Optical data coupler

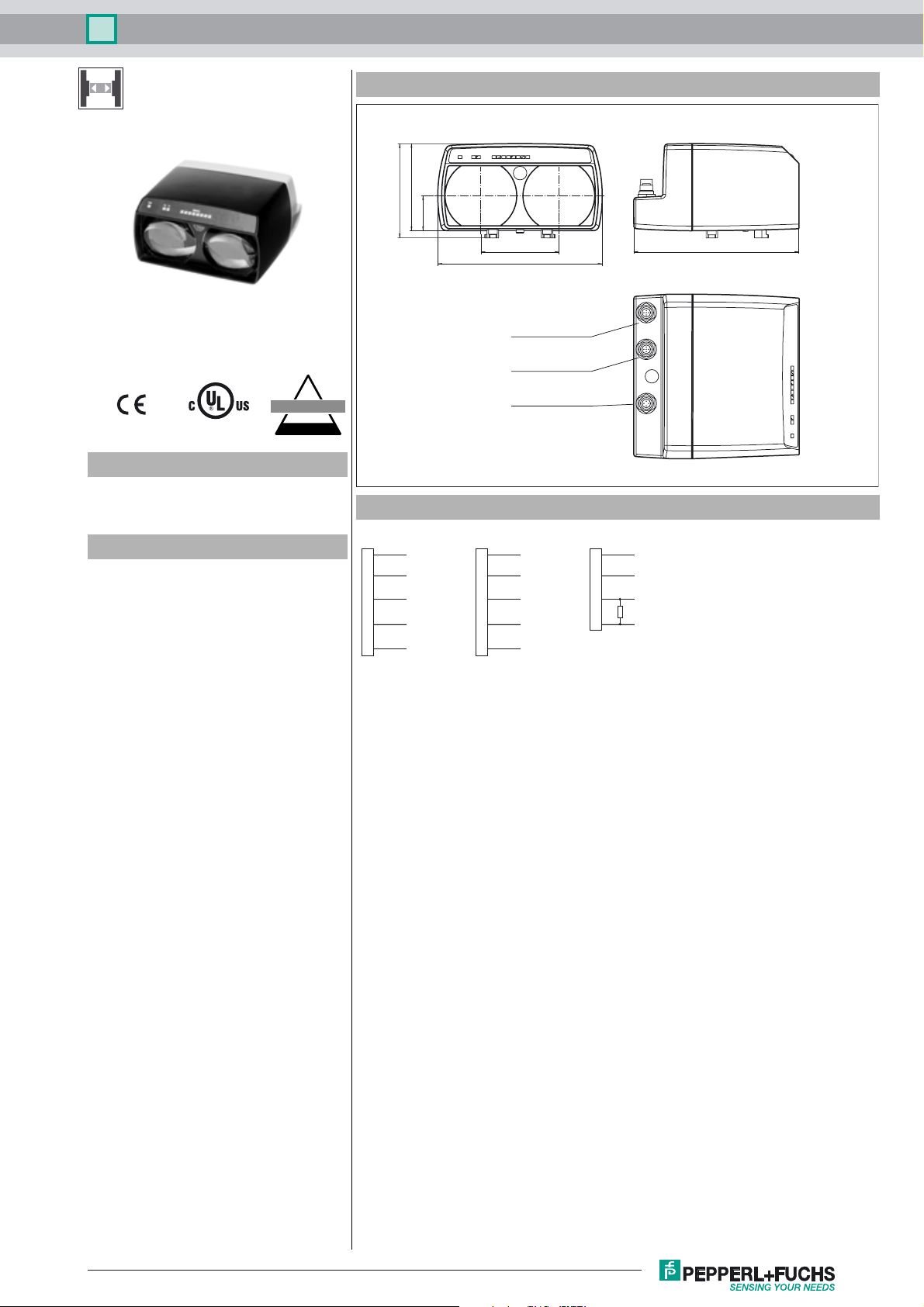

Dimensions

90

97,5

36

LS610-DA-IBS/F1

I

NTERBUS

Model Number

LS610-DA-IBS/F1

Optical data coupler

Features

•Devices for INTERBUS

• Plug connection for fast mounting

• No parameterization

• Usable up to detection range 0

• Line indicator for signal strength

Electrical connection

1

2

3

4

5

Plug M12 x 1, 5-pin

B-coded

DO

/DO

DI

/DI

GND GND

1

2

3

4

5

Socket M12 x 1, 5-pin

B-coded

81

170

Remote Bus IN

Connector M12 x 1, 5-pin

B-coded

Remote Bus OUT

Socket M12 x 1, 5-pin

B-coded

Power

Connector M12 x 1, 4-pin

DO

/DO

DI

/DI

PowerRemote Bus OUTRemote Bus IN

1

2

3

4

Plug M12 x 1, 4-pin

A-coded

171

+UB+UB

n.c.

