Pepperl+Fuchs KFD2-HLC-Ex1.D, KFD2-HLC-1.D.2W, KFD2-HLC-Ex1.D.2W, KFD2-HLC-1.D.4S, KFD2-HLC-1.D User Manual

...Page 1

MANUAL

HART LOOP CONVERTER

KFD2-HLC-(EX)1.D(.**)

PROCESS AUTOMATION

HANDBUCH

ISO9001

PROZESSAUTOMATION

Page 2

With regard to the supply of products, the current i ssue of the following document is applicable:

The general terms of delivery for products and s ervices of the electrical industry, as published

by the central association of the "Elektrot echnik und Elektroindustrie (ZVEI) e.V.",

including the supplementary clause "E xtended reservation of title".

Page 3

Date of issue 11/30/07 805639

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Table of contents

1 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Range of application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Model variants. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Explosion protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 Installation and connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.1 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.2 Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.2.1 Connection input (field circuit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.2.2 Connection output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.3 Setting parameters of HART field device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.4 Front. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.5 Meaning of LED indication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6 Display modes and error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7 Description of HART operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8 Editing device data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.1 Parameterization mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.1.1 Invocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.1.2 Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8.1.3 Navigation method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.1.4 Lowest menu level: select values, enter normal numbers . . . . . . . . . . . . . . . . . . . . . . 19

8.1.5 Lowest menu level: enter floating decimal numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.2 Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1

Page 4

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Table of contents

8.3 HARTcom. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.3.1 Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.3.2 TimeOut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.3.3 ShortAddress and LocateMethod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.3.4 Rebuild . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.4 Current outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.4.1 Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.4.2 Characteristic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.4.3 Start value and end value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8.4.4 Error current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8.5 Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8.5.1 Trip value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.5.2 Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.5.3 Switching characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.5.4 Trip point and hysteresis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.5.5 Restart inhibit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.5.6 Response delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.5.7 Fault indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.6 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.7 Default settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Date of issue 11/30/07 805639

2

Page 5

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Symbols used

1 Symbols used

This symbol warns of possible danger.

Failure to heed this warning may result in personal injury or death, or property damage,

including destruction.

Warning

This symbol warns the user of a possible fault.

Failure to heed this warning can lead to total failure of the device and any other

connected equipment.

Attention

Note

This symbol draws attention to important information.

2 Overview

2.1 Range of application

The K-System devices from Pepperl+Fuchs are used for transmitting signals between field devices

and a process control system/control system.

The devices marked with "Ex" in the type designation are suitable for the connection of field devices

used in potentially explosive atmospheres. Safe field circuits for these devices are intrinsically safe

and are galvanically isolated from non-intrinsically safe circuits. The devices thus establish an

electromagnetic separation between the potentially explosive atmospheres and the safe areas in a

system.

Devices without Ex-identification can be used to transmit signals between field devices and the

process control system/control unit.

Date of issue 11/30/07 805639

3

Page 6

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Overview

The HART system allows digital communication with HART field devices via cables for analogue

4 mA ... 20 mA field circuits.

HART

More information (for example, certificates and data sheets for the HLC and the operating manual for

the K-System) can be found on our webpage www.pepperl-fuchs.com (enter *HLC* in the product

search).

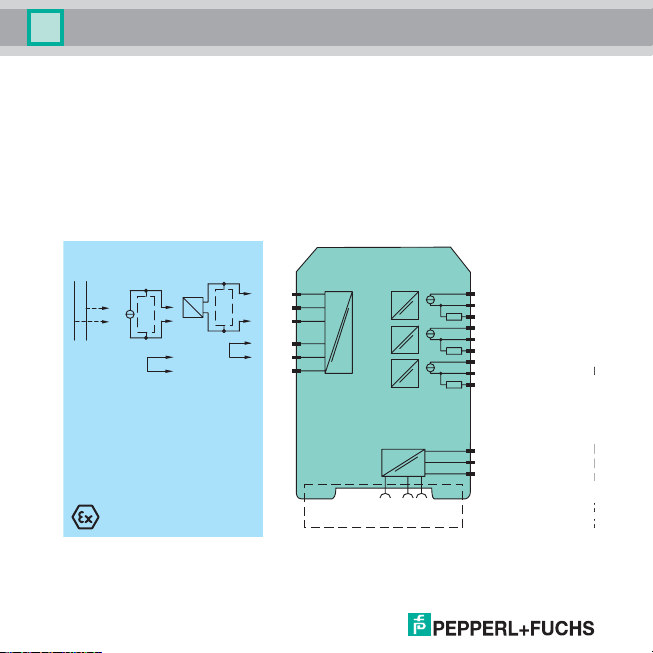

The HART Loop Converter

KFD2-HLC-(Ex)1.D(.**) from the K-System

(HLC) evaluates up to four HART variables

(PV, SV, TV, QV). The information can be

converted to three different 4 mA ... 20-mA

current signals and conveyed to display

devices or analogue inputs on the process

control system/control system, for example.

In addition, two or four configurable trip values

from the HART variables can be monitored via

the relay outputs on the KFD2-HLC(Ex)1.D.2W or KFD2-HLC-(Ex)1.D.4S.

HART

PV, SV,

TV, QV

2.2 Model variants

The following variants of the HART Loop Converter are available:

KFD2-HLC-**1.D.**

.2W = with 2 change-over contacts

.4S = with 4 normally open contacts

no identification letters = without relay

Ex = for connection of field devices in areas exposed to danger of

explosion

without identifier letters = for connection of field devices in the

secure area

3x

4x

Date of issue 11/30/07 805639

4

Page 7

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Safety instructions

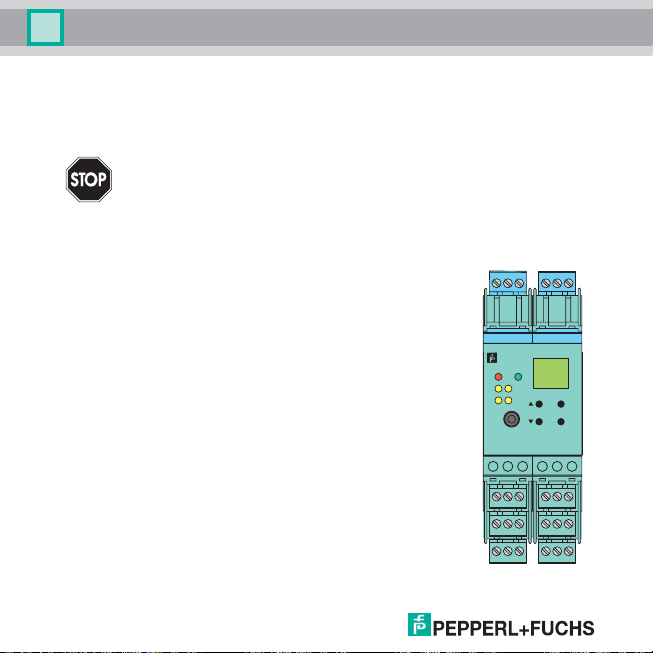

3 Safety instructions

The HART Loop Converter KFD2-HLC-(Ex)1.D(.**) may only be operated by trained

professionals in a manner corresponding to this operating manual.

