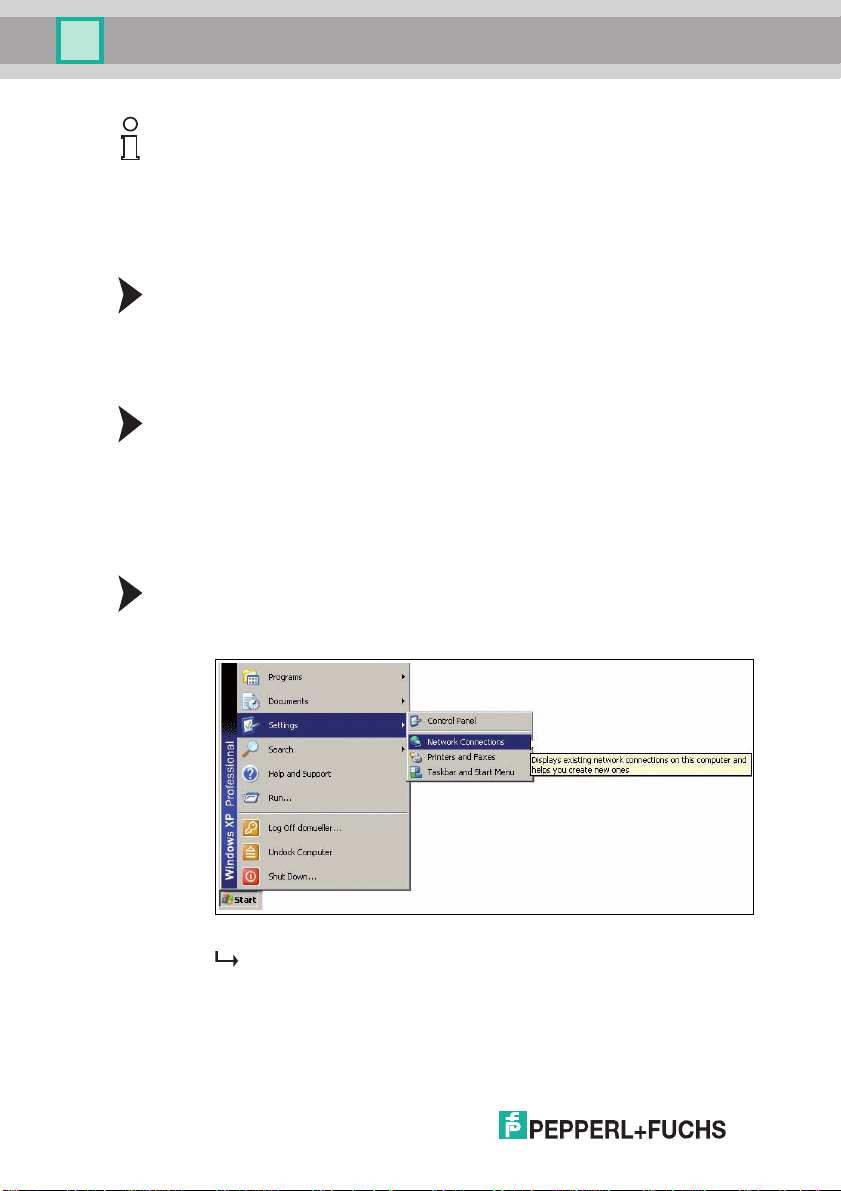

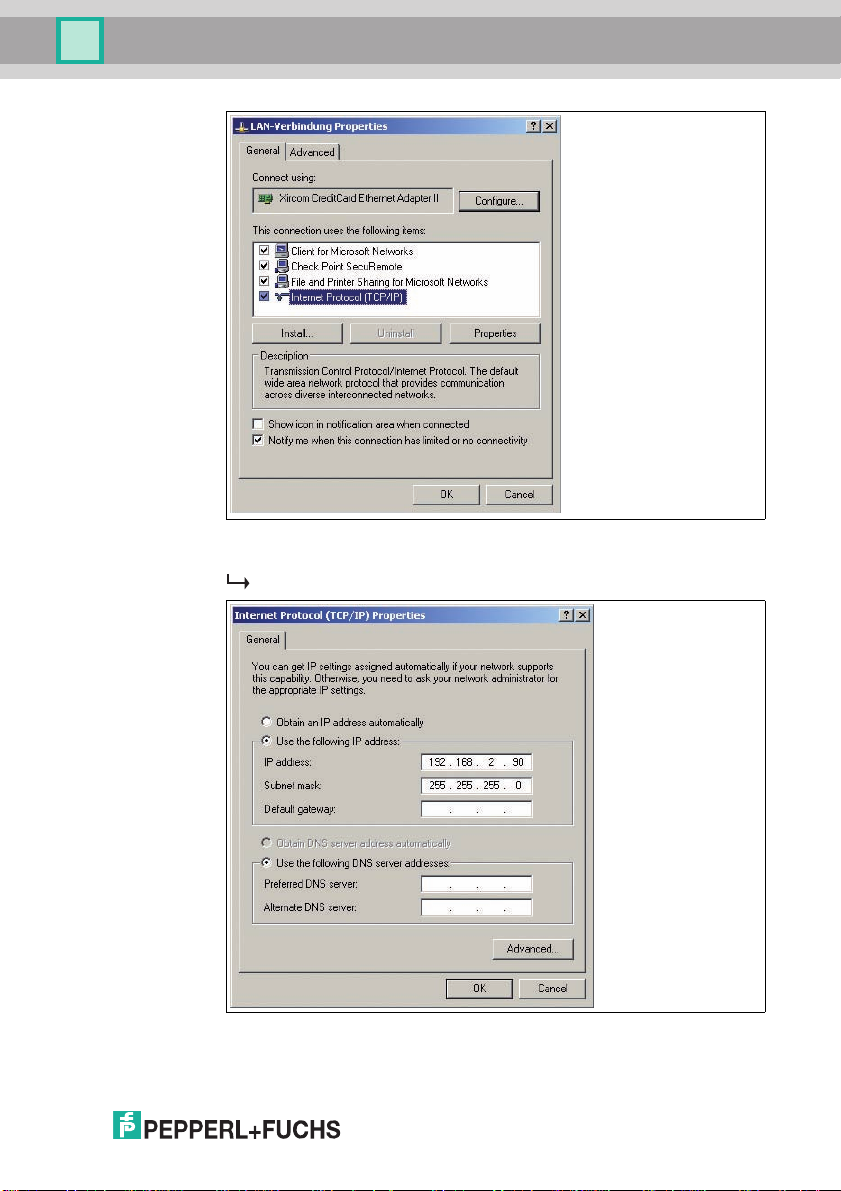

5.4 Assigning an IP address to a network connection using Windows XP

To assign an IP address to a network connection using Windows XP,

proceed as follows.

1. First select "Network Connections".

14

2. Then open the required connection by double clicking on it.

The Properties dialog box for the relevant connection will open.

216677 2012-05

Page 15

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Installation

3. Select the "Internet Protocol (TCP/IP)" element from the Properties dialog

box by double clicking on it.

The TCP/IP properties dialog box will open.

4. In the TCP/IP properties dialog box, activate "Use the following IP

address".

216677 2012-05

15

Page 16

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Installation

5. Enter an IP address which only differs from the sensor IP address in the very

last segment.

6. Enter 255.255.255.0 as the subnet mask.

7. Then confirm your entries on the TCP/IP properties page and the LAN

connection properties page using "OK" and "Close".

