Inductive sensor NCB10-30GM40-N0-50M

Technical Data

General specifications

Switching function Normally closed (NC)

Output type NAMUR

Rated operating distance sn10 mm

Installation flush

Assured operating distance sa0 ... 8.1 mm

0102

Model Number

NCB10-30GM40-N0-50M

Features

• 10 mm flush

• Stainless steel housing

Actual operating distance s

Reduction factor rAl 0.35

Reduction factor r

Reduction factor r

Nominal ratings

Nominal voltage Uo8 V

Switching frequency f 0 ... 200 Hz

Hysteresis H 1 ... 15 typ. 5 %

Reverse polarity protection reverse polarity protected

Short-circuit protection yes

Current consumption

Measuring plate not detected

Measuring plate detected

Switching state indicator all direction LED, yellow

Functional safety related parameters

MTTFd 1870 a

Mission Time (T

Diagnostic Coverage (DC) 0 %

Ambient conditions

Ambient temperature -25 ... 100 °C (-13 ... 212 °F)

Storage temperature -40 ... 100 °C (-40 ... 212 °F)

Mechanical specifications

Connection type cable PVC , 50 m

Core cross-section 0.75 mm

Housing material Stainless steel 1.4305 / AISI 303

Sensing face PBT

Degree of protection IP67

Cable

Bending radius

General information

Use in the hazardous area see instruction manuals

Category

Compliance with standards and directives

Stan dard conf ormit y

NAMUR

Electromagnetic compatibility

Sta ndar ds

Approvals and certificates

UL approval cULus Listed, General Purpose

CSA approval cCSAus Listed, General Purpose

CCC approval CCC approval / marking not required for products rated ≤36 V

0.3

Cu

0.75

304

) 20 a

M

9 ... 11 mm typ.

