Page 1

ISO9001

MANUAL

HART Loop Converter

KFD2-HLC-Ex1.D(.**)

PROCESS AUTOMATION

Page 2

HART Loop Converter KFD2-HLC-Ex1.D(.**)

With regard to the supply of products, the current issue of the following document is applicable:

The General Terms of Delivery for Products and Services of the Electrical Industry,

(Zentralverband Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most recent version

published by the Central Association of the Electrical Industry

as well as the supplementary clause: "Expanded reservation of proprietorship"

Page 3

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1 Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Content of this Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Target Group, Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Symbols Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Device Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Mounting and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 DIN Mounting Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Power Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4 Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1 Configuration via Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.2 Configuration via Keypad on the Device . . . . . . . . . . . . . . . . . . 26

5 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.1 Indicators during Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.2 Fault Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

6 Dismounting, Maintenance, and Repair . . . . . . . . . . . . . . . 56

7 Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.1 Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

315702 2018-01

EN

EN - 1

Page 4

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

Introduction

1Introduction

1.1 Manufacturer

Pepperl+Fuchs GmbH

Lilienthalstraße 200, 68307 Mannheim, Germany

Internet: www.pepperl-fuchs.com

1.2 Content of this Document

This document contains information that you need in order to use your product throughout

the applicable stages of the product life cycle. These can include the following:

• Product identification

• Delivery, transport, and storage

• Mounting and installation

• Commissioning and operation

• Maintenance and repair

• Troubleshooting

• Dismounting

• Disposal

Note!

This document does not substitute the instruction manual.

Note!

For full information on the product, refer to the instruction manual and further

documentation on the Internet at www.pepperl-fuchs.com.

315702 2018-01

2 - EN

Page 5

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Introduction

The documentation consists of the following parts:

• Present document

• Instruction manual

• Datasheet

Additionally, the following parts may belong to the documentation, if applicable:

• EU-type examination certificate

• EU declaration of conformity

• Attestation of conformity

• Certificates

• Control drawings

• Additional documents

1.3 Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation, maintenance, and

dismounting lies with the plant operator.

Only appropriately trained and qualified personnel may carry out mounting, installation,

commissioning, operation, maintenance, and dismounting of the product. The personnel

must have read and understood the instruction manual and the further documentation.

Prior to using the product make yourself familiar with it. Read the document carefully.

1.4 Symbols Used

This document contains symbols for the identification of warning messages and of

informative messages.

Warning Messages

You will find warning messages, whenever dangers may arise from your actions. It is

mandatory that you observe these warning messages for your personal safety and in order

to avoid property damage.

315702 2018-01

EN

EN - 3

Page 6

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

Introduction

Depending on the risk level, the warning messages are displayed in descending order as

follows:

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warnin g!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants, or

result in their complete failure.

Informative Symbols

Note!

This symbol brings important information to your attention.

Action

This symbol indicates a paragraph with instructions. You are prompted to perform an action

or a sequence of actions.

315702 2018-01

4 - EN

Page 7

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Product Specifications

2 Product Specifications

2.1 Device Versions

The following device versions described in this manual:

•HART Loop Converter KFD2-HLC-Ex1.D

• HART Loop Converter KFD2-HLC-Ex1.D.2W

• HART Loop Converter KFD2-HLC-Ex1.D.4S

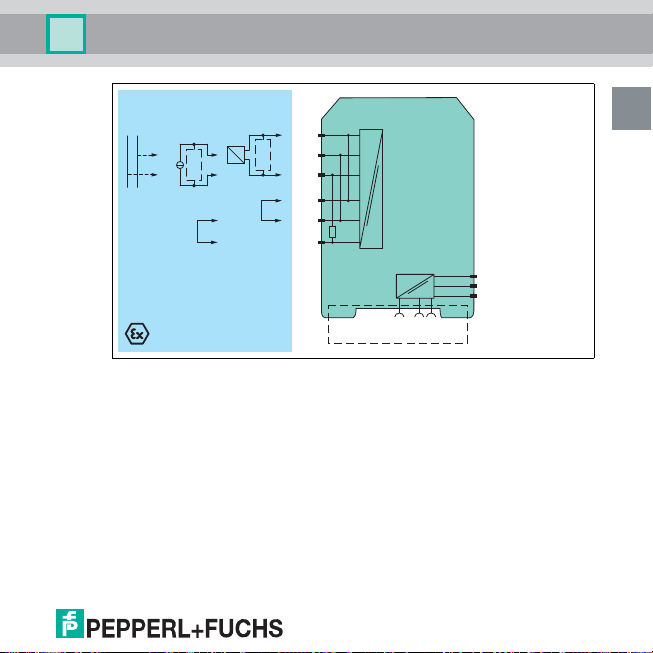

2.2 Function

General

The HART Loop Converter is an isolated barrier suitable for intrinsically safe applications.

The device supplies field devices and can be connected in parallel to existing HART circuits.

The device analyzes up to four HART variables (PV, SV, TV, QV). Three HART variables

can be transformed into varying current signals from these four HART variables. These

signals are used to display the values via the analog inputs of the process control system.

The device is easily configured by the use of keypad or with the PACTware configuration

software.

KFD2-HLC-Ex1.D.2W

In addition to the current outputs, the device has two changeover contacts. These

changeover contacts can be programmed so that the changeover contacts function as

limit values for the HART variables.

KFD2-HLC-Ex1.D.4S

In addition to the current outputs, the device has four NO contacts. These NO contacts can

be programmed so that the NO contacts function as limit values for the HART variables.

