Page 1

ISO9001

K-System

Isolated Barriers

Manual

Page 2

With regard to the supply of products, the current issue of the following document is applicable:

The General Terms of Delivery for Products and Services of the Electrical Industry, published by the Central

Association of the Electrical Industry (Zentralverband Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most

recent version as well as the supplementary clause: "Expanded reservation of proprietorship"

Worldwide

Pepperl+Fuchs Group

Lilienthalstr. 200

68307 Mannheim

Germany

Phone: +49 621 776 - 0

E-mail: info@de.pepperl-fuchs.com

North American Headquarters

Pepperl+Fuchs Inc.

1600 Enterprise Parkway

Twinsburg, Ohio 44087

USA

Phone: +1 330 425-3555

E-mail: sales@us.pepperl-fuchs.com

Asia Headquarters

Pepperl+Fuchs Pte. Ltd.

P+F Building

18 Ayer Rajah Crescent

Singapore 139942

Phone: +65 6779-9091

E-mail: sales@sg.pepperl-fuchs.com

https://www.pepperl-fuchs.com

Page 3

K-System – Isolated Barriers

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Content of this Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Target Group, Personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Symbols Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Housing Styles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4 Color Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5 Status Indicators of the Isolators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.6 Operating Elements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.7 Label Carrier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.8 DIN Mounting Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.9 Power Rail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3 Mounting and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2 Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.1 Fault Monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.2 Fault Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.3 Current and Voltage Standard Signals . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6 Dismounting, Maintenance, and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.1 Dismounting the Isolated Barrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7 Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.2 Model Number Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2021-03

3

Page 4

K-System – Isolated Barriers

Contents

2021-03

4

Page 5

K-System – Isolated Barriers

Introduction

1 Introduction

1.1 Content of this Document

This document contains information that you need in order to use your product throughout

the applicable stages of the product life cycle. These can include the following:

• Product identification

• Delivery, transport, and storage

• Mounting and installation

• Commissioning and operation

• Maintenance and repair

• Troubleshooting

• Dismounting

• Disposal

Note

This document does not substitute the instruction manual.

Note

For full information on the product, refer to the instruction manual and further documentation

on the Internet at www.pepperl-fuchs.com.

The documentation consists of the following parts:

• Present document

• Instruction manual

• Datasheet

Additionally, the following parts may belong to the documentation, if applicable:

• EU-type examination certificate

• EU declaration of conformity

• Attestation of conformity

• Certificates

• Control drawings

• Additional documents

2021-03

5

Page 6

K-System – Isolated Barriers

Introduction

1.2 Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation, maintenance,

and dismounting lies with the plant operator.

Only appropriately trained and qualified personnel may carry out mounting, installation,

commissioning, operation, maintenance, and dismounting of the product. The personnel

must have read and understood the instruction manual and the further documentation.

Prior to using the product make yourself familiar with it. Read the document carefully.

1.3 Symbols Used

This document contains symbols for the identification of warning messages and of informative

messages.

Warning Messages

You will find warning messages, whenever dangers may arise from your actions.

It is mandatory that you observe these warning messages for your personal safety and in order

to avoid property damage.

Depending on the risk level, the warning messages are displayed in descending order

as follows:

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants,

or result in their complete failure.

Informative Symbols

Note

This symbol brings important information to your attention.

Action

This symbol indicates a paragraph with instructions. You are prompted to perform an action

or a sequence of actions.

2021-03

6

Page 7

K-System – Isolated Barriers

Control

system

Sensor

Actuator

Product Specifications

2 Product Specifications

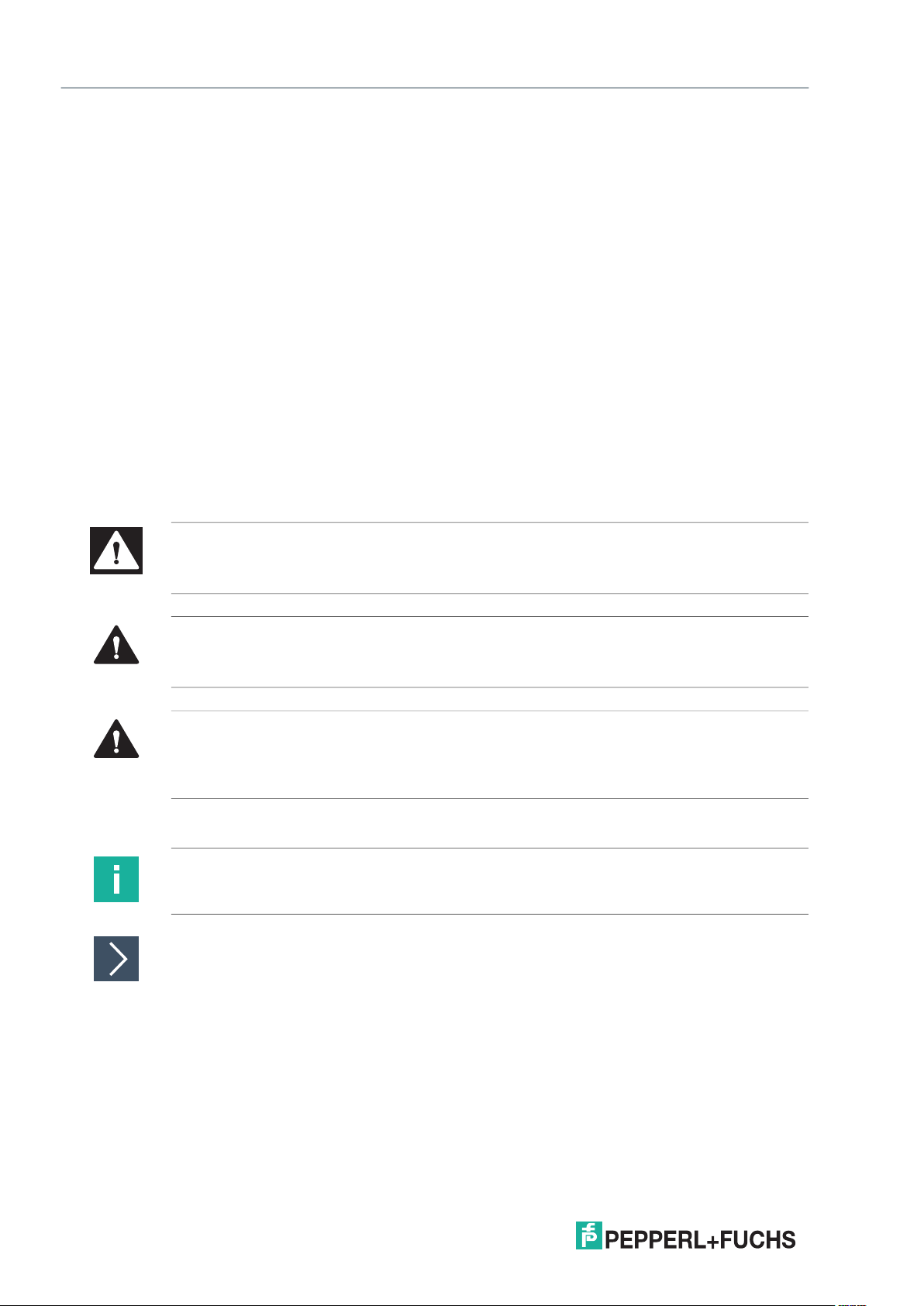

2.1 Function

Isolated barriers are isolators used for protection of intrinsically safe circuits in hazardous

areas. In addition to the required current, voltage and power limitation, the isolated barriers

have a galvanic isolation between the field circuit and the controller.

Figure 2.1 Function – isolating, amplifying and transforming signals

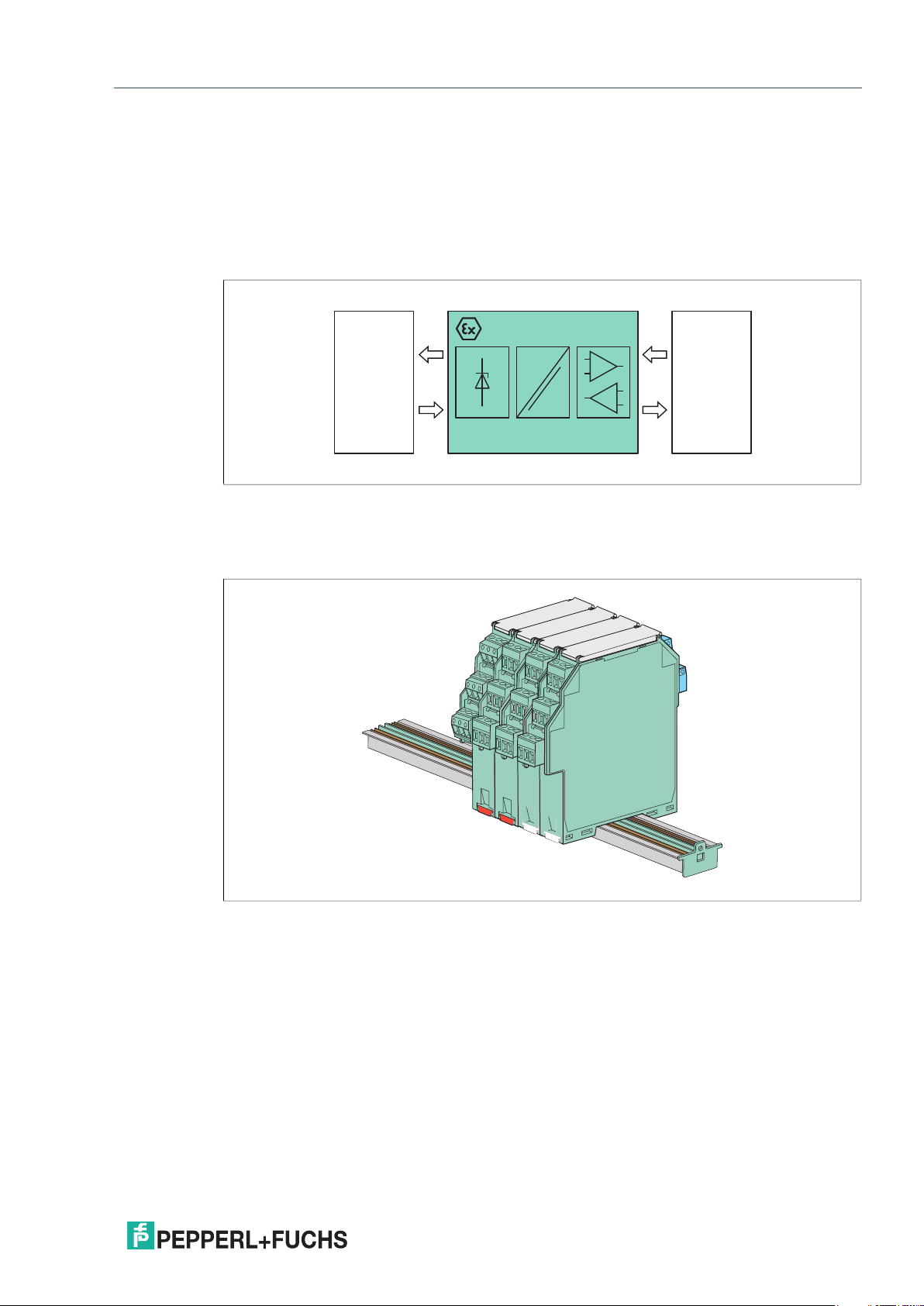

The K-System consists of wide range of isolated barriers suitable for mounting on 35 mm

DIN mounting rail. K-System is easy to specify, integrate and expand. Our extensive line of

intrinsic safe isolators for hazardous location applications contains over 150 different devices.

