Page 1

ISO9001

PROCESS AUTOMATION

TECHNICAL INFORMATION

Level Probe LGC2

Hydrostatic Level

Measurement

Page 2

Level Probe LGC2

With regard to the supply of products, the current issue of the following document is applicable:

The General Terms of Delivery for Products and Services of the Electrical Industry,

published by the Central Association of the Electrical Industry (Zentralverband Elektrotechnik und

Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the supplementary clause:

"Expanded reservation of proprietorship".

Application

The device is a pressure sensor for hydrostatic level measurement.

Pepperl+Fuchs offers three different versions of the device:

• Device with a stainless steel housing, external diameter of 22 mm (0.87 inch):

This version is excellently suited to drinking water applications and for use in bore holes and wells with

small diameters

• Device with a stainless steel housing, external diameter of 42 mm (1.65 inch):

Heavy-duty version and easy to clean thanks to flush-mounted process isolating diaphragm, ideally

suited to wastewater and wastewater treatment plants

• Device with plastic insulation, external diameter of 29 mm (1.14 inch):

Robust version for use in salt water and excellently suited to applications on ships (e. g. ballast water

tanks)

Your benefits

• High resistance to overload

• High-precision, robust ceramic measuring cell with long-term stability

• Climate proofed sensor thanks to completely potted electronics and 2-filter pressure compensation

system

• Simultaneous measurement of level and temperature with optionally integrated Pt100 resistance

thermometer

• Accuracy

• Standard reference accuracy ±0.2 %

• Plantinum version ±0.1 %

• Automatic density compensation to increase accuracy

• Usage in drinking water: KTW, NSF, ACS

• Approvals: ATEX, FM, CSA

• Extensive range of accessories provides complete measuring point solutions

Page 3

Level Probe LGC2

Content

1 Important Document Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Terms and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Turn down calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 Function and System Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Device Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 Measuring Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3 Measuring System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.4 Communication Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5 System Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3 Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1 Measured Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2 Measuring Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3 Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1 Output Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2 Signal Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3 Maximum Load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5 Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1 Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2 Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3 Current Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.4 Connecting the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.5 Terminals in the Terminal Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.6 Probe Connection (Extension Cable) . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.7 Cable Resistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.8 Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.9 Residual Ripple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2017-02

3

Page 4

Level Probe LGC2

Content

6 Performance Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1 Reference Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.2 Reference Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.3 Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.4 Long-Term Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.5 Influence of Medium Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.6 Warm-up Period. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.7 Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

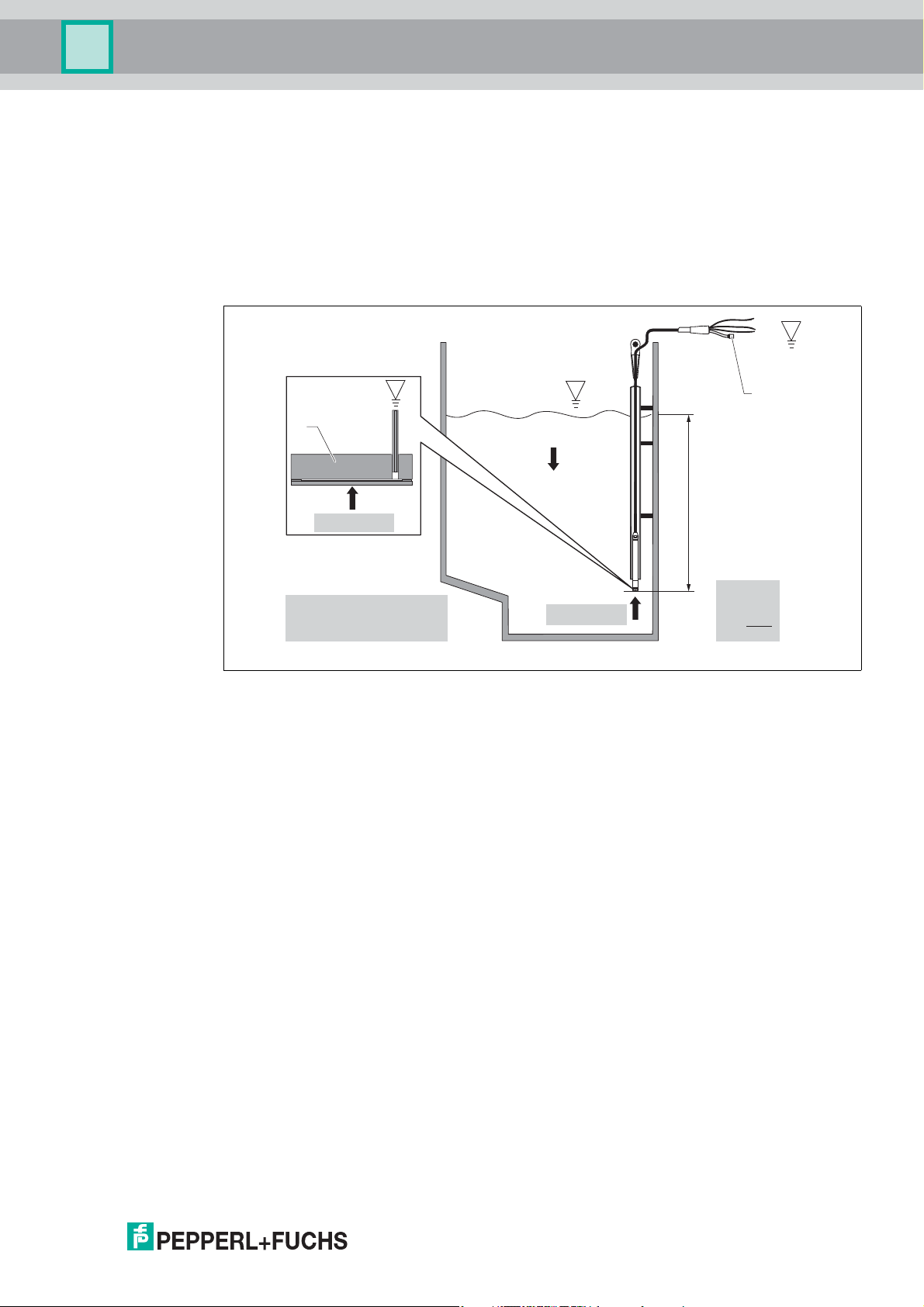

7 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.1 Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.2 Additional Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.3 Cable Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.4 Technical Data for Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.5 Cable Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.6 Cable Shortening Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8 Ambient Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.1 Ambient Temperature Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.2 Storage Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.3 Degree of Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.4 Electromagnetic Compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.5 Surge Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9 Process Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.1 Medium Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.2 Medium Temperature Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10 Mechanical Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.1 Dimensions of the Level Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.2 Dimensions of the Suspension Clamp . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.3 Dimensions of Cable Mounting Screw . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.4 Dimensions of Terminal Box IP66, IP67 with Filter . . . . . . . . . . . . . . . 36

4

2017-02

Page 5

Level Probe LGC2

Content

10.5 Dimensions of the HUT Temperature Head Transmitter . . . . . . . . . . 37

10.6 Terminal Box with Integrated HUT Temperature Head Transmitter . 37

10.7 Additional Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

10.8 Testing Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

10.9 Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

10.10 Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

11 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

12 Certificates and Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

12.1 CE Mark. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

12.2 Approvals for hazardous area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

12.3 Potable Water Approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

12.4 Other Standards and Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

12.5 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

12.6 Calibration, Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

12.7 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

13 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

13.1 Product Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

13.2 Scope of Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

13.3 Configuration Data Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

14 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

15 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

15.1 Technical Information (TI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

15.2 Brief Instructions (KA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

15.3 Manual (BA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

15.4 Instruction Manuals (SI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

15.5 Potable Water Approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

16 Registered Trademarks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

2017-02

5

Page 6

Level Probe LGC2

Important Document Information

1 Important Document Information

1.1 Document Conventions

1.1.1 Symbols Used

This document contains symbols for the identification of warning messages and of informative

messages.

Warning Messages

You will find warning messages, whenever dangers may arise from your actions. It is

mandatory that you observe these warning messages for your personal safety and in order to

avoid property damage.

Depending on the risk level, the warning messages are displayed in descending order as

follows:

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants, or result in

their complete failure.

Informative Symbols

Note!

This symbol brings important information to your attention.

Action

This symbol indicates a paragraph with instructions. You are prompted to perform an action or

a sequence of actions.

2017-02

6

Page 7

Level Probe LGC2

)

*

Important Document Information

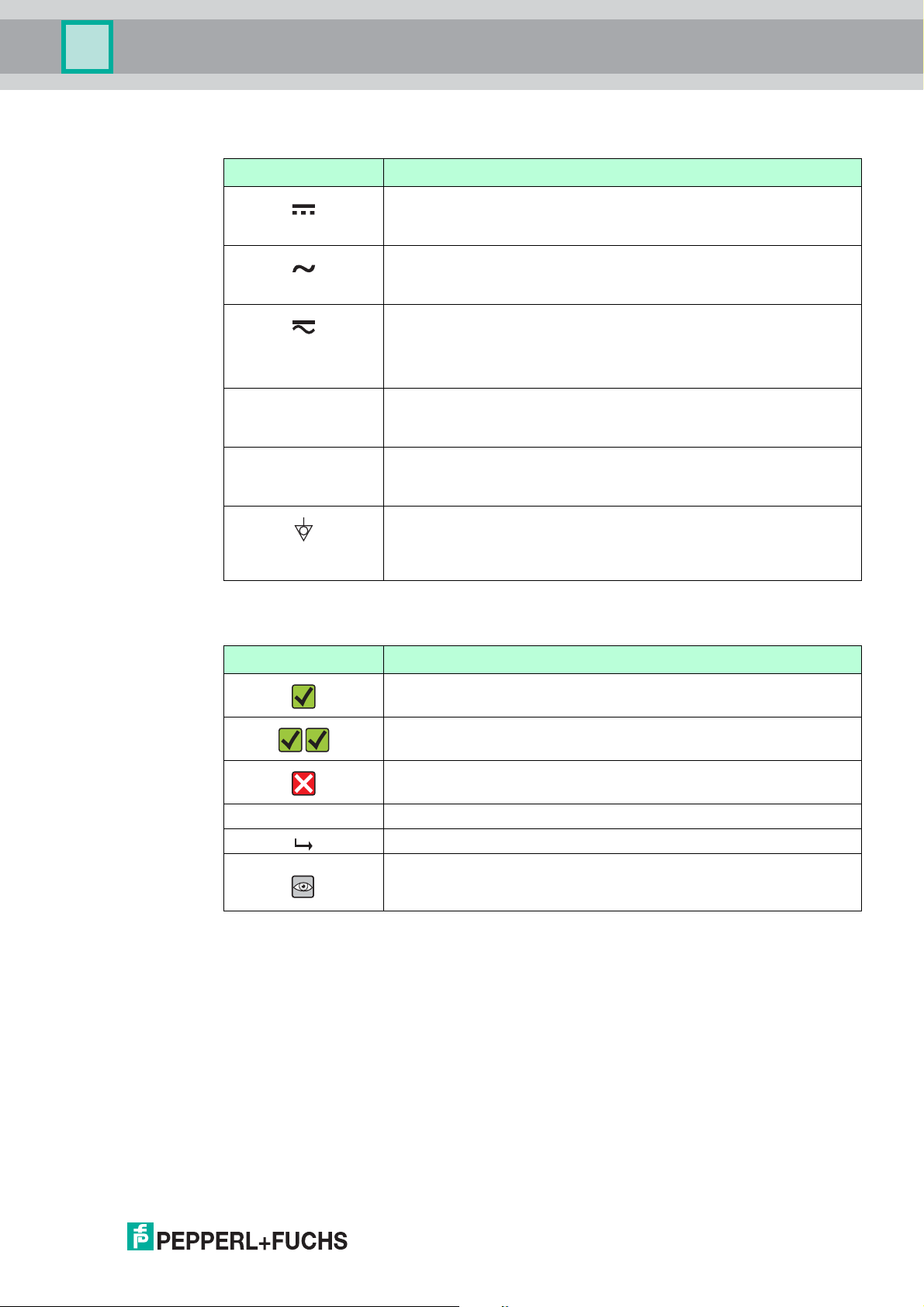

1.1.2 Electrical symbols

Symbol Meaning

Table 1.1

Direct current

A terminal to which DC voltage is applied or through which direct

current flows.

