Page 1

3

PROCESS AUTOMATION

MANUAL

HART Multiplexer

System

KFD*-HM*-16

ISO9001

Page 2

HART Multiplexer System KFD*-HM*-16

With regard to the supply of products, the current issue of the following document is applicable: The General Terms of

Delivery for Products and Services of the Electrical Industry, published by the Central Association of the Electrical

Industry (Zentralverband Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the

supplementary clause: "Expanded reservation of proprietorship"

Page 3

HART Multiplexer System KFD*-HM*-16

Content

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Content of this Document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Target Group, Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Symbols Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Device Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 The Basic Principles of HART Communication . . . . . . . . . . . . . . . . . . 10

3.2 Possible Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 Integration into Operating Software . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.4 System Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Mounting and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1 DIN Mounting Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Power Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.4 Connecting the Multiplexer Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.5 Connecting the Multiplexer Slaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.6 Connecting the Termination Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.7 Information Regarding Electromagnetic Compatibility . . . . . . . . . . . 27

5 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.1 Data Access to the Connected Field Devices . . . . . . . . . . . . . . . . . . . 28

5.2 Configuration of the Multiplexer Master. . . . . . . . . . . . . . . . . . . . . . . . 28

2018-04

3

Page 4

HART Multiplexer System KFD*-HM*-16

Content

6 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.1 Introduction to PACTware Operating Software. . . . . . . . . . . . . . . . . . 33

6.2 Software Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3 PACTware Main Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.4 Connecting with the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.5 Inserting the Communication DTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.6 Inserting the Multiplexer Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.7 Displaying Device Information and Setting Parameters . . . . . . . . . . 44

6.8 HART Scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.9 Adding DTMs Manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7.1 Device Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7.2 Software Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.3 Diagnosis and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

8 Dismounting, Maintenance, and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

9 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

9.1 Supported HART Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

9.2 Assignment of the 26-Pin IDC Socket with Analog HART Signals . . 84

9.3 Bibliography . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9.4 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

2018-04

4

Page 5

HART Multiplexer System KFD*-HM*-16

Introduction

1Introduction

1.1 Manufacturer

Pepperl+Fuchs GmbH

Lilienthalstraße 200, 68307 Mannheim, Germany

Internet: www.pepperl-fuchs.com

1.2 Content of this Document

This document contains information that you need in order to use your product throughout

the applicable stages of the product life cycle. These can include the following:

• Product identification

• Delivery, transport, and storage

• Mounting and installation

• Commissioning and operation

• Maintenance and repair

• Troubleshooting

• Dismounting

• Disposal

Note!

This document does not substitute the instruction manual.

Note!

For full information on the product, refer to the instruction manual and further documentation

on the Internet at www.pepperl-fuchs.com.

The documentation consists of the following parts:

• Present document

• Instruction manual

•Datasheet

Additionally, the following parts may belong to the documentation, if applicable:

• EU-type examination certificate

• EU declaration of conformity

• Attestation of conformity

• Certificates

• Control drawings

• Additional documents

2018-04

5

Page 6

HART Multiplexer System KFD*-HM*-16

Introduction

1.3 Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation, maintenance,

and dismounting lies with the plant operator.

Only appropriately trained and qualified personnel may carry out mounting, installation,

commissioning, operation, maintenance, and dismounting of the product. The personnel must

have read and understood the instruction manual and the further documentation.

Prior to using the product make yourself familiar with it. Read the document carefully.

1.4 Symbols Used

This document contains symbols for the identification of warning messages and of

informative messages.

Warning Messages

You will find warning messages, whenever dangers may arise from your actions.

It is mandatory that you observe these warning messages for your personal safety and in order

to avoid property damage.

Depending on the risk level, the warning messages are displayed in descending order

as follows:

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants,

or result in their complete failure.

Informative Symbols

Note!

This symbol brings important information to your attention.

Action

This symbol indicates a paragraph with instructions. You are prompted to perform an action

or a sequence of actions.

2018-04

6

Page 7

HART Multiplexer System KFD*-HM*-16

Product Specifications

2 Product Specifications

2.1 Device Versions

This manual describes the following devices:

• HART multiplexer master KFD2-HMM-16, hereinafter referred to as the multiplexer master

• HART multiplexer slave KFD0-HMS-16, hereinafter referred to as the multiplexer slave

2.2 Function

The HART multiplexer system consists of one HART multiplexer master KFD2-HMM-16 and

several HART multiplexer slaves KFD0-HMS-16. The HART multiplexer system is used

to establish a HART connection to analog field devices and thereby maintain the conventional

analog 4 mA to 20 mA circuits. The devices of the HART multiplexer system act as gateways

between the field devices and the control side.

The devices of the HART multiplexer system can be used in the Zone 2 hazardous area or

in the non-hazardous area. The devices are supplied with 24 VDC. The devices are connected

to a maintenance station or the process control system via an RS-485 interface.

The supply, the analog signals, and the RS-485 interface are galvanically isolated from each

other. The individual HART channels are decoupled. This does not affect

the 4 mA to 20 mA signal.

Using the configuration software, you can search for available field devices automatically and

query the HART variables of the field devices automatically.

2018-04

7

Page 8

HART Multiplexer System KFD*-HM*-16

1

2

3

4

5

6

7

8

19

17131816

201421

15

KFD0-HMM-16

1

26

26-pin connector

LED orange:

Operation

14-pin connector

Removable terminals

green

LED red:

Fault signal

LED green:

Power supply

Product Specifications

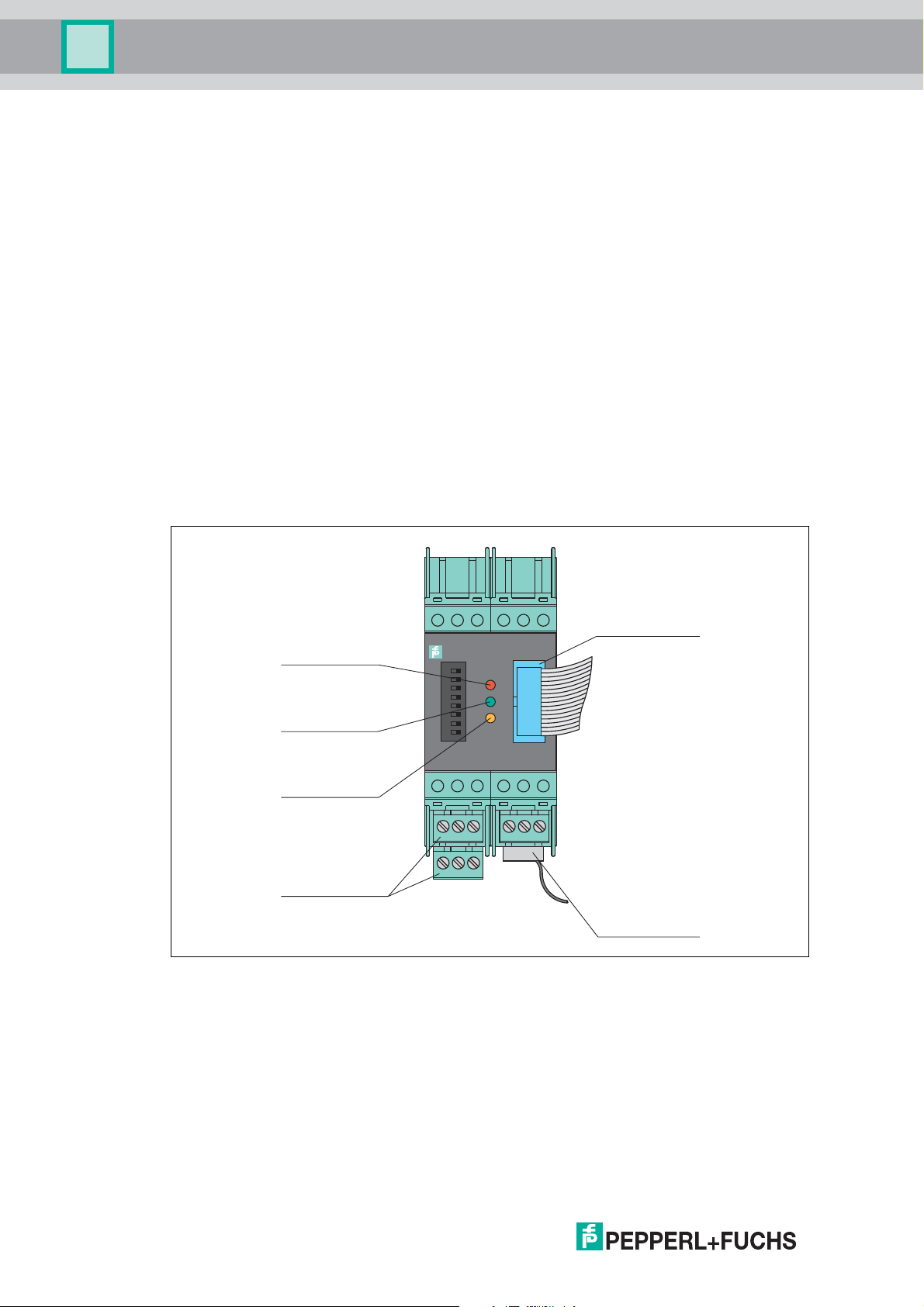

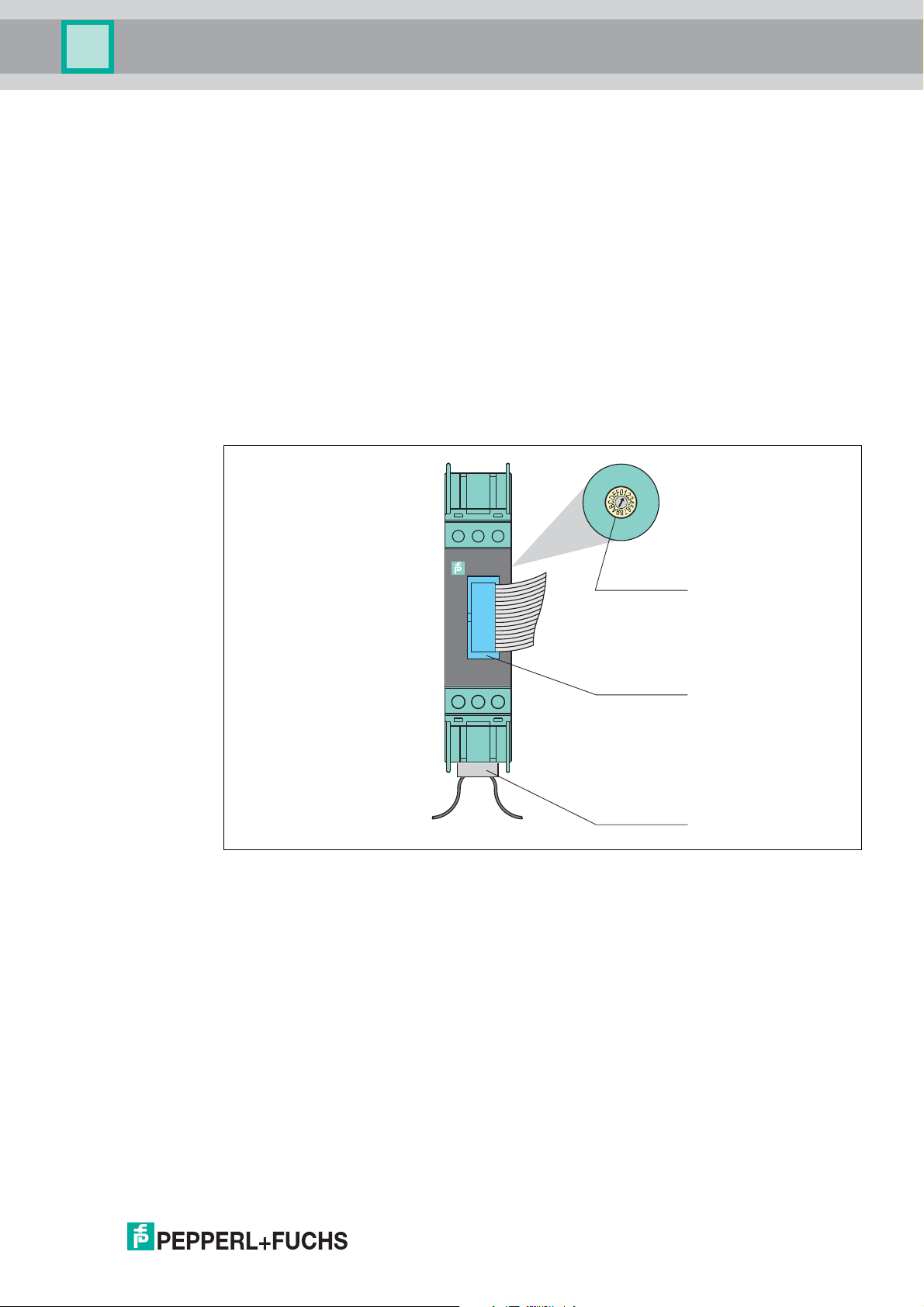

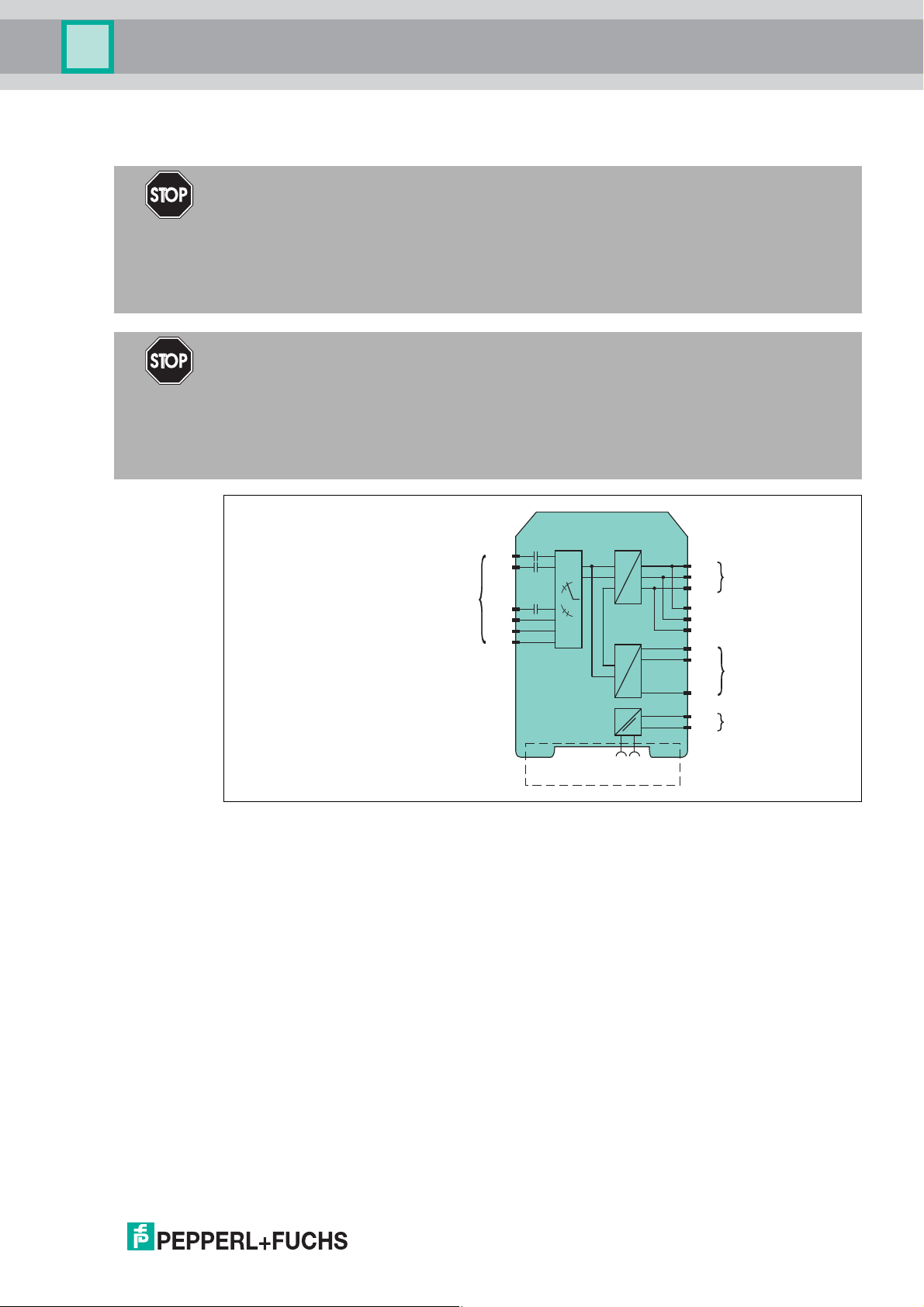

2.2.1 HART Multiplexer Master KFD2-HMM-16

In addition to the master unit, the multiplexer master has an integrated slave unit. A maximum

of 16 field devices can be connected to this slave unit. If more than 16 field devices have

to be connected, a maximum of 15 additional HART multiplexer slaves KFD0-HMS-16 can

be connected to the multiplexer master. This enables a maximum of 256 analog field devices

to be connected to the HART multiplexer system.

The device is supplied with power via the Power Rail or via terminals.

The device is connected to a maintenance station via the RS-485 interface. You can connect

additional participants via an additional RS-485 interface. The transfer rate is max.

57600 baud.

The device is connected to the multiplexer slaves via a 14-pin ribbon cable. The device has

a 14-pin IDC socket on the bottom of the device for this purpose.

The device is connected to the termination board via a 26-pin ribbon cable. The device has

a 26-pin IDC socket on the front of the device for this purpose.

The device can be used as a primary or secondary master.

The device address and the transfer rate are set via DIP switch.

8

Figure 2.1 Assembly of the KFD2-HMM-16 HART multiplexer master

2018-04

Page 9

HART Multiplexer System KFD*-HM*-16

KFD0-HMS-16

1

26

Rotary switch

26 pin

connector

14 pin

connector

Product Specifications

2.2.2 HART Multiplexer Slave KFD0-HMS-16

A maximum of 16 analog field devices can be connected to the multiplexer slave. The device

can only be used in conjunction with the HART multiplexer master KFD2-HMM-16.

The device is supplied with power by the multiplexer master via the 14-pin ribbon cable.

The device is connected with the multiplexer master and additional multiplexer slaves

via a 14-pin ribbon cable. The device has a 14-pin IDC socket on the bottom of the device for

this purpose.

The device is connected to the termination board via a 26-pin ribbon cable.

The device has a 26-pin IDC socket on the front of the device for this purpose.

The device address is set using a rotary switch. You can assign addresses 1 to 15.

The address 0 is reserved for the multiplexer master and may therefore not be used. If several

multiplexer slaves are connected to the multiplexer master, different addresses must

be assigned. The sequence is irrelevant.

2018-04

Figure 2.2 Assembly of the KFD0-HMS-16 HART multiplexer slave

9

Page 10

HART Multiplexer System KFD*-HM*-16

+0.5 mA

-0.5 mA

0

1200 Hz 2200 Hz

"1"

"0"

20 mA

4 mA

Analog

signal

C = Command

R = Response

Time (seconds)

HART signal

C

R

C

R

C

R

System Description

3 System Description

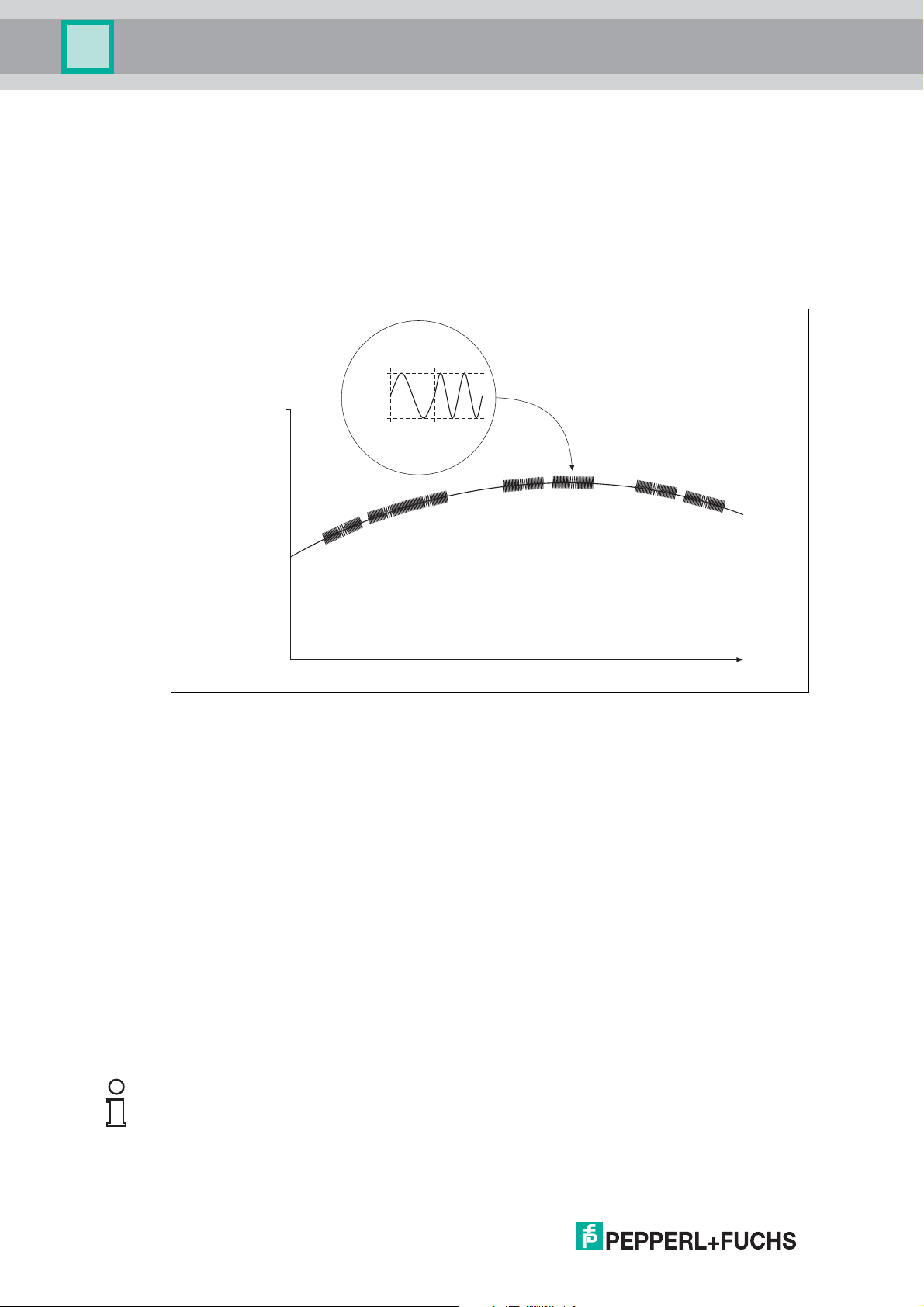

3.1 The Basic Principles of HART Communication

The HART protocol is supported by many conventional 4mAto20mA field devices that use it

to enable digital communication for configuration and maintenance purposes. Many of the

device parameters, and the measured value itself, can be digitally transferred to and from

the device. This digital communication runs in parallel to the 4 mA to 20 mA signal on the same

line. This is enabled via current modulation, which is superimposed on the desired signal.

Figure 3.1

The high-frequency HART signal consists of the sine frequencies 1200 Hz and 2200 Hz.

The average value of the signal is 0 and can therefore be filtered through the standard circuit of

the analog input. This does not affect the analog signal.

The HART protocol is a master-slave protocol. This means that a field device responds only

when it is addressed. Burst mode is an exception. The message duration is a few hundred

milliseconds, meaning that two to three messages can be transferred per second.

The HART commands are divided into 3 groups:

• Universal commands

These commands must be supported by all field devices.

• Common practice commands

These commands correspond to common practice and are suitable for many field devices.

• Device-specific commands

These commands are only suitable for certain field devices.

All three types of commands are used in the HART multiplexer system. This document

includes a list of commands. See chapter 9.1.

Note!

Additional information can be found in /1/, /2/, /3/, see chapter 9.3.