r

≥ 2.2 mA

≤ 1 mA

> 10 x cable diameter

1G; 2G; 3G; 1D; 3D

EN 60947-5-6:2000

IEC 60947-5-6:1999

NE 21:2007

EN 60947-5-2:2007

IEC 60947-5-2:2007

2

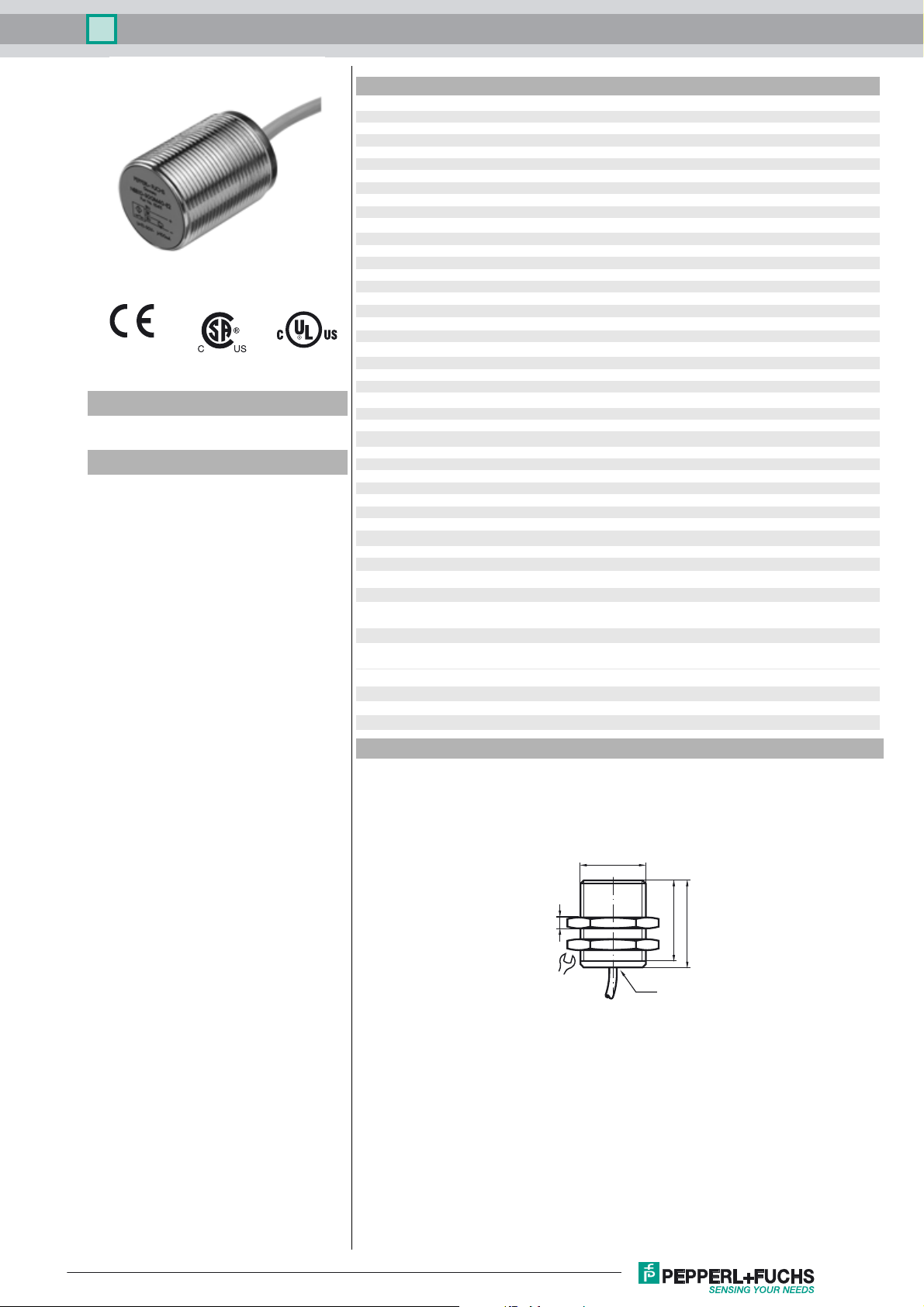

Dimensions

M30x1,5

LED

37

40

5

36

Release date: 2016-11-09 09:17 Date of issue: 2016-11-09 246522_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

1

Inductive sensor NCB10-30GM40-N0-50M

Electrical Connection

BN

BU

L+

L-

Release date: 2016-11-09 09:17 Date of issue: 2016-11-09 246522_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Inductive sensor NCB10-30GM40-N0-50M

Equipment protection level Ga

Instruction Manual electrical apparatus for hazardous areas

Device category 1G for use in hazardous areas with gas, vapour and mist

EC-Type Examination Certificate PTB 00 ATEX 2048 X

CE marking 0102

ATEX marking ¬ II 1G Ex ia IIC T6…T1 Ga The Ex-related marking can also be printed on the

Standards EN 60079-0:2012+A11:2013 EN 60079-11:2012 Ignition protection "Intrinsic safety"

Appropriate type NCB10-30GM...-N0...

Effective internal inductivity C

Effective internal inductance L

Ge n e r a l The apparatus has to be operated according to the appropriate data in the data sheet

Ambient temperature Details of the correlation between the type of circuit connected, the maximum per-

Installation, commissioning Laws and/or regulations and standards governing the use or intended usage goal

Maintenance No changes can be made to apparatus, which are operated in hazardous areas.

Special conditions The connecting parts of the sensor must be set up in such a way that degree of pro-

Protection from mechanical danger

Electrostatic charge

i

i

enclosed label.

Use is restricted to the following stated conditions

≤ 105 nF ; a cable length of 10 m is considered.

≤ 100 µH ; a cable length of 10 m is considered.

and in this instruction manual.

The EU-type examination certificate has to be observed. The special conditions

must be adhered to!

The ATEX directive and therefore the EU-type examination certificates apply in general only to the use of electrical apparatus under atmospheric conditions.

The use in ambient temperatures of > 60 °C was tested with regard to hot surfaces

by the mentioned certification authority.

If the equipment is not used under atmospheric conditions, a reduction of the permissible minimum ignition energies may have to be taken into consideration.

missible ambient temperature, the temperature class, and the effective internal reactance values can be found on the EC-type examination certificate. Note:

temperature table for category 1 !!! The 20 % reduction in accordance with EN 11271 has already been applied to the temperature table for category 1.

must be observed.

The intrinsic safety is only assured in connection with an appropriate related apparatus and according to the proof of intrinsic safety.

The associated apparatus must satisfy the requirements of category ia.

