Page 1

Your automation, our passion.

K23-SSI/Rx/IU-C

Signal converter

Manual

Page 2

K23-SSI/Rx/IU-C

The latest version of the General Terms of Supply for Products

and Services in the Electronics Industry set out by the German

Electrical and Electronic Manufacturers' Association (ZVEI) and

the "Extended Reservation of Proprietorship" supplementary

clause apply to this document.

2

Page 3

| TABLE OF CONTENTS

Table of Contents

1. Safety and Responsibility ......................................................................................................... 5

1.1 General Safety Information ................................................................................................ 5

1.2 Intended Use ..................................................................................................................... 5

1.3 Installation ......................................................................................................................... 6

1.4 Cleaning, Care, and Maintenance Instructions .................................................................. 6

2. General Information .................................................................................................................. 7

2.1 Operating Modes ............................................................................................................... 7

2.2 Function Diagram .............................................................................................................. 7

2.3 Power LED / Error Messages ............................................................................................ 7

3. Electrical Connections .............................................................................................................. 9

3.1 DC Voltage Supply (X1)..................................................................................................... 9

3.2 Auxiliary Voltage Output (X2) ............................................................................................ 9

3.3 Incremental Rotary Encoder Input (X2) ............................................................................ 10

3.4 Absolute Rotary Encoder Input (X2) ................................................................................ 12

3.5 Start/Stop Encoder Inputs (X2) ........................................................................................ 13

3.6 Control Inputs (X5) .......................................................................................................... 14

3.7 Analog Output (X4) .......................................................................................................... 16

3.8 Serial Interface (X3) ......................................................................................................... 16

3.9 Control Outputs (X6) ........................................................................................................ 17

3.10 USB Interface (X7) .......................................................................................................... 18

4. Operating Software OS6.0 / OS10.0 ....................................................................................... 19

4.1 General Menu .................................................................................................................. 22

4.2 Frequency Mode ............................................................................................................. 25

4.3 Counter Mode .................................................................................................................. 31

4.4 SSI Mode ........................................................................................................................ 33

4.5 Start/Stop Mode .............................................................................................................. 36

4.6 Preselection Values ......................................................................................................... 40

4.7 Preselection 1 Menu ........................................................................................................ 41

4.8 Preselection 2 Menu ........................................................................................................ 45

4.9 Preselection 3 Menu ........................................................................................................ 46

4.10 Preselection 4 Menu ........................................................................................................ 47

4.11 Preselection 5 Menu ........................................................................................................ 49

4.12 Preselection 6 Menu ........................................................................................................ 50

4.13 Serial Menu ..................................................................................................................... 51

4.14 Analog Menu ................................................................................................................... 54

4.15 Command Menu .............................................................................................................. 56

4.16 Linearization Menu .......................................................................................................... 59

3

Page 4

5. Appendix ................................................................................................................................. 60

5.1 Reading Out Data via Serial Interface .............................................................................. 60

5.2 Modbus RTU Interface ..................................................................................................... 61

5.2.1 Parameter Settings ................................................................................................... 61

5.2.2 Read Holding Registers and Write Multiple Registers ............................................... 62

5.2.3 Read Coils and Write Single Coil .............................................................................. 64

5.2.4 Diagnostics ............................................................................................................... 65

5.3 Parameter List / Serial Codes .......................................................................................... 65

5.4 Serial Codes of the Commands ....................................................................................... 74

5.5 Linearization .................................................................................................................... 74

5.6 Reading in the SSI Value ................................................................................................. 77

5.7 Operating Modes / OP Modes of the Start/Stop Interface ................................................. 81

5.8 Dimensions ...................................................................................................................... 83

4

Page 5

| SAFETY AND RESPONSIBILITY

1. Safety and Responsibility

1.1 General Safety Information

This description is an essential part of the device and contains important

information regarding installation, function and use. Failure to observe these

instructions may result in damage or impair the safety of people and attachments.

Please read this description carefully and observe all safety and warning

messages before commissioning the device for the first time. Keep this

description for future reference.

A prerequisite for using this device description is that the relevant personnel have

the appropriate qualifications. The device may be installed, configured,

commissioned and maintained only by a trained electrician.

