Page 1

Manual

BA268F/00/en 02.03 Part No. 52017696

KFD2-HMM-16

HART Multiplexer Master

PROCESS AUTOMATION

PEPPERL+FUCHS

Page 2

The general terms of delivery for products and services produced or provided by the electrical industry as

published by the Zentralverband Elektrotechnik und Elektroindu stri e (ZVEI) e.V.

in its most recent edition as well as the supplementary proviso: "Extended property proviso" are applicable.

We at Pepperl+Fuchs feel obligated to contribute to the future;

this publication is, therefore, printed on paper bleached without the use of chlorine.

Page 3

HART Multiplexer Master KFD2-HMM-16

Table of contents

Table of contents

1INTRODUCTION ....................................................................................................................5

1.1 Explanation of the symbols used in the manual ...................................... ................................................5

1.2 Aim of the manual .............................................................. ..........................................................................5

1.3 Intended use .................................................................................................................................................5

1.4 Responsibilities of the user ........................................................................................................................6

1.5 Marking .........................................................................................................................................................6

2PRODUCT DESCRIPTION .......................................................................................................7

2.1 HART multiplexer master .................. ................................................................ ..........................................7

2.1.1 Delivery package ....................................... ................................................................. ...................................7

2.1.2 Accessories/Product family ............................................................................................................................7

2.1.3 Description of the hardware ...........................................................................................................................7

2.1.4 Galvanic isolation ...........................................................................................................................................9

2.1.5 Cabling for the analogue signals ...................................................................................................................9

2.1.6 Device function ..............................................................................................................................................9

2.1.7 Start-up sequence ..... ...... ....... ................................................................ ....... ...... ........................................11

2.1.8 Operation .....................................................................................................................................................11

2.1.9 LED indicators .............................................................................................................................................12

2.1.10 Device parameter, parameterisation ....................................................... .................... ................... .............. 12

2.1.11 Connection to the service station (PC, DCS/Process control system) ........................................................13

2.1.12 DIP switch settings ......................................................................................................................................13

2.1.13 Co nne ction and Connection Assignment of RS 485 ................................................................ ...... ..... .........14

2.2 Description of the HART communication ........................ ...... ....... ...... ....... ...... ....... ...... ....... ...... ..............15

2.3 System construction ............................... ................................................................. .................................16

2.3.1 System description ......................................................................................................................................16

2.3.2 Service station .............................................................................................................................................16

2.3.3 Integration in the operating software (Asset Management Systems) ..........................................................16

2.3.4 System construction with and without mul ti ple xer slaves .............................................................. ..............17

2.3.5 System structure with Flex-interface solutions ............................................................................................18

2.3.6 Structure with motherboard solutions ..........................................................................................................19

2.4 HART Multiplexer Slave ....................................... .....................................................................................20

2.5 Slave connection .......................................................................................................................................20

3INSTALLATION ...................................................................................................................21

3.1 Storage and transportation .................................................................. ....... ...... ....... ...... ...........................21

3.2 Unpacking ..................................................................................................................................................21

3.3 Installation ...................... .......................................................... ..................................................................21

3.4 Electrical connection .................................................................................................................................21

3.4.1 General notes for connect ion ..................................................... ..................................................................21

3.4.2 Location of electrical connections ................................................................................................................21

3.4.3 Note on electromagnetic compatability (EMC) .................... ...... ................................................................. .22

3.5 Dismantling, packaging and disposal .....................................................................................................22

Part No.: 109143, Date of issue 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

3

Page 4

HART Multiplexer Master KFD2-HMM-16

Table of contents

4COMMISSIONING ...............................................................................................................23

4.1 Commissioning check list ........................................................................................................................ 23

4.2 Data access to the connected transmitters ......................................................... ...... ............................. 23

5DIAGNOSIS AND FAULT ELIMINATION ................................................................................. 24

5.1 General ................................ ................... ............. .................... ................... ................................................ 24

5.2 LEDs ............................. .................................................... .......................................................................... 24

5.3 Status/Response code (Response code) ...............................................................................................24

5.3.1 General .......................................................................................................................................................24

5.3.2 Structure of the first byte ............................................................................................................................. 24

5.3.3 Device status (structure of the second byte) ............................................................................................... 26

5.4 Extended device status ............................................................................................................................ 27

6APPENDIX .........................................................................................................................28

6.1 Supported commands .............................................................................................................................. 28

6.2 Terminal assignment of the 26 pin connector with analogue HART signals ...................................... 31

6.3 Literature ...................................................................................................................................................32

6.4 Glossary ....................... ............. .................... ................... ................... .................... ................................... 32

Part No.: 109143, Date of issue 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

4

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

Page 5

1 Introduction

1.1 Explanation of the symbols used in the manual

This symbol warns of danger. If the instruction given in this warning is not heeded the result

could be the injury or death of personnel and/or the severe damage or destruction of equipment.

This symbol advises of a possible failure. If the instructio n gi ven in this warni ng is not heeded,

the device and any plant or systems connected to it could develop a fault or even fail completely.

This symbol indicates important information.

HART Multiplexer Master KFD2-HMM-16

Introduction

1.2 Aim of the manual

This manual should enable the user to install the HART multiplexer master, to commission it and to maintain

it. It provides all the information required on status and fault messages and also provides a guide to fault

diagnosis and rectifi ca tio n.

In addition, the manual provides an introduction to HART communication. For additional information, the attention of the user is directed to the bibliography in the appendix and to other literature on the subject, including the pub li ca tions of the HART Communication Foundation

(www.hartcomm.org).

Where reference to the bibliography is made in this manual it is indicated thus: /3/.

The appendix also explains many terms and abbreviations used in this manual.

1.3 Intended use

The HART multiplexer master KFD2-HMM-16 provides full HART access to up to 256 field de vices and

hence operation with the conventional 4m A.. .2 0mA current loops. It thus acts as a transparent gateway

between the service station (PC, or proc es s co ntro l sy s tem ) and the trans mit ter s.

The multiplexer can be used within Zone 2 hazardous areas or in the safe area. Power is provided by a 24 V

(nominal voltage) DC power su ppl y . Connec ti on to the pr oc es s co ntr ol sys tem or PC is via an R S485

interface.

It should be stressed that the HART multiplexer master KFD2-HMM-16 is approved for use in

zone 2 and therefore may not be used in zone 0 or 1 hazardous areas. If the equipment is used

in conjunction with intrinsically safe or associated apparatus, then this use must take place in

front of the Ex-barrier (e. g. transmitter power supply device).

Reference should be made to the statement of conformity contained in TÜV 00 ATEX 1547 X.

Part No.: 109143, Date of issue 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

5

Page 6

1.4 Responsibilities of the user

In order to avoid damage, incorrect operation and equipment failures, the user must make himself acquainted with the equipment and must have read and understood the manual before undertaking i t s inst a llation and commissioning.

Repairs to the device must only be undertaken by spec ialist personnel and in compliance with

the relevant regulations.

We strongly recommend that repairs are undertaken by the manufacturer. No guarantee claims

will be accepted by Pepperl+Fuchs GmbH resulting from improper repair work.