This completes the network configuration and the sensor can be used.

5.5 Storage and transport

For storage and transport purposes, package the unit using shockproof

packaging material and protect it against moisture. The best method of protection

is to package the unit using the original packaging. Furthermore, ensure that the

ambient conditions are within allowable range.

16

216677 2012-05

Page 17

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Commissioning

6 Commissioning

6.1 Connecting the stationary reader

The reader has its own web server. You have the option of making settings on the

stationary reader using a standard web browser.

Aligning the stationary reader

To find the ideal alignment for the device, use the two laser diodes in the

stationary reader.

1. Supply power to the reader via the D-Sub connector.

2. Adjust the stationary reader so that both points generated by the laser diodes

are positioned on top of each other on the code to be read.

This sets the ideal reading distance between the stationary reader and the

code to be read.

216677 2012-05

17

Page 18

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

7Operation

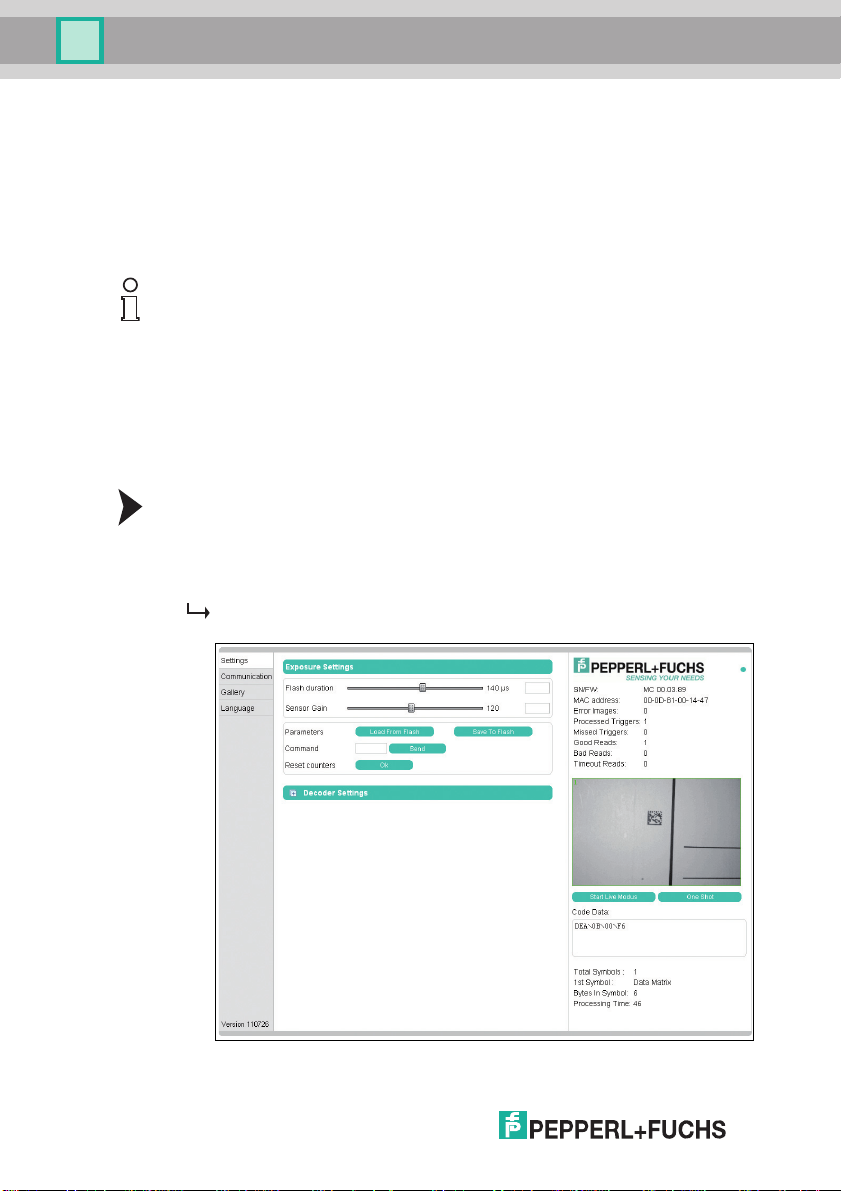

7.1 Web-based operator interface

You have the option of configuring and operating the sensor via a web-based

operator interface and using it to display information. The web-based user

interface should be used only for setup and troubleshooting purposes when the

machine is shut down.

Note!

To start the operator interface of the sensor, you need a standard web browser

(e.g., Windows Internet Explorer or Mozilla Firefox) with Java script activated.

We recommend the following browser versions

Firefox 3.6.8 or higher Communication between MAC and

Internet

Explorer

Starting the operator interface

To start the operator interface, proceed as follows.

In the input field of a standard web browser, enter the IP address of the stationary

reader (192.168.2.2) and press return to confirm.

6.0.2900.2180 or higher Communication between MAC and

PC via LAN interface

PC via LAN interface

18

The following tab opens as the start page: Settings.

216677 2012-05

Page 19

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

The following four tabs can be found on the left-hand side of the display:

■ Settings

■ Communication

■ Gallery

■ Language

Various information is displayed in the central section–depending on which tab is

active.

On the right-hand side, various status information (such as the software/firmware

version, the MAC address, the number of reads, etc.) is displayed, as well as the

last image captured and the decoded information. On the right of the

Pepperl+Fuchs company logo there is a pictorial representation of a status LED.

This status LED lights up green when a device is connected. Otherwise it is red.

Activating live image capture

Note!

By viewing the captured images on the operator interface during operation, the

image refresh rate reduces significantly.

To activate live image capture, click the Star t Liv e Modebutton on the right-hand

side of the display screen.

The stationary reader starts to capture images. The captured images are

displayed in the results window. The decoded information is displayed beneath it

in a separate window.

Starting single image capture

On the right-hand side of the display screen, click on the button Single image.

Clicking the button triggers a single image capture.