Alternating current

A terminal to which alternating voltage is applied or through which

alternating current flows.

Direct current and alternating current

• A terminal to which alternating voltage or DC voltage is applied.

• A terminal through which alternating current or direct current

flows.

Ground connection

A grounded terminal which, as far as the operator is concerned, is

grounded via a grounding system.

Protective ground connection

A terminal which must be connected to ground prior to establishing

any other connections.

Equipotential connection

A connection that has to be connected to the plant grounding

system: This may be a potential equalization line or a star grounding

system depending on national or company codes of practice.

1.1.3 Symbols for certain types of information

Symbol Meaning

Allowed

Indicates procedures, processes or actions that are allowed.

Preferred

Indicates procedures, processes or actions that are preferred.

Forbidden

Indicates procedures, processes or actions that are forbidden.

1., 2., 3. ... Series of steps

Result of a sequence of actions

Visual check

Table 1.2

2017-02

7

Page 8

Level Probe LGC2

URL OPLMWP

LRL

0

p

LRV

URV

1

2

3

4

Important Document Information

1.1.4 Symbols in graphics

Symbol Meaning

1, 2, 3 ... Item numbers

,…,1. 2. 3.

A, B, C, ... Views

A-A, B-B, C-C, ... Sections

-

.

Table 1.3

1.2 Terms and Abbreviations

Series of steps

Hazardous area

Indicates a hazardous area.

Safe area (non-hazardous area)

Indicates a non-hazardous location.

Figure 1.1

8

2017-02

Page 9

Level Probe LGC2

Important Document Information

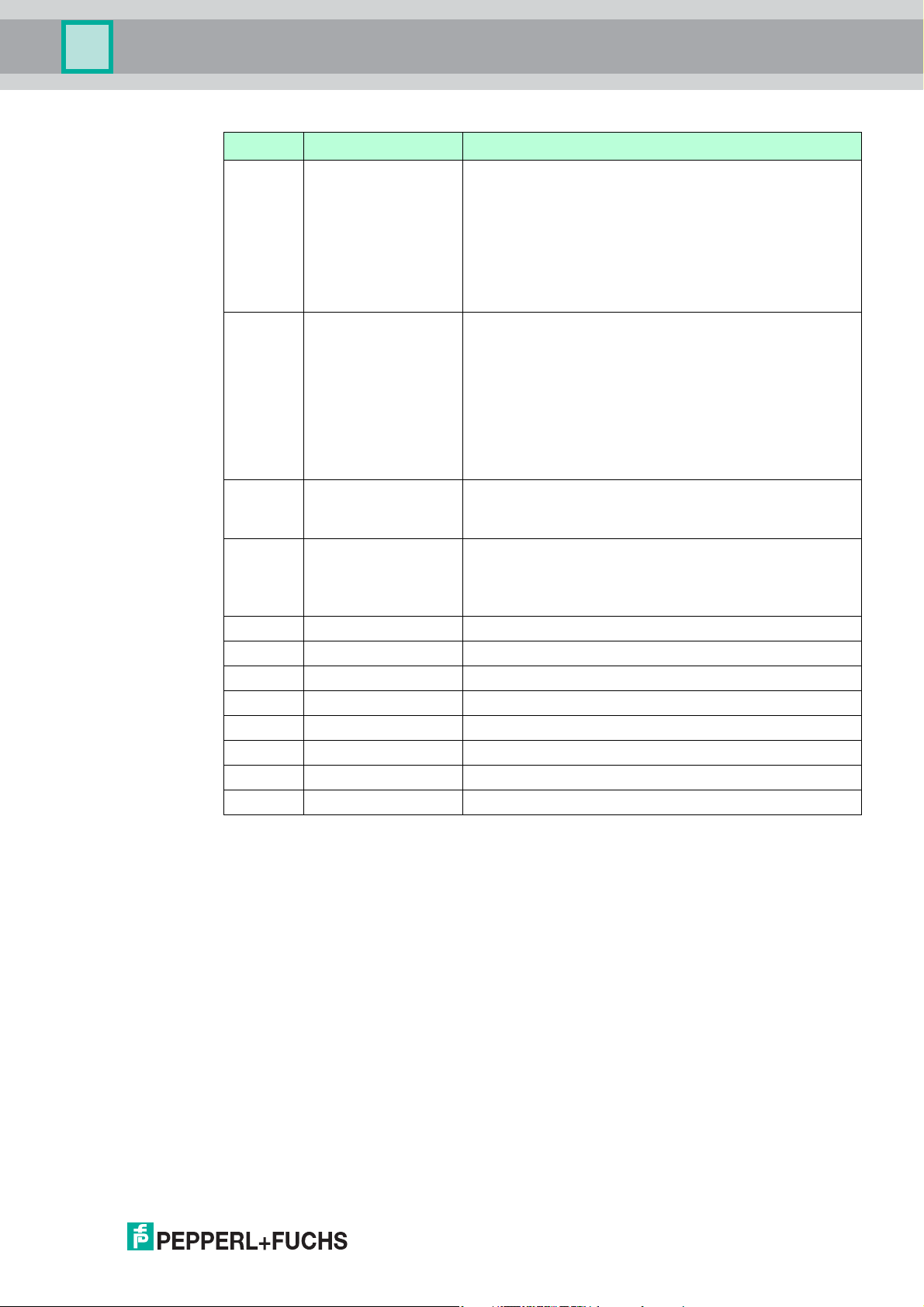

Position Terms/abbreviations Explanation

1 OPL The OPL (over pressure limit = sensor overload limit) for

2 MWP The MWP (maximum working pressure) for the sensors

3 Maximum sensor

measuring range

4 Calibrated/adjusted

span

p – Pressure

– LRL Lower range limit

– URL Upper range limit

– LRV Lower range value

– URV Upper range value

– TD (Turn down) Turn down: Example see the following section.

– PE Polyethylene

– FEP Fluorinated ethylene propylene

Table 1.4

the measuring device depends on the lowest-rated

element, with regard to pressure, of the selected

components, i. e. the process connection has to be taken

into consideration in addition to the measuring cell. Also

observe pressure-temperature dependency. For the

relevant standards and additional notes, see the

"Pressure specifications" section.

The OPL may only be applied for a limited period of time.

depends on the lowest-rated element, with regard to

pressure, of the selected components, i. e. the process

connection has to be taken into consideration in addition

to the measuring cell. Also observe pressuretemperature dependency. For the relevant standards

and additional notes, see the "Pressure specifications"

section.

The MWP may be applied at the device for an unlimited

period. The MWP can also be found on the nameplate.

Span between LRL and URL

This sensor measuring range is equivalent to the

maximum calibratable/adjustable span.

Span between LRV and URV

Factory setting: 0 to URL

Other calibrated spans can be ordered as customized

spans.

2017-02

9

Page 10

Level Probe LGC2

LRV

URLURV

LRL

1 = 2

3

Important Document Information

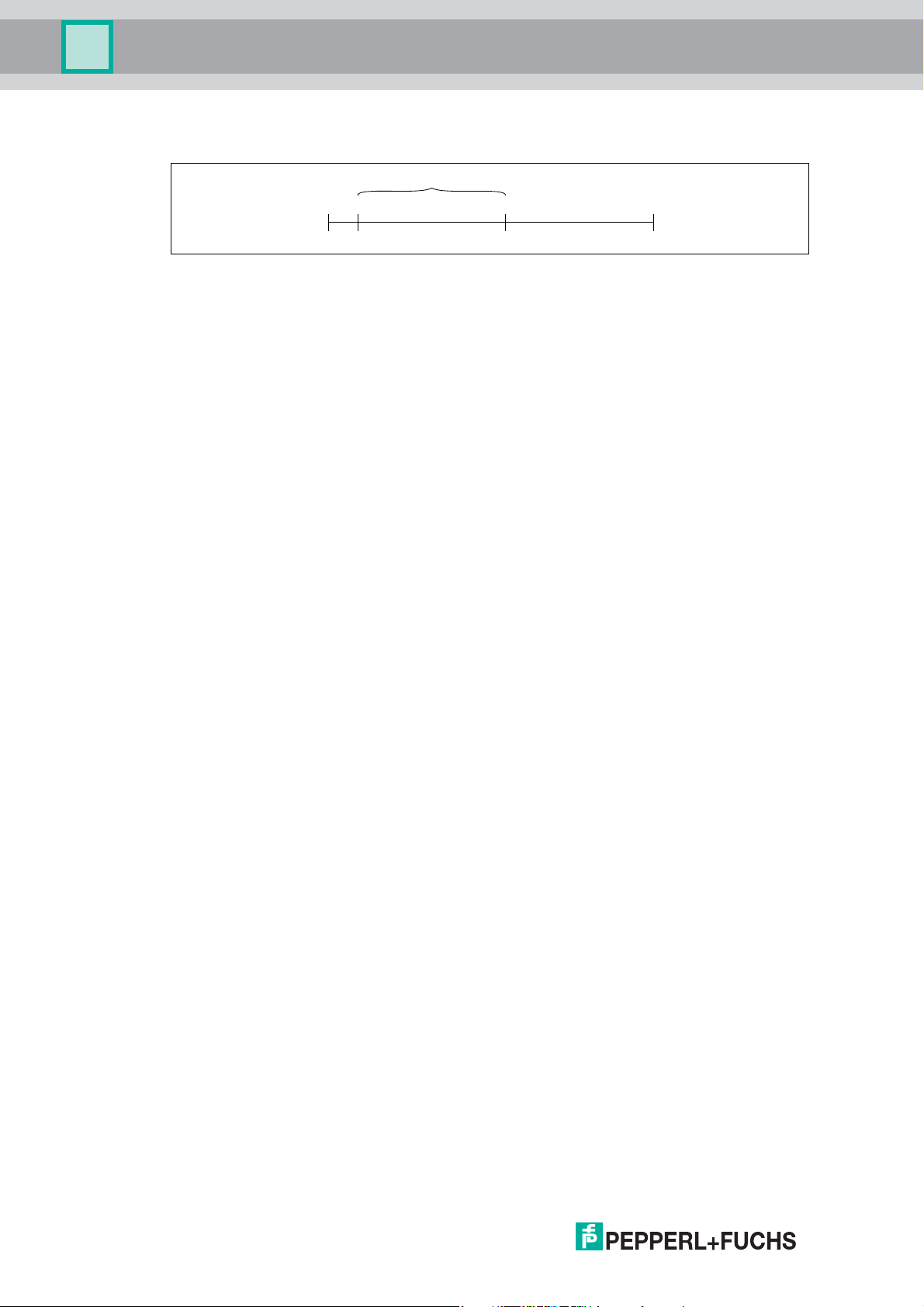

1.3 Turn down calculation

Figure 1.2

1 Calibrated/adjusted span

2 Zero point-based span (4 to 20 mA analog: customer-specific span can only be set at the

factory when ordered)

3 Upper range value

Example

• Sensor: 10 bar (150 psi)

• Upper range value (URL) = 10 bar (150 psi)

• Calibrated/adjusted span: 0 to 5 bar (0 to 75 psi)

• Lower range value (LRV) = 0 bar (0 psi)

• Upper range value (URV) = 5 bar (75 psi)

TD = URL/(URV – LRV)

TD = 10 bar (150 psi)/(5 bar (75 psi) – 0bar (0psi)) = 2

In this example, the TD is 2:1. This span is based on the zero point.