315702 2018-01

EN

EN - 5

Page 8

EN

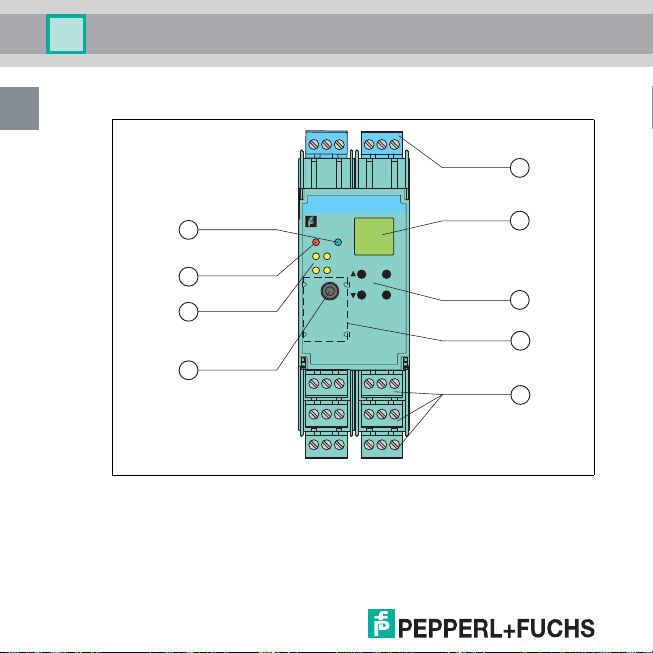

2.3 Assembly

ESC

OK

KFD2-HLCEx1.D.4S

RS232

PWRERR

12

3

4

OUT

19 21

15

9

13

7

20

14

8

22 24

18

121610

23

17

11

132465

3

1

2

6

7

8

9

4

5

6 - EN

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Product Specifications

Operating and indicating elements

Figure 2.1 Example front view KFD2-HLC-Ex1D.4S

315702 2018-01

Page 9

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Product Specifications

1 Removable terminals, blue

315702 2018-01

2 LC display Display for showing

3 Keypad

ESC

OK

4 Place for labeling

5 Removable terminals, green

6 Programming socket Interface for connecting a computer for parameterization and

7 yellow LEDs Outputs Out 1 to 4, indicating relay status

8 red LEDs Indicating faults

9 green LEDs Indicating power supply

•the measured values

• the current output values

• the fault messages

• the parameterization mode

Four keys for selecting the displayed values, the current output

values and for setting the parameters of the device

Up

Down

Escape

Confirmation

diagnostics of the device with the PACTware operating

software, using the K-ADP-USB adapter

EN

EN - 7

Page 10

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

Product Specifications

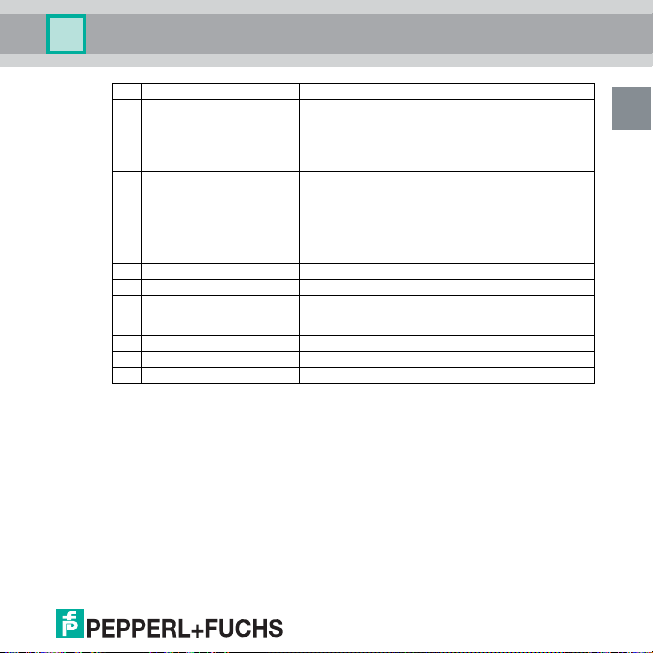

2.4 Dimensions

Housing Type C2

8 - EN

40 mm (1.6 inch)

Figure 2.2

Number of terminal blocks max. 10

• Dimension drawing with screw terminals

• When using screw terminals with test sockets the device is 124 mm (4.9 inch) in height.

• When using spring terminals the device is 131 mm (5.16 inch) in height.

115 mm (4.5 inch)

46 mm (1.82 inch)58 mm (2.28 inch)

104 mm (4.1 inch)

119 mm (4.7 inch)

315702 2018-01

Page 11

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Mounting and Installation

3 Mounting and Installation

Danger!

Explosion hazard from damaged electronic components

Premature wear of electronic components in a device that was previously used in a

general electrical installation can cause sparks that can ignite the surrounding potentially

explosive atmosphere.

Never install devices that have already been operated in general electrical installations in

electrical installations used in combination with hazardous areas!

Danger!

Explosion hazard from pollution

An excessively polluted surface of the device can become conductive and consequently

ignite a surrounding potentially explosive atmosphere.

Ensure that you install the device only in environments with a pollution degree 2 or better

according to IEC/EN 60664–1.

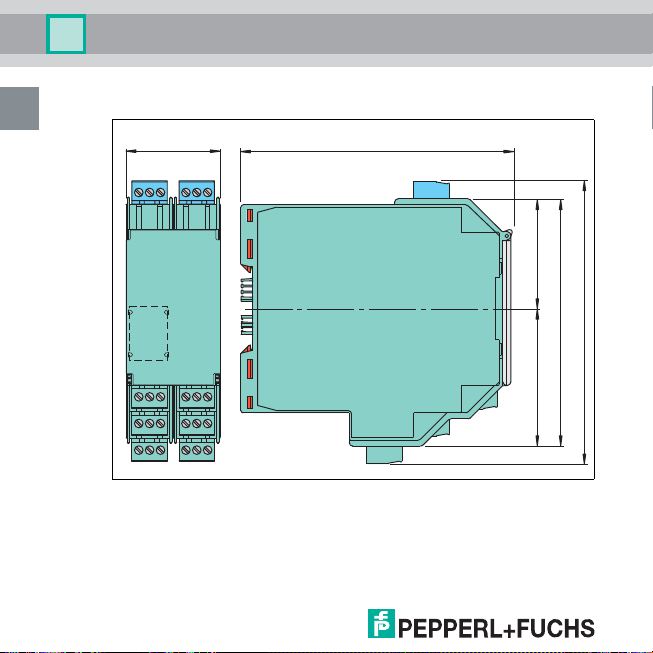

3.1 DIN Mounting Rail

The devices are mounted on a 35 mm DIN mounting rail according to EN 60715.

Figure 3.1 Example: DIN mounting rail UPR-MR (35 mm x 15 mm)

315702 2018-01

EN

EN - 9

Page 12

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

1

2

34

Mounting and Installation

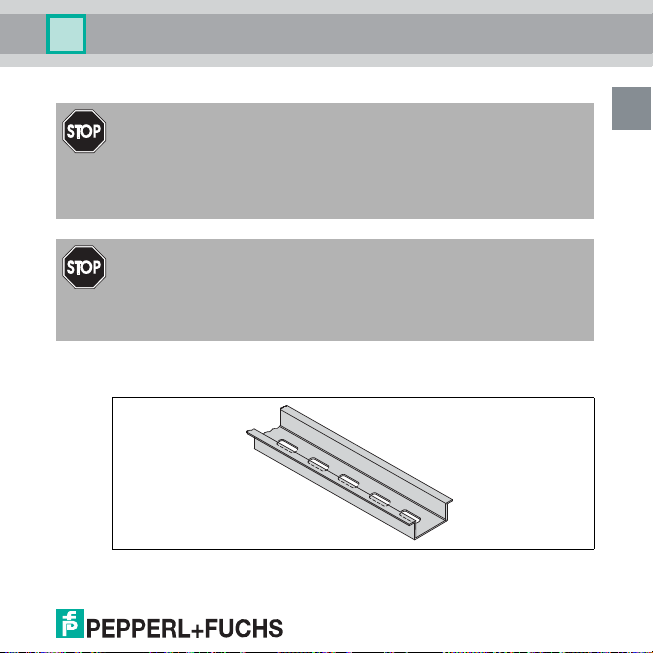

3.2 Power Rail

To reduce wiring and installation costs, Power Rail is the optimum solution. The Power Rail

is a DIN mounting rail with plastic insert, that delivers power to the devices (24 V DC) and

transfers bus signals and a collective error message.

The Power Rail is factory-equipped with cover and end caps. These parts cover empty and

open segments of the Power Rail. Thus, the Power Rail is protected from contamination.

Additionally the cover and end caps prevent that electrically conductive parts come in

contact with the Power Rail.

Power Rail UPR-03

The Power Rail UPR–03 has 3 conductors.

• 2 conductors for power

• 1 conductor for collective error messaging

10 - EN

Figure 3.2 Example: Power Rail UPR-03

1 Cover UPR-COVER

2 Insert UPR-INS-03

3 DIN mounting rail UPR-MR (35 mm x 15 mm)

4 End cap UPR-E

315702 2018-01

Page 13

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Mounting and Installation

3.3 Mounting

Danger!

Danger to life from electric shock

Absent or insufficient insulation can result in electric shock.

Only connect supplies that provide protection against electric shock to power feed

modules (e. g. SELV or PELV).

Caution!

Property damage from use of isolators for Power Rail supply

Using the isolators for Power Rail supply can damage the isolators and make the

Power Rail fail.

Do not supply the Power Rail via isolators.

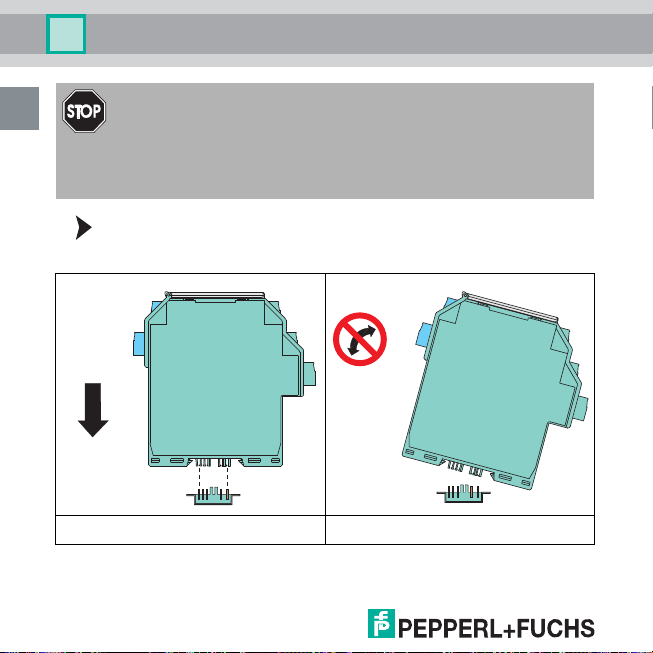

Mounting in the Non-Hazardous Area

Mounting the Device

Snap the device onto the DIN mounting rail in a vert ical downward movement.