216677 2012-05

19

Page 20

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

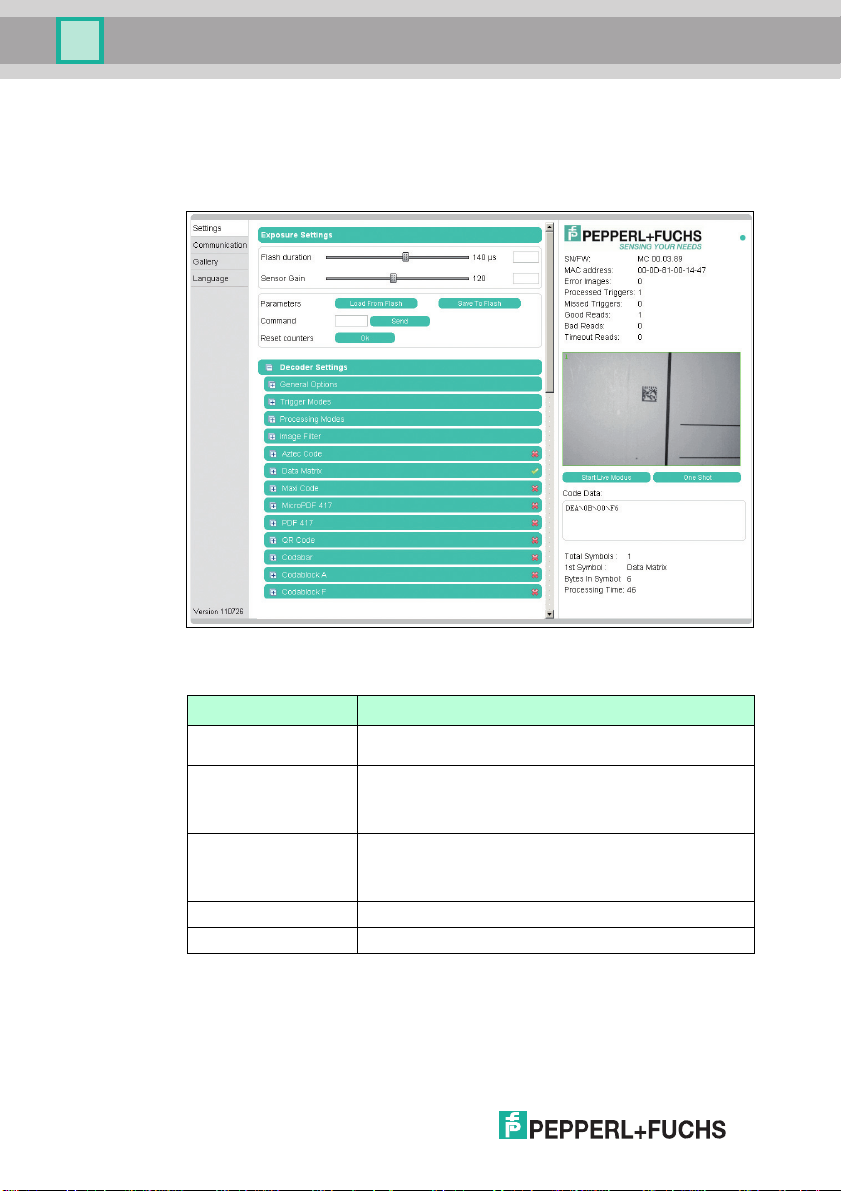

7.1.1 Settings Ta b

The Settings tab enables you to configure various parameters and send

commands to the sensor. In the left display area, you can navigate to the other

tabs Communication, Gallery and Language.

20

In the center of the screen, the following functions are available in different fields:

Sensor parameters

Settings Explanation

Flash duration This parameter is used to set the duration of the flash at

Ga i n This parameter is used to set the electronic brightness gain. A

Parameter set Load from Flash: Use this button to load parameter settings

Command Send individual commands to the sensor.

Reset counter The trigger counter value can be reset to 0 here.

intervals of 10 µs.

high value electronically increases the brightness of the

captured image and can improve the readability of the code

considerably in the event of poor ambient conditions.

from the internal memory (Flash EEPROM).

Save to Flash: Use this button to save your current parameter

settings in the internal memory (Flash EEPROM).

216677 2012-05

Page 21

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

Sending a command

You have the option of sending individual commands to the sensor. The

commands are made up of 4-digit hexadecimal numbers (0 ... 9, A ... F). An

overview of the available commands can be found in the appendix.

1. If you are not already on the Settings tab, navigate to it.

2. Enter a valid, 4-digit hexadecimal number for the required command in the

Command field.

3. Click on Send.

The relevant command will be sent to the sensor, where it will be

executed.

Decoder parameters

Settings can be applied to the individual symbologies via the “Decoder

parameters” menu option. The green checkmark and red cross show which

symbologies have been activated and which have not. They can be activated or

deactivated via the respective menus. You can configure settings to the general

operating principle of the sensor via the Gen era l s e t ti ngs menu option.

General settings

■ Any new values entered in a text box are sent to the reader automatically

after approximately 1.5 seconds. Pressing the enter key is not absolutely

required.

■ If an invalid character is entered in a text box (e.g., a letter in a numerical

field), the background is highlighted red and the value is not sent to the

reader. If a value outside the validity range is entered, the background is

also highlighted red.

The general settings for operation are entered here.

■ Trigger signal edge: Configures the inputs for rising edge or falling edge

■ Triggers for edge/level (individual triggers only): Configures the inputs

for edge and level sensitivity

■ Decoder mode: Configuration option of automatic or assisted. If the

option automatic is selected, no defined distances between the reader

and the code are adopted. If the option assisted is selected, a fixed read

distance between the reader and code carrier is adopted (refer to the

technical data in the data sheet for the read distance). This defines the size

of the code. However, additional settings are required as a result (reading

window width).

■ Contrast improvements: The following options can be used to increase

the detection reliability of codes and images with low levels of contrast.

Either general linear codes (apart from Interleaved 2/5), just Interleaved

2/5, or both can be activated. Activating these options can result in longer

decoding times and must be assessed on a case-by-case basis.

■ Average reading window width (mm): The value range is 10 mm ... 200

mm. Input of the average reading window width.

216677 2012-05

21

Page 22

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

■ Image mode: How the code is to be read. If mirrored is selected, then the

reader expects a mirrored code (read via a deviation mirror).

■ Select parameter file: A backup file can be loaded into the sensor. Use

the Browse...button to select the file and then load it into the sensor with

the Send button.

■ Download parameter file: The settings that you have made can be saved

in a backup file.

■ Set default decoder parameters: Resets all values to their default values.

Explanation of trigger signal edge and triggers for edge/level:

Trigger signal edge: The sensor responds to edges, i.e., signal changes

(rising/falling edge) that are triggered by a photoelectric sensor.

Trigger rising edge

Trigger

Decoder

Result

Figure 7.1 Pulse diagram trigger rising edge

22

Triggers for edge/level: The sensor responds to a pending level, which means it

initiates synchronous trigger cycles as long as the signal is pending, i.e., image

capture, decoding, image capture, decoding, image capture, decoding.

Automatic sensor start

If “Trigge rs fo r edge/ le v el” mode is activated, it is possible for the sensor to start

running automatically and trigger, if the trigger input wiring is connected

permanently to High (or Low).

Procedure: Triggers for level active and single trigger mode active -> Trigger as

long as level is High.

216677 2012-05

Page 23

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Trigger

Decoder

Result

Trigger

Trigger rising edge

Operation

Figure 7.2 Pulse diagram trigger rising edge and level

Figure 7.3 Decoder settings - General Options

216677 2012-05

23

Page 24

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

Trigger modes

Under the Trigger modes menu item, you can select whether to process one or

several triggers and specify how these triggers should be processed.

Trigger modes: Single trigger

In Single trigger mode, one image is captured and decoded for each external

trigger. Any other triggers that arise during the decoding process are ignored.

Activating the function Permit asynchronous triggers permits triggers during

decoding.

■ Suppress unsuccessful read (RS232 & TCP/IP): Specifies whether the

output of the signal or output string from an unsuccessful read should be

suppressed (activated) or not suppressed (deactivated).

■ Machine cycle: Machine cycle setting. The value must be greater than

20 ms. The value specifies the time gap between each incoming external

trigger (minimum time). The setting has an effect on the timeout.

■ Permit asynchronous triggers: Specifies whether or not asynchronous

triggers are permitted. If the field is activated, another trigger can be

processed while a captured image is being processed.

machine cycle

Trigger

Picture

recording

mc

24

Decoder

Result

Figure 7.4 Pulse diagram single trigger

216677 2012-05

Page 25

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

Trigger modes: Interval burst trigger

In Interval burst trigger mode, several images are captured and decoded for each

external trigger. An interval is defined, during which several images are captured.