Warning

The protection of operating personnel and of the system is only ensured if the devices

are used in accordance with their intended purpose. Any other type of operation than

that described in this manual places the safety and functionality of the devices and

Warning

Warning

Warning

Note

Date of issue 11/30/07 805639

systems connected to them in question.

The devices may only be installed, connected, and adjusted by electrical professionals

outside the hazardous area.

If faults cannot be eliminated, the devices must be taken out of operation and protected

from being placed in service again inadvertently. Devices must only be repaired directly

by the manufacturer Pepperl+Fuchs. Tampering with or making changes to the devices

is dangerous and therefore not permitted. They render the warranty void.

The responsibility for the adherence to local safety standards lies with the operator.

5

Page 8

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Explosion protection

4 Explosion protection

For primary explosion protection, that is, for measures to be taken to

prevent or hinder the development of a dangerous explosive

atmosphere, please observe the guideline 1999/92/EC (ATEX 137) or

the corresponding national guidelines.

For secondary explosion protection, that is, for measures to hinder the

ignition of a surrounding explosive atmosphere by electrical devices,

Pepperl+Fuchs will gladly make the "Explosion Protection Manual"

available to you for a nominal fee.

Note in particular DIN EN 60079-10, DIN EN 60079-14, DIN EN 50014

and DIN EN 50020, or the corresponding national guidelines.

Pepperl+Fuchs also offers a seminar on the topic of explosion

protection.

5 Installation and connection

5.1 Installation

The HART Loop Converter KFD2-HLC-(Ex)1.D(.**) is constructed in protection degree

IP20 and must therefore be protected from undesirable ambient conditions (water,

small foreign objects).

Attention

The devices of the K-system from Pepperl+Fuchs and thus also the

HART Loop Converter KFD2-HLC-(Ex)1.D(.**) can be mounted on a 35 mm

standard rail corresponding to DIN EN 50022. The devices must be snapped

onto the rail vertically, and never slanted or tipped to the side.

Additional possibilities for mounting, e. g. using the Power Rail, can be found

in the K-System operating manual on our webpage www.pepperl-fuchs.com

*HLC* in the product search).

(enter

Date of issue 11/30/07 805639

6

Page 9

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Installation and connection

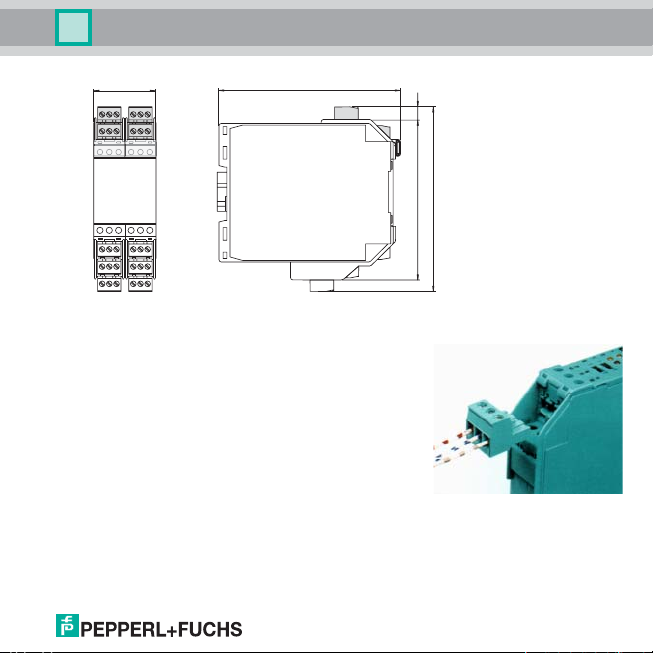

115

5.2 Connection

The detachable terminals of the KF-ser ies considerably simplify

the connection and the switch cabinet assembly. They make it

possible to replace devices quickly and without error if a

customer service becomes necessary.

Terminals are equipped with screws, are self-opening, have a

large connection area for a wire cross-section up to 2.5 mm²

and coded plugs, making it impossible to mix them up.