See figure below.

Mounting in Areas that Require the Equipment Protection Level Gc

Danger!

Explosion hazard from live wiring of non-intrinsically safe circuits

If you connect or disconnect energized non-intrinsically safe circuits in a potentially

explosive atmosphere, sparks can ignite the surrounding atmosphere.

Only connect or disconnect energized non-intrinsically safe circuits in the absence of a

potentially explosive atmosphere.

315702 2018-01

EN

EN - 11

Page 14

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

Mounting and Installation

Danger!

Explosion hazard from wrong mounting

The device safety can be impaired by external environmental influences and by

mechanical stress. This can lead to sparking that can ignite a surrounding potentially

explosive atmosphere.

Mount the device in a surrounding enclosure that complies with IEC/EN 60079–0and that

is rated with the degree of protection IP54 according to IEC/EN 60529.

Mounting the Device

Snap the device onto the DIN mounting rail in a vert ical downward movement. See figure

below.

CORRECT: Device snapped on vertically. INCORRECT: Device snapped on from the side.

Figure 3.3

Can damage the contacts and cause the device to fail.

315702 2018-01

12 - EN

Page 15

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Mounting and Installation

Mounting the Terminal Blocks

Connect the terminal blocks or disconnect the terminal blocks.

3.4 Connection

Danger!

Danger to life from incorrect installation

Incorrect installation of cables and connection lines can compromise the function

and the electrical safety of the device.

• Observe the permissible core cross section of the conductor.

• When using stranded conductors, crimp wire end ferrules on the conductor ends.

• Use only one conductor per terminal.

• When installing the conductors the insulation must reach up to the terminal.

• Observe the tightening torque of the terminal screws.

Danger!

Explosion hazard from live wiring of non-intrinsically safe circuits

If you connect or disconnect energized non-intrinsically safe circuits in a potentially

explosive atmosphere, sparks can ignite the surrounding atmosphere.

Only connect or disconnect energized non-intrinsically safe circuits in the absence

of a potentially explosive atmosphere.

315702 2018-01

EN

EN - 13

Page 16

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

Mounting and Installation

Danger!

Explosion hazard from wrong separation distances

If you do not observe the minimum separation distances between intrinsically safe circuits

of associated apparatus and non-intrinsically safe circuits, this can lead to added currents

or voltages. This can result in a current/voltage flashover generating sparks. The sparks

can ignite the surrounding potentially explosive atmosphere.

Ensure that you observe the compliance of the separation distances to all non–intrinsically

safe circuits according to IEC/EN 60079–14.

Danger!

Danger to life from electric shock

Absent or insufficient insulation can result in electric shock.

• Maintain sufficient distance between the connection lines, terminals, housing, and the

environment.

• Insulate connection lines, terminals, and the housing from the environment.

Danger!

Danger to life from electric shock

Absent or insufficient insulation can result in electric shock.

Only connect supplies that provide protection against electric shock (e. g. SELV or PELV).

315702 2018-01

14 - EN

Page 17

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Mounting and Installation

Danger!

Danger to life from electric shock

Working on live parts at voltages higher than 50 V AC or 120 V DC can result in electric

shock.

1. De-energize the device.

2. Secure the circuit against reconnection.

3. Verify that the device is de-energized at all poles.

4. Provide protection from adjacent live parts, if present.

The removable terminal blocks simplify connection and control cabinet construction

significantly. These terminal blocks offer adequate space for the connection of leads with

core cross-sections of up to 2.5 mm2 (14 AWG). The terminal blocks are coded with red

coding pins so misconnection of terminal blocks are eliminated.

Connecting Circuits

1. Connect the field circuit.

2. Connect the control circuit.

315702 2018-01

EN

EN - 15

Page 18

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

Mounting and Installation

3.4.1 Input Connection (Field Circuit)

Danger!

Explosion hazard from wrong separation distances

If you do not observe the minimum separation distance between 2 intrinsically safe circuits,

this can lead to added currents or voltages. This can result in a current/voltage flashover

generating sparks. The sparks can ignite the surrounding potentially explosive

atmosphere.

Ensure that you observe all separation distances between 2 adjacent intrinsically safe

circuits according to IEC/EN 60079-14.

Connecting the Field Circuit

1. Connect the field circuit to the blue terminals.

2. Observe the tightening torque of the terminal screws. The tightening torque is

0.5 Nm to 0.6 Nm.

The intrinsically safe field circuit may be routed in the hazardous area with connection lines

in accordance with DIN EN 60079-14. You can connect the following field devices:

1. any separately supplied HART current circuit with transmitter or positioner connected in

parallel

Connection to terminals 2 and 3

2. a HART-capable active current source, e. g., a separately supplied HART measuring

transmitter

Connection to terminals 2 and 3 with bridge between terminals 5 and 6

3. a 2-wire HART measuring transmitter, e. g., HART measuring transmitter with an analog

output signal of 4 mA to 20 mA

The HART measuring transmitter is supplied by the isolated barrier

Connection to terminals 1 and 3 with bridge between terminals 4 and 5

315702 2018-01

16 - EN

Page 19

Power Ra il

24 V DCFau lt

Zone 0, 1, 2

Div. 1, 2

HART

+

-

HART

+

-

+

HART

mA

1+

2+

3-

4

5

6

250 Ω

315702 2018-01

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Mounting and Installation

Figure 3.4

EN

EN - 17

Page 20

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

KFD2-HLC-Ex1.D

7

8+

9-

14+

15-

13

20+

21-

19

Zone 2

Div. 2

24 V DC

23+

24-

22

Power Ra il

24 V DCFau lt

HART

II

III

I

mA

mA

mA

+

-

V

+

-

V

+

-

V

250 Ω

Mounting and Installation

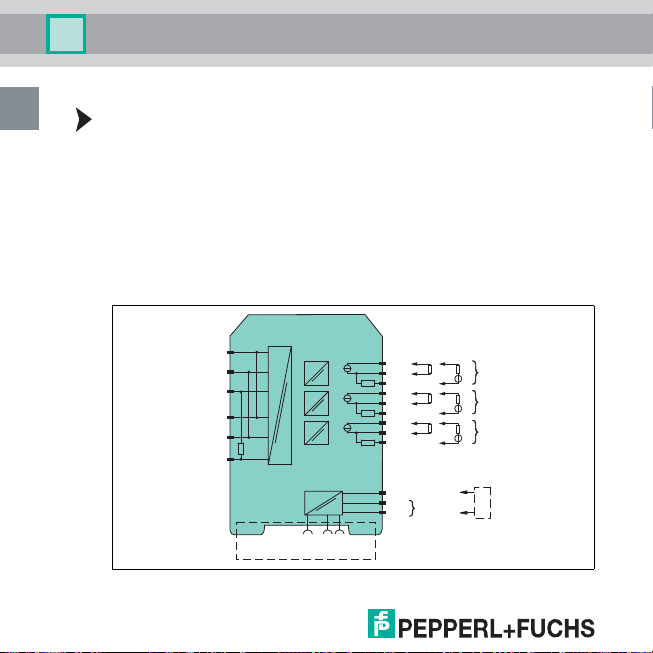

3.4.2 Output Connection (Control Circuit)

Connecting the Control Circuit

1. Connect the control circuit to the green terminals.

2. Note the tightening torque of the terminal screws. The tightening torque is

0.5 Nm to 0.6 Nm.

Connection KFD2-HLC-Ex1.D

The following connections are available:

• Terminals 7 to 9: output I, current output as source (7/8) or sink (7/9)

• Terminals 13 to 15: output II, current output as source (13/14) or sink (13/15)

• Terminals 19 to 21: output III, current output as source (19/20) or sink (19/21)

• Terminals 22/24: connection of HART handheld

• Terminals 23/24: power supply 24 VDC

18 - EN

Figure 3.5

315702 2018-01

Page 21

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Mounting and Installation

Connection KFD2-HLC-Ex1.D.2W

Danger!