The burst length and time limit define the minimum number of images or decoding

attempts: Number N = burst length / (20 ms + time limit). Any other triggers that

arise during the burst are ignored and counted as missed triggers.

■ Suppress unsuccessful read (RS232 & TCP/IP): Specifies whether the

output of the signal or output string from an unsuccessful read should be

suppressed (activated) or not suppressed (deactivated).

■ Burst length: Burst length setting in ms. The value range is 0 ms ... 30000

ms. Entering the number 30001 is the equivalent of setting no limit, i.e.,

once the reader starts triggering, it carries on continuously. Continuous

burst mode can be terminated by a command (8400) or pulse at the second

input.

■ Decoder timeout: Specifies the decoder timeout, between 10 ms and

10000 ms. Here, enter the maximum time that the decoder should attempt

to decode a captured image.

■ Stop after good reading: Specifies whether the burst is stopped after a

good reading. If the burst length is set to infinite, the burst does not stop

after a good reading.

■ Duplicate suppression (ms): The value range is 0 ms ... 30000 ms. Here,

enter the maximum time that the last decoding result should be ignored.

Example: A code is ignored if it cannot be retrieved quickly enough from the

read area and the same code is read again.

■ Gain hysteresis: Activate or deactivate the gain hysteresis. The gain value

hysteresis may be useful if the contrast of symbols scheduled for scanning

is varied. The hysteresis can be deactivated or activated with ± 1 increment

up to an increment quantity of ± 15 increments . When an increment width

of 2 is entered, a total of 5 captures are triggered.

Example: The gain is set to 100, the gain hysteresis is activated with 2

increments, and the increment width is set to 5, which means that when a

trigger occurs, 5 images with the following gain values are captured in

succession: 100, 105, 95, 110, 90. The preset gain value is the average

value of the hysteresis, so to speak. (Note: The gain value range extends

from 0 to 255. If the upper or lower limit is exceeded as a result of the

hysteresis process, the relevant gain value is limited to 0 or 255. Example:

Gain 50, 4 increments, increment width 20, -> gain values: 50, 70, 30, 90,

10, 110, 0, 130, 0). The gain hysteresis stops if decoding is successful.

216677 2012-05

25

Page 26

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Trigger

Picture

recording

Decoder

Result

Burst length

Operation

Figure 7.5 Pulse diagram burst trigger interval

216677 2012-05

26

Page 27

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Trigger

Picture

recording

Decoder

Result

Interval

Operation

Trigger modes: Frame burst trigger

In Frame burst trigger mode, several images are captured and decoded for each

external trigger. The maximum number of images and the time between each

image captured in a burst is defined. Any other triggers that arise during the burst

are ignored and counted as missed triggers. The frame burst trigger stops if

decoding is successful.

■ Number of images per burst: Specifies the maximum number of images

captured in each burst. Option of selecting between 2 and 9.

■ Interval between frames: Specifies the length of the intervals between

the frames. Option of selecting between 20 ms and 30000 ms.

■ Decoder timeout: Entry specifying the decoder timeout. Option of

selecting between 10 ms and 10000 ms. Here, enter the maximum time

that the decoder should attempt to decode a captured image.

Figure 7.6 Pulse diagram burst trigger frame

216677 2012-05

27

Page 28

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

Processing modes

Under Processing mode, you can specify whether an image should contain one or

several symbols and whether these symbols should be imported. If several

symbols are scheduled to be read, you will need to specify how the individual

results will be used to compile the output string.

Processing mode: Single window

In Single window mode, you can search for and decode 1 symbol in 1 active

window. The size and position of the window can be selected as required. Only

the window area is processed to enable quicker decoding.

■ Reference code/match code: The reference code/match code function

can be used only in Single window processing mode.

■ Comparison code: The comparison code is entered here. When the

mouse is moved over the comparison code input window, the popup menu

containing the nonprinting characters appears see Figure 7.8 on page

29.

■ Read next code: Press the OK button if you would like to accept the

content of the next decoded symbol as reference content for the

comparison code.

■ Good read output: Specifies the character string that will be output if

decoding was successful. This field uses Tooltip functionality. A table

appears if the mouse pointer remains over one of the two input fields for

more than 1 second. The table contains placeholders that can be inserted

manually or by clicking the mouse. At present, the following information can

be output as part of the output string: Code content, code length, status,

decoding time, symbol coordinates, etc. A description of the placeholders

can be found in the appendix see chapter 9.3.

■ Bad read output: Specifies the character string that will be output if

decoding was unsuccessful. A match code or timeout error will also result

in the output of this string. A table appears if the mouse pointer remains

over one of the two input fields for more than 1 second. The table contains

placeholders that can be inserted manually or by clicking the mouse. At

present, the following information can be output as part of the output string:

Status, decoding time. A description of the placeholders can be found in

the appendix see chapter 9.3.

Setting the detection range

The window areas selected in Single window and Multiwindow mode are visible

only when the corresponding operating mode is activated.

1. The size and position of the individual windows can be adjusted only by using

the mouse.

2. Move the cursor over the window you wish to modify.

3. Press the left mouse button while holding down the shift key to adjust the size.

Move the mouse to change the size of the window.

4. Press the left mouse button to adjust the position. Move the mouse to change

the position of the window.

Repeat the process for all the windows you wish to modify.

28

216677 2012-05

Page 29

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

Figure 7.7 Menu item processing modes - single window

Figure 7.8 Tooltip matchcode

216677 2012-05

29

Page 30

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

Processing mode: Multiwindow

In Multiwindow mode, you can search for and decode 1 symbol in a maximum of 4

different activated windows. The unread codes must be positioned completely

inside the window to ensure that the individual area can be assigned reliably. The

complete output string is compiled from the active read areas (linking) .

■ Window: Activates or deactivates the individual areas scheduled for

evaluation.

■ Good read output: Specifies the character string that will be output if

decoding was successful. This field uses Tooltip functionality. A table

appears if the mouse pointer remains over one of the two input fields for

more than 1 second see Figure 7.10 on page 31. The table contains

placeholders that can be inserted manually or by clicking the mouse. At

present, the following information can be output as part of the output string:

Code content, code length, status, decoding time, symbol coordinates, etc.

A description of the placeholders can be found in the appendix see chapter

9.3.

■ Bad read output: Specifies the character string that will be output if

decoding was unsuccessful. A timeout error will also result in the output of

this string. A table appears if the mouse pointer remains over one of the two

input fields for more than 1 second see Figure 7.10 on page 31. The

table contains placeholders that can be inserted manually or by clicking the

mouse. At present, the following information can be output as part of the

output string: Status, decoding time. A description of the placeholders can

be found in the appendix see chapter 9.3.

Setting the detection range

The window areas selected in Single window and Multiwindow mode are visible

only when the corresponding operating mode is activated.

1. The size and position of the individual windows can be adjusted only by using

the mouse.

2. Move the cursor over the window you wish to modify.

3. Press the left mouse button while holding down the shift key to adjust the size.

Move the mouse to change the size of the window.

4. Press the left mouse button to adjust the position. Move the mouse to change

the position of the window.

Repeat the process for all the windows you wish to modify.

