Pepperl+Fuchs KFD HM 16 Series Manual

ISO9001

PROCESS AUTOMATION

MANUAL

HART Multiplexer

System

KFD*-HM*-16

3

HART Multiplexer System KFD*-HM*-16

With regard to the supply of products, the current issue of the following document is

applicable: The General Terms of Delivery for Products and Services of the Electrical

Industry, published by the Central Association of the Electrical Industry (Zentralverband

Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the

supplementary clause: "Expanded reservation of proprietorship"

HART Multiplexer System KFD*-HM*-16

Table of contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Aim of the manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Responsibilities of the user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 General safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Used symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6 Delivery, transport and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.7 Installation and Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.8 Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.9 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.10 Applied standards and directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Product specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 HART Multiplexer Master. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Description of the HART communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 System construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.1 Commissioning check list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.2 Data access to the connected transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3 FDT framework PACTwareTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.4 Multiplexer configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

DOCT-0120D 06/2014

3

HART Multiplexer System KFD*-HM*-16

Table of contents

6 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.1 PACTwareTM introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.2 Installing the software components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.3 Connection with the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.4 Adding the Communications DTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.5 Adding the HART Multiplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.6 Setting the parameters of the HART Multiplexers . . . . . . . . . . . . . . . . . . . . . . . . . 34

7 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.1 Device functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8 Diagnosis and fault elimination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.2 LED indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.3 Status/response code (response code). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.4 Extended device status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

9 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9.1 Supported commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9.2 Terminal assignment of the 26 pin connector with analog HART signals. . . . . . 60

9.3 Literature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.4 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

DOCT-0120D 06/2014

4

HART Multiplexer System KFD*-HM*-16

Note

Warni ng

Introduction

1Introduction

1.1 Aim of the manual

This manual should enable the user to install the HART Multiplexer Master, to

commission it and to maintain it. It provides all the information required on status and

fault messages and also provides a guide to fault diagnosis and rectification.

In addition, the manual provides an introduction to HART communication. For

additional information, the attention of the user is directed to the bibliography in the

appendix and to other literature on the subject, including the publications of the

HART Communication Foundation (www.hartcomm.org).

Where reference to the bibliography is made in this manual it is indicated thus: /3/.

The appendix also explains many terms and abbreviations used in this manual.

1.2 Responsibilities of the user

In order to avoid damage, incorrect operation and equipment failures, the user must

make himself acquainted with the equipment and must have read and understood

the manual before undertaking its installation and commissioning.

Repairs to the device must only be undertaken by specialist personnel and in

compliance with the relevant regulations.

We strongly recommend that repairs are undertaken by the manufacturer. No

guarantee claims will be accepted by Pepperl+Fuchs GmbH resulting from

improper repair work.

DOCT-0120D 06/2014

5

HART Multiplexer System KFD*-HM*-16

Warni ng

Attention

Note

Note

Safety instructions

2 Safety instructions

2.1 General safety instructions

The operator of the system is responsible in terms of planning, mounting,

commissioning, operating and maintenance.

Installation and commissioning of all devices must be performed by a trained

professional only.

Protection of operating personnel and the system is not ensured if the product is not

used in accordance with its intended purpose.

Laws and regulations applicable to the usage or planned purpose of usage must be

observed. Devices are only approved for proper usage in accordance with intended

purpose. Improper handling will result in voiding of any warrantee or manufacturer's

responsibility.

The Declaration of Conformity, Certificate of Compliance and data sheets are an

integral part of this document. The data sheet contains the electrical data of the

Declaration of Conformity and the Certificate of Compliance.

The documents mentioned are available from http://www.pepperl-fuchs.com or

contact your local Pepperl+Fuchs representative.

2.2 Used symbols

This symbol indicates a warning about a possible danger. Failure to observe this

warning may result in personal injury or death, or property damage or destruction.

This symbol warns of a possible fault. If the instruction given in this warning is not

heeded, the device and any plants or systems connected to it could develop a fault

or even fail completely.

This symbol brings important information to your attention.

2.3 Declaration of Conformity

All products have been developed and manufactured taking into consideration

applicable European standards and regulations

A Declaration of Conformity can be requested from the manufacturer.

6

The manufacturer of this product, Pepperl+Fuchs GmbH in Mannheim, Germany,

has a certified quality assurance system in conformity with ISO 9001.

ISO9001

DOCT-0120D 06/2014

HART Multiplexer System KFD*-HM*-16

Warni ng

Safety instructions

2.4 Intended use

Identification The following identification is affixed to the Multiplexer Master:

The KFD-HMM-16(referred to as "Multiplexer Master" or "Multiplexer" in the

following sections) and the KFD0-HMS-16 (referred to as "Multiplexer Slave" or

"Multiplexer" in the following sections) provides full HART access to up to 256 field

devices and hence operation with the conventional 4 mA ... 20 mA current loops. It

thus acts as a transparent gateway between the service station (PC or PCS (Process

Control System) and the transmitters.

The Multiplexer can be used within zone 2 hazardous areas or in the safe area.

Power is provided by a 24 V (nominal voltage) DC power supply. Connection to the

PCS or PC is via an RS 485 interface.

It should be stressed that the Multiplexer is approved for use in zone 2 and

therefore may not be used in zone 0 or 1 hazardous areas. If the equipment is used

in conjunction with intrinsically safe or associated apparatus, then this use must

take place in front of the Ex-barrier (e. g. transmitter power supply device).

Reference should be made to the statement of conformity.

Pepperl+Fuchs GmbH

2.5 Maintenance

Lilienthalstrasse 200, 68307 Mannheim, Germany

KFD2-HMM-16

PF07 CERT 1143 X

II 3 G Ex nA IIC T4 Gc

The following identification is affixed to the Multiplexer Slave:

Pepperl+Fuchs GmbH

Lilienthalstrasse 200, 68307 Mannheim, Germany

KFD0-HMS-16

PF07 CERT 1143 X

II 3 G Ex nA IIC T4 Gc

The device must not be cleaned with caustic fluids.

The devices are maintenance-free. However, to guarantee perfect operation of the

complete system, check the operation, including all system parts, at least once a

year.

2.6 Delivery, transport and storage

Check the packaging and contents for damage. In the event of damage, notify the

postal service or express agent and inform the supplier.

Check the scope of supply for completeness and correctness using the order and

delivery papers.

Keep the original packaging.

The device should always be stored or transported in the original packaging.

Always store the device in a dry and clean environment. Observe the permissible

storage temperature (see data sheet).

DOCT-0120D 06/2014

7

HART Multiplexer System KFD*-HM*-16

Safety instructions

2.7 Installation and Commissioning

2.7.1 Installation of the warning device

The device must only be installed outside potentially explosive zones. The device

must not be installed in places with potentially aggressive vapors.