10

2017-02

Page 11

Level Probe LGC2

Function and System Design

2 Function and System Design

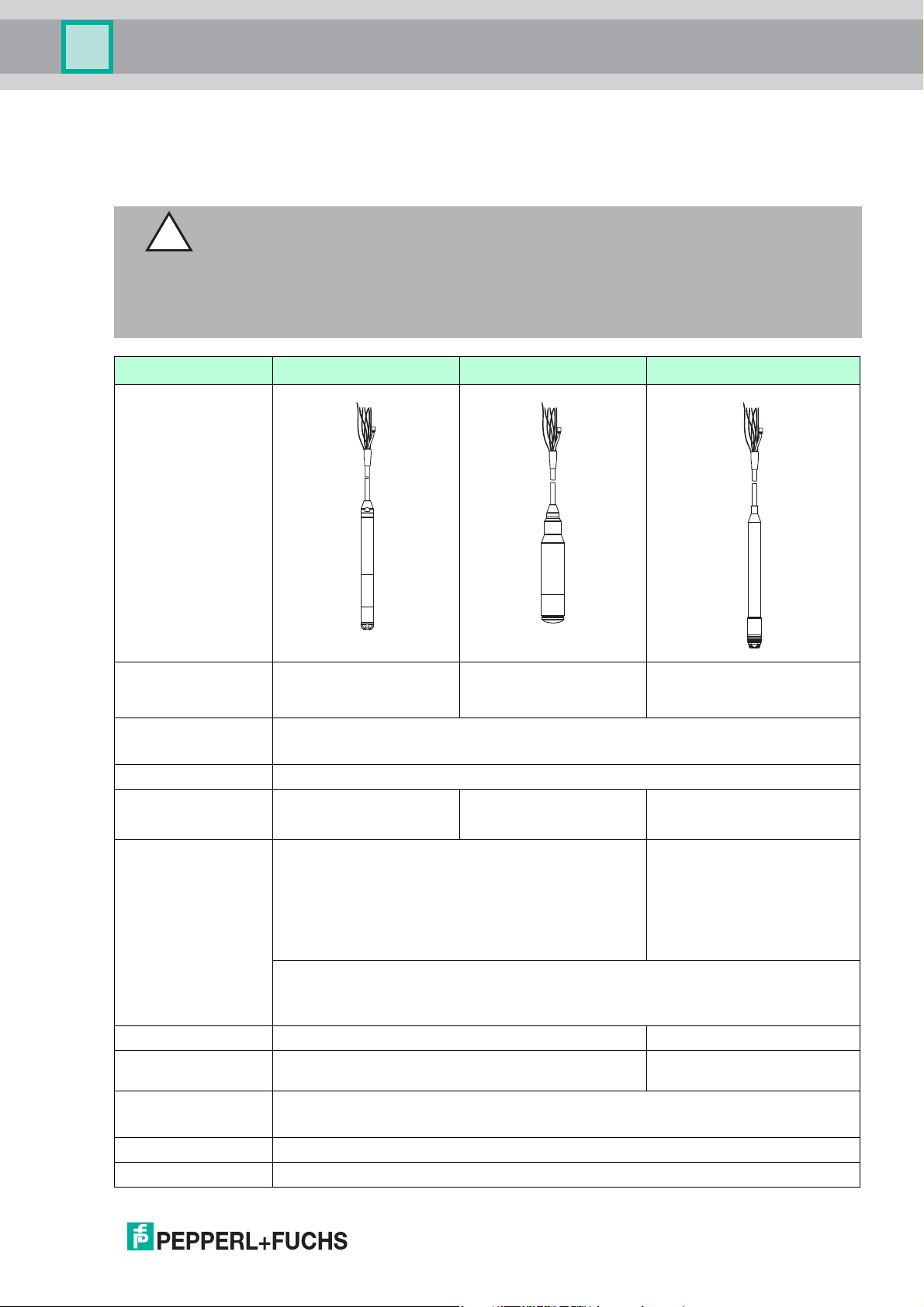

2.1 Device Versions

Caution!

Gas loss when using the device in biogas plants

The device is not suitable for use in biogas plants since the gases can diffuse through the

elastomers (seals, probe connection).

Use the devices LHCR-51, LHCS-51 for applications involving biogas.

Outer diameter 22 mm (0.87 inch) 42 mm (1.65 inch) max. 29 mm (1.14 inch)

Field of application Hydrostatic level

Process connection

(extension cable)

Probe connection PE, FEP

Seals •FKM Viton

Measuring ranges • Relative pressure: 0 to 0.1 bar (0 to 1.5 psi) to

Overload to 40 bar (600 psi) to 25 bar (375 psi)

Process temperature

range

Reference accuracy • ±0.2 % of the set span

Supply voltage 10.5 to 35 V DC, Ex: 10.5 to 30 V DC

Output 4 to 20 mA Analog

2017-02

measurement in deep

wells e. g. drinking water

• Suspension clamp

• Cable mounting screw with G1-1/2A thread or NPT1-1/2 thread

•EPDM

0 to 20 bar (0 to 300 psi)

• Absolute pressure: 0 to 2 bar (0 to 30 psi) to

0 to 20 bar (0 to 300 psi)

• Customer-specific measuring ranges; factory-calibrated.

• The following output units can be configured: %, mbar, bar, kPa, MPa, mm H2O,

m H2O, inch H2O, foot H2O, psi and numerous level units.

-10 to +70 °C (+14 to +158 °F) 0 to +50 °C (+32 to +122 °F)

• optional: ±0.1 % of the set span (Platinum version)

1

Hydrostatic level

measurement in

wastewater

FKM Viton •FKM Viton

Hydrostatic level

measurement in saltwater

•EPDM

• Relative pressure:

0 to 0.1 bar (0 to 1.5 psi)

to 0 to 4 bar (0 to 60 psi)

• Absolute pressure:

0 to 2 bar (0 to 30 psi) to

0 to 4 bar (0 to 60 psi)

1

11

Page 12

Level Probe LGC2

Function and System Design

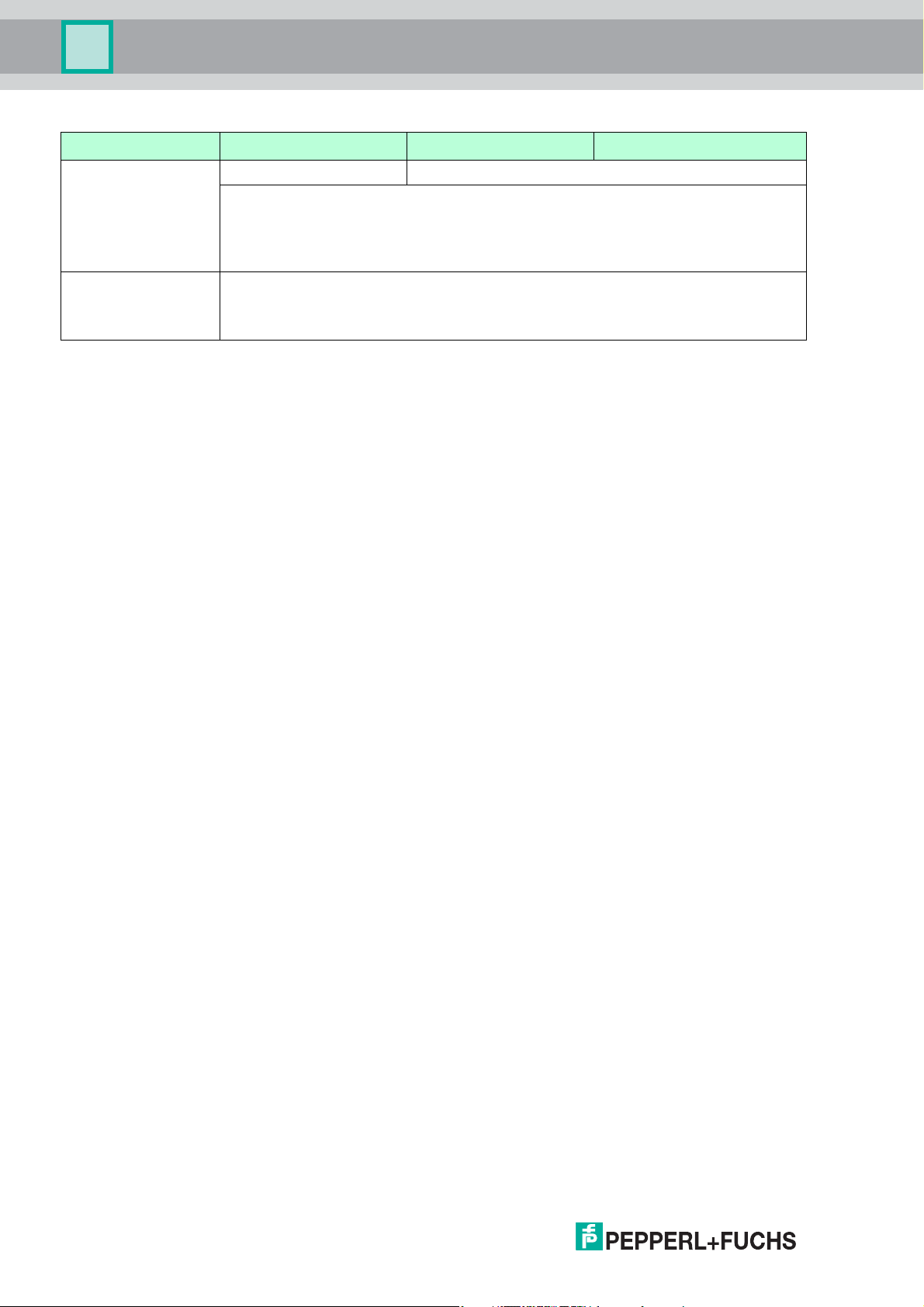

Outer diameter 22 mm (0.87 inch) 42 mm (1.65 inch) max. 29 mm (1.14 inch)

Options Drinking water approval –

• Wide range of approvals, including ATEX, FM, CSA

• Numerous accessories

• Integrated Pt100 resistance thermometer and HUT temperature head transmitter

(4 to 20 mA)

Specialties • High-precision, robust ceramic measuring cell with long-term stability

• Automatic density compensation

• Customer-specific cable marking

1

Recommended for drinking water applications, not suitable for use in hazardous areas.

12

2017-02

Page 13

Level Probe LGC2

.

.

2

1

ρ x g

h ~ p

h =

p

p

hydr

p

atm

p

atm

p = p +

atm hydr.

p

h

p = p + p

atm hydr

p

atm

Rel.: p = (p + p ) -

sens atm hydr.

Abs.: p = (p +

sens atm hydr.

p)

p

atm

Function and System Design

2.2 Measuring Principle

The ceramic measuring cell is a dry measuring cell i. e. the pressure acts directly on the robust,

ceramic process isolating diaphragm of the device. Changes in air pressure are guided via a

pressure compensation tube through the extension cable to the rear of the ceramic process

isolating diaphragm and are compensated for. A pressure-dependent change in capacitance,

caused by the movement of the process isolating diaphragm, is measured at the electrodes of

the ceramic carrier. The electronics unit then converts this to a signal that is proportional to the

pressure and linear to the level.

Figure 2.1

1 Ceramic measuring cell

2 Pressure compensation tube

h Height level

p Total pressure = atmospheric pressure + hydrostatic pressure

r Density of the medium

g Acceleration due to gravity

P

hydr.

P

atm

P

sens

Temperature measurement with optional Pt100 resistance

thermometer

For simultaneous measurement of level and temperature, Pepperl+Fuchs offers the device

with an optional 4-wire Pt100 resistance thermometer. The Pt100 ressistance thermometer is

categorized as Accuracy Class B as per DIN/EN 60751.

Hydrostatic pressure

Atmospheric pressure

Pressure displayed on the sensor

1

2017-02

1

Not for use in hazardous areas.

13

Page 14

Level Probe LGC2

ON

1

2

E

-+-

%

Function and System Design

Temperature measurement with optional Pt100 resistance thermometer

and HUT temperature head transmitter

To convert the temperature signal to an analog, scalable 4 to 20 mA output signal,

Pepperl+Fuchs also offers the HUT temperature head transmitter. Ordering information:

product structure, feature "Accessories", option "XP".