30

216677 2012-05

Page 31

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

Figure 7.9 Menu item processing modes - multi window

Figure 7.10 Tooltip good read message - bad read message

216677 2012-05

31

Page 32

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

Processing mode: Multisymbology

Up to 4 different symbologies can be read in this mode. In contrast to Multiwindow

mode, the entire image is always processed here. The position of the symbols

within the image area is not important. The complete output string is compiled

from the fixed sequence of preset symbologies (linking). The symbologies must

be different and selected symbologies must also be activated globally in the

respective sections so that a defined output string sequence can be allocated if

the position of the image to be read is not defined. If the position of the read image

is always the same, several identical symbologies can also be read

simultaneously. Here, the sequence is from top to bottom and from left to right.

■ Symbology: Specifies the symbology or symbology family.

■ Good read output: Specifies the character string that will be output if

decoding was successful. This field uses Tooltip functionality. A table

appears if the mouse pointer remains over one of the two input fields for

more than 1 second see Figure 7.10 on page 31. The table contains

placeholders that can be inserted manually or by clicking the mouse. At

present, the following information can be output as part of the output string:

Code content, code length, status, decoding time, symbol coordinates, etc.

A description of the placeholders can be found in the appendix see chapter

9.3.

■ Bad read output: Specifies the character string that will be output if

decoding was unsuccessful. A timeout error will also result in the output of

this string. A table appears if the mouse pointer remains over one of the two

input fields for more than 1 second see Figure 7.10 on page 31. The

table contains placeholders that can be inserted manually or by clicking the

mouse. At present, the following information can be output as part of the

output string: Status, decoding time. A description of the placeholders can

be found in the appendix see chapter 9.3.

32

Figure 7.11 Menu item processing modes - multi symbol

216677 2012-05

Page 33

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

Figure 7.12 Tooltip good read message - bad read message

Prefilter

Definition of prefilters to make subsequent decoding easier.

■ Median filter: Elimination of minor interference. The filter can be enabled

or disabled with filter sizes 3, 5, 7, 9, 11.

■ Morphological filters (module enlargement): Morphological filters are

frequently used to suppress noise, segment images, etc. The filter can be

disabled to Erosion/Dilatation or Opening/Closing. A filter size of 1 ... 6 can

be selected.

■ Foreground (print color): Specifies the print color. The values available

are dark and light.

216677 2012-05

33

Page 34

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

Aztec Code

The Aztec Code tab allows you either to deactivate the detection of these codes

(deactivated), activate detection (normal), invert detection of the codes (all white

fields are black and vice versa; inverse) or activate the detection of the codes

irrespective of whether they are normal or inverted (normal & inverse).

Example:

Data Matrix

The Data Matrix tab allows you to make the following settings:

■ Data Matrix: You can either deactivate the detection of this code

(deactivated) or activate the detection of this code, whereby the detection

of normally printed codes (dark code, light code background), inversely

printed codes (light code, dark code background) or both types (normal &

inverse) can be activated simultaneously.

■ Rectangular Data Matrix activated: You can activate the detection of

rectangular Data Matrix codes.

■ Module size (µm): Use this parameter to specify the minimum and

maximum module size in µm.

■ Number of modules: Use this parameter to specify the minimum and

maximum number of modules.

■ Pixel / module: Use this parameter to specify the number of pixels

permitted per module.

■ Direction angle: The orientation of the code can be set here. You have the

choice of selecting parallel to the axes or any . Parallel to the axes can be

selected when the sides of the code are positioned in parallel to the edges

of the image. Any must be selected when the code is rotated to any

position around its center point.

■ Permit non-square modules: Permits the distortions that occur with some

printing methods. (Rectangular distortion)

■ Permits print misalignment in multipart Data Matrix codes: Permits

print misalignment in "multi-tile" codes (> 32 x 32 modules).

34

Example:

216677 2012-05

Page 35

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

Maxi Code

In the Maxi Code tab, you are able to define individual modes of the Maxi Code

symbology.

Example:

216677 2012-05

35

Page 36

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

MicroPDF 417

In the MicroPDF 417 tab, you can either activate or deactivate detection of the

MicroPDF 417 code.

Example:

PDF 417

In the PDF 417 tab, you can either activate or deactivate detection of PDF 417

codes.

Example:

36

QR Code

In the QR Code tab, you can activate various modes.

Example:

216677 2012-05

Page 37

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

Codabar

In the Codabar tab, you can either activate or deactivate detection of the Codabar

code. You can also activate or deactivate the checksum checker.

■ Checksum handling: This feature enables you to activate or deactivate

checking of the checksum using one of two options. One option is to

compare the read code with the checksum and then to output the code with

the checksum (check). The other option is to compare the code that has

been read with the checksum and then to output the code without the

checksum (check & remove).

■ Permit smaller quiet zone: Codes with smaller quiet zones are also

decoded.

Example:

Codablock A

In the Codablock A tab, you can either activate or deactivate detection of the

Codablock A code.

Example:

Codablock F

In the Codablock F tab, you can either activate or deactivate detection of the

Codablock F code.

Example:

216677 2012-05

37

Page 38

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

Code 11

In the Code 11 tab, you can either activate or deactivate detection of the Code 11

code.

■ Checksum handling: This feature enables you to activate or deactivate

checking of the checksum using one of two options. One option is to

compare the read code with the checksum and then to output the code with

the checksum (check). The other option is to compare the code that has

been read with the checksum and then to output the code without the

checksum (check & remove).

Example:

Code 39

In the Code 39 tab, you can either activate or deactivate detection of the Code 39

code.

■ Checksum handling: This feature enables you to activate or deactivate

checking of the checksum using one of two options. One option is to

compare the read code with the checksum and then to output the code with

the checksum (check). The other option is to compare the code that has

been read with the checksum and then to output the code without the

checksum (check & remove).

■ ASCII decoding activated: Specifies whether ASCII decoding has been

activated or not.

■ Permit smaller quiet zone: Codes with smaller quiet zones are also

decoded.

38

Example:

216677 2012-05

Page 39

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

Code 93

In the Code 93 tab, you can either activate or deactivate detection of the Code 93

code.

■ Permit smaller quiet zone: Codes with smaller quiet zones are also

decoded.

Example:

Code 128

In the Code 128 tab, you can either activate or deactivate detection of the Code

128 code.

■ Permit smaller quiet zone: Codes with smaller quiet zones are also

decoded.

Example:

Composite Code

In the Composite Code tab, you can either activate or deactivate detection of the

Composite code.

216677 2012-05

39

Page 40

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

Hong Kong Code

In the Hong Kong Code tab, you can either activate or deactivate detection of the

Hong Kong code.

■ Minimum code length: Specifies the minimum size of the code that is to

be detected.

Interleaved 2 of 5

In the Interleaved 2 of 5 tab, you can either activate or deactivate detection of the

Interleaved 2 of 5 code.

■ Checksum handling: This feature enables you to activate or deactivate

checking of the checksum using one of two options. One option is to

compare the read code with the checksum and then to output the code with

the checksum (check). The other option is to compare the code that has

been read with the checksum and then to output the code without the

checksum (check & remove).

■ Permit smaller quiet zone: Codes with smaller quiet zones are also

decoded.

■ Minimum code length: Specifies the minimum size of the code that is to

be detected.

40

Beispiel:

216677 2012-05

Page 41

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

Matrix 2 of 5

In the Matrix 2 of 5 tab, you can either activate or deactivate detection of the Matrix

2 of 5 code.

■ Checksum handling: This feature enables you to activate or deactivate

checking of the checksum using one of two options. One option is to

compare the read code with the checksum and then to output the code with

the checksum (check). The other option is to compare the code that has

been read with the checksum and then to output the code without the

checksum (check & remove).