Due to the possible danger of ignition, which can arise due to faults and/or transient

currents in the equipotential bonding system, galvanic isolation of the power supply

and signal circuit is preferable. Associated apparatus without electrical isolation must

only be used if the appropriate requirements of IEC 60079-14 are met. If the Exrelated marking is printed only on the supplied label, then this must be attached in

the immediate vicinity of the sensor. The sticking surface for the label must be clean

and free from grease. The attached label must be legible and indelible, including in

the event of possible chemical corrosion.

Repairs to these apparatus are not possible.

tection IP20, in accordance with lEC 60529, is achieved as a minimum.

When using the device in a temperature range of -60 °C to -20 °C, protect the sensor

against the effects of impact by installing an additional enclosure.

The information regarding the minimum ambient temperature for the sensor as provided in the datasheet must also be observed.

Electrostatic charges must be avoided on the mechanical housing components.

Dangerous electrostatic charges on the mechanical housing components can be

avoided by incorporating these in the equipotential bonding. Avoid electrostatic

charges that can cause electrostatic discharge when installing or operating the

device. Additional requirements for gas group IIC. Information on electrostatic hazards can be found in the technical specification IEC/TS 60079-32-1.

Use the

Release date: 2016-11-09 09:17 Date of issue: 2016-11-09 246522_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

3

Inductive sensor NCB10-30GM40-N0-50M

Equipment protection level Gb

Instruction Manual electrical apparatus for hazardous areas

Device category 2G for use in hazardous areas with gas, vapour and mist

EC-Type Examination Certificate PTB 00 ATEX 2048 X

CE marking 0102

ATE X m ar king ¬ II 1G Ex ia IIC T6…T1 Ga

Standards EN 60079-0:2012+A11:2013 EN 60079-11:2012 Ignition protection "Intrinsic safety"

Appropriate type NCB10-30GM...-N0...

Effective internal inductivity C

Effective internal inductance L

Ge n e r a l The apparatus has to be operated according to the appropriate data in the data sheet

Maximum permissible ambient temperature T

Installation, commissioning Laws and/or regulations and standards governing the use or intended usage goal

Maintenance No changes can be made to apparatus, which are operated in hazardous areas.

Special conditions The connecting parts of the sensor must be set up in such a way that degree of pro-

Protection from mechanical danger

Electrostatic charge

i

i

amb

The Ex-significant identification is on the enclosed adhesive label

Use is restricted to the following stated conditions

≤ 105 nF ; a cable length of 10 m is considered.

≤ 100 µH ; a cable length of 10 m is considered.

and in this instruction manual. The EU-type examination certificate has to be

observed. The special conditions must be adhered to!

The ATEX directive and therefore the EU-type examination certificates apply in general only to the use of electrical apparatus under atmospheric conditions.

The use in ambient temperatures of > 60 °C was tested with regard to hot surfaces

by the mentioned certification authority.

If the equipment is not used under atmospheric conditions, a reduction of the permissible minimum ignition energies may have to be taken into consideration.

Details of the correlation between the type of circuit connected, the maximum permissible ambient temperature, the temperature class, and the effective internal reactance values can be found on the EC-type examination certificate.

must be observed. The intrinsic safety is only assured in connection with an appropriate related apparatus and according to the proof of intrinsic safety.

If the Ex-related marking is printed only on the supplied label, then this must be

attached in the immediate vicinity of the sensor. The sticking surface for the label

must be clean and free from grease. The attached label must be legible and indelible, including in the event of possible chemical corrosion.

Repairs to these apparatus are not possible.

tection IP20, in accordance with lEC 60529, is achieved as a minimum.

When using the device in a temperature range of -60 °C to -20 °C, protect the sensor

against the effects of impact by installing an additional enclosure. The information

regarding the minimum ambient temperature for the sensor as provided in the

datasheet must also be observed.

Electrostatic charges must be avoided on the mechanical housing components.

Dangerous electrostatic charges on the mechanical housing components can be

avoided by incorporating these in the equipotential bonding.