Date of issue 11/30/07 805639

Dimensions of the

KFD2-HLC-(Ex)1.D(.**) in mm

11940105 7

7

Page 10

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

2

2

I

Installation and connection

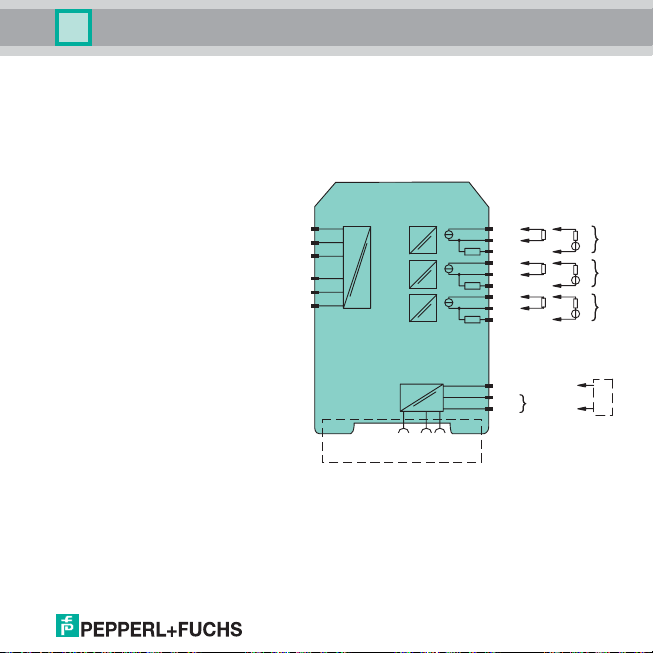

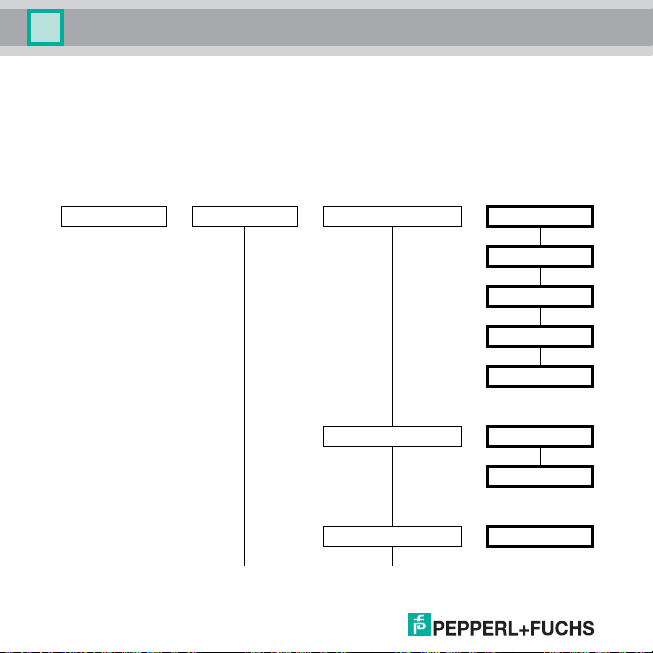

5.2.1 Connection input (field circuit)

The intrinsically safe field circuit is connected to the blue terminals 1 to 6 on the KFD2-HLC-Ex1.D(.**).

This may be conducted using DIN EN 60079-14-compliant leads into the hazardous area.

You can connect the following three operating modes:

1. any separately powered HART loop with a transmitter or positioner in a parallel circuit (as with

HART handheld terminals, terminals 2 and 3)

2. an active HART-compatible mA source, e. g. a separately powered HART transmitter (terminals 2

and 3, bridge between terminals 5 and 6)

3. a 2-wire HART transmitter (HART transmitter with analogue 4 mA ... 20 mA output signal) powered

by the HLC (terminals 1 and 3, bridge between terminals 4 and 5)

12 3

HART

Zone 0, 1, 2

Div. 1, 2

+

-

HART

HART

+

1+

2+

3-

4

5

6

KFD2-HLC-Ex1.D

Power Rail

7-

8+

9-

13+

14-

15+

19

20

21

22

23+

24-

24 V DCERR

8

+--

+--

+--

24 V DC

+

+

+

Zone

Div.

I

II

II

HART

Date of issue 11/30/07 805639

Page 11

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Installation and connection

5.2.2 Connection output

The non-intrinsically safe field circuit is connected to the green terminals 1 to 6 on the KFD2-HLC-

1.D(.**).

The remaining green terminals have the following functions:

KFD2-HLC-Ex1.D

• Terminals 7 ... 9: output I, current

output as source (7/8) or sink (7/9)

• Terminals 13 ... 15: output II,

current output as source (13/14) or

sink (13/15)

• Terminals 19 ... 21: output III,

current output as source (19/20) or

sink (19/21)

• Terminals 22/24: HART handheld

terminal connection

• Terminals 23/24: power supply

24 V DC

Date of issue 11/30/07 805639

KFD2-HLC-Ex1.D

Power Rail

13+

1415+

19

20

21

22

23+

24-

24 V DCERR

78+

9-

+--

+--

+--

24 V DC

+

+

+

Zone 2

Div. 2

I

II

III

HART

9

Page 12

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Installation and connection

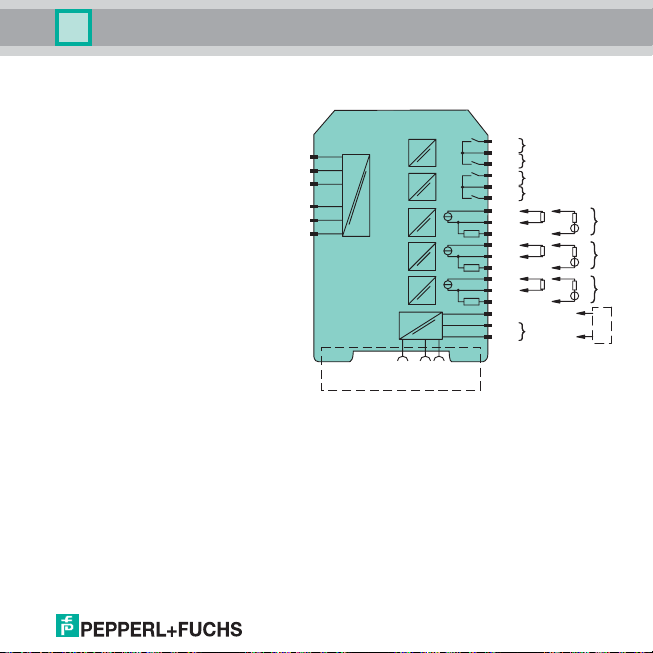

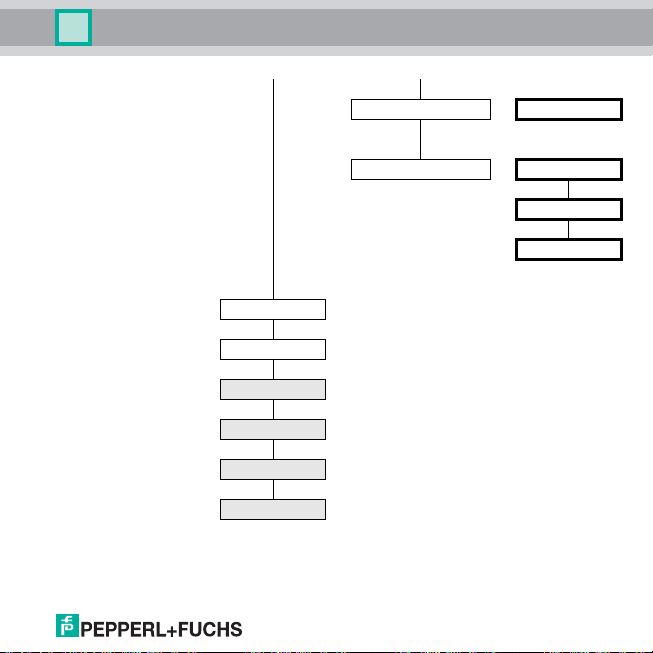

KFD2-HLC-Ex1.D.2W

• Terminals 10 ... 12: output I

(relay 1 (change-over contact))