1.5 Marking

The following identification is affixed to the KFD2-HMM-16 multiplexer:

Pepperl+Fuchs G mbH

D-68307 Mannheim

KFD2-HMM-16

HART Multiplexer Master KFD2-HMM-16

Introduction

TÜV 00 ATEX 1547 X II 3G EEx n A II T4

Part No.: 109143, Date of issue 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

6

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

Page 7

2 Product description

2.1 HART multiplexer master

2.1.1 Delivery package

Included in the delivery package of the devic e are:

• One device KFD2-HMM-16

• One product supplement (manual, data sheet, installation instruction)

2.1.2 Accessories/Product family

In addition to the HART multiplexer master, the following items from the HART multiplexer system family of

products are availab le from Pepperl+Fuchs:

• KFD0-HMS-16, HART multiplexer slave, for extending the HART channels

• KSD2-HC, HART RPI control module, for connecting the HART multiplexer to the RPI product family

• K-HM14, cable master ↔ slave, for connecting the master with the slaves

• FI-***, HART flexible interface, handover interface of the analogue signals between transmitter, multiple-

xer and PLC/DCS (control sys tem spe ci fi c)

• MB-***, motherboard, carrier board for Ex-isolator module

• K-HM26, cable master/slave ↔ FI-***/MB-***, for connection of master/slave with flexible interface FI-***

or motherboard MB-***, res pectively

• Interface converter RS 485 ↔ RS 232 (Telebyte Model No. 285), converter RS 485 ↔ RS 232,

Pepperl+Fuchs o rd e r code: Telebyte Model 285M

HART Multiplexer Master KFD2-HMM-16

Product description

The complete product family is described in the Pepperl+Fuchs p ro duc t catalogues.

Please refer to the ordering instructions detailed in the catalogues.

2.1.3 Description of the hardware

The HART multiplexer can operate up to 256 analogue transmitters. The built-in slave unit operates the first

16 loops, and a maximum of a further 15 KFD0-HMS-16 slaves can be connected.

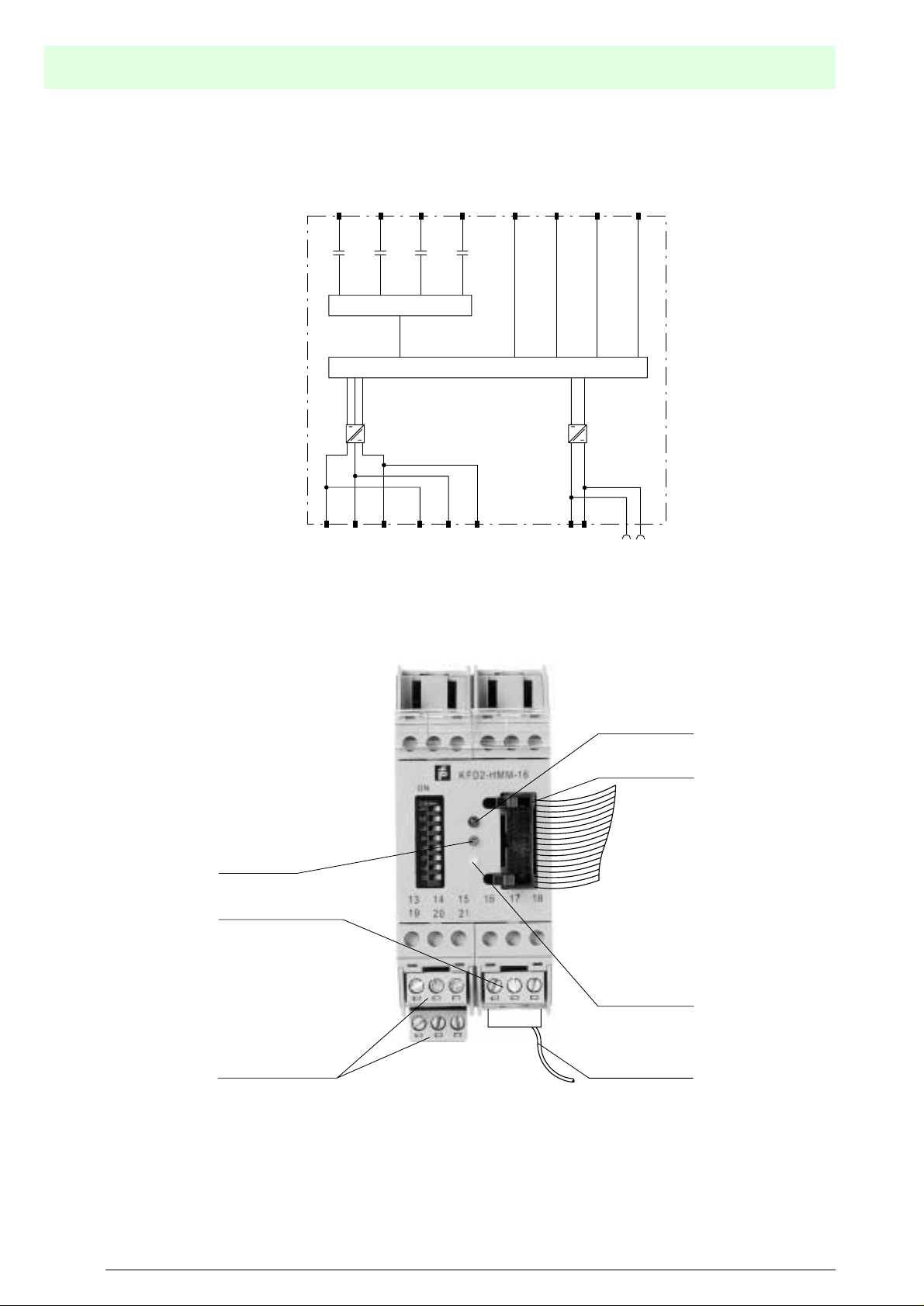

The external connections are shown in Fi gu re 2.1 and Figure 2.2.

The power supply (2 4 VDC nominal voltage) is provided via the power rail or terminals 17 and18. The op-

tional slave units or the RPI control module are connected with the master via a 14-core flat cable (K-HM14).

Its connector is placed on the same housing side as the terminals for the R S485 interface and the voltage

supply. The analogue signals for each unit are connected separately via a 26-core cable. 16 leads are provided for the HART signals of the analogue instrument circuits, the other 10 are connected to ground. The

minimum load resistance of the analogue instrument circuits is 2 30Ω (min. load resistance in accordance

with the HART specification), the max. load resistance is 5 0 0Ω. Load resistances of up to 1000 Ω are pos-

sible, however, resistance values greater than 500 Ω can interfer e with the HA RT communi cation. The connector for these conn ectio ns i s locat ed on th e top of the housing. A proces s control sys tem or a PC ca n be

connected via a RS485 interface (terminals 13, 14 and 15). Up to 31 KFD2-HMM-16 can be operated on

one RS 485 interface. Terminals 19, 20 and 21 can be used to connect additional stations to the R S485

interface. The DIP-switch on the housing front is for the setting of the R S485 address and the baud rate.

Part No.: 109143, Date of issue 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