Figure 2.2 K-System on Power Rail

2021-03

7

Page 8

K-System – Isolated Barriers

Product Specifications

2.2 Housing Styles

Depending on the functionality and application, K-System devices have 3 different housing

widths:

• KC devices with 12.5 mm width

• KF devices with 20 mm width

• KF devices or KH devices with 40 mm width

The 3 housing widths versions have the same system characteristics. All devices

can be mounted on the 35 mm DIN mounting rail or the Power Rail. See chapter 2.9

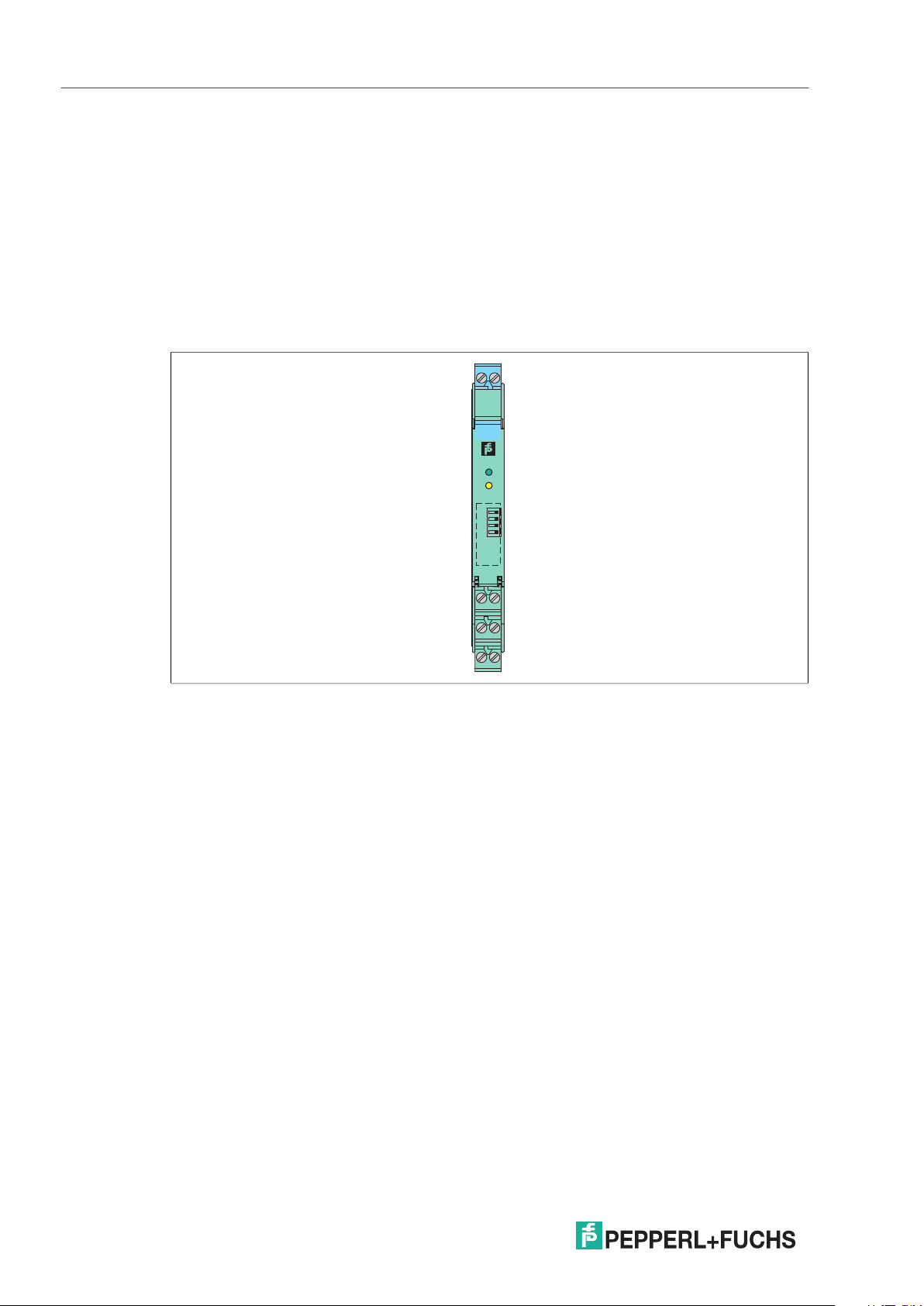

KC Device Housing

3

KCD2-SREx1.LB

PWR

OUT/CHK

1

2

S

3

4

241

I

II

Figure 2.3 KC device housing (12.5 mm)

Used for high signal integrity

• Compact 12.5 mm housing

• High packing density with single loop integrity

675

8

9

10

2021-03

8

Page 9

K-System – Isolated Barriers

Product Specifications

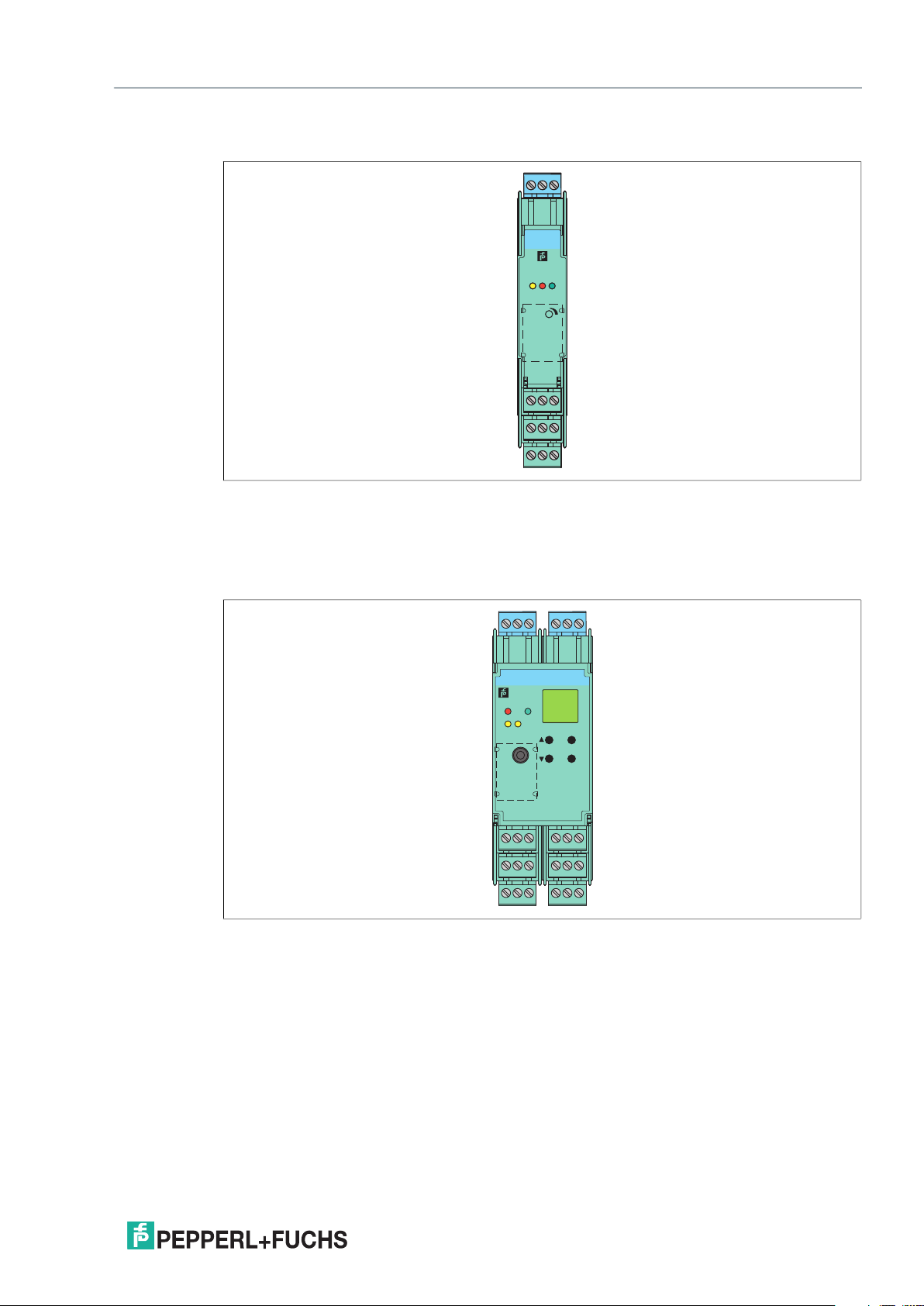

KF Device Housing

3

1

2

5

6

4

KFD2-ER-Ex1.W.LB

OUT CHK PWR

sens.

9107

8

12

11

13 15

14

Figure 2.4 KF device housing (20 mm)

Used for high channel density

• Compact 20 mm housing

• Packing density from 5 mm per channel

132465

KFD2-WAC2Ex1.D

PWR

FLT

12

OUT

11

17

22 24

23

ESC

OK

121610

18

RS232

8

14

19 21

20

9137

15

Figure 2.5 KF device housing (40 mm)

Used for applications with high functionality

• Digital devices monitor speed, direction of rotation, slip, flow rates and time.

• Analog devices monitor transmitter signals, temperature signals and load cells.

