Float Switch LFL2-CK-U-PUR5-EMS

Technical Data

Electrical specifications

Model Number

LFL2-CK-U-PUR5-EMS

Features

• Switch element: Micro switch,

mercury-free

• Limit value detection for fluids

• Sleeve design: small diameter,

mounting through G1 tap hole possible

Description

The microswitch (change-over contact)

is integrated in a PP float and is

activated in the event of deviations from

the horizontal position. The switching

ball in the float, which moves along an

axis, activates the microswitch.

Accessories

LFL-Z132-EMS

Gland screw connection

LFL-Z32-EMS

Ballast weight for float switch

Contact loading 250 V AC/3 A; 150 V DC/0.25 A resistive load; 60 V DC/1 A

Rated insulation voltage 300 V

Pulse withstand voltage 4 kV

Electrical life ≥ 5 x 10

Directive conformity

Low voltage

Directive 2014/35/EU

Conformity

Degree of protection IEC 60529:2001

Application

Description microswitch with switching ball, change-over contact

Function and system design

Equipment architecture This device may be used with any sequential circuit, as long as the

Operating conditions

Installation conditions

Installation instructions

Process conditions

Process pressure (static pressure)

Density

Ambient conditions

Ambient temperature 5 ... 70 °C (41 ... 158 °F)

Storage temperature -25 ... 70 °C (-13 ... 158 °F)

Altitude ≤ 2000 m above MSL

Mechanical specifications

Degree of protection IP68

Cable

Length L

Mechanical construction

Material float: PP (Polypropylene)

Switching point switch angle, measured against the horizontal:

General information

Supplementary information Statement of Conformity, Declaration of Conformity, Attestation of

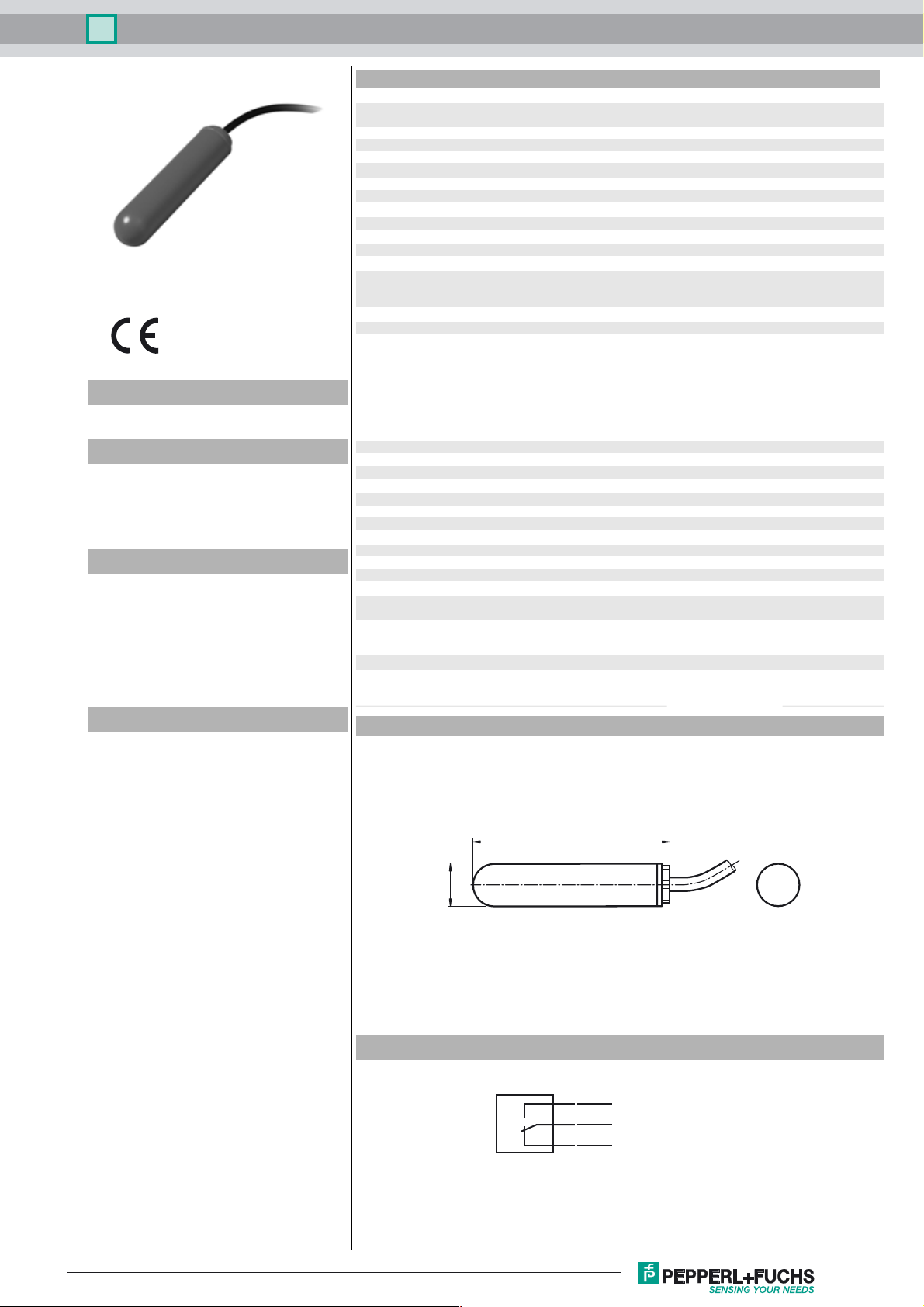

Dimensions

resistive load

4

switching cycles

EN 60947-5-1:2004 + Cor.:2005 + A1:2009

circuit can support the electrical circuit values of the switching

elements.

range of application and minimum length between mounting and

float:

≥ 100 mm (4 inch), preferred for fuels, heating oils, oily fluids

mounting:

- The float switch is mounted either from sidewards through a cable

gland ≥ G1A into the vessel or

- by means of a counter weight or rods (e. g. float switch

combination) from the top.