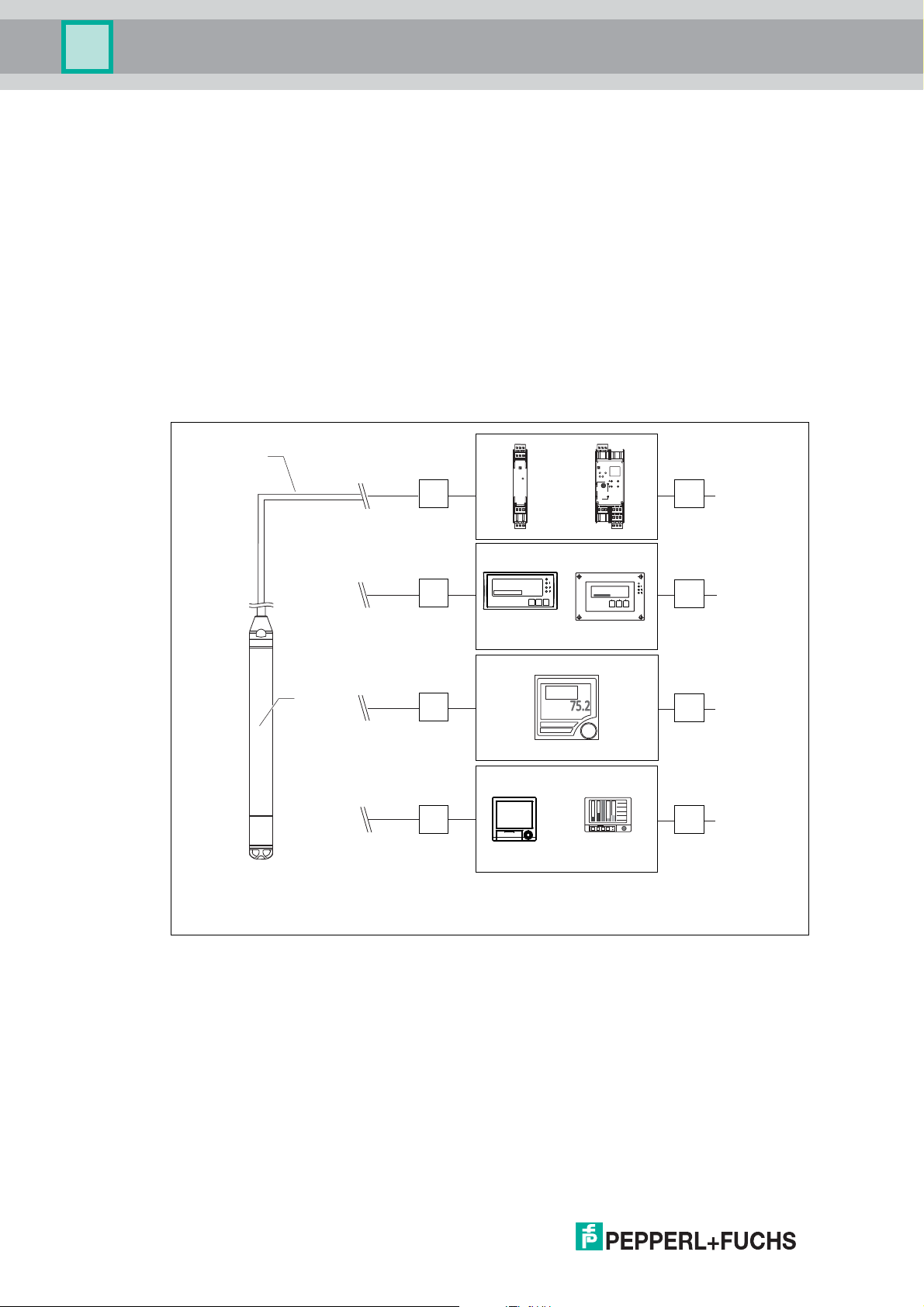

2.3 Measuring System

Application Examples

As standard, the complete measuring system consists of a level probe and a transmitter power

supply unit with a supply voltage of 10.5 to 30 V DC (hazardous areas) or 10.5 to 35 V DC

(non-hazardous areas).

Possible measuring point solutions with a signal converter and evaluation device:

2

1

A

3

3

2

1

5

6

4

KFD2-CR4-1

PWR

9107

12

11

13 15

14

B

ON

3

132465

KFD2-CRG2-

1.D

PWR

FLT

12

OUT

RS232

9137

8

15

14

19 21

20

12401.5

ESC

OK

121610

11

18

17

22 24

23

E

-+-

4

5

ON

1

2

4

5

C

1

3

4

5

D

4

5

Figure 2.2

3

1 Level probe LGC

2 4to20mA

3 and 4 Surge protection device, e. g. for DIN mounting rail mounting, selection in accordance

with supply voltage, not for use in hazardous areas

5 Power supply

14

1

Not for use in hazardous areas.

2017-02

Page 15

Level Probe LGC2

E

F

2

3

4

3

4

5

5

5

6

6

6

7

7

7

1

2

5

12401.5

E

-+-

ON

1

2

ON

1

2

E

-+-

ON

1

2

E

-+-

ONON

1

2

E

-+-

ONON

1

2

E

-+-

%

ESC

OK

KFD2-CRG2-

1.D

RS232

PWR

12

FLT

OUT

19 21

15

9137

20

14

8

22 24

18

121610

23

17

11

132465

ESC

OK

KFD2-CRG2-

1.D

RS232

PWR

12

FLT

OUT

19 21

15

9137

20

14

8

22 24

18

121610

23

17

11

132465

Function and System Design

A: Easy and cost-effective measuring point solution: power supplied to the device in

hazardous and non-hazardous areas via a transmitter power supply. Power supply and

additional control of two appliances, such as pumps, via a trip amplifier with local display.

B: An evaluation device offers power supply, local display and two switch outputs.

C: If several pumps are used, the pump service life can be prolonged by alternate switching.

With alternating pump control, the pump which was out of service for the longest period of time

is switched on. Use a suitable evaluation device for this application.

D: State-of-the-art recording technology with graphic display recorders for documentation,

monitoring, visualization and archiving purposes.

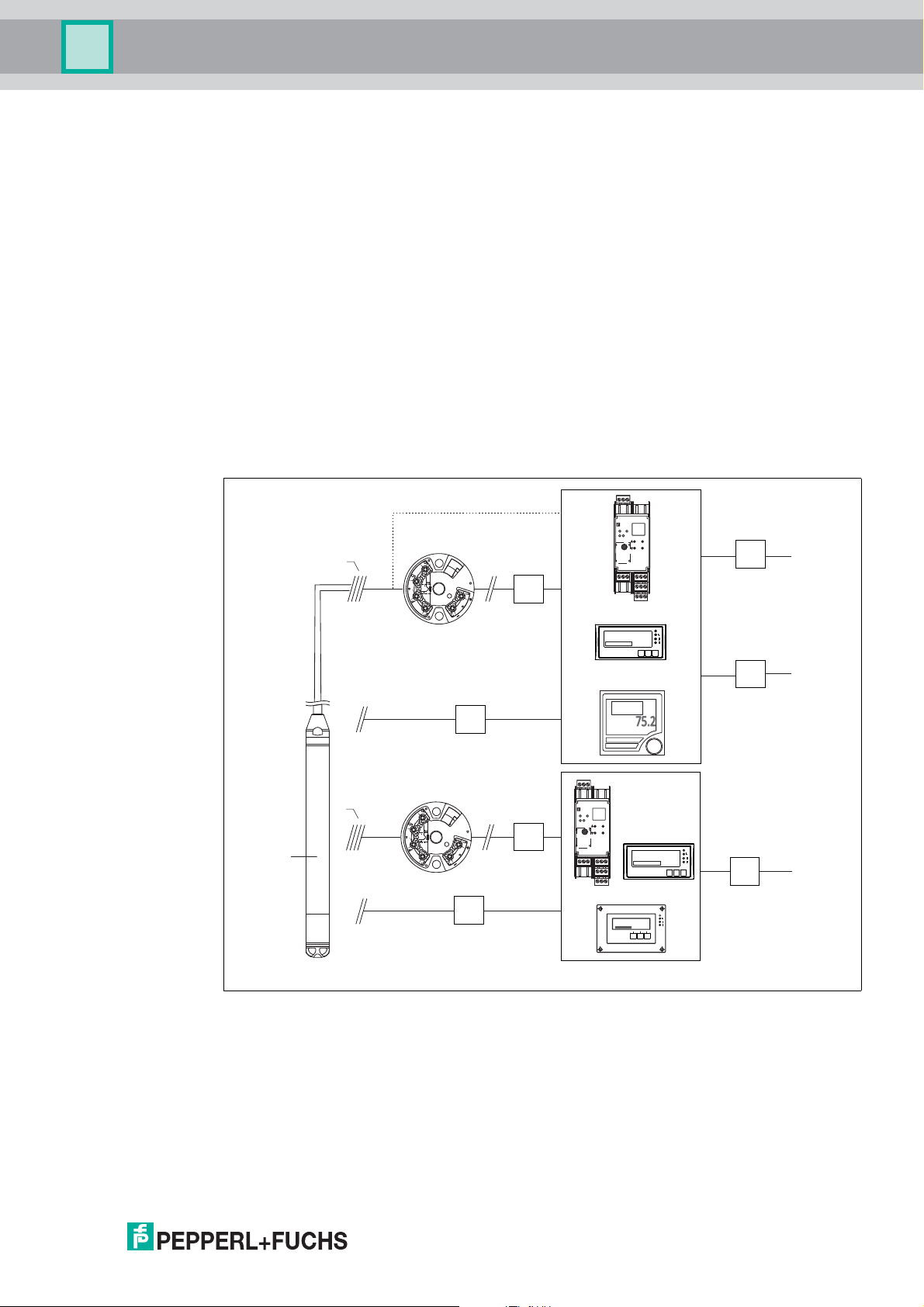

Application Examples with the Pt100 Resistance Thermometer

As standard, the complete measuring system consists of a level probe and a transmitter power

supply unit with a supply voltage of 10.5 to 30 V DC (hazardous areas) or 10.5 to 35 V DC

(non-hazardous areas).

Possible measuring point solutions with a signal converter and evaluation device:

Figure 2.3

2017-02

15

Page 16

Level Probe LGC2

Function and System Design

1 Level probe LGC

2 Connection for integrated Pt100 in the device

3 Temperature for 4 to 20 mA

4 Level for 4 to 20 mA

5 Surge protection device, e. g. on the sensor side for field installation: for DIN mounting

rail mounting, selection in accordance with supply voltage, not for use in hazardous areas

6 Surge protection device, e. g. for DIN mounting rail mounting, selection in accordance

with supply voltage, not for use in hazardous areas

7 Power supply

E: If you wish to measure, display and evaluate the temperature as well as the level, e. g. to

monitor the temperature in fresh water for the purpose of detecting temperature limits for germ

formation, the options available to you include the following: The optionally available HUT

temperature head transmitter can convert the Pt100 signal into a 4 to 20 mA signal and

transfer it to any commonly used evaluation device. Some evaluation devices also offer a

direct input for the Pt100 signal.

F: If you wish to record and evaluate the level and temperature measured value with one

device, use evaluation devices with two inputs. It is even possible to mathematically link the

input signals with this unit.

2.4 Communication Protocol

4to20mA Analog

Ordering information: product structure, feature "Electrical output", option "I2"

2.5 System Integration

The device can be given a tag name.