2018-04

10

Page 11

HART Multiplexer System KFD*-HM*-16

System Description

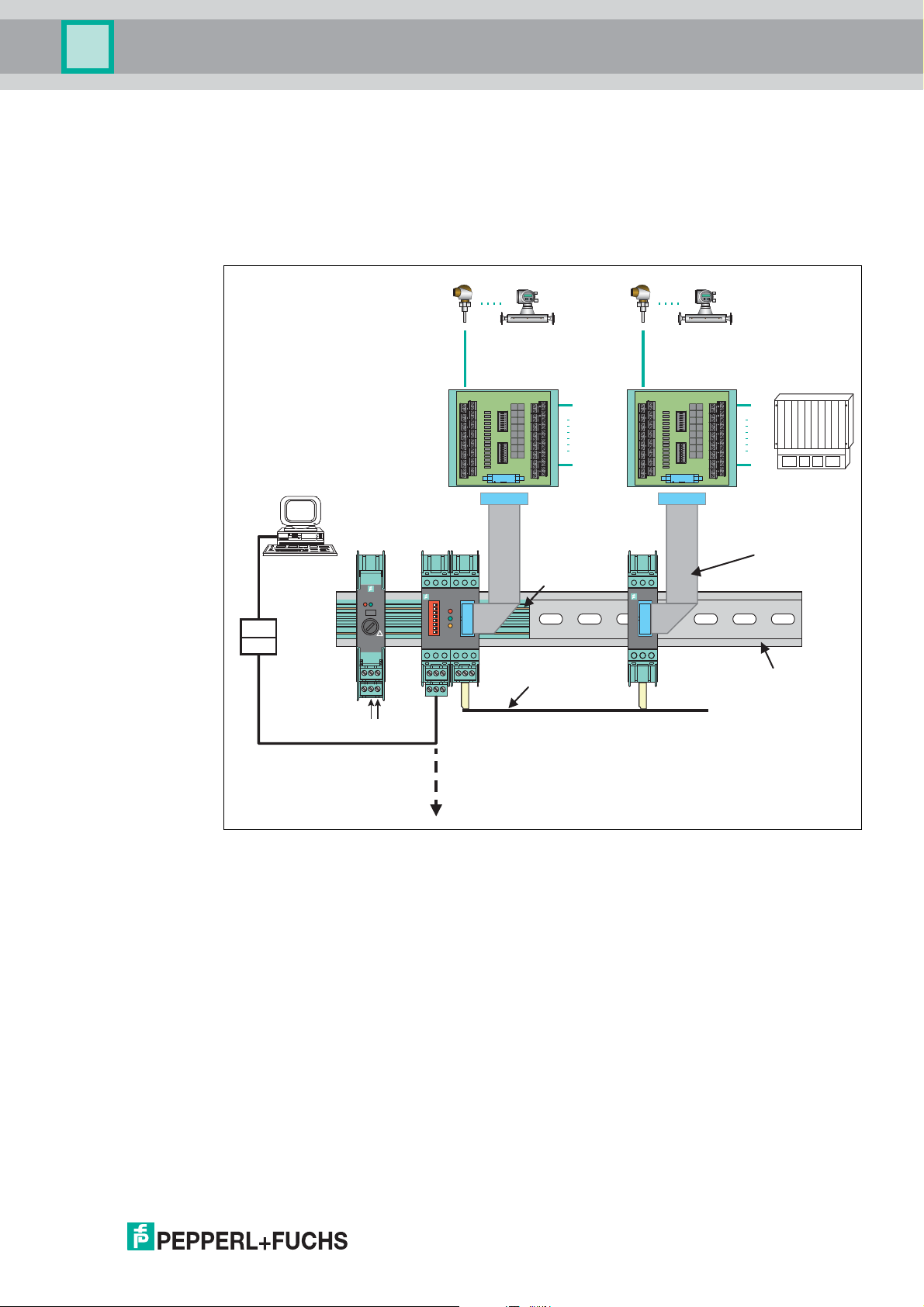

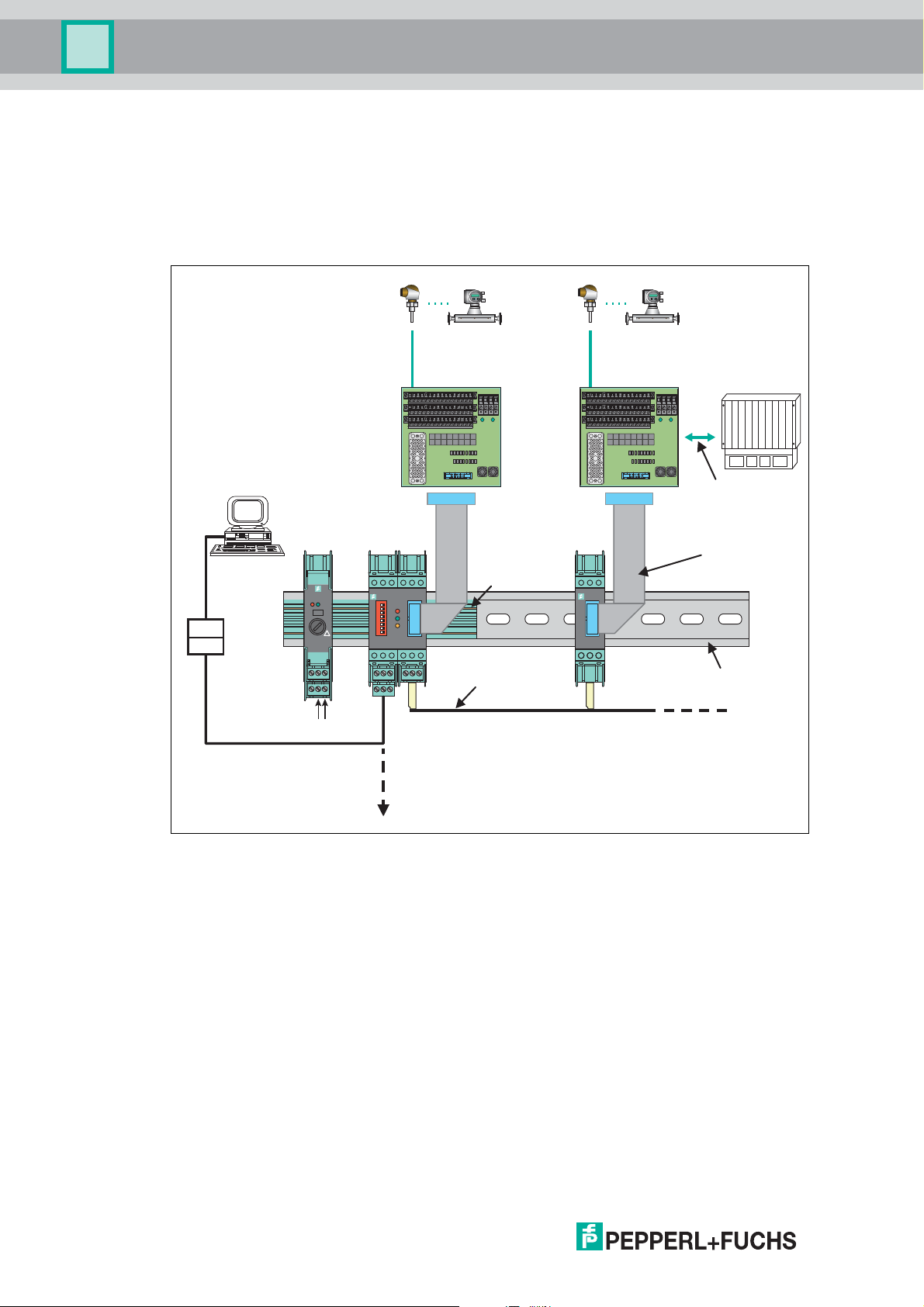

3.2 Possible Applications

General Applications

In process engineering plants, many field devices are distributed over a large area.

The characteristic values of these field devices must be monitored and logged or adjusted if

process variables are changed.

The HART multiplexer system from Pepperl+Fuchs enables communication between a

computer or a process control system and field devices that support the HART protocol.

The following figure shows the basic system structure.

HART communication 1 HART communication 2

19

KFD0-HMM-16

1

2

3

4

5

6

7

8

1713 181620142115

Host

Computer-based

maintenance station

or process control system

HART multiplexer system

Field devices

Figure 3.2 Basic structure

HART-compatible field devices allow information such as the measuring range and device

address to be saved in the field device itself. Access to this data is usually achieved with a

handheld. This means that a connection to the field device must be established manually for

each value to be changed.

If certain data has to be logged as part of quality assurance processes, this increases the effort

for the process control system. For example, the relevant data has to be requested cyclically

and saved in a database by the system.

The HART multiplexer system establishes the connection between the computer and the

HART-compatible field devices. All access to the field device takes place parallel to the

transmission of the 4 mA to 20 mA signal and therefore has no affect on the processing of

measured values by the process control system.

The system provides a subordinate service level. The HART multiplexer system can also

detect measured values. For field devices that are mounted in hazardous areas,

the connection takes place on the non-hazardous side of the control unit.

Pepperl+Fuchs offers corresponding control units, e. g., KCD2-STC-**, KCD2-SCD-**.

The HART multiplexer system can also be connected to control units from other

manufacturers. Existing plants can therefore be extended very easily, taking full advantage of

the HART communication.

2018-04

The system can consist of a maximum of 31 HART multiplexer devices that are connected to a

computer via an RS-485 interface. Each multiplexer master can manage up to

15 multiplexer slaves. Each device, regardless of whether it is a multiplexer master or

multiplexer slave, establishes the connection to 16 field devices. One computer can therefore

be used to address up to a maximum of 7936 field devices.

Operation using a handheld is still possible, since the HART protocol accepts two masters in

one system, i. e., a computer and a handheld.

11

Page 12

HART Multiplexer System KFD*-HM*-16

System Description

Maintenance Station

A computer is often used as a maintenance station to operate and maintain the

HART multiplexer system. The computer is used to fulfill parameterization functions or logging

functions independently of the process control system. For this computer, operating software

that fulfills the required purpose is available from various manufacturers. See chapter 3.3.

However, in some cases, no computer is used as a maintenance station. Instead,

the process control system communicates with the field devices directly via an

RS-485 interface using the HART multiplexer system. The low speed of the

HART communication imposes limitations on this method of operation.

3.3 Integration into Operating Software

The full functionality of the HART multiplexer system unfolds through the integration into

modern asset management systems such as PACTwa re (open source), SIMATIC PDM

(Siemens), AMS (Fisher-Rosemount), Cornerstone (Applied System Technologies), and Valve

Manager (Neles Automation). These operating tools integrate the device functions of the

devices in the multiplexer system into a standardized interface and convenient operation in

the form of menu commands. However, the representation and designation of the functions in

the individual operating tools may vary greatly. A representation that is valid generally is not

possible at this point.

Information regarding the configuration, parameterization, operation, and diagnostic options

of the HART multiplexer system can be found in the manual "Installation and Configuration

Device Type Manager (DTM)".

3.4 System Structure

The field devices and the devices of the HART multiplexer system are connected to

the process control system using termination boards. The following chapters describe

three basic connection options. These connection options serve as examples as there are

many other connection options.

Note!

For further information about the connection layout of the termination boards used, see the

corresponding datasheets.

The following accessories are available for the HART multiplexer system:

• 14-pin ribbon cable K-HM14 for connecting the multiplexer master with the

multiplexer slaves.

• 26-pin ribbon cable K-HM26 for connecting the multiplexer master or the multiplexer slave

with the termination board.

• Interface converter in different variants depending on the available interfaces

• Cordset for the connection between the termination board and the process control system.

This cordset is available in different variants depending on the available interfaces and

the control system manufacturer.

12

Note!

Additional information you can find under www.pepperl-fuchs.com.

2018-04

Page 13

HART Multiplexer System KFD*-HM*-16

Converter

26 -pin ribbon cable

14-pin ribbon cable

DIN mounting rail

up to 31 HART multiplexer masters

up to 15 HART multiplexer slaves per master

24 V DC

RS-485

connection

Up to 16

field devices

Up to 16

field devices

DCS

Computer-based

maintenance station

1

2

3

4

5

6

7

8

19

1713 181620142115

KFD0-HMM-16

KFD0-HMS-16

1

3

4

6

2

5

13 15

12

9

10

7

14

11

8

KFD2-EB2

ERRPWR

!

5 AT

IIIS1

Termination

board

Termination

board

Power Rail

System Description

3.4.1 External Mounting

The multiplexer master and multiplexer slaves are connected to a termination board.

The termination board forwards the signals via screw terminals. The termination board

establishes the connection to the connected multiplexer masters and multiplexer slaves in

parallel or series. This type of mounting is independent of the process control system used and

of any existing control units.

2018-04

Figure 3.3

13

Page 14

HART Multiplexer System KFD*-HM*-16

Converter

26 -pin ribbon cable

14-pin ribbon cable

DIN mounting rail

up to 15 HART multiplexer slaves per master

24 V DC

Up to 16

field devices

Up to 16

field devices

DCS

Connection via

system connector

Computer-based

maintenance station

up to 31 HART multiplexer masters

RS-485

connection

1

2

3

4

5

6

7

8

19

1713 181620142115

KFD0-HMM-16

KFD0-HMS-16

1

3

4

6

2

5

13 15

12

9

10

7

14

11

8

KFD2-EB2

ERRPWR

!

5 AT

IIIS1

Termination

board

Termination

board

Power Rail

System Description

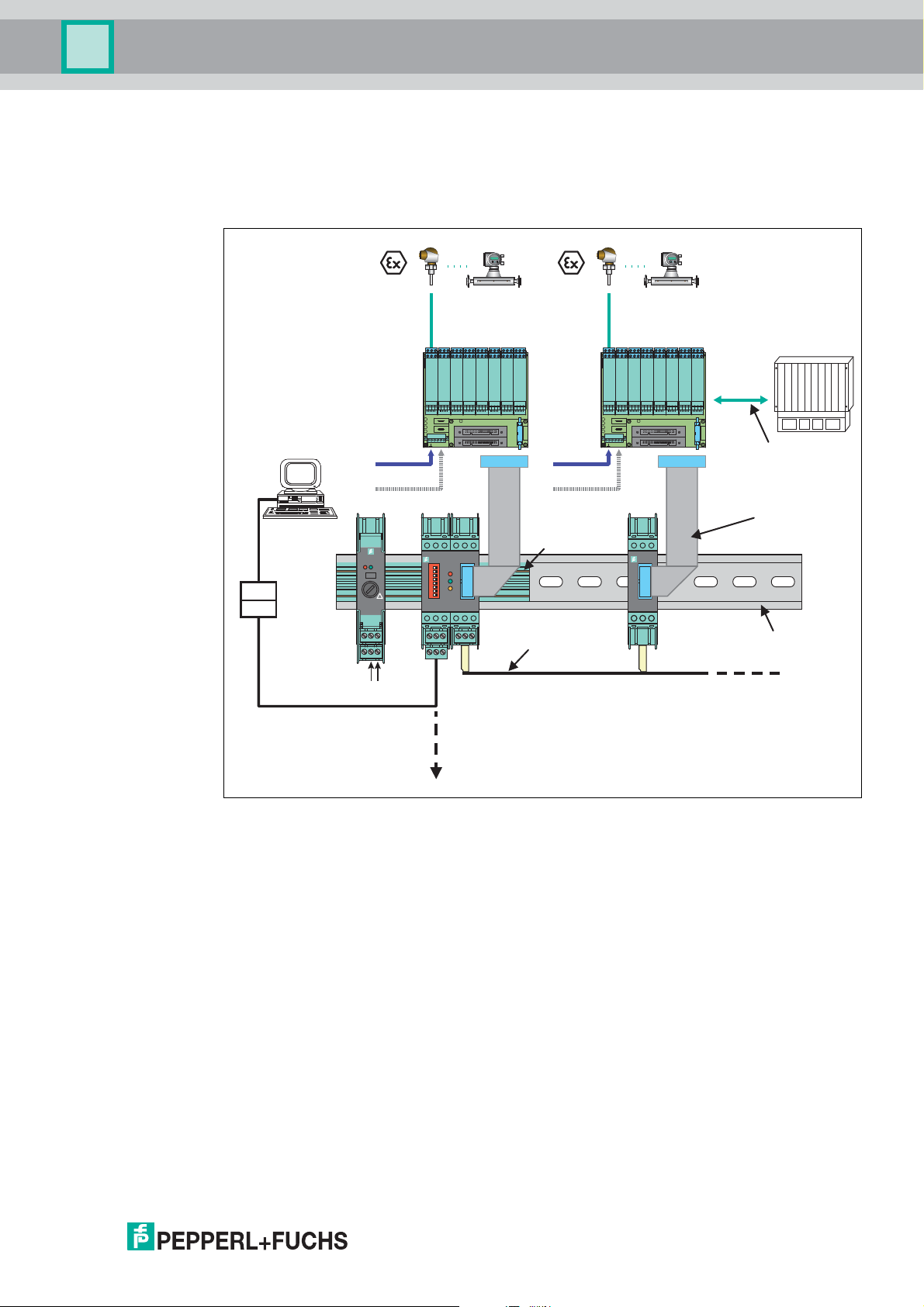

3.4.2 Mounting Integrated in the Process Control System

The multiplexer master and multiplexer slaves are connected to a termination board.