Danger to life from electric shock

Working on live parts at voltages higher than 50 V AC or 120 V DC can result in electric

shock.

1. De-energize the device.

2. Secure the circuit against reconnection.

3. Verify that the device is de-energized at all poles.

4. Provide protection from adjacent live parts, if present.

The following connections are available:

• Terminals 10 to 12: output I (relay 1 (change-over contact))

• Terminals 16 to 18: output II (relay 2 (change-over contact))

• Terminals 7 to 9: output III, current output as source (7/8) or sink (7/9)

• Terminals 13 to 15: output IV, current output as source (13/14) or sink (13/15)

• Terminals 19 to 21: output V, current output as source (19/20) or sink (19/21)

• Terminals 22/24: connection of HART handheld

• Terminals 23/24: power supply 24 VDC

315702 2018-01

EN

EN - 19

Page 22

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

KFD2-HLC-Ex1.D.2W

7

8+

9-

14+

15-

13

20+

21-

19

Zone 2

Div. 2

I

II

10

11

12

16

17

18

24 V DC

23+

24-

22

Power Ra il

24 V DCFau lt

HART

+

IV

V

III

-

mA

mA

mA

V

+

-

V

+

-

V

250 Ω

Mounting and Installation

Figure 3.6

20 - EN

315702 2018-01

Page 23

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Mounting and Installation

Connection KFD2-HLC-Ex1.D.4S

Danger!

Danger to life from electric shock

Working on live parts at voltages higher than 50 V AC or 120 V DC can result in electric

shock.

1. De-energize the device.

2. Secure the circuit against reconnection.

3. Verify that the device is de-energized at all poles.

4. Provide protection from adjacent live parts, if present.

The following connections are available:

• Terminals 10/11: output I (relay 1 (NO contact))

• Terminals 11/12: output II (relay 2 (NO contact))

• Terminals 16/17: output III (relay 3 (NO contact))

• Terminals 17/18: output IV (relay 4 (NO contact))

• Terminals 7 to 9: output V, current output as source (7/8) or sink (7/9)

• Terminals 13 to 15: output VI, current output as source (13/14) or sink (13/15)

• Terminals 19 to 21: output VII, current output as source (19/20) or sink (19/21)

• Terminals 22/24: connection of HART handheld

• Terminals 23/24: power supply 24 VDC

315702 2018-01

EN

EN - 21

Page 24

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

KFD2-HLC-Ex1.D.4S

7

8+

9-

14+

15-

13

20+

21-

19

Zone 2

Div. 2

10

11

12

16

17

18

I

III

24 V DC

23+

24-

22

Power Ra il

24 V DCFau lt

HART

IV

II

VI

VII

V

mA

mA

mA

+

-

V

+

-

V

+

-

V

250 Ω

Mounting and Installation

Figure 3.7

22 - EN

315702 2018-01

Page 25

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Mounting and Installation

3.4.3 Connecting a HART Handheld to the Field Device

You have two options for connecting a HART handheld to the field device:

• Connection to terminals 22/24 of the isolated barrier, see chapter 3.4.2

• Connection to the field cables from the isolated barrier to the field device

Danger!

Risk of explosion

Danger of explosion when using a non-certified HART handheld in a hazardous area.

Use a HART handheld certified for use in hazardous areas if the field cables lead into

a hazardous area.

Transmitting the HART signal using the current outputs of the isolated barrier is not possible.

3.4.4 Description of HART Operations

Dynamic Query of Variables

Universal HART command 3 is used to query dynamic variables from the field device.

This query is done either directly or by activating burst mode.

Burst Mode

Burst mode is the preferred method because this mode guarantees the fastest signal

transmission. The isolated barrier always tries to set the connected field device to

burst mode. See chapter 4.2.6.

The command for burst mode activation is sent to the field device under the following

conditions:

• after a restart or

• after resetting the isolated barrier after restarting the field device. In the process,

communication between the field device and isolated barrier must have been

reestablished again after a time-out.

315702 2018-01

EN

EN - 23

Page 26

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

Mounting and Installation

Polling Mode (Command and Answer)

The isolated barrier deactivates the burst configuration of the field device. The isolated

barrier performs the field device query using HART command 3. See chapter 4.2.6.

Procedure to Restore Burst Mode

If the isolated barrier does not receive any more data from the field device in burst mode, the

following actions are taken:

• The isolated barrier switches to polling mode.

• The isolated barrier checks whether another HART master has started in the query

signal circuit. If the isolated barrier has detected a HART master, the restoring of

burst mode is interrupted.

• If the isolated barrier does not detect any other HART masters, the isolated barrier

attempts to activate burst mode.

• As soon as the isolated barrier receives a burst message from the field device, the

isolated barrier switches from polling mode to burst mode.

This process enables other HART masters to deactivate burst mode momentarily for service

work.

Time-out (Communication Loss)

When the time-out time has been exceeded in the absence of communication, all outputs

switch to the defined safe state. Time-out can be adjusted.

315702 2018-01

24 - EN

Page 27

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Configuration

4 Configuration

4.1 Configuration via Software

Danger!

Explosion hazard from sparking when plugging or pulling the adapter

Plugging or pulling the adapter in a potentially explosive atmosphere can cause sparks that

can ignite the surrounding atmosphere.

Only plug or pull the adapter in the absence of a potentially explosive atmosphere.

Caution!

Fault in the plant

Changing the device data changes the device function.

Before entering new device data, make sure the plant is not endangered by changing the

device data.

The devices can configured using the PACTwareTM operating software.

Connection between Device and Computer

Connect the device and the computer using the K-ADP-USB adapter. This adapter can be

ordered as an accessory.

Connecting the Device to the Computer via the USB Interface

1. Mount the device.

2. Connect the device to the power supply.

3. Connect the device to the PC via the adapter.

- Connection on the device: front programming socket

- Connection on the PC: USB interface

4. Refer to the "Installation and Configuration DTM Collection Conventional Interface

Introduction" manual for further steps.

315702 2018-01

EN

EN - 25

Page 28

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

Configuration

The operating software and the necessary device and communication DTMs can be

downloaded from our internet page www.pepperl-fuchs.com (product search, enter

PACTware). The manual "Installation and Configuration DTM Collection Conventional

Interface Introduction" guides you through the installation steps necessary to install the

software. The manual can be found on our internet page www.pepperl-fuchs.com (product

search, enter PACTware).

Note!

The configuration and operation of the device via software is not described in this manual.

4.2 Configuration via Keypad on the Device

Danger!

Explosion hazard from sparking when using operating elements

Using operating elements in a potentially explosive atmosphere can cause sparks that can

ignite the surrounding atmosphere.

Only use operating elements (e.g., switch, slider, button, etc.) in the absence of a

potentially explosive atmosphere.

Caution!

Fault in the plant

Changing the device data changes the device function.

Before entering new device data, make sure the plant is not endangered by changing the

device data.

315702 2018-01

26 - EN

Page 29

HART Loop Converter KFD2-HLC-Ex1.D(.**)

OK →

← ESC

← ESC

← ESC

← ESC

← ESC

OK →

← ESC

▼ ▲

▼ ▲

▼ ▲

▼ ▲

Iout1

4 - 20 NE43

Assignment

Characteristic

Start Value

End Value

Fault Current

Lowest menu level

Configuration

Configuring the Device

Configure the device using the buttons on the front side. Use the , , ESC, and OK

buttons for navigation. The following chapters contain more detailed information about the

menus.