■ Minimum code length: Specifies the minimum size of the code that is to

be detected.

Example:

MSI Plessey

In the MSI Plessey tab, you can either activate or deactivate detection of the MSI

Plessey code.

■ Checksum deactivated: Allows you to deactivate the checksum

Example:

216677 2012-05

41

Page 42

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

NEC 2 of 5

In the NEC 2 of 5 tab, you can either activate or deactivate detection of the NEC 2

of 5 code.

■ Checksum handling: This feature enables you to activate or deactivate

checking of the checksum using one of two options. One option is to

compare the read code with the checksum and then to output the code with

the checksum (check). The other option is to compare the code that has

been read with the checksum and then to output the code without the

checksum (check & remove).

■ Minimum code length: Specifies the minimum size of the code that is to

be detected.

GS1 DataBar (RSS)

The RSS (Reduced Space Symbology) tab allows you to select the different

detection options of the RSS code.

42

Example:

216677 2012-05

Page 43

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

Industrial/Standard 2 of 5 (2 bar start/stop codes)

In the Straight 2 of 5 tab (2 bar start/stop codes), you can either activate or

deactivate detection of the Straight 2 of 5 code (2 bar start/stop codes).

■ Minimum code length: Specifies the minimum size of the code that is to

be detected.

Example:

Industrial/Standard 2 of 5 (3 bar start/stop codes)

In the Straight 2 of 5 tab (3 bar start/stop codes), you can either activate or

deactivate detection of the Straight 2 of 5 code (3 bar start/stop codes).

■ Minimum code length: Specifies the minimum size of the code that is to

be detected.

Example:

Telepen Code

In the Telepen tab, you can either activate or deactivate detection of the Telepen

code.

Example:

216677 2012-05

43

Page 44

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

Trioptic Code 39

In the Trioptic Code 39 tab, you can either activate or deactivate detection of the

Trioptic Code 39 code.

■ Permit smaller quiet zone: Codes with smaller quiet zones are also

decoded.

Example:

UPC/EAN/JAN

In the UPC/EAN/JAN tab, you can either activate or deactivate detection of the

UPC/EAN/JAN code.

■ Permit smaller quiet zone: Codes with smaller quiet zones are also

decoded.

44

Example:

216677 2012-05

Page 45

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

Pharma Code

In the Pharma tab, you can either activate or deactivate detection of the Pharma

code.

■ Number of bars: Enter the minimum and maximum number of bars in the

code.

■ Code contents: Enter the number range that is to be decoded.

■ Direction angle: Specify whether the code is to be read in a horizontal or a

vertical direction.

■ Decoding direction: Specify whether the code is to be read from left to

right or from right to left.

■ Color bars: If this setting is deactivated, only black color bars will be read

cleanly.

Example:

216677 2012-05

45

Page 46

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

Postal Code

In the Postal Code tab, you can either activate or deactivate detection of the Postal

code.

■ Direction angle: Enter the direction angle of the code here.

Omnidirectional is the standard setting, although this means that it will take

longer to read the code.

■ Australia Post Code with zero FCC & DPID activated: Activate or

deactivate the Australia Post Code with zero FCC & DPID.

■ Number of lines: Enter the minimum and maximum number of lines in the

code.

■ Output of non-decodable symbols in the field (mm): Enter the field in

which non-decodable symbols are located that need to be detected.

Example:

46

216677 2012-05

Page 47

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

OCR

■ OCR: Specifies whether OCR font recognition is deactivated

(deactivated) or activated, whereby the detection of normally printed font

(dark font, light background), inversely printed fonts (light font, dark font

background) or both types (normal & inverse) can be activated

simultaneously.

■ Tex t f l ow di re c t ion :Specifies the direction in which the OCR code should

be read. For example, it is necessary to indicate whether the character

string HOHOHO on a OCR code should be read from right to left or from left

to right.

■ Individual line: Specifies whether an individual line for placing a template

is output if there are other characters immediately above or below it.

■ Remove checksum: You have the option of removing a read checksum

before the decoded OCR code is output. The output code no longer

contains the checksum as a result.

■ Inhomogeneous background: You can select this field to enhance OCR

recognition. This field is recommended if you have selected the pass

template. Many countries print a pattern behind the OCR code on the ID,

which prevents the code from being read properly. However, the processing

time increases when the field is selected.

■ Output ambiguous characters: This function only influences OCR output

when the pass template is selected.

■ Disable '.' characters: Suppresses the detection/output of '.' characters

(e.g., decimal point, end of sentence). '.' characters that form part of a user

template are ignored.

■ Ignore pass checksums: You also have the option of reading identity

cards, visas, and passports that do not meet ICAO checksum standards. If

the function is deactivated and the ID does not meet ICAO standards, no

results are generated.

■ Te mp l a te s : You have the option of choosing from a selection of existing

templates.

■ User template:Selecting the “User-defined” field under “Te m p l a t e s ” allows

you to compile your own template. A table is displayed if the mouse pointer

remains over one of the two input fields for more than 1 second. The table

contains placeholders that can be inserted manually or by clicking the

mouse.

216677 2012-05

47

Page 48

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

48

216677 2012-05

Page 49

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

The following font types are supported:

OCR-A

OCR-B

MICR E-13B

SEMI OCR

216677 2012-05

49

Page 50

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

7.1.2 Communication Tab

The Communication tab allows you to configure various network and

transmission parameters. In the left display area, you can navigate to the other

tabs Settings, Gallery and Language.

50

In the center of the screen, the following functions are available in different fields:

Param eters Explanation

IP address Assign a new IP address to the sensor using this field.

Subnet mask Change the subnet mask using this field.

Ga t e w a y Change the gateway using this field.

TCP/ IP po rt fo r process

communication

Output signal length Change the temporal length of the output signal using this

Trigger delay [ms] Change the trigger delay using this field. Value range: 1 ms …

Baud rate Change the baud rate using this field.

Serial port Activate or deactivate the RS232 interface output.

Change the TCP/IP port using this field. The output strings

are sent to the remote station (e.g., PLC) via this port. After

making the changes, you must press OK to confirm your

entries and reboot the system.

field.

255 ms

Transferring parameters

1. Carry out the desired settings.

2. Transfer the settings by clicking OK .

216677 2012-05

Page 51

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

7.1.3 Tab Ga l l e r y

The Gallery allows you to view the saved error images and save them locally on

the PC if necessary. You can navigate to the other tabs Settings,

Communication and Languagein the left display area.

In the upper section of the display, the last 6 error images saved in the stationary

reader are shown as a preview.

You can save the images locally in pgm or gif format.

Saving an image locally

Note!

In the following instructions, the asterisk [*] stands for the file name of the image,

since the button name varies depending on the preview image selected.

1. Click the *.pgm or *.gif button below the image display.

2. Select the memory location, change the file name if necessary, and click

Save.

216677 2012-05

51

Page 52

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Operation

7.1.4 Dialog box Language

The Language enables you to change the language for the entire operator

interface. You can navigate to the other tabs Settings, Communication and

Ga l l e r y in the left display area.

52

Selecting/changing the language

1. Choose one of the options Ge r m a n , English and Chinese.

2. To implement the selection, click OK.

The selected language will be adopted.

216677 2012-05

Page 53

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Troubleshooting

8Troubleshooting

8.1 What to do in the event of an error

Before requesting a service call, please check that the following actions have

been taken.