• Terminals 16 ... 18: output II

(relay 2 (change-over contact))

• Terminals 7 ... 9: output III, current

output as source (7/8) or sink (7/9)

• Terminals 13 ... 15: output IV,

current output as source (13/14) or

sink (13/15)

• Terminals 19 ... 21: output V,

current output as source (19/20) or

sink (19/21)

• Terminals 22/24: HART handheld

terminal connection

• Terminals 23/24: power supply

24 V DC

KFD2-HLC-Ex1.D.2W

Power Rail

10

I

11

12

16

17

II

18

7-

+

+

+

Zone 2

Div. 2

III

IV

V

HART

Date of issue 11/30/07 805639

8+

+--

913+

14-

+--

15+

19

20

+--

21

22

23+

24 V DC

24-

24 V DCERR

10

Page 13

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Installation and connection

KFD2-HLC-Ex1.D.4S

• Terminals 10/11: output I

(relay 1 (change-over contact))

• Terminals 10/12: output II

(relay 2 (change-over contact))

• Terminals 16/17: output III

(relay 3 (change-over contact))

• Terminals 16/18: output IV

(relay 4 (change-over contact))

• Terminals 7 ... 9: output V, current

output as source (7/8) or sink (7/9)

• Terminals 13 ... 15: output VI,

current output as source (13/14) or

sink (13/15)

• Terminals 19 ... 21: output VII,

current output as source (19/20) or

sink (19/21)

• Terminals 22/24: HART handheld

terminal connection

• Terminals 23/24: power supply

24 V DC

More information on connecting the HLC (e. g. using the power rail with collective error message) can

be found in the data sheets and the K-System operating manual on our webpage www.pepperlfuchs.com (enter

Date of issue 11/30/07 805639

*HLC* in the product search).

KFD2-HLC-Ex1.D.4S

Power Rail

10

11

12

16

17

18

78+

913+

1415+

19

20

21

22

23+

24-

24 V DCERR

I

II

III

IV

+--

+--

+--

24 V DC

+

+

+

VII

Zone 2

Div. 2

V

VI

HART

11

Page 14

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Installation and connection

5.3 Setting parameters of HART field device

In order to set the parameters of the connected HART field device, you will require a HART handheld

terminal which you can connect to terminals 22/24 or the field cables. Transmitting the HART signal

via the current outputs of the HLC is not possible.

When connecting the field cables, use an old handheld terminal if the field cables lead

through a hazardous area.

Warning

5.4 Front

The following are located on the front of the HLC:

• a display for showing the measured values, the current output values

and fault messages and for displaying in parameterization mode

• four keys for selecting the displayed values/current output value and for

setting the parameters of the HLC:

S (Up) T (Down) ESC (Escape) OK

• RS 232 serial interface for a connection to a PC for setting parameters

and diagnosis of the HLC using PACT ware

TM

(available from 2009)

• LED ERR (red) to indicate a fault

• LED PWR (green) to indicate the presence of the supply voltage

also for KFD2-HLC-(Ex)1.D.2W and KFD2-HLC-(Ex)1.D.4S:

• LED OUT 1 (yellow) to indicate that relay 1 is active

123

KFD2-HLCEx1.D.4S

1

IN /

CH

K

21

OUT

43

RS232

789

13 14 15

19 20 21

• LED OUT 2 (yellow) to indicate that relay 2 is active

also for KFD2-HLC-(Ex)1.D.4S:

• LED OUT 3 (yellow) to indicate that relay 3 is active

• LED OUT 4 (yellow) to indicate that relay 4 is active

PWR

456

ESC

OK

10 11 12

16 17 18

22 23 24

Date of issue 11/30/07 805639

12

Page 15

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Installation and connection

5.5 Meaning of LED indication

LED Indication Meaning

green off missing power

green regularly flashing power-up self-test phase (unit not yet working)

green on normal operating mode

yellow on Out 1 ... 4, output relay energised

red flashes briefly single HART error message received from the field device

red regularly flashing HART data invalid (communication loss or field device fault)

red on HLC self-test error detected (faulty unit, possible loss of functions)

red on HLC is in reset condition, all other LEDs are off

Date of issue 11/30/07 805639

13

Page 16

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Display modes and error messages

6 Display modes and error messages

The following appear on the display in normal mode:

• the current values for HART variables PV, SV, TV, QV in the selected unit and

• the actual current output values Ch1, Ch2, Ch3 in mA.

• Please use the S and T keys to select the displayed measured value

or current output value.

• To select the units for the measured values see section 8.2.

• The display is updated every time the HLC receives a HART command 3 message from the field

device.

• Current output values are displayed as a four-digit number. The decimal point is set to give the best

possible resolution.

• The floating decimal values for the HART variables are displayed as follows:

− if possible as a four-digit number with decimal point and without an exponent (negative values

have three digits because of minus sign)

− a number may be rounded up (0.3456 appears as 0.346)

− if this display is not possible, the mantissa and exponent are displayed alternately.

If the restart inhibit (see section 8.5.5 and 8.5.7) is triggered but the device continues operating

normally, a corresponding message appears in the second line of the display.

If a fault occurs, one of the following messages is displayed until the fault is rectified:

• Err device fault (red LED lights up)

• Err communication error (red LED flashes)

• Err sensor fault (red LED flashes)

If switching the HLC on/off and checking the cables does not rectify the fault, please contact

Pepperl+Fuchs or the field device manufacturer.

The relays power down when a fault occurs.

For information on the behaviour of the current output in the event of a fault, see section 8.4.4.

Date of issue 11/30/07 805639

14

Page 17

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Description of HART operations:

7 Description of HART operations

Dynamic variable acquisition

HART command 3 is always used to obtain the applicable dynamic variables, either directly or by

activating it in the Burst Mode.

Burst Mode operation

The HART Burst Mode is the HLC preferred one because it ensures a faster operation. The HLC will

therefore always try to set the connected device in the Burst Mode. The Burst Mode activation

command will be sent to the field device in the following situations:

• after an HLC unit power-up (or after an internally generated reset)

• after a field device power-up

• when the communication with the field device is recovered after a time-out.

"Command and answer" operation

If the field device doesn't support the Burst Mode, the HLC will use the normal "command and answer"

mode.