The navigation principle is shown using the following example:

The menu items from the lowest menu level are outlined in bold.

EN

315702 2018-01

EN - 27

Page 30

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

▼ ▲

▼ ▲

▼ ▲

HARTcom

Unit

Main menu

parameterization mode

Output

Service

Display mode

OK + ESC (simultaneously for 1 s) →

← ESC

Configuration

4.2.1 Parameterization Mode

After being switched on, the device is in display mode. If you have password protection

enabled, you must enter the password every time you transition from display mode to

parameterization mode.

Calling up Parameterization Mode

Press the OK and ESC buttons simultaneously for approx. 1 second.

The device changes from display mode to parameterization mode.

Exiting Parameterization Mode

1. Press the ESC once or multiple times. The number of times depends on which menu

level you are in.

2. If you have not pressed a button for 10 minutes in parameterization mode, the device

switches back automatically to display mode.

28 - EN

The device changes from parameterization mode to display mode.

315702 2018-01

Page 31

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Configuration

4.2.2 Password Protection

You can activate password protection to protect parameterization from unauthorized

changes. If password protection is enabled, you can view the parameter settings but not

change them. Password protection is deactivated during delivery. The password is preset

and cannot be changed by the operator. The password is 1234. Information about enabling

password protection see chapter 4.2.9.

Entering the Password

1. As soon as you try to change the parameterization, the device switches automa tically to

the input window for password access.

The first digit of the password flashes.

2. Set the first digit of the password using the and buttons.

3. Confirm your entry with OK.

The next digit flashes.

4. Repeat steps 2 and 3, until all digits have been entered.

5. Confirm your entry with OK.

If the password was correct, the device changes to parameterization mode.

The device can now be parameterized.

If the password was not correct, cancel password access and begin password entry

again using step 1.

Canceling Password Entry

You can cancel password entry at any time.

Press the ESC button.

The device switches to display mode.

315702 2018-01

EN

EN - 29

Page 32

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

OK →

← ESC

OK ↓

← ESC

← ESC

▼ ▲ ↓

Parameter Current value, flashing

New value, flashing,

not stored

New value, not flashing,

stored

Configuration

4.2.3 Entering Numbers

At the lowest menu level of the Paramete r menu, you have the option of selecting or

entering a numerical value.

Selecting a Numerical Value

1. Select the parameter for which you want to change the numerical value.

2. Press the OK button.

The current value flashes.

3. Select a value from the list of values using the and buttons.

The new value flashes. The value is not stored.

4. Confirm your selection with OK.

The new value does not flash. The value is stored.

Entering a Numerical Value

1. Select the parameter where you want to enter the numerical value.

2. Press the OK button.

The current value flashes.

3. To change the value in steps, press the or button. or

To change the value more quickly, press and hold the or button.

30 - EN

The new value flashes. The value is not stored.

4. Confirm your selection with OK.

The new value is stored.

315702 2018-01

Page 33

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Configuration

4.2.4 Entering Floating Point Figures

At the lowest menu level of the Paramete r menu, you have the option of entering floating

point figures.

The floating point figures can have the following structure:

Positive number Input Negative number Input

43210000 43.21 E06 -3210000 -3.21 E06

4321000 4321 E03 -321000 -321 E03

432100 4 32.1 E03 -32100 -32.1 E03

43210 43.21 E03 -3210 -3.21 E03

4321 4321 E00 -321 -321 E00

432.1 4 32.1 E00 -32.1 -32.1 E00

43.21 43.21 E00 -3.21 -3.21 E00

1.234 1 .234 E00

0.1234 123.4 E-03 -0.123 -123 E-03

0.01234 12.34 E-03 -0.0123 -12.3 E-03

0.001234 1.234 E-03 -0.00123 -1.23 E-03

0.0001234 123.4 E-06 -0.00 0123 -123 E-06

Table 4.1

For a floating point figure, you must enter the following parameters:

• four digits of the mantissa (decimals) for positive numbers

• a minus sign and three digits for the mantissa for negative numbers

• the position of the decimal point in or after the mantissa

• the exponents

315702 2018-01

EN

EN - 31

Page 34

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

Configuration

Entering a Numerical Value

1. Select the parameter for which you want to enter the numerical value.

2. Press the OK button.

The current value from the mantissa and exponent flashes.

3. Press the OK button.

With positive numbers, the first digit of the mantissa flashes.

With negative numbers, the minus sign flashes.

4. To change the value in steps from 0 to 9, press the or button.

To enter a minus sign, press the button until the first digit is less than 0.

5. Confirm your selection with OK.

The next digit of the mantissa flashes.

6. Repeat steps 4 and 5, until all digits have been entered.

7. Confirm your entry with OK.

The position of the decimal point flashes.

8. Press the or button to specify the position of the decimal point.

9. Confirm your entry with OK.

The exponent flashes.

10. To specify the value of the exponent, press the or button. You can select the

exponents from E-33 to E33 in increments of three.

11. Confirm your entry with OK.

The new value is stored.

315702 2018-01

32 - EN

Page 35

HART Loop Converter KFD2-HLC-Ex1.D(.**)

OK →

← ESC

← ESC

← ESC

← ESC

OK →

← ESC

▼ ▲

▼ ▲

▼ ▲

auto

OK →

← ESC

OK →

← ESC

OK →

← ESC

OK →

← ESC

custom

Custom Tag

▼ ▲ ▼ ▲

PV

SV

OK →

← ESC

TV

QV

see below

Unit

same as PV

same as PV

same as PV

Ty p e

Configuration

4.2.5 Unit

At the lowest menu level of the Unit menu, you have the option of selecting the unit type for

the HART variables.

• auto

The device displays the unit which is transferred from connected HART field devices

for the HART variables PV, SV, TV, QV.

• custom

The device displays the unit which was defined by you for the HART variables

PV, SV, TV, QV in the Custom Tag menu.

EN

315702 2018-01

EN - 33

Page 36

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

Configuration

Changing the Custom Tag of HART Variables

1. Select the HART variable for which you would like to change the custom tag.

2. Press the OK button.

3. Select the Custom Tag menu.

The device displays:

if a value has not been defined: the insert mark and the symbol

If a value is defined: the insert mark on the first character, the following character, and

the symbol .

4. To select one of eight possible positions for the insert mark before the symbol , press

the or button.

5. Confirm your selection with OK.

The insert mark flashes.

6. To select a character, press the or button.

7. Confirm your entry with OK.

8. Repeat steps 4 and 7, until all characters have been entered. You can also define

spaces.

9. To select the symbol , press the or button.

10. Confirm your entry with OK.

The new value for Custom Tag has been stored.

Canceling the Value Input for HART Variables

You can cancel the value entry at any time.

Press the ESC button.

315702 2018-01

34 - EN

Page 37

HART Loop Converter KFD2-HLC-Ex1.D(.**)

OK →

← ESC

← ESC

← ESC

← ESC

OK →

← ESC

▼ ▲

▼ ▲

▼ ▲

secondary

OK →

← ESC

OK →

← ESC

OK →

← ESC

primary

▼ ▲

Mode

ShortAddress

← ESC

▼ ▲

OK →

← ESC

TimeOut

LocateMethod

Rebuild

OFF Rebuild

▼ ▲

HARTcom

fixed

On Rebuild

search

▼ ▲

← ESC

▼ ▲

OK →

← ESC

ComControl

auto detect

polling

▼ ▲

burst

▼ ▲

5 s to 60 s

0 to 15

Configuration

4.2.6 HARTcom

The HARTcom menu offers the option of specifying the method for communication between

device and field device. If available, the device activates burst mode of the

HART field device for the fastest possible communication. To query variables

(PV, SV, TV, QV, if present) the device uses the universal HART command 3.