Ordering information: product structure, feature "Marking", option "1Z"

16

2017-02

Page 17

Level Probe LGC2

Input

3Input

3.1 Measured Value

Level probe and Pt100 (optional)

• Hydrostatic pressure of a liquid

• Pt100: temperature

HUT temperature head transmitter (optional) for device with

4 to 20 mA Analog

Temperature

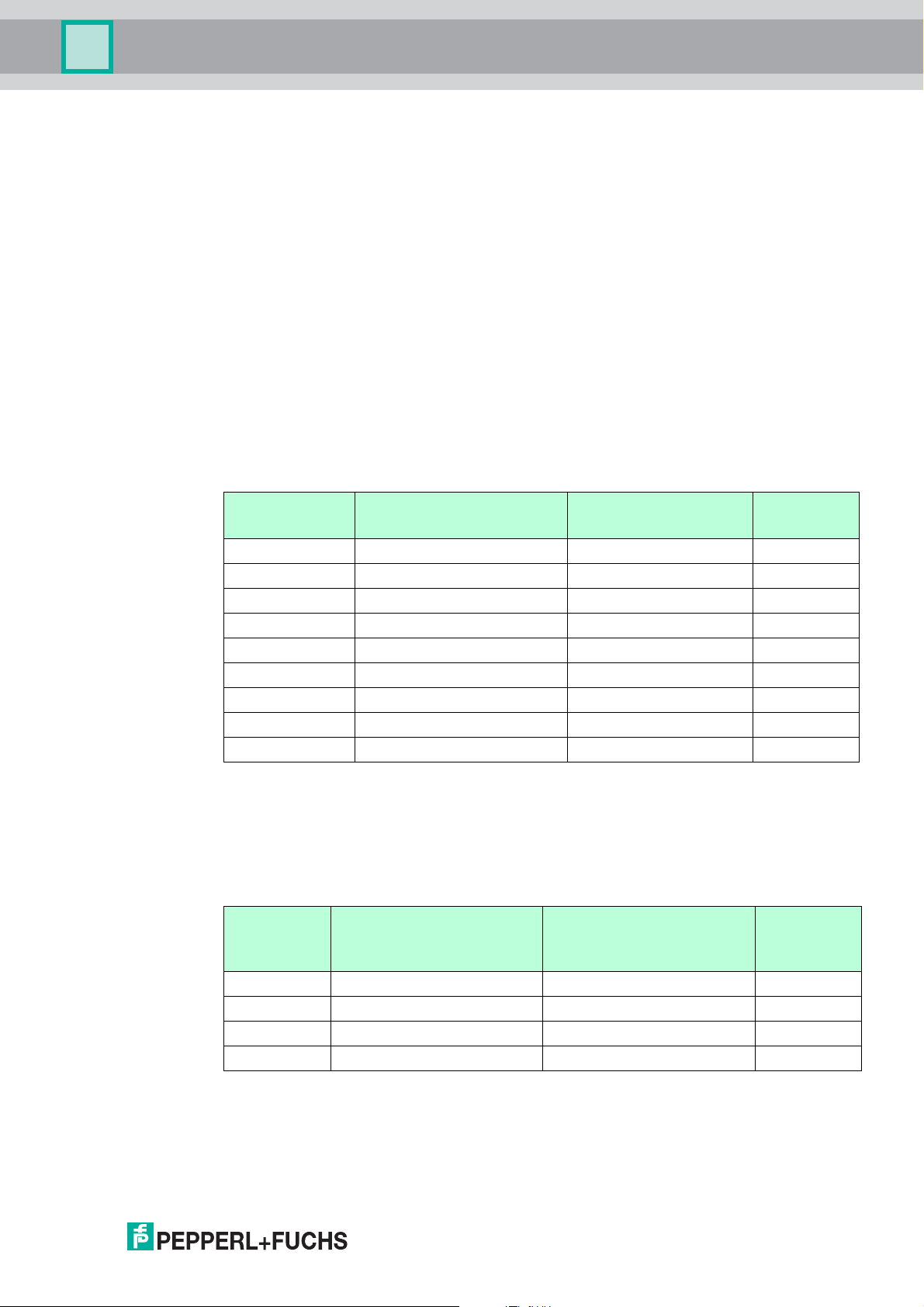

3.2 Measuring Range

• Customer-specific measuring ranges or calibration that has been preset in the factory

• Temperature measurement of -10 to +70 °C(+14to+158°F) with Pt100 (optional)

Relative pressure

Measuring range

[bar (psi)]

0.1 (1.5) 0.01 (0.15) 0.3 (4.5) R1A

0.2 (3.0) 0.02 (0.3) 0.3 (4.5) R1C

0.4 (6.0) 0.04 (1.0) 0 R1D

0.6 (9.0) 0.06 (1.0) 0 R1E

1.0 (15.0) 0.1 (1.5) 0 R2A

2.0 (30.0) 0.2 (3.0) 0 R2C

4.0 (60.0) 0.4 (6.0) 0 R2D

10.0 (150)

20.0 (300)

Table 3.1

3

3

Lowest calibratable span

[bar (psi)]

1.0 (15) 0 R3A

2.0 (30) 0 R3C

1

Vacuum resistance

[bar

abs

(psi

abs

Option

2

)]

1

Largest turn down that can be configured at the factory: 10:1, higher turn down can be configured on request.

2

See ordering information: product structure, feature "Measuring range".

3

These measuring ranges are not available for the special version with plastic insulation, external diameter of

29 mm (1.14 inch).

Absolute pressure

Measuring

range

Lowest calibratable span

[bar (psi)]

1

Vacuum resistance

[bar

abs

(psi

abs

)]

[bar (psi)]

2.0 (30.0) 0.2 (3.0) 0 A2C

4.0 (60.0) 0.4 (6.0) 0 A2D

10.0 (150)

20.0 (300)

Table 3.2

1

Largest turn down that can be configured at the factory: 10:1, higher turn down can be configured on request.

2

See ordering information: product structure, feature "Measuring range".

3

These measuring ranges are not available for the special version with plastic insulation, external diameter of

29 mm (1.14 inch).

2017-02

3

1.0 (15) 0 A3A

3

2.0 (30) 0 A5A

Option

2

17

Page 18

Level Probe LGC2

Input

3.3 Input Signal

Level probe and Pt100 (optional)

• Change in capacitance

• Pt100: change in resistance

HUT temperature head transmitter (optional) for device with

4...20mAAnalog

Pt100 resistance signal, 4-wire

18

2017-02

Page 19

Level Probe LGC2

413

630

195

1065

35

20

255

15

847

30

3020 25158

35

10

1080

880

480

280

680

80

R

Lmax

–2x0.09

xL–R

U–10.5 V

23 mA

m

–

R

U

–

8 V

0.025 A

R

Lmax

add

add

10.

R

[]

U

[ ]

V

A

B

R

[]

U

[]

V

Output

4Output

4.1 Output Signal

Level probe and Pt100 (optional)

• 4 to 20 mA Analog, 2-wire for hydrostatic pressure measured value.

Ordering information: product structure, feature "Electrical output", option "I2".

• Pt100: temperature-dependent resistance value

HUT temperature head transmitter (optional) for device with

4 to 20 mA Analog

4 to 20 mA Analog for temperature measured value, 2-wire

4.2 Signal Range

3.8 to 20.5 mA

4.3 Maximum Load

The maximum load resistance depends on the supply voltage (U) and must be determined

individually for each current loop, see formula and diagrams for device and temperature head

transmitter. The total resistance resulting from the resistances of the connected devices, the

connecting cable and, where applicable, the resistance of the probe connection may not

exceed the load resistance value.

Figure 4.1

A Load diagram of the device for estimating the load resistance. Additional resistances,

such as the resistance of the extension cable, have to be subtracted from the value

calculated as shown in the equation.

B Load diagram for HUT temperature head transmitter for estimating the load

resistance. Additional resistances must be subtracted from the value calculated as

R

Lmax

R

add

shown in the equation.

Max. load resistance []

Additional resistances such as resistance of evaluating device and/or display unit,

cable resistance []

U Supply voltage [V]

L Basic length of probe connection [m] (cable resistance per wire 0.09 /m)

2017-02

19

Page 20

Level Probe LGC2

Output

Note!

When using the measuring device in hazardous areas, installation must comply with the

corresponding national standards and regulations and the instruction manuals or installation or

control drawings (SI, ZD).

20

2017-02

Page 21

Level Probe LGC2

Supply

5Supply

Warning!

Danger to life from wrong connection of the device

The electrical safety of the device is not guaranteed.

When using the measuring device in a hazardous area, the relevant national standards and

guidelines as well as the instruction manuals (SI) or installation or control drawings (ZD) must

be adhered to. All data relating to explosion protection can be found in separate

documentation which is available on request. This documentation is supplied with the devices

as standard, see chapter 15.

5.1 Supply voltage

Level probe and Pt100 (optional)

• 10.5to35VDC (non-hazardous areas)

• 10.5to30VDC (hazardous areas)

HUT temperature head transmitter (optional) for device with

4 to 20 mA Analog

8to35VDC

5.2 Power Consumption

Level probe and Pt100 (optional)

• 0.805 W at 35 V DC (non-hazardous areas)

• 0.690 W at 30 V DC (hazardous areas)

HUT temperature head transmitter (optional) for device with

4 to 20 mA Analog

0.875 W at 35 V DC

5.3 Current Consumption

Level probe and Pt100 (optional)

• Max.current consumption: 23 mA

• Min. current consumption: 3.6 mA

HUT temperature head transmitter (optional) for device with

4 to 20 mA Analog

• Max. current consumption: 25 mA

• Min. current consumption: 3.5 mA

2017-02

21

Page 22

Level Probe LGC2

Supply

5.4 Connecting the Device

•Device

Reverse polarity protection is integrated into the device and the temperature head

transmitter. Changing the polarities will not result in damage to the devices.

• The cable must end in a dry room or a suitable terminal box. The terminal box (IP66/IP67)

with GORETEX

®

filter from Pepperl+Fuchs is suitable for outdoor installation. The terminal

box may be ordered as an accessory using the order code for the device, ordering

information: product structure, feature "Accessories", option "SP".

The electrical connection is made with the corresponding wires of the probe cable and with the

optional use of the terminal box and a power supply (e. g. transmitter power supply (see

chapter 2.3)).

Level probe and Pt100

AB

)

a

)

RD

BK

LGC

b

c

d

)

a

)

BK

RD

WH

LGC

b

c

d

YE BU

BR

e

Figure 5.1

A Level probe LGC

B Level probe and Pt100 resistance thermometer (not for use in hazardous areas), ordering

information, feature "Accessories", option "BN"

a Not for the level probe with external diameter of 29 mm (1.14 inch)

b 10.5 to 30 V DC (hazardous area), 10.5 to 35 V DC

c 4to20mA

d Resistance (R

)

L

e Pt100 resistance thermometer

22

2017-02

Page 23

Level Probe LGC2

RD BKWHYE

BU

BR

)

)

a

b

c

f

d

cd

g

6

5

4

3

2

1

e

LGC 4 ... 20 mA Analog

Supply

Level probe with Pt100 and HUT temperature head transmitter for device

with 4to20mAAnalog

Figure 5.2

a Not for the level probe with external diameter of 29 mm (1.14 inch)

b 10.5to35VDC

c 4to20mA

d Resistance (R

)

L

e Temperature head transmitter HUT (4 to 20 mA) (not for use in hazardous area)

f 8to35VDC

g Pt100 resistance thermometer

1to6 Terminal assignment

Ordering information:

Pt100 resistance thermometer: product structure, feature "Accessories", option "BN".

HUT temperature head transmitter: product structure, feature "Accessories", option "XP"

Wire colors

RD = red, BK = black, WH = white, YE = yellow, BU = blue, BR = brown

Connection data

Connection classification as per IEC 61010-1:

• Overvoltage category 1

• Pollution level 1

Connection data in the hazardous area

See relevant instruction manuals (SI, ZD).

2017-02

23

Page 24

Level Probe LGC2

Supply

5.5 Terminals in the Terminal Box

• Three terminals as standard in the terminal box. The terminal box can optionally be

ordered as an accessory.

• 4-terminal strip can be ordered as an accessory, cable cross section 0.08 to 2.5 mm

(28to14AWG)

Note!

The 4-terminal strip is not designed for use in hazardous areas incl. CSA General Purpose.

5.6 Probe Connection (Extension Cable)

• Overall external diameter: 8 mm (0.31 inch) ±0.25 mm (0.01 inch)

• Pressure compensation tube with PTFE filter: external diameter 2.5 mm (0.1 inch), internal

diameter 1.5 mm (0.06 inch)

Cross section

• Device: 3 x 0.2 mm2 (3 x 26 AWG) and pressure compensation tube with PTFE filter

• Level probe and Pt100 (optional): 7 x 0.2 mm

tube with PTFE filter

2

(7 x 26 AWG) and pressure compensation

2

5.7 Cable Resistance

per wire: 0.09 /m

5.8 Cable Specifications

Pepperl+Fuchs recommends using shielded, twisted-pair two-wire cables.