TM

• Configured using keypad or PACTware

software, see also manual "Installation

and Configuration Device Type Manager (DTM)"

• AC/DC wide range supply available

2021-03

9

Page 10

K-System – Isolated Barriers

Product Specifications

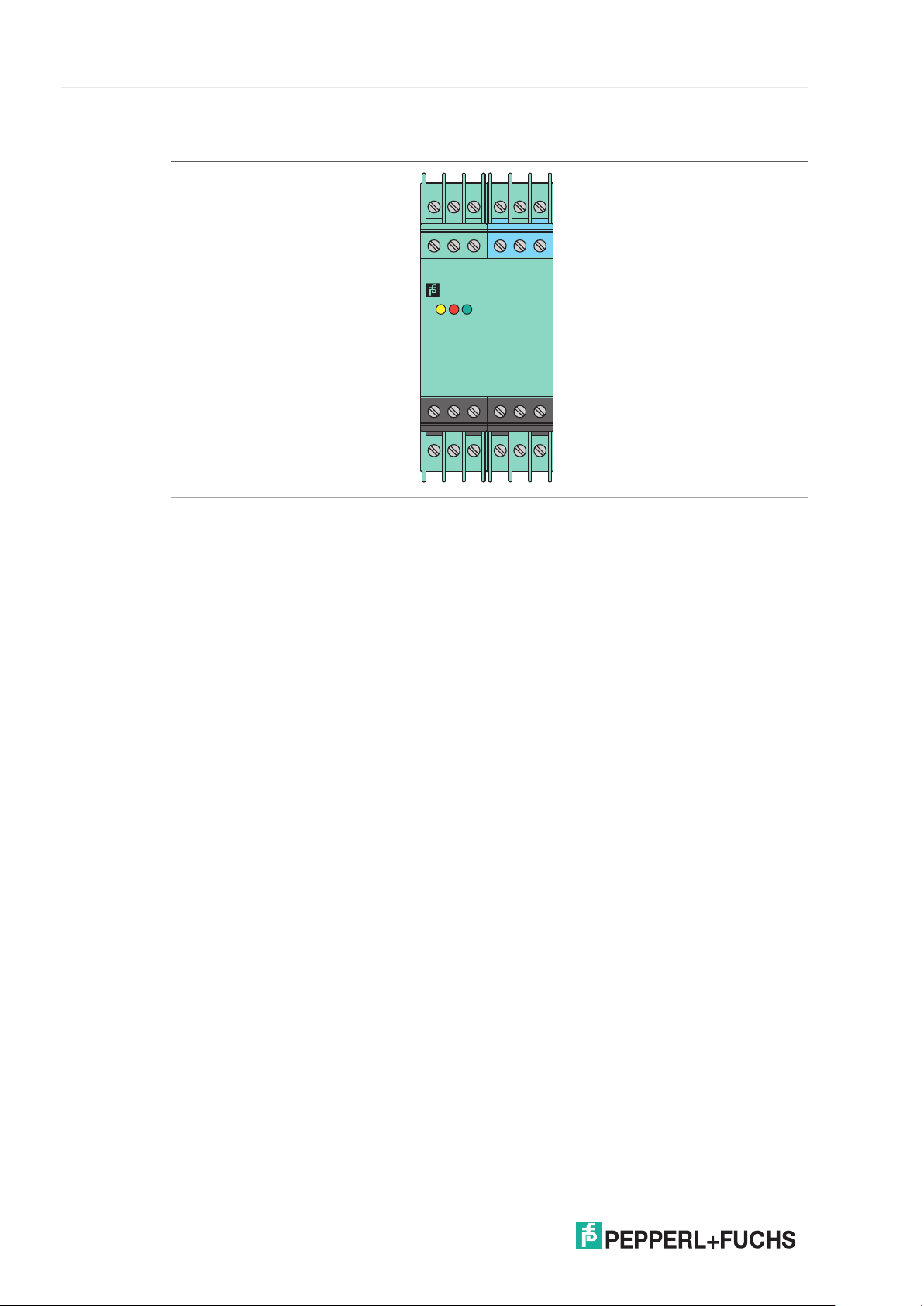

KH Device Housing

Figure 2.6 KH device housing (40 mm)

123

789

KHA6-SHEx1

1

CHKPWROUT

13 14 15

19 20 21

456

10 11 12

S

16 17 18

22 23 24

10

2021-03

Page 11

K-System – Isolated Barriers

12

9

10

7118

1

3

4

6

2

5

12

9

10

7118

1

3

4

6

2

5

12

9

10

7118

1

3

4

6

2

5

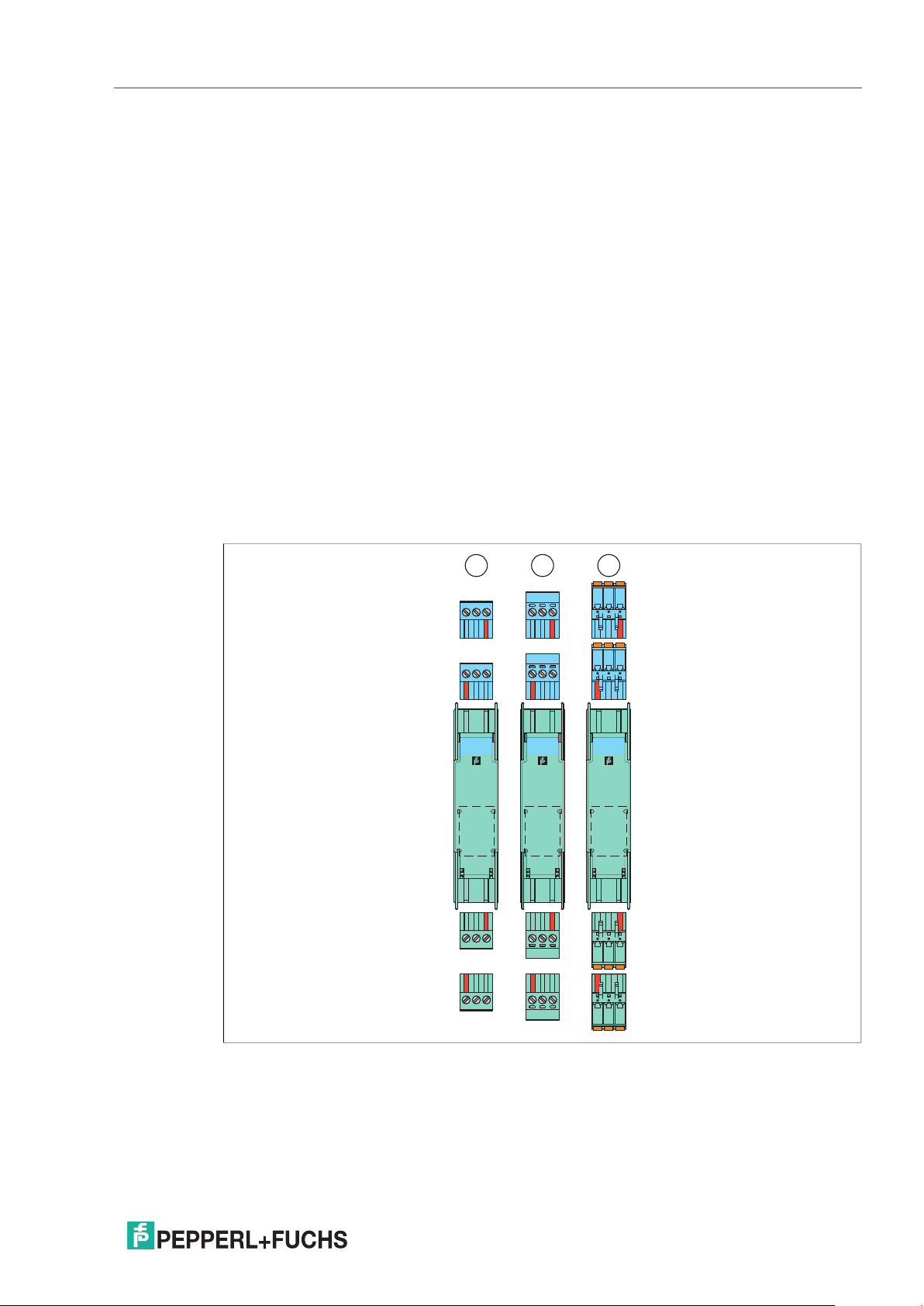

1 2 3

Product Specifications

2.3 Terminals

2.3.1 Removable Terminal Blocks

The removable terminal blocks simplify connection and control cabinet assembly.

The terminal blocks offer space for the connection of leads with core cross-sections

of up to 2.5 mm

so misconnection of terminal blocks are eliminated.

Observe the tightening torque of the terminal screws. The tightening torque

is 0.5 Nm to 0.6 Nm.

The 20 mm and 40 mm wide KF devices are factory-equipped with screw terminals.

The KC devices are available with screw terminals or spring terminals. The order designation

of the versions of the KC devices with spring terminals has the extension ".SP".

As an alternative to the factory-equipped terminal blocks the devices can be used

with other terminal blocks:

• Terminal blocks with screw terminals

• Terminal blocks with screw terminals and test plug socket

• Terminal blocks with spring terminals and test plug socket

These terminal blocks are available as accessories. The terminal blocks can be easily coded

with KF-CP coding pins (available optionally).

2

(14 AWG). The terminal blocks are coded with red coding pins

2021-03

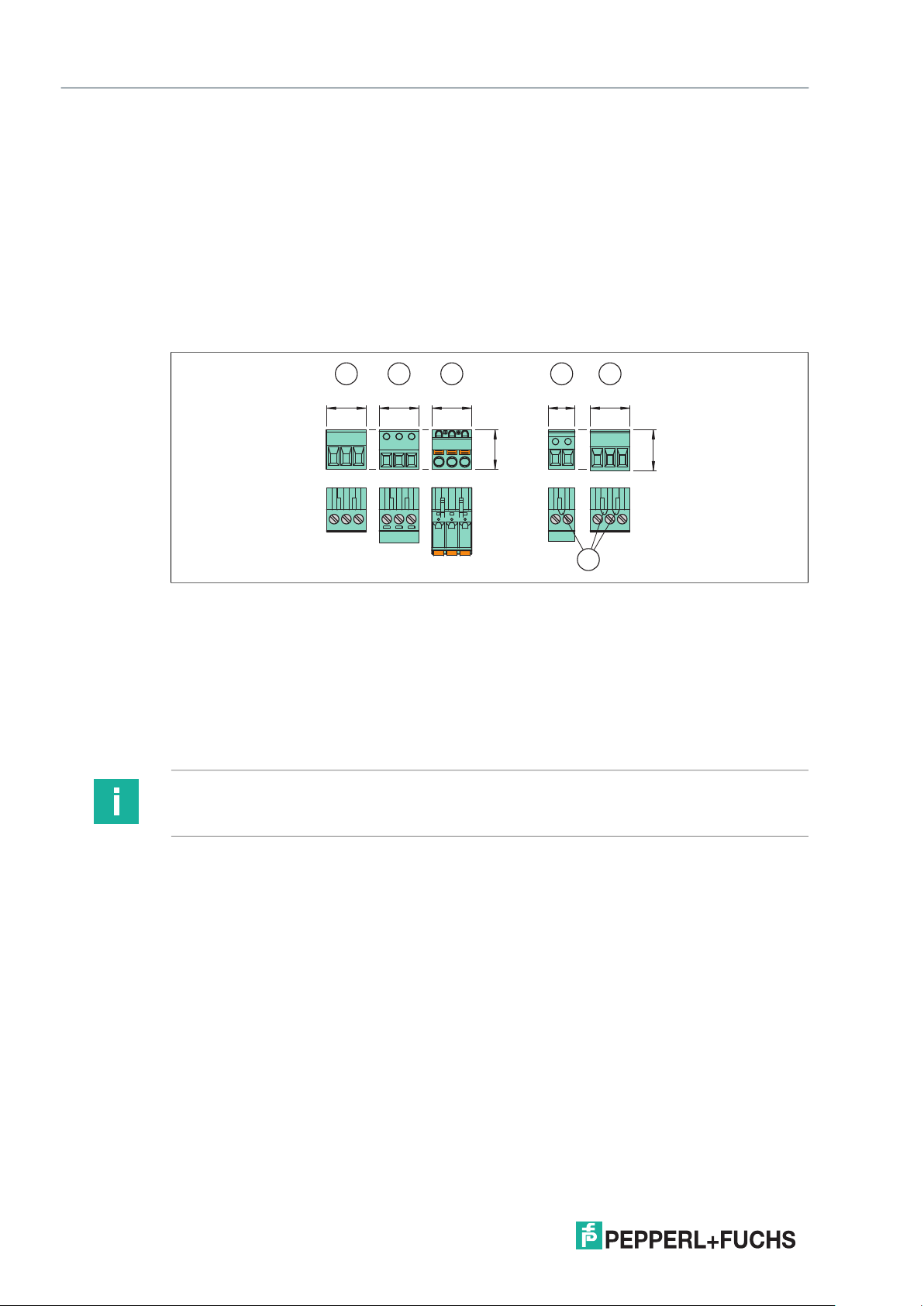

Figure 2.7 K-System removable terminal blocks

1 Terminal blocks with screw terminals

2 Terminal blocks with screw terminals and test sockets

3 Terminal blocks with spring terminals and test sockets

11

Page 12

K-System – Isolated Barriers

Product Specifications

Protection against direct contact

The removable terminal blocks have different heights:

• Height 15 mm (1), (2), (3): These terminal blocks are used in applications that have rated

voltages lower than 50 V AC. The insulation of the removable terminal blocks provides

protection against direct contact. The insulation corresponds to a reinforced insulation

according to EN 61010-1 for a rated insulation voltage of 50 V AC.

• Height 15.5 mm (4), (5): These terminal blocks are used in applications that have rated

voltages higher than 50 V AC. The insulation of the removable terminal blocks provides

protection against direct contact. The insulation corresponds to a basic insulation

according to EN 61010-1 for a rated insulation voltage of 300 V AC. The higher terminals

are marked (X).

1 52 3 4

15.115.115.1

15

Figure 2.8 Removable terminal blocks with different heights

15.110.1

15.5

X

1 Terminal block with screw terminals, height 15 mm

2 Terminal block with screw terminals and test sockets, height 15 mm

3 Terminal block with spring terminals and test sockets, height 15 mm

4 Terminal block with screw terminals and test sockets, height 15.5 mm

5 Terminal block with screw terminals, height 15.5 mm

X Marking

Note

See corresponding datasheets for further information.

12

2021-03

Page 13

K-System – Isolated Barriers

9

10

8

675

241

3

3 4

1 2

7 8

5 6

9 10

1

3

4

6

2

5

13 15

12

9107

14

11

8

4 5 6

1 2 3

7 8 9

10 11 12

13 14 15

Product Specifications

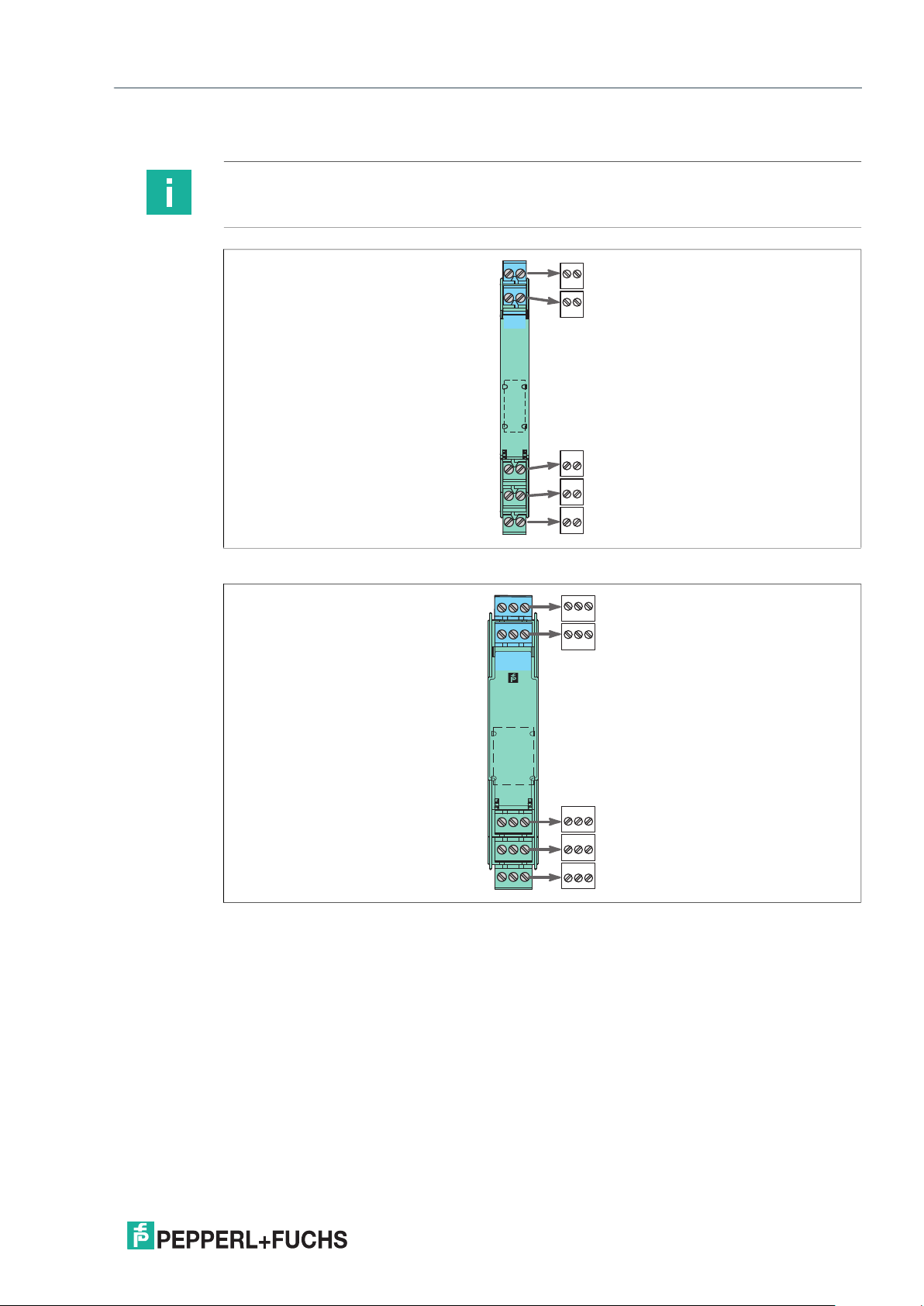

2.3.2 Terminal Designation

Note

See corresponding datasheets for precise terminal designation.

Figure 2.9 KC device housing (12.5 mm)

Figure 2.10 KF device housing (20 mm)

2021-03

13

Page 14

K-System – Isolated Barriers

Product Specifications

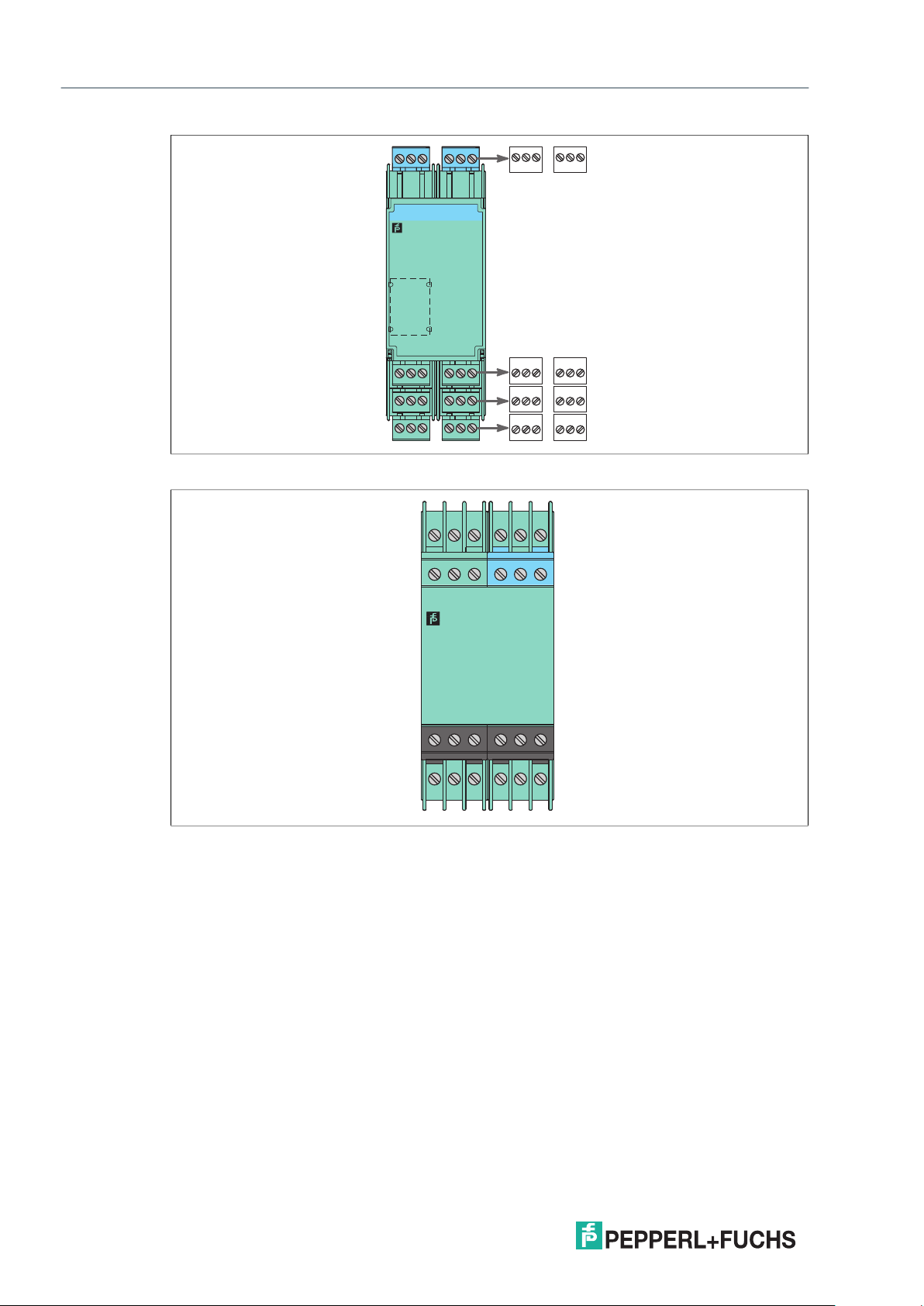

Figure 2.11 KF device housing (40 mm)

132465

9137

8

15

14

19 21

20

11

17

22 24

23

1 2 3

4 5 6

121610

18

7 8 9

10 11 12

13 14 15

16 17 18

19 20 21

22 23 24

Figure 2.12 KH device housing (40 mm)

123

789

13 14 15

19 20 21

456

10 11 12

16 17 18

22 23 24

14

2021-03

Page 15

K-System – Isolated Barriers

ESC

OK

KFU8-UFTEx2.D

RS232

PWR1

12

3

2

4

IN/

CHK

OUT

19 21

15

9137

20

14

8

22 24

18

121610

23

17

11

132465

KFD2-ER-Ex1.W.LB

1

3

4

6

2

5

13 15

12

9107

14

11

8

OUT CHK PWR

sens.