EN

315702 2018-01

EN - 35

Page 38

EN

36 - EN

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Configuration

Selecting a Mode

The device functions as primary or secondary HART master according to the

HART standard. The device is compatible with each HART handheld and for every other

HART master.

1. Use the or buttons to select whether the device should operate as a primary or

secondary HART master.

2. Confirm your selection with OK.

Defining TimeOut

If the device does not receive a valid HART message within the specified time, the

communication fault fault message is output.

1. To change the time in steps, press the or buttons.

Set the time from 5 s to 60 s in increments of 5 seconds.

2. Confirm your entry with OK.

Defining ComControl

You can specify the communication type between isolated barrier and field device.

The change in communication type is effective immediately. It is not necessary to restart the

isolated barrier. See chapter 3.4.4.

1. Select the type of communication using the or buttons.

2. Select auto detect.

If you select this type of communication, the burst configuration of the field device is

not changed.

3. Choose polling.

If you select this type of communication, the isolated barrier deactivates the

burst configuration of the field device. The isolated barrier performs the field device

query using HART command 3.

4. Choose burst.

If you choose this type of communication, the isolated barrier activates the

burst configuration of the field device for HART command 3.

5. Confirm your entry with OK.

315702 2018-01

Page 39

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Configuration

315702 2018-01

Note!

Note that the field device can be put into burst mode, in accordance to the isolated barrier

configuration. This also applies when a different HART master is in the HART circuit.

If a different HART master changes the burst configuration of the field device, the isolated

barrier waits until the other HART master logs out of the HART circuit. The isolated barrier

assumes that the other HART master is logged off when it does not send a message for

approximately 60 s. After this period of time, the isolated barrier activates the

burst configuration of the field device.

Defining ShortAddress

The defined short address is needed for identification of the field device during the

localization phase.

1. To enter a short address between 0 to 15, press the or buttons.

2. Confirm your entry with OK.

Selecting LocateMethod

According to the HART standard, more than one HART field device can be present in a

HART circuit. But the device can communicate only with a single HART field device.

This HART field device is identified during the localization phase.

1. Select the localization method with the or buttons.

2. Select fixed.

The device communicates with the field device that has a short address defined

under ShortAddress.

3. Choose search.

During booting, the device searches for the field device with the smallest short

address, beginning with the short address defined under ShortAdress. The address of

the field device found is stored by the device under ShortAddress. This accelerates

the device starting when it boots again.

4. Confirm your entry with OK.

EN

EN - 37

Page 40

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

OK →

← ESC

OK →

← ESC

▼ ▲

disabled

PV

▼ ▲ ▼ ▲

Iout1

OK →

← ESC

OK →

← ESC

4 - 20

unlimited

4 - 20 NE43

▼ ▲

SV

▼ ▲

TV

▼ ▲

QV

▼ ▲

OK →

← ESC

▼ ▲

▼ ▲

Output Assignment

Characteristic

Start Value

see section

Configuration

Activating Rebuild

If the connection to the field device has been lost, the localization phase can be performed

with Rebuild without switching the device off and on again.

1. Select On Rebuild with the or buttons.

2. Confirm your selection with OK.

The display On Rebuild flashes.

3. Press the OK button.

The device searches for connected field devices when booting.

4. Press the ESC button once or multiple times to switch to display mode.

4.2.7 Current Outputs

In the Output menu, you have the option of defining current outputs 1 to 3 of the device. The

menu structure is identical for the three current outputs. Current output 1 is described as an

example. For information on relay contact outputs, see chapter 4.2.8.

38 - EN

315702 2018-01

Page 41

HART Loop Converter KFD2-HLC-Ex1.D(.**)

▼ ▲

Iout2

OK →

← ESC

▼ ▲

Iout3

▼ ▲

Rel1

▼ ▲

Rel2

▼ ▲

Rel3

Rel4

OK →

← ESC

down

up

▼ ▲

hold

▼ ▲

OK →

← ESC

▼ ▲

OK →

← ESC

1 2

1 2

1

1

End Value

see section

Fault Current

same as Iout1

same as Iout1

Configuration

315702 2018-01

1

Relay contact outputs for KFD2-HLC-Ex1.D.4S

2

Relay contact outputs for KFD2-HLC-Ex1.D.2W

Selecting an Assignment

The values of the selected HART v ariable (PV, SV, TV, QV) are shown on the current outp ut.

The number of available variables depends on the HART field device. When selecting

disabled, the downscale fault current of 0 mA or 2 mA is constantly present at the current

output, depending on the characteristic.

1. Select the desired HART variable using the or buttons.

2. Confirm your selection with OK.

EN

EN - 39

Page 42

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

Configuration

Defining a Characteristic

The choice of characteristic defines the limits for measuring underrange and overrange.

Measuring underranges or overranges outside the specified range cannot be analyzed. If

measuring ranges are undercut or exceeded, the minimum or maximum value is issued

constantly.

1. Select the characteristic using the or buttons.

2. Select the characteristic 4 - 20 unlimited.

For the characteristic 4 - 20 unlimited, measuring underranges are analyzed

linearly up to 0 mA, and measuring overranges are analyzed linearly up to

approx. 23 mA by the device.

3. Select the characteristic 4 - 20 NE43.

For the characteristic 4 - 20 NE43, measuring underranges are analyzed linearly

up to 3.8 mA, and measuring overranges are analyzed linearly up to 20.5 mA by the

device.

4. Confirm your entry with OK.

Defining the Start Value

Make sure during configuration that the start value is at least 1% less than the end value. If

the start value does not meet this requirement, the start value will not be accepted by the

device.

1. Enter the start value as a floating point figure. For entering floating point figures,

see chapter 4.2.4. The defined unit from the Unit menu is used as the unit.

See chapter 4.2.5.

2. Confirm your entry with OK.

Define the End Value

Make sure during configuration that the end value is at least 1 % greater than the start value.

1. Enter the end value as a floating point figure. For entering floating point figures,

see chapter 4.2.4. The defined unit from the Unit menu is used as the unit.

See chapter 4.2.5.

2. Confirm your entry with OK.

315702 2018-01

40 - EN

Page 43

1.9

4.0

3.8

0

20.0

20.5

2 10 bar

10.25

mA

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Configuration

Example

Characteristic 4 - 20 NE43, start value 2 bar, end value 10 bar

Figure 4.1

Defining the Fault Current (fault message)

The type of fault current chosen will define how the current output transmits the fault

message to the controller.

1. Select the type of fault current using the or buttons.

2. Select the fault current down.

The fault message is indicated by a low current value.

3. Select the fault current up.

The fault message is indicated by a high current value.

4. Select the fault current hold.

The last measured value before the fault occurred is stored.

5. Confirm your entry with OK.

315702 2018-01

EN

EN - 41

Page 44

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

▼ ▲

Iout2

▼ ▲

Iout1

OK →

← ESC

▼ ▲

Iout3

▼ ▲

Rel1

▼ ▲

Rel2

▼ ▲

Rel3

Rel4

OK →

← ESC

▼ ▲

OK →

← ESC

OK →

← ESC

OK →

← ESC

1

1 2

1 2

1

same as Rel1

same as Rel1

same as Rel1

Output

Tr i p

Faul t

Configuration

4.2.8 Relay Contact Outputs

In the Output menu, you have the option of defining relay contact outputs 1 to 4

device. The menu structure of the four relay contact outputs is identical. Relay contact output

1 is described as an example. Information on the current outputs see chapter 4.2.7.

1

Relay contact outputs for KFD2-HLC-Ex1.D.4S

2

Relay contact outputs for KFD2-HLC-Ex1.D.2W

42 - EN

1 2

of the

315702 2018-01

Page 45

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Configuration

Selecting Relay Contact Output Menus

1. Select the desired relay contact output using the or buttons.

2. Confirm your entry with OK.

The relay contact output menus Tr i p and Faul t are displayed. The active menu is

marked as On.

3. If you would like to activate the other menu, select this menu with or .

4. Press the OK button twice.

The active menu is marked as On. The submenu is displayed.