■ Test the equipment according to the following checklists,

■ Telephone assistance from the Service Center in order to isolate the

problem.

Check list

Error Cause Remedy

"ST" LED not lit up The power supply is

"ST" LED not lit up The Sub-D socket is not

"ST" LED not lit up Wiring fault in the

"ST" LED not lit up Supply line to the sensor is

No connection to the

device

No connection to the

device

switched off.

connected to the connector

on the sensor.

distributor or control

cabinet.

damaged.

Network cable not

connected.

Wrong network cable used. Direct connection between PC and device:

Check whether there is a reason for it being

switched off (installation or maintenance work

etc.). Switch the power supply on if

appropriate.

Connect the Sub-D socket to the sensor and

tighten the screws by hand.

Check the wiring carefully and repair any

wiring faults.

Replace the damaged wire.

Connect the network cable.

Use a crossover network cable.

Connection via an existing network: Use a

twisted-pair network cable.

■ If none of the above remedies have had the desired effect, please contact

the Service Center. Please have the fault patterns and version number of

the ODT-MAC4** system at hand. The version number can be found at the

bottom left of the operator interface.

216677 2012-05

53

Page 54

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Appendix

9 Appendix

9.1 Command format

Commands

Each command consists of 4 ASCII-coded hexadecimal digits (CD

<CR> or <LF> .

Meaning of the individual digits

Syntax:

Meaning

Example

Each sent hexadecimal character is echoed by the device. A <LF><CR> is sent

after the 4 valid characters are received. Other characters are interpreted as the

next command.

V1 prompt

A command code such as 0123 would cause the following echo:

C:0123<LF><CR>.

V1 command termination

Press the“ESC”button to terminate a command at any point in the 4 ASCII

character string. In this case, the device does not wait for the next character. If

ESC is pressed for the first character, the device responds with

C:<ESC><LF><CR>.

Timeout

A V1 command character must be input within one second. If no characters are

input within this time, <LF><CR> is sent and the device waits for the first

character again.

V1 data information

All D commands trigger an output. Characters 2 and 3 of the sent command are

always echoed at the start of this operation.

<C> <D2> <D1> <D0>

C Command

D

2

D

1

D

0

Command: Read (8)

Detail none (000)

2D1D0

Detail 2

Detail 1

Detail 0

Complete command: 8000

) without

54

Caution!

Characters 2 and 3 are always echoed as uppercase letters, regardless of

whether they were lowercase or uppercase beforehand.

Example: Input:D100 => Output:D100<LF><CR>10Decoder

Ver.4.01.0T<LF><CR>.

216677 2012-05

Page 55

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Appendix

Stat us me ssage

The status message is generated automatically when decoding is triggered and

the decoding process is complete.

Stat us me ssage

Syntax <Command> <fOk> <Error code> <ECC> <Data> <cr> <lf>

Meaning

Example

Command

(1 hex digits)

fOk

(1 decimal digit)

Data

(unlimited number)

LF ASCII end character: 0A

CR ASCII end character: 0D

Good reading

Bad reading

The first digit of the command is

output

0: Ok, 1: Error

Data contained in larger/smaller

(>/<) characters, if data output is

active

MAC34x only:

800001>DataFromDataMatrix<

MAX4xx/MAC5xx:

80>DataFromDataMatrix<

MAC34x only: 81FF00

MAX4xx/MAC5xx: 81FAIL

216677 2012-05

55

Page 56

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Appendix

9.2 Command overview

This table contains a list of all the commands which you can send individually to

the stationary reader from the Settings tab page.

Alternatively, these commands but also about the process interface are (RS232 /

TCP / IP) is sent.

The following notation is used.

H: Here you can enter setting values as hexadecimal numbers.

X: Here you can enter any hexadecimal numbers. These values are ignored for

the settings.

Commands 0 to 8

Command

D2D1D

0 H H X

2 H H X

5 H H X

8 0 0 0

8 4 0 0 Trigger stop with interval burst trigger

DescriptionC

0

Flash duration in intervals of 10 µs. Example: 0120

180 µs

Sets the pulse length of the outputs (D2D1)

Video gain, default=50H (decimal:80)

For continuous reading, the burst length must be set to 30001

Trigger resolution for single reading

Trigger start with interval burst trigger

sets the flash duration to

H

Command

D2D1D

A H H X

56

Command A

DescriptionC

0

Set shutter time D2D1.

Shutter time in 30 µs increments (default=00, shutter time follows flash duration)

216677 2012-05

Page 57

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Appendix

Command C

216677 2012-05

57

Page 58

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Appendix

Command

D2D1D

5 H H

6 0 H

C

4 0 0 Set V1 standard interface (default, no other interface currently available)

7 H H Change baud rate

58

DescriptionC

0

Advanced commands

Para mete r D2 indicates the advanced command

Sets the filter parameters to be used when specifying the filter type using C6xx.

The possible parameter values are, therefore, entered using the command C6xx.

Important:

This command must be issued before the command C6xx!

The entered values become invalid when the C6xx command is issued (can only

be used once!)

Filter selection for preprocessing and debug

Important:

Enter the filter parameters first using the command C5xx!!

Val ue Set Func tion

0x00 All filters are disabled

0x01

0x02 Open or close areas (opening/closing)

0x03

Wert Baud rate

0x00 9600 baud

0x01 19200 baud

0x02 38400 baud

0x03 57600 baud

0x04 76800 baud

0x05 115200 baud

0x06 4800 baud

0x07 2400 baud

Extend areas (erosion/dilatation)

Possible parameter values using C5xx:

0x00 Filter off

Filter size in X and Y direction, possible values in each

0xXY

0x01 Filter off

0x02

Use median filter (homogenization in the case of grainy

codes/images)

Possible parameter values using C5xx:

0x01 Filter off

0x0X Quadratic filter size 3, 5, 7, 9, and 11 (0x0B)

case:

0x1 to 0x6: extend light areas.

0x9 to 0xE: extend dark areas (0x1 to 0xE plus offset 0x8)

(for both dimensions 1 ... 6 or 9 ... E, but areas not mixed)

Filter size in X and Y direction, possible values 1 to 6 in

each case:

0x1 to 0x6: extend light areas.

0x9 to 0xE: extend dark areas (0x1 to 0xE plus offset 0x8)

(for both dimensions 1 ... 6 or 9 ... E, but areas not mixed)

216677 2012-05

Page 59

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Appendix

Command

D2D1D

A X 0

A X 1 Restoring default settings

A X 2 Reset IP / subnet / gateway to 192.168.2.2 / 255.255.255.0 / 0.0.0.0

B 0 0 Saving parameters in flash.

E H H

F 00 Reserved

C

F H Sets resolution

F X H Sets partial capture. Always begins at line 0

DescriptionC

0

Loading parameters from the flash memory.

A differentiation is not made between the default and the working area.

Error image processing

Error images are only saved if the system has sufficient resources. Decoding and

image capture have top priority.