KFA5-ER-Ex1.W.LB

1

3

4

6

2

5

13 15

12

9107

14

11

8

OUT CHK PWR

sens.

21 3

4

Product Specifications

2.4 Color Identification

The color identification of the devices has the following meaning:

• Green (1) indicates devices with DC power supply.

• Black (2) indicates devices with AC power supply.

• Gray (3) indicates devices with AC/DC wide range supply.

• Blue (4) indicates devices that process signals from the hazardous area.

Figure 2.13 Color identification of devices

1 green

2 black

3 gray

4 blue

2021-03

15

Page 16

K-System – Isolated Barriers

OUT CHK PWR

1 2 3

Product Specifications

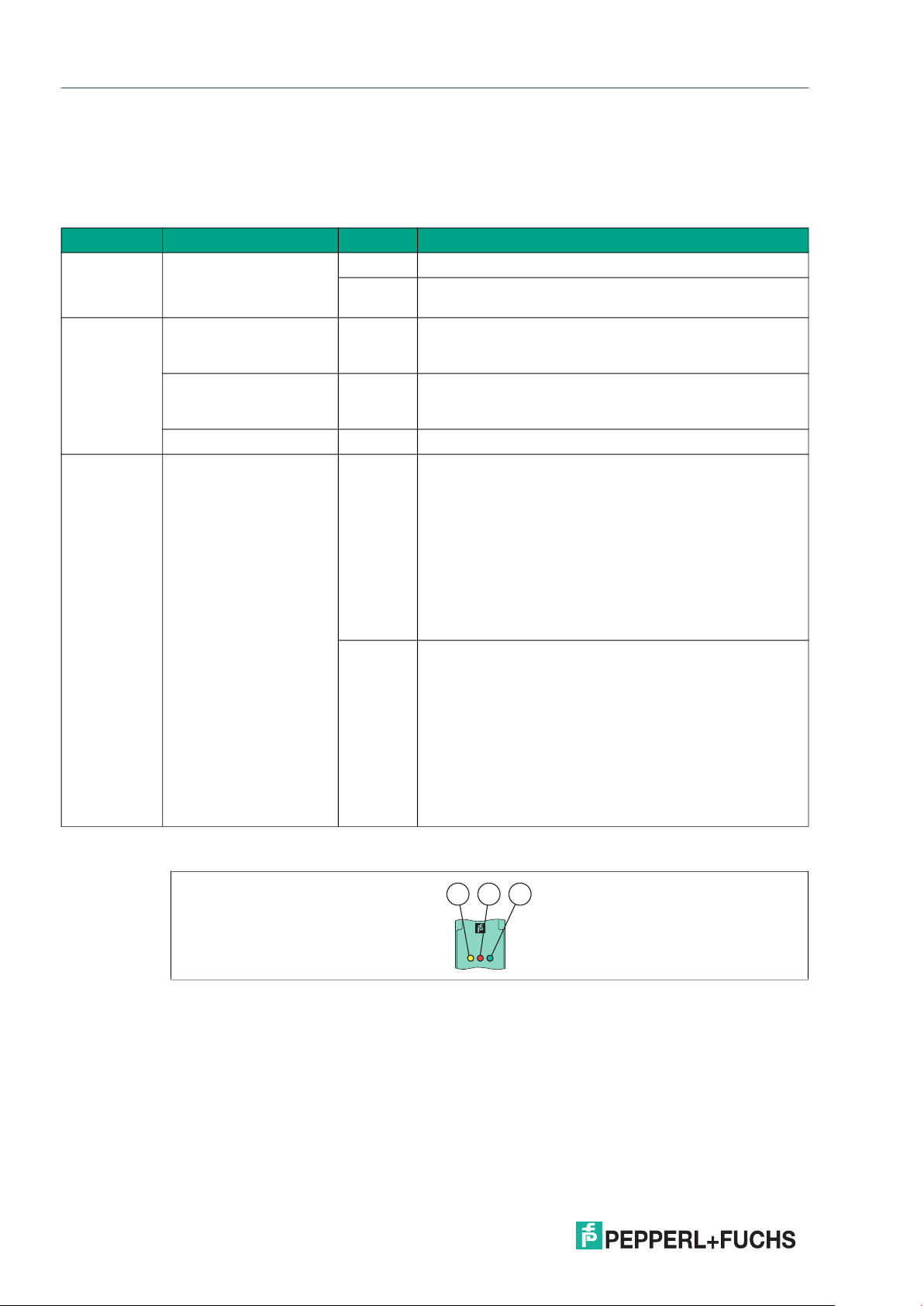

2.5 Status Indicators of the Isolators

LEDs are often used on isolators to indicate different statuses (e. g. for power supply,

device failure, status messages, binary switching states). Standard LED colors are assigned

to the status display according to NAMUR NE44.

LED Display function Display Meaning

Green LED Power supply On Power supply OK

Off No power supply or insufficient power supply – device

faulty

Red LED Device fault, device

failure

Line fault Flashing External fault signal, failure signal – fault/failure display

No fault Off No malfunction, device is operating properly

Yellow LED Switching states of

binary inputs and

outputs

On Internal fault signal, failure signal – fault/failure display

of causes detected inside the device, device needs

replacing

of causes detected outside the device, inspection

and elimination of fault required

On Possible causes of the output:

• The relay is energized.

• The NO contact (also a change-over contact)

is actively closed.

• The open collector is switched through.

• The switching voltage generated inside the device

is applied.

Possible causes of the input:

• A binary switching signal is present.

• An analog limit value is reached.

Off Possible causes of the output:

• The relay is de-energized.

• The NO contact (also a change-over contact)

is actively opened.

• The open collector is not switched through.

• The switching voltage generated inside the device

is not applied.

Possible causes of the input:

• A binary switching signal is present.

• An analog limit value is reached.

Table 2.1 Meaning of status indicators

16

Figure 2.14 Example status indicators

1 Yellow LED "OUT"

Switching state of the output

2 Red LED "CHK"

Lead breakage and short circuit status indicator

3 Green LED "PWR"

Power supply status indicator

2021-03

Page 17

K-System – Isolated Barriers

S2

S1

S3

III

1

SPAN

ZERO

1

Product Specifications

2.6 Operating Elements

Many devices of the K-System can be adapted to different applications.

Depending on the device different operating elements are available for this configuration.

These operating elements are:

DIP switches

Via DIP switches you can configure the basic functions of the device.

Figure 2.15

1 DIP switch

Rotary switches

Via rotary switches you can configure the basic functions of the device.

1

0

1

9

2

8

3

S2

7

4

6

5

Figure 2.16

1 Rotary switch

Potentiometers

Via potentiometers you can configure the calibration of input and output characteristics.

Figure 2.17

1 Potentiometer

2021-03

17

Page 18

K-System – Isolated Barriers

PROGRAM

1

Product Specifications

Keypad and LC display

Via keypad you can configure the settings of the device parameters. Measured values,

fault signals and configuration settings are displayed on the LC display.

Figure 2.18

1 LC display

2 Keypad

21

ESC

OK

Programming sockets for the connection of a PC with parameterization

software PACTware

TM

Via parameterization software PACTwareTM you can configure the device easily.

The configuration data can be edited and saved. The parameterization software helps users

for maintenance, diagnostics and troubleshooting.

Figure 2.19

1 Programming socket

Note

See manual "HART Multiplexer System KFD*-HM*-16" for further information for

communication via software.

Note

See corresponding datasheets for further information.

2021-03

18

Page 19

K-System – Isolated Barriers

21 2 3 4

Product Specifications

2.7 Label Carrier

For individual labeling, the isolated barriers are equipped ex works with a label carrier.

Labels can be inserted into the label carrier.

It is also possible to attach an adhesive label to the transparent front flap.

Figure 2.20 Devices with transparent front flap

1 Label carrier on KC devices with label 22 mm x 9 mm

2 Label carrier on KF devices for with 22 mm x 16.5 mm

3 Adhesive label 22 mm x 11 mm for all KC and KF devices, can only be used on devices

with a transparent front flap

4 Label carrier on KF devices with label 18 mm x 8 mm, can only be used on devices

without a transparent front flap

2.8 DIN Mounting Rail

The devices are mounted on a 35 mm DIN mounting rail according to EN 60715.

Figure 2.21 Example: DIN mounting rail UPR-MR (35 mm x 15 mm)

2021-03

19

Page 20

K-System – Isolated Barriers

1

2

34

Product Specifications

2.9 Power Rail

To reduce wiring and installation costs, Power Rail is the optimum solution. The Power Rail

is a DIN mounting rail with plastic insert, that delivers power to the devices (24 V DC)

and transfers bus signals and a collective error message.

The Power Rail is factory-equipped with cover and end caps. These parts cover empty

and open segments of the Power Rail. Thus, the Power Rail is protected from contamination.

Additionally the cover and end caps prevent that electrically conductive parts come in contact

with the Power Rail.

Power Rail is available in two versions:

Power Rail UPR-03

The Power Rail UPR–03 has 3 conductors.

• 2 conductors for power

• 1 conductor for collective error messaging

Power Rail UPR-05 (only for KFD2-WAC2-(Ex)1.D)

The Power Rail UPR–05 has 5 conductors.

• 2 conductors for power

• 1 conductor for collective error messaging

• 2 conductors for serial data exchange

Figure 2.22 Example: Power Rail UPR-03

1 Cover UPR-COVER

2 Insert UPR-INS-03

3 DIN mounting rail UPR-MR (35 mm x 15 mm)

4 End cap UPR-E

2021-03

20

Page 21

K-System – Isolated Barriers

Mounting and Installation

3 Mounting and Installation

Danger!

Explosion hazard from damaged electronic components

Premature wear of electronic components in a device that was previously used in a general

electrical installation can cause sparks that can ignite the surrounding potentially explosive

atmosphere.

Never install devices that have already been operated in general electrical installations

in electrical installations used in combination with hazardous areas!

Danger!

Explosion hazard from pollution

An excessively polluted surface of the device can become conductive and consequently ignite

a surrounding potentially explosive atmosphere.

Ensure that you install the device only in environments with a pollution degree 2 or better

according to IEC/EN 60664–1.

3.1 Mounting

Danger!

Danger to life from electric shock

Absent or insufficient insulation can result in electric shock.