The device must be free of voltage during installation and maintenance. The warning

system must only be connected to the supply voltage after complete mounting and

connection of the sensors.

The name plate must not be removed.

2.8 Repair

The devices may not be repaired, changed or manipulated. If there is a defect, the

product must always be replaced with an original part.

2.9 Disposal

Disposal of devices and their packaging material must be performed in compliance

with the applicable laws and guidelines of the corresponding country.

The devices do not contain batteries which need to be disposed of separately from

the products.

2.10 Applied standards and directives

See Declaration of Conformity.

DOCT-0120D 06/2014

8

HART Multiplexer System KFD*-HM*-16

Note

Product specification

3 Product specification

3.1 HART Multiplexer Master

3.1.1 Delivery package

Included in the delivery package of the KFD2-HMM-16 are:

• HART Multiplexer Master KFD2-HMM-16

• Operating instructions

Included in the delivery package of the KFD0-HMS-16 are:

• HART Multiplexer Slave KFD2-HMS-16

• Operating instructions

3.1.2 Accessories/product family

In addition to the HART Multiplexer Master, the following items from the HART

Multiplexer System family of products are available from Pepperl+Fuchs:

• KFD0-HMS-16, HART Multiplexer Slave, for extending the HART channels

• KSD2-HC, HART RPI control module, for connecting the HART Multiplexer to the

RPI product family

• K-HM14, cable Master <> Slave, for connecting the Master with the Slaves

• FI-***, HART flexible interface, handover interface of the analog signals between

transmitter, Multiplexer and PLC/DCS (control system specific)

• K-HM26, cable Master/Slave <> FI-***/MB-***, for connection of Master/Slave

with flexible interface FI-*** or motherboard MB-***, respectively

• Interface converter RS 485 <> RS 232 (Telebyte Model No. 285), converter

RS 485 <> RS 232, Pepperl+Fuchs order code: Telebyte Model 285M

The complete product family is described in the Pepperl+Fuchs product catalogs.

Please refer to the ordering instructions detailed in the catalogs.

3.1.3 Description of the hardware

The HART Multiplexer can operate up to 256 analog transmitters. The built-in Slave

unit operates the first 16 loops, and a maximum of a further 15 KFD0-HMS-16 Slaves

can be connected.

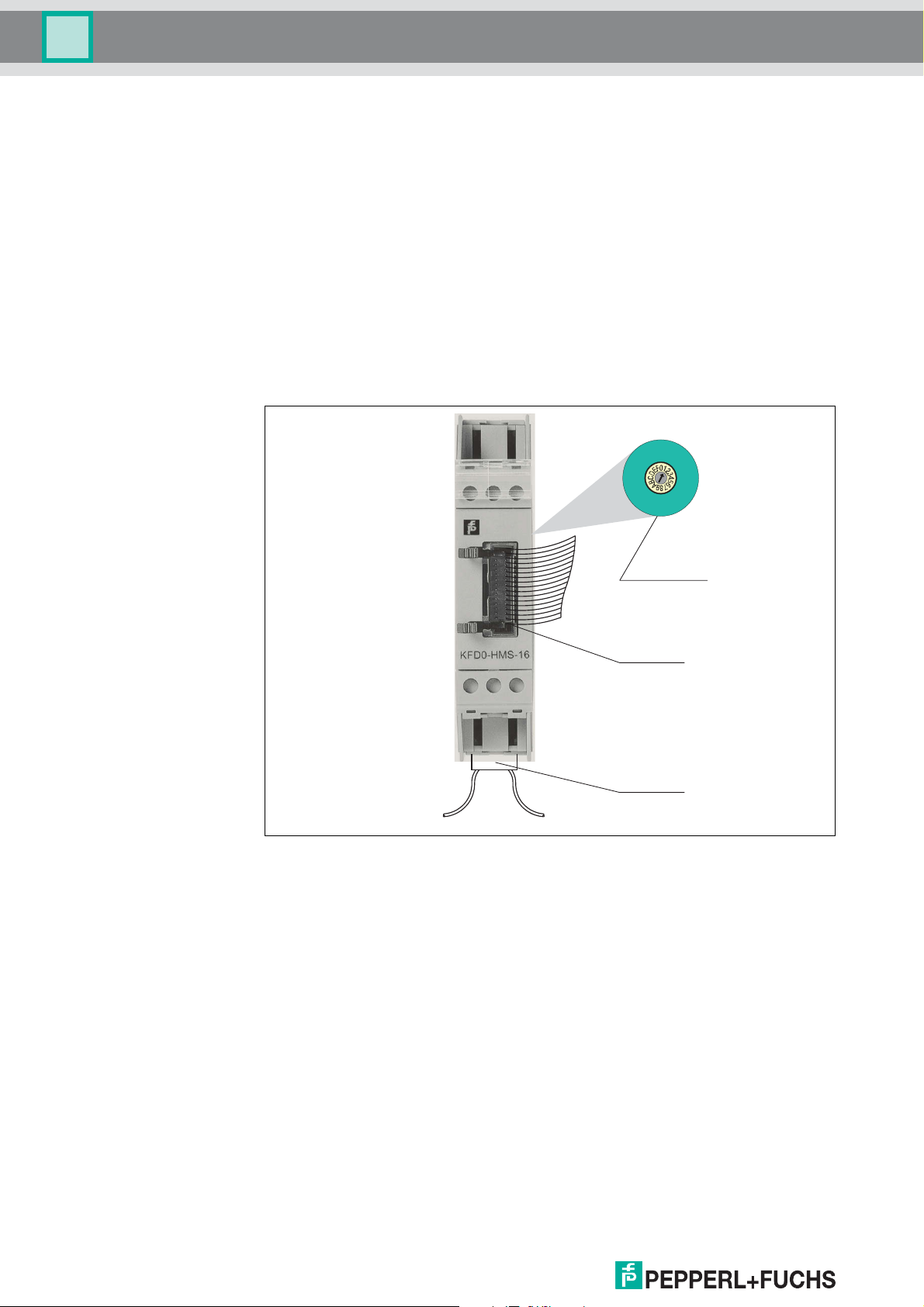

The external connections are shown in Figure 3.1 and Figure 3.2.