Exclusion of liability: The manufacturer is not liable for any personal injury or

property damage that may occur as a result of improper installation,

commissioning, use or servicing, or due to human misinterpretations or errors

within this device description. In addition, the manufacturer reserves the right to

make technical changes to the device or description at any time without prior

notice. Therefore, possible discrepancies between the device and the description

cannot be ruled out.

The safety of the plant or of the overall system in which this device is integrated is

the responsibility of the installer of the plant or the overall system.

All general, country-specific, and application-specific safety regulations and

standards must be observed and followed during installation, operation, and

maintenance work.

If the device is used in processes in which a possible failure or incorrect

operation can result in damage to the plant or personal injury, appropriate

precautions must be taken to ensure that such consequences are safely

prevented.

1.2 Intended Use

This device is intended for use in industrial machinery and plants only. Any other

use is not deemed to be in compliance with the provisions and is solely the

responsibility of the user. The manufacturer is not liable for damage caused by

improper use. The device may only be installed in the correct manner and be

used and operated in a technically perfect condition—in accordance with the

technical data. The device is not suitable for explosion-protected areas or in

areas of application not included in DIN EN 61010-1.

5

Page 6

| SAFETY AND RESPONSIBILITY

1.3 Installation

The device may only be installed and operated in an environment that meets the

permissible temperature range. Adequate ventilation must be ensured and the

device must not have any direct contact with hot or aggressive gases or liquids.

The unit must be disconnected from all voltage sources prior to installation and

before any maintenance work. It must also be ensured that no further danger can

arise from touching the disconnected voltage sources.

Devices that are supplied with AC voltage may only be connected to the lowvoltage network via switches or circuit breakers. This switch must be positioned

close to the device and must have a marking that identifies it as a disconnector.

Input and output cables for extra-low voltages must be separated from

dangerous, current-carrying cables by means of double or reinforced insulation

(SELV circuits).

All cables and insulation selected must correspond to the intended voltage and

temperature range. Device and country-specific standards must also be

observed, which apply to the cables in terms of design, shape, and quality. For

information on permissible cable cross sections for the screw terminal

connections, refer to the technical data.

Before commissioning, all connections and cables must be checked for a solid fit

in the screw terminals. All screw terminals (including unused ones) must be

screwed in as far as they will go to ensure that they are securely fastened and

cannot come loose in the event of mechanical vibrations.

Overvoltages at the connections to the device must be limited to the values of the

gas group II overvoltage category.

The general standards for switch cabinet construction in the machinery industry

and the manufacturer's specific shielding regulations apply with regard to

installation, wiring, ambient conditions, and shielding and grounding of supply

cables.

1.4 Cleaning, Care, and Maintenance Instructions

To clean the front, use only a soft, slightly damp cloth. No cleaning work is

intended or required for the rear of the device. Unscheduled cleaning is the

responsibility of the competent maintenance personnel or the relevant technician.

During normal operation, the device does not require any maintenance

procedures. In the event of unexpected problems, errors or malfunctions, the

device must be sent to the manufacturer to be checked and repaired if

necessary. Unauthorized opening and repair can result in impairment or even

failure of the protective measures supported by the device.

6

Page 7

2. General Information

The device is designed as a signal converter with control inputs and outputs. Its

extensive functions make it suitable for universal use.

2.1 Operating Modes

In general, all functions must be configured in the parameter menu. The device

can be used in the following operating modes:

Operation as a frequency converter for incremental input signals

Operation as a position converter/counter for incremental input signals

Operation as an absolute value converter for SSI signals

2.2 Function Diagram

| GENERAL INFORMATION

2.3 Power LED / Error Messages

The device has a green LED on the front film. This lights up continuously as soon

as the supply voltage of the device has been established. If an error occurs, the

LED flashes in a 1-Hz cycle. The analog output is also modulated with 0 V or

0/4 mA. When there is no longer an error, the LED automatically lights up

continuously again and the analog output reacts once more to the result currently

pending.

The exact error can be read out on the user interface (OS 6.0) via the serial

interface. ( Variable: Error_Status, Code: ";3"). See Chapter 4.

