Page 1

MANUAL

LGS Series

Switching Automation Light Grid

FACTORY AUTOMATION

Page 2

LGS Series

With regar d to the supply of products, the curre nt issue of the following documen t is applicable: The

General Terms of Delivery for Products a nd Se rvic es of the Electrical Indust ry, p ublished by the

Central Association of the Ele ctrica l Industry (Zentralve rband Elektrotechnik und Elektroindustrie

(ZVEI) e.V.) in its most recent version as well as the supplementary clause: "Expanded rese rvation

of proprietorship"

Page 3

LGS Series

Contents

1 Introduction......................................................................... 5

2 Declaration of Conformity ................................................. 6

2.1 Declaration of Conformity ..................................... ............... .........................6

3 Safety................................................................................... 7

3.1 Symbols Relevant to Safety ............... ................................................. .......... 7

3.2 Intended Use ............ ................................................. ............... ....................7

4 Product Description ........................................................... 9

4.1 Use and Applicat ion ..................................... .............. ...................................9

4.2 Indicato rs and Operating Elements ......................................................... ......9

4.3 Interfaces and Connections .......... .............................................................. 11

4.4 Accessories ................... ............... ................................................. ............. 12

4.5 Scope of Delivery ........... ................................................. ............... .............12

5 Installation ........................................................................ 13

5.1 Preparation . .............. ................................................. ............... ..................13

5.2 Mou ntin g ..... .............. ................................................. ............... ..................13

5.3 Multiple Positions ................................................................. ............... ........16

5.4 Connecting the Senso r Rails........................ .............. .................................17

5.5 Storage and Transportation .................................................. ............... ........20

6 Commissioning................................................................. 21

6.1 Final Ass embly ......... ............... ................................................. .............. ....21

6.2 Commis sioning the Light Grid......................................... ............... .............21

7 Operation........................................................................... 22

7.1 Operating the Light Gri d . ................................................. ............... .............2 2

7.1.1 Object Detection (Overhang Control) .......... ............... ............................27

7.1.2 Monitoring the Object Height with Height Controls .................... .............28

7.1.3 Object Identification ............. ................................................. .............. ....29

7.2 Commis sioning and Operating the Light Grid with IO-L ink ..........................30

8 Maintenance and Repair.................................................. 32

8.1 Mainten ance ........................................... .............. ......................................32

8.2 Repair ....................... ............... ................................................. .............. ....32

9 Troubleshooting................................................................33

9.1 Troubleshooting ............................ ............... ............................................... 33

239596 2019-09

3

Page 4

LGS Series

Contents

10 Appendix........................................................................... 35

10.1 Technical Data ............ ............... ............... ................................................ . 35

10.2 Type Code .......................................................... ............... ......................... 37

10.3 Response Times and Numb er of Beams .................................................... 38

10.4 Profile Length and Weight ..... ............... ................................................. ..... 41

10.5 Accessorie s ............................... ............... ................................................ . 4 2

10.5.1 Installation Accessories .................................................................... ..... 42

10.5.2 Co nnecting Cables ........... ............... ................................................. ..... 46

10.5.3 Accessories for IO -Link Operation ........................... ............... ............... 46

10.6 Parameterizing the Lig ht Grid ..... ............................................................... . 47

239596 2019-09

4

Page 5

LGS Series

Introduction

1 Introduction

Congratulations

You have chosen a devic e manufactured by Pepp erl+Fuchs. Pepper l+Fuchs

develops, produces and dist ribu tes electronic se nsors and interface modu les for

the market of automation techn ology on a worldwide sca le.

Before you install this device and p ut it into operation, please read the operating

instructions thoroug hly. The instructions and notes contained in this operat ing

man ual will guide you step-by-st ep throug h the installation and commissioning

procedures to ensure troub le-free use of this product. By doing so, you:

■

guarantee safe operation of the device

■

can utilize the entire ran ge of device functions

■

avoid faulty operation and associated errors

■

reduce costs from downtimes and incidental repairs

■

increase the e ffectiveness and ope rating efficiency of your plant.

Store this op erating manual somewhere safe in order to have it available for future

work on the device.

Directly after opening the packaging, please ensure that the device is intact and

that the p acka ge is c omplete.

Contact

If you have any questions about the device, its functions, or a ccess ories, pleas e

contact u s at:

Pepperl+Fuchs Gm bH

Lilienthalstraße 200

68307 Mannheim, Germany

Telephone: +49 (0)621 7 76-1111

Fax: +49 ( 0)621 776-271 111

Email: fa-info@de.pepperl-fuchs.com

Sym bols use d

The following symbols are used in this manual:

Note

This symbol draws your attention to important information.

Handling instructions

You will find hand ling instructions bes ide this symbol

239596 2019-09

5

Page 6

LGS Series

ISO9001

Declaration of Confo rmity

2 Declaration of Conformity

2.1 Declaration of Conformity

This product was d eveloped and ma nufactured unde r observan ce o f the

applica ble E uropean standards and guidelines.

Note

A Declaration of Conformity can be requested from the man ufacturer.

The product manufacturer, Pepper l+Fuchs GmbH, D-68 307 Mannheim, has a

certified quality a ssur ance system that con forms to ISO 9001.

6

239596 2019-09

Page 7

LGS Series

Safety

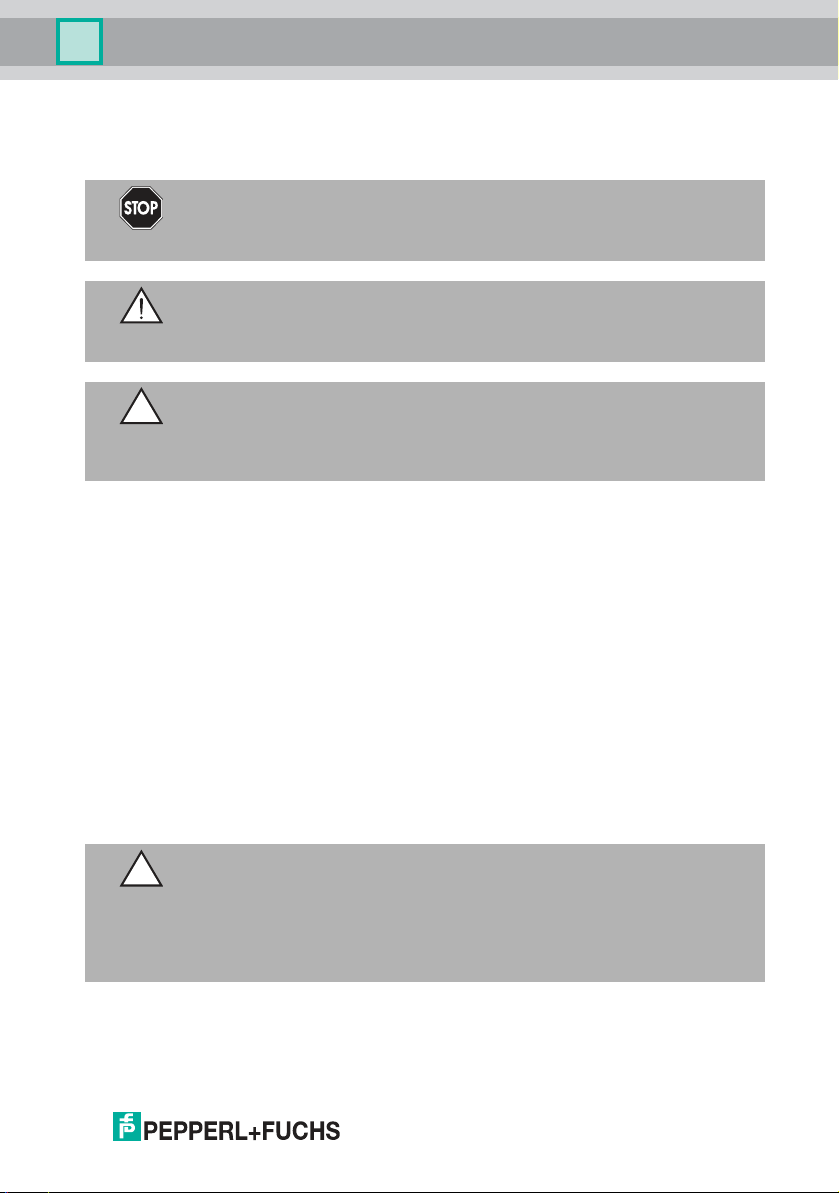

3 Safety

3.1 Symbols Relevant to Safety

Danger!

This symbol ind icates an imminent danger.

Non-observance will result in pers onal injury or death.

Warning!

This symbol ind icates a possible fau lt or danger.

Non-observance m ay cau se p ersonal injury or serious prope rty damage.

Caution!

This symbol ind icates a possible fau lt.

Non-observance co uld interrupt the dev ice and any conne cted systems and

plants, or result in their complete failure.

3.2 Intended Use

The LGS autom ation light grid is a comp act optical light grid that consists of a

emitter strip and a receiver strip. The detection field to be m onitored is located

between the emitte r strip and the receiver strip. The electronics for level

mea surement are located in the receiver strip.

Area s of Use

■

Object detection in the packaging and material hand ling secto rs

■

Detecting and counting irre gular objects

■

Measuring an d sorting objects of differen t heights (height co ntrol)

■

Presence and overhang cont rol in material handling systems

■

Overha ng control of load heights in tran spo rt systems a nd mater ial

handling applica tions

■

Web sag m onitorin g

■

Position or shape m onitoring

■

Gap detection

Caution!