The power supply (24 V DC nominal voltage) is provided via the Power Rail or

terminals 17 and 18. The optional Slave units (KFD0-HMS-16) or the RPI control

module (KSD2-HC) are connected with the Master via a 14-core flat cable

(K-HM14). Its connector is placed on the same housing side as the terminals for the

RS 485 interface and the voltage supply. The analog signals for each unit are

connected separately via a 26-core cable. 16 leads are provided for the HART

signals of the analog instrument circuits, the other 10 are connected to ground. The

minimum load resistance of the analog instrument circuits is 230 (min. load

resistance in accordance with the HART specification), the max. load resistance is

500 . Load resistances of up to 1000 are possible, however, resistance values

greater than 500 can interfere with the HART communication. The connector for

these connections is located on the top of the housing. A process control system or a

PC can be connected via a RS 485 interface (terminals 13, 14 and 15). Up to 31

KFD2-HMM-16 can be operated on one RS 485 interface. Terminals 19, 20 and 21

can be used to connect additional stations to the RS 485 interface. The DIP switch

on the housing front is for the setting of the RS 485 address and the baud rate.

DOCT-0120D 06/2014

9

HART Multiplexer System KFD*-HM*-16

KFD2-HMM-16

20

19

21

24 V DC

RS 485

17+

18-

Power Rail

24 V DC

HART

14

13

15

T-

GND

T+

1

2

14

...

KFD0-HMS-16

1

2

23

...

...

HART

Termination

Board FI

24

25

26

Zone 2

Div. 2

1

2

3

4

5

6

7

8

19

1713 1816

201421

15

KFD0-HMM-16

1

26

Front view

26 pin connector

LED orange:

Operational

14 pin connector

Removable terminals

green

LED red:

Fault signal

LED green:

Power supply

Product specification

Figure 3.1 Connection diagram KFD2-HMM-16

10

Figure 3.2 Position of the operating and display elements of the KFD2-HMM-16

DOCT-0120D 06/2014

HART Multiplexer System KFD*-HM*-16

Attention

Product specification

3.1.4 Galvanic isolation

he voltage supply, the analog signals and the RS 485 interface are galvanically

separated. This galvanic isolation is achieved through the use of transformers and

opto couplers.

For the direct current components, the individual HART channels are isolated by

means of two capacitors. Thus the 4 mA ... 20 mA signal is not affected.

The connected current repeaters are galvanically interconnected unilaterally

through the common ground connection of the analog signals.

If the galvanic isolation is to be properly maintained, the individual ground cables

must be isolated by capacitors. Suitable Fl and MB boards can be supplied by

Pepperl+Fuchs for this purpose.

Notwithstanding the common ground connection of the analog signals from the

Masters/Slaves, the galvanic isolation of the current repeaters is secured if

• FI and MB boards are used, which are fitted with capacitors.

• KFD2-STC4-Ex1 or KFD2-STC4-Ex2 Ex isolation modules are used as current

repeaters.

3.1.5 All the functions at a glance

The following list gives all the functions once again at a glance:

• 16 channels, extendable to 256 channels by the connection of up to

15 KFD0-HMS-16 Slaves

• up to 7936 loops per interface (31 Multiplexers with in each case 256 channels)

• automatic search of all existing HART field devices (REBUILD)

• facility for self-standing cyclic interrogation of the HART variables (SCAN)

• acts as a primary or secondary Master

• fast RS 485 interface (multidrop) with up to 38400 Baud

• integrated modem

• removable terminals

•supply via Power Rail

• approval for zone 2

DOCT-0120D 06/2014

11

HART Multiplexer System KFD*-HM*-16

-0.5 mA

+0.5 mA

0

1200 Hz 2200 Hz

"1"

"0"

20 mA

Analog

signal

C

R

C

R

C

R

4 mA

C = Command

R = Response

Time (seconds)

FSK signal

The high frequency HART signal consists of

the sinusoidal frequencies 1200 Hz and

2200 Hz. This signal has an average value of

zero, so that it does not affect the analog

signal. It is removed by standard analog input

circuit filtering.

Product specification

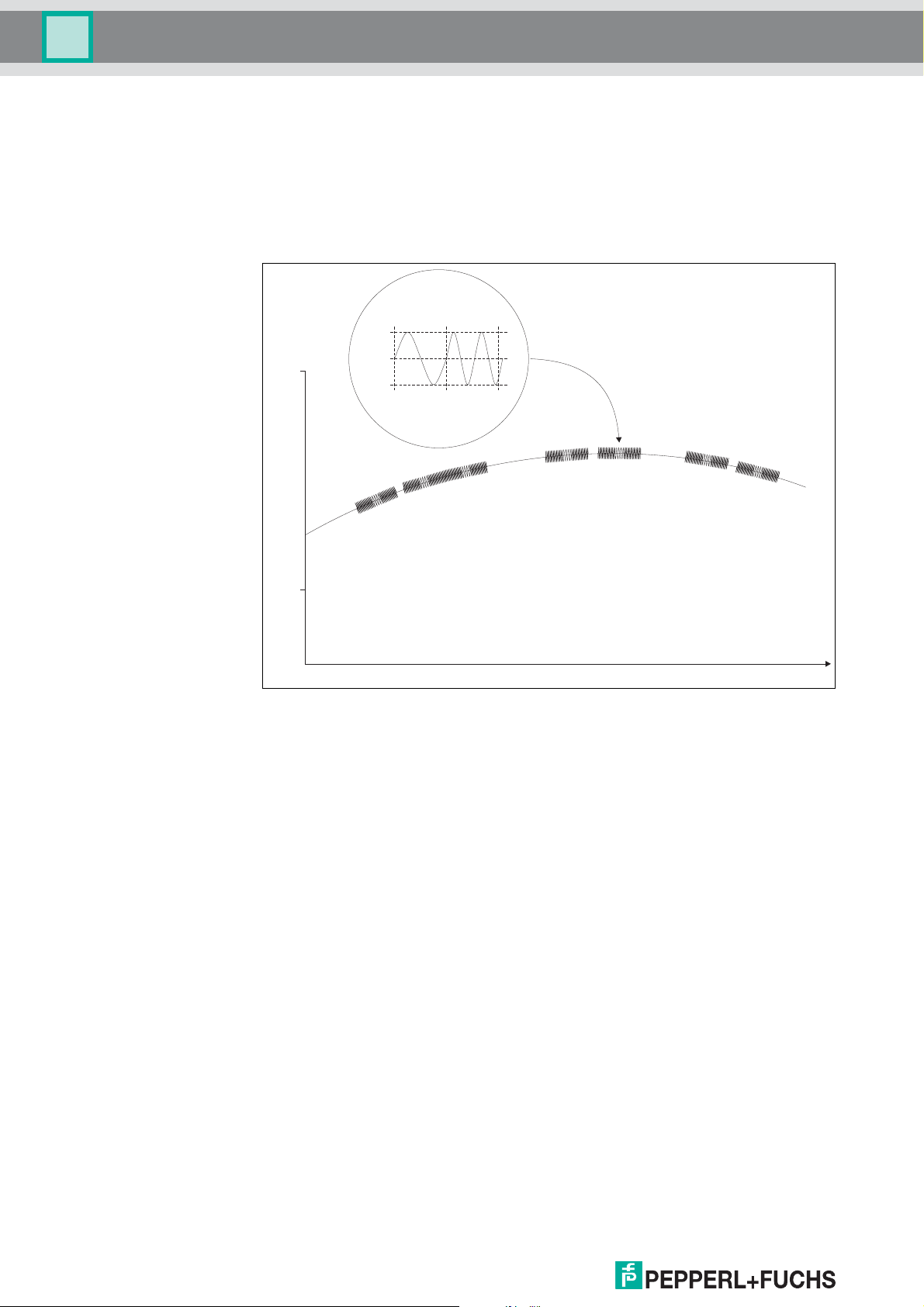

3.2 Description of the HART communication

The HART protocol (Highway Addressable Remote Transducer) is supported by

many conventional 4 mA ... 20 mA field devices, which thus enable digital

communication for configuration and servicing purposes. Many device parameters

and also the measured values themselves can thus be digitally transferred to and

from the device. This digital communication runs in parallel with the 4 mA ... 20 mA