7

Page 8

HART Multiplexer Master KFD2-HMM-16

Product description

13 14 15 19 20 21

grd T- T+

Figure 2.1: Block diagramm KFD2-HMM-16

26 pin connector

for up to

16 analog signal sources

Multiplexer

RS 485

Repeater

Micro processor

14 pin connector

for up to

15 KFD0-HMS-16 devices

+ -

17+ 18-

Power supply

Power Rail

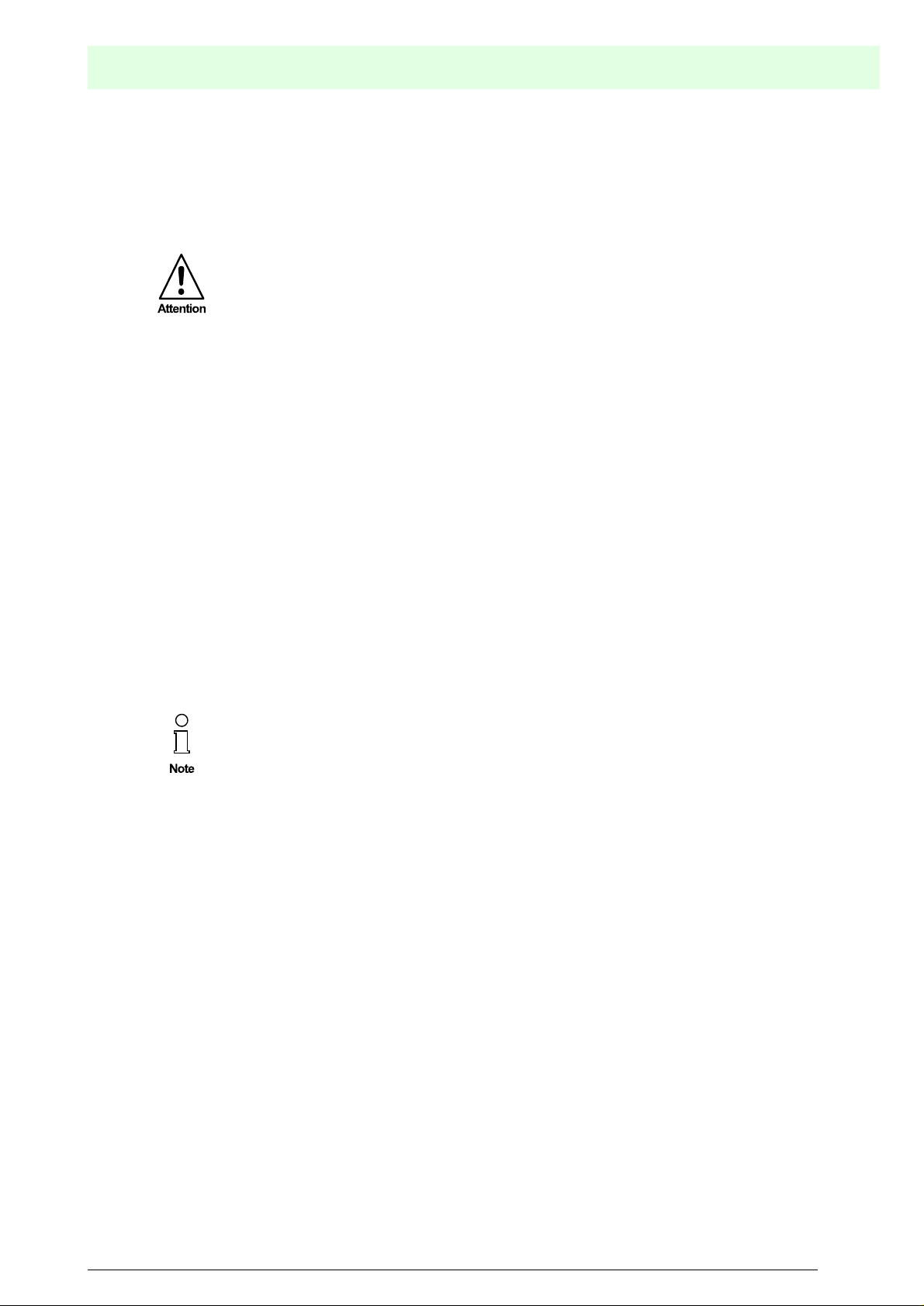

Front view

LED red:

Fault signal

26 pin connector

1

LED green:

Power supply

26

Power supply

LED orange:

operational

Connectors RS 485

14 pin connector

Figure 2.2: Location of the plug connectors and controls and the indicators of the KFD2-HMM-16

Part No.: 109143, Date of issue 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

8

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

Page 9

2.1.4 Galvanic isolation

The voltage supply, the analogue signals and the RS 485 interface are galvanically separated. This galvanic

isolation is achieved through the use of transformers and opto couplers.

For the direct current components, the individual HART channels are isolated by means of capacitors. Thus

the 4 mA ... 20 mA signal is not affected .

The connected current repeaters are galvanically interconnected unilaterally through the common ground connection of the analogue signals.

If the galvanic isolation is to be properly maintained, the individual ground cables must be isolated by capacitors. Suitable Fl and MB boards can be supplied by Pepperl+Fuchs for this purpose.

Notwithstanding the common ground connection of the analogue signals from the masters/slaves, the galvanic isolation of t he cur r ent repeaters is secured if

• FI and MB boards are used, whic h a re fitted with capacitors.

• KFD2-STC4-Ex1 or KFD2-STC4-Ex2 Ex isolation modules are used as current repeaters.

2.1.5 Cabling for the analogue signals

The individual I/O components of the HART product family are connected by a single 26-pin system plug

connector for the connecti on of the individual current repeaters (for plug pin assignmentsee section 6.2).

Pepperl+Fuchs provide specially developed connector units (HART interfaces type FI-***) for this purpose.

As required, the connection to these units can be via a system cable or even by means of conventional

screwconnections. If the current repeaters are mounted on a motherboard (MB-***), the connection is made

directly from the board to the multiplexer via a flat cable type K-HM26.

The control system is conne cte d via a s yste m spe cif ic connecto r of the motherboard or the Flex-interface.

Flex-interfaces with screw terminals are available for the purpose of individual wiring.

HART Multiplexer Master KFD2-HMM-16

Product description

2.1.6 Device function

The software functions described in this section are normally integrated into the operating software for the servicing station, i.e. the functions are not generally (de- ) ac ti vated via the des c ribed HART commands. In contrast the operating software uses func ti on s (menu command s) to

control these procedures. However the basic HART commands are described as well, because

the functions may be named different in the various operating softwares and the basic function

may not be obvious. Information on the supported commands can be found in section 6.1.

Channel number

The HART multiplexer master KFD2-HMM-16 provides 16 channels for the connection of "smart“ transmitters or control devices, which support digital communication in accordance with the HART specification. A

maximum of 15 additional KFD0-HMS-16 slaves can be connected, each of which in turn support 16 channels. Thus in a full assembly, a loop of 256 channels can be achieved with just one master. When using the

multiplexer master with the RPI product family, no slave units are necessary. On RPI, communication takes

place via the power rail.

Multiplexer table (module table)

The multiplexer master and the connected multiplexer slaves must be designated as 'available' in a multiplexer table (command 157). Only those modules defined as 'available' in this table are used in the communication process. The multiplexer table consists of 16 bit, one for each possible multiplexer address

(default: module 0 (master) and 1 activa ted).

Part No.: 109143, Date of issue 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

9

Page 10

HART Multiplexer Master KFD2-HMM-16

Product description

Interface

In this way, the multiplex er ma ste r act s as a transpa r ent gate way between the service station (typically a

PC with suitable software, see section 2.3.2) and the field devices. The service station is able to communicate with up to 31 multiplexer master via up to 38400 baud R S485 connection. Because each master is

able to communicate with 256 field devices, up to 7936 field devices are controlable over a singl e RS485

interface.

HART

As a digital communication system for servicing and configuration purposes, the HART protocol is supported by many field devices with conventional analogu e 4m A. . .2 0mA current loops. The HART signal is

thus modulated on the analogue current as an FSK signal (see se cti on 2.2). The modulator/demodulator

circuitry (Modem) required for this is integrated in the multiplexer. Only one HART transmitter can be connected at each multiple xe r HART con necti on (n o "multidrop“ functionality).

Special procedures in respect to HART commun i cation:

• On the host side (RS 485) always the long frame address is used (except for command 0).

• On the field devices side, either the sho rt address or the long frame address is used, depending on

necessity.

• The operating modes "Primary Master“ and "Secondary Master" and the corresponding time responses

are supported on the field device side.

• On the host side, only the commands 0 ... 3 and 1 1. . .13 are accepted from the secondary h o st. Other

commands are not accepted/are ignored.

• Commands to connected field devices are only accepted by the primary host.

• Extended messages and messages in the Burst Mode are recognised and used, but not generated by

the multiplexer itself.

• An answer buffer is available for a delayed message response. This can be used to intermediately store

a message, the command for whic h req uir es a long execution time.