Not a safety co mponent

The light grid is not a certified safety ligh t grid in accordance with EN 61496. It is

also not a safety com ponent under the terms of the EU Machiner y

Directive 2006 /42/EC. The ligh t grid must therefore not be used for the purpose o f

preventing r isk to individuals or parts of the bo dy.

Always operat e the device as desc ribed in th ese instructions to ensure that the

device and conn ected systems function correctly. The protection of operating

personnel and plant is only guaranteed if the device is operated in acco rdance

with its intended use.

239596 2019-09

7

Page 8

LGS Series

Safety

The device and its inp ut and output circuits must be operated from a power supp ly

that fulfills the req uirem ents of PELV/SELV systems.

Only use recommende d original accessor ies.

The operating com pany bears resp ons ibility for observing locally app licable

safety regulations.

Installation and commissioning of all devices may only be performed by trained

and qualified per sonnel.

User modification and or repair are dangerous and will void the warranty and

exclude the ma nufacturer from any liability. If serious faults occur, stop using the

device. Secure the device against inadverten t operation. In the event of repairs,

return the device to your local Pepper l+Fuchs representative o r sa les office.

239596 2019-09

8

Page 9

LGS Series

Product De scription

4 Product Description

4.1 Use and Application

LGS series: Tou ch it, save it—i ntelligent automation light grid with extras

Features

■

Adjustable b eam crossover for refining the resolution. The beam crossover

does no t alter the resp onse time

■

Optical synchronization o f both outer beams possible

■

Three separate o utputs for height control

■

Light-o n or dark- on op tions

■

Parameterizable object detection

■

Parameterizable bea m suppres sion (blanking )

■

Operation via touch field or extern al inp ut

■

IO-Link interface for ser vic e and process d ata, and for parameterization

Desc ript ion

In ad dition to the usual s tandard functions, LGS series light grids feature a range

of u seful extra functions previously found only in much more expensive dev ice

classes. These functions include ultra-quick ob ject detection even with beam

crossover, the option of identifying objects, and remote c ommunication via an IOLink interface. The blanking fun ction can be used to deactivate two connected

beam areas if unfavorable installation c onditions result in plant c omponents

exten ding into and interrupting the det ection field. The standby operating mode is

another feature for applications where light grids are n ot in con tinuou s op eration.

The LGS is modular in d esign and available with five different beam gaps (8 mm,

17 mm, 25 m m, 5 0 mm, and 100 mm) and detection field heights ranging from

100 mm to 3200 mm to enable extensive monitoring of the evalua tion a rea.

Integrated signa l evaluation means it is no t ne cessary to mo unt a sep arate

add itional switching device. The slimline profiles c an ea sily be mounted us ing

existing holes, the rear continuous groove, or the fixture s availab le as

accessories, enabling light grids in the LGS series to be used to maximum effect

and t ailored to the specific ap plication.

The switching light grid has one swit ching output, which displays an identified

object, and three height control outputs.

The LGS receiver strip also has an IO-Lin k interface, enabling advanced

parameter ization, extens ive configuration, identification, and diagnos is of the light

grid. This requires operation on an IO-Link master.

The SC (stability control) diagnostic output indicates an insufficient functional

reserve, e.g., due to misalignment or soiling. The receiver strip can be taught in for

various objects via a teach-in input. The touch b utton can also be replicated

externally via this input.

239596 2019-09

9

Page 10

LGS Series

2

3

2

3

Q

H1H2H3 F

2

Product De scription

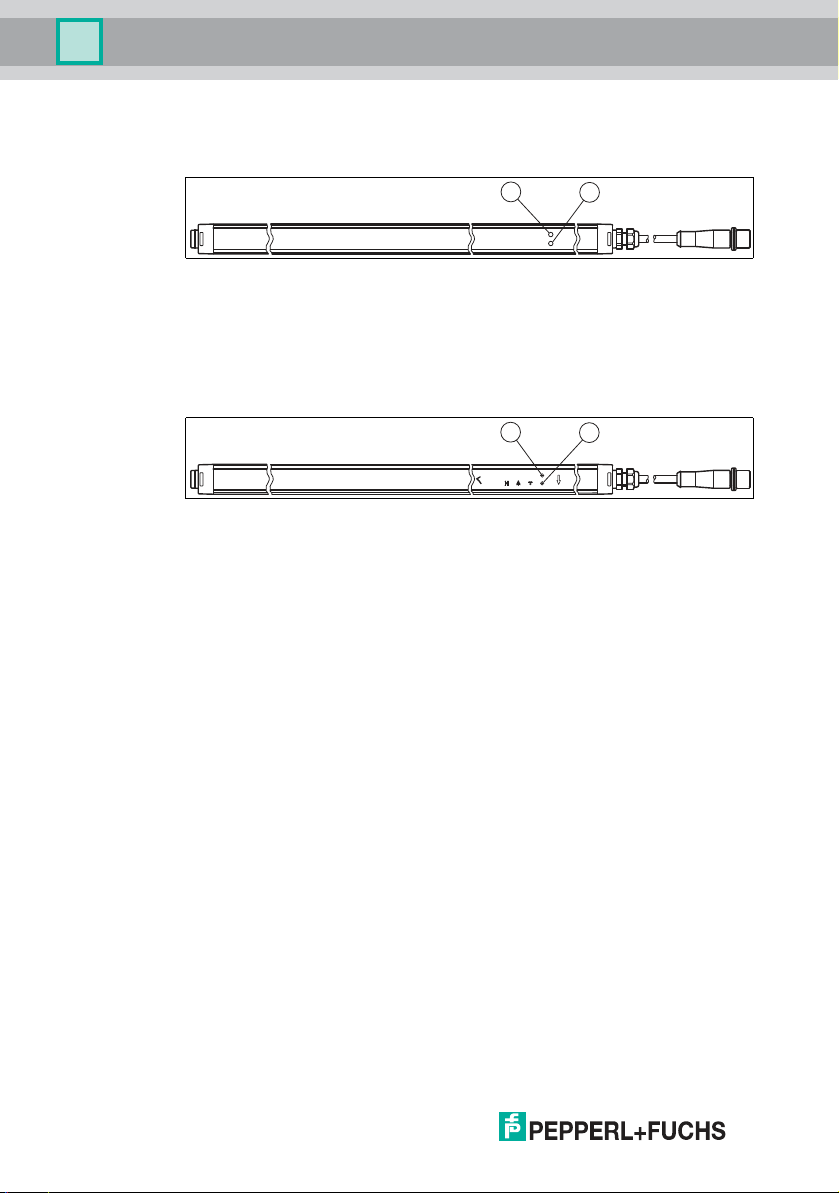

4.2 Indicators and Operating Elements

Emitter strip

Figure 4.1 Function indicator on the emitter strip

2 O perating indicator : Indicates power on or power save mode

3 S tatus indicator: Indicates transmi ssion power, fault state, or activ e test input

Receive r strip

Figure 4.2 Function indicator on the receiver strip

2 O perating indicator : Indicates power on, power save mode, active IO-Link, or fault state

3 S tatus indicator: Indicates detectio n field status, functional rese rve, or fault s tate

10

On the receiver strip be hind the plastic front panel the re are 12 illuminated

pictograms. The pictogra ms indicate the functional state and allow you to

parame terize the system. The two outer pictograms indicate the position of th e

two oper ating buttons (capacitive touch buttons) for pa ramet erization.