5. If you would like to cancel activation, press the ESC button after the first OK.

315702 2018-01

EN

EN - 43

Page 46

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

OK →

← ESC

disabled

PV

▼ ▲ ▼ ▲

OK →

← ESC

OK →

← ESC

min

max

▼ ▲

SV

▼ ▲

TV

▼ ▲

QV

▼ ▲

OK →

← ESC

▼ ▲

▼ ▲

Min/Max

OK →

← ESC

▼ ▲

Assignment

Tr i p

see section

Hyteresis

see section

Trip (On)

Configuration

Limit Value (Trip)

Calling up a Limit Value

1. Select the Tr i p menu with the or buttons.

2. If the Tr i p menu is activated, press the OK button once.

The Assignment submenu is displayed.

3. If the Tr i p menu is not activated, press the OK button twice.

The Assignment submenu is displayed. The Tri p menu is activated and is marked

as On.

44 - EN

315702 2018-01

Page 47

HART Loop Converter KFD2-HLC-Ex1.D(.**)

OK →

← ESC

▼ ▲ ▼ ▲

OK →

← ESC

On

OFF

▼ ▲

OK →

← ESC

▼ ▲

Mode

Delay

Restart Inhibit

passive

active

0 s to 250 s

Configuration

Selecting an Assignment

The values of the HART variables selected here (PV, SV, TV, QV) are monitored using a

relay contact output. The number of available variables depends on the HART field device.

When disabled is selected, the relay remains constant in a de-energized state.

1. Select the desired HART variable using the or buttons.

2. Confirm your selection with OK.

Defining Switching Characteristics

Selecting the switching characteristics defines the switching direction and the direction of

operation. See applications.

1. Select the switching direction min or max with the or buttons.

2. Confirm your selection with OK.

3. Select the direction of operation passive or active with the or buttons.

4. Confirm your selection with OK.

315702 2018-01

EN

EN - 45

Page 48

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

Configuration

You can implement the following applications:

• Switching direction max, direction of operation active: alarm if there is a

limit value overrange, e. g., sounder on

• Switching direction max, direction of operation passive: switch off during

limit value overrange, e. g., pump, heating, ... off, for larger hysteresis Min-Max

operation (pump, heater, ... on/off)

• Switching direction min, direction of operation active: alarm if there is a

limit value underrange, e. g., sounder is on.

• Switching direction min, direction of operation passive: switch off during

limit value underrange, e. g., pump, heating, ... off, for larger hysteresis Min-Max

operation (pump, heater, ... off/on)

The exact switching characteristics of the device are shown in the following illustration:

Val ue

Max

Max – hysteresis

Min + hysteresis

Min

46 - EN

Switching direction max, mode active:

de-energized

Switching direction max, mode passive:

de-energized

Switching direction min, mode active:

de-energized

Switching direction min, mode passive:

de-energized

Figure 4.2

Time

energized

energized

energized

energized

315702 2018-01

Page 49

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Configuration

Defining the Trip Point

1. Enter the starting point as a floating point figure. For entering floating point figures,

see chapter 4.2.4. The defined unit from the Unit menu is used as the unit.

See chapter 4.2.5.

2. Confirm your entry with OK.

Defining Hysteresis

Make sure during input that the hysteresis is at least 1 % greater than the trip point.

This avoids "fluttering" of the relay.

1. Enter the hysteresis as a floating point figure. For entering floating point figures,

see chapter 4.2.4. The defined unit from the Unit menu is used as the unit.

See chapter 4.2.5.

2. Confirm your entry with OK.

Activating the Restart Inhibit

The restart inhibit is used to prevent momentary limit value violations from not being noticed

by operating personnel.

1. Use the or buttons to select On.

2. Confirm your selection with OK.

The relay status is retained after switching the relay.

3. If you would like to reset the relay status, press the ESC or

button or restart the device.

The relay is reset. Exception: there is a limit value violation.

Defining the Response Delay

Inputting a response delay > 0 s prevents momentary limit value violations from triggering an

alarm.

1. To change the time in steps, press the or buttons.

Set the time from 0 s to 250 s in increments of 5 seconds.

2. Confirm your entry with OK.

315702 2018-01

EN

EN - 47

Page 50

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

Configuration

Response delay has the following effects:

• When the value of the trip point is out of range (exceeded or not reached) for a period

of time longer than the delay time, the relay switches.

• When the value of the trip point ± hysteresis is in range (not reached or exceeded) for a

period of time longer than the delay time, the relay switches back.

• Shorter overranges/underranges do not have an effect.

The following illustration shows an example of switching characteristics with response delay

Val ue

Max – hysteresis

Max

48 - EN

Switching direction max, mode active, with delay:

Figure 4.3

energized

de-energized

Delay Delay

Time

315702 2018-01

Page 51

HART Loop Converter KFD2-HLC-Ex1.D(.**)

OK →

← ESC

On

OFF

▼ ▲

OK →

← ESC

Restart InhibitFault (On)

Configuration

Fault Message

Calling up a Fault Message

1. Use the or buttons to select the Fault message menu.

2. If the fault message menu is activated, press the OK button once.

The Restart inhibit submenu is displayed.

3. If the fault message menu is not activated, press the OK button twice.

The Restart inhibit submenu is displayed. The Fault message menu is activated

and is marked as On.

Activating the Restart Inhibit

The restart inhibit is used to prevent momentary limit value violations from not being noticed

by operating personnel.

1. Use the or buttons to select On.

2. Confirm your selection with OK.

The relay status is retained after switching the relay.

3. If you would like to reset the relay status, press the ESC or

button or restart the device.

The relay is reset. Exception: there is a fault message.

EN

315702 2018-01

EN - 49

Page 52

EN

OK →

← ESC

← ESC

OK →

← ESC

▼ ▲

OK →

← ESC

▼ ▲

← ESC

▼ ▲

OK →

← ESC

Reset

▼ ▲

Service

On Reset

OFF Reset

▼ ▲

← ESC

OK →

← ESC

Ver si on

ENG

DE

▼ ▲

Language

Passw ord

OFF Password

On Password

Version No.

50 - EN

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Configuration

4.2.9 Service

In the Service menu, you have the option of specifying basic device parameters.

Select language

1. Use the or buttons to select which language is used by the device display.

2. Select ENG for English.

3. Confirm your selection with OK.

4. Select DE for German.

5. Confirm your selection with OK.

315702 2018-01

Page 53

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Configuration

Activating Password Protection

To protect parameterization from unauthorized changes, you can enable password

protection. Information about password protection see chapter 4.2.2.

1. Use the or buttons to select the desired setting.

2. To enable password protection, select On Password.

3. Confirm your selection with OK.

4. To disable password protection, select Off Password.

5. Confirm your selection with OK.

Resetting the Device to Factory Settings

1. Use the or buttons to select On Reset.

On Reset flashes.

2. Confirm your selection with OK.

The device is reset to factory settings. All entries you have defined in

parameterization mode will be lost.

Displaying the Software Version

Use the or buttons to display the version.

The software version of the device software is displayed.

315702 2018-01

EN

EN - 51

Page 54

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

Operation

5Operation

Danger!

Explosion hazard from live wiring of non-intrinsically safe circuits

If you connect or disconnect energized non-intrinsically safe circuits in a potentially

explosive atmosphere, sparks can ignite the surrounding atmosphere.

Only connect or disconnect energized non-intrinsically safe circuits in the absence of a

potentially explosive atmosphere.

Danger!

Explosion hazard from sparking when using operating elements

Using operating elements in a potentially explosive atmosphere can cause sparks that can

ignite the surrounding atmosphere.

Only use operating elements (e.g., switch, slider, button, etc.) in the absence of a

potentially explosive atmosphere.

315702 2018-01

52 - EN

Page 55

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Operation

5.1 Indicators during Operation

The isolated barrier displays the following operating modes and fault messages during

operation.