signal on the same cable. This is possible through a current modulation, which is

superimposed on the user signal.

Figure 3.3 The modulated HART signal

HART is a Master-Slave protocol: a field device does only respond when requested

(except in "Burst mode"). The message duration is several hundred milliseconds, so

that between two and three messages can be transferred per second.

On HART, there are three groups of commands:

• The Universal commands; these must be supported by all field devices,

• the Common practice commands; these are pre-defined commands, suitable for

many field devices, which, if they are supported by the device, must be

implemented in the pre-defined form,

• device-specific commands; these are commands, which are particularly suitable

for this field device.

The HART Multiplexer contains commands in all three groups. Details of the

supported commands are given in section 9.1.

DOCT-0120D 06/2014

12

HART Multiplexer System KFD*-HM*-16

Product specification

3.3 System construction

3.3.1 System description

In process engineering plants, there are many field devices distributed over a large

area. The characteristic values of these field devices must be monitored, for

example, in the context of ISO 9000 and recorded and adapted to changes in

process parameters.

The HART Multiplex System from Pepperl+Fuchs enables on-line communication

between a PC and "smart" field devices that support the HART protocol.

SMART transmitters and intelligent valve positioners enable information such as

measurement range and tag number to be stored in the field device itself. Access to

these data is usually obtained using a handheld terminal. This means, that when

changes to information are required, connection to the field device must be carried

out "by hand".

When specific data has to be recorded in the context of quality assurance - in

accordance with ISO 9000 - this means that there is an increased demand on the

process control system or the DCS. For example, the data has to be cyclically

interrogated and then stored by the system in a database.

The HART Multiplex System from Pepperl+Fuchs provides the coupling between the

PC and the intelligent "HART capable" field devices. All access to the field device

takes place in parallel with the transfer of the 4 mA ... 20 mA measuring signal and

therefore has no affect on the processing of measured values by the process control

system.

3.3.2 Service station

The system thus provides a subordinate service interface. It is also possible to obtain

measured values through the HART Multiplex System. On field devices, which are

installed in hazardous areas, the coupling takes place on the safe area side of the

current repeaters.

Pepperl+Fuchs can supply the appropriate SMART transmitter power supplies

(e.g.KFD2-STC4-**) and SMART repeater (e.g.KFD2-STV4-**). Similarly, the

HART Multiplex System can also be connected to other SMART Ex-isolation stages.

This means that existing systems can be expanded very easily, thus taking full

advantage of the HART communication system.

The system comprises a max. of 31 HART Multiplexer Masters, which are connected

to the PC via a RS 485 interface. Each HART Multiplexer Master can control up to 15

HART Multiplexer Slaves. Each Multiplexer, irrespective of Master or Slave, can

connect up to 16 transmitters.

Thus one PC can be used to address up to 7936 field devices for the exchange of

data. Operation using a handheld terminal also remains possible, since the HART

protocol accepts two Masters in one system, i. e. PC and handheld terminal.

Besides the control system a PC is frequently used as the service station, with which

the parameter functions or data logging functions can be carried out. Operating

programs for the PC are available from various manufacturers (see section 3.3.3) to

provide the necessary back-up for this purpose.

However, in some cases the communication is provided by a process control system

via a RS 485 interface direct (via the HART Multiplexer) to the field devices without a

connected service station. But the low speed of the HART communication imposes

limitations on this method of operation.

DOCT-0120D 06/2014

13

HART Multiplexer System KFD*-HM*-16

Note

Product specification

3.3.3 Integration in the operating software (Asset Management Systems)

The full potential of the HART Multiplexer System is realized through integration in

modern Asset Management Systems such as PACTware

SIMATIC PDM (Siemens), AMS (Fisher-Rousemount), Cornerstone (Applied

System Technologies) and Valve Manager (Neles Automation). These operating

tools combine the device functions of the Multiplexer in the form of menu commands

in a unified interface providing a very convenient method of operation. The

presentation and description of the functions in the individual operating tools can be

very different, however; thus a generally applicable presentation is not possible here.

Information on the configuration, parameter assignment, operation and diagnostics

options of the Multiplexer is provided in the documentation accompanying the

various operating tools.

TM

(open source),

DOCT-0120D 06/2014

14

HART Multiplexer System KFD*-HM*-16

Note

Management

Software

KFD2-EB2

4 AT

!