Note!

The probe cables are shielded for device versions with outer diameters of 22 mm (0.87 inch)

and 42 mm (1.65 inch).

Level probe and Pt100 (optional)

• Commercially available instrument cable

• Terminals, terminal box: 0.08 to 2.5 mm

HUT temperature head transmitter (optional) for device with

4 to 20 mA Analog

• Commercially available instrument cable

• Terminals, terminal box: 0.08 to 2.5 mm

• Transmitter connection: max. 1.75 mm

5.9 Residual Ripple

2

(28to14AWG)

2

(28to14AWG)

2

(15 AWG)

24

Level probe and Pt100 (optional)

No impact on the 4 to 20 mA signal up to ±5 % residual ripple within the permitted voltage

range.

HUT temperature head transmitter (optional)

Uss 5V at U 13 V, f

max.

=1kHz

2017-02

Page 25

Level Probe LGC2

Performance Characteristics

6 Performance Characteristics

6.1 Reference Conditions

Level probe and Pt100 (optional)

• As per IEC 60770

• Ambient temperature T

• Humidity = constant, in the range: 20 to 80 % r.F

•Ambient pressure p

• Position of measuring cell constant, vertical in the range ±1°

• Supply voltage constant: 21 V DC to 27 V DC

• Pt100: DIN EN 60770, T

HUT temperature head transmitter (optional) for device with

4 to 20 mA Analog

Calibration temperature +23 °C(+73°F) ±5K

= constant, in the range: +21 to +33 °C(+70to+91°F)

amb

= constant, in the range: 860 to 1060 mbar (12.47 to 15.37 psi)

amb

= +25 °C(+77°F)

amb

6.2 Reference Accuracy

Level probe and Pt100 (optional)

The reference accuracy comprises the non-linearity after limit point configuration, hysteresis

and non-reproducibility in accordance IEC 60770.

1

Standard version

Setting ±0.2 %

• to TD 5:1: < 0.2 % of set span

• from TD 5:1 to TD 20:1: ±(0.02 x TD + 0.1)

Platinum version

Setting ±0.1 % (optional)

• to TD 5:1: < 0.1 % of set span

• from TD 5:1 to TD 20:1: ±(0.02 x TD)

Class B as per DIN EN 60751

Pt100: max. ±1K

HUT temperature head transmitter (optional) for device with

4 to 20 mA Analog

• ±0.2 K

• With Pt100: max. ±0.9 K

:

2

:

1

Ordering information: product structure, feature "Reference accuracy", option "G".

2

2017-02

Ordering information: product structure, feature "Reference accuracy", option "D".

25

Page 26

Level Probe LGC2

Performance Characteristics

6.3 Resolution

Current output: 1 A

6.4 Long-Term Stability

Level probe and Pt100 (optional)

• 0.1 % of URL/year

• 0.25 % of URL/5 years

HUT temperature head transmitter (optional) for device with

4 to 20 mA Analog

0.1 K per year

6.5 Influence of Medium Temperature

• Thermal change in the zero output and the output span:

0to+30°C (+32 to +86 °F): <(0.15+0.15xTD)% of set span

-10 to +70 °C (+14 to +158 °F): < (0.4 + 0.4 x TD) % of set span

• Temperature coefficient (T

-10 to +70 °C (+14 to +158 °F): 0.1%/10K of URL

) of the zero output and the output span

K

6.6 Warm-up Period

Level probe and Pt100 (optional)

• Device: < 6 s

• Pt100: 20 m

HUT temperature head transmitter (optional) for device with

4 to 20 mA Analog

4s

6.7 Response Time

Level probe and Pt100 (optional)

• Device: 400 ms (T90 time), 500 ms (T99 time)

• Pt100: 160 s (T90 time), 300 s (T99 time)

26

2017-02

Page 27

Level Probe LGC2

-

OPEN

CLOSE

90°

90°

1

2

3

4

5

6

7

8

9

Installation

7Installation

7.1 Installation Instructions

Figure 7.1

1 Cable mounting screw can be ordered as an accessory

2 Terminal box can be ordered as an accessory

3 Bending radius of extension cable > 120 mm (4.72 inch)

4 Mounting clamp can be ordered as an accessory

5 Probe connection (extension cable), cable length

6 Guide tube

7 Level probe LGC

8 Additional weight can ordered be an accessory for the level probe with external diameter

of 22 mm (0.87 inch) and 29 mm (1.14 inch)

9 Protection cap

2017-02

27

Page 28

Level Probe LGC2

Installation

7.2 Additional Installation Instructions

• Sideways movement of the level probe can result in measuring errors. For this reason,

install the probe at a point free from flow and turbulence, or use a guide tube. The internal

diameter of the guide tube should be at least 1 mm (0.04 inch) greater than the external

diameter of the selected device.

• To avoid mechanical damage to the measuring cell, the device is equipped with a

protection cap.

• The cable must end in a dry room or a suitable terminal box. The terminal box from

Pepperl+Fuchs provides humidity and climatic protection and is suitable for installation

outdoors, see chapter 14.

• Cable length tolerance: < 5 m (16 foot): ±17.5 mm (0.69 inch); > 5 m (16 foot): ±0.2 %

• If the cable is shortened, the filter at the pressure compensation tube must be reattached.

Pepperl+Fuchs offers a cable shortening kit for this purpose, see chapter 14.

• Pepperl+Fuchs recommends using twisted, shielded cable.

• In shipbuilding applications, measures are required to restrict the spread of fire along cable

looms.

• The length of the extension cable depends on the intended level zero point. The height of

the protection cap must be taken into consideration when designing the layout of the

measuring point. The level zero point (E) corresponds to the position of the process

isolating diaphragm. Level zero point = E; tip of probe = L (see the following diagram).

For dimensions, see chapter 10.

Figure 7.2

7.3 Cable Length

• Pay attention to the load.

• Cable lengths available for order

• Customer-specific in meters or feet.

• Limited cable length when performing installation with freely suspended device with

cable mounting screw or mounting clamp, as well as for Ex approval: max. 300 m

(984 foot).

Note!

When using the measuring device in hazardous areas, installation must comply with the

corresponding national standards and regulations and the instruction manuals (SI) or

Installation or Control Drawings (ZD).

E

L

28

2017-02

Page 29

Level Probe LGC2

A

Installation

Figure 7.3

A Length of probe connection (extension cable)

1

Option

Probe connection (extension cable)

2A 10 m cable, shortable, PE

2C 20 m cable, shortable, PE

2M 30 foot cable, shortable, PE

2N 60 foot cable, shortable, PE

3A 10 m cable, shortable, FEP

3C 20 m cable, shortable, FEP

3M 30 foot cable, shortable, FEP

3N 60 foot cable, shortable, FEP

CF Specification in foot cable, shortable, FEP

CM Specification in m cable, shortable, FEP

XF Specification in foot cable, shortable, PE

XM Specification in m cable, shortable, PE

Table 7.1

1

Ordering information: product structure, feature "Probe connection"

7.4 Technical Data for Cable

• Minimum bending radius: 120 mm (4.72 inch)

• Tensile strength: max. 950 N (213.56 lbf)

• Cable extraction force (= tensile force required to extract the cable from the probe):

•PE, FEP: typically 400 N (89.92 lbf)

• when used in hazardous area: 100 N (73.75 lbf)

• UV-resistant (UV = ultraviolet)

• PE: for use in drinking water

2017-02

29

Page 30

Level Probe LGC2

Installation

7.5 Cable Marking

Figure 7.4

• To make installation easier, Pepperl+Fuchs marks the extension cable if a customerspecific length has been ordered.

Ordering information: product structure, feature "Service", option "RI" or "SI".

• Cable marking tolerance (distance to lower end of level probe):

Cable length < 5 m (16 foot): ±17.5 mm (0.69 inch)

Cable length > 5 m (16 foot): ±0.2 %

• Material: PET, stick-on label: acrylic

• Immunity to temperature change: -30 to +100 °C(-22to+212°F)

Note!

The marking is used exclusively for installation purposes. The mark must be thoroughly

removed without trace in the case of devices with drinking water approval. The extension cable

must not be damaged in the process.

Not for use of the device in hazardous areas.

7.6 Cable Shortening Kit

30

Figure 7.5

The cable shortening kit is used to shorten a cable easily and professionally.

Note!

The cable shortening kit is not designed for the device with FM/CSA approval.

Ordering information: product structure, feature "Accessories", option "WP"

2017-02

Page 31

Level Probe LGC2

Ambient Conditions

8 Ambient Conditions

8.1 Ambient Temperature Range

Level probe and Pt100 (optional)

• With external diameter of 22 mm (0.87 inch) and 42 mm (1.65 inch):

-10 to +70 °C(+14to+158°F) (= medium temperature)

• With external diameter of 29 mm (1.14 inch):

0to+50°C(+32to+122°F) (= medium temperature)

Probe connection (extension cable)

(when mounted in a fixed position)

•With PE: -30to+70°C (-22 to +158 °F)

•With FEP: -40to+70°C(-40to+158°F)

Te rm i n a l bo x

-40 to +80 °C(-40to+176°F)

HUT temperature head transmitter (optional) for device with

4 to 20 mA Analog

-40 to +85 °C(-40to+185°F)

Temperature head transmitter 2-wire, configured for a measuring range of -20 to +80 °C

(-4 to +176 °F). This configuration offers a temperature range of 100 K which can be easily

mapped. Please note that the Pt100 resistance thermometer is suitable for a temperature

range of -10 to +70 °C (14 to +158 °F).

Note!

The temperature head transmitter is not designed for use in hazardous areas incl. CSA

General Purpose.

8.2 Storage Temperature Range

Level probe and Pt100 (optional)

-40 to +80 °C(-40to+176°F)

Probe connection (extension cable)

(when mounted in a fixed position)

•With PE: -30to+70°C(-22to+158°F)

•With FEP: -30to+80°C(-22to+176°F)

Te rm i n a l bo x

-40 to +80 °C(-40to+176°F)

HUT temperature head transmitter (optional) for device with

4 to 20 mA Analog

-40 to +100 °C (-40 to +212 °F)

2017-02

31

Page 32

Level Probe LGC2

Ambient Conditions

8.3 Degree of Protection

Level probe and Pt100 (optional)

IP68, permanently hermetically sealed at 20 bar (290 psi) (~200 m H2O)

Terminal box (optional)

IP66, IP67

HUT temperature head transmitter (optional) for device with

4 to 20 mA Analog

IP00, condensation permitted

When installed in the optional terminal boxes: IP66/IP67

8.4 Electromagnetic Compatibility (EMC)

Level probe and Pt100 (optional)

• EMC in accordance with all relevant requirements of EN 61326 series. For details, refer to

the Declaration of Conformity.

• Maximum deviation: < 0.5 % of span.

HUT temperature head transmitter (optional) for device with

4 to 20 mA Analog

Interference emission to EN 61326 Class B equipment, interference immunity to EN 61326

Appendix A (Industrial). For details, refer to the Declaration of Conformity.

8.5 Surge Protection

Level probe and Pt100 (optional)

• Integrated overvoltage protection as per EN 61000-4-5 (500 V symmetrical/1000 V

asymmetrical)

• Overvoltage protection 1.0 kV, external if necessary

HUT temperature head transmitter (optional) for device with

4 to 20 mA Analog

Provide overvoltage protection, externally if necessary, see chapter 2.3.

32

2017-02

Page 33

Level Probe LGC2

Process Conditions

9 Process Conditions

9.1 Medium Temperature Range

Level probe and Pt100 (optional)

• With external diameter of 22 mm (0.87 inch) and 42 mm (1.65 inch):

-10 to +70 °C(+14to+158°F)

• With external diameter of 29 mm (1.14 inch):

0to+50°C(+32to+122°F)

HUT temperature head transmitter (optional) for device with

4 to 20 mA Analog

-40 to +85 °C (-40 to +185 °F) (= ambient temperature), install temperature head transmitter

outside the medium.