Loop construction/REBUILD (Software function)

On power-up, the device searches the multiplexers in the multiplexer table for the connected HART field

devices (commands 0 a nd 4

1

) and generates the internally required access tables. This function can also

be carried out by the connected service station, as is necessary, for example, in communication with newly

connected HART field devices. The duration of this function depends on the number of connected multiplexer slaves and HART field devices and also on the type of loop search (see command 153) and the permissible number of message repeats. With 16 HART devices (e.g. by using only one master without slaves) the

duration is between 1 5s and 3 0s. The number of permissible message repeats is set to "2" in the factory

setting and the loop search type to "single analogue".

During the REBUILD phase, only certain read commands are accepted from the service station (commands

0, 1, 2, 3, 11, 12, 13, 48, and 129). All other commands are followed by the response "Busy" (Code 32, see

section 5.3.2), until the REBUILD phase ends.

Cyclic data interrogation/SCAN (software function)

The multiplexer can read cyclic data from up to 31 transmitters. In this case th e SCAN option must be set

for the transmitter (command 137) and the SCAN function activated in the multiplexer (command 149,

function 1). Which data is transferred is determined by the "SCAN command" option (command 147).

If the SCAN function is activated, the transmitters, on which the SCAN option is activated are regularly chekked for data. In this case, the SCAN command is executed, with which one or more variables are read from

the transmitter. If a fiel d device does not res pond, it is designate d as having "disappeared" (see command

129), but it remains in the search list (i. e., it is searched for again on the next run sequence). If a device

has disappeared, but responds correctly on the next search command, it is then listed as "appeared". If,

instead of this, another device has answered, then the status "mismatched" is assigned.

10

1. Command 4 is additionally used on transmitters which only support the old HART specifications up to 4.

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

Part No.: 109143, Date of issue 29.11.2000

Page 11

HART Multiplexer Master KFD2-HMM-16

Product description

Variation on the SCAN function (special SCAN function)

The multiplexer offers in addition a second SCAN function. With this special SCAN function (command 149,

function 2) an additional parameter is used, which defines the minimum length of the expected number of

data bytes. This can be different for each current loop, but must be set for each current loop that is to be

scanned.

The SCAN function itself takes place as above, however, the response of the transmitter is compared with

the expected data length. If the length of the response is less than the set minimum data length, the answer

is rejected. If the minimum length is 0, the answer is always saved.

Delay on channel change/Loop switch delay (software function when used with RPI)

If the HART multiplexer is used with the RPI HART control module KSD2-HC, a pause time must be inserted

when the multiplexer channel is changed. This pause time is necessary, since the RPI HART control module

has to monitor the communication channel of the multiplexer and recognise the channel change. This pause

time can be set by means of command 161.

All the functions at a glance

The following list gives all the functions once again at a glance:

• 16 channels, extendable to 256 channels by the connection of up to 15 KFD0- HMS- 16 slaves.

• Up to 7936 loops per interface

• Automatic search of all existing HART field devices (REBUILD)

• Facility for self-standing cyclic interrogation of the HART variables (SCAN)

• Acts as a primary or sec ondary master

• Fast RS 485 interface (multidrop) with up to 38400 baud

• Integrated Modem

• Removable terminals

• Supply via power rail

• Approval for zone 2

2.1.7 Start-up sequence

Following connection of the power supply, the device executes an initialisation procedure with self test. The

function is indicated by a flashing green LED, any errors detected are indicated by a red LED. Next a search

is made of the multiplexers in the multiplexer table (command 157) for available HART compatible field

devices (REBUILD). This function is indicated by a flashing orange LED. The REBUILD function can also

be started via the service station, e. g. in order to include connected transmitters in the communication

process during the operating phase. The duration of this function is dependent on the number of connected

transmitters, multiplexer slav es and message repeats in the case of errors, or if an interroga tio n has not

been answered. The factory setting for the number of repeats is "2". The search duration for this lies

between approx. 30 s and several minutes (full structure).

In addition, transient data are set to their pre-setting. Non-volatile stored data are retained. see section

2.1.10.

2.1.8 Operation

The multiplexer master KFD2 -HM M-16 al so func ti ons as a HART device (see also section 2.1.10). However, due to the incorporation into the operating software of the service station (see section 2.3.3), this

remains concealed from the user. The HART commands that are supported by the multiplexer can be found

in section 6.1.

For HART communication with the transmitters, the commands of the service station are passed through

without modifications.

Part No.: 109143, Date of issue 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

11

Page 12

2.1.9 LED indicators

The device has three LEDs, located on the front of the housing.

The meaning of these LEDs is given in the following table:

Colour Meaning

Red Error indications (detected during the initialisation phase)

Green Operating indications

Orange HART communication with a field device

During the initialisation phase, the green LED flashes, the other two are off.

During the REBUILD function, the green LED is ON and the orange flashes.

If all three LEDs flash one after the other, the DIP switch 1 (test) is in the "ON" position. Set the

switch to "OFF“ and repeat the commissioning.

2.1.10 Device parameter, parameterisation

For the identification and programming of the multiplexer master, this contains - as do other HART field

devices - specific parameters that are in the non-volatile memory. The following list shows these parameters

and how the programming must be carried out.

• Unambiguous device identification (see commands 0, 11)

The device identification provides information about the device (type, type-ID, serial number and revision

numbers) and the manufacturer and cannot be changed.

• Message (see commands 12 and 17)

An arbitrary 32 char ac ter long item of text can be stored in the device under this param ete r.

• Tag, description and date (see commands 13 and 18)

A tag (8 characters), description (16 characters) and a date, can be saved under these parameters.

• The number of preambles in message responses (see command 59)

This parameter is used to establish how many preambles are inserted in message responses. The presetting is 4, the setting range is 2 ... 20.

• Number of message repeats (retry) (see commands 144 and 145)

The number of message repeats can be separately set for the repeats in the case of communication

errors and for the response code "Busy" (see section 5.3.2).

The range of adjustment is 0.. .11 repeats. In the cas e of commun i cation errors, the pre-setting is 2, in

the case of the response code "Busy" it is 0.

• SCAN command (see section 2.1.6 and commands 146 and 147)

Of the available SCAN parameters, only the SCAN command is stored by non-volatile means. It signifies

which HART command (1, 2 or 3) is to be sent to the transmitter as the SCAN command.

• Master type (primary or secondary master) (see command 151)

This controls the priority for access to the HART field devices. A primary master always initiates a connection with a field device. A secondary master initiates a connection to a field device through an arbitration function (i.e. only when the primary master does not achieve access). The pre-setting of the

multiplexer is "Primary Master". A typical example of a secondary master is a hand-held operatin g

device.

• Loop type search (command 153)

At present, the multiplexer does not support a multidrop with HART, i. e. only one HART field device is

connected to each HART channel. With loop construction (REBUILD, see above )the connected field

devices are either always searched on the short address 0 ("single analogue"), or, in preparation for

multidrop, on the sh ort add ress es 0 ... 15, in which the first one found is addres sed (" si ngl e unk nown ").

• Module table (see section 2.1.6 and command 157)

• Delay time on channel change (loop-switch delay) (see section 2.1.6 and command 161)

HART Multiplexer Master KFD2-HMM-16

Product description

12

Part No.: 109143, Date of issue 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

Page 13

HART Multiplexer Master KFD2-HMM-16

2.1.11 Connection to the service st ation (PC, DCS/Process cont rol system)

The connection to the service station or to the control system is made via a multidrop able RS 485 interface.

The baud rate of this interface can be set to 9600, 19200 or 38400 baud via the DIP switches 2 and 3 (see

section 2.1.12). The device address for the communication via RS 485 is set by the DIP switches 4 to 8 (see

section 2.1.12).

When setting the address, care should be taken to ensure that no address is assigned more

than once, since this can lead to com mu nic ati on er ro rs or even communication failure.

The adjusted baud rate must comply with the service station.

2.1.12 DIP switch settings

8 DIP switches are located on the top of the device. DIP switch 1 is used by the manufacturer for testing the

device and must therefore always be set to "OFF".