KFD2-HMM-16

ON

13 14 15

19 20 21

16 17 18

ON

KFD0-HMS-16

78 9

10 11 12

Flex-InterfaceFlex-Interface

Converter

Power Rail insert

26 way ribbon cable

14 way ribbon cable

DIN Rail

up to 31 HART Multiplexer Masters

up to 15 HART Multiplexer Slaves per Master

24 VDC

RS 485

connection

Up to

16

field devices

Up to

16

field devices

DCS

RS 232

RS 485

Product specification

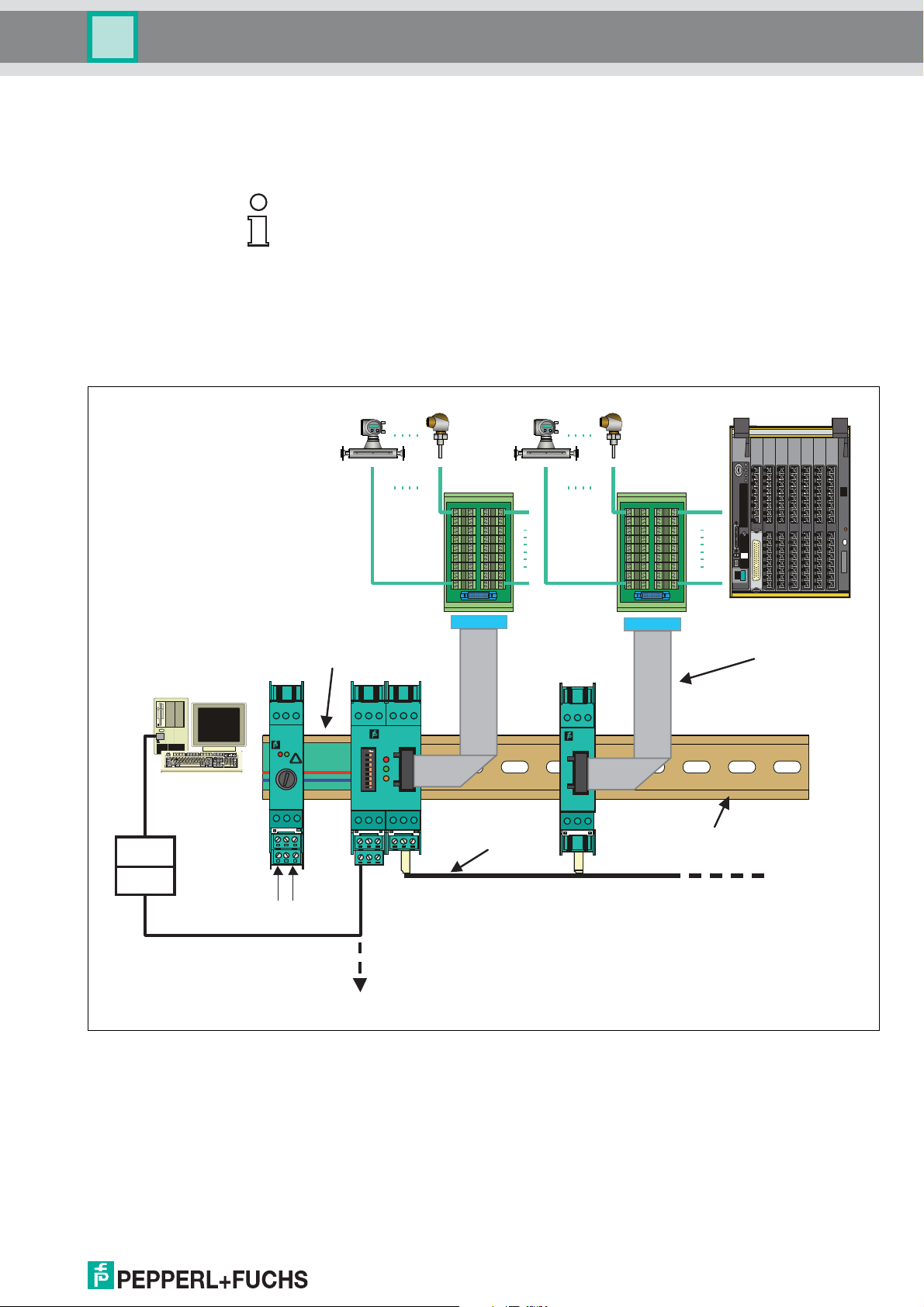

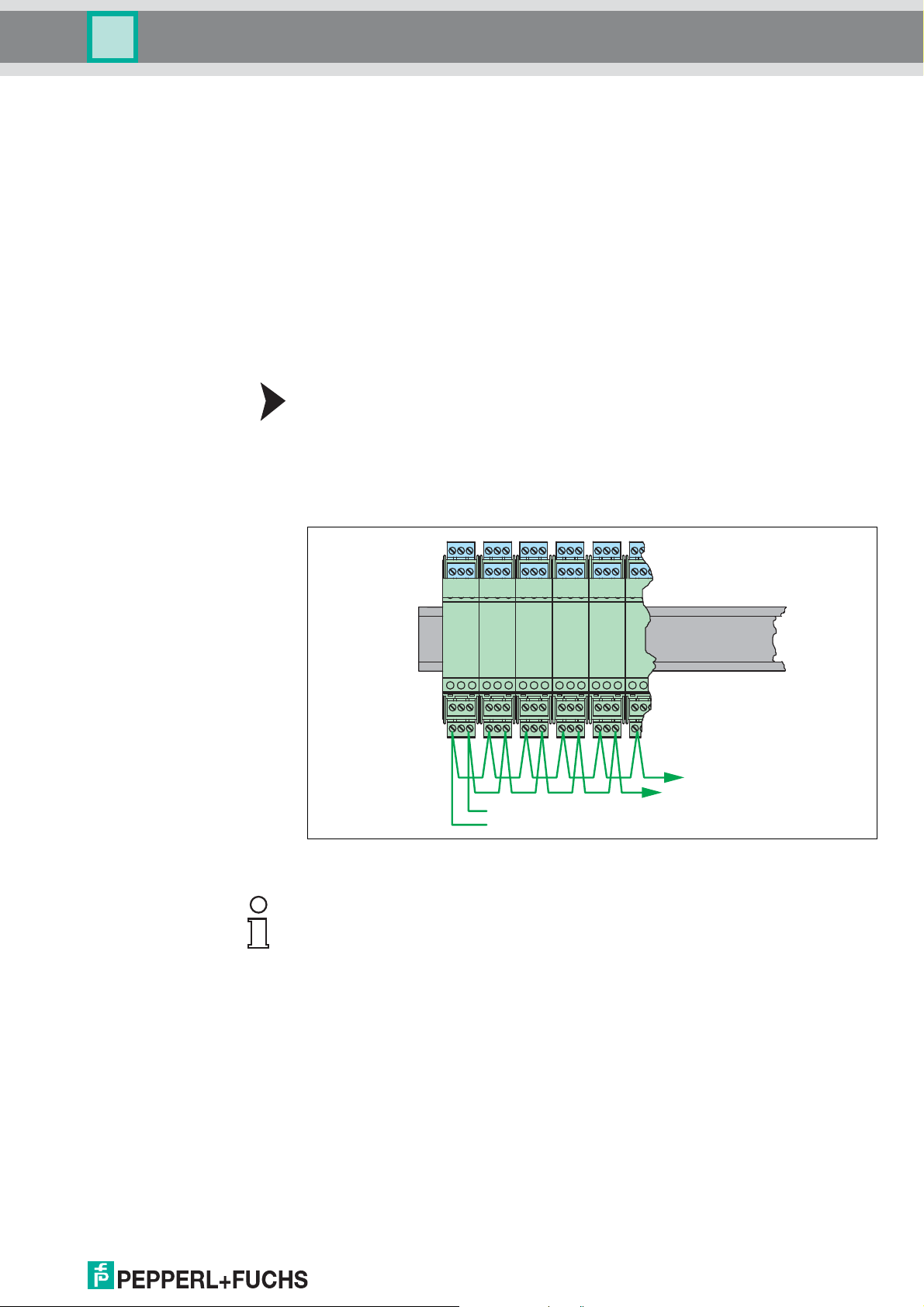

3.3.4 System construction

External assembly Multiplexer Master and Slaves are installed on Flex Interfaces, which transmits the

The wiring of the single I/O components of the HART product portfolio is done via a

Termination Board. Since a wide variety of Termination Boards is available, only the

basic wiring options should be described here.