239596 2019-09

Page 11

LGS Series

7

6

5

4

2

1

11

10

9

8

12

3

Q

H1

H2

H3 F

2

Product De scription

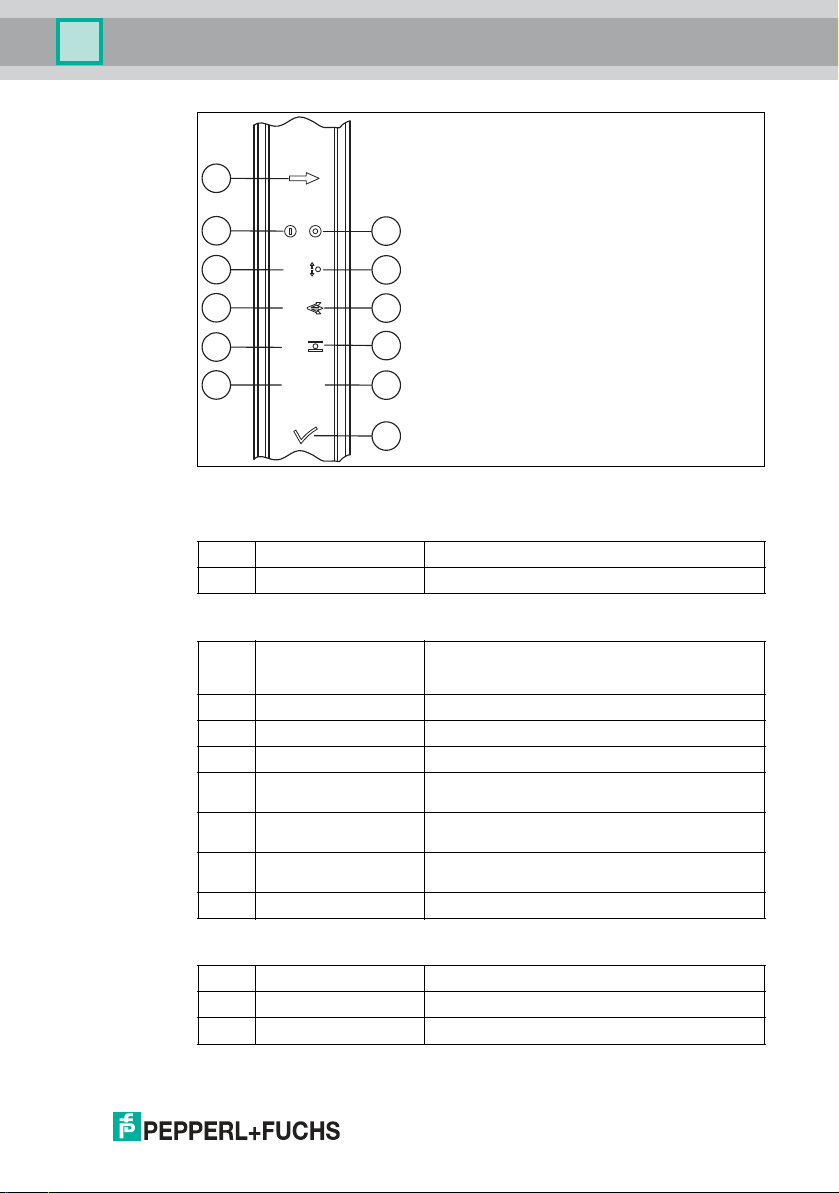

Figure 4.3 Touch field: Functi on indicators on the receiver strip

Touch buttons

1 Menu button Function selecti on

12 OK butto n Function confirmation

Function status ind icators, level 1

4 Detection field status

and object teach-in

switching output

5 Height output 1 Teach in height 1 o r display taug ht-in hei ght 1

6 Height output 2 Teach in height 2 o r display taug ht-in hei ght 2

7 Height output 3 Teach in height 3 o r display taug ht-in hei ght 3

8 Object p ositio n Object detec tion for moving objec ts

9 Crossover Beam crossover active

10 Object to lerance Tolerance beam for obj ects active

239596 2019-09

11 F2 Activate s econd level

Function status ind icators, level 2

4 Q (F2) Beam suppre ssion (blank ing) for inter fering object s

5 H1 (F2) Inverse operation (gap detection)

6 H2 (F2) Light-on or d ark-o n switchi ng type

Teach in objec t or dis play object det ection

Object detec tion for static objects

Beam crossover deactivated

Tolerance for obj ects deactivated

11

Page 12

LGS Series

1

3

4

2

1

4

6

7

8

53

2

Product De scription

7 H3 (F2) Reset factor y setting

8 Object positi on (F2) Signal tracking acti ve

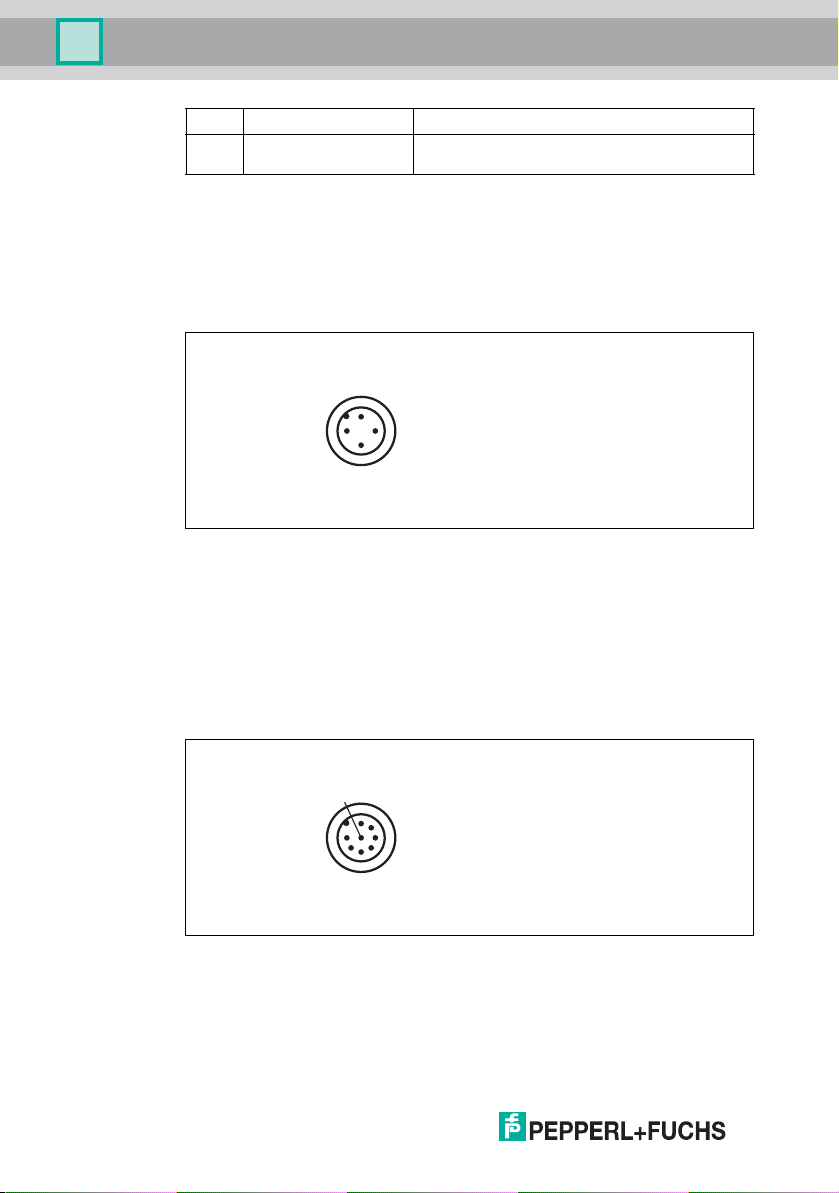

4.3 Interfaces and connections

The electrical connections are established usin g two M12 connectors. The

transmitter strip has a cable with a 4-pin conne ctor and the rec eiver strip a cable

with an 8-pin connector.

Transmitter s trip

Figure 4.4 Emitter unit connection layout

1 24 V DC

2 R ange (In)

3 0 V DC

4 T est (In)

Signal tracking inac tive

12

Receive r strip

Figure 4.5 Receiver strip connection layout

1 + UB

2 S C (Stability Contr ol, Out)

3 0 V DC

239596 2019-09

Page 13

LGS Series

Product De scription

4 C/Q (IO-Link / Out)

5 H1 (O ut)

6 H2 (O ut)

7 H3 (O ut)

8 Teach-in (In)

IO-Link communication is established via the C/Q connector (pin 4).

4.4 Accessories

An extensive range of accessories w ith detailed descriptions can be foun d in t he

appe ndix see chap ter 10.5 .

4.5 Scope of Delivery

The scop e of deliver y includes:

■

Emitter strip and receiver strip

■

Manual

■

Cable lug an d spare housing screw

Fixtures and cab les are not included in the scope of delive ry. S ee the appendix or

visit http://www.pepper l-fuchs.com for a selection of c ompatible mounting aids

and r ecommended cables.

239596 2019-09

13

Page 14

LGS Series

Installation

5 Installation

5.1 Preparation

Unpacking the Device

1. Check the p ackaging and con tents for d amage.

In the event of dam age, inform the shipping co mpany and notify the

supplier.

2. Check the p ackage contents against your order and the shipping do cuments

to ens ure that all items are presen t an d correct.

Should you have any q ues tions, direct them to Pepperl+Fuchs.

3. Retain the original pa ckaging in case the d evice is to b e stored o r shipped

again at a later date.

Note

Preven ting Extraneou s Light and Reflections

Situations in whic h the receiver is exposed to power ful extraneous light (e.g., from

flashing lamps or direct sunlight) must b e avoided. The influenc e of other optical

sens ors should also be prevent ed thro ugh s uitable positioning o r the use of

par titions. There must be n o reflective surfaces in the detection field, sinc e

reflections may prevent the detection of objects.

5.2 Mounting

Remember to kee p the detection field free of o bstac les wherever poss ible. The

first or last bea m in par ticular is used for visual synchron ization between the

emitter strip and the rece iver strip. If both synchronous beams are interrupted, the

detection field is no longer measured.

239596 2019-09

13

Page 15

Q

H1

Fix

H2

H3 Fn

Transmitter

Detection field + 159

n Beam

1. Beam

Receiver

Detection field

5

21.2 137.8

20

30.5

LGS Series

Installation

Figure 5.1 Light Grid Dimensio n Drawing

To mount the slim panels, use customized bore holes (d = 4.5 mm for M4 screws)

or a rear, continuous groove (for flat M6 nuts in accordance with ISO 4035).

Various fixtures are available for mounting the light grid see chapter 10.5.1.

Mounting Using the Rear Groove

There is a continuous g roove located on the r ear of the strip on the ligh t grid.

Standard flat M6 nuts in accordan ce with DIN 4 035 fit into this gro ove. Once these

nuts have been inse rted , they can b e use d to mou nt the light grid.

Mounting Using Holes D rilled by the Customer

The light grids can be mounted using user-defined holes. The ma ximu m screw

size is M4. Make sure you follow the instru ctions whe n po sitioning the hole.

Improper handling can damage the interna l electronics.

Drilling Holes

1. Mark the pos ition of the holes. Focus on the continuous line on the side of the

light grid .

2. Mark the p osition of the holes.

3. Using a 4.5 mm diam eter drill, drill all the way through the hous ing.

4. Deburr the hole.

5. Repeat the first steps until all ho les have been drilled.

6. Make sure that the aluminum chips do not scratch the optical surface.

14

239596 2019-09

Page 16

LGS Series

9

Installation

Secure the light grid in its final position using the drilled holes.

Figure 5.2 Position of the central point for the mounting holes

Figure 5.3 Mounti ng ho les

Mounting

1. Align the em itter strip and rece iver s trip so the y are parallel with one another

and at the same height.