Burst mode recovery procedure

If the HLC stop receiving the burst frames, the following recovery procedure will be applied:

• The HLC immediately goes into the "command and answer" mode.

• The HLC then check if another HART master is sending messages on the loop; if another master

is found, the HLC will not try to re-enable the Burst Mode.

• If no other HART master is found the HLC will keep trying to re-enable the Burst Mode.

• As soon as any Burst frame is again received, the HLC immediately return to the Burst Mode.

This procedure makes possible for another HART master to temporary disable the Burst Mode, as

could be required for servicing reasons.

"Communication-loss" time-out

If the time-out is exceeded at missing communication, then all outputs switch in a defined safe state.

The time-out can be set.

Date of issue 11/30/07 805639

15

Page 18

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: Parameterization mode

8 Editing device data

A change in device data will change the operation of the device!

Before entering new data into the device, you should ascertain that no danger to the

installation will result.

Warning

8.1 Parameterization mode

8.1.1 Invocation

Display mode

You can return to display mode from any point in the menu in parameterization mode by pressing the

ESC key (possibly multiple times). If you do not press any key for 10 minutes in parameterization

mode, the device automatically switches back into display mode.

OK + ESC (simultaneously for 1 sec) →

← ESC

Main menu parameterization mode

Unit (8.2)

HARTcom (8.3)

Output (8.4 and 8.5)

Service (8.6)

Date of issue 11/30/07 805639

16

Page 19

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: Parameterization mode

8.1.2 Password

You can protect the parameter s ettings from unauthorized changes using a passwor d (see section 8.6,

inactive when HLC delivered).

If password protection is active, the various settings in parameterization mode can be viewed without

entering the password, but not changed.

The password cannot be changed and is 1234.

The password is entered as follows:

• On the first attempt to make a change, the device immediately prompts for a password.

• The first digit of the password flashes.

• Now enter each number of the password by pressing the S and T keys (numbers 0 to 9) and press

OK to confirm each individual number. The next digit of the password then flashes.

• You can abort password entry at any time by pressing ESC.

• If you enter the last digit and press OK to confirm but the password is incorrect, the last digit of the

password continues to flash. You can either enter the last digit again or press ESC to cancel the

entry and make another attempt from the beginning.

• If you enter the last digit, press OK to confirm and the password is correct, the parameter change

is accepted.

The password must be entered for each transition from display mode to parameterization mode, once

each time.

Date of issue 11/30/07 805639

17

Page 20

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: Parameterization mode

8.1.3 Navigation method

The following diagram illustrates the navigation method in parameterization mode using the S, T, OK

and ESC keys:

Iout1

OK →

← ESC

← ESC ← ESC

← ESC

← ESC

← ESC

Assignment

TS

Characteristic

TS

Start value

TS

End value

TS

Error current

OK →

4 - 20 NE43

Date of issue 11/30/07 805639

18

Page 21

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: Parameterization mode

8.1.4 Lowest menu level: select values, enter normal numbers

On the lowest level of the menu, you can either select one of several possible values, or enter a

number for the individual parameters.

Proceed as follows (for floating decimal number, see section 8.1.5):

Lowest menu level

Para meter

When entering normal numeric values, please note:

• If you press the S or T keys, the value changes step by step.

• If you hold the S or T keys, the value "rolls" to higher or lower values.

8.1.5 Lowest menu level: enter floating decimal numbers

Enter floating decimal numbers as follows:

• positive numbers with four-digit mantissa, decimal point in or after the mantissa, exponent in three

stages from E-33 and E00 to E33

• negative numbers with minus sign, three-digit mantissa, decimal point in or after the mantissa,

exponent in three stages from E-33 and E00 to E33

Date of issue 11/30/07 805639

OK →

← ESC

← ESC

← ESC

Current value, flashing

S, T: ↓

New value, flashing,

not saved

OK ↓

New value, not flashing,

saved

19

Page 22

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: Parameterization mode

The following table provides an overview:

Positive number Entry Negative number Entry

43 210 000 43.21 E06 - 3 210 000 -3.21 E06

4 321 000 4321 E03 - 321 000 -321 E03

432 100 432.1 E03 - 32 100 -32.1 E03

43 210 43.21 E03 - 3 210 -3.21 E03

4 321 4321 E00 - 321 -321 E00

432.1 432 .1 E00 - 32.1 -32.1 E00

43.21 43.21 E00 - 3.21 -3.21 E00

1.234 1.234 E00

0.123 4 123.4 E-03 - 0.123 -123 E-03

0.012 34 12.34 E-03 - 0.012 3 -12.3 E-03

0.001 234 1.234 E-03 - 0.001 23 -1.23 E-03

0.000 123 4 123.4 E-06 - 0.000 123 -123 E-06

Floating decimal numbers contain six elements, which you must enter individually: four digits for the

mantissa or three digits with minus sign for the mantissa, position of the decimal point in or after the

mantissa, exponent. Make entries as follows:

• When accessing the lowest menu level, the total current value of the floating decimal number

(mantissa and exponent) flashes first of all. Press OK again. The first digit of the mantissa (or the

minus sign) flashes.

• Now enter each number of the mantissa individually by pressing the S and T keys: numbers 0 to

9, minus sign in the first position below 0 (press the T key). Press OK to confirm each entry. The

next digit of the mantissa then flashes.

• When you enter the last digit of the mantissa, the digit after the decimal point flashes. Determine

the required position of the decimal point by pressing the S and T keys and press OK to confirm.

The exponent appears and begins to flash.

• Now enter the exponent value by pressing the S and T keys (values from E-33 and E00 to E33 in

three steps) and press OK to confirm.

Date of issue 11/30/07 805639

20

Page 23

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: Unit

8.2 Unit

The following illustration shows the unit menu. Items from the lowest menu level are outlined in bold.

Unit —— PV —— Type —— auto

Custom tag —— (see below)

SV —— same as PV

TV —— same as PV

QV —— same as PV

• If you select auto, the unit transferred by the HART field device for the relevant variable (PV, SV,

TV, QV) appears on the HLC display.

• If you select custom, the Custom Tag appears on the HLC display as the unit for the relevant

variable (PV, SV, TV, QV).

• The selected unit is also used for all corresponding settings in parameterization mode.

Enter the Custom Tag as follows:

• Initial display: ↵ (or previous Custom Tag with as first character and ↵ )

• Select one of the eight positions in front of ↵ for the by pressing the T or S keys.

• Select OK. The flashes.