Temperature head transmitter 2-wire, configured for a measuring range of -20 to +80 °C

(-4 to +176 °F). This configuration offers a temperature range of 100 K which can be easily

mapped. Please note that the Pt100 resistance thermometer is suitable for a temperature

range of -10 to +70 °C (14 to +158 °F).

Note!

The temperature head transmitter is not designed for use in hazardous areas incl. CSA

General Purpose.

9.2 Medium Temperature Limit

Level probe and Pt100 (optional)

With external diameter of 22 mm (0.87 inch) and 42 mm (1.65 inch): -20 to +70 °C

(-4 to +158 °F)

Note!

In hazardous area incl. CSA General Purpose, the medium temperature limit is

-10 to +70 °C(+14to+158°F).

With external diameter of 29 mm (1.14 inch): 0 to +50 °C(+32to+122°F)

Note!

The device may be operated in this temperature range. The specification values, such as

accuracy, may be exceeded.

2017-02

33

Page 34

Level Probe LGC2

Mechanical Construction

10 Mechanical Construction

10.1 Dimensions of the Level Probe

ABC

1

2

Ø8(0.31)

Ø8(0.31)

(9.13)

±0.1

(9.72)

232

247

249 (9.80)

259 (10.2)

18 (0.71)

33 3

Ø22 (0.87)

1

2

18 (0.71)

Ø42 (1.65)

Ø42.5 (1.67)

Ø8(0.31)

(10.2)

(10.6)

258

268

1

2

27 (1.06)

Ø29≤(1.14)

34

Figure 10.1

A Ordering information: product structure, feature "Probe tube", option "S" or "Accessories"

B Ordering information: product structure, feature "Probe tube", option "R"

C Ordering information: product structure, feature "Probe tube", option "P"

1 Pressure compensation tube

2 Probe connection (extension cable)

3 Protection cap

Measuring unit mm (inch)

2017-02

Page 35

Level Probe LGC2

22 (0.87)

48... 52 (2.0)

≤

175 (6.89)

52 (2.05)

~53

(2.1)

~71 (2.8)

Ø55(2.17)

~71 (2.8)

NPT

36

41

G1-1/2A

1-1/2

A

B

Mechanical Construction

10.2 Dimensions of the Suspension Clamp

Figure 10.2

Ordering information: product structure, feature "Accessories", option "OP"

Measuring unit mm (inch)

10.3 Dimensions of Cable Mounting Screw

Figure 10.3

A G1-1/2A, ordering information: product structure, feature "Accessories", option "PQ"

B NPT1-1/2, ordering information: product structure, feature "Accessories", option "PR"

Measuring unit mm (inch)

Note!

Use only in unpressurized vessels.

2017-02

35

Page 36

Level Probe LGC2

55 (2.17)

120 (4.72)

60 (2.36)

0.5±

10 (0.39)

80 (3.15)

~30

(1.18)

Ø4.5 (0.18)

50.2

(1.98)

108.2 (4.26)

OPEN

CLOSE

90°

90°

Warning:

Avoid electrostatic charge in explosive atmosphere.

See instructions

Ter mi nal Bo x

5

3

4

2

1

Mechanical Construction

10.4 Dimensions of Terminal Box IP66, IP67 with Filter

Figure 10.4

1 Stopping plug M20 x 1.5

2 Cable gland M20 x 1.5

3

4 to 20 mA; terminals for 0.08 to 2.5 mm (28 to 14 AWG) 0.08 to 2.5 mm

4

Ground connection; terminals for 0.08 to 2.5 mm (28 to 14 AWG) 0.08 to 2.5 mm

5

GORE-TEX

®

filter

2

2

Measuring unit mm (inch)

Terminal box IP66/IP67 with GORE-TEX® filter incl. 3 installed terminals. The terminal box is

also suitable for the installation of a temperature head transmitter or four other terminals.

Ordering information:

• Terminal box: product structure, feature "Accessories", option "SP", see chapter 14

• HUT temperature head transmitter: product structure, feature "Accessories", option "XP",

see chapter 14

Note!

The terminal box is not designed for the device with type of protection Ex nA in hazardous

areas. If the terminal box is used in a hazardous area, the Safety Instructions of the relevant

device must be observed, as well as the applicable regulations for explosion protection.

If the device with optional Pt100 is supplied, a terminal block is provided with the terminal box

for the purpose of wiring the Pt100.

36

Note!

The 4-terminal block is not designed for use in hazardous areas incl. CSA General Purpose.

2017-02

Page 37

Level Probe LGC2

Ø5(Ø0.19)

33 (1.30)

Ø44 (1.73)

Ø7 (0.27)

21 (0.83)

3

4

5

3

6

1

2

> 7 (0.28)12 3

Mechanical Construction

10.5 Dimensions of the HUT Temperature Head Transmitter

Figure 10.5

Measurement unit mm (inch)

Ordering information: product structure, feature "Accessories", option "XP", see chapter 14

10.6 Terminal Box with Integrated HUT Temperature Head Transmitter

Figure 10.6

1 Terminal box

2 Terminal block/terminals

3 Temperature head transmitter HUT

Measuring unit mm (inch)

Note!

A distance of > 7 mm (0.28 inch) must be maintained between the terminal block and the HUT

temperature head transmitter.

2017-02

37

Page 38

Level Probe LGC2

M14 x 1

105.8 (4.16)

110.6 (4.35)

Ø22(0.87)

Mechanical Construction

10.7 Additional Weight

For device with external diameter of 22 mm (0.87 inch) or 29 mm

(1.14 inch)

• Pepperl+Fuchs offers additional weights to prevent sideways movement that results in

measuring errors, or to make it easier to lower the device in a guide tube. You can screw

several weights together. The weights are screwed directly onto the device. For the device

with external diameter of 29 mm (1.14 in), a maximum of 5 weights may be screwed on. In

conjunction with the Ex nA approval, a maximum of one additional weight is permitted for

the device with external diameter of 29 mm (1.14 in).

• Ordering information: product structure, feature "Accessories", option "UP"

Figure 10.7

Measuring unit mm (inch)

10.8 Testing Adapter

For device with external diameter of 22 mm (0.87 inch) or 29 mm

(1.14 inch)

• Pepperl+Fuchs offers a testing adapter to ease function-testing of the level probes.

• Observe the maximum pressure for compressed air hose and maximum overload for level

probe, see chapter 3.

• Maximum pressure for the quick coupling piece provided:10 bar (145 psi)

• Adapter material: 304 (1.4301)

• Material of quick coupling piece: anodized aluminum

• Ordering information: product structure, feature "Accessories", option "VP"

38

2017-02

Page 39

Level Probe LGC2

M14 x 1

~25 (0.98)

22

13

12

~33 (1.3)

2

1

Mechanical Construction

Figure 10.8

1 LGC level probe connection

2 Compressed air hose connection, internal diameter, quick coupling piece

4 mm (0.16 inch)

Measuring unit mm (inch)

10.9 Weight

Component Weight

Level probe, external diameter of 22 mm (0.87 inch) 344 g

Level probe, external diameter of 42 mm (1.65 inch) 1376 g

Level probe, external diameter of 29 mm (1.14 inch) 394 g

Probe connection

(extension cable)

Suspension clamp 170 g

Cable mounting screw G1-1/2A 770 g

Cable mounting screw NPT1-1/2 724 g

Terminal box 235 g

HUT temperature head trasnmitter 40 g

Additional weight 300 g

Testing adapter 39 g

Table 10.1

PE 52 g/m (0.035 lbs/foot)

FEP 108 g/m (0.072 lbs/foot)

2017-02

39

Page 40

Level Probe LGC2

BA

C

6

7

6

7

6

7

5

3

4

1

2

4

5

3

1

2

5

3

4

1

2

1.1

1.2

Mechanical Construction

10.10 Materials

Figure 10.9

Materials in contact with process

Position Component Material

1 • A: Level probe, external diameter of

22 mm (0.87 inch)

• B: Level probe, external diameter of

42 mm (1.65 inch)

• C: Level probe, external diameter of max.

29 mm (1.14 inch)

1.1 Sensor sleeve PPS (Polyphenylene sulfide)

1.2 Heat-shrink tube Polyolefin and hot melt adhesive

The heat-shrink tube around the level probe acts as insulation. It prevents electrical contact

between the level probe and the tank. Electrochemical corrosion is thus avoided.

2 Protection cap for A and C: with outer diameter

22 mm (0.87 inch) and 29 mm (1.14 inch)

Protection cap for B: device with outer

diameter 42 mm (1.65 inch)

3 Process ceramic Al2O3 (Aluminum oxide ceramic)

4 Seal EPDM

5 Probe connection insulation (extension cable)

Additional information

Table 10.2

316L (1.4404/1.4435)

POM

PFA

1

FKM Viton

2

Choose from:

• PE-LD (low-density polyethylene)

• FEP (fluorinated ethylene propylene)

1

Product structure, feature "Seal", option "2"

2

Product structure, feature "Seal", option "1"

40

2017-02

Page 41

Level Probe LGC2

1

2

5

6

7

8

9

3

4

1

2

34

5

Mechanical Construction

Materials not in contact with process

Position Component Material

6 Pressure compensation tube PA

7 Heat-shrink tube Polyolefin

Table 10.3

Terminal box (not in contact with process)

Figure 10.10

1 Housing, PC

2 Mounting screws (4 x), A2

3 Seal, CR (chloropren rubber)

4 Stopping plug M20 x 1.5, PBT-GF30

5 Cable gland M20 x 1.5, PE-HD

6 Cable gland M20 x 1.5, PA6

7 Cable gland M20 x 1.5, PA6-GF30

8 Pressure compensation filter, PA6-GF10, ePTFE

9 Pressure compensation filter O-ring, silicone (VMQ)

Cable mounting screw (not in contact with process)

Figure 10.11

1 Cover for cable mounting screw, 1.4301/304

2 Sealing ring, NBR

3 Clamping sleeves, PA66-GF35

4 Adapter for cable mounting screw G1-1/2A, NPT1-1/2, 1.4301/304

5 Seal, only for G1-1/2A, EPDM

2017-02

41

Page 42

Level Probe LGC2

Mechanical Construction

Suspension clamp

Figure 10.12

1.4404/316L and fiber-glass reinforced PA (polyamide)

Additional weight

Figure 10.13

1.4435/316L

Testing adapter for device with outer diameter 22 mm (0.87 inch) or

29 mm (1.14 inch)

Figure 10.14

Adapter, 1.4301/304

Quick coupling piece, anodized aluminum

42

2017-02

Page 43

Level Probe LGC2

Mechanical Construction

Testing adapter for device with outer diameter 42 mm (1.65 inch)

Figure 10.15

Adapter, 1.4301/304

Quick coupling piece, anodized aluminum

Probe connection (extension cable)

PE FEP

• Abrasion-resistant extension cable with

strain relief members made of highstrength PE fibers

• Shielded (aluminum)

• Insulated with polyethylene (PE), black

• Copper wires, twisted

• Pressure compensation tube with PTFE

filter

Table 10.4

• Abrasion-resistant extension cable

• Shielded with galvanized steel wire

netting

• Insulated with fluorinated ethylene

propylene (FEP), black

• Copper wires, twisted

• Pressure compensation tube with PTFE

filter

2017-02

43

Page 44

Level Probe LGC2

Operation

11 Operation

No display or other operation facility is required to operate the device. However, the measured

values can be read out with optional evaluation devices.

44

2017-02

Page 45

Level Probe LGC2

Certificates and Approvals

12 Certificates and Approvals

Note!

The following documents are also available in the download area of the Pepperl+Fuchs

website: www.pepperl-fuchs.com

12.1 CE Mark

The device meets the legal requirements of the relevant EU directives. Pepperl+Fuchs

confirms that the device has been successfully tested by applying the CE mark.

12.2 Approvals for hazardous area

•ATEX

•CSA C/US

•FM

•IEC

Note!

• The approvals apply exclusively to the device without Pt100 resistance thermometer and

without HUT temperature head transmitter.

• The device is only available for use in hazardous areas with the FKM Viton seal.

• All explosion protection data are given in separate documentation which is available upon

request. Ex documentation is included with all Ex devices as standard, see chapter 15.