Only connect supplies that provide protection against electric shock to power feed modules

(e. g. SELV or PELV).

Caution!

Property damage from use of isolators for Power Rail supply

Using the isolators for Power Rail supply can damage the isolators and make

the Power Rail fail.

Do not supply the Power Rail via isolators.

2021-03

21

Page 22

K-System – Isolated Barriers

Mounting and Installation

Mounting in the Non-Hazardous Area

Mounting the Isolated Barrier

Snap the device onto the DIN mounting rail in a vertical downward movement.

See following figure.

Mounting in Areas that Require the Equipment Protection Level Gc

Danger!

Explosion hazard from live wiring of non-intrinsically safe circuits

If you connect or disconnect energized non-intrinsically safe circuits in a potentially

explosive atmosphere, sparks can ignite the surrounding atmosphere.

Only connect or disconnect energized non-intrinsically safe circuits in the absence

of a potentially explosive atmosphere.

Danger!

Explosion hazard from wrong mounting

The device safety can be impaired by external environmental influences and

by mechanical stress. That can lead to sparking that can ignite a surrounding potentially

explosive atmosphere.

Mount the device in a surrounding enclosure that complies with IEC/EN 60079–0

and that is rated with the degree of protection IP54 according to IEC/EN 60529.

Mounting the Isolated Barrier

Snap the device onto the DIN mounting rail in a vertical downward movement.

See following figure.

CORRECT: Device snapped on vertically. INCORRECT: Device snapped on from the side.

Can damage the contacts and cause the device to fail.

Figure 3.1

2021-03

22

Page 23

K-System – Isolated Barriers

1

3

4

6

2

5

1

3

4

6

2

5

1

3

4

6

2

5

1

3

4

6

2

5

13

12

9

10

7

14 15

11

8

13

12

9

10

7

14 15

11

8

13

12

9

10

7

14 15

11

8

13

12

9

10

7

14 15

11

8

Mounting and Installation

Vertical and horizontal mounting

Low heat dissipation allows vertical or horizontal mounting without separation distance.

Operation is guaranteed over the full temperature range of the system in any mounting

direction and without restriction.

Figure 3.2 Vertical mounting without separation distance (group mounting)

3

1

2

5

4

8

11

13

14 15

3

3

1

1

2

11

14 15

2

5

5

6

4

9107

8

8

12

11

13

14 15

6

4

9107

12

13

3

1

2

5

6

6

4

9107

9107

8

12

12

11

13

14 15

Figure 3.3 Horizontal mounting without separation distance (group mounting)

2021-03

23

Page 24

K-System – Isolated Barriers

Mounting and Installation

Mounting Conditions for Operating the Device at Higher Ambient

Temperature

Certain devices with a maximum allowable ambient temperature of 60 °C (140 °F)

can be operated at ambient temperatures up to 70 °C (158 °F) if mounted horizontally.

These devices have a corresponding reference to this manual in the datasheet.

Caution!

Device failure due to overlooking heat dissipation

Overlooking heat dissipation can compromise the function and the electrical safety

of the device.

• Mount the device on the DIN mounting rail in a horizontal mounting position.

• Mount the device on the DIN mounting rail according to the specified minimum

separation distance.

• Do not operate devices without this reference in the datasheet at an ambient temperature

up to 70 °C (158 °F).

Mounting the Isolated Barriers with Separation Distance

Mount the device on the DIN mounting rail. Observe the specified minimum

separation distance.

See following figures.

• KC devices with 12.7 mm housing width, housing type A*: min. 6 mm

• KF devices with 20 mm housing width, housing type B*: min. 10 mm

• KF devices with 40 mm housing width, housing type C*: min. 15 mm

12.7 ≥6 12.7 ≥6

Figure 3.4 Horizontal mounting of KC devices with 12.7 mm housing width (single device mounting)

24

2021-03

Page 25

K-System – Isolated Barriers

40 ≥15 40 ≥15

Mounting and Installation

20 ≥10 20 ≥10

3

1

2

5

6

4

9107

8

12

11

13

14 15

3

1

2

5

6

4

9107

8

12

11

13

14 15

3

1

2

5

6

4

9107

8

12

11

13

14 15

Figure 3.5 Horizontal mounting of KF devices with 20 mm housing width (single device mounting)

Figure 3.6 Horizontal mounting of KF devices with 40 mm housing width (single device mounting)

2021-03

25

Page 26

K-System – Isolated Barriers

Mounting and Installation

Mounting the Terminal Blocks

Danger!

Danger to life from electric shock

Working on live parts at voltages higher than 50 V AC or 120 V DC can result

in electric shock.

Switch off the voltage.

1.

2. Connect the terminal blocks or disconnect the terminal blocks.

3.2 Connection

1. De-energize the device.

2. Secure the circuit against reconnection.

3. Verify that the device is de-energized at all poles.

4. Provide protection from adjacent live parts, if present.

Danger!

Explosion hazard from live wiring of non-intrinsically safe circuits

If you connect or disconnect energized non-intrinsically safe circuits in a potentially

explosive atmosphere, sparks can ignite the surrounding atmosphere.

Only connect or disconnect energized non-intrinsically safe circuits in the absence

of a potentially explosive atmosphere.

Danger!

Danger to life from electric shock

Absent or insufficient insulation can result in electric shock.

• Maintain sufficient distance between the connection lines, terminals,

surrounding enclosure, and the environment.

• Insulate connection lines, terminals, and the surrounding enclosure

from the environment.

Danger!

Danger to life from incorrect installation

Incorrect installation of cables and connection lines can compromise the function

and the electrical safety of the device.

• Observe the permissible core cross section of the conductor.

• When using stranded conductors, crimp wire end ferrules on the conductor ends.

• Use only one conductor per terminal.

• When installing the conductors the insulation must reach up to the terminal.

• Observe the tightening torque of the terminal screws.

26

2021-03

Page 27

K-System – Isolated Barriers

Mounting and Installation

Danger!

Explosion hazard from exposed conductors

Exposed conductors of inadequately attached cables can cause sparks that can ignite

the surrounding potentially explosive atmosphere.

When installing the device ensure that the cables are adequately attached.

Caution!

Property damage from use of inappropriate tool

Using an inappropriate tool may damage the screw heads.

• Use a slot-head screwdriver with a size of 3.5 x 0.5.

• Observe the tightening torque of the terminal screws. The tightening torque

is 0.5 Nm to 0.6 Nm.

Note

See corresponding datasheets for further information.

3.2.1 Field Side Connection

Danger!

Explosion hazard from wrong separation distances

If you do not observe the minimum separation distance between 2 intrinsically safe circuits,

this can lead to added currents or voltages. This can result in a current/voltage flashover

generating sparks. The sparks can ignite the surrounding potentially explosive atmosphere.

Ensure that you observe all separation distances between 2 adjacent intrinsically safe circuits

according to IEC/EN 60079-14.

Danger!

Explosion hazard from wrong separation distances

If you do not observe the minimum separation distances between intrinsically safe circuits

of associated apparatus and non-intrinsically safe circuits, this can lead to added currents

or voltages. This can result in a current/voltage flashover generating sparks.

The sparks can ignite the surrounding potentially explosive atmosphere.

Ensure that you observe the compliance of the separation distances to all non–intrinsically

safe circuits according to IEC/EN 60079–14.

Connecting the Field Side

Connect the field devices via the screw terminals or spring terminals.

2021-03

27

Page 28

K-System – Isolated Barriers

Mounting and Installation

3.2.2 Control Side Connection

Connection of Devices with Relay Output

Danger!

Danger to life from electric shock

Working on live parts at voltages higher than 50 V AC or 120 V DC can result in electric shock.

1. De-energize the device.

2. Secure the circuit against reconnection.

3. Verify that the device is de-energized at all poles.

4. Provide protection from adjacent live parts, if present.

Warning!

Risk of short circuit

Live working can cause injuries to the operator and/or damage to the device.

Disconnect the device, before you plug or unplug the plugs.

Connection of other Devices

Danger!

Danger to life from electric shock

Absent or insufficient insulation can result in electric shock.

Only connect circuits that provide protection against electric shock (e. g. SELV or PELV).

Warning!

Risk of short circuit

Live working can cause injuries to the operator and/or damage to the device.

Disconnect the device, before you plug or unplug the plugs.

Connecting the Control Side

Connect the control system via the screw terminals or spring terminals.

28

2021-03

Page 29

K-System – Isolated Barriers

Mounting and Installation

3.2.3 Power Supply Connection

The devices are available with different supply voltages.

• 24 V DC power supply

• 115 V AC or 230 V AC power supply for applications where direct current is not available

• AC/DC wide range supply with 24 V DC or 115/230 V AC

Note

The supported supply voltage for each device is identified on the side plate.

The devices are supplied with power in various ways.

• Power supply without Power Rail, see chapter 3.2.3.1

• Power supply with Power Rail, see chapter 3.2.3.2

• Non-redundant supply with power feed module

• Redundant supply with power feed module

• Direct supply with power supply

3.2.3.1 Power Supply without Power Rail

If devices with AC or universal power supplies are used, the advantages of Power Rail

are not available.

Conventional power supplies create complicated and expensive wiring systems.

After all isolated barriers are connected, there is a significant amount of wiring and more wiring

must be added for extra functions such as line fault detection.

Connection of KCD and KFD Devices

Danger!

Danger to life from electric shock

Absent or insufficient insulation can result in electric shock.

Only connect supplies that provide protection against electric shock (e. g. SELV or PELV).

Connection of KFA, KFU, and KHA Devices

Danger!

Danger to life from electric shock

Working on live parts at voltages higher than 50 V AC or 120 V DC can result in electric shock.

1. De-energize the device.

2. Secure the circuit against reconnection.

3. Verify that the device is de-energized at all poles.

4. Provide protection from adjacent live parts, if present.

Connecting the Power Supply

Connect the power supply via the screw terminals or spring terminals.

2021-03

29

Page 30

K-System – Isolated Barriers

1

3

4

6

2

5

1

3

4

6

2

5

1

3

4

6

2

5

1

3

4

6

2

5

13

12

9107

14 15

11

8

13

12

9107

14 15

11

8

13

12

9107

14 15

11

8

13

12

9107

14 15

11

8

1

24 V DC

Mounting and Installation

Figure 3.7 Conventional installation

1 DIN mounting rail

3.2.3.2 Power Supply with Power Rail

For devices with a 24 V DC supply voltage, use of the Power Rail reduces wiring and

installation costs. The Power Rail almost completely eliminates the risk of wiring faults

and facilitates expansion.

Power is supplied to the Power Rail via a power feed module which provides a voltage

of 24 V DC (max. 4 A) to a maximum of 80 devices.

The power feed module features a replaceable 5 A fuse at the front. This fuse ensures

that the Power Rail and connecting contacts are protected. It prevents damage caused

by reverse supply voltage or by installing too many isolators. The isolators on the Power Rail

feature integrated device fuses. Any faults in the isolator or in the signal leads do not affect

the Power Rail supply system. The 5 A fuse permits a rated current of up to 4 A across

the entire temperature range.