DIP sw i tch 1 Meaning

Setting

OFF Normal st atus ( LED test de-activated)

ON LED test activated; all three LEDs flash one afte r the other

Product description

DIP switches 2 and 3 determine the baud rate of the RS 485 interface.

DIP sw i tch 2 3 Meaning

OFF OFF 9600 Baud

Setting

OFF ON 19200 Baud

ON OFF 38400 Baud

ON ON Not permitted

DIP switches 4 to 8 determine the RS485 address. A value is assigned to each of the individual DIP

switches for this purpose. The resulting address is given by the addition of the set values.

DIP sw i tch 4 5 6 7 8 Meaning

ON Value 16

ON Value 8

Setting

ON Value 4

ON Value 2

ON Value 1

Example: OFF ON ON OFF ON address = 8 + 4 + 1 = 13

To accep t the values set on the DIP switches, the device must be isolated briefly from power

supply.

Condition on delivery

DIP sw i tch 1 2 3 4 5 6 7 8 Meaning

Manufacturer te st d e- activat e d

Setting OFF OFF OFF OFF OFF OFF OFF OFF

Baud rate 9600 baud

RS 485 ad dr es s 0

The address 0 is set on the device when delivered. Care should be taken that no address is

assigned more than once.

Part No.: 109143, Date of issue 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

13

Page 14

2.1.13 Connection and Connection Assignment of RS 485

Connector assignment of the removable terminals:

Terminal Description Meaning

13, 19 Screen Cable screening

HART Multiplexer Master KFD2-HMM-16

Product description

14, 20 RxD/TxD + (RS 485 B)

RS 485 differential signal

15, 21 RxD/TxD - (R S485 A)

If the screen is grounded, the grounding should only be connected to one end of the cable, in

order to avoid equipotential bonding currents. However, in all cases, existing guidelines and

regulati ons must be observed.

To conne ct a s tand ard PC with a R S232 interface an interface converter R S485 to R S232 is

required. A convert er that has b een tes ted and re co mmended by Pep perl+Fuchs is manufactured by Telebyte (Telebyte Model No. 285). This can be obtained from Pepperl+Fuchs under the

part number "Telebyte Model 285M“.

In accordance with the RS 485 specification up to 32 stations ("multidrop") can be connected to a up to

1200 m cable (for data rates less than 100 kBaud). Pepperl+Fuchs recommends that this length of cable is

not exceeded. Even though problems seldom occur at these data rates, screened twisted two-wire cabling

should be used.

In addition a terminating resistor should be connected to each end of the R S485 cable. If the multiplexer

master is such a device, i. e. the RS 485 cable ends here and is not routed to other devices, then the second

available connection terminal for the RS 485 can be used for the connection of a terminating resistance.

The terminating resistor terminates the cables with its characteristic impedance. At minimal baud rates and

with short lengths of cable, in practice quite often no terminating resistors are used. If communication errors

arise, or if these are to be positively excluded from the outset, terminating resistors typically of

120 Ω ... 220 Ω should be used. Such can, for example, be connected between terminals 20 and 21.

If an interface converter is used, a terminating r es istor shou ld be con nec ted to the conver ter

and another to the other end of the cable.

14

Part No.: 109143, Date of issue 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

Page 15

2.2 Description of the HART communication

HART Multiplexer Master KFD2-HMM-16

Product description

The HART

1

protocol is supported by many conventional 4 mA ... 20 mA field devices, which thus enable

digital communication for configuration and servicing purposes. Many device parameters and also the measured values themselves can thus be digitally transferred to and from the device. This digital communication

runs in parallel with t h e 4m A. . .2 0mA signal on the same cable. This is possible through a current modulation, which is superimposed on the user signal.

FSK signal

+0,5 mA

0

20 mA

-0,5 mA

Analogue

signal

1200 Hz

"1"

C

R

2200 Hz

"0"

C

R

C

R

The high frequency HART signa l cons ists of

the sinusoidal frequenc ies 1 200 Hz and

4 mA

C = Command

R = Response

2200 Hz. This signal has an average value of

zero, so that it does not affect the analogue

signal. It is removed by standard analogue

input circuit filtering.

Time (seconds)

Figure 2.3: The modulated HAR T-S i gnal

HART is a master-slave protocol: a field device does only respond when requested (except in "Burst mode"). The message duration is several hundred milliseconds, so that between two and three messages can

be transferred per second.

On HART, there are three groups of co mma nds :

• The "Universal" commands; these must be supported by all field devices;

• the "Common practice" commands; these are pre-defined commands, suitable for many field devices,

which, if they are suppo rt ed by the dev ice, mus t be im ple men ted in the pre-defined form;

• device-specific commands; these are commands, which are particularly suitable for this field device.

The HART multiplexer contains comma nds in all three groups. Details of the supported commands are

given in section 6.1.

Part No.: 109143, Date of issue 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

1. HART = Highway Addressable Remote Transducer

15

Page 16

2.3 System construction

2.3.1 System description

In process engineering plants, there are many field devices distributed over a large area. The characteristic

values of these field devices must be monitored, for example, in the context of ISO 9000 and recorded and

adapted to changes in process parameters.

The HART multiplex system from Pepperl+Fuchs enables online communication between a PC and "smart"

field devices that support the HART protocol.

Smart transmitters and intelligent valve positi oners enable information such as measurement range, tag

number, ID number and manufacturer to be stored in the field device itself. Access to these data is usually

obtained using a handheld terminal. This means, that when changes to information are required, connection

to the field device mus t be carri ed out "B y han d".

When specific data has to be recorded in the context of quality assurance - in accordance with ISO 9000 this means that there is an increased demand on the process control system or the DCS. For example, the

data has to be cyclically interroga ted and then s tor ed by the sy st em in a databa se .

The HART multiplex system from Pepperl+Fuchs provides the coupling between the PC and the intelligent

"HART-capable" field devices. All access to the field device takes place in parallel with the transfer of the

4 mA ... 20 mA measuring signal and therefore has no affect on the processing of measured values by the

process control system.

The system thus provides a subordinate service interface. It is also possible to obtain measured values

through the HART multiplex system. On field devices, which are installed in hazardous areas, the coupl in g

takes place on the safe area side of the current repeaters.

Pepperl+Fuchs can supply the appropriate KFD2-STC4-Ex1/KFD2-STC4-Ex2 smart current repeaters and

KFD2-SCD-Ex1.32, KFD2-SCD-Ex1.LK smart isolated transformers. Similarly, the HART multiplex system

can also be connected to other smart Ex-isolation stages. This means that existing systems can be expanded very easily, thus taking full advantage of the HART communication system.

The system comprises a max. of 31 HART multiplexer masters, which are connected to the PC via a RS 485

interface. Each HART multiplexer master can control up to 15 HART multiplexer slaves. Each multiplexer,

irrespective of maste r or slav e, can c onne ct up to 16 tra ns mi t t ers.

Thus one PC can be used to address up to 7936 field devices for the exchange of data. Operation using a

handheld terminal also remains possible, since the HART protocol accepts 2 masters in one system, i. e.

PC and handheld terminal.

HART Multiplexer Master KFD2-HMM-16

Product description

2.3.2 Service station

Besides the control sy s tem a PC is frequently used as the service station, with whi ch the par am ete r

functions or data logging functions can be carried out. Operating programs for the PC are available from

various manufactur ers (see se cti on 2.3.3 ) to provide the nec es sa ry b ack -up for this purpo se .

However, in some cases the communication is provided by a process control system via a RS 485 interface

direct (via the HART multiplexer) to the field devices without a connected service station. But the low speed

of the HART com munication imposes limitations on this method of operation.