Field devices and DCS are connected via Termination Boards in every case. More

detailed information to connection layout can be found in the data sheet of the

according Termination Board

signals via screw terminals. In this case the Termination Board provides the

connection to the Multiplexer parallel or serial. This assembly method is completely

independent of DCS and eventually used field barriers.

Figure 3.4 External assembly of Multiplexers

DOCT-0120D 06/2014

15

HART Multiplexer System KFD*-HM*-16

Product specification

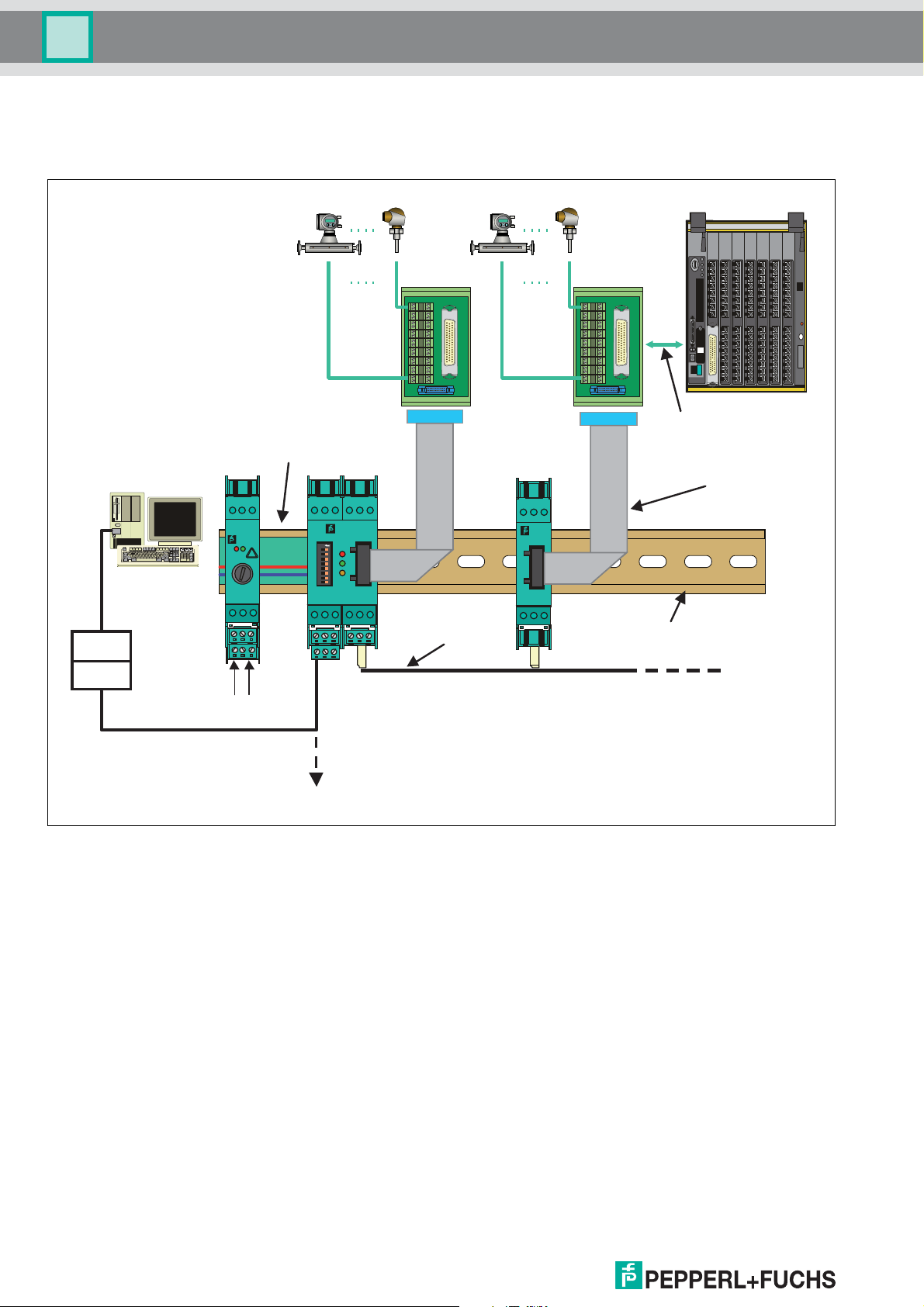

Assembly integrated

in the DCS

Management

Software

Multiplexer Master and Slaves are installed on Flex Interfaces, which transmits the

signals via screw terminals and system cable to the DCS. In this case the

Termination Board provides the connection to the Multiplexer parallel or serial. The

Termination Boards are designed especially for individual DCS.

DCS

Flex-InterfaceFlex-Interface

Up to

16

field devices

Connection via

system connector

26 way ribbon cable

Power Rail insert

KFD2-EB2

!

Up to

field devices

KFD2-HMM-16

ON

ON

16

Converter

RS 232

RS 485

4 AT

78 9

10 11 12

24 VDC

RS 485

connection

Figure 3.5 Assembly integrated in the DCS

13 14 15

16 17 18

19 20 21

14 way ribbon cable

up to 15 HART Multiplexer Slaves per Master

up to 31 HART Multiplexer Masters

KFD0-HMS-16

DIN Rail

16

DOCT-0120D 06/2014

HART Multiplexer System KFD*-HM*-16

Management

Software

KFD2-EB2

4 AT

!