Val ue Output

00 Provides the number of saved error images

01 - 05 CE01 to CE05 display error images 1 to 5

09 Displays the last captured image

10 Displays the last captured image

Val ue Resolution

1 VGA 640x480

5 WVGA 752x480

Val ue

0 1/1 (standard)

1 1/2 (half image captured)

2 1/3 (only the first third of the image is evaluated)

3 1/3 (only the first third of the image is evaluated)

4 1/3 (only the first third of the image is evaluated)

5 3/4 (only three quarters of the image is evaluated)

Image height

as a proportion of the overall image height, beginning at line 0

216677 2012-05

59

Page 60

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Appendix

Command D (only works via the serial interface)

Command

D2D1D

1 0 0 Decoding software version (ends with <CR><LF>)

D

3 X X Video gain

6 X X Additional information

6 1 X Flash duration

6 3 X Timeout, reading

Additional commands for stationary readers with laser pointer

Command

D2D1D

F 0 H Control laser pointer

E

DescriptionC

0

Send information

Para meter D

followed by the values.

The string is tested for 10D OR 10M with autodetect and it must not be longer

than 20 characters.

DescriptionC

0

Val ue Effect

0 All laser pointer off

1 Laser pointer 1 off, laser pointer 2 on

2 Laser pointer 1 on, laser pointer 2 off

3 All laser pointer on

specifies the type of information. First, D2 is repeated in the output,

2

60

216677 2012-05

Page 61

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Appendix

9.3 Input of nonprintable characters

The following syntax is used to display nonprintable characters. A \ character is

appended to the ASCII value of the character as a 2-digit hex number.

Example: A Carriage Return (CR) character is coded ASCII 013 (decimal) or 0D

(hex). \0D is entered in the web interface.

In principle, every character can be set in this way. For reasons of legibility,

however, we recommend that printable characters be entered directly.

Limitations

The null byte (ASCII 0) cannot be used. (Permissible range: \01 ... \FF)

The \ character itself must be entered as \24

You can also enter whole character strings.

Examples of character strings

\02ABCDEFGH STX byte, followed by the letters A to H

\02[ STX byte, followed by a [character

\A0\B0777\03 ASCII A0 (hex), ASCII B0 (hex), 777 and an ETX byte

You can enter the space character from the keyboard in the normal way. For

reasons of legibility, however, it is displayed as \20 once entered.

Selected nonprintable characters and their meaning

Decimal

000 00 N/A The null byte cannot be displayed so please do not use it!

001 01 \01 SOH - start of heading

002 02 \02 STX - start of text

003 03 \03 ETX - end of text

004 04 \04 EOT - end of transmission

005 05 \05 ENQ - enquiry

006 06 \06 ACK - acknowledge

007 07 \07 BELL - bell

008 08 \08 BS - backspace

009 09 \09 TAB - tabulator

010 0A \0A LF - linefeed

011 0B \0B VT - vertical tab

012 0C \0C FF - formfeed page

013 0D \0D CR - carriage return

014 0E \0E SO - shift out

015 0F \0F SI - shift in

216677 2012-05

Hexadecimal

Web

Interface

Meaning, alternative designation

61

Page 62

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Appendix

Decimal

016 10 \10 DLE - data link escape

017 11 \11 DC1

018 12 \12 DC2

019 13 \13 DC3

020 14 \14 DC4

021 15 \15 NAK - negative acknowledge

022 16 \16 SYN - synchronous idle

023 17 \17 ETB - end of transmission block

024 18 \18 CAN - cancel

025 19 \19 EM - end of medium

026 1A \1A SUB - substitute

027 1B \1B ESC - escape

028 1C \1C FS - field separator

029 1D \1D GS - group separator

030 1E \1E RS - record separator

031 1F \1F DEL

032 20 \20 SPC - Space

Table 9.1 Nonprintable characters

Hexadecimal

Web

Interface

Meaning, alternative designation

It is also possible to enter the following placeholders in the Good Read Message

and No Read Message field so that predefined information can be output.

Placeholders and their meaning

Placeholder Meaning

\PSTR Decoded code content

\PSTR (x,y)

\PSTR (E,x)

\PLEN

\PQ01

\PANG Angle between the lower symbol edge and horizontal (long) image edge

\PCON

\PCWD Code words from the code (Data Matrix only)

\PTIM

From character x (counting starts at 0), with length y, length positive.

Example: \PSTR (0,5) -> the first 5 characters of the code are output.

x characters from the end until the end

Example: \PSTR (E,3) -> the last 3 characters of the decoded string are output.

Length of the code in characters/bytes, 4-digit numerical value, decimal, range: 0000 ...

9999

Quality value 1, unused error correction with certain symbologies, 3-digit numerical value,

decimal, range: 000 ... 100. If no symbol was decoded, 000 will be output.

Contrast value across the range of the decoded code, 3-digit numerical value, decimal,

range: 000 ... 100. Low values indicate a low level of contrast. If no symbol was decoded,

000 will be output.

Actual cycle time. Time required to capture and decode an image. 4-digit numerical value,

decimal, range: 0000 ... 9999. Also valid in the event of Timeout and No Read.

62

216677 2012-05

Page 63

ODT-MAC400-* / ODT-MAC401-* / ODT-MAC403-*

Appendix

Placeholder Meaning

Status bytes. Two-digit numerical value, decimal

80 - Good reading

\PSTS

\PCXC

\PCYC

\PCXL

\PCYL

Table 9.2 Placeholder for Good Read and No Read message

81 - Bad reading

82 - Good reading of match code, match OK

83 - Good reading of match code, match NOT OK

84 - Bad reading because timeout reached

X coordinate of the center point of the code relative to the center point of the image, 4-digit

numerical value, decimal, range: -999 ... 0000 ... 9999, unit: pixel

Y coordinate of the center point of the code relative to the center point of the image, 4-digit

numerical value, decimal, range: -999 ... 0000 ... 9999, unit: pixel

X coordinate of the center point of the code relative to the top left corner of the image, 4-digit

numerical value, decimal, range: 0000 ... 9999, unit: pixel

Y coordinate of the center point of the code relative to the top left corner of the image, 4-digit

numerical value, decimal, range: 0000 ... 9999, unit: pixel

Examples of Good Read message

\PSTR\0D\0A Code content, Carriage Return, New Line

\02>\PSTR<\03\0D

\0A

#\PSTS_\PQ01_\P

CON

\PST R(0,3 )\PSTR (

E,2)

STX, > character, code content, < character, ETX, Carriage

Return, New Line

# character, status byte, _ character, quality 1, _ character,

contrast

The first 3 characters and the last 2 characters of the code content

Examples of No Read message

NO_READ\0D\0A "NO_READ" String, Carriage Return, New Line

\02>FAIL<\03\0D\0ASTX, > character, "Fail" string, < character, ETX, Carriage Return,

#\PSTS_\PTIM # character, status bytes, _ character, cycle time

216677 2012-05

New Line

63

Page 64

FACTORY AUTOMATION –

SENSING YOUR NEEDS

Worldwide Headquarters

Pepperl+Fuchs GmbH

68307 Mannheim · Germany

Tel. +49 621 776-0

E-mail: info@de.pepperl-fuchs.com

USA Headquarters

Pepperl+Fuchs Inc.

Twinsburg, Ohio 44087 · USA

Tel. +1 330 4253555

E-mail: sales@us.pepperl-fuchs.com

Asia Pacific Headquarters

Pepperl+Fuchs Pte Ltd.

Company Registration No. 199003130E

Singapore 139942

Tel. +65 67799091

E-mail: sales@sg.pepperl-fuchs.com

www.pepperl-fuchs.com

Subject to modifications

Copyright PEPPERL+FUCHS • Printed in Germany

216677 TDOCT1750B_ENG

05/2012

Loading...

Loading...