2.3.3 Integration in the oper ating software (Asset Management System s)

The full potential of the HART multiplexer System is realised through integration in modern Asset Management Systems such as PACTware (open source), SIMATIC PDM (Siemens), AMS (Fisher-Rousemount),

Cornerstone (Applied System Technologies) and Valve Manager (Neles Automation). These operating

tools combine the device functions of the multiplexer in the form of menu commands in a unified interface

providing a very convenient method of operation. The presentation and description of the functions in the

individual operating tools can be very different, however; thus a generally applicable presentation is not

possible here.

Information on the configuration, parameter assignment, operation and diagnostics options of

the multiplexer is provided in the documentation accompanying the various operating tools.

Part No.: 109143, Date of issue 29.11.2000

16

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

Page 17

HART Multiplexer Master KFD2-HMM-16

PACTware

PACTware™ is the first open source Process Automation Configuration Tool with an open FDT interface

(Field Device Tool). For the first time this enables all

of the manufacturer, to be configured and assigned parameters using a single

Representative example on the basis of PACTware

The PACTware user interface is divided into two parts: The project tree is located in the left part; the data

and input fields being represented in the right.

The system structure is represented in the project tree. Above the HART multiplexer there is a HART driver

and above that a host sys tem (P C) . All the connected multiplexer slaves are to be found und er the HAR T

multiplexer master and also the internal one that is indicated as having the slave address 0.

Under these slave units there are the HART-compatible field devices.

2.3.4 System construction with and without multiplexer slaves

In a system structure without multi ple xe r sl aves , only one multiplexer master is used. The arrangement is

restricted to 16 HART channels. With two to three messages per second, the system cycle time can be up

to one minute.

In a system structure with multiplexer slaves, one multiplexer master and up to 15 slaves are used. The

number of channels per slave is extended by 16, so that in the fully-developed structure 256 HART channels

are available. With two to t hree messages per second, the system cy cl e time i s several minutes.

field buses and field devices in a system, independent

Product description

engineering tool.

RS 232

RS 485

KFD2-EB2

78 9

10 11 12

24 VDC

Management

Software

Converter

Power Rail Insert

!

4 AT

13 14 15

19 20 21

HART signals from smart field instruments -

16 smart field devices per Slave and Master

HART connector to Flexible Interface Board or Motherboard

26 way ribbon cable

KFD2-HMM-16

ON

ON

16 17 18

14 way ribbon cable

KFD0-HMS-16

KFD0-HMS-16

DIN Rail

Up to 15 HART Mux Slaves per Master

RS 485

Up to 31 HART Mux Masters

Figure 2.4: Multiplexer system structure

The connection between the field devices and the control system is the same in both cases and can take

place via motherboard s or Flex- Inte rfa ce s (s ee se cti on 2.3.5 and 2.3.6).

Part No.: 109143, Date of issue 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

17

Page 18

2.3.5 System structure with Flex-interface solutions

For general purpose applications, Pepperl+Fuchs offers Flex-interfaces in various versions. The HART connection for one multiplexer is common to all versions. The connections for the maximum of 16 field devices

are provided as screw terminals or in the form of Pepperl+Fuchs system connectors for cable tree installation. The connections for the con tro l system are likewise either provided as scr ew ter mi nal s or as contr ol

system-specific connectors. Such a system is presen ted in Figure 2.5.

The distinguishing characteristics of the FI-*** in detail:

• Power feed option (also redundant), switchable for each individ ual mo dul e.

• Fuses

• 250 Ω resistance

• Control system-specific connector (also redundant)

• Screw terminals/Sys tem connector

HART Multiplexer Master KFD2-HMM-16

Product description

Process control system

Up to 16 field devices

Slave

or

KFD0-HMS-16

ON

13 14 15

19 20 21

Master

KFD2-HMM-16

ON

16 17 18

Flex-interface

Connection

via system

connector

Service station

Management

Software

18

RS 485

Figure 2.5: System with Flex-interface

Part No.: 109143, Date of issue 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

Page 19

2.3.6 Structure with motherboard solutions

-

2

3

-

2

3

-

2

3

-

2

3

-

2

3

-

2

3

-

2

3

-

2

3

For applications in hazardous areas, motherboard solutions are employed. Motherboards serve as carriers

for Ex-isolation modules, such as current repeaters and isolated transformers and have connections both

for power supply, one or more HART system connectors suitable for the family of multiplexer devices and

a control system-specific connector for direct connection to the control system. Such a system is shown in

Figure 2.6.

The distinguishing char ac ter i sti c s of the MB - *** in detail:

• Power feed (also redundant) with fuses and LEDs

• 250 Ω resistance

• Control system-specifi c co nne cto r (als o red unda nt)

• Control system-specific arrangement of the Ex-isolation modules (Number and type)

Ex

HART Multiplexer Master KFD2-HMM-16

Product description

Process control system

Motherboard

with isolation modules

supply

Redundant

Power supply

Slave Master

KFD0-HMS-16

Up to 16 field devices

1 2

1 2

1 2

4

KFD2

STC4-Ex

7 8

10

13 14

or

4

PWR

KFD2

STC4-Ex

7 8

10

13 14

1 2

4

4

PWR

PWR

PWR

KFD2

KFD2

STC4-Ex

STC4-Ex

7 8

7 8

10

10

13 14

13 14

KFD2-HMM-16

ON

ON

13 14 15

16 17 18

19 20 21

1 2

4

KFD2

STC4-Ex

7 8

10

13 14

1 2

1 2

4

PWR

KFD2

STC4-Ex

7 8

10

13 14

1 2

4

4

PWR

PWR

PWR

KFD2

KFD2

STC4-Ex

STC4-Ex

7 8

7 8

10

13 14

Connection

10

13 14

via system

connector

Service statio n

Management

Software

RS 485

Figure 2.6: System with motherboard

Part No.: 109143, Date of issue 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

19

Page 20

2.4 HART Multiplexer Slave

The HART multiplexer slave is supplied from the HART multiplexer master via the 14-core flat cable. The

contacting of the flat cable is provided via IDC connectors, so that the cable can be tapped at any position.

By this means, the power supply and data cables are looped on from station to station. The address 1 ... 15

is set via a 16-step rotary swit ch. Addres s 0 is reserved for the multiplexer master and must therefore not

be used. If a number of slaves are operated on the KFD2-HMM-16, different addresses must be assigned.

The sequence therefore plays no role in this.

The analogue signals are fed via a 26 core flat cable into the KFD0-HMS-16. 16 of these are intended for

the HART signal of the analogue instrument circuit (the remaining 10 are to ground) (for the assignment,

see section 6.2).

The minimum load resistance of the analogue measuring circuit is 23 0Ω (minimum load impedance in

accordance with HART specification), the maximum resistive load being 500 Ω. Load resistances of up to

1000 Ω are possible, however, resistance values greater than 50 0Ω can interfere with the HART communication.

Front View

HART Multiplexer Master KFD2-HMM-16

Product description

Rotary switch

2.5 Slave connection

HART multiplexer masters and slaves must be connected together via a separate K-HM14 flat cable.

The length of cable required should be stated when ordering. Hence the wiring of the HART multiplexer is

significantly simplified and the danger of wiring faults is excluded.

1

26

26 pin

Connector

Housing type A1

(see system description)

14 pin

Connector

20

Part No.: 109143, Date of issue 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

Page 21

3 Installation

3.1 Storage and transportation

For storage and transportation, the multiplexer must be protected from shock loading and dampness by means of suitable packaging. O ptim um pr ote cti on is affo r ded by the or ig ina l pac kag in g.

In addition, the permissible ambient conditions must prevail (see datasheet).

3.2 Unpacking

Make sure that the multiplexer is undamaged. Damages should be reported to the mail or forwarding agent

as well as the supplier.

The consignment should be in compliance with the order and shipment documents. Check the following

items:

• Quantity supplied

• Device type and version in accordance with the type plate

• Accessories (man ual, etc.)

Keep the original packing if the device is to be stored and shipped at a later date.