2. The strips must be aligned with one another with an accuracy of

approximately ± 5°.

3. During mounting , ensure that the two strips have the same orientation. (Cable

outlet facing eith er upward or downward on both strips.)

4. The maximum d etection range must not be exceeded.

239596 2019-09

15

Page 17

LGS Series

Offset Y [mm]

Distance X [m]

Characteristic response curve

800

700

600

500

400

300

200

100

0

0 1 2 3 4 5 6 7 8

x

y

E1 S1 S2 E2

Installation

Figure 5.4 Maximum offset between emitter and receiver

5.3 Multiple Positions

Note

If several light grids are operating close to each other, care must be taken to

prevent cross-talk. This can be achieved by swapping the emitter an d receiver, or

by ensuring a sufficient distance between the two light grids.

The illustration below indicates how to m ount two light grids with a swapped

emitter and receiver.

16

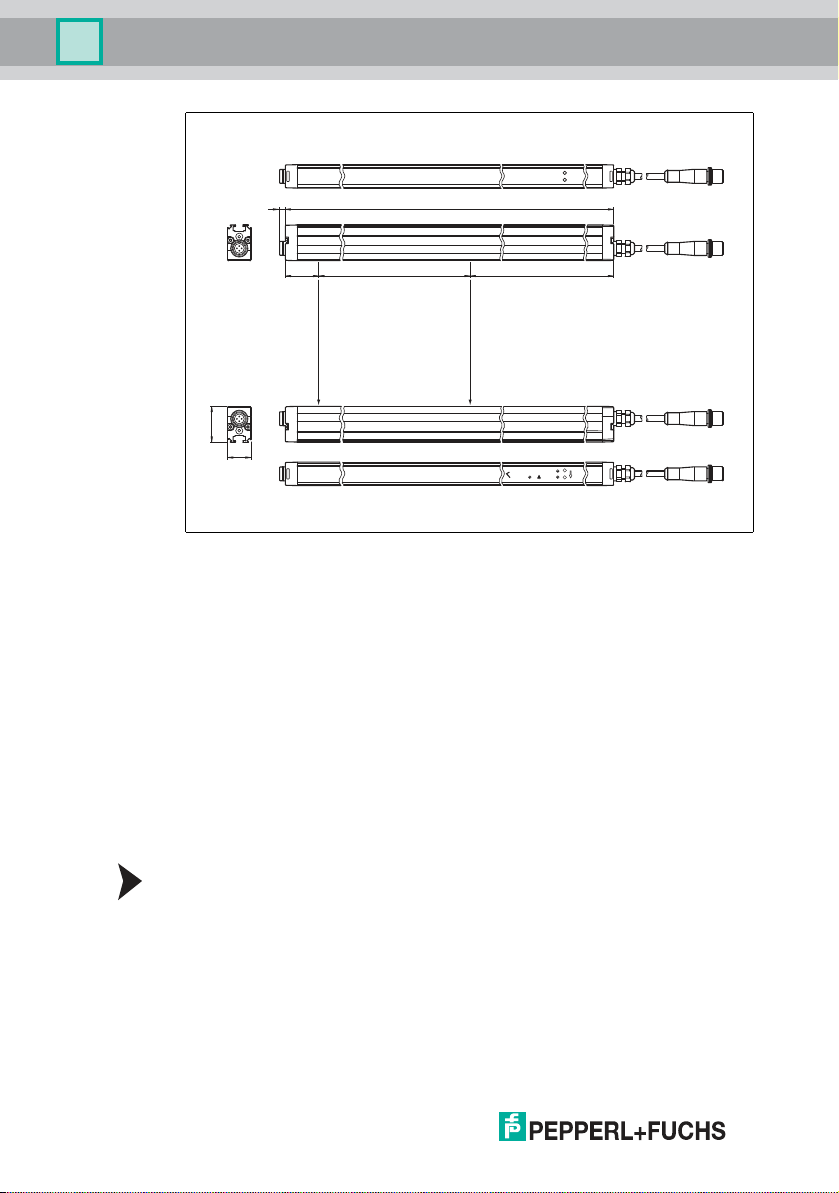

Figure 5.5 Multiple assi gnment of two pair s of lig ht grid s

239596 2019-09

Page 18

LGS Series

1

3

4

2

Installation

5.4 Connecting the Sensor Rails

Caution!

Elec trical connection

Wiring work tha t requires the op ening an d closing o f elec trical connections m ust

always be per formed with the power disconnected.

Use a Class 2 power supply to s upp ly the power (certified according to UL 1310).

Connecting the Emitter Strip

Figure 5.6 Emitter unit connection layout

1 24 V DC

2 Range (In)

3 0 V DC

4 Test (In)

Connect the emitter strip after the top pinout. Insulate the unused wires. See the

switching example sho wn on the following pag e see Figure 5. 8 on page 19.

Range input

The transmitter strip has a range input (pin 2) that adapts the transmitting power to

the relevant sensing range in the application. The trans mitte r attains a maximum

sens ing range of 1.6 m (or 2 m with option /35) if the input is open. If the

app lication requ ires a longer sensing range (6 m or 8 m with /35), the input

mu st be connect ed either to + UB or 0 V. The reduction in the tran smitting

power also preven ts extrane ous light from interfering with other sensors located in

the direct vicinity.

Test input

The transmitter strip has a test input (pin 4) tha t can be used to test th e function of

all switching outputs on the system by activating the test input or operate the

system in energy-saving mode. The inp ut can be connected either to + UB or 0 V.

239596 2019-09

17

Page 19

LGS Series

1

4

6

7

8

53

2

Installation

Conne cting the Receiver Strip

Figure 5.7 Receiver strip connection layout

1 + UB

2 S C (Stability Contr ol, Out)

3 0 V DC

4 C /Q (IO-Link / Out)

5 H 1 (Out)

6 H 2 (Out)

7 H 3 (Out)

8 T eac h-in (In)

■

Function tes t: When the strip is activated for le ss than 1.2 s, the

transmitter beams switch off and the outputs on the receiver strip switch on

in the same way as when a beam is interrup ted. The outputs for the height

control can also b e tested in this way, if the relevant h eight control

parameters are available.

■

Energy-saving mode: If the test input is activated for longer tha n 1.2 s, the

system switches to ener gy-saving mode with minimal energy c onsumption

and no func tions. The light grid reverts back to normal mode immediately

when the test input is dea ctivated .

18

Conne ct the receiver strip after the top pinout. All ou tputs are s hort-circuit pro of.

Insulate the u nused wires. See the switch ing example shown on the followin g

page see Figur e 5.8 on page 19.

Stability C ontrol Output (SC)

The SC switching output indicates an insufficient functional reserve and makes

status indicator 3 flash at 4 Hz with a delay of 5 seconds. T he SC switching output

only switches off o nce there is sufficient functiona l reserve again, for example, if

the front lenses are cleaned or the strips are read juste d.

Switching Output (C /Q)

This signal output is active (switch ed o n for da rk on, opp osit e for light on) if an

object is within the detection ran ge, or if a t aught-in object is detected . This is

shown by status indicator 3 and 4 respectively.

239596 2019-09

Page 20

LGS Series

24 V

0 V

Test

Transmitter strip Receiver

strip

24 V DC

Stability Control

0 V

C/Q

HQ1

HQ2

HQ3

Teach-In

24 V

Range

0 V

Test

Test

RangeRange

Menu buttonOK button

1

2

3

4

5

6

7

8

1

2

3

4

Installation

Height Control Outputs (H1 , H2, H3)

These three indepen den t signal outputs are active if objects in the detection field

match the position of the taug ht-in heigh t controls see c hapter 7.1.2. The outputs

then report the same statuses as the function status indic ators 5 (H1), 6 (H2), and

7 (H3 ). If no height controls are parameterized, the sign al outputs are always

inactive.

Connecting External Operating Buttons (Teach-In Input)

The receiver strip is equipped with a teach-in input. This input can be us ed to

route out the two operating buttons and to connect them externally. The function

of the me nu bu tton is connected via an external normally-op en contact to + UB.

The OK b utton is connected via an external no rmally-op en contac t to 0 V. To

prevent a short circuit when both normally-open con tacts are actuated

simultaneously, a 1 k /2 W resistor must be installed b etween the NO con tact

and 0 V.

Parameterization can be locked to prevent the menu button being pressed

unintentionally (keybo ard lock). To do this, set the external teac h-in input

permanently to + UB.

Switching Example

The LEDs on the o utputs are o ptional.

Figure 5.8 Connection example LGS

239596 2019-09

Grou nding/Shielding

The system does not require grounding in stand ard cases. If EMC faults occur,

use a grounding cable with the cable lug supplied in the scope of delivery. The

groun ding/shielding must always be moun ted on the receiver str ip. This is purely

functional grou nding rather than pro tective grou nding. It acts solely as a down

conductor for cab le-related faults and is not subject to any safety guidelines (e.g.,

personnel protection ).

Ground/s hield the d evice as follows:

19

Page 21

LGS Series

Installation

1. Make up a groundin g cable (max. 1 mm2) using the s upp lied cable lug.

2. Remove one housing sc rew from the cover at the cab le end, us ing a Torx T8

screwd river.

3. Place the cable lug with the prepare d cable und er the cove r and tighten the

housing screw again.

4. Connect the other e nd of the g roun d cable to adjacent metal compone nts

(e.g., mount ing b ase, frame, etc.).

The sens or is now grounded.

5.5 Storage and Transportation

Keep the original packaging. Always store and transp ort the device in the original

packaging.