Release date: 2016-11-09 09:17 Date of issue: 2016-11-09 246522_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

4

Inductive sensor NCB10-30GM40-N0-50M

Equipment protection level Gc (nL)

Note This instruction is only valid for products according to EN 60079-15:2005, valid until

Instruction Manual electrical apparatus for hazardous areas

Device category 3G (nL) for use in hazardous areas with gas, vapour and mist

CE marking

ATEX marking ¬ II 3G Ex nL IIC T6 X

Standard conformity EN 60079-15:2005 Ignition protection category "n"

Effective internal capacitance C

Effective internal inductance L

Ge n e r a l The apparatus has to be operated according to the appropriate data in the data sheet

Installation, commissioning Laws and/or regulations and standards governing the use or intended usage goal

Maintenance No changes can be made to apparatus, which are operated in hazardous areas.

Special conditions

for Pi=34 mW, Ii=25 mA, T6

for Pi=34 mW, Ii=25 mA, T5

for Pi=34 mW, Ii=25 mA, T4-T1

for Pi=64 mW, Ii=25 mA, T6

for Pi=64 mW, Ii=25 mA, T5

for Pi=64 mW, Ii=25 mA, T4-T1

for Pi=169 mW, Ii=52 mA, T6

for Pi=169 mW, Ii=52 mA, T5

for Pi=169 mW, Ii=52 mA, T4-T1

for Pi=242 mW, Ii=76 mA, T6

for Pi=242 mW, Ii=76 mA, T5

for Pi=242 mW, Ii=76 mA, T4-T1

≤ 105 nF ; a cable length of 10 m is considered.

i

≤ 100 µH ; A cable length of 10 m is considered.

i

01-May-2013

Use is restricted to the following stated conditions

and in this instruction manual. The data stated in the data sheet are restricted by this

operating instruction!

The special conditions must be observed!

The ATEX Directive applies only to the use of apparatus under atmospheric conditions.

If you use the device outside atmospheric conditions, consider that the permissible

safety parameters should be reduced.

must be observed. The sensor must only be operated with an energy-limited circuit,

which satisfies the requirements of IEC 60079-15. The explosion group complies

with the connected, supplying, power limiting circuit.

Repairs to these apparatus are not possible.

55 °C (131 °F)

55 °C (131 °F)

55 °C (131 °F)

55 °C (131 °F)

55 °C (131 °F)

55 °C (131 °F)

52 °C (125.6 °F)

52 °C (125.6 °F)

52 °C (125.6 °F)

44 °C (111.2 °F)

44 °C (111.2 °F)

44 °C (111.2 °F)

Protection from mechanical danger

Protection from UV light

Protection of the connection cable

Electrostatic charge

Connection parts

The sensor must not be exposed to ANY FORM of mechanical danger. When used

in the temperature range below -20 °C the sensor should be protected from knocks

by the provision of an additional housing.

The sensor and the connection cable must be protected from damaging UV-radiation. This can be achieved when the sensor is used in internal areas.

The connection cable must be prevented from being subjected to tension and torsional loading.

Electrostatic charges must be avoided on the mechanical housing components.

Dangerous electrostatic charges on the mechanical housing components can be

avoided by incorporating these in the equipotential bonding.

The connection parts are to be installed, such that a minimum protection class of

IP20 is achieved, in accordance with IEC 60529.

Release date: 2016-11-09 09:17 Date of issue: 2016-11-09 246522_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

5

Inductive sensor NCB10-30GM40-N0-50M

Equipment protection level Gc (ic)

Instruction Manual electrical apparatus for hazardous areas

Device category 3G (ic) for use in hazardous areas with gas, vapour and mist

Certificate of Compliance PF 13 CERT 2895 X

CE marking

ATE X m ar king ¬ II 3G Ex ic IIC T6…T1 Gc

Standards EN 60079-0:2012+A11:2013 EN 60079-11:2012 Ignition protection category "ic"

Effective internal inductivity C

Effective internal inductance L

Ge n e r a l The apparatus has to be operated according to the appropriate data in the data sheet

Installation, commissioning Laws and/or regulations and standards governing the use or intended usage goal

Maintenance No changes can be made to apparatus, which are operated in hazardous areas.