The termination board forwards the signals to the process control system via screw terminals

and system cables. The termination board establishes the connection to the connected

multiplexer masters and multiplexer slaves in parallel or series. The termination boards are

specifically tailored to the individual process control systems.

14

Figure 3.4

2018-04

Page 15

HART Multiplexer System KFD*-HM*-16

Converter

26 -pin ribbon cable

14-pin ribbon cable

DIN mounting rail

up to 15 HART multiplexer slaves per master

24 V DC

Up to 16

field devices

DCS

Redundant

power supply

Power supply

Termination board

with isolators

Up to 16

field devices

Redundant

power supply

Power supply

Termination board

with isolators

Connection via

system connector

Computer-based

maintenance station

up to 31 HART multiplexer masters

RS-485

connection

1

2

3

4

5

6

7

8

19

1713 181620142115

KFD0-HMM-16

KFD0-HMS-16

1

3

4

6

2

5

13 15

12

9

10

7

14

11

8

KFD2-EB2

ERRPWR

!

5 AT

IIIS1

Power Rail

System Description

3.4.3 Mounting Integrated into the K-System

If you use this connection option, the signals can be transferred directly from the

termination boards of the K-system to the multiplexer master and multiplexer slaves via a

system connector.

2018-04

Figure 3.5

15

Page 16

HART Multiplexer System KFD*-HM*-16

Mounting and Installation

4 Mounting and Installation

Danger!

Explosion hazard from damaged electronic components

Premature wear of electronic components in a device that was previously used in a general

electrical installation can cause sparks that can ignite the surrounding potentially explosive

atmosphere.

Never install devices that have already been operated in general electrical installations in

electrical installations used in combination with hazardous areas!

Danger!

Explosion hazard from pollution

An excessively polluted surface of the device can become conductive and consequently

ignite a surrounding potentially explosive atmosphere.

Ensure that you install the device only in environments with a pollution degree 2 or better

according to IEC/EN 60664–1.

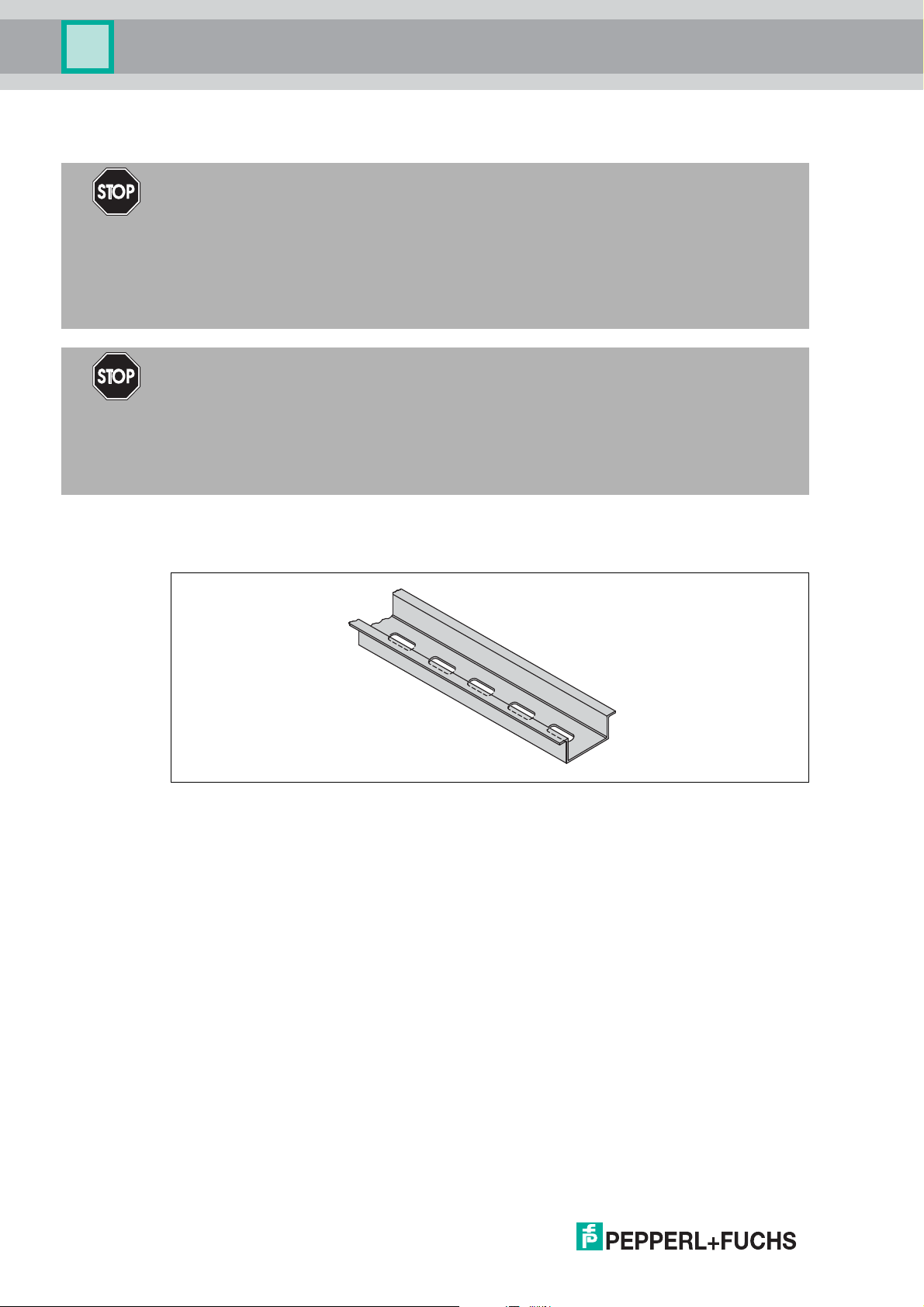

4.1 DIN Mounting Rail

The devices are mounted on a 35 mm DIN mounting rail according to EN 60715.

Figure 4.1 Example: DIN mounting rail UPR-MR (35 mm x 15 mm)

16

2018-04

Page 17

HART Multiplexer System KFD*-HM*-16

1

2

34

Mounting and Installation

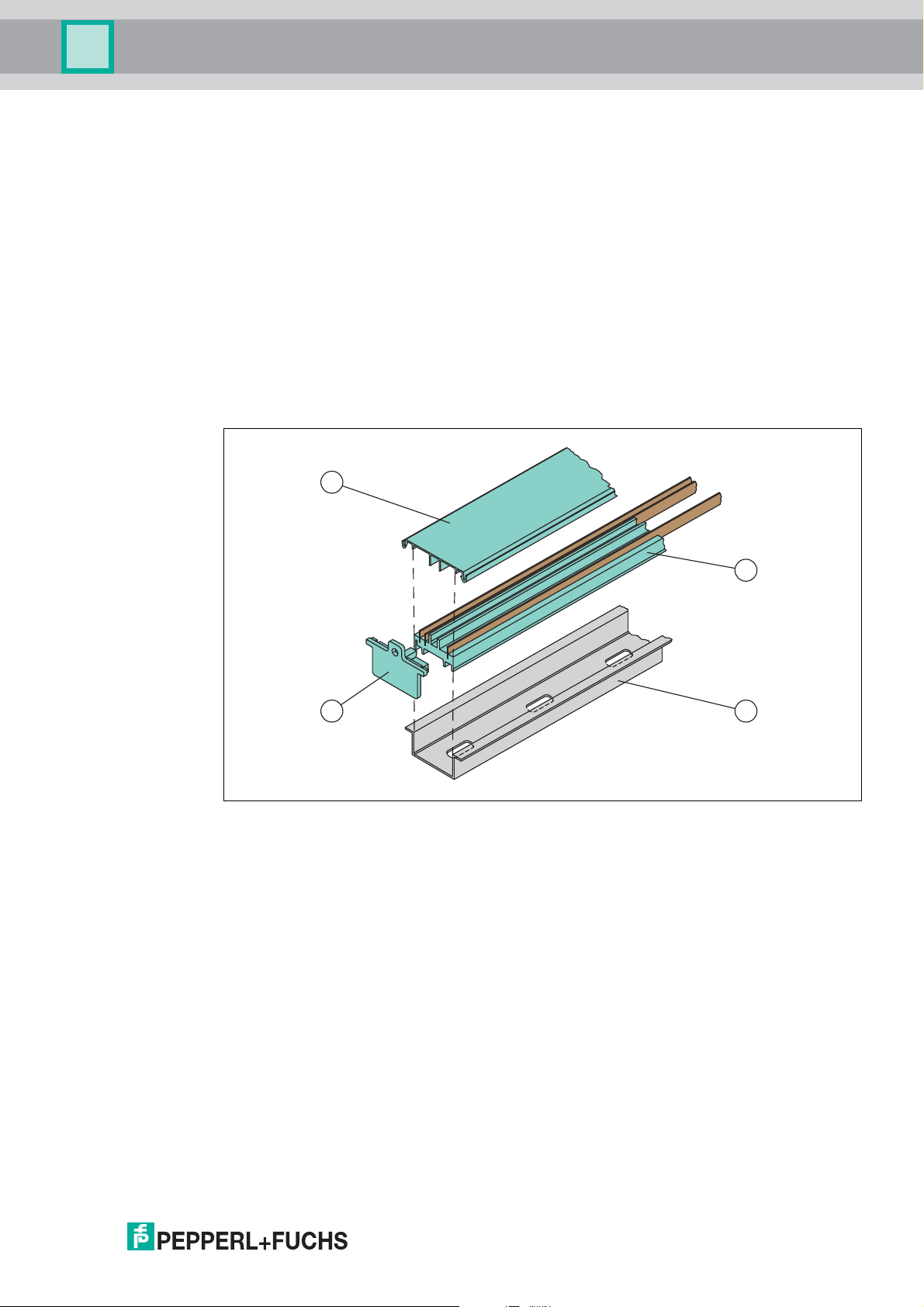

4.2 Power Rail

To reduce wiring and installation costs, Power Rail is the optimum solution. The Power Rail is a

DIN mounting rail with plastic insert, that delivers power to the devices (24 V DC) and transfers

bus signals and a collective error message.

The Power Rail is factory-equipped with cover and end caps. These parts cover empty and

open segments of the Power Rail. Thus, the Power Rail is protected from contamination.

Additionally the cover and end caps prevent that electrically conductive parts come in contact

with the Power Rail.

Power Rail UPR-03

The Power Rail UPR–03 has 3 conductors.

• 2 conductors for power

• 1 conductor for collective error messaging

Figure 4.2 Example: Power Rail UPR-03

1 Cover UPR-COVER

2 Insert UPR-INS-03

3 DIN mounting rail UPR-MR (35 mm x 15 mm)

4 End cap UPR-E

2018-04

17

Page 18

HART Multiplexer System KFD*-HM*-16

Mounting and Installation

4.3 Mounting

Mounting in a Non-Hazardous Area

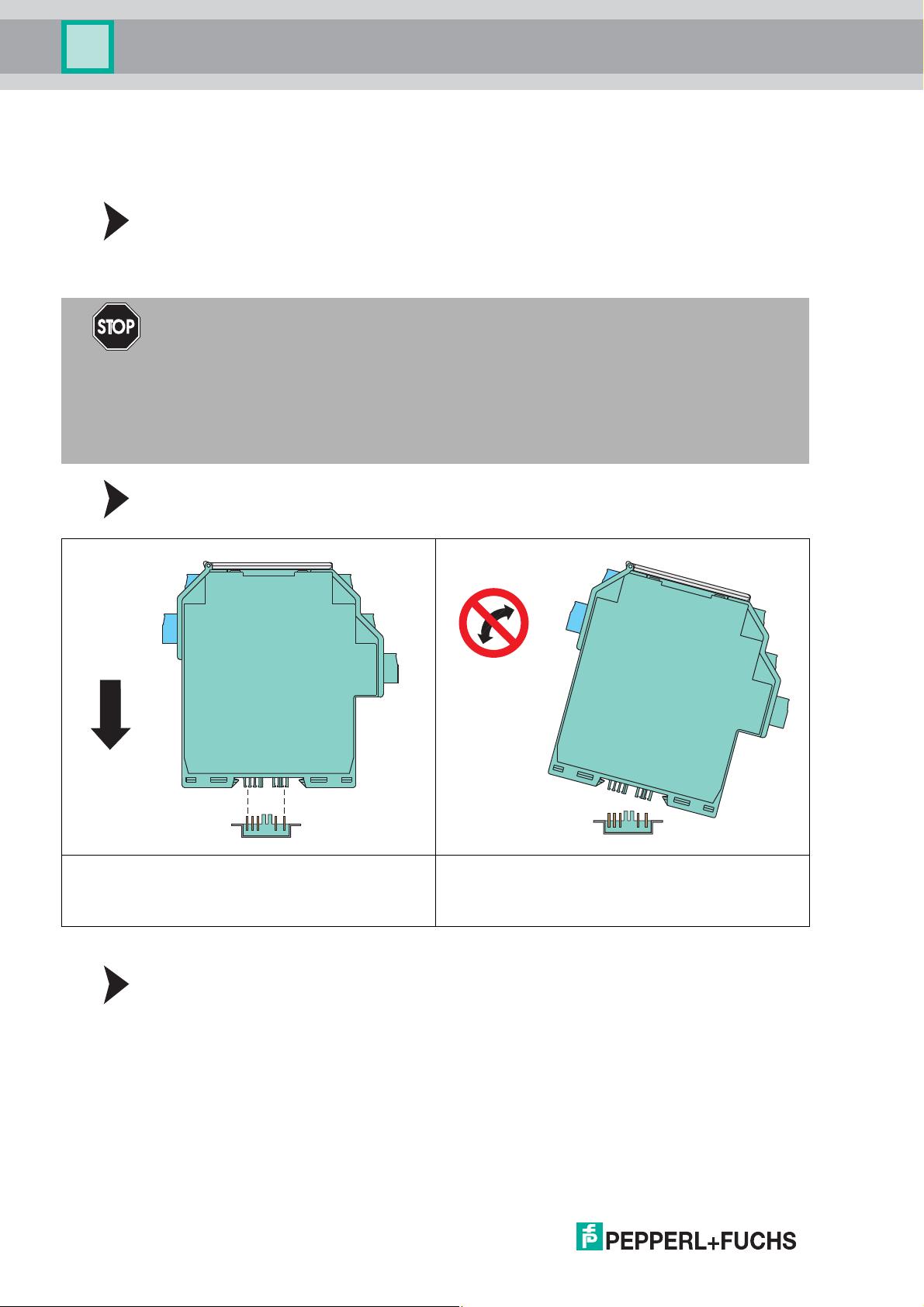

Mounting the Device

Snap the device onto the DIN mounting rail from above. See the next figure.