Status Indicators

LED Status Description

315702 2018-01

Green LED Off No power supply

Red LED Flashes briefly Displays a single HART fault message received by the field device

Yellow

LEDs

Table 5.1

Flashes regularly Start-up phase, self-test

On Normal function

Flashes regularly Invalid HART data (missing communica tion or fault in the

On Device self-test of isolated barrier detected a fault

On Isolated barrier is in reset state, all other LEDs are off

On For KFD2-HLC-Ex1.D.2W and KFD2-HLC-Ex1D.4S:

field device)

• Output Out 1, relay energized

• Output Out 2, relay energized

For KFD2-HLC-Ex1D.4S:

• Output Out 3, relay energized

• Output Out 4, relay energized

EN

EN - 53

Page 56

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

Operation

Display Indicators

In normal operation, the display shows:

• the current values of the HART variables PV, SV, TV, QV in the selected unit

• the present current output values for the three current outputs in mA

•the current device status

This display shows information about the device status of the field device (1 byte) and

about the response code (1 byte) of the field device. These two bytes are displayed in

the first line of the display in hexadecimal form with the code RC on the left side.

• the current setting of the type of communication

•LOOP Locate

The isolated barrier reestablishes the HART circuit. The isolated barrier

performs the field device query using the HART command 3.

• LOOP Poll

The isolated barrier performs the field device quer y using the HART command 3.

•LOOP Burst

The isolated barrier receives the HART command 3 of the field device.

• LOOP Mixed

The isolated barrier performs the field device query using the HART command 3

(polling). The field device is in burst mode, however it references a different

HART command than 3.

In the event of a fault, the display shows:

•Err Device Fault

Displays a device fault in the isolated barrier – red LED lights up.

• Err Communication

Displays a communication fault – red LED flashes.

• Err Field Device Malfunction

Displays a field device failure – red LED flashes.

315702 2018-01

54 - EN

Page 57

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Operation

Display Options for Current Output Values and HART Variables

• To select the displayed measured values or current output values, use the

and buttons.

• To select units for measured values, use the Unit menu. See chapter 4.2.5.

• Every time the isolated barrier receives a HART command 3 message from the

field device, the display is updated.

• The isolated barrier displays the current output values as a four-digit number. The

decimal point is set to provide the best possible resolution.

• The isolated barrier shows the floating point value for HART variables as follows:

• If possible, as a four-digit number with decimal point and without exponent.

Negative values are shown on the device with three digits because of the minus

sign.

• A digit is rounded as necessary. For example, the number 0.3456 is shown as

0.346.

• If the isolated barrier cannot show the floating point value, the mantissa and

exponent are shown in alternation.

5.2 Fault Message

The following table shows which fault message the current outputs send to the controller,

based on the characteristic.

Setting 4 - 20 unlimited 4 - 20 NE43

315702 2018-01

down 0 mA

up approx. 23 mA

hold Last measured value before the fault

Table 5.2

Cannot be distinguished from falling below the start value

Cannot be distinguished from the end value being exceeded

EN

2.0 mA

21.5 mA

EN - 55

Page 58

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

Dismounting, Maintenance, and Repair

6 Dismounting, Maintenance, and Repair

Danger!

Explosion hazard from live wiring of circuits

If you connect or disconnect energized circuits in a potentially explosive atmosphere,

sparks can ignite the surrounding atmosphere.

Only connect or disconnect energized circuits in the absence of a potentially explosive

atmosphere.

Danger!

Danger to life from electric shock

Working on live parts at voltages higher than 50 V AC or 120 V DC can result in electric

shock.

1. De-energize the device.

2. Secure the circuit against reconnection.

3. Verify that the device is de-energized at all poles.

4. Provide protection from adjacent live parts, if present.

Danger!

Danger to life from using damaged or repaired devices.

Using a defective or repaired device can compromise its function and its electrical safety.

• Do not use a damaged or polluted device.

• The device must not be repaired, changed or manipulated.

• If there is a defect, always replace the device with an original device from

Pepperl+Fuchs.

315702 2018-01

56 - EN

Page 59

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Dismounting, Maintenance, and Repair

Disconnecting Circuits

1. Disconnect the field circuit.

2. Disconnect the control circuit.

3. Disconnect the power supply.

Removing the Device

Use for dismounting of the device a slotted screwdriver

1. Insert the screwdriver (4) into the groove of the red mounting slider (3).

2. Turn the screwdriver (4) in the groove until the red mounting slider (3) springs back.

3. Repeat these steps on the other side of the device.

4. Remove the device (2) from the DIN mounting rail (1).

315702 2018-01

EN

EN - 57

Page 60

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

3 1

4

4

2

Dismounting, Maintenance, and Repair

Figure 6.1 Dismounting of the device from the DIN moun ting rail

1 35 mm DIN mounting rail

2 Device

3 Mounting slider

4 Slotted screwdriver

58 - EN

315702 2018-01

Page 61

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Technical Specifications

7 Technical Specifications

7.1 Default Settings

The following table provides an overview of th e default settings. Information about resetting

the device to the default setting see chapter 4.2.9.

Tip

If the device parameters have changed, enter these changes in the "Custom Value"

column. This provides an overview of your individual device settings.

Menu Parameters Default setting Custom value

Unit PV Type auto

HARTcom Mode secondary

Output Iout1 Assignment disabled

Output Iout2 Assignment disabled

315702 2018-01

SV Type auto

TV Type auto

QV Type auto

TimeOut 10 s

ComControl auto detect

ShortAddress 0

LocateMethod search

Characteristic 4 - 20 NE43

Start value 0.000

End value 100.0

Fault current down

Characteristic 4 - 20 NE43

Start value 0.000

End value 100.0

Fault current down

EN

EN - 59

Page 62

HART Loop Converter KFD2-HLC-Ex1.D(.**)

EN

Technical Specifications

Menu Parameters Default setting Custom value

Output Iout3 Assignment disabled

Output Rel1 1

Output Rel2

Characteristic 4 - 20 NE43

Start value 0.000

End value 100.0

Fault current down

2

Limit value (Trip) On (selected)

Limit value Assignment disabled

Limit value Min/Max min

Limit value Trip point 80.00

Limit value Hysteresis 10.00

Limit value Operating mode passive

Limit value Restart inhibit OFF

Limit value Response delay 0 s

Fault message not selected

1 2

Limit value (Trip) On (selected)

Limit value Assignment disabled

Limit value Min/Max min

Limit value Trip point 80.00

Limit value Hysteresis 10.00

Limit value Operating mode passive

Limit value Restart inhibit OFF

Limit value Response delay 0 s

Fault message not selected

315702 2018-01

60 - EN

Page 63

HART Loop Converter KFD2-HLC-Ex1.D(.**)

Technical Specifications

Menu Parameters Default setting Custom value

Output Rel3

Output Rel4

Service Language ENG

Table 7.1

1

Relay contact outputs for KFD2-HLC-Ex1.D.4S

2

Relay contact outputs for KFD2-HLC-Ex1.D.2W

315702 2018-01

1

Limit value (Trip) On (selected)

Limit value Assignment disabled

Limit value Min/Max min

Limit value Trip point 80.00

Limit value Hysteresis 10.00

Limit value Operating mode passive

Limit value Restart inhibit OFF

Limit value Response delay 0 s

Fault message not selected

1

Limit value (Trip) On (selected)

Limit value Assignment disabled

Limit value Min/Max min

Limit value Trip point 80.00

Limit value Hysteresis 10.00

Limit value Restart inhibit OFF

Limit value Response delay 0 s

Fault message not selected

Password OFF

EN

EN - 61

Page 64

PROCESS AUTOMATION –

PROTECTING YOUR PROCESS

Worldwide Headquarters

Pepperl+Fuchs GmbH

68307 Mannheim · Germany

Tel. +49 621 776-0

E-Mail: info@de.pepperl-fuchs.com

For the Pepperl+Fuchs representative

closest to you check www.pepperl-fuchs.com/contact

www.pepperl-fuchs.com

Subject to modifications

Copyright PEPPERL+FUCHS

· Printed in Germany

315702 DOCT-1377E

01/2018

Loading...

Loading...