• Select a character by pressing the S or T keys. Select OK.

• Repeat the position and character selection process until the character string is complete.

Date of issue 11/30/07 805639

custom

21

Page 24

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: HARTcom

• Leave empty spaces if necessary.

• Select the position ↵ and then press OK. The character string is saved.

• Or press ESC to exit Custom Tag entry mode without accepting the changes.

8.3 HARTcom

The following illustration sh ows the HART communication menu. Items from the lowes t menu level are

outlined in bold.

HARTcom —— Mode (8.3.1) —— secondary

primary

TimeOut (8.3.2) —— 5 s ...60 s

ShortAddress (8.3.3) —— 0 ... 15

LocateMethod (8.3.3) —— fixed

search

Rebuild (8.3.4) —— On Rebuild

OFF Rebuild

Date of issue 11/30/07 805639

22

Page 25

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: HARTcom

If available, the HLC activates Burst Mode for the HART field device to achieve maximum

communication speed. The HLC uses the universal HART command 3 to retrieve variables (PV, SV,

TV, QV, if available).

8.3.1 Mode

Depending on the setting, the HLC operates as a primary or secondary HART master device according

to HART standards and is fully compatible with each HART handheld terminal and any other HART

master devices.

8.3.2 TimeOut

If the HLC does not receive a valid HART message after the preset time, the fault indication

Communication fault is issued. Time-out range is 5 s to 60 s in increments of 5 seconds.

8.3.3 ShortAddress and LocateMethod

More than one HART field device may be present in a HART loop, as specified in the HART standards.

However, the HLC can only communicate with one HART field device at a time. This field device is

identified during the localization phase.

• If you select LocateMethod fixed, the HLC communicates with the field device that was assigned a

short address under ShortAddress.

• If you select LocateMethod, the HLC runs a search for the shortest address – beginning with the

address assigned under ShortAddress – and then communicates with this device. The device

address is saved to accelerate the next start-up process under ShortAddress.

8.3.4 Rebuild

If the connection to the HART field device is lost, you can use Rebuild to run through the localization

phase without having to switch the HLC off and on again.

Pressing the OK key when On Rebuild is flashing prompts the HLC to start searching for connected

HART devices (see section 8.3.3) in the same way as during start-up.

Date of issue 11/30/07 805639

23

Page 26

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: Current outputs

8.4 Current outputs

The following illustrations show the current output menus. Items from the lowest menu level are

outlined in bold.

Pressing the OK key in the Iout1, Iout2 and Iout3 menu items gives you access to a menu for entering

separate parameters for the selected current output. The three menus are identical and are therefore

described only once. For the relay outputs on the KFD2-HLC-(Ex)1.D.2W or KFD2-HLC-(Ex)1.D.4S,

see section 8.5.

Output —— Iout1 —— Assignment8.4.1) —— disabled

Characteristic (8.4.2) —— 4 - 20 unlimited

4 - 20 NE43

Start value —— (8.4.3)

Continued on next page

PV

SV

TV

QV

Date of issue 11/30/07 805639

24

Page 27

Date of issue 11/30/07 805639

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: Current outputs

End value —— (8.4.3)

Error current (8.4.4) —— down

Iout2

Iout3

Rel1

Rel2

Rel3

Rel4

up

hold

25

Page 28

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: Current outputs

8.4.1 Assignment

The values of the HART variable selected here (PV, SV, TV, QV) are displayed at the current output

(see section 8.4.2). The number of available variables depends on the HART field device.

If disabled is selected, the downscale error current is issued constantly at the current output (0 mA or

2 mA depending on the characteristic, see section 8.4.4).

8.4.2 Characteristic

The Start value and End value parameters (see section 8.4.3) allow you to define a value range for

the assigned HART variable, which is used as a measurement range in the application. This

measurements range is represented at the output signal in linear form (start value to 4 mA, end value

to 20 mA, proportional intermediate values).

• In the characteristic 4 - 20 unlimited, you can evaluate measurement range shortfalls up to 0 mA

and excess measurement ranges up to approx. 23 mA.

• In the characteristic 4 - 20 NE43, you can evaluate measurement range shortf alls up to 3.8 mA and

excess measurement ranges up to 20.5 mA.

• Measurement ranges that exceed the specified linear range cannot be evaluated. If the range is

exceeded, the minimum and maximum stated values are issued continually.

Example of an illustration of a measurement range on the output signal

Characteristic 4 - 20 NE43, start value 2 bar, end value 10 bar

mA

20.5

20.0

4.0

3.8

0

21010.251.9

bar

Date of issue 11/30/07 805639

26

Page 29

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: Relay

8.4.3 Start value and end value

Please remember the following when entering the Start value and End value:

• Both values must be entered as floating decimal numbers in the unit selected under Unit (see

section 8.1.4 and 8.2).

• The start value must be 1 % smaller than the end value. This is checked by the device and a start

value bigger than the end value will not be accepted. In this case the end value must be entered

prior the start value.

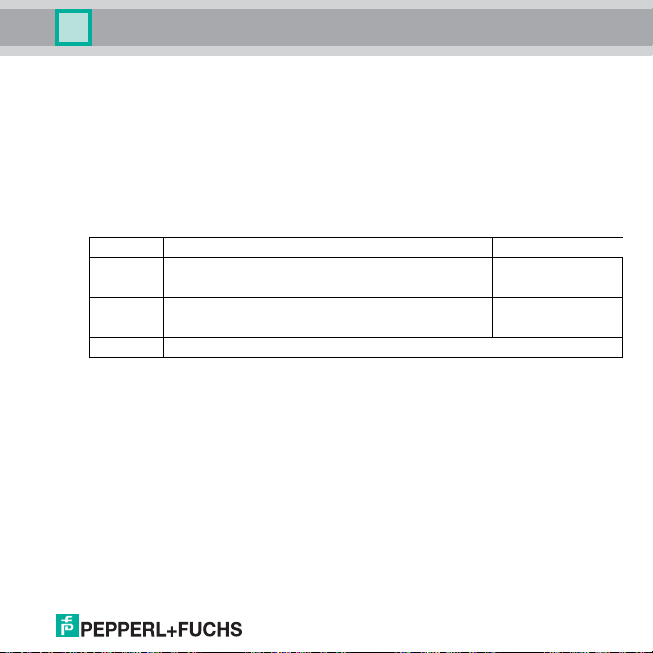

8.4.4 Error current

The following table shows what the current output issues for each characteristic after a fault.