Mounting in Areas that Require Equipment Protection Level Gc

Danger!

Explosion hazard from wrong mounting

The device safety can be impaired by external environmental influences and by mechanical

stress. That can lead to sparking that can ignite a surrounding potentially explosive

atmosphere.

Mount the device in a surrounding enclosure that complies with IEC/EN 60079–0and that is

rated with the degree of protection IP54 according to IEC/EN 60529.

Mounting the Device

Snap the device onto the DIN mounting rail from above. See the figure below.

CORRECT:

Device snapped on vertically from above.

Figure 4.3

INCORRECT:

Device snapped on at an angle from the side.

This may result in damage to the contacts and the

failure of the device.

Mounting Terminal Blocks

Attach the terminal blocks or remove the terminal blocks.

2018-04

18

Page 19

HART Multiplexer System KFD*-HM*-16

Mounting and Installation

4.4 Connecting the Multiplexer Master

Danger!

Explosion hazard from using of non-intrinsically safe circuits in intrinsically safe circuits

Using non-intrinsically safe devices in intrinsically safe circuits suspends the type of

protection. This can ignite the surrounding potentially explosive atmosphere.

Do not use HART multiplexer devices and HART termination boards in intrinsically safe

circuits.

Danger!

Explosion hazard from live wiring of circuits

If you connect or disconnect energized circuits in a potentially explosive atmosphere, sparks

can ignite the surrounding atmosphere.

Only connect or disconnect energized circuits in the absence of a potentially explosive

atmosphere.

KFD2-HMM-16

Termination

Board

1

2

...

23

24

25

26

Power Rail

HART

...

24 V DC

Figure 4.4 Connection of the KFD2-HMM-16 HART multiplexer master

19

20

21

13

14

15

14

17+

18-

1

2

...

GND

TT+

RS-485

KFD0-HMS-16

24 V DC

Zone 2

2018-04

19

Page 20

HART Multiplexer System KFD*-HM*-16

DIN mounting rail

1

2

3

4

5

6

7

8

19

1713 181620142115

KFD0-HMM-16

24 V DC

Mounting and Installation

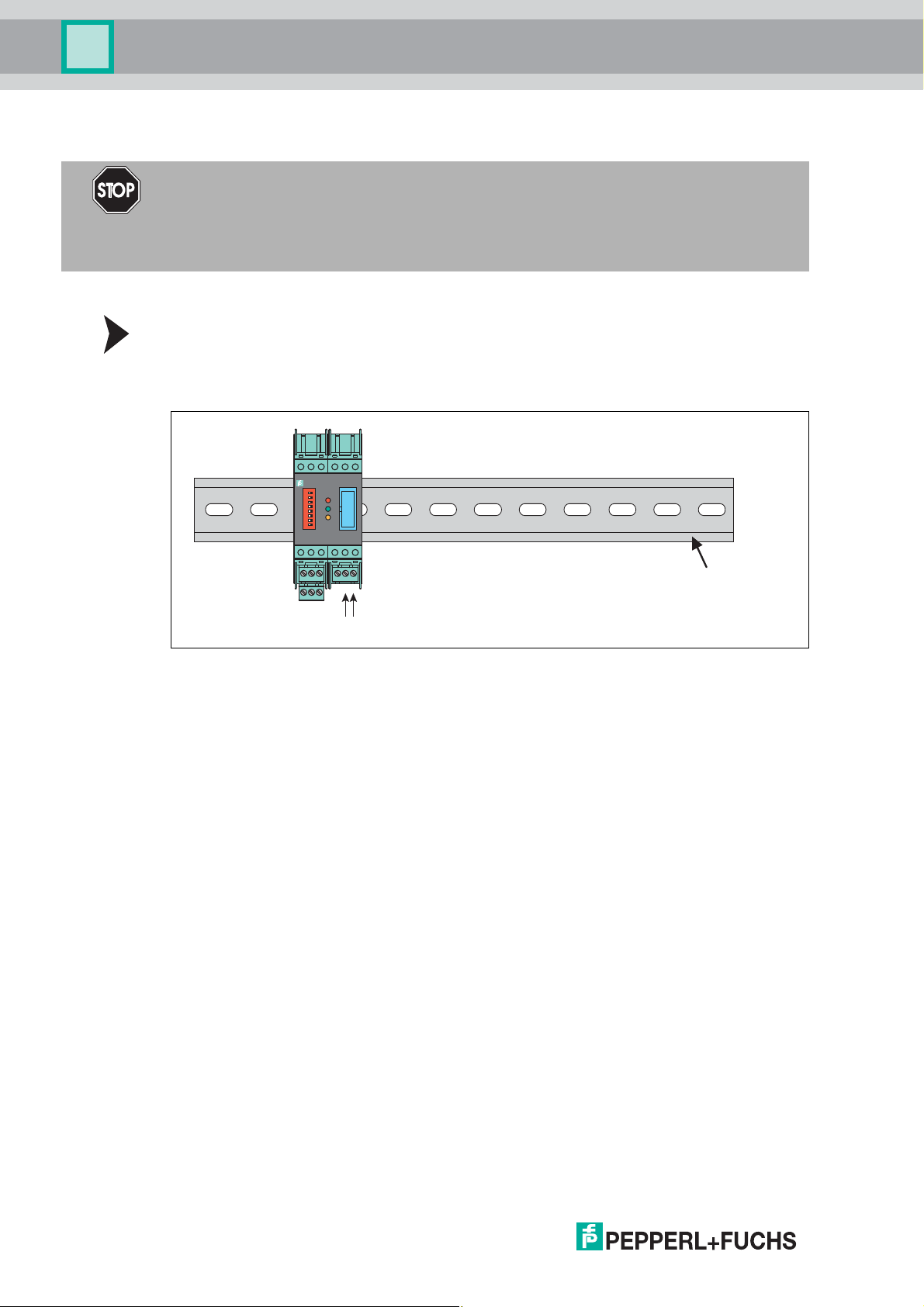

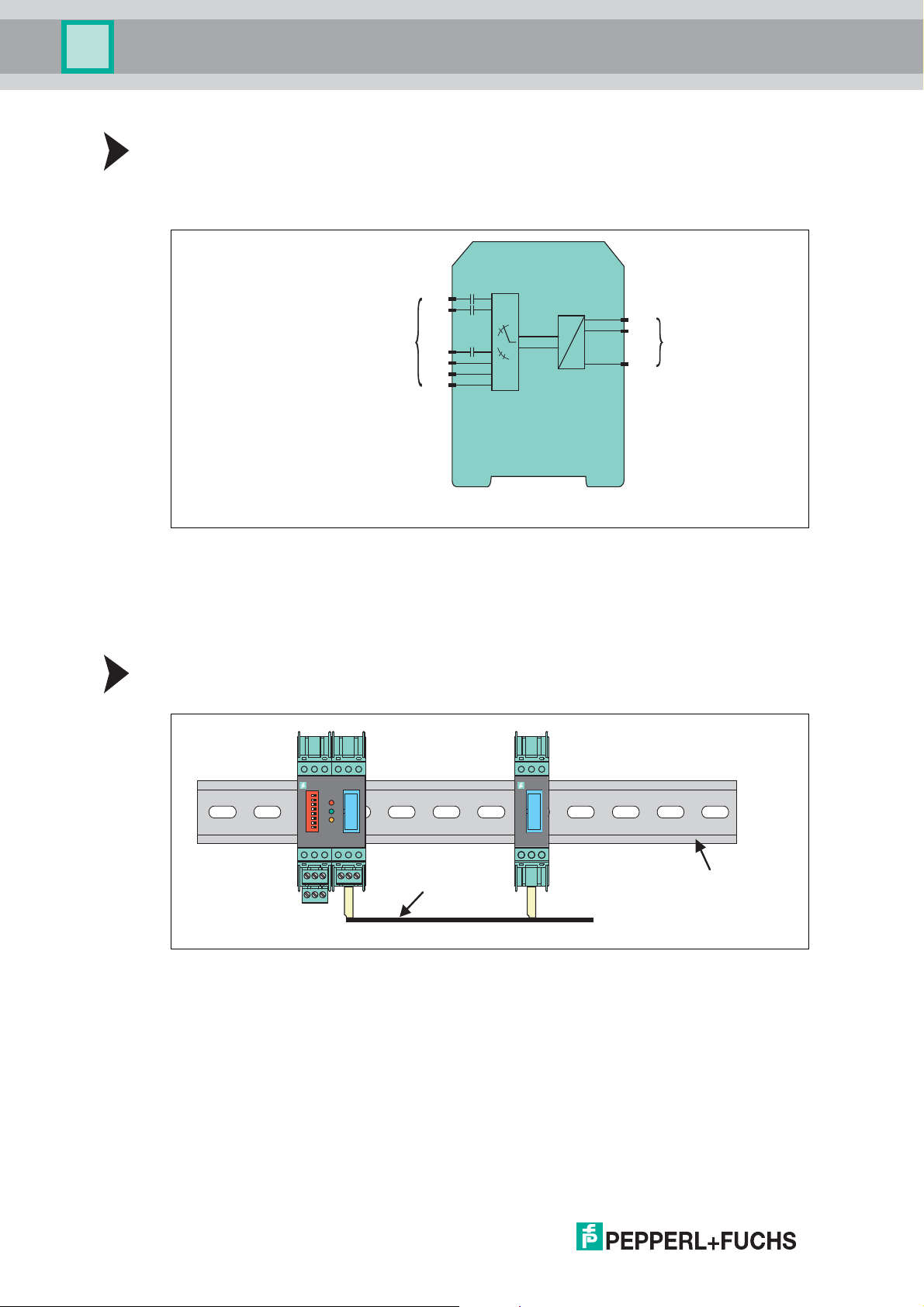

4.4.1 Supplying the Multiplexer Master with Power without Power Rail

Danger!

Danger to life from electric shock

Absent or insufficient insulation can result in electric shock.

Only connect supplies that provide protection against electric shock (e. g. SELV or PELV).

You can use the terminals to supply the multiplexer master with 24 VDC.

Connecting the Multiplexer Master Power Supply

Connect the power supply to terminals 17 and 18.