KFD2-HMM-16

ON

13 14 15

19 20 21

16 17 18

ON

KFD0-HMS-16

78 9

10 11 12

Converter

Power Rail insert

26 way ribbon cable

14 way ribbon cable

DIN Rail

up to 31 HART Multiplexer Masters

up to 15 HART Multiplexer Slaves per Master

24 VDC

RS 485

connection

Up to 16

field devices

Up to 16

field devices

DCS

Connection via

system connector

Redundant

power supply

Power supply

Redundant

power supply

Power supply

Motherboard

with isolator module

Motherboard

with isolator module

RS 232

RS 485

Product specification

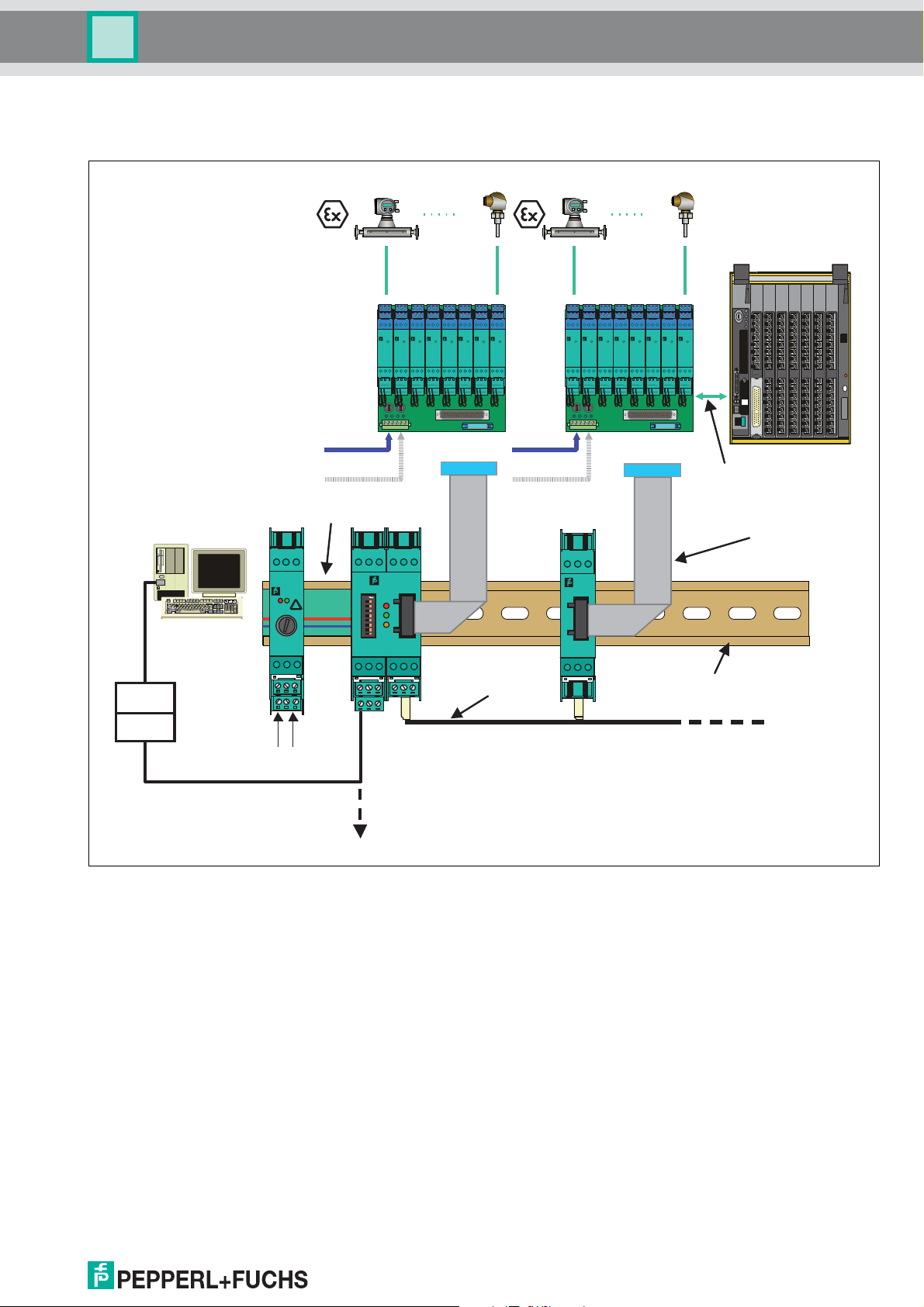

Assembly integrated

in the K-System

When using the K-System of Pepperl+Fuchs the signals can be transmitted directly

from the Termination Boards of the K-System to the Multiplexer Master or Slave via a

system plug.