Setting 4 mA ... 20 mA unlimited 4 mA ... 20 mA NE43

down

up

hold Last value measured before the fault

(does not differ from the shortfall of the start value)

(does not differ from the exceeded end value)

0 mA

approx. 23 mA

8.5 Relay

The following illustrations show menus for the relay outputs on the KFD2-HLC-(Ex)1.D.2W or KFD2HLC-(Ex)1.D.4S. For the current outputs, see section 8.4.

Pressing the OK key in the Rel1 and Rel2 menu items on the KFD2-HLC-(Ex)1.D.2W or Rel1 to Rel4

menu items on the KFD2-HLC-(Ex)1.D.4S gives you access to a menu for entering separate

parameters for the selected relay. The two or four menus are identical and are therefore described

only once.

On indicates that the function of a relay (Trip value or Fault indication) is enabled. If you want to enable

a different function, first call it up with the S and T keys. Then press the OK key twice. After the first

OK, you can cancel with ESC.

Date of issue 11/30/07 805639

2.0 mA

21.5 mA

27

Page 30

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: Relay

Output —— Iout1

Iout2

Iout3

Rel1 —— Trip value (8.5.1)

Fault indication (8.5.7)

Rel2

Rel3

Rel4

8.5.1 Trip value

The following illustrations show the menu levels that follow the Trip value menu item (see section 8.5).

Items from the lowest menu level are outlined in bold.

If the Trip value function is enabled (On), press the OK key in the Trip value menu item to access the

Assignment menu item. If you enable the Trip value function again (see section 8.5), pressing the OK

key a second time gives direct access to the Assignment menu item.

Date of issue 11/30/07 805639

28

Page 31

Date of issue 11/30/07 805639

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: Relay

Trip value (on) —— Assignment8.5.2) —— disabled

PV

SV

TV

QV

Min/Max (8.5.3) —— Min

Max

Trip point —— (8.5.4)

Hysteresis —— (8.5.4)

Continued on next page

29

Page 32

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: Relay

Switching mode (8.5.3) —— Passive

Active

Restart inhibit (8.5.5) —— On

OFF

Response delay (8.5.6) —— 0 s ... 250 s

8.5.2 Assignment

The values of the HART variables selected here (PV, SV, TV, QV) are monitored via the relay output

(see section 8.5.3). The number of available variables depends on the HART field device. If disabled

is selected, the relay remains without power permanently.

8.5.3 Switching characteristics

The Max or Min switching direction and the Active or Passive switching mode can be preset (see

section 8.5.1).

Application areas:

• Switching direction Max, switching mode Active: Alarm after trip overrange, e. g. horn on

• Switching direction Max, switching mode Passive: Shutdown after trip overrange, e. g. pump,

heating, ... off, if the Min/Max operation hysteresis is large (pump, heating, ... on/off)

• Switching direction Min, switching mode Active: Alarm after trip underrange, e. g. horn on

• Switching direction Min, switching mode Passive: Shutdown after trip underrange, e. g. pump,

heating, ... off, if the Min/Max operation hysteresis is large (pump, heating, ... on/off)

Date of issue 11/30/07 805639

30

Page 33

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: Relay

The following illustration shows the exact switching characteristics of the HLC:

8.5.4 Trip point and hysteresis

Please remember the following when entering values for Trip point and Hysteresis:

• Both values must be entered as floating decimal numbers in the unit selected under Unit (see

• The selected hysteresis must be > 1 % of the trip point to prevent the relay from vibrating.

Date of issue 11/30/07 805639

Measured value

Max. trip point

Max. - hysteresis

Min. + hysteresis

Min. trip point

Switching direction Max, switching mode Active:

energized

de-energized

Switching direction Max, switching mode Passive:

energized

de-energized

Switching direction Min, switching mode Active:

energized

de-energized

Switching direction Min, switching mode Passive:

energized

de-energized

section 8.1.4 and 8.2).

Time

31

Page 34

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: Relay

8.5.5 Restart inhibit

With the restart inhibit, you prevent momentary trip violations from going unnoticed by

operating personnel.

If Restart inhibit on is selected, after the relay switches, the new status remains active until the ESC

key is pressed or the device is restarted. This will rese t the relay unless the trip violation is still pending.

8.5.6 Response delay

Setting a response delay > 0 seconds prevents momentary trip violations from triggering an alarm.

• The relay only switches when the trip value exceeds or falls below the trip point for a period longer

than the delay time without interruptions.

• The relay only switches back when the trip value exceeds or falls below the trip point/hysteresis for

a period longer than the delay time without interruptions.

• Momentary excesses/shortfalls have no effect.

The following illustration shows the switching characteristics, in this example, switching dire ction Max,

switching mode Active.

Measured value

Max. trip point

Max. - hysteresis

Switching direction Max, switching mode Active, with delay

energized

de-energized

Delay

Delay

Time

Date of issue 11/30/07 805639

32

Page 35

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: Relay

8.5.7 Fault indication

The following illustration shows the menu levels that follow the Fault indication menu item (see

section 8.5). Items from the lowest menu level are outlined in bold.

If the fault indication function is enabled (On), press the OK key in the Fault indication menu item to

access the Restart inhibit menu item. If you enable the Fault indication function again (see

section 8.5), pressing the OK key a second time gives direct access to the Restart inhibit menu item.

Fault indication (on) —— Restart inhibit —— On

Off

A relay with the fault indication function is energized during normal operation. The relay is deenergized if the device detects a fault (see section 6).

With the restart inhibit, you prevent momentary fault indications from going unnoticed by operating

personnel.

If Restart inhibit on is selected, after the relay switches, the new status remains active until the ESC

key is pressed or the device is restarted. This will reset the relay unless the fault indication is still

pending.

Date of issue 11/30/07 805639

33

Page 36

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: Service

8.6 Service

The following illustration shows the service parameter menus. Items from the lowest menu level are

outlined in bold.

Service —— Language —— ENG (English)

DE (German)

Password (8.1.3) —— On password

OFF password

Reset (see below) —— On reset

OFF reset

Reset: Pressing the OK key when On Reset is flashing resets all settings on the HLC to default (see

section 8.7). Any entries that you have made in parameterization mode are lost.