Store the device in a clean an d dry environment. The pe rmitted ambient

conditions m ust be co nsidered, see da tasheet.

20

239596 2019-09

Page 22

LGS Series

Commissioning

6 Commissioning

6.1 Final Assem bly

Checkin g the Mou nting an d Settings

1. Check the position of th e ligh t strips in relation to o ne anot her. The emitter

strip an d receive r strip must be a ligne d with one another with an accuracy

of approximately ± 5°.

2. The light strips ca n be opera ted briefly to che ck that the final asse mbly has

been performed correctly. The light strips are a ligne d perfectly with each

other when the yellow status LED on the receiver strip does not light up continuously or flash.

3. Now secure the light strips. Check all screw connections and tighten as necessary.

4. Check the cabling, referring to the wiring diagrams.

Remember to kee p the detection field free of o bstac les wherever poss ible. The

first or last bea m in par ticular is used for visual synchron ization between the

emitter strip and the rece iver strip. If both synchronous beams are interrupted, the

detection field is no longer measured.

The sign al needs t o be calibrat ed to ac hieve the bes t possible resolution for the

relevant application. Therefore, after a ny m odifications to the ap plication

(installation situation), s tart the system to recalibrate the signal and maintain the

sam e level of availability.

The sign al output respond s to detected objects, h eavy s oiling on t he lenses, or

misaligned profiles. The electronics compe nsate for s ignal changes caused by

grad ual soiling or temperature changes. If a minimum o f one light bea m is

inter rupted, the output rem ains active until the light bea m is interrupted (with dark

on) or soiling is detected.

6.2 Commissioning the Light Grid

Commissionin g

1. Check that the light grid is in the co rrect position.

2. Switch on the supply voltage. The operating status indicators on the emitter

strip a nd receiver strip light up green.

3. If the status LED is n ot lit, the light grid is aligned. The status L ED lights up

when the device is misaligned or an object is detected.

The two s trips are per fectly aligned with one another and can now b e

configured see chapter 7.1.

To commiss ion and operate the light grid via th e IO- Link inter face, please refer to

the following sec tion see chapter 7.2.

239596 2019-09

21

Page 23

LGS Series

Operation

7 Operation

7.1 Operating the Light Grid

No objects o r he ight controls are p arameter ized on delivery.

The grid is o perated using the to uch field o n the front of the receiver strip. The

system can be parameterized as required using the two operating elemen ts and

the icons on the receiver strip. Parameterize the light grid by pres sing the menu

button. The "Q" ico n flashes in parame teriza tion mode.

■

Rapid flashing means: The function is not yet activated /taugh t in (the LED

turns on briefly a nd then turns o ff for a long period)

■

Slow flashing means: The function is activated/taught in (the LED tur ns on

for a long per iod and then turns o ff br iefly)

Pressing the menu button again activates a ll parameterizable func tion s in

succes sion, and each relevant icon flash es b rightly.

To teach in or activate the current pa rameter, press the OK button .

For information on o pera ting v ia an externa l connection, see chapter 5.4.

If no operating buttons are presse d within a timeout p eriod of 30 s econds,

parame terization a utomatica lly e nds. Any previously mo dified parameters are

retained.

Factory Settings

To restore the factory settings, proceed as follows:

22

1. Press the M enu button to enter parameterization mod e.

2. Press the Menu button repeat edly until the "F2" icon st arts flashing.

3. Press the Menu button . This will take you to the 2nd parameterization

level.

4. Press the Menu bu tton repeat edly until the "H3 " icon starts flashing .

If you now press the OK button , the light grid will be restored to its

factor y settings.

239596 2019-09

Page 24

LGS Series

Operation

Factory Se tting

Parameter Status

Heig ht control 1 – 3 Inactive

Beam cross over (3-way) Active

Objec t positio n Floating

Objec t tolerance Active

Light-on/dark-on switching Dark on

Beam supp ression (blanking) Inactive

Inverse oper ation (gap d etectio n) Inactive (solid objects )

Signal track ing Inactive

Table 7.1 Factory settings of the light grid

Parameterization Status Indicator

To display the cur rent statuses parameterized on the 1s t level, briefly pre ss the

OK button outside of the para meterization me nu.

This disp lays all the active functions for five seconds.

■

Icon dimly lit: Function has not been parameterized or is disabled

■

Icon b right and constantly lit: Function has been parameterized or is

activate d

The status of functions on the 2nd level can only be read wh ile the relevan t

function is being parameterized:

LED flash ing quickly = function disa bled

LED flash ing slowly = fun ction ena bled

239596 2019-09

23

Page 25

LGS Series

Operation

Touch Field Overview

24

Figure 7.1 Touch field on the sensor for parameter izatio n

239596 2019-09

Page 26

LGS Series

Operation

Touch Field: Configurable Parame ters, 1st Leve l

Param eter

Q ob ject Q Explanation of fun ction: Teach in objec t. The

Heig ht

control 1

Heig ht

control 2

Heig ht

control 3

Objec t

positi on

Beam

crossover

Objec t

tolerance

Touch field

icon Description

object c urrentl y located in the detection field is

taught i n. Output Q is ac tivated when the object is

detected dur ing operation. The "Q" icon lights up

brightly to indi cate this status.

Detection fie ld vacant: If the detection field is

vacant when the OK butto n is pressed, any ob ject

previously taught in will be deleted and the

Q switching outp ut will respond to any interruption in

the beam.

Display function: The "Q" icon sig nals each

interruption in the detection field in parallel to status

indicator 3.

H1 Explanation of fun ction: Teach in objec t height.

H2 Function as des cribed for height control 1.

H3 Function as des cribed for height control 1.

The upp ermost beam interrupted by the object

currently located in the detection field is taught in as

the height control. The H1 output switches on

whenever this b eam i s interrupted duri ng operation.

The "H1" ico n lights up b rightly to indicate this

status.

Synchronizatio n interrupted: Th e H1 output

switches on if synchroni zation is lost, even if there is

no correspondi ng object loc ated in the detectio n

field.

Detection fie ld vacant: If the detectio n field is

vacant when the OK butto n is pressed, any height

control previously taught in wi ll be d eleted and the

H1 switching output will no longer resp ond.

The H2 switching output is activated .

The H3 switching output is activated .

Explanation of fun ction: Type of objec t position.

The ob ject position is "floating " in the factory setti ng.

Change function: Pressi ng the OK button changes

the object pos ition of a taught-in object from

"floatin g" to "fixed."

Reset function: Pressing the OK bu tton again sets

the object pos ition to "floating" again.

Beam crossover is ac tive in the factory setting.

Change function: Pressing the O K button dis ables

beam crossover.

Reset function: Pressing the OK bu tton again

enables beam c rossover again.

Explanation of fun ction: When object toleranc e is

activated , this permi ts a devi ation in the relevant

object s izes of a resolution unit and improves ob ject

detection when beams are interrupted due to

vibrations. The tolerance app lies to both beam

suppress ion (blanking ) areas.

Object tolera nce is active in the fac tory setting .

Change function: Pressing the O K button dis ables

active tolerance of a resolution unit for object

detection.

Reset function: Pressing the OK bu tton again

enables object tolerance again.

239596 2019-09

25

Page 27

LGS Series

F

2

F

2

F

2

F

2

F

2

Operation

Paramete r

2nd parameter

ization level

Table 7.2 Touch field: configurable param eters, 1st level

Touch field

icon Description

Enable fun ction : Pressing the OK button enables

the 2nd parameterization level.

Disable function : Pressing the OK button again

quits the par ameterization proces s.

Touch Field: Config urable Parameters, 2nd Leve l

Paramete r

Beam

suppress ion

(blanking )

Inverse

operation (gap

detection)

Light-on/darkon switc hing

Reset factory

setting

Touch field

icon Description

Explanation of fun ction: Any beams detec ted

within t he taught-in object area during operation do

Q

H1

H2

H3

not trigger a switching element function.

Teach in obje ct: Press the OK button: The object

currently locate d in the detecti on field is taught in as

beam supp ression.

Two different areas can be taught in simu ltaneo usly.

However, at least one of the two outer synchronous

beams must remain free.

If the detection field is vacant when the OK button is

pressed , any previously taught in beam suppr ession

area is deleted again.

The p arameter can be modified before or after

teachi ng in an objec t.

Object type detection is set to "solid " in the factory

settin g.

Modify: Pressing the OK but ton mod ifies the objec t

type of a taught-in ob ject fro m "solid" to "inverse" for

gap detection.

Reset: Pressing the OK button again sets obj ect

type detection to "solid" again.

Explanation of fun ction: Dark on: The switching

output is activated when beam s in the detection field

are interrupted (or the re is no synchronizatio n with

the emitter).

Light on: The switching output is acti vated when the

detection field is vacant.

The switching type is set to "da rk on" in the factory

settin g.

Enable fun ction : Pressing the OK button changes

the switc hing type of all Q, H1, H2, H3 switc hing

outputs from "dark on" to "l ight on."

Disable function : Pressing the OK button again

sets the switching type to "dark on" again.

Pressing the OK bu tton resets all parameters to the

factory setting.

Pressing the menu button again instea d qui ts the

parameterization pr ocess.

239596 2019-09

26

Page 28

LGS Series

F

2

Operation

Param eter

Signal track ing

Table 7.3 Touch field: co nfigurable parame ters, 2nd level

Touch field

icon Description

Explanation of fun ction: In non-stable ambient

conditions, e.g., soili ng and temperature changes,

Object

position

signal tracking ensures that the response threshold

remains constant. Reflective obje cts that are

occasionally present along the detection fiel d can

distor t signal tracking and caus e switchi ng faults. In

the wor st-case scenario, permanent detec tion is

signaled even though there is no object in the

monitoring fiel d. In this case, the function must be

disabled.