1 23

1 23

1 23

1 23

1 23

1 23

1 23

1 23

1 23

1 23

1 23

1 23

1 23

1 23

4 5 6

4 5 6

4 5 6

4 5 6

PWR

KFD2-

KFD2-

STC4-Ex2

STC4-Ex2

7 8 9

7 8 9

10

10

13 14 15

13 14 15

4 5 6

PWR

PWR

PWR

KFD2-

KFD2-

KFD2-

STC4-Ex2

STC4-Ex2

STC4-Ex2

7 8 9

7 8 9

7 8 9

10

10

10

13 14 15

13 14 15

13 14 15

1 23

4 5 6

4 5 6

4 5 6

PWR

PWR

PWR

PWR

KFD2-

KFD2-

KFD2-

STC4-Ex2

STC4-Ex2

STC4-Ex2

7 8 9

7 8 9

7 8 9

10

10

10

13 14 15

13 14 15

13 14 15

4 5 6

4 5 6

4 5 6

4 5 6

PWR

KFD2-

KFD2-

STC4-Ex2

STC4-Ex2

7 8 9

7 8 9

10

10

13 14 15

13 14 15

4 5 6

PWR

PWR

PWR

KFD2-

KFD2-

KFD2-

STC4-Ex2

STC4-Ex2

STC4-Ex2

7 8 9

7 8 9

7 8 9

10

10

10

13 14 15

13 14 15

13 14 15

1 23

4 5 6

4 5 6

4 5 6

PWR

PWR

PWR

PWR

KFD2-

KFD2-

KFD2-

STC4-Ex2

STC4-Ex2

STC4-Ex2

7 8 9

7 8 9

7 8 9

10

10

10

13 14 15

13 14 15

13 14 15

Figure 3.6 Assembly integrated in the K-System

DOCT-0120D 06/2014

17

HART Multiplexer System KFD*-HM*-16

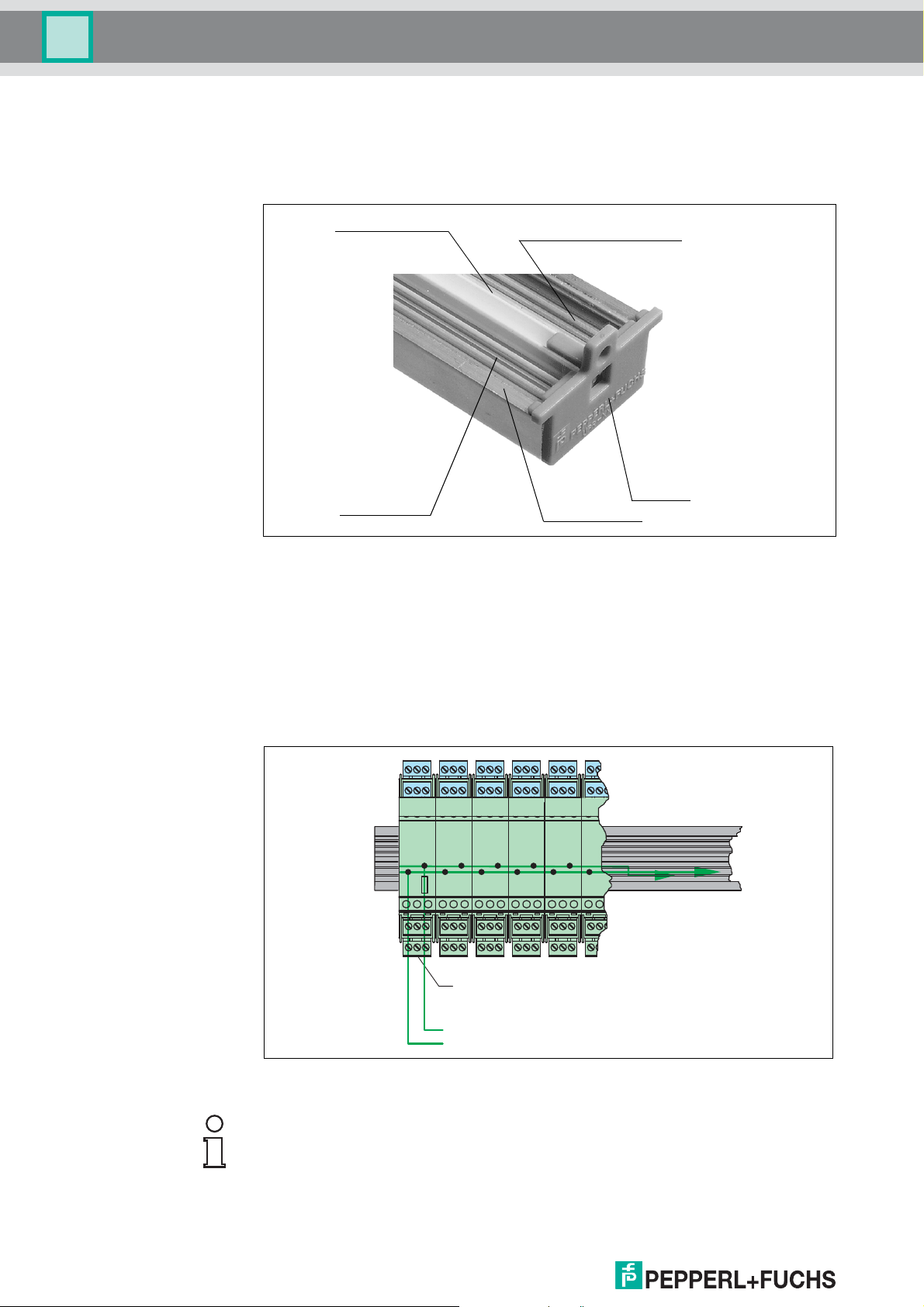

1

26

Rotary switch

26 pin

Connector

14 pin

Connector

Product specification

3.3.5 HART Multiplexer Slave

The HART Multiplexer Slave is supplied from the HART Multiplexer Master via the

14-core flat cable. The contacting of the flat cable is provided via IDC connectors, so

that the cable can be tapped at any position. By this means, the power supply and

data cables are looped on from station to station. The address 1 ... 15 is set via a 16step rotary switch. Address 0 is reserved for the Multiplexer Master and must

therefore not be used. If a number of Slaves are operated on the KFD2-HMM-16,

different addresses must be assigned. The sequence therefore plays no role in this.

The analog signals are fed via a 26 core flat cable into the KFD0-HMS-16. 16 of

these are intended for the HART signal of the analog instrument circuit (the

remaining 10 are to ground) (for the assignment, see section 9.2).

The minimum load resistance of the analog measuring circuit is 230 (minimum

load impedance in accordance with HART specification), the maximum resistive load

being 500 . Load resistances of up to 1000 are possible, however, resistance

values greater than 500 can interfere with the HART communication.

Slave connection HART Multiplexer Masters and Slaves must be connected together via a separate K-

3.3.6 Operation

18

Figure 3.7 Front view HART Multiplexer Slave

HM14 flat cable.

The length of cable required should be stated when ordering. Hence the wiring of the

HART Multiplexer is significantly simplified and the danger of wiring faults is

excluded.

The Multiplexer also functions as a HART device (see also section 5.4.5). However,

due to the incorporation into the operating software of the service station (see

section 3.3.3), this remains concealed from the user. The HART commands that are

supported by the Multiplexer can be found in section 9.1.

For HART communication with the transmitters, the commands of the service station

are passed through without modifications.

DOCT-0120D 06/2014

HART Multiplexer System KFD*-HM*-16

Power 24 V DC

Note

Installation

4 Installation

4.1 Mounting

The K-System allows three different types of mounting:

1. wall or panel mounting

2. mounting on 35 mm DIN EN 60715 mounting rail

– TH 35-7.5 (installation height 7.5 mm)

– TH 35-15 (installation height 15 mm, material thickness 1.5 mm)

3. mounting on 35 mm DIN rail with a Power Rail insert

Wall or panel mounting Panel mounting is only recommended when a very small number of isolation

components must be installed.

Mounting the device on the wall.

Pull the two clip fasteners out of the back of the device until the clips audibly click

into place.

Fasten the device to the wall or panel with 3 mm screws.

The device is mounted

Mounting on

DIN rail

When mounting on DIN rail, the device is simply snapped into place.

Figure 4.1

The wiring effort for power supply with the isolation modules of the K-Systems can

be greatly reduced by using Power Rail.

DOCT-0120D 06/2014

19

HART Multiplexer System KFD*-HM*-16

2 leads for

power supply

End cap

Power Rail insert

1 lead for centralized error

UPR-03-*

DIN mounting rail

Power 24 V DC

Power feed module

KFD2-EB*.***.*

Note

Installation

Mounting on DIN rail with

Power Rail

The Power Rail UPR-03-* is an insert for a DIN rail which Pepperl+Fuchs has

developed for this application.

The Power Rail provides two leads for power supply of the modules and one lead for

centralized error messages. The devices of the K-System are supplied with power

through these two leads.

Figure 4.2

Standard devices of types KFD2-... and KCD2-... have gold-plated contacts to

connect to the power supply rails of the Power Rail. By snapping it onto the DIN rail,

the device automatically receives power. Thus separate wiring of the power supply is

eliminated. An included cover provides for the mechanical and electrical protection

of unused spaces. Furthermore, any reserved spaces are automatically connected to

the power supply.

Third-party devices which can be mounted on a DIN EN 60715 mounting rail can

easily be mounted on the Power Rail as well. Mixed devices from different device

manufacturers are thus possible.

Figure 4.3

When supplying power via the Power Rail, the wiring effort is greatly reduced.

Moreover, there is the option of the centralized error message and redundant power

supply. Failure of the power supply is indicated through the message contact of the

power supply component.

20

DOCT-0120D 06/2014

Loading...

Loading...