The pivot of the cable should always be horizontal.

≤ 3 bar (43.5 psi) at 20 °C (68 °F)

≥ 0.8 g/cm

5 m

cable: PUR, highly flexible (3 x 0.50 mm

- upper switch point +25° ±10°

- lower switch point -14°±10°

Conformity and instr ved where applicable.

For information see

3

2

)

Release date: 2017-11-15 11:12 Date of issue: 2017-11-15 262201_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

135

ø 29.2

Electrical Connection

BU

BK

BN

1

Float Switch LFL2-CK-U-PUR5-EMS

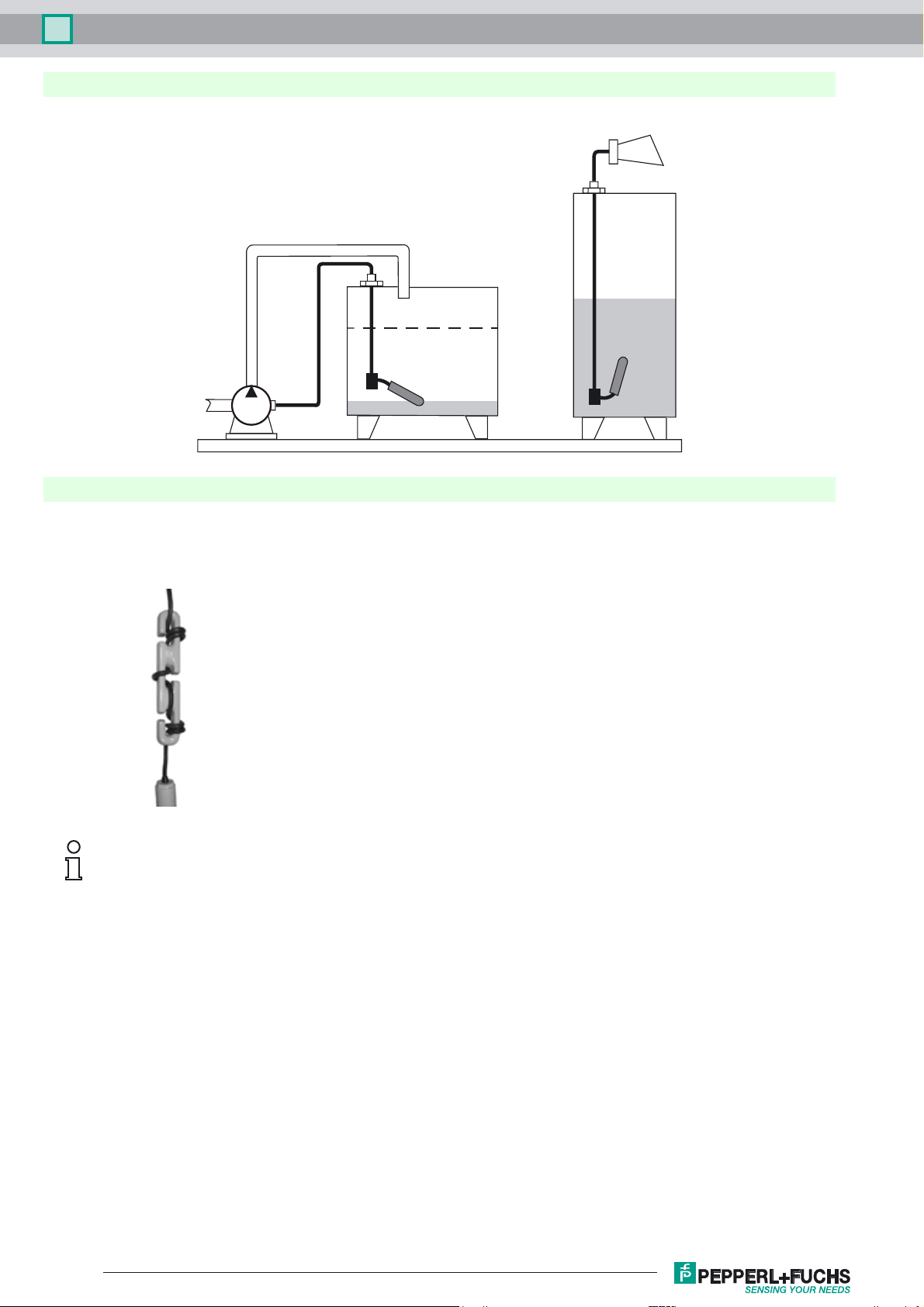

Application

Controlling pumps and valves with one switch or signal level height or limit

Mounting

Mount the float switch in the following way:

• Insert the float switch into the tank through a tapped hole G1A.

• Srcew the float switch with the gland screw connection G1A.

• If it is installed from above, use the counter weight LFL-Z32 or LFL-Z33 for mounting.

The fulcrum of the cable should always be horizontal.

The cable length between the fixture and the floating body is dependent on the cable type.

When using the counter weight, place an extra strain relief (e. g. a knot in the cable) behind the gland screw connection

– on the outside of the tank.

Release date: 2017-11-15 11:12 Date of issue: 2017-11-15 262201_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Loading...

Loading...