0 V

Alarm

Release date: 2013-08-21 13:02 Date of issue: 2013-08-21 131634_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

1

Optical data coupler

LS610-DA-IBS/F1

Technical data

General specifications

Effective detection range 0 ... 120 m

Threshold detection range 140 m

Light type modulated infrared light

Approvals CE, cULus

Diameter of the light spot 2 m at a distance of 100 m

Angle of divergence 1.1 °

Ambient light limit > 10000 Lux

Functional safety related parameters

MTTFd 260 a

Mission Time (T

Diagnostic Coverage (DC) 0 %

Indicators/operating means

Data flow display LED green: emitter

Function display alignment aid: flashing front red LED Signal strength (8 LED:

Electrical specifications

Operating voltage UB18 ... 30 V DC

No-load supply current I

Data rate 0 ... 2 MBit/s

Operation frequency F1 = 8.25 MHz

Interface

Interface type RS 422 , galvanically isolated

Output

Pre-fault indication output 1 PNP (switches if there is sufficient stability control) short-circuit

Sta nd ard confor mi ty

Stan dar ds EN 60947-5-2 , CE , EN 61000-6-2

Ambient conditions

Ambient temperature -10 ... 50 °C (14 ... 122 °F)

Storage temperature -20 ... 70 °C (-4 ... 158 °F)

Mechanical specifications

Protection degree IP65

Connection 4-pin, M12x1 connector, standard (supply) ,

Material

Housing ABS / PC

Optical face plastic

Mass 700 g

) 20 a

M

0

LED yellow: receiver

Red, yellow, green)

200 mA

protected, max. 200 mA

5-pin, M12x1 connector, B-coded (Remote Bus In) ,

5-pin, M12x1 socket, B-coded (Remote Bus Out)