Observe the tightening torque for the terminal screws. The tightening torque is

0.5 Nm to 0.6 Nm.

Figure 4.5

20

2018-04

Page 21

HART Multiplexer System KFD*-HM*-16

DIN mounting rail

24 V DC

1

2

3

4

5

6

7

8

19

1713 181620142115

KFD0-HMM-16

PWR

1

3

4

6

2

5

13 15

12

9107

14

11

8

Power Rai l

24 V DC

Mounting and Installation

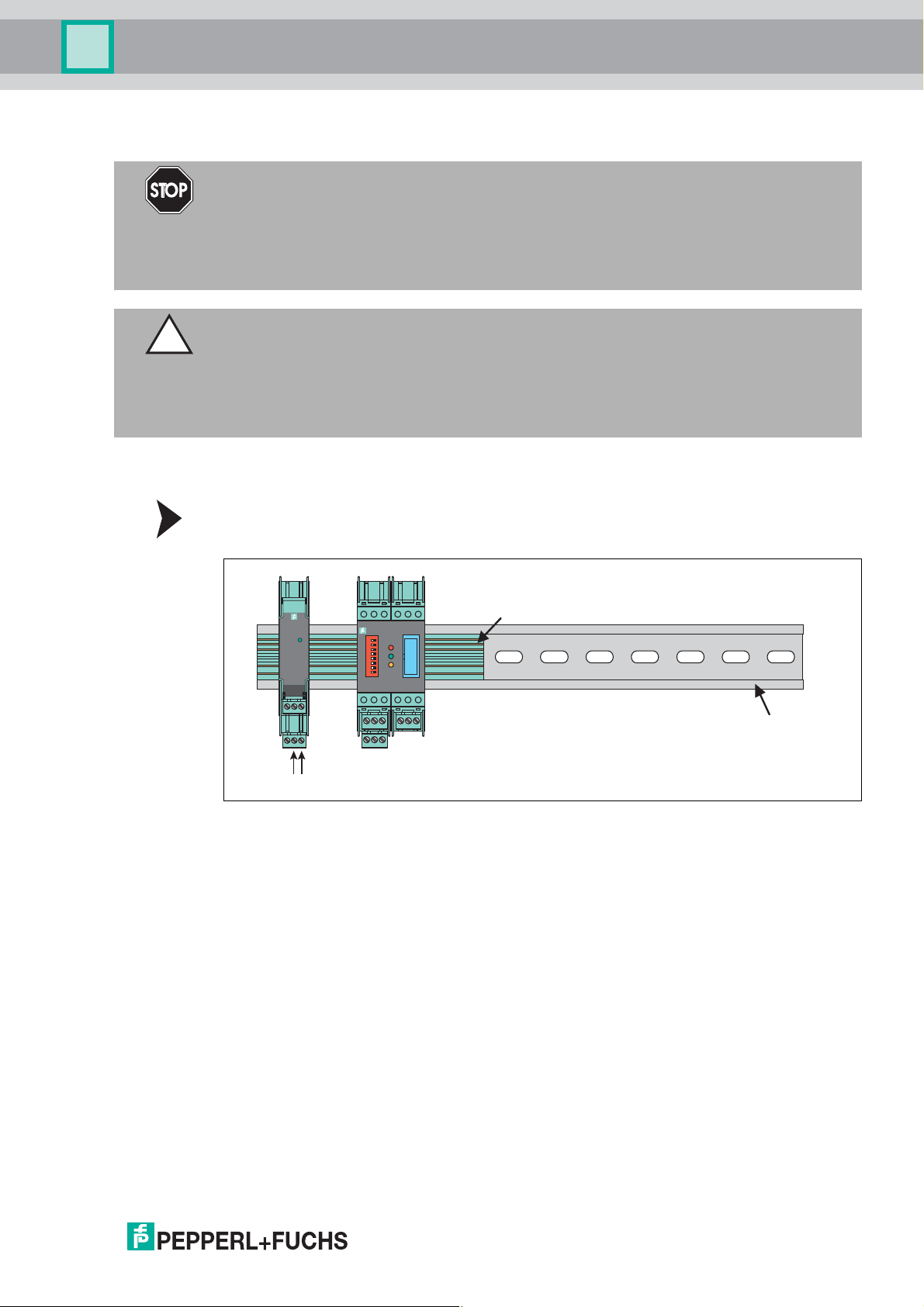

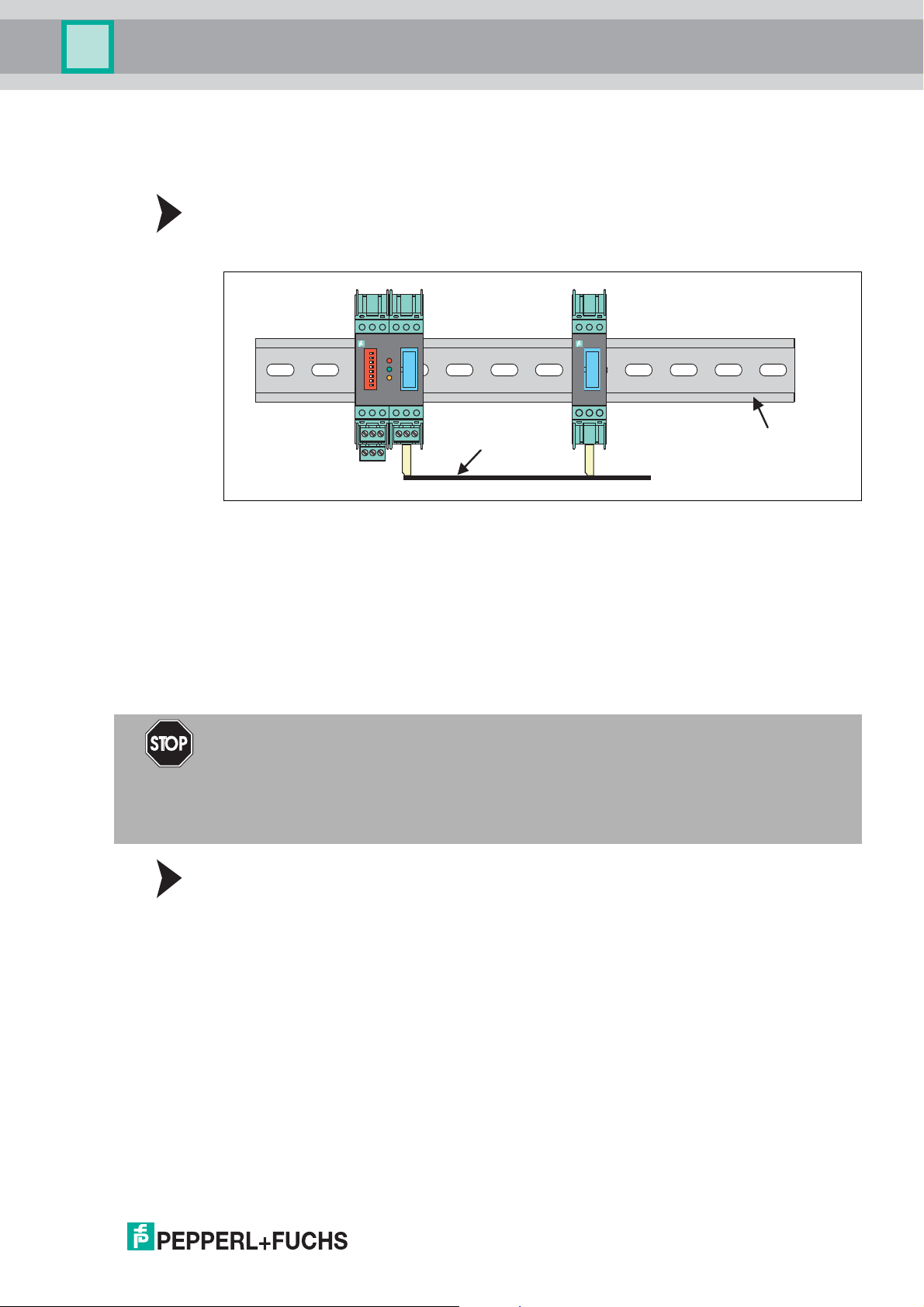

4.4.2 Supplying the Multiplexer Master with Power with Power Rail

Danger!

Danger to life from electric shock

Absent or insufficient insulation can result in electric shock.

Only connect supplies that provide protection against electric shock to power feed modules

(e.g.SELVorPELV).

Caution!

Property damage from use of isolators for Power Rail supply

Using the isolators for Power Rail supply can damage the isolators and make the Power Rail

fail.

Do not supply the Power Rail via isolators.

You can use the Power Rail to supply the multiplexer master with 24 VDC. The supply is

provided using the KFA6-STR-1.24.500 power supply, for example.

Connecting the Multiplexer Master Power Supply

Connect the power supply via Power Rail.

Figure 4.6

2018-04

21

Page 22

HART Multiplexer System KFD*-HM*-16

Mounting and Installation

4.4.3 Connecting the Multiplexer Master to a Computer

The multiplexer master is connected to the computer via an RS-485 interface.

Terminal Designation Meaning

13, 19 Shield Cable shielding

14, 20 RxD/TxD - (RS-485 B–) RS-485 differential signal

15, 21 RxD/TxD + (RS-485 B+)

Table 4.1 Connector assignment for removable terminals

Caution!

Risk of electric shock or property damage due to inadequate grounding

If the cable shield is not connected to the protective earth correctly, this may result in potential

equalization currents. These currents may injure operating personnel or cause property

damage.

Ground the cable shield at only one end of the line. Observe the applicable laws, standards,

and directives for the operating location.

Note!

To connect the multiplexer master and computer, you need an interface converter.

Different interface converters are required depending on the connection on your computer.

We recommend the following converters:

• Interface converter from RS-485 to RS-232: Telebyte model 285, from Telebyte

• Interface converter from RS-485 to RJ45, Com-Server++, from W&T

• Interface converter from RS-485 to USB: I-7561-CR, from ICP

Connecting the Multiplexer Master to a Computer

1. Connect a computer or a process control system to terminals 13, 14, and 15.

Observe the tightening torque for the terminal screws. The tightening torque is

0.5 Nm to 0.6 Nm.

Do not exceed a maximum cable length of 1200 m. Use a shielded, twisted, two-core cable.

2. In the case of long cable lengths and high baud rates, install a terminator at each end of the

RS-485 line. Use terminators of 120 to 220 .

If the RS-485 line ends at the multiplexer master and is not routed to other devices, use the

second RS-485 connection at terminals 20 and 21 to connect a terminator.

If you use an interface converter, install a terminator on the interface converter and an

interface converter at the other end of the line.

In the case of short cable lengths and low baud rates, no terminators are required.

Observe the RS-485 specifications.

3. Connect additional participants to terminals 19, 20, and 21.

Observe the tightening torque for the terminal screws. The tightening torque is

0.5 Nm to 0.6 Nm.

Do not exceed a cable length of 1200 m. Use a shielded, twisted, two-core cable.

22

2018-04

Page 23

HART Multiplexer System KFD*-HM*-16

Mounting and Installation

4.4.4 Connecting the Multiplexer Devices to the Termination Board

The device is connected to the termination board via a 26-pin ribbon cable. The device has a

26-pin IDC socket on the front of the device for this purpose. 16 cables are intended for

the HART signal of the analog measuring circuits of the field devices. The remaining 10 cables

are connected to ground. For the assignment of the IDC socket, see chapter 9.2.

Pepperl+Fuchs provides special termination boards. Various connection options are available

for these termination boards.

Danger!

Explosion hazard from exposed conductors

Exposed conductors of inadequately attached cables can cause sparks that can ignite

the surrounding potentially explosive atmosphere.

When installing the device ensure that the cables are adequately attached.

Connecting Multiplexer Devices, Field Devices, and the Termination Board

Connect the multiplexer device to the termination board via the 26-pin ribbon cable K-HM26.

See chapter 3.4.

4.5 Connecting the Multiplexer Slaves

Danger!

Explosion hazard from using of non-intrinsically safe circuits in intrinsically safe circuits

Using non-intrinsically safe devices in intrinsically safe circuits suspends the type of

protection. This can ignite the surrounding potentially explosive atmosphere.

Do not use HART multiplexer devices and HART termination boards in intrinsically safe

circuits.

Danger!

Explosion hazard from live wiring of circuits

If you connect or disconnect energized circuits in a potentially explosive atmosphere, sparks

can ignite the surrounding atmosphere.

Only connect or disconnect energized circuits in the absence of a potentially explosive

atmosphere.

Danger!

Explosion hazard from exposed conductors

Exposed conductors of inadequately attached cables can cause sparks that can ignite

the surrounding potentially explosive atmosphere.

2018-04

When installing the device ensure that the cables are adequately attached.

23

Page 24

HART Multiplexer System KFD*-HM*-16

KFD0-HMS-16

1

2

23

...

...

1

2

14

...

Termination

Board

KFD2-HMM-16/

KFD0-HMS-16

24

25

26

Zone 2

HART

14-pin ribbon cable

DIN mounting rail

1

2

3

4

5

6

7

8

19

1713 181620142115

KFD0-HMM-16

KFD0-HMS-16

Mounting and Installation

Connecting the Device

1. Connect the terminationboard via the 26-pinribboncable K-HM26.

2. Connect the multiplexer master and additional multiplexer slaves via the 14pin ribbon cable K-HM14.

Figure 4.7 Connection of the KFD0-HMS-16 HART multiplexer slave

4.5.1 Supplying the Multiplexer Slaves

The multiplexer slaves are supplied with power from the multiplexer master

via the 14-pin ribbon cable.

Connecting the Multiplexer Slave Power Supply

Connect the multiplexer slave to the multiplexer master via the 14-pin ribbon cable K-HM14.

Figure 4.8

24

2018-04

Page 25

HART Multiplexer System KFD*-HM*-16

14-pin ribbon cable

DIN mounting rail

1

2

3

4

5

6

7

8

19

1713 181620142115

KFD0-HMM-16

KFD0-HMS-16

Mounting and Installation

4.5.2 Connection between Multiplexer Master and Multiplexer Slaves

The multiplexer slaves are connected to the multiplexer master via the 14-pin ribbon cable.

Connecting Multiplexer Master and Multiplexer Slaves

Connect the multiplexer master and the multiplexer slaves via the 14-pin ribbon cable

K-HM14.

Figure 4.9

4.5.3 Connecting the Multiplexer Devices to the Termination Board

The device is connected to the termination board via a 26-pin ribbon cable. The device has a

26-pin IDC socket on the front of the device for this purpose. 16 cables are intended for

the HART signal of the analog measuring circuits of the field devices. The remaining 10 cables

are connected to ground. For the assignment of the IDC socket, see chapter 9.2.

Pepperl+Fuchs provides special termination boards. Various connection options are available

for these termination boards.

Danger!

Explosion hazard from exposed conductors

Exposed conductors of inadequately attached cables can cause sparks that can ignite

the surrounding potentially explosive atmosphere.

When installing the device ensure that the cables are adequately attached.

Connecting Multiplexer Devices, Field Devices, and the Termination Board

Connect the multiplexer device to the termination board via the 26-pin ribbon cable K-HM26.

See chapter 3.4.

2018-04

25

Page 26

HART Multiplexer System KFD*-HM*-16

Mounting and Installation

4.6 Connecting the Termination Board

Danger!

Explosion hazard from using of non-intrinsically safe circuits in intrinsically safe circuits

Using non-intrinsically safe devices in intrinsically safe circuits suspends the type of

protection. This can ignite the surrounding potentially explosive atmosphere.

Do not use HART multiplexer devices and HART termination boards in intrinsically safe

circuits.

Danger!

Explosion hazard from live wiring of circuits

If you connect or disconnect energized circuits in a potentially explosive atmosphere, sparks

can ignite the surrounding atmosphere.

Only connect or disconnect energized circuits in the absence of a potentially explosive

atmosphere.

Danger!

Danger to life from electric shock

Absent or insufficient insulation can result in electric shock.

Only connect supplies that provide protection against electric shock to power feed modules

(e.g.SELVorPELV).

Danger!

Danger to life from electric shock

Absent or insufficient insulation can result in electric shock.

• Maintain sufficient distance between the connection lines, terminals, housing, and

the environment.

• Insulate connection lines, terminals, and the housing from the environment.

Danger!

Danger to life from incorrect installation

Incorrect installation of cables and connection lines can compromise the function and

the electrical safety of the device.

• Observe the permissible core cross section of the conductor.

• When using stranded conductors, crimp wire end ferrules on the conductor ends.

• Use only one conductor per terminal.

• When installing the conductors the insulation must reach up to the terminal.

• Observe the tightening torque of the terminal screws.

26

2018-04

Page 27

HART Multiplexer System KFD*-HM*-16

Mounting and Installation

4.6.1 Connecting Field Devices to the Termination Board

Pepperl+Fuchs provides special termination boards. Various connection options are available

for these termination boards. See the manual "K-System – Isolators and Termination Boards."