Signal tracking is inactive in the factory setti ng.

Enable func tion: Pressing the OK button enables

signal tracking.

When signal tracking is enabled, the specifi ed

resolution is r eached. The value of the switchi ng

threshold is set to 60 %.

Paramete rization via IO-Link

Parameterization via IO-Link allows the resp onse

threshold and signal track ing to be defi ned

independently of each other.

=> Without tracking: The response threshol d can

be selec ted in 10 % increments between

0 = m inimum thres hold, 1 = 10 %, and 9 = 90 %.

■

0 = minimum threshold, no tracking, maximum

gain, default value

■

1 = 10 % of value of response thres hold, no

track ing

■

2 = 20 % of value of response thres hold, no

track ing

■

...

■

9 = 90 % of value of response thres hold, no

track ing

=> With tracking: The re spons e threshold ca n be

freely selected between 10 % ... 90 %. This allows

customized configu ration between fine resolution

(high threshold) and high immu nity to reflective

objects (low threshold).

■

10 % … 90 % = value for response threshol d that

can be freely sel ected, with tracking

Disable function : Pressing the OK button again

disables signal tracking.

When signal tracking is di sabled, the lowes t

switching threshold is configured. The optical

resolution is increas ed by 4 m m.

7.1.1 Object detection (overha ng control)

The LGS switching light grid uses th e factory settings a nd does not require any

further parameterization. Switchin g output Q reacts to every single object in the

detection field.

Possible application-spe cific settings:

■

Deactivate beam crossover

■

Beam suppr ession (blanking) of permanen t installations in the detection

field

■

239596 2019-09

Set switching mod e of outputs to light on

27

Page 29

LGS Series

Operation

7.1.2 Monitoring the object height with height controls

The LGS switching light grid has been designe d e.g. to monitor the load heights of

pallets. An H switching outp ut is t herefore allocated for every load height. For

example, the up per edge of the sm alles t object is taugh t in as height control 1

(H1), the upp er edge of the middle object as height control 2 (H2) and the up per

edge of the largest object as h eight control 3 (H3). No height output will switch on

for any ob ject smaller than height control 1. Only output H1 will switch on for

objects larger than or equal to height control 1 b ut smaller than heigh t control 2.

Larger o bjects will trigger outputs H2 and H3 as well. The assignm ent of more

than one beam to a height control is only possible via IO-Link. Switching output Q

is activated every time an object is detected.

Possible app lication-specific setting s:

■

Deactivate be am crossover

■

Beam supp ression (blanking) of permane nt ins tallations in the detection

field

■

Set switching mod e of outp uts to light on

28

239596 2019-09

Page 30

LGS Series

Operation

7.1.3 Object identifi cation

The switching light grid ca n identify solid or pe rforated objects in the de tection

field from the interrupted light beams. Output Q is switched f or the entire t ime that

the objec t is in the d etection field.

The object ca n also be set to a floating or fixed location in the detection field. If a

fixed p osition is conf igured , output Q will only switch o n if the identified o bjec t is

exactly at this taught location. The invers e ob ject identification operating mo de is

intended to detect ho les, e. g., in plates. Either individual holes or contiguous hole

patterns can be detected. The position of the outer edg e of the plate in the

detection field is irrelevant.

Possible application-spe cific settings:

■

Deactivate beam crossover

■

Beam suppr ession (blanking) of permanen t installations in the detection

field

■

Set switching mod e of outputs to light on

239596 2019-09

29

Page 31

LGS Series

Operation

7.2 Commissioning and Operating the Light Grid with IO-Link

Commissioning with IO-Link

To activate the sensor via the IO-Link, p roceed with the following steps:

1. Set the corresponding port on the IO-Link master to which the sensor is connected to IO-Link status.

2. When commun ication is succe ssfully established, the green operating

indicator flashes with short interrup tion s every second.

The sens or now transmits process d ata and can be parametrized or

diagnosis can be run.

Use preset p arameters to c onfigure, par ameterize, and d iagnose the se nsors. To

parame terize the sensors with an engineer ing to ol, u se the device description

(IODD), which can be load ed into all system environments with IO-Link support.

To operate the sens or in an FDT enviro nment, you can also use a DTM.

30

239596 2019-09

Page 32

LGS Series

Operation

See the d evice description and software, e.g., the IODD, DTM, and the FDT

mas ter ap plication within the p roduct at www.pe pperl-fuchs.com/io-link.

239596 2019-09

31

Page 33

LGS Series

Maintenance and Repair

8 Maintenance and Repair

8.1 Maintenance

To get the best possible performance out of your device, clean the optical unit on

the device when necessary and always keep it clean.

When c leaning the optical unit yo u sho uld note the following :

■

Do not touch the optical unit w ith your fingers.

■

Do not imm erse the d evice in water. Do not spray th e device with water or

other liquids.

■

Do not use a scouring agent to clea n the surface of the d evice.

■

Use a cotton or paper cloth moistene d with water or isopropyl alcohol. The

cloth must not be soaked!

■

Remove any residual alco hol using a cotton or paper cloth moistened w ith

distilled water. The cloth m ust not be soa ked!

■

Wipe the device s urfaces d ry using a lint-free cloth.

8.2 Repair

The device must not be repaired, changed, or manipu lated. In case of failure,

always replace the device with an original device.

Note

If it appe ars that safe operation of th e sens or system is no long er possible, it must

be taken out of ope ration and secured against inad vertent use.

32

Always send both parts o f the d evice (transmitter and receiver strip) to

Pepperl+Fuchs together for repa ir.

239596 2019-09

Page 34

LGS Series

Troubleshoot ing

9 Troubleshooting

9.1 Troubleshooting

Before requesting field service, check that th e following actions have been

taken:

■

The plant h as been tested according t o the following check lists.

■

Telephone assistance obtained from the Service Cen ter to isolate the

problem .

Interference

■

The sensor must be firmly m ounted. It m ust not vibrate.

■

The sensor must not be installed behind a cover.

■

The sensor should be installed so it is protected from rain.

Eliminating Interference

Sour ce of fault Cause Action

Emit ter:

Status ind icator flashes

quickly at 8 Hz

Receiver:

Operating indi cator (green)

flashes in pulses at 0.8 Hz

Receiver:

Operating indi cator (green)

flashes at 4 Hz

Receiver:

Status ind icator flashes at

4 Hz

Receiver:

Status ind icator flashes

quickly at 8 Hz

Receiver: Switching

output with detection signal

although there is no object

in the detec tion field

Non-specific flashi ng of the

indic ators on the light grid

Fault state 1. Check the operating

Low voltage Check the o perating

Short circuit at the outp uts Check the wiring a t the

Insuffic ient functi onal

reserve

Fault state during signal

meas urement

Reflective objec ts parallel

to the detect ion field

voltage.

2. Switch the voltage off

and on again.

voltage.

outputs.

Clean the fro nt pane ls;

adjust the em itter and

receiver.

1. Check the op eratin g

voltage.

2. Switch the voltage off

and on again.

Deactivate signal tracking

(2nd level, object pos ition).

Switch the voltage off and

on again.

■

If none of the sug gestions above c orrec ts th e problem, please co ntact the

Service Center.

Load factory setting

Factor y Setting s

To restore the factory s ettings, p roceed as follows:

1. Press the Menu button to enter para meterization m ode.

239596 2019-09

33

Page 35

LGS Series

Troubleshoot ing

2. Press the Menu button repeat edly until the "F2" icon st arts flashing.

3. Press the Menu button . This will take you to the 2nd parameterization

level.

4. Press the Menu bu tton repeat edly until the "H3 " icon starts flashing .

factor y settings.

If you now press the OK button , the light grid will be restored to its

34

239596 2019-09

Page 36

LGS Series

Appendix

10 Appendix

10.1 Technische Daten

General specifications

Effective detec tion

range

Threshold detecti on

range

Light sour ce IRED

Light type modulated in frared light , 8 50 nm

Fiel d height See chap ter 10.3

Beam cross over Factory set ting: three beam crossing, deactivateable

Beam blank ing adjustab le max. 2 fixed sup pressib le beam areas (blanking)

Beam spac ing LGS8 = 8,33 mm; LGS17 = 16,67 mm; LGS25 = 25 mm;

Number of beams See chap ter 10.3

Operating mode Emitte r: Emitter power adjustable in tw o ranges

Optic al reso lution withou t beam crossover: see beam spac ing

Angl e of divergence 10 °

Ambi ent light limit > 50000 Lu x (if external light source is outs ide the opening

Standard : 0.3 ... 6 m

Option /35: 0.5 ... 8 m

LGS100: When beam crossover i s activated, the detection

range starts at 0.6 m

Standard : 7.5 m

Option /35: 10 m

LGS50 = 50 mm; LGS100 = 100 m m

with beam crossover: 4 / 8,5 / 12,5 / 25 / 50 mm .