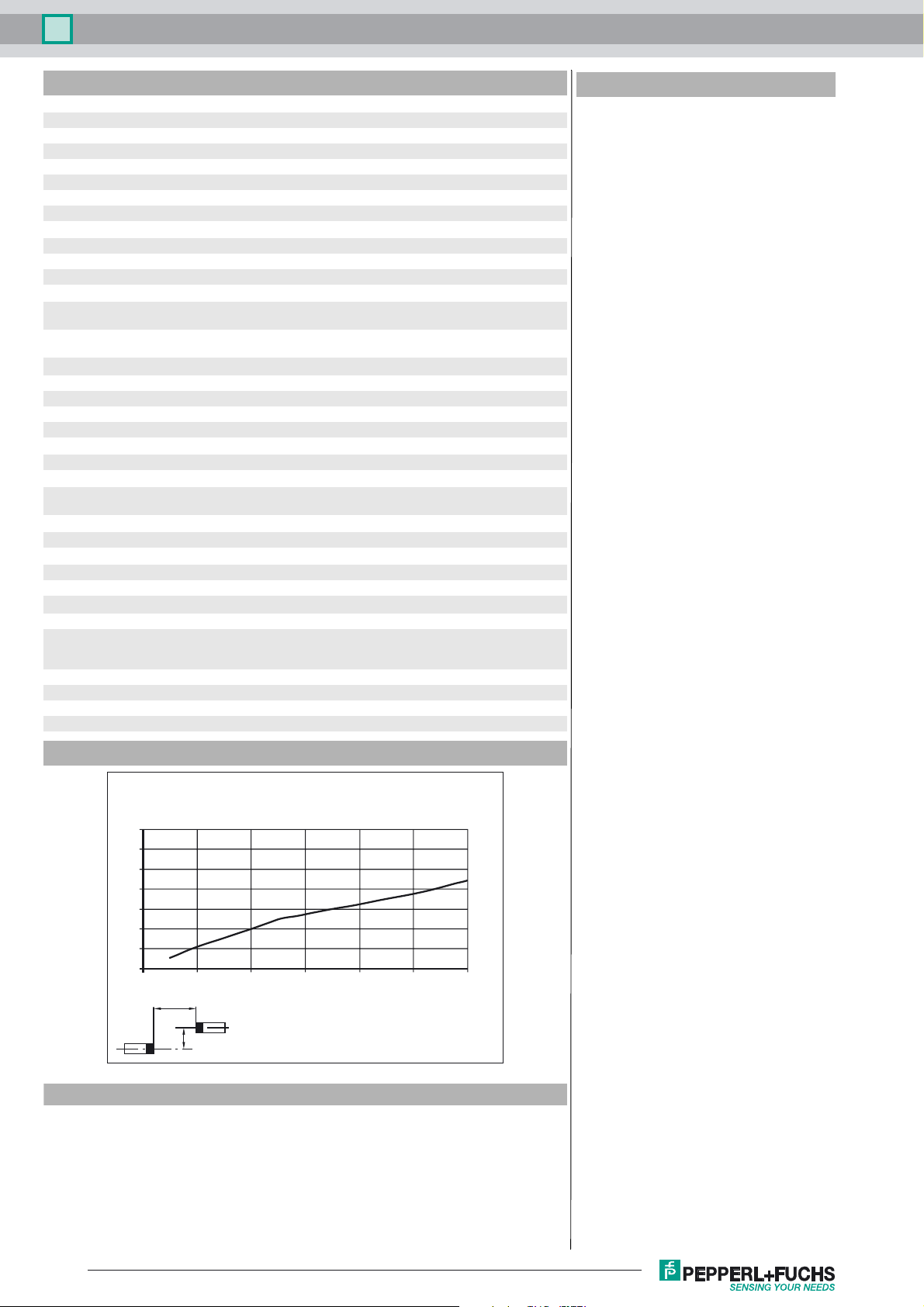

Curves/Diagrams

Accessories

V15SB-G

Cable connector, M12, for PROFIBUS,

adjustable

V15B-G

Cable socket, M12, for PROFIBUS, adjustable

V15-G-PG9

Female connector, M12, 5-pin, field attachable

Funktionserdung LS610/VDM100 Zubehoer

Function grounding for LS610 / LS611 /

VDM100 series

Schutzkappe LS610 Zubehoer

M12 protective cap set (connector + socket) for series LS610 / LS611

OMH-LS610-01

Mounting bracket for optical data coupler

OMH-LS610-02

Direct mounting set consisting of 4 x M4

threaded inserts

OMH-LS610-03

Mounting bracket with deviation mirror for

optical data coupler

OMH-LS610-05

Mounting bracket for optical data coupler

and distance measurement devices

OMH-LS610-31

Mounting bracket for optical data coupler

and distance measurement devices

OMH-LS610-32

Mounting bracket for optical data coupler

and distance measurement devices

Characteristic response curve

Offset Y [mm]

1400

1200

1000

800

600

400

200

0

0 20 40 60 80 100 120

x

y

LS 610-DA...

Distance X [m]