Connecting the Termination Board and Field Devices

1. Connect the HART-compatible field devices to the termination board using screw terminals

or spring terminals. See chapter 3.4.1 and 3.4.2.

Observe the tightening torque for the terminal screws. The tightening torque is

0.5 Nm to 0.6 Nm.

or

2. Control units are mounted on the termination board. Connect the field devices to the

control unit using screw terminals or spring terminals. See chapter 3.4.3.

Observe the tightening torque for the terminal screws. The tightening torque is

0.5 Nm to 0.6 Nm.

4.6.2 Connecting the Process Control System to the Termination Board

Pepperl+Fuchs provides special termination boards. Various connection options are available

for these termination boards.

Connecting the Termination Board and Process Control System

1. Connect the process control system to the termination board using screw terminals

or spring terminals. See chapter 3.4.1.

Observe the tightening torque for the terminal screws. The tightening torque is

0.5 Nm to 0.6 Nm.

or

2. Connect the process control system to the termination board via a manufacturer-specific

system connector. See chapter 3.4.2 and 3.4.3.

4.7 Information Regarding Electromagnetic Compatibility

The device is intended for use in electrically conductive and grounded switch cabinets.

Shielding Cables

1. Shield cables that are leaded into the switch cabinet.

2. Connect the switch cabinet and shield directly in the cable gland.

3. Lead unshielded cables (e. g. supply lines) into the switch cabinet via filter.

2018-04

27

Page 28

HART Multiplexer System KFD*-HM*-16

Commissioning

5 Commissioning

Checklist for Commissioning

The commissioning of the multiplexer master is summarized in the following checklist.

The steps required for commissioning the multiplexer master refer to the chapters where

the respective procedure is described.

1. Installation of field devices

2. Selection and connection of the termination boards, see chapter 3.4

3. Selection and connection of the control units

4. Connection of the process control system

5. Connection of the multiplexer master, see chapter 4.4

6. Connection of the maintenance station.

If necessary, use interface converters, see chapter 4.4.3.

Observe the polarity of the RS-485 connection, see chapter 4.4.3.

Specify the RS-485 address and the baud rate.

7. Wait for the switch-on process, see chapter 5.2.4.

8. Perform parameterization, see chapter 5.2.5.

9. Specify the multiplexer devices used in the module table, see chapter 7.1.2.

10. Build signal loops, see chapter 7.1.5.

11. If desired, activate the scan function, see chapter 7.1.6.

5.1 Data Access to the Connected Field Devices

The operating tool used determines how data on the connected field devices is accessed.

The field devices are generally found in a project tree beneath the multiplexer slaves.

The multiplexer master integrates the slave unit with slave address 0. Device data,

device parameters, and device diagnoses can be accessed via the project tree.

For the structure of a project tree, see chapter 6.8.

The data, parameter, and diagnostic windows display the data of the underlying

HART commands that differ according to the field device. Only universal commands and

common practice commands have the same function for all devices. The information about the

devices themselves, the process values, and some diagnostic information can thus be

represented in a uniform manner.

5.2 Configuration of the Multiplexer Master

5.2.1 Connection to the Maintenance Station or to the

Process Control System

28

The connection to the maintenance station or to the process control system is via a multidropenabled RS-485 interface, see chapter 4.4.3. The baud rate for this interface can be set via the

DIP switch. The device address for communication via RS-485 is also set via the DIP switch.

When setting the address, make sure that no address is assigned more than once, as

otherwise this may lead to communication faults and even communication failure. The

baud rate set must match that of the maintenance station.

2018-04

Page 29

HART Multiplexer System KFD*-HM*-16

Commissioning

5.2.2 DIP Switch Settings

Danger!

Explosion hazard from sparking when using operating elements

Using operating elements in a potentially explosive atmosphere can cause sparks that can

ignite the surrounding atmosphere.

Only use operating elements (e. g., switch, slider, button, etc.) in the absence of a potentially

explosive atmosphere.

The device is equipped with 8 DIP switches on the front.

DIP switch 1 is used for device testing by the manufacturer and must therefore always be in

the off position.

DIP switch 1 Meaning

Position Off Normal state

Table 5.1

DIP switches 2 and 3 determine the baud rate of the RS-485 interface.

DIP switch 2 3 Meaning

Position Off Off 9600 baud

Off On 19200 baud

On Off 38400 baud

On On 57600 baud

Table 5.2

DIP switches 4 to 8 define the RS-485 address. A value assigned to each of the DIP switches.

The address is calculated from the sum of the values.

DIP switch 4 5 6 7 8 Meaning

Position On Off Off Off Off Value 16

Off On Off Off Off Value 8

Off Off On Off Off Value 4

Off Off Off On Off Value 2

Off Off Off Off On Value 1

Example Off On On Off On Address=8+4+1=13

Table 5.3

2018-04

Note!

Briefly disconnect the device from the power supply to apply the values set using

the DIP switches.

29

Page 30

HART Multiplexer System KFD*-HM*-16

Commissioning

Factory Setting

DIP switch 1 2 3 4 5 6 7 8 Meaning

Position Off Off Off Off Off Off Off Off Manufacturer test disabled,

Table 5.4

Note!

In the factory setting, the address 0 is set. Ensure that you do not assign any addresses more

than once.

5.2.3 LED Indication

The device is equipped with three LEDs which are located on the front of the housing.

The LEDs have the following meanings:

Color Meaning

Red Fault indication, detected during the initialization process

Green Operating indication

Orange HART communication with a field device

Table 5.5

baud rate 9600 baud

RS-485 address 0

LED indication during the initialization process

Color Status Meaning

Red Off Initialization process

Green Flashes

Orange Off

Table 5.6

LED indication during the scanning process

Color Status Meaning

Red Off Scanning process

Green Lit

Orange Flashes

Table 5.7

Note!

For further information about the scanning process, see chapter 5.2.4.

Faulty LED indication during commissioning

Color Status Meaning

Red Flashes If all three LEDs flash one after the other, DIP switch 1 (test) is in

Green Flashes

Orange Flashes

Table 5.8

the on position. Turn the switch to off and repeat commissioning.

30

2018-04

Page 31

HART Multiplexer System KFD*-HM*-16

Commissioning

5.2.4 Switch-On Behavior

When the power supply has been switched on, the multiplexer master performs an

initialization process with a self-test. The process is indicated by a flashing green LED.

Any faults detected are indicated by a red LED. The multiplexer devices defined in

the multiplexer table (command 157) are then scanned for any available HART-compatible

field devices. This process is indicated by the flashing orange LED.

Once the multiplexer master has completed the scan process, a list of the field devices

connected is saved in the device.

Note!

If a field device is connected to the multiplexer device during operation, a scan must be

performed afterwards so that the field device can be addressed via HART. This scanning

process is triggered automatically when the multiplexer device is switched on,

see chapter 7.1.5. The process can also be started manually in the maintenance station,

see chapter 7.2.1. The duration of the scanning process is dependent

• on the number of connected multiplexer slaves,

• on the number of connected HART-compatible field devices,

• on the loop search type, see chapter 9.1, command 153,

• on the number of message repeats in the case of a fault, or

• on whether the query has been answered.

The factory setting for the number of message repeats is set to 2. The search duration is

between approximately 30 seconds and several minutes in the case of maximum

configuration. On completion of this phase, the orange LED goes out. Volatile data is set to its

default setting. Data stored in non-volatile memory is retained.

Note!

Scanning Process with Several Interconnected Multiplexer Devices

If several multiplexer devices are interconnected through a shared RS-485 line and

a field device is replaced between the multiplexer devices, a scan must be performed

on both multiplexer devices. Otherwise, no communication with the affected field device is

possible.

2018-04

31

Page 32

HART Multiplexer System KFD*-HM*-16

Commissioning

5.2.5 Device Parameters, Parameterization

Caution!

Potential device malfunction from change of device function

Changes in the device function can lead to device malfunction. The function of the device

is no longer guaranteed.

Before transferring the new device function, make sure that the changed device function

does not cause a danger to the device and the plant.

For the identification and parameterization of the multiplexer master, just like other

HART field devices, the multiplexer master contains certain parameters that are saved in

the non-volatile memory. The following list shows these parameters and how the

parameterization must be performed.

• Unique device identification, see commands 0 and 11

The device identification provides information about the device (type, type ID,

serial number, revision numbers) and the manufacturer and cannot be changed.

• Message, see commands 12 and 17

Under this parameter, any text of up to 32 characters can be stored in the device.

• Tag, description, and date, see commands 13 and 18

A tag (8 characters), a measuring point description (16 characters), and a date can be

stored under these parameters.

• Number of preambles in message responses, see command 59

This parameter is used to define the number of preambles inserted in the message

responses. The default setting is 4, the adjustment range is 2 to 20.

• Number of message repeats, see commands 144 and 145

The number of message repeats can be set separately for repeats in the event of

communication faults and in the event of response code Busy. The adjustment range is

0 to 11 repeats in each case. In the event of communication faults, the default setting is 2.

For response code Busy, the default setting is 0.

• Scan command, see chapter 7.1.7 and commands 146 and 147

Of the existing scan parameters, only the scan command is stored in non-volatile memory.

The command indicates which HART command (1, 2, or 3) is to be a scan command to

the field devices.

• Master type (primary or secondary master), see command 151

This sets the priority for access to the HART field device. A primary master always initiates

a connection to a field device. A secondary master initiates a connection to a field device

only if the primary master does not access the field device. The default setting for

the multiplexer master is primary master. A typical example of a secondary master is a

handheld.

• Loop search type, see command 153

The multiplexer master currently does not support multidrop with HART, i. e., only one

HART field device is connected to each HART channel. During construction of the

signal loop (scanning process, see chapter 7.1.5), the connected field devices are either

always searched for polling address 0 (single analog) or for polling addresses 0 to 15

in preparation for multidrop operation. In multidrop operation, the first polling address

found is addressed (single unknown).

• Module table, see chapter 7.1.2 and command 157

32

This document includes a list of commands. See chapter 9.1.

2018-04

Page 33

HART Multiplexer System KFD*-HM*-16

Configuration

6Configuration

Caution!

Potential device malfunction from change of device function

Changes in the device function can lead to device malfunction. The function of the device

is no longer guaranteed.

Before transferring the new device function, make sure that the changed device function

does not cause a danger to the device and the plant.

Note!

The steps are described using the FDT framework program PACTwa re 4 .1 as an example.

6.1 Introduction to PACTware Operating Software

FDT Concept

The FDT concept (FDT – Field Device Tool) created a standard that can be used to integrate

devices in various user interfaces (framework applications such as PACTware ).

The FDT concept enables open and continuous device operation from the control level to

the field, regardless of the bus systems used. The FDT concept specifies the data exchange

between the device-specific driver and the framework application. Every communicating

device has a device-specific driver (DTM) that is integrated in the framework application.

PACTwareTM Operating Software

PACTw ar e (PACTwa re – Process Automation Configuration Tool) is

a manufacturer-independent operating software for devices. In the past, it was often necessary

to use multiple manufacturer-specific programs to be able to operate different devices.

PACTw ar e enables you to operate any number of devices with just this software. PACTw ar e is

not only a configuration tool, it also offers an interface to HART-compatible field devices as

well as to bus systems such as PROFIBUS, MODBUS, and ControlNet. PACTwa re offers

many features that allow users to simplify the plant documentation, to create trend curves, and

to monitor signals using HART data.

Device and Communication DTM

The DTM (DTM – Device Type Manager) contains all the data and functions of a device.

Every DTM contains its own user interface optimized for the device. The device and

communication DTMs can be integrated in any FDT frame application, such as PAC Tware .

The DTM offers almost no restriction with regard to display and user guidance. This means that

all available device functions can be operated according to the user's needs. Operation is

supported by graphics. The DTM technology enables consistent operation of a device in all

FDT systems.

Pepperl+Fuchs generates DTMs for HART-compatible devices by converting the

device description (DD) of these devices for use with PACTwar e.

2018-04

33

Page 34

HART Multiplexer System KFD*-HM*-16

Configuration

Essentially, there are two different types of DTM:

• Device DTMs

Device DTMs are DTMs for configuring field devices such as transmitter power supplies,

signal converters, and trip amplifiers.

• Communication DTMs

Communication DTMs are required for communication with a device via a point-to-point

connection or via any network structures. The communication DTMs are available for

various interfaces, such as an RS-232 interface or a USB interface.

6.2 Software Components

To configure the device with a user program, you need the following software components:

• Microsoft

• PAC Twa re 4. 1 or higher

In accordance with FDT Specification 1.2, PAC Twa re is used as a framework application

for DTMs supplied by manufacturers of the field devices as configuration software.

• HART Multiplexer DTM

The DTM collection comprises all device DTMs required for the parameterization of

multiplexer devices. The DTMs are used to establish communication with the field devices

using communication protocols such as the HART protocol or PROFIBUS protocol.

• DTM HART Comm

This package contains the HART communication DTM, which is necessary for

communication between the host and the HART multiplexer DTM.

• DTMs of the field devices

The manufacturers of field devices provide specific DTMs which allow access to all

functions of the respective devices and therefore allow detailed parameterization.

For further information, please contact the manufacturer of the field devices used.

• Ge n e r i c H A R T D T M

The Generic HART DTM provides the basic HART functionalities of the field devices.

If no matching device DTM is available, the Generic HART DTM is used for

basic parameterization. Therefore, we recommend that this DTM is always available.

®

.NET Framework 3.5 or higher

DTM HART Comm HART Multiplexer DTM

KFD0-HMM-16

1

2

3

4

5

6

7

8

19

HART multiplexer system

Master Slave Master Slave

Host

Computer-based

maintenance station

or process control system

HART communication 1 HART communication 2

1713 181620142115

Field device DTMs

Field devices

Figure 6.1 Software components

Note!