Only between 25 % ... 75 % of range

angle)

Functional safety related parameters

LGS8 LGS17 LGS25 LGS 50 LGS100

MTTF

d

Miss ion Time (TM) 20 a 20 a 20 a 20 a 20 a

Diagnostic

Coverag e (DC)

21 a 25 a 34 a 56 a 7 8 a

60 % 60 % 60 % 60 % 6 0 %

Indicators/op erating means

Operation indica tor Power on: LED green, staticall y lit , Und ervoltage indicator :

Function indicator Emitter: Yellow LE D, illuminates at high emitting power, off a t

Control elements Receiver: 2 touch buttons for programming

239596 2019-09

Green LED, pulsing (ap prox. 0.8 H z) , short-c ircuit : LED

green flas hing (approx. 4 Hz )

low emittin g power

Receiver: Yellow L ED: illuminates when an object is detected

flashes when falling short of the stabi lity control (4 H z)

Error message: Yellow L ED flas hes (8 Hz) in emitter and

receiver

35

Page 37

LGS Series

Appendix

Electrical specifications

Interface

Input

Output

Operating voltage 18 ... 30 V DC

Ripple 10 %

No-loa d supply cu rrent Emitter : 50 m A

Interface type IO-Link

Protoco l IO-Link V1.0

Mode COM 2 (38.4 kBaud)

Test input Emi tter sw itch-off with +UB or 0 V at pin 4 (em itter)

Function input Range input activation from 1.6 m (or 2 m in case of option

Pre-fault indicati on

output

Switching type Factory setting: dark ON , Switc hable to light ON mode

Signal output Switch output (detecti on field C/Q) 1 push-pul l (4 in 1) output,

Switching threshold Factory setting: The signal tra cking for the thresho ld value is

Switching voltage max. 30 V DC

Switching current max. 100 mA

Voltage drop 2 V DC

Switching frequency max. 118 Hz, see datas heet

Response time Se e chapter 10.3

Timer function Off-del ay programmable from 0 ... 1.25 s in 5 ms steps

Receiver: 150 mA (without outputs)

/35) with +UB or 0 V on pin 2 (emitter)

Teach-In input for programming on pin 8 (receiver)

Stability Contro l (SC) 1 PNP, short-c ircuit protected , reverse

polarity protected on pin 2 ( receiver )

short-c ircuit protected , reverse polarity prote cted on pin 4

(receiver ),

Height monitoring (H1, H 2. H 3) 3 push-pull (4 in 1) outputs ,

short-c ircuit proof, reverse polarity protected on p in 5, pin 6,

pin 7 (receiver)

deactivated, increasi ng the opti cal resolution by a max imum

of 4 mm; switch able to active signal tracki ng

(adjustm ent via IO-Link only)

36

Compliance with standards and directives

Directive conformity

EMC Directive

2004/108/EC

EN 60947-5-2:2007

239596 2019-09

Page 38

LGS Series

Appendix

Standard conformit y

Product standard EN 609 47-5-2:2007

IEC 60947-5-2:2007

Approvals and c ertificates

Protection class III ( IEC 61140 )

UL approval cU Lus L isted

CC C appr oval CCC approval / marking not req uired for products rated 36 V

Ambient con ditions

Ambi ent temperature Stand ard : -10 ... 60 °C (14 ... 140 °F )

Storage temperature -30 ... 70 °C (-22 ... 158 °F)

Option /146: -30 ... 60 ° C (-22 ... 140 °F)

Mechani cal speci fications

Housi ng length L See chapter 10.4

Protection degree IP67

Connection Emitte r: 200 mm connecti ng cable with 4-pin, M12x1

Material

Housi ng extrud ed aluminum secti on , Silver ano dized

Optic al face Plastic pane , Polycarbonate

Mass See chapter 10.4

connector

Receiver: 200 mm connecting cable with 8-pi n, M12 x 1

connector Ca ble cross sec tion min. 0.25 mm2

Max. cable length 30 m

10.2 Type Code

Automation ligh t grids from the LGS series are designated using a code as

follows:

LGSx x-yyyy-IO/Options

Here, xxx indicates the resolution, y yyy indicates the height of the detection field,

IO indicates the integrated IO interface, and Op tions indicates a dditional op tions.

Resolution [mm]

xxx yyyy IO /35/110/115b/146

8 100, 300, … 2100 IO /35/110/115b/146

17 100, 300, … 3200 IO /35/110/115b /146

25 100, 300, … 3200 IO /35/110/115b /146

239596 2019-09

Detection field

[mm] IO-Link interface Options

37

Page 39

LGS Series

Appendix

Resolu tion [mm]

50 300, 600, … 3000 IO /35/110/115b/146

100 300 , 600, … 3000 IO /35/110/115b/146

Detection field

[mm ] IO-Link interface Options

Clarification of Options

/35 Increased detection rang e: 8 m instead of 6 m

/110 Push-pull 0.1 A switching output, short-circuit proof, protected against

/115b M12 plug with 200 mm co nnectio n cable (series)

/146 Extended temperature range: -30 °C instea d of -10 °C

reverse polarity (series )

10.3 Response Times and N umber of Beams

The mechanical beam spacing determine s the minimum detectable object size

(signal tracking active). By crossing the light beams, the reso lution of the light grid

increases by a max imum of 100 %. The inc reased resolution is available in the

area between 25 % ... 75 % of the detection range between the e mitter strip and

the receiver s trip. Make su re that all ob jects pass the e mitter strip or receiver strip

at this d ista nce. The crossover function is activated by default. Deactivating the

crossover func tion d oes not alter the response time.

Response time [ms]

Variants

LGS8100

LGS8300

LGS8600

LGS8900

LGS81200

LGS81500

LGS81800

LGS82100

Detection

field [ mm]

100 13 3 4 5 7

300 37 3 6 7 10

600 73 5 8 9 15

900 109 6 11 11 19

1200 145 7 13 13 24

1500 181 8 15 16 28

1800 217 9 17 18 33

2100 253 10 20 20 37

Number

of beams

C/Q output witho ut

object

parameterization

Typical Maximum Typi cal Maximum

C/Q o utput with

object

parameterization

Height control

outputs H1, H2, H3

38

239596 2019-09

Page 40

LGS Series

Appendix

Variants

LGS17100

LGS17300

LGS17600

LGS17900

LGS171200

LGS171500

LGS171800

LGS172100

LGS172400

LGS172700

LGS173000

LGS173100

LGS173200

Response time [ms]

C/Q outp ut with

Detection

field [mm ]

100 7 2 4 5 7

300 19 3 5 6 8

600 37 3 6 7 10

900 55 4 7 8 13

1200 73 5 8 9 15

1500 91 5 10 10 17

1800 109 6 11 11 19

2100 127 6 12 12 22

2400 145 7 13 13 24

2700 163 7 14 15 26

3000 181 8 15 16 28

3100 187 8 16 16 29

3200 193 8 16 16 30

Number

of beams

C/Q o utput without

object

parameterization

Typical Maximum Typi cal Maximum

object

parameterization

Height control

outputs H1, H2, H3

LGS25100

LGS25300

LGS25600

LGS25900

LGS251200

LGS251500

LGS25-

239596 2019-09

1800

100 5 2 4 5 6

300 13 3 5 5 7

600 25 3 5 6 9

900 37 3 6 7 10

1200 49 4 7 7 12

1500 61 4 8 8 13

1800 73 5 8 9 15

39

Page 41

LGS Series

Appendix

Variants

LGS252100

LGS252400

LGS252700

LGS253000

LGS253100

LGS253200

Response time [ms]

C/Q o utput with

Detection

field [ mm]

2100 85 5 9 10 16

2400 97 5 10 10 18

2700 109 6 11 11 19

3000 121 6 11 12 21

3100 125 6 12 12 21

3200 129 6 12 12 22

Number

of beams

C/Q output witho ut

object

parameterization

Typical Maximum Typi cal Maximum

object

parameterization

Height control

outputs H1, H2, H3

40

LGS50300

LGS50600

LGS50900

LGS501200

LGS501500

LGS501800

LGS502100

LGS502400

LGS502700

LGS503000

LGS100300

LGS100600

LGS100900

300 7 3 4 5 7

600 13 3 5 5 7

900 19 3 5 6 8

1200 25 3 5 6 9

1500 31 3 6 6 10

1800 37 3 6 7 10

2100 43 4 7 7 11

2400 49 4 7 7 12

2700 55 4 7 8 13

3000 61 4 8 8 13

300 4 2 4 5 6

600 7 2 4 5 7

900 10 3 5 5 7

239596 2019-09

Page 42

LGS Series

Appendix

Variants

LGS1001200

LGS1001500

LGS1001800

LGS1002100

LGS1002400

LGS1002700

LGS1003000

Table 10.1 Response times w ith and without objec t paramete rization

Detection

field [mm ]

1200 13 3 5 5 7

1500 16 3 5 5 8

1800 19 3 5 6 8

2100 22 3 5 6 9

2400 25 3 5 6 9

2700 28 3 6 6 9

3000 31 3 6 6 10

Number

of beams

10.4 Profile Length and Weight

Response time [ms]

C/Q outp ut with

C/Q o utput without

object

parameterization

Typical Maximum Typi cal Maximum

object

parameterization

Height control

outputs H1, H2, H3

Prof ile length and weight

Overall length of the

Detection field [mm]

100 260 200

200 360 250

300 460 300

400 560 350

500 660 400

600 760 450

700 860 500

800 960 550

900 1060 600

1000 1160 650

1100 1260 700

1200 1360 750

1300 1460 800

1400 1560 850

239596 2019-09

transmitter / receiver strip

[mm]

Weight of transmitter /

receiver strip [g]

41

Page 43

LGS Series

Appendix

Table 10.2 Profi le length and weight per strip

Overall leng th of the

Detection field [mm]

1500 16 60 900

1600 17 60 950

1700 18 60 1000

1800 19 60 1050

1900 20 60 1100

2000 21 60 1150

2100 22 60 1200

2200 23 60 1250

2300 24 60 1300

2400 25 60 1350

2500 26 50 1400

2600 27 60 1450

2700 28 60 1500

2800 29 60 1550

2900 30 60 1600

3000 31 60 1650

3100 32 60 1700

3200 33 60 1750

transmitter / receiver strip

[mm ]