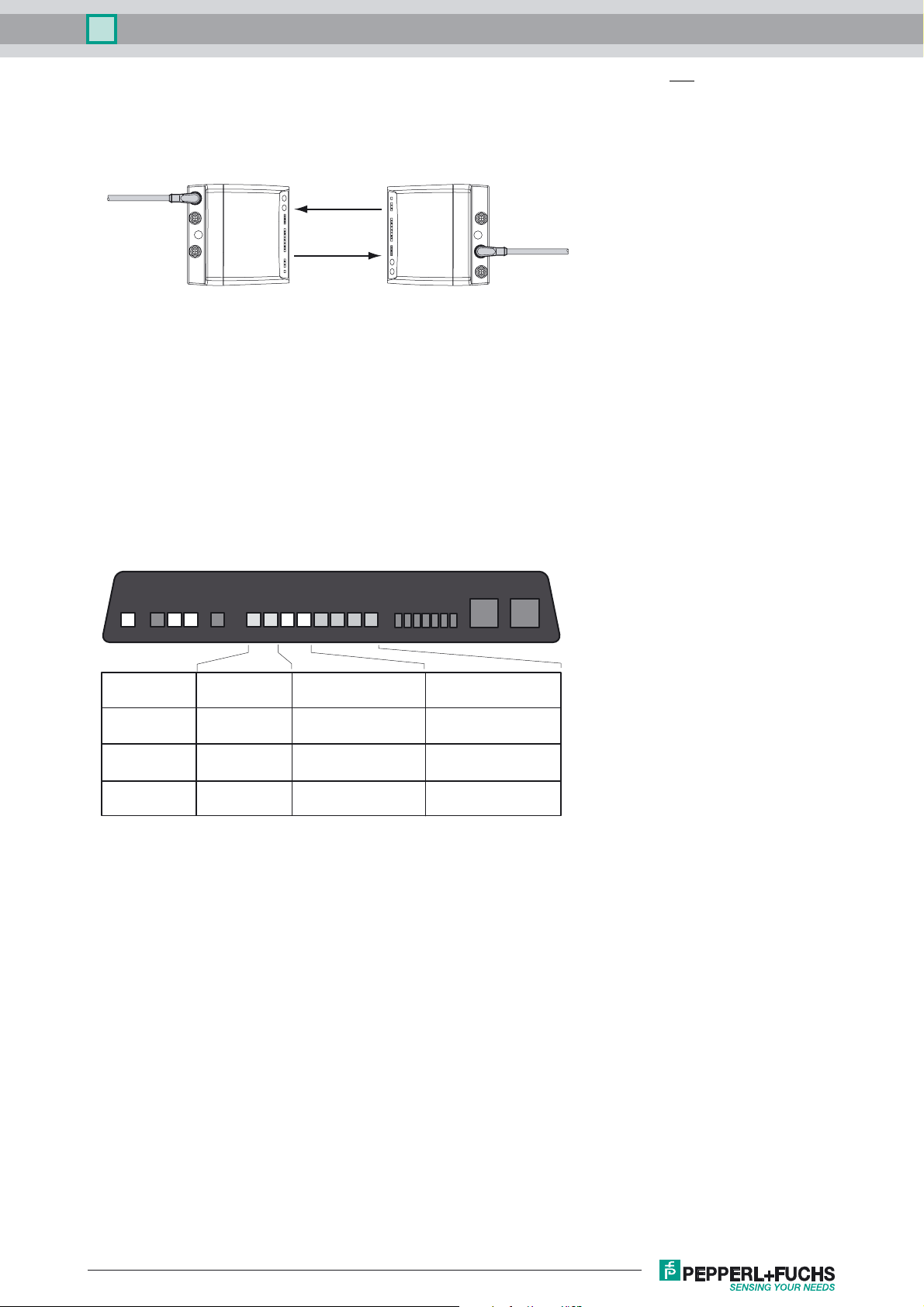

Function

The LS610-DA-IBS is a device for serial data transmission in INTERBUS systems

with transmision rates of up to 2 MBit/sec and ranges up to 240 m. For data rates

and operating ranges lower than these values, the device can also be used with no

problems.

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Release date: 2013-08-21 13:02 Date of issue: 2013-08-21 131634_eng.xml

Optical data coupler

LS610-DA-IBS/F1

For one data transmission connection, an LS 610-DA-IBS unit with a mean frequency of F1 and an LS 610-DA-IBS unit with

mean frequency F2 are required.

The LS610-DA-IBS is intended for the direct connection of Interbus S units ("extension of bus cables"). It contains no bus connection logic, and is thus not suited for spur line installations. For this reason, only one of the M12 connectors should be used

at a time.

Bus incoming

Bus outgoing

F2 or F1F1 or F2

Data transmission

Data is transmitted in both directions using modulated infrared light. The information carried on the incoming bus is modulated

on the carrier signal in real time using frequency shift keying (FSK). In the reciever, the corresponding demodulation is performed and the data is output on the outgoing bus. The complete transmission process is performed using no protocols.

The LS610 DA-IBS includes level-type regeneration as well as complete voltage isolation of the data transmission circuits from

the power supply.

Function displays/function reserves

For alignment, there is an alignment LED on the unit's face which is visible from a distance. As soon as a receiver detects the

transmission light of the opposite unit, the blink frequency of the alignment aid is lowered. When it is extinguished, this signals

that the units are optimally aligned with one another, and enough functional reserve is available. For fine adjustment, the data

system is equipped with a bar graph display (signal display) which enables optimal alignment.

PWRPWR RX TX SIGNAL

State weak signal sufficient signal strength signal with

function reserve

Transmission blocked released transmission with

function reserve

Alignment-LED fast flashing slow flashing off

Signal-indicator red area yellow area green area

(at least one LED)

Connection between display and operational status

If the bus is active, a yellow LED "RX" is lit for received data and a green LED "TX" for transmitted data.

Installation

Installation is done with the corresponding accessories, for instance, OMH-LS610-01 for wall mounting.

The x/y adjustment is premounted at the factory. It is fastened to the mounting bracket in the desired transmission direction

(±90° rotation possible) with the two M4 screws and a central M6 screw. The middle screw is for fastening after adjustment and

should only be tightened afterwards.

The data photo sensor is inserted into the notches of the adjustment device while holding both of the front bolts together with

holding tabs. After insertion, the bolts are released and hold the unit securely by springing back.

Using the two adjustment screws (Inbus 5mm), the transmission axis can now be directed in the X and Y directions, and the

adjustment fixed in place by tightening the middle screw.

Release date: 2013-08-21 13:02 Date of issue: 2013-08-21 131634_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

3

Loading...

Loading...