Special conditions

for Pi=34 mW, Ii=25 mA, T6

for Pi=34 mW, Ii=25 mA, T5

for Pi=34 mW, Ii=25 mA, T4-T1

for Pi=64 mW, Ii=25 mA, T6

for Pi=64 mW, Ii=25 mA, T5

for Pi=64 mW, Ii=25 mA, T4-T1

for Pi=169 mW, Ii=52 mA, T6

for Pi=169 mW, Ii=52 mA, T5

for Pi=169 mW, Ii=52 mA, T4-T1

for Pi=242 mW, Ii=76 mA, T6

for Pi=242 mW, Ii=76 mA, T5

for Pi=242 mW, Ii=76 mA, T4-T1

Protection from mechanical danger

i

i

The Ex-significant identification is on the enclosed adhesive label

Use is restricted to the following stated conditions

≤ 105 nF ; a cable length of 10 m is considered.

≤ 100 µH ; A cable length of 10 m is considered.

and in this instruction manual. The data stated in the data sheet are restricted by this

operating instruction!

The special conditions must be observed!

The ATEX Directive applies only to the use of apparatus under atmospheric conditions.

If you use the device outside atmospheric conditions, consider that the permissible

safety parameters should be reduced.

must be observed. The sensor must only be operated with energy-limited circuits,

which satisfy the requirements of IEC 60079-11. The explosion group complies with

the connected, supplying, power limiting circuit. If the Ex-relevant identification is

printed exclusively on the adhesive label provided, this label must be affixed in the

immediate vicinity of the sensor! The background surface to which the adhesivelabel

is to be applied must be clean and free from grease! The applied label must be durable and remain legible, with due consideration of the possibility of chemical corrosion!

Repairs to these apparatus are not possible.

55 °C (131 °F)

55 °C (131 °F)

55 °C (131 °F)

55 °C (131 °F)

55 °C (131 °F)

55 °C (131 °F)

52 °C (125.6 °F)

52 °C (125.6 °F)

52 °C (125.6 °F)

44 °C (111.2 °F)

44 °C (111.2 °F)

44 °C (111.2 °F)

The sensor must not be mechanically damaged.

When used in the temperature range below -20 °C the sensor should be protected

from knocks by the provision of an additional housing.

Electrostatic charge

Connection parts

Electrostatic charges must be avoided on the mechanical housing components.

Dangerous electrostatic charges on the mechanical housing components can be

avoided by incorporating these in the equipotential bonding.

The connection parts are to be installed, such that a minimum protection class of

IP20 is achieved, in accordance with IEC 60529.

Release date: 2016-11-09 09:17 Date of issue: 2016-11-09 246522_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

6

Inductive sensor NCB10-30GM40-N0-50M

Equipment protection level Da

Instruction Manual electrical apparatus for hazardous areas

Device category 1D for use in hazardous areas with combustible dust

EC-Type Examination Certificate PTB 00 ATEX 2048 X

CE marking 0102

ATEX marking ¬ II 1D Ex ia IIIC T135°C Da The Ex-related marking can also be printed on the

Standards EN 60079-0:2012+A11:2013 EN 60079-11:2012 Ignition protection "Intrinsic safety"

Appropriate type NCB10-30GM...-N0...

Effective internal inductivity C

Effective internal inductance L

Ge n e r a l The apparatus has to be operated according to the appropriate data in the data sheet

Maximum permissible ambient temperature T

Installation, commissioning Laws and/or regulations and standards governing the use or intended usage goal

Maintenance No changes can be made to apparatus, which are operated in hazardous areas.

Special conditions The connecting parts of the sensor must be set up in such a way that degree of pro-

Protection from mechanical danger

Electrostatic charge

i

i

amb

enclosed label.

Use is restricted to the following stated conditions

≤ 105 nF ; a cable length of 10 m is considered.

≤ 100 µH ; a cable length of 10 m is considered.

and in this instruction manual.

The EU-type examination certificate has to be obser ved.

The ATEX directive and therefore the EU-type examination certificates apply in general only to the use of electrical apparatus under atmospheric conditions.

The use in ambient temperatures of > 60 °C was tested with regard to hot surfaces

by the mentioned certification authority.

If the equipment is not used under atmospheric conditions, a reduction of the permissible minimum ignition energies may have to be taken into consideration.

Details of the correlation between the type of circuit connected, the maximum permissible ambient temperature, the surface temperature, and the effective internal

reactance values can be found on the EC-type-examination certificate.

The maximum permissible ambient temperature of the data sheet must be

noted, in addition, the lower of the two values must be maintained.

must be observed.