The power feed module also has the task of outputting a collective error message or power

failure of the isolators via a separate relay output.

Alternatively, supply of the Power Rail can be provided using the power supply

KFA6-STR-1.24.*. In this case, no collective error message is possible.

30

2021-03

Page 31

K-System – Isolated Barriers

1

3

4

6

2

5

1

3

4

6

2

5

1

3

4

6

2

5

1

3

4

6

2

5

13

12

9107

14 15

11

8

13

12

9107

14 15

11

8

13

12

9107

14 15

11

8

13

12

9107

14 15

11

8

1

3

4

6

2

5

13

12

9107

14 15

11

8

3

2

24 V DC

1

Mounting and Installation

Supply with Power Feed Module

Danger!

Danger to life from electric shock

Absent or insufficient insulation can result in electric shock.

Only connect supplies that provide protection against electric shock to power feed modules

(e. g. SELV or PELV).

Caution!

Property damage from use of isolators for Power Rail supply

Using the isolators for Power Rail supply can damage the isolators and make

the Power Rail fail.

Do not supply the Power Rail via isolators.

Connecting the Power Supply

Connect the power supply via the Power Rail.

Non-Redundant Supply

The power feed module mounts on the Power Rail for easy and reliable distribution of power

to all connected isolators. This method eliminates the wiring loops (daisy chain) necessary

on a conventional installation without Power Rail.

Figure 3.8 Power Rail installation

1 Replaceable fuse

2 Power feed module

3 Power Rail

2021-03

31

Page 32

K-System – Isolated Barriers

1

3

4

6

2

5

13

12

9107

14 15

11

8

1

3

4

6

2

5

13 15

12

9107

14

11

8

1

3

4

6

2

5

1

3

4

6

2

5

13

12

9107

14 15

11

8

13

12

9107

14 15

11

8

4

2 3

24 V DC 24 V DC

1

Mounting and Installation

Redundant Supply

Two power supplies or a redundant power supply with two power feed modules offer

a high degree of availability. If a power supply or the fuse in a power feed module fails,

the redundant supply continues to energize the isolators through their Power Rail connection.

Figure 3.9 Redundant power connections

1 Replaceable fuse

2 Power feed module 1

3 Power feed module 2

4 Power Rail

32

2021-03

Page 33

K-System – Isolated Barriers

1

3

4

6

2

5

1

3

4

6

2

5

13

12

9107

14 15

11

8

13

12

9107

14 15

11

8

21

115/230 V AC

24 V DC

1

3

4

6

2

5

1

3

4

6

2

5

13

12

9107

14 15

11

8

13

12

9107

14 15

11

8

PWR

1

3

4

6

2

5

13 15

12

9107

14

11

8

1

115/230 V AC

2

24 V DC

Mounting and Installation

Direct Supply with Power Supply

A complete power solution for a K-System installation is possible by using the following

power supplies:

• KFA6-STR-1.24.4 from 115/230 V AC to 24 V DC/4 A or

• KFA6-STR-1.24.500 from 115/230 V AC to 24 V DC/500 mA

The power supplies snap on the Power Rail to easily and efficiently distribute power

to the isolated barriers.

Figure 3.10 Integrated power supply (4 A)

1 Power supply

2 Power Rail

Figure 3.11 Integrated power supply (500 mA)

1 Power supply

2 Power Rail

2021-03

33

Page 34

K-System – Isolated Barriers

Mounting and Installation

3.2.4 Establishing the Communication via Software

Danger!

Explosion hazard from sparking when plugging or pulling the adapter

Plugging or pulling the adapter in a potentially explosive atmosphere can cause sparks

that can ignite the surrounding atmosphere.

Only plug or pull the adapter in the absence of a potentially explosive atmosphere.

Caution!

Fault in the plant

Changing the device data changes the device function.

Before entering new device data, make sure the plant is not endangered by changing

the device data.

Establishing the Communication via Software

Establish the HART communication via K-ADP-USB adapter and HART multiplexer

on the control side, if available.

Note

See manual "HART Multiplexer System KFD*-HM*-16" for further information

for communication via software.

34

2021-03

Page 35

K-System – Isolated Barriers

Configuration

4 Configuration

Danger!

Explosion hazard from sparking when using operating elements

Using operating elements in a potentially explosive atmosphere can cause sparks

that can ignite the surrounding atmosphere.

Only use operating elements (e. g., switch, slider, button, etc.) in the absence of a potentially

explosive atmosphere.

Caution!

Potential device malfunction from change of device function

Changes in the device function can lead to device malfunction. The function of the device

is no longer guaranteed.

Before transferring the new device function, make sure that the changed device function

does not cause a danger to the device and the plant.

Configuring the Device

Set the particular operating elements as described in section "Configuration" of the data sheet.

Note

See corresponding datasheets for further information.

2021-03

35

Page 36

K-System – Isolated Barriers

Operation

5 Operation

Danger!

Explosion hazard from live wiring of non-intrinsically safe circuits

If you connect or disconnect energized non-intrinsically safe circuits in a potentially

explosive atmosphere, sparks can ignite the surrounding atmosphere.

Only connect or disconnect energized non-intrinsically safe circuits in the absence

of a potentially explosive atmosphere.

Danger!

Explosion hazard from sparking when using operating elements

Using operating elements in a potentially explosive atmosphere can cause sparks that can

ignite the surrounding atmosphere.

Only use operating elements (e. g., switch, slider, button, etc.) in the absence of a potentially

explosive atmosphere.

5.1 Fault Monitoring

Numerous faults can occur between measurement of the process variable and evaluation

in the control system. This can lead to undesirable process statuses under certain

circumstances. These process statuses may result in plant downtime or quality problems

or even present a hazard to persons and the environment. Depending on the device version,

the isolators enable monitoring of the following faults:

• Line faults

Here, the connection cables between the isolator, the field device and the control system

are monitored for lead breakages or short circuits.

• Device faults

The isolators are designed so that internal faults are detected and reported.

In the case of a power failure, the outputs are switched to the de-energized state.

36

2021-03

Page 37

K-System – Isolated Barriers

2-

1+

7

8 (+/-)

FAU LT

10

11

12

2+

1+

7+

9-

FAU LT

Operation

5.2 Fault Output

Depending on the configuration of the devices, these faults are transmitted to the outputs

at the control side and in separate fault indication outputs as additional information.

• Red fault indication LEDs on the isolator

• Fault indication output

• Collective error message on Power Rail

Fault Indication Output

Line and device faults are transmitted if the device has a fault indication output (FAULT).

The fault indication output is active in a normal state and inactive in a fault state (closed-circuit

principle). Is it impossible to reverse the detection direction of the fault indication output.

Figure 5.1

Line Fault Transparency (LFT)

Line fault transparency makes electrical conditions on the field side visible on the control side

of the isolator. This enables line faults between the isolator and the field device to be detected

and transmitted to the control system via the signal line.

Figure 5.2 Example of line fault transparency with digital input

2021-03

37

Page 38

K-System – Isolated Barriers

Operation

Collective Error Message on Power Rail

The fault can also be output via the Power Rail as a collective error message (FAULT).

24 V DC

Power Rail

24 V DCFAULT

Figure 5.3

The collective error message enables line fault detection of many isolators without requiring

additional wiring. In the event of a fault, a fault message signal is transmitted to the Power Rail

from an isolator. The power feed module evaluates the signal and transmits the fault message

signal to the controller by means of a potential-free contact.

The potential-free contact simultaneously reports the device power failure or the failure

of one device minimum.

1

1

4

11

13 15

14

3

2

5

6

9107

8

12

3

3

1

1

2

2

5

5

6

4

4

9107

8

8

12

11

14 15

11

13

14 15

13

3

1

1

2

2

5

8

11

14 15

5

6

4

9107

8

12

11

13

14 15

6

4

9107

12

13

2

3

6

9107

12

4

24 V DC

3

Figure 5.4 Collective error message via power feed module

1 Power feed module

2 Fault indication on one of the devices (red LED flashes)

3 Process control system

4 Fault indication output

2021-03

38

Page 39

K-System – Isolated Barriers

I [mA]

42021

0 %

100 %

20.53.6 3.8

1 12

Operation

5.3 Current and Voltage Standard Signals

The following signals have established themselves as the standard:

• the 0/4 mA to 20 mA current signal

• the 0/2 V to 10 V voltage signal

• the 0/1 V to 5 V voltage signal

Analog sensor signals and digital frequency signals are converted into one of the two standard

signals for processing in a wide variety of measurement, regulatory and control tasks.

This offers the measurement and control technician an easy-to-measure standard signal

common to all manufacturers. Sensor signals are converted into standard signals via signal

converters.

For more diagnostic options, the NAMUR organization published NAMUR recommendation

NE43, dividing the value range of the signal (e. g. current signal) into several areas.

Valid, defined measurement value information is transferred within the range

from 3.8 mA to 20.5 mA. Failure information is available when the signal current is < 3.6 mA

or > 21 mA i. e. outside of the range for measured value information. The same applies

to the voltage signal.

Figure 5.5 Signal ranges according to NAMUR NE43 (e. g. current signal)

1 Failure information

2 Measuring information

2021-03

39

Page 40

K-System – Isolated Barriers

Dismounting, Maintenance, and Repair

6 Dismounting, Maintenance, and Repair

Danger!

Explosion hazard from live wiring of non-intrinsically safe circuits

If you connect or disconnect energized non-intrinsically safe circuits in a potentially

explosive atmosphere, sparks can ignite the surrounding atmosphere.

Only connect or disconnect energized non-intrinsically safe circuits in the absence

of a potentially explosive atmosphere.

Danger!

Danger to life from using damaged or repaired devices.

Using a defective or repaired device can compromise its function and its electrical safety.

• Do not use a damaged or polluted device.

• The device must not be repaired, changed or manipulated.

• If there is a defect, always replace the device with an original device from Pepperl+Fuchs.

Danger!

Danger to life from electric shock

Working on live parts at voltages higher than 50 V AC or 120 V DC can result in electric shock.

1. De-energize the device.

2. Secure the circuit against reconnection.

3. Verify that the device is de-energized at all poles.

4. Provide protection from adjacent live parts, if present.

Disconnecting Circuits

1.

Disconnect the power supply.