12.3 Potable Water Approval

For device with an external diameter of 22 mm (0.87 inch) with EPDM seal

Designation Option

KTW QL

NSF61 RL

Table 12.1

1

Ordering information: product structure, feature "Other approval"

1

12.4 Other Standards and Guidelines

The applicable European guidelines and standards can be found in the relevant certificates.

The following were also applied:

IEC/EN 60770:

Transmitters for use in industrial process control systems part 1: Methods for performance

evaluation

Methods for evaluating the performance of transmitters for control and regulation in industrial

process control systems.

DIN 16086:

Electrical pressure measuring instruments, pressure sensors, pressure transmitters, pressure

measuring instruments, concepts, specifications on data sheets

Procedure for writing specifications in data sheets for electrical pressure measuring

instruments, pressure sensors and pressure transmitters.

2017-02

45

Page 46

Level Probe LGC2

Certificates and Approvals

EN 61326:

Electrical equipment for measurement, control and laboratory use - EMC requirements

IEC/EN 61010-1:

Protection Measures for Electrical Equipment for Measurement, Control, Regulation and

Laboratory Procedures

EN 60529:

Degrees of protection provided by enclosures (IP code)

12.5 Calibration

Designation Option

Factory calibration certificate, 5-point 1F

Table 12.2

1

Ordering information: product structure, feature "Calibration"

12.6 Calibration, Unit

Designation Option

Sensor range, % A

Sensor range, mbar/bar B

Sensor range, kPa/MPa C

Sensor range, mm H2O/m H2O D

Sensor range, inch H2O/foot H2O E

Sensor range, psi F

Customized pressure, see additional specification J

Table 12.3

1

Ordering information: product structure, feature "Calibration, Unit"

12.7 Service

1

1

46

Designation Option

in m cable marking > installation, according to specification: 2 ... 299 m RI

in foot cable marking > installation, according to specification: 6 ... 982 foot SI

Special version XX

Table 12.4

1

Ordering information: product structure, feature "Service"

1

2017-02

Page 47

Level Probe LGC2

Ordering Information

13 Ordering Information

13.1 Product Structure

Note!

This overview does not mark options which are mutually exclusive.

Option with * = on request/in preparation

Option with ** = multiple options can be selected

Device

LGC2 Level probe

Reference accuracy

D Platinum, accuracy 0.1 %

G Standard, accuracy 0.2 %

Probe tube

P Ø29 mm, PPS/Polyolefin, application salt-water

R Ø42 mm, 1.4435/316L, flush mount

S Ø22 mm, 1.4435/316L

X Special version

Measuring range

R1A 100 mbar/10 kPa/1.5 psi relative, 1 m H2O/3 foot H2O/40 inch H2O

R1C 200mbar/20kPa/3psi relative, 2mH2O/6footH2O/80inchH2O

R1D 400 mbar/40 kPa/6 psi relative, 4 m H2O/13 foot H2O/160 inch H2O

R1E 600 mbar/60 kPa/9 psi relative, 6 m H2O/20 foot H2O/240 inch H2O

R2A 1 bar/100 kPa/15 psi relative, 10 m H2O/33 foot H2O/400 inch H2O

R2C 2 bar/200 kPa/30 psi relative, 20 m H2O/67 foot H2O/800 inch H2O

R2D 4 bar/400 kPa/60 psi relative, 40 m H2O/133 foot H2O/1600 inch H2O

R3A 10 bar/1 MPa/150 psi relative, 100 m H2O/333 foot H2O/4000 inch H2O

R3C 20 bar/2 MPa/300 psi relative, 200 m H2O/667 foot H2O/8000 inch H2O

A2C 2 bar/200 kPa/30 psi absolute, 20 m H2O/67 foot H2O/800 inch H2O

A2D 4 bar/400 kPa/60 psi absolute, 40 m H2O/133 foot H2O/1600 inch H2O

A3A 10 bar/1 MPa/150 psi absolute, 100 m H2O/333 foot H2O/4000 inch H2O

A5A 20 bar/2 MPa/300 psi absolute, 200 m H2O/667 foot H2O/8000 inch H2O

XXX Special version

Electrical output

I2 2-wire, 4 to 20 mA

Seal

1 Measurement cell sealing: FKM Viton

2 Measurement cell sealing: EPDM

2017-02

47

Page 48

Level Probe LGC2

Ordering Information

Probe connection (extension cable)

2A 10 m cable, shortable, PE

2C 20 m cable, shortable, PE

2M 30 foot cable, shortable, PE

2N 60 foot cable, shortable, PE

3A 10 m cable, shortable, FEP

3C 20 m cable, shortable, FEP

3M 30 foot cable, shortable, FEP

3N 60 foot cable, shortable, FEP

CF Specification in foot cable, shortable, FEP

CM Specification in m cable, shortable, FEP

XF Specification in foot cable, shortable, PE

XM Specification in m cable, shortable, PE

XX Special version

Calibration, unit

A Sensor range, %

B Sensor range, mbar/bar

C Sensor range, kPa/MPa

D Sensor range, mm H2O/m H2O

E Sensor range, inch H2O/foot H2O

F Sensor range, psi

J Customized pressure

X Special version

Approval

C1 CSA C/US IS Cl. I Div. 1 Group A-D, Ex ia, Zone 1

CG CSA General Purpose

E3 ATEX II 3G Ex nA IIC T6...T4 Gc

EX ATEX II 2G Ex ia IIC T6...T4 Gb

F1 FM IS Cl. I Div. 1 Group A-D, AEx ia, Zone 1

IC IEC Ex ia IIC T6...T4 Gb

NA Version for non-hazardous area

48

Other approval

NA Without potable water approval

QL KTW potable water approval

RL NSF potable water approval

Probe connection length

L Specified length of the cable:

• Options CF, XF: 3 to 985 foot

• Options CM, XM: 1 to 300 m

2017-02

Page 49

Level Probe LGC2

Ordering Information

Additional Options

Calibration

1F Factory calibration certificate, 5-point

Service

RI Cable marking > installation, specification in m: 2 to 299 m

SI Cable marking > installation, specification in foot: 6 to 982 foot

XX Special version

Accessories

BN Pt100 resistance thermometer, 4-wire

OP Suspension clamp, 316L

QP Cable mounting screw G1-1/2, 304

RP Cable mounting screw NPT1-1/2, 304

SP Terminal box, IP66/67

UP Additional weight, 316L

VP Adapter, function test

WP Shortening kit for probe connection

XP HUT temperature head transmitter, 2-wire, 4 to 20 mA

X9 Special version

Marking

1Z Tagging (TAG), see additional specification

13.2 Scope of Delivery

•Measuring device

• Optional Accessories

• Brief instructions

• Approvals and certificates

2017-02

49

Page 50

Level Probe LGC2

Ordering Information

13.3 Configuration Data Sheet

Pressure

The following configuration data sheet must be completed and included with the order if option

"Customized pressure" has been selected for order code "Calibration, unit" in the product

structure.

Pressure unit

mbar mm H2O mm Hg Pa

bar mH2O kPa

foot H2O MPa

psi inch H2O kgf/cm

Table 13.1

Calibration range/output

Lower-range value (LRV): __________ [pressure engineering unit]

Upper-range value (URV): __________ [pressure engineering unit]

Table 13.2

2

Damping

Damping: __________ s

Table 13.3

50

2017-02

Page 51

Level Probe LGC2

3

4

5

3

6

1

2

A

B

A G1-1/2A

B NPT1-1/2

Accessories

14 Accessories

Note!

Observe the additional information in the individual sections "Mechanical Construction",

"Ambient Conditions", "Process Conditions", and "Installation".

Designation Figure Description Ordering information

Suspension clamp For easy installation of

the device,

Pepperl+Fuchs offers a

mounting clamp.

Product structure, feature

"Accessories", option

"OP"

Terminal box Terminal box for terminal

block, temperature head

transmitter and Pt100

resistance thermometer

4-terminal

4-terminal block for wiring

block/terminals

HUT temperature head

transmitter for device with

4to20mAAnalog

Temperature head

transmitter for the

conversion of various

input signals

Cable mounting screws Pepperl+Fuchs offers a

cable mounting screw for

easy device mounting

and to seal the

measuring aperture.

Additional weight for

device with outer

diameter 22 mm

(0.87 inch) or 29 mm

(1.14 inch)

Pepperl+Fuchs offers

additional weights to

prevent sideways

movement that results in

measuring errors, or to

make it easier to lower

the device in a guide

tube.

Product structure, feature

"Accessories", option

"SP"

Product structure, feature

"Accessories", option

"XP"

• G1-1/2A

Product structure,

feature

"Accessorie s", option

"QP"

•NPT1-1/2

Product structure,

feature

"Accessorie s", option

"RP"

Product structure, feature

"Accessories", option

"UP"

2017-02

51

Page 52

Level Probe LGC2

Accessories

Designation Figure Description Ordering information

Cable shortening kit The cable shortening kit

Testing adapter for

device with outer

diameter 22 mm

(0.87 inch) or 29 mm

(1.14 inch)

Testing adapter for

device with outer

diameter 42 mm

(1.65 inch)

Table 14.1

is used to shorten a cable

easily and professionally.

Pepperl+Fuchs offers a

testing adapter to ease

function-testing of the

level probes.

Pepperl+Fuchs offers a

testing adapter to ease

function-testing of the

level probes.

• Observe the

maximum pressure

for compressed air

hose and maximum

overload for level

probe.

•Maximum pressure

for the quick coupling

piece provided:

10 bar (145 psi)

Product structure, feature

"Accessories", option

"WP"

Product structure, feature

"Accessories", option

"VP"

52

2017-02

Page 53

Level Probe LGC2

Documentation

15 Documentation

The documents listed are available on the product detail page of the appropriate product.

15.1 Technical Information (TI)

Planning aid for your device: TI00431O

The document contains all the technical data on the device and provides an overview of the

accessories and other products that can be ordered for the device.

15.2 Brief Instructions (KA)

Getting the 1st measured value quickly: 4 to 20 mA Analog – KA01244O

The brief instructions contain all the essential information from incoming acceptance to initial

commissioning.

15.3 Manual (BA)

Your comprehensive reference: 4 to 20 mA Analog – BA01605O

These manual contain all the information that is required in various phases of the life cycle of

the device: from product identification, incoming acceptance and storage, to mounting,

connection, operation and commissioning through to troubleshooting, maintenance and

disposal.

15.4 Instruction Manuals (SI)

Depending on the approval, the following instruction manuals (SI) are supplied with the device.

They are an integral part of the documentation.

Option

E3 ATEX II 3G Ex nA IIC T6...T4 Gc SI00485O

EX ATEX II 2G Ex ia IIC T6...T4 Gb SI00454O

IC IEC Ex ia IIC T6...T4 Gb SI00455O

C1 CSA C/US IS Cl. I Div. 1 Group A-D, Ex ia, Zone 1 ZD00232O

F1 FM IS Cl. I Div. 1 Group A-D, AEx ia, Zone 1 ZD00231O

Table 15.1

1

Note!

The nameplate indicates the instruction manuals (SI) that are relevant to the device.

1

Approval Documentation

See ordering information: product structure, feature "Approval".

15.5 Potable Water Approval

• NSF potable water approval SD00289O

• KTW potable water approval: SD00319O

2017-02

53

Page 54

Level Probe LGC2

Registered Trademarks

16 Registered Trademarks

GORE-TEX®: Trademark of W.L. Gore & Associates, Inc., USA

54

2017-02

Page 55

Level Probe LGC2

Notes

2017-02

55

Page 56

Subject to modifications

Copyright PEPPERL+FUCHS • Printed in Germany

www.pepperl-fuchs.com

Worldwide Headquarters

Pepperl+Fuchs GmbH

68307 Mannheim ·

Germany

Tel. +49 621 776-0

E-mail: info@de.pepperl-fuchs.com

For the Pepperl+Fuchs representative

closest to you check www.pepperl-fuchs.com/contact

PROCESS AUTOMATION –

PROTECTING YOUR PROCESS

DOCT-0730A

02/2017

TI00431O/98/EN/16.16

Loading...

Loading...