The intrinsic safety is only assured in connection with an appropriate related apparatus and according to the proof of intrinsic safety.

If the Ex-related marking is printed only on the supplied label, then this must be

attached in the immediate vicinity of the sensor. The sticking surface for the label

must be clean and free from grease. The attached label must be legible and indelible, including in the event of possible chemical corrosion.

Repairs to these apparatus are not possible.

tection IP20, in accordance with lEC 60529, is achieved as a minimum.

When using the device in a temperature range of -60 °C to -20 °C, protect the sensor

against the effects of impact by installing an additional enclosure. The information

regarding the minimum ambient temperature for the sensor as provided in the

datasheet must also be observed.

Electrostatic charges must be avoided on the mechanical housing components.

Dangerous electrostatic charges on the mechanical housing components can be

avoided by incorporating these in the equipotential bonding. Avoid electrostatic

charges that can cause electrostatic discharge when installing or operating the

device. Information on electrostatic hazards can be found in the technical specification IEC/TS 60079-32-1. Do not attach the nameplate provided in areas where electrostatic charge can build up.

Release date: 2016-11-09 09:17 Date of issue: 2016-11-09 246522_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

7

Inductive sensor NCB10-30GM40-N0-50M

Equipment protection level Dc (tc)

Instruction Manual electrical apparatus for hazardous areas

Device category 3D for use in hazardous areas with combustible dust

Certificate of Compliance PF 15CERT3774 X

CE marking 0102

ATEX marking ¬ II 3D Ex tc IIIC T80°C Dc

Standards EN 60079-0:2012+A11:2013, EN 60079-31:2014

Ge n e r a l The corresponding datasheets, declarations of conformity, EC-type examination certifi-

Installation, commissioning Laws and/or regulations and standards governing the use or intended usage goal must

Maintenance No changes can be made to apparatus, which are operated in hazardous areas.

Special conditions

Minimum series resistance R

Maximum operating voltage U

Maximum permissible ambient temperature T

at U

using an amplifier in accordance with EN 60947-5-6

Protection from mechanical danger

Protection from UV light

Protection of the connection cable

Electrostatic charge

=9 V, RV=562 Ω

Bmax

V

Bmax

Umax

The Ex-related marking can also be printed on the enclosed label.

Protection by enclosure "tc" Some of the information in this instruction manual is more

specific than the information provided in the datasheet.

cates, certifications, and control drawings, where applicable (see datasheets), form an

integral part of this document. These documents can be found at www.pepperlfuchs.com. The maximum surface temperature of the device was determined without a

layer of dust on the apparatus. Some of the information in this instruction manual is more

specific than the information provided in the datasheet.

be observed. If the Ex-relevant identification is printed exclusively on the adhesive label

provided, this label must be affixed in the immediate vicinity of the sensor! The background surface to which the adhesivelabel is to be applied must be clean and free from

grease! The applied label must be durable and remain legible, with due consideration of

the possibility of chemical corrosion!

Repairs to these apparatus are not possible.

A minimum series resistance RV is to be provided between the power supply voltage

and the proximity switch in accordance with the following list. This can also be assured

by using a switch amplifier.

The maximum permissible operating voltage UBmax must be restricted to the values

given in the following list. Tolerances are not permitted.

Values can be obtained from the following list, depending on the max. operating voltage

Ub max and the minimum series resistance Rv.

66 °C (150.8 °F)

66 °C (150.8 °F)

The sensor must not be exposed to ANY FORM of mechanical danger.

The sensor and the connection cable must be protected from damaging UV-radiation.

This can be achieved when the sensor is used in internal areas.

The connection cable must be prevented from being subjected to tension and torsional

loading.

Electrostatic charges must be avoided on the mechanical housing components. Dan-

gerous electrostatic charges on the mechanical housing components can be avoided by

incorporating these in the equipotential bonding. Avoid electrostatic charges that can

cause electrostatic discharge when installing or operating the device. Information on

electrostatic hazards can be found in the technical specification IEC/TS 60079-32-1. Do

not attach the nameplate provided in areas where electrostatic charge can build up.

Release date: 2016-11-09 09:17 Date of issue: 2016-11-09 246522_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

8

Loading...

Loading...