Weight of transmitter /

receiver strip [g]

10.5 Accessories

10.5.1 Installation accesso ries

The following products are available as mo unting ac cessories:

42

239596 2019-09

Page 44

LGS Series

Appendix

Compatible mounting acce sso ries for the light grid

No. Des ignation Illustration Description

1 OMH-S LCT-01 Mounting bracket

2 OMH-LGS-01

3 OMH-S LCT-03 Mounting bracket

4 OMH-S LCT-04 Mounting bracket

5 OMH-S LCT-05 Mounting bracket

Only in

combination with

OMH-S LCT-01

Mounting bracket

239596 2019-09

43

Page 45

LGS Series

Appendix

Table 10.3 Accessories list

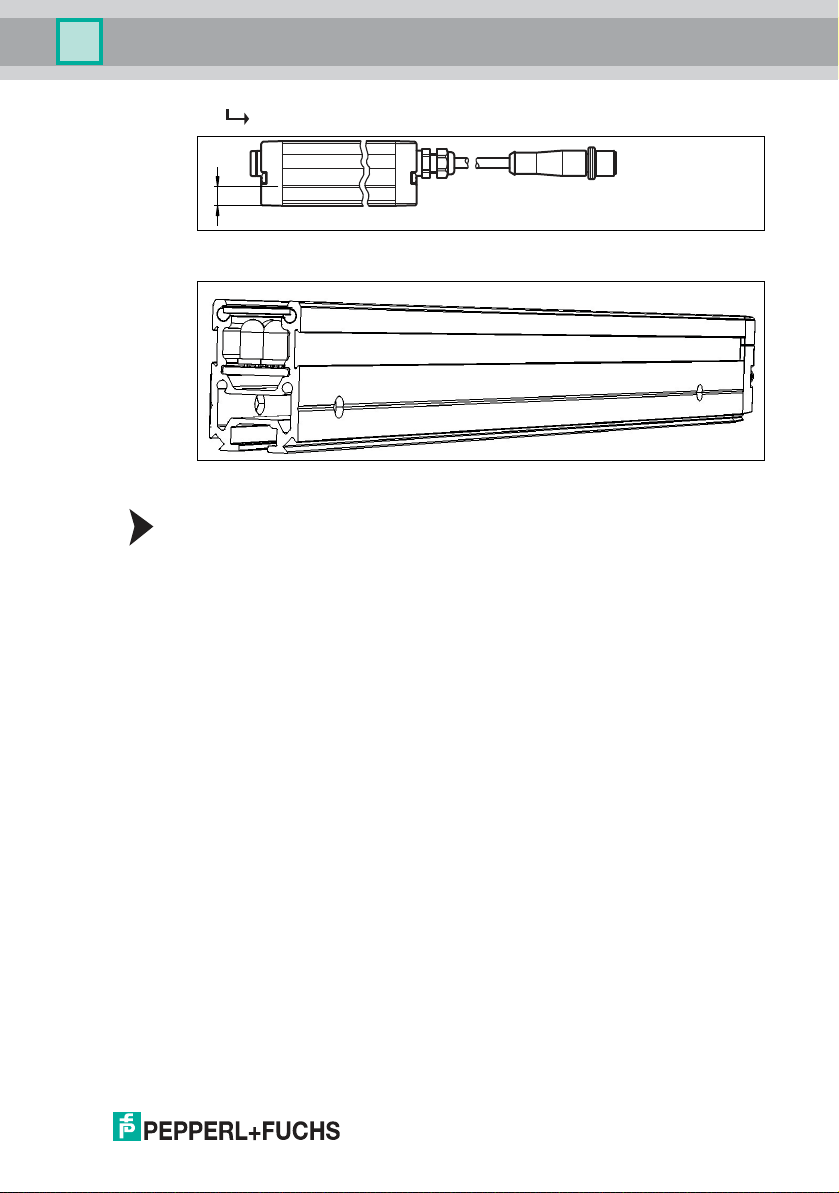

Mounting Aid OMH-SLCT -01

Model number: OMH-SLCT-01

The emitters/receivers can be secured using mou nting aids that grip the dove tail

guide. There are dovetail guides o n three sides of the profile. When mounting and

aligning the unit, avoid subjec ting the profile to mechanical tension.

A minim um of two mounting aids must be used to se cure the emitter or receiver. If

vibrations or shoc ks are expected, we recommend a ttach ing mounting aids at

intervals of 500 m m.

Mounting Aid OMH-LGS-01

Model number: OMH-LGS-0 1

The OMH-LGS-01 mounting aid acts a s a f ixed be aring and sec ures the position

of the light curtain in t he event of t hermal expansion , mechanical vibration, or

shock.

No. Designatio n Illustration Desc ription

6 AA SLCT-01 Profile alignment

tool

44

239596 2019-09

Page 46

LGS Series

ø 4.3

8.3

16

ø 4.3

7228

OMH-LGS-01

OMH-SLCT-01

38.6

45.4

42.8

53

OMH-LGS-01

OMH-SLCT-01

Appendix

Figure 10.1 Dimensional drawin g and fitting mounting accessory OMH-LGS-01

Figure 10.2 Alignment aid

Orde r code: AA-SLCT-01

The trans mitte r and receiver should always b e aligned at the same height in

parallel to one a nother. The AA-SLCT-01 alignm ent aid with bub ble level assists

the perpendicular alignment of the profile. The AA-SLCT-01 alignment aid is

simp ly clipped into the gr oove o n the side of the profile.

239596 2019-09

45

Page 47

LGS Series

ø 21

24.5

11.1

ø 5.5

20

139

14

23.4

21.5

PUSH

PUSH

Appendix

Figure 10.3 Dimensional drawing and assembly of the alignment A A-SLCT-01

10.5.2 Connecting Ca bles

Various 4-pin and 8-pin connec ting cables are available in different cab le lengths.

Conne cting cables for automa tion light grids

Use Model number

Length 2 m Length 5 m Length 10 m Length 15 m

4-pin cable

(transm itter

strip)

8-pin cable

(receiver strip)

V1-G-BK2MPUR-UL

V19-G -BK2MPUR-IEC

10.5.3 Accessories for IO-Link Operation

The following accessories are available for operat ing the receiver strip in IO-Link

mode.

Designation Descripti on

IO-Link-Master02-USB IO-Link master param eterization tool

46

V19-G-B K2M-PUR-UV1-G

Adapter cable for offli ne parameterization M12 x 1, 8-pin to

M12 x 1, 4-pin, length 2 m

V1-G-BK5MPUR-UL

V19-G -BK5M PUR-IEC

V1-G-BK10M PUR-UL

V19-GBK10M-PURIEC

V1-G-BK15M PUR-U L

239596 2019-09

Page 48

LGS Series

Appendix

Desi gnation Description

IO Device Description Device d escrip tion on how to operate and control automation

IO Device Description

Interpreter

light grids via an IO -Link master

(available as a download on the product page)

IO Device Description interpreter and device type manag er

for use via IO Device Description within an FDT environment

10.6 Parameterizing the light grid

Parameterizing the light grid using a flow chart.

239596 2019-09

47

Page 49

Press menu button

Q Object pictogram flashes fast

Press menu button

Place object

in beam path

Press OK Button

H1 pictogram flashes fast

Place object

in beam path

Press OK ButtonPress menu button

H2 pictogram flashes fast

Press menu button

Place object

in beam path

Press OK Button

H3 Pictogram flashes fast

Place object

in beam path

Press OK ButtonPress menu button

no settings

Teach an object

Object has been taught

Teaching height

of object

no settings

Height of object

has been taught

no settings

Teaching height

of object

Height of object

has been taught

Teaching height

of object

Height of object

has been taught

no settings

LGS Series

Appendix

Figure 10.4 Parameterizing the l ight grid using a fl ow chart, left page

48

239596 2019-09

Page 50

LGS Series

floating = LED long light duration / short break

fixed = LED short light duration / long break

active = LED long light duration / short break

disabled = LED short light duration / long break

active = LED long light duration / short break

disabled = LED short light duration / long break

no settings

no settings

no settings

Press menu button

2nd level

End of parameterization

2nd level pictogram flashes fast

Press menu button

Object tolerance pictogram

flashes fast

Press menu button

changed

change

changed

Press OK button

Object position pictogram

flashes fast

Press menu button

Selection

floating

or

fixed

change

changed

Press OK Button

Beam crossover pictogram

flashes fast

change

Beam crossover

activate or deactivate

Press OK Button

Object tolerance

activate or deactivate

Press OK Button

Appendix

Figure 10.5 Paramete riz ing the light grid us ing a flow chart, rig ht page

239596 2019-09

49

Page 51

Sub ject to modifica tions

Cop yrigh t P EPPERL+F UCHS • Prin ted in Germany

www.pepperl-fuchs.com

FACTORY AUTOMATION –

SENSING YOUR NEEDS

Worldwide Headquarters

Pepperl+Fuchs Group

68307 Mannheim · Germany

Tel. +49 621 776-0

E-mail: info@de.pepperl-fuchs.com

USA Headquarters

Pepperl+Fuchs Inc.

Twinsburg, Ohio 44087 · USA

Tel. +1 330 4253555

E-mail: sales@us.pepperl-fuchs.com

Asia Pacific Headquarters

Pepperl+Fuchs Pte Ltd.

Company Registration No. 199003130E

Singapore 139942

Tel. +65 67799091

E-mail: sales@sg.pepperl-fuchs.com

23959 6 DOCT-2493F

09/2019

Loading...

Loading...