HART Multiplexer Master KFD2-HMM-16

Installation

3.3 Installation

The installation options are described in the accompanying product information about the K-System, KFD

series.

3.4 Electrical connection

3.4.1 General notes for connection

Work on live installations and electrical connect ion s mus t o nly be carried out by appropriately

trained personnel.

When connecting the RS 485, reference should be made to the instructions in section 2.1.13 .

3.4.2 Location of electrical connec t i ons

The power supply (24 V DC nominal voltage) is provided via the power rail or terminals 1 7(+) and1 8(-).

The device is protected against reverse polarity by means of a protection diode.

The connection of a higher level control unit (PLC, PC) is achieved via an RS 485 interface on terminals 13,

14 and 15. The RS 485 bus is looped through to terminals 19, 20 and 21. In this way, the three terminals

can be used alternatively, or simultaneously, (for the connection of other devices with R S485, or for the

connection of a terminating resistor). If a standard PC with an RS 232 interface is to be used, an interface

converter is required (see section 2.1.2).

The connection of the KFDO-HMS-16 HART Multiplexer slaves is via the 14 pin plug connector on the side

of the device.

The analogue HART signals are connected to the current repeaters via the 26 pin plug connector on the

front of the device.

Part No.: 109143, Date of issue 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

21

Page 22

3.4.3 Note on electromagnetic compatability (EM C)

The device is intended for use in electrically conductive and earthed control cabinets. Leads that are fed

into the control cabinet should be screened and the screen should be connected with the control cabinet at

the point of entry, preferably directly in the cable gland. Unscreened leads in the control cabinet (e.g. power

supply leads) should be fed via filters.

3.5 Dismantling, packaging and disposal

When dismantling the device, keep it in the original packaging for future use.

The multiplexer sho uld ev entually be disposed of in accordanc e with national regulations on

disposal / recycling.

The device does not contain batteries which would have to be separately disposed of.

HART Multiplexer Master KFD2-HMM-16

Installation

22

Part No.: 109143, Date of issue 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

Page 23

4 Commissioning

4.1 Commissioning check list

The commissioning of the Multiplexer Master i s summarised in the followin g check list. You should follow

the list through in sequence, actions that have already been carried out can be skipped. The steps required

for commissioning the multiplexer refer to the section in which the respective procedure is described in

detail.

The usual commissioning procedure is as follows:

Installation

• Installation of the field devices

• Selection and connection of the motherboard and Flex-Interface (see also section 2.3.5 and 2.3.6)

• Selection and connection of the isolating modules

• Connection of the process control system

• Connection of the Multiplexer Masters and Slaves ( see section 2.3 .5 and 2.3.6)

• Connection of the Service Station. If necessary, install the interface converters.

Set up the RS 485 address and set the baudrate(see section 2.1.12)

Caution: Note the polarity of the R S485 connection (see section 2.1.13).

HART Multiplexer Master KFD2-HMM-16

Commissioning

The device must be disconnected briefly from the power supply in order to accept the values set

on the DIP switches.

Operation

• Wait for the start-up sequ ence to fini sh (s ee se ct ion 2.1.7)

• Start the parameter assignment (see section 2.1.10), in particular, establish the position of the multiple-

xers that are being used in the module table (see section 2.1.6)

• Carry out the loop construction (REBUILD, see section 2.1.6)

• Activate the SCAN function, if required (see section 2.1.6)

4.2 Data access to the connected transmitters

The way in which data access to the connected field devices can take place depends on the operator tool

that is being used.

In general, however, the field devices are to be found in a project tree under the HART Multiplexer Slaves

(the master integrates the slave unit on slave address 0), where device data, parameters and diagnostics

can be accessed via menu functions. A project tree of this type is described in section 2.3.3.

The data, parameters and diagnostic windows accommodate data for the underlying HART commands,

which differ considerabl y, dep end ing on the field device.

Only the "Univers al" commands and general response codes have the same functions on all devi ces, so

that information relating to the devices themselves, as well as the process values and several items of

diagnostic information can be represented in a consistent manner.

Part No.: 109143, Date of issue 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

23

Page 24

5 Diagnosis and Fault Elimination

5.1 General

This section provides operating instructions to be used if faults occur and describes the possible causes of

such faults.

Faults and failures are signalled via the following means:

• LEDs (see section 2.1.9 and 5.2)

• Status/response code (see section 5.3)

• Extended device status (see section 5.4)

5.2 LEDs

The following fault conditions can occur during the initialisation phase after start-up:

Red Green Orange Cause Corrective action

Off Off Off • No power supply available

• LED(s) defect

On On On Fault in device hardware

(CPU, ROM)

On Off Off Fault in dev ice hardware

(CPU, ROM)

On On Off • Fault in device hardware

(CPU, RAM)

• Device parameter assignment

incorrect (Parameter Loop

Switch Delay, Command 161)

HART Multiplexer Master KFD2-HMM-16

Diagnosis and Fault Elimination

• Check power supply

• Select DIP switch 1, isolate power

supply briefly; LEDs flash one after

the other

Send device to Pepperl+Fuchs for repai r.

Send device to Pepperl+Fuchs for repai r.

• Send device to Pepperl+Fuchs for

repair.

• Parameterise device again. If this is

not successful, the device must be

sent to Pepperl+Fuchs for repair.

5.3 Status/Response code (Response code)

5.3.1 General

Two status bytes, also re fer re d to as the "Response code“ are contained in ev ery mes s age fr om a fi eld

device. These contain three types of information: Communication errors, command responses and the

device status. Depending on bit 7, the first two types are contained in the first status byte. The device status

is always transferred in the second byte.

5.3.2 Structure of the first byte

If bit 7 is set (1), the first status byte contains a summary of the communication errors. This information is

coded bit by bit.

If bit 7 is cleared (0), the first status byte contains a summary of the command responses. This information

is numbered consecuti ve ly and not coded bit by bit.

Communication error

This byte contains information concerning the reception of a message.

The individual bits indicate a detected error, which has resulted in non-acceptance of the message. Thus

neither can a response be given to the message. It is necessary to repea t the c ommand, to check the connections, to use the terminating resistors or to reduce the baud rate.

24

Part No.: 109143, Issue date 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

Page 25

HART Multiplexer Master KFD2-HMM-16

Diagnosis and Fault Elimination

Bit

7 6 5 4 3 2 1 0

Meaning

1 Communication error, if bit 7 = 1; coded bit by bit

1 1 Parit y error

1 1 Overrun error

1 1 Message error

1 1 Checksum error

1 0 Always 0 (reserved)

1 1 Input buffer overrun

1 1 (undefined)

Details can be found in /1/.

Command responses

The first byte contains information relating to the execution of a command. The command-specific response

code thus documents the execution of the command.

In contrast to the communication error, the command responses are not coded bit by bit, but are numbered

consecutively from 0 to 127.

Of the command responses signalled by the multiplexer, two instances are warnings (codes 8 and 31), in

which the processing of the command is continued. In the other cases, errors are indicated, that means that

the initiating command could not be correctly executed. Here, the remedy is given by the meaning of the

code.

All the codes that occ ur on the HART system are described in /1/.

The following response codes can occur on the multiplexer:

Code Description Meaning

Can occur with

commands ...

2 Invalid selection The selected code/index is not permissible. 147, 149, 151, 153

3 The parameter value was

59, 129, 155

too large

4 The parameter value was

59

too small

5 Too few data bytes received The message has no error, but it contains

fewer bytes than expected for the execution

of the command.

17, 18, 59,

129 ... 141, 145, 147,

149, 151, 153, 154,

155, 157

8 Warning Here (132): Preamble length not within

132

range 5 ... 20 and has been set to 5 or 20.

9 1st parameter too large The first of the two parameters is too large. 145

11 2nd parameter too large The second of the two parameters is too

145

large.