The latest software components can be found online at www.pepperl-fuchs.com in the

product selector under Products > Software.

2018-04

34

Page 35

HART Multiplexer System KFD*-HM*-16

Configuration

Installing Software Components

1. Install Microsoft® .NET Framework.

2. Install PAC Twa re .

3. Install the HART multiplexer DTM.

4. Install the DTM HART Comm.

5. Install the field device-specific DTMs from the manufacturer of the field devices.

6. Install the DTM Generic HART if necessary.

Note!

The cross-device properties of the software are described in the manual "Installation and

Configuration Device Type Manager (DTM)." You can download this manual free of charge

from our website www.pepperl-fuchs.com in the product selector under

Products > Software > PACTware > Product list > PACTware 4.1 > Documents.

The following section describes only the device-specific settings for the

HART multiplexer master KFD2-HMM-16.

2018-04

35

Page 36

HART Multiplexer System KFD*-HM*-16

Configuration

6.3 PACTware Main Window

The main window is divided into the project window and the editing window.

Project window In the project window, you build the current project tree of your system by adding

the various components. In the project window, select the device you want to edit,

monitor, diagnose, or simulate. The selected object is highlighted in a different color.

Editing window In the editing window, various windows required for editing your system are opened.

In the first processing step, the selection window with the drivers and devices or

the device catalog for the structure of the system is shown.

For the configuration and parameterization, the corresponding windows for the drivers

and devices are opened in the editing window.

For subsequent operation, the menus for diagnosis, measured value, trend, or

simulation are opened in the editing window. In addition, the communication monitor

for the communication protocol can be opened.

Menu bar The menu bar contains the following drop-down menus:

• File: Here you can create a new project, save the current project, or load an

existing project.

• Edit: Contains the copy, cut, and paste functions.

• View: Here you can display or hide various symbol and status bars, as well as

thedevicecatalog, fault monitoring, etc.

• Project: Contains the basic project functions, such as loading device(s), writing to

device(s), reading the device status.

• Device: Contains the functions for editing the device data of the device currently

selected in the project tree. Here you can also establish or disconnect the

connection to the selected device.

• Extras: Here you can manage the device catalog, the users, the options, and

the add-ins.

• Window: Here you can open the various current view windows.

• Help: The PACTwa re help is called up.

Command bar The command bar is located below the menu bar and contains buttons for all important

functions for adding, removing, and editing components within the project.

You can also read the device status, edit the device data, and establish or disconnect

the connection to the system.

36

2018-04

Page 37

HART Multiplexer System KFD*-HM*-16

Project window Editing window

Command bar

Menu bar

Configuration

Figure 6.2 PAC Twa re main window

Note!

Additional information on PAC Twa re can be found in the manual "Installation and

Configuration Device Type Manager (DTM)."

2018-04

37

Page 38

HART Multiplexer System KFD*-HM*-16

Configuration

6.4 Connecting with the Device

Connecting the Computer to the Device

1. Mount the device. See chapter 4.

2. Connect the device to the power supply.

3. Connect the computer and the device via an interface converter. See chapter 4.4.3.

4. Start PAC Twar e as described in the manual "Installation and Configuration

Device Type Manager (DTM)".

The PACTwa re main window is displayed. See chapter 6.3.

Enabling Memory-Optimized Operation

In combination with the DTMs for the multiplexer master, we recommend enabling

the Memory-optimized operation option.

1. Open the menu Extras > Options.

2. Enable Use memory-optimized project management.

3. Confirm your selection with OK.

You have enabled the memory-optimized operation.

38

2018-04

Page 39

HART Multiplexer System KFD*-HM*-16

Configuration

6.5 Inserting the Communication DTM

In a PAC Twar e project, the multiplexer master can only be addressed via the

communication DTM HART communication. Information detailing how to create and edit a

project can be found in the "Installation and Configuration Device Type Manager (DTM)"

manual.

If there is no communication DTM in your project, add a communication DTM from

thedevicecatalog.

Note!

Do not use the communication DTM HART Driver FDT. This communication DTM is

an obsolete IDL-DTM.

Adding Communication DTMs

1. In the project window, select HOST PC using the right mouse button.

2. In the context menu, select Add device.

3. Select the DTM HART communication from the list.

4. Confirm your selection with OK.

The communication DTM is included in the project. In the project tree, the

communication DTM bears the name of the COM port on which the device is

physically connected with the computer (e. g. COM8).

Figure 6.3 Device catalog

2018-04

39

Page 40

HART Multiplexer System KFD*-HM*-16

Configuration

Setting Parameters

1. In the project window, double-click the communication DTM. It bears the name of the

COM port on which the device is physically connected with the computer (e. g. COM8).

2. Close the Parameters window by clicking the OK button.

If you have made changes to parameters, these changes will be saved.

The following parameters are adjustable:

• Communication interface:

Select the option HART multiplexer as the interface.

• Serial interface:

Select the COM port to which the multiplexer master is connected.

• Baud rate:

Select the baud rate according to the settings of the DIP switches on

the multiplexer master, see chapter 5.2.2.

• RTS control:

Depending on the type of interface converter used, switching the request-to-send control

on or off may be necessary to switch cleanly between receive and transmit mode.

• HART protocol:

Master: 2 HART masters may be connected to a HART signal loop, whereby

the parameterization must differentiate between the primary master and the

secondary master. This setting is defined here.

Preamble: In accordance with the HART standard, a corresponding number of

FF characters must be sent in advance as a preamble. The number of characters is

defined here.

Number of communication retries: Number of repeated attempts to make contact in

the event of an fault.

• Address scan: start address and end address:

Here you can set the address range in which the HART communication DTM should

search for the multiplexer devices connected to the RS-485 interface.

• Communication timeout:

Here you can set how long the HART communication DTM should search for

the multiplexer devices connected to the RS-485 interface.

40

2018-04

Page 41

HART Multiplexer System KFD*-HM*-16

Configuration

Figure 6.4 HART communication parameter window

2018-04

41

Page 42

HART Multiplexer System KFD*-HM*-16

Configuration

6.6 Inserting the Multiplexer Devices

The connected multiplexer devices can be scanned in the communication DTM

via the Additional functions > Scanlist function.

Updating the Scan List

1. In the project window, right-click to select the HART communication DTM (e. g. COM8).

2. In the context menu select Additional functions.

3. Select Scanlist.

4. Start the scan by clicking Update.

The scan list is updated and displayed.

Figure 6.5 HART communication window, scan list

42

2018-04

Page 43

HART Multiplexer System KFD*-HM*-16

Configuration

The multiplexer devices must be added to the project manually.

Inserting Multiplexer Devices via Device Catalog

1. Open the device catalog by clicking View > Device catalog

2. Use drag-and-drop to move the KFD2-HMM-16 DTM from the device catalog to

the HART communication DTM (e. g. COM8) in the project tree.

The KFD2-HMM-16 DTM is added to the project.

Inserting Multiplexer Devices via Context Menu

1. In the project window, right-click to select the HART communication DTM (e. g. COM8).

2. In the context menu, select Add device.

3. Select the KFD2-HMM-16 DTM from the list and confirm by clicking OK.

The KFD2-HMM-16 DTM is added to the project.

Note!

To establish the connection to a device in the project tree or to disconnect the connection,

right-click to select the corresponding device in the project window. In the context menu,

select Connect or Disconnect.

Alternatively, you can select the device in the project window and click the corresponding field

in the command bar.

2018-04

43

Page 44

HART Multiplexer System KFD*-HM*-16

Configuration

6.7 Displaying Device Information and Setting Parameters

6.7.1 Loading Device Data

Loading Data and Establishing a Connection

1. In the project window, right-click to select multiplexer master KFD2-HMM-16.

2. Select Load from device in the context menu.

3. If no connection has been established previously, a window opens and you are asked

whether you want to establish the connection to the device. Select Ye s .

The connection to the multiplexer master is established and the device data

can be read.

Figure 6.6 Load data from device

44

2018-04

Page 45

HART Multiplexer System KFD*-HM*-16

Configuration

6.7.2 Device Information

General information about the device is displayed in the Ge n e r a l menu:

Displaying Device Information

1. Use the mouse to double-click the multiplexer master KFD2-HMM-16 in

the project window.

2. In the editing window, open the Configuration > General menu.

The Ge n e r a l window is displayed.

3. Click Apply to confirm your selection.

4. Select Revert to reset your selection.

Information

General, unchangeable information about the device is displayed in the Information section:

• Manufacturer: Manufacturer of the multiplexer device (Pepperl+Fuchs).

• Device ID: Type designation of the device.

• Device type ID: This number identifies the type of device and is unique depending on

the manufacturer. Together with the manufacturer ID, the device type ID can be used

to identify the device type uniquely.

• Serial number: The serial number of the device.

• Hardware revision: Hardware revision of the multiplexer master.

• Software revision: Software revision of the multiplexer master.

• Device revision: The revision of the devices supported.

• Date: The date on which the device parameters were last changed.

• Configuration changed: Indicates whether a parameter has been changed in

the configuration of the device, see chapter 7.2.4.

Identification

Identification information is displayed in the Identification section. This information can be

changed and saved by the user.

• Ta g : Tag for the identification of the multiplexer master.

• Descriptor: Description for the multiplexer master.

• Message: Communication without any special function which can be used freely by

the user (e. g. for identification).

2018-04

45

Page 46

HART Multiplexer System KFD*-HM*-16

Configuration

Figure 6.7 General window (device information)

46

2018-04

Page 47

HART Multiplexer System KFD*-HM*-16

Configuration

6.7.3 Parameterizing Communication

Displaying Communication Parameters

1. Use the mouse to double-click the multiplexer master KFD2-HMM-16 in

the project window.

2. In the editing window, open the Configuration > Communication menu.

The Communication window is displayed.

3. Click Apply to confirm your selection.

4. Select Revert to reset your selection.

The communication parameters between the host, HART multiplexer system, and field device

are displayed and set in the Communication menu:

HART communication 1 HART communication 2

Data request Cyclic data request

Cache data

(Command caching)

KFD0-HMM-16

1

2

3

4

5

6

7

8

1713 181620142115

19

Host

Computer-based

maintenance station

or process control system

HART multiplexer system

Field devices

Figure 6.8

Communication with the Multiplexer Master

In this case, the communication between the host and the HART multiplexer system

(HART communication 1) is described.

The Communication to host HART master (as field device) section displays the following

information about the device:

• Address: The RS-485 address of the multiplexer master is displayed here.

• Unique identifier: The unique, non-variable long address of the multiplexer master.

• HARTrevision: HART revision under which the multiplexer master is operated.

• Minimum number of preambles: Minimum number of preambles.

2018-04

47

Page 48

HART Multiplexer System KFD*-HM*-16

Configuration

Communication with the Field Devices

In this case, the communication between the HART multiplexer system and the field devices

(HART communication 2) is described.

The Communication to field devices (as HART master) section displays the following

information. This information can be changed and saved by the user.

• Master type: 2 HART masters may be connected to a HART signal loop, whereby

the parameterization must differentiate between the primary master and the

secondary master. The setting at this point indicates whether the multiplexer master

addresses the field devices as primary or secondary HART master.

• Retries on "Busy": Number of repeat attempts to establish communication

with the field device if the field device reports Busy.

• Retries on error: Number of repeat attempts to establish communication

with the field device if a fault occurs.

• Loop scan address range: This defines the address range in which the field devices on

the individual signal loops are searched for, see chapter 6.7.4:

• Scan address 0 only: The multiplexer master uses only address 0 to search for

connected devices.

• Scan addresses 0 to 15: The multiplexer master searches for all

polling addresses between 0 and 15 and identifies the first device to respond.

Figure 6.9 Communication window

48

2018-04

Page 49

HART Multiplexer System KFD*-HM*-16

Configuration

6.7.4 Command Caching Function

Cyclical Data Retrieval

With cyclical data retrieval, the HART multiplexer master periodically retrieves data from the

connected field devices and stores the data in its internal memory.

If the process control system queries the data of the field devices, this data can be forwarded

more quickly. The data is no longer read directly from the field device. Instead, it is read

directly from the memory of the multiplexer master. See chapter 6.7.3.

Displaying the Command Caching Function Settings

1. Use the mouse to double-click the multiplexer master KFD2-HMM-16 in

the project window.

2. In the editing window, open the Configuration > Command caching menu.

The Command caching window is displayed.

3. Click Apply to confirm your selection.

4. Select Revert to reset your selection.

The command parameters for the multiplexer master are displayed and set in the

Command caching menu:

• Mode: This switches the Command caching function on or off.

• Disabled: The function is switched off.

• Default caching: The function is switched on. This is the default setting.

The commands selected are cached, see below.

• HARTcommand: Here you can use a drop-down menu to select which values are to

be read out from the field devices:

• Command1-ReadPrimaryVariable: Only the primary variable of the field device

is read out.

• Command2-ReadLoopCurrentandPercentOfRange: The current value in mA

is read out.

• Command3-ReadDynamicVariablesandLoopCurrent: All variables of

the field device are read out.

2018-04

49

Page 50

HART Multiplexer System KFD*-HM*-16

Configuration

Figure 6.10 Command caching window

50

2018-04

Page 51

HART Multiplexer System KFD*-HM*-16

Configuration

6.7.5 Active Multiplexer Devices

Selecting Active Multiplexer Devices

1. Use the mouse to double-click the multiplexer master KFD2-HMM-16 in

the project window.

2. In the editing window, open the Configuration > Activated modules menu.

The Activated modules window is displayed.

3. Click Apply to confirm your selection.

4. Select Revert to reset your selection.

In the Activated modules window, select the active multiplexer slaves for each

multiplexer master. By default, only the master is activated. Select the connected

multiplexer slaves depending on the expansion level.

• Click Select all to select all multiplexer devices.

• Click Select none to select no multiplexer devices.

• With a single click, you can place or remove individual checkmarks in the list.

The checkmarks specify the active multiplexer devices.

Note!