2. Disconnect the field circuit.

3. Disconnect the control circuit.

4. Disconnect the HART communication, if available.

40

2021-03

Page 41

K-System – Isolated Barriers

3 1

4

4

2

Dismounting, Maintenance, and Repair

6.1 Dismounting the Isolated Barrier

Dismounting the Isolated Barrier

Use for dismounting of the device a slotted screwdriver

1. Insert the screwdriver (4) into the groove of the red mounting slider (3).

2. Turn the screwdriver (4) in the groove until the red mounting slider (3) springs back.

3. Repeat these steps on the other side of the device.

4. Remove the isolator (2) from the DIN mounting rail (1).

Figure 6.1 Dismounting of the isolated barrier from the DIN mounting rail

1 35 mm DIN mounting rail

2 Isolated barrier

3 Mounting slider

4 Slotted screwdriver

2021-03

41

Page 42

K-System – Isolated Barriers

Technical Specifications

7 Technical Specifications

7.1 Technical Data

Electrical Data

Non-Hazardous Area Signals or Control Circuit Signals

• 0/4 mA to 20 mA signal level according to NE 43

• 0/2 V to 10 V signal level according to NE 43

• 0/1 V to 5 V signal level according to NE 43

• Current output HART compatible

• Current input HART compatible

• Digital output: active or passive electronic output 100 mA/30 V, short-circuit protected

• Relay output 2 A, minimum load 1 mA/24 V

• Logic level 24 V according to IEC 60946

• Functional isolation or safe isolation according to IEC 61140 and NAMUR NE 23

Hazardous Area Signals or Signals in the Field Circuit

• Transmitter power supply up to 17 V DC

• Current output HART compatible

• Pt100, 2-, 3-, (4)-wire technology

• Resistor 0 to 400 with freely definable characteristic

• Potentiometer

• Thermocouples of all types, internal cold junction, external reference

• Current output HART compatible

• Digital input according to NAMUR EN 60947-5-6

• Digital output for standard Ex-i valves, short-circuit protected

Characteristic Safety Values

• MTBF: Mean Time Between Failures

Conformity

General

• Isolators with and without explosion protection, mostly with Ex ia IIC/Class I Div. 1,

international approvals

• EMV according to

• EN 61326-1

• EN 61326-3-2, only for devices with SIL rating, where the data sheet mentions

this standard.

If you operate the device with a DC supply voltage, you must ensure that the bridging

of the 20 ms voltage interruption is realized by the power supply.

• NAMUR NE 21

If you operate the device with a DC supply voltage, you must ensure that the bridging

of the 20 ms voltage interruption is realized by the power supply.

42

2021-03

Page 43

K-System – Isolated Barriers

Technical Specifications

• LEDs according to NAMUR NE 44

• Software according to NAMUR NE 53

• Switch-on pulse suppression

• K*D2 devices:

• Supply voltage 20 V DC to 30 V DC via Power Rail or supply terminals

• Collective error message via Power Rail

• K*A devices:

• Supply voltage 115 V/230 V AC, details see datasheet

• K*U devices:

• Supply voltage 24 V DC or 115/230 V AC, details see datasheet

• Safety devices according to VDE 0660, part 209, AK according to DIN 19250

Digital Inputs and Outputs according to NAMUR

• IEC/EN 60947-5-6: Low voltage switch gear and control gear – part 5 and 6:

Control devices and switching elements – DC interface for proximity sensors

and switch amplifiers (NAMUR), 1999

Ambient Conditions

Ambient Temperature

• -20 °C to 60 °C (-4 °F to 140 °F), exceptions see data sheets

• extended ambient temperature range up to 70 °C (158 °F), necessary mounting

conditions see chapter 3.1

Storage Temperature

• -40 °C to 90 °C (-40 °F to 194 °F), exceptions see data sheets

Reference Conditions for Adjustment

• 20 °C (68 °F)

Relative Humidity

• max. 95 % without moisture condensation

Vibration Resistance

• according to EN 60068-2-6, 10 Hz to 150 Hz, 1 g, high crossover frequency

Shock Resistance

• according to EN 60068-2-27, 15 g, 11 ms, half-sine

Mechanical Specifications

Mounting

• Snap-on 35 mm DIN mounting rail according to EN 60715. Can be mounted horizontally

or vertically, side by side.

• Panel mount: The lugs on the base of the isolator must be extended and used

for mounting purposes with 3 mm screws.

• K-MS mounting base for screw attachment

Housing Material

• Polycarbonate (PC)

Dimensions

• Dimension drawings please refer to chapter Dimensions.

Protection Degree

• IP20 according to EN 60529

2021-03

43

Page 44

K-System – Isolated Barriers

Technical Specifications

Connection

• KH* devices: self-opening terminals for max. core diameter of 1 x 2.5 mm

• KF* and KC* devices: removable connector with integrated self opening terminals

for leads of up to a max. of 1 x 2.5 mm

• Observe the tightening torque of the terminal screws. The tightening torque

is 0.5 Nm to 0.6 Nm.

Fire Protection Class

• Housing: V2 according to UL 94 standard. Unless stated otherwise all details relate

to the reference conditions.

Labeling

Place for labeling on the front side:

• KC devices (12.5 mm): label 22 mm x 9 mm

• KF devices (20 mm and 40 mm): label 22 mm x 16.5 mm

• All KC and KF devices: adhesive label 22 mm x 11, can only be used on devices

with a transparent front flap

• KF devices: label 18 mm x 8 mm, can only be used on devices without a transparent front

flap

2

(14 AWG)

2

(14 AWG)

Note

See corresponding datasheets for further information.

44

2021-03

Page 45

K-System – Isolated Barriers

K - -Ex .

1 System

2 Construction type

3 Type of power supply

4 Level of power supply

9 Special function,

if available

8 Number of channels

7 Isolated Barriers,

not applicable to Signal Conditioners

6 Device generation (2 to X)

5 Device function

Technical Specifications

7.2 Model Number Description

Position 1 K K-System

Position 2 C Version with removable terminal blocks, 12.5 mm width

F Version with removable terminal blocks, 20 mm or 40 mm width

H Version without removable terminal blocks, 20 mm or 40 mm width

Position 3 D DC power supply

A AC power supply

U AC/DC power supply

Position 4 0 without power supply

2 24 V

4 100 V

5 115 V

6 230 V

8 24 V DC or 115/230 V AC

Position 5 CC Converter for current/voltage

2021-03

CD Active current driver

CR Transmitter power supply, current output

CRG Transmitter power supply with trip value

CS Passive current driver

DU Switch amplifier, time relay

DWB Overspeed/underspeed monitor, logic control unit

EB Power feed module

ELD Ground fault detection

ER Conductivity switch amplifier

FF RS 232 repeater

45

Page 46

K-System – Isolated Barriers

Technical Specifications

Position 5 GS Trip amplifier for current/voltage

GU Universal trip amplifier

GUT Temperature converter with trip value

HLC HART Loop Converter

HMM HART Multiplexer Master

HMS HART Multiplexer Slave

LGH Place holder isolator

PT Potentiometer converter

RC Converter for resistors

RCI Solenoid driver

RO Relay module

RR Thermometer resistance repeater

RSH Relay module in fail-safe technology

SCD SMART current driver

SCS SMART current driver/repeater

SD Solenoid driver, loop powered

SH Switch amplifier in fail-safe technology

SL Solenoid driver, bus powered

SLD Solenoid driver, bus and loop powered

SON Switch amplifier with NAMUR output

SOT Switch amplifier with passive, potential free transistor output

SR Switch amplifier with relay output

SRA Switch amplifier with relay output, 2:1 operation mode

SRT Switch amplifier with active transistor and relay output

ST Switch amplifier with active transistor output

STC SMART transmitter power supply with current output

STR Power supply

STV SMART transmitter power supply with voltage output

TR RTD converter

TT Converter for thermocouple/mV signal

UFC Universal frequency converter

UFT Frequency converter with direction and synchronization monitoring

USC Universal signal converter with trip value

UT Universal temperature converter

VC Converter for current/voltage

VCR Transmitter power supply, repeater for current/voltage

VD Solenoid driver

VM Solenoid driver

VR Voltage repeater

WAC Strain gauge converter

46

2021-03

Page 47

K-System – Isolated Barriers

12,7 mm

(0.5")

114 mm (4.49'')

46 mm (1.82'')58 mm (2.28'')

119 mm (4.7'')

104 mm (4.1'')

20 mm

115 mm

==

107 mm

93 mm

Technical Specifications

7.3 Dimensions

7.3.1 Housing Types Isolated Barriers K-System

Housing Type A2

Figure 7.1

Number of terminal blocks max. 5

• Dimension drawing with screw terminals

• When using screw terminals with test sockets the device is 124 mm (4.9 in) in height.

• When using spring terminals the device is 131 mm (5.16 in) in height.

Housing Type B1

Figure 7.2

Number of terminal blocks maximum 4

• Dimension drawing with screw terminals

• When using screw terminals with test sockets the device is 115 mm (4.6 in) in height.

• When using spring terminals the device is 122 mm (4.8 in) in height.

2021-03

47

Page 48

K-System – Isolated Barriers

Technical Specifications

Housing Type B2

20 mm

115 mm

46 mm58 mm

104 mm

119 mm

Figure 7.3

Number of terminal blocks maximum 5

• Dimension drawing with screw terminals

• When using screw terminals with test sockets the device is 124 mm (4.9 in) in height.

• When using spring terminals the device is 131 mm (5.16 in) in height.

Housing Type C1

40 mm (1.6'')

115 mm (4.5'')

==

93 mm (3.66'')

107 mm (4.21'')

Figure 7.4

Number of terminal blocks max. 8

• Dimension drawing with screw terminals

• When using screw terminals with test sockets the device is 115 mm (4.6 in) in height.

• When using spring terminals the device is 122 mm (4.8 in) in height.

48

2021-03

Page 49

K-System – Isolated Barriers

40 mm (1.6 inch)

115 mm (4.5 inch)

46 mm (1.82 inch)58 mm (2.28 inch)

119 mm (4.7 inch)

104 mm (4.1 inch)

Technical Specifications

Housing Type C2

Figure 7.5

Number of terminal blocks max. 10

• Dimension drawing with screw terminals

• When using screw terminals with test sockets the device is 124 mm (4.9 inch) in height.

• When using spring terminals the device is 131 mm (5.16 inch) in height.

Housing Type D2

60 mm (2.36'')

115 mm (4.5'')

46 mm (1.82'')58 mm (2.28'')

119 mm (4.7'')

104 mm (4.1'')

Figure 7.6

Number of terminal blocks max. 15

• Dimension drawing with screw terminals

• When using screw terminals with test sockets the device is 124 mm (4.9 in) in height.

• When using spring terminals the device is 131 mm (5.16 in) in height.

2021-03

49

Page 50

K-System – Isolated Barriers

140 mm (5.51'')88 mm (3.46'')

99 mm (3.9'')

103,5 mm (4.07'')

PE L1 N

+-

Primarily Secondary

Technical Specifications

Housing Type E

40 mm (1.6'')

Figure 7.7

Housing Power Supply 4 A

115 mm (4.5'')

==

93 mm (3.66'')

Figure 7.8

2021-03

50

Page 51

K-System – Isolated Barriers

Notes

2021-03

51

Page 52

Pepperl+Fuchs Quality

Download our latest policy here:

www.pepperl-fuchs.com/quality

© Pepperl+Fuchs · Subject to modifications

www.pepperl-fuchs.com

Printed in Germany / DOCT-0187V

Loading...

Loading...