16 Access restricted The command has been ignored, since the

current device status does not permit the

command to be carried out correctly.

6, 17, 18, 38, 41, 42,

48, 59, 106,

128 ... 157

Part No.: 109143, Issue date 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

25

Page 26

HART Multiplexer Master KFD2-HMM-16

Diagnosis and Fault Elimination

Code Description Meaning

17 Too many items r equested 131, 132, 133,

31 Warning Here (137): SCAN value has not been chan-

ged, since it is identical.

32 Busy The device is executing a function, which

cannot be interrupted by this command.

64 Command not implemented The command does not exist and therefore

cannot be executed.

This error message is also output if an error

occurs that cannot be accurately specified

by the device.

65 Not specified Parameter not in the permissible range. 132, 137

5.3.3 Device status (structure of the second byte)

If a communication error is indicated in the first byte (bit 7 = "1"), the second byte described here has no

significance (always 0).

In the other case, it contains the status of the field device in full, i.e. independent of commands.

The individual bits ha ve the following meaning:

Can occur with

commands ...

135 ... 141, 154

137

6, 17, 18, 38, 41, 42,

59, 106, 128,

130 ... 157

Almost all

Bit Description Meaning Correcti ve action

7 Error function of the field

device

(malfunction)

Hardware fault. The extended

device status may provide further

information (see section 5.4).

• Read extended device status

(section 5.4)

• Check LEDs (section 5.2)

• Re-parameterise device

6 Configuration changed

(Configuration changed)

5 Start-up sequence is ru nning The power supply has been con -

A write command has b een executed.

nected or a reset has been activa-

This bit can be cleared by command 38.

Wait for the start-up sequence,

then parameterise the device.

ted. Transient data are reset to the

preset values.

4 Extended device status

available

Further s t atus messages are

available and can be called up; see

Read extended device status

(section 5.4)

section 5.4.

3 Analogue output current

fixed (primary variable)

The primary variable is fixed at the

requested value and no longer follows the process.

Always 1

(Has no function on the multiple-

xer, since there is no analogue

output)

2 Analogue output current has

reached its limit (primary

variable)

1 Var i ables (not the primary

one) outside the range

The primary variable lies outside its

limit value and therefore no longer

corresponds to the process value.

The values detected by the sensor

(not for the primary v ariable) lie outside the operating range. The

Always 0

(Has no function on the multiple-

xer)

Always 0

(Has no function on the multiple-

xer)

extended device status may yield

additional informati on (s ee sec ti on

5.4).

0 Primary variable outside the

range

The measured value detected by

the sensor lies outside the operating range.

Always 0

(Has no function on the multiple-

xer)

26

Part No.: 109143, Issue date 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

Page 27

5.4 Extended device status

The extended device status can be called up via command 48. It provides five bytes of information, which

are thematically arranged:

1st byte: Operation in progress

The byte indicates which operation is in progress. The information is coded bit by bit. The coding is shown

in the following table:

Bit Operation in progress Meaning

7 Reset Start-up seq uen ce running and must be completed

6 REBUILD REBUILD function is running and must be completed

5 Internal EEPROM write function Switching off the power supply can result in loss of the

4 SCAN SCAN function is running and must be completed

3 Self test (command 41) The device self test is executed (as when the power

2...0 Reserved Reserved.

HART Multiplexer Master KFD2-HMM-16

Diagnosis and Fault Elimination

parameter assignment

supply is switched on); if no error occurs, the "Malfunction" status message (see se cti on 5.3.3) clears (if

it is set)

2nd byte: Hardware fault

This byte, which is also bit by bit coded, indicates any hardware faults that have been found. Hardware faults

are only detected during the initialisation sequence after the power supply has been switched on.

Bit Detect ed hardware fault Meaning/Remedial action

7 Current loop OR logic operation on all detected hardware faults in the current

loops. Check the transmitter and its cabling, then execute

REBUILD.

6 ROM error Send device to Pepperl+Fuchs for repair

5 EEPROM error Send device to Pepperl+Fuchs for repair

4...0 Reserved Reserved

3rd byte: SCAN er ror

The byte indicates an OR logic op er ation for all err or s that hav e been detected during the SCAN function.

Example: If a field device has been detected as having "Disappeared" and another as "Mismatched", then

these two bits are set simultaneously.

The bit by bit coded information is shown in the following table:

Bit State Meaning Corrective action

7 Reserved Reserved

6 Searching Transmitter is searched for (due to having disap-

peared)

•Check cabling

• Check transmitter

5 Disappeared Transmitter no longer responds

4 Appeared Transmitter responds again Check cabling

3 Mismatche d Despite this, another transm itter has responded Transmitter has been

exchanged for another type.

Check type, rebuild loop.

2 ... 0 Reserved Reserved

Part No.: 109143, Issue date 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

27

Page 28

6 Appendix

6.1 Supported commands

The following tables show the HART commands supported by the multiplexer, ordered by the three groups

"Universal", "Comm on- pr ac ti ce " and "Dev i ce spec ifi c" c omm and s (s ee als o se cti on 2.2) . Th e read c ommands are caracter is ed by ! and the write commands by ".

The "Universal" and "Common-practice" commands are described in detail in /1/. In this section only the

functions are explained, not the data structure of the lower layer of the HART protocol.

"Universal" commands:

Command Action Meaning

!

0

1

2

3

6

11

12

13

17

18

Read unique identifier 12 bytes device identifier are given in the response.

!

Read HART variables

(process val u e s)

!

!

"

Write polling address

Read unique identifier ass oc iat ed

!

with tag

!

Read "Message" Read the 32 digit message (see also 17).

!

Read tag, description and date

"

Write "Message" Write the 32 digit message (see also 12).

"

Write tag, description and date

HART Multiplexer Master KFD2-HMM-16

Appendix

Commands are only supported for compatibility purposes and are without any meaning. Used with transmitters

(e.g. SCAN function) they have the following meanings:

1: Read primary variable

2: Read primary variable as current (in mA) and percent

of range

3: Read primary variable as current (in mA) and four

(predefined) dyn amic variables

This command is never accepted and the mess age s

"Access restricted" or "Busy" (see section 5.3.2) will be

returned.

A response will contain 12 bytes device identifier, if the

given tag complies to the tag of the multiplexer.

Read the 8 digit tag, the 16 digit description and the

date.

Write the 8 digit tag, the 16 digit description and the

date.

28

Part No.: 109143, Date of issue 29.11.2000

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

Page 29

HART Multiplexer Master KFD2-HMM-16

"Common-practice" c ommands:

Command Action Meaning

38

41

42

48

59

106

"Device specific " com man ds :

Command Action Meaning

128

129

130

131

132

133

134

135

136

Reset "Configuration

"

changed" flag

"

Perform device self test

"

Perform device reset

Read additional device

!

status

Write number of the

"

response preambles

Delete all delayed

responses pending for

"

the host

Read parameterisation of the mul-

!

tiplexer

!

Read loop status

Read transmitter list (max. 49 entries, beginning with the gi ven

!

index)

Read static data of up to 22 trans-

!

mitters

Write static data of up to 22 trans-

"

mitters

Remove transmitter from transmit-

"

ter list (max. 35 at the same time)

Read SCAN list (max. 49 entries,

!

beginning with the given index)

Read dynamic data of up to 7

!

transmitters

Read SCAN status of up to 31

!

transmitters

Reset the "Configuration changed" response code, see section

5.3.3.

Initiates the self tes t functi on in the device (as during power up); if

no error occurs the response code "malfunction" (see section 5.3.3)

is cleared (if set).

Immediately after the response the microprocessor of the device

will be reset.

See section 5.4.

The number of preambles insert in response telegrams can vary

from 2 to 20. Default setting is 4.

All pending response telegrams are deleted. Because only one

response buffer exists, the buffer is always deleted (independent