Date of issue 11/30/07 805639

34

Page 37

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: Default settings

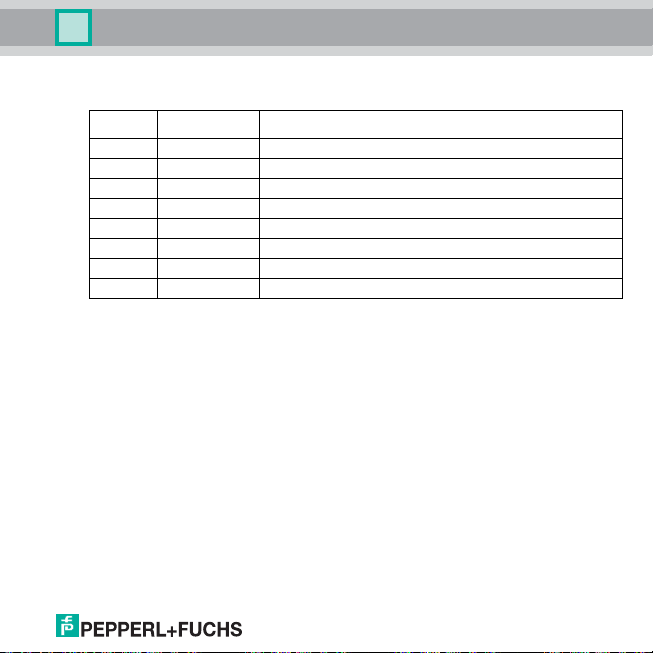

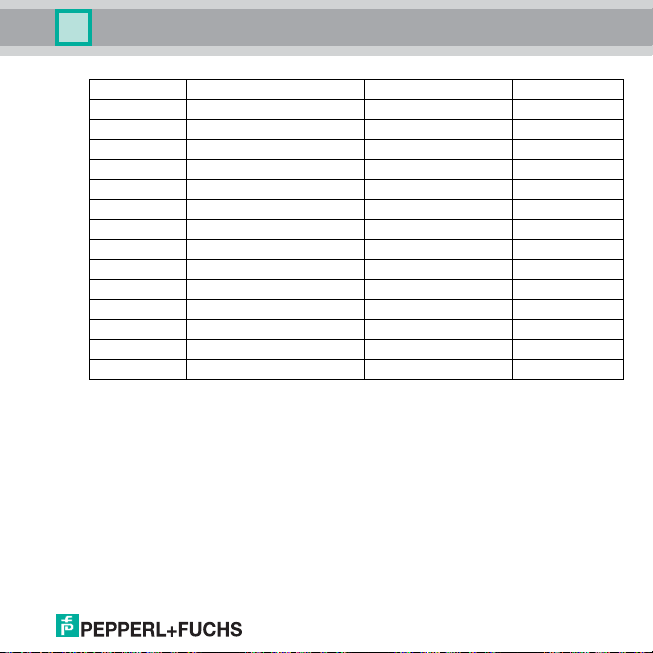

8.7 Default settings

Rel1 and Rel2 are available with the KFD2-HLC-(Ex)1.D.2W and KFD2-HLC-(Ex)1.D.4S, Rel3 and

Rel4 are available with the KFD2-HLC-(Ex)1.D.4S.

Menu Parameter Default setting Separate value

Unit PV → type auto

HARTcom Mode primary

Output Iout1 Assignment disabled

Output Iout2 Assignment disabled

Output Iout3 Assignment disabled

Date of issue 11/30/07 805639

SV → type auto

TV → type auto

QV → type auto

TimeOut 10 sec

ShortAddress 0

LocateMethod search

Characteristic 4 - 20 NE43

Start value 0.000

End value 100.0

Error current down

Characteristic 4 - 20 NE43

Start value 0.000

End value 100.0

Error current down

Characteristic 4 - 20 NE43

Start value 0.000

End value 100.0

35

Page 38

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: Default settings

Menu Parameter Default setting Separate value

Error current down

Output Rel1 Trip value On (= selected)

Output Rel2 Trip value On (= selected)

Output Rel3 Trip value On (= selected)

Assignment disabled

Min/Max (= switching direction) Min

Trip point 80.00

Hysteresis 10.00

Switching mode passive

Restart inhibit OFF restart inhibit

Response delay 0 sec

Fault indication not selected

Assignment disabled

Min/Max (= switching direction) Min

Trip point 80.00

Hysteresis 10.00

Switching mode passive

Restart inhibit OFF restart inhibit

Response delay 0 sec

Fault indication not selected

Assignment disabled

Min/Max (= switching direction) Min

Trip point 80.00

Hysteresis 10.00

Switching mode passive

Date of issue 11/30/07 805639

36

Page 39

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Editing device data: Default settings

Menu Parameter Default setting Separate value

Restart inhibit OFF restart inhibit

Response delay 0 sec

Fault indication not selected

Output Rel4 Trip value On (= selected)

Assignment disabled

Min/Max (= switching direction) Min

Trip point 80.00

Hysteresis 10.00

Switching mode passive

Restart inhibit OFF restart inhibit

Response delay 0 sec

Fault indication not selected

Service Language ENG

Password OFF PASS

Date of issue 11/30/07 805639

37

Page 40

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Notes

Date of issue 11/30/07 805639

38

Page 41

Date of issue 11/30/07 805639

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Notes

39

Page 42

HART Loop Converter KFD2-HLC-(Ex)1.D(.**)

Notes

Date of issue 11/30/07 805639

40

Page 43

With regard to the supply of products, the current iss ue of the following document is applicable:

The general terms of delivery for products a nd services of the electrical industry, as publi shed

by the central association of the "Elektrotechni k und Elektroindustrie (ZVEI) e.V.",

including the supplementary clause "Extende d reservation of title".

Page 44

PROCESS AUTOMATION –

PROTECTING YOUR PROCESS

Worldwide Headquarters

Pepperl+Fuchs GmbH

68307 Mannheim · Germany

Tel. +49 621 776-0

E-mail: info@de.pepperl-fuchs.com

USA Headquarters

Pepperl+Fuchs Inc.

Twinsburg, Ohio 44087 · USA

Tel. +1 330 4253555

E-mail: sales@us.pepperl-fuchs.com

Asia Pacific Headquarters

Pepperl+Fuchs Pte Ltd.

Company Registration No. 199003130E

Singapore 139942

Tel. +65 67799091

E-mail: sales@sg.pepperl-fuchs.com

www.pepperl-fuchs.com

Subject to modifications

Copyright PEPPERL+FUCHS • Printed in Germany

DOCT-1377A 805639

11/2007

Loading...

Loading...