7

Page 8

| GENERAL INFORMATION

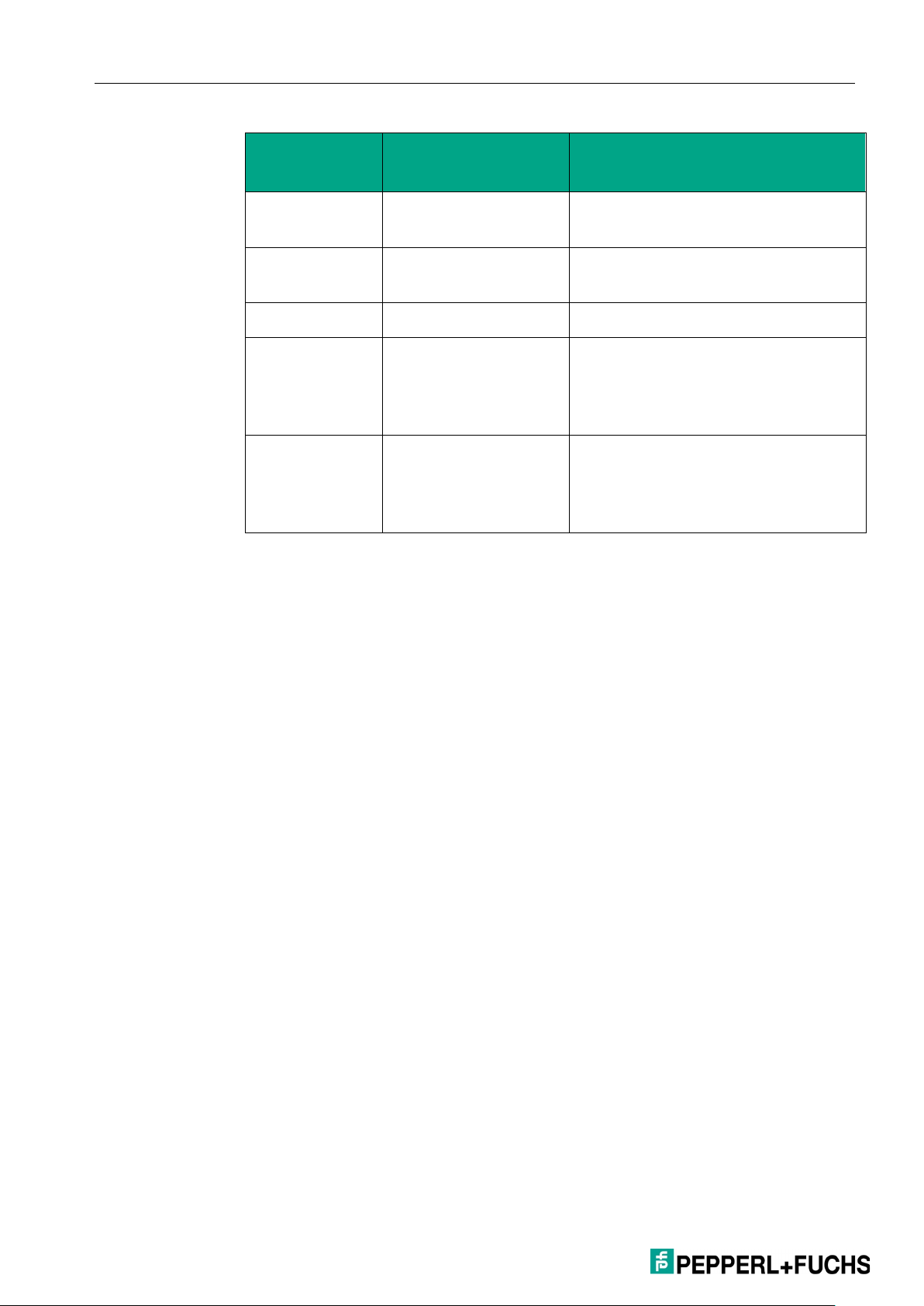

Error code

(Error_Status)

Error name

Error description

0x00000001

Maximum Value

Measured value is greater than

0x00000002

Minimum Value

Measured value is less than 0x00000004

SSI Encoder Error

SSI Error bit set

0x00000010

Frequency (Input A)

The maximum or minimum

0x00000020

Frequency (Input B)

The maximum or minimum

The individual error codes are explained in more detail below:

99,999,999

99,999,999

out of range

permissible input frequency at input

A was exceeded or not reached with

the exponential filter setting used.

out of range

permissible input frequency at input

B was exceeded or not reached with

the exponential filter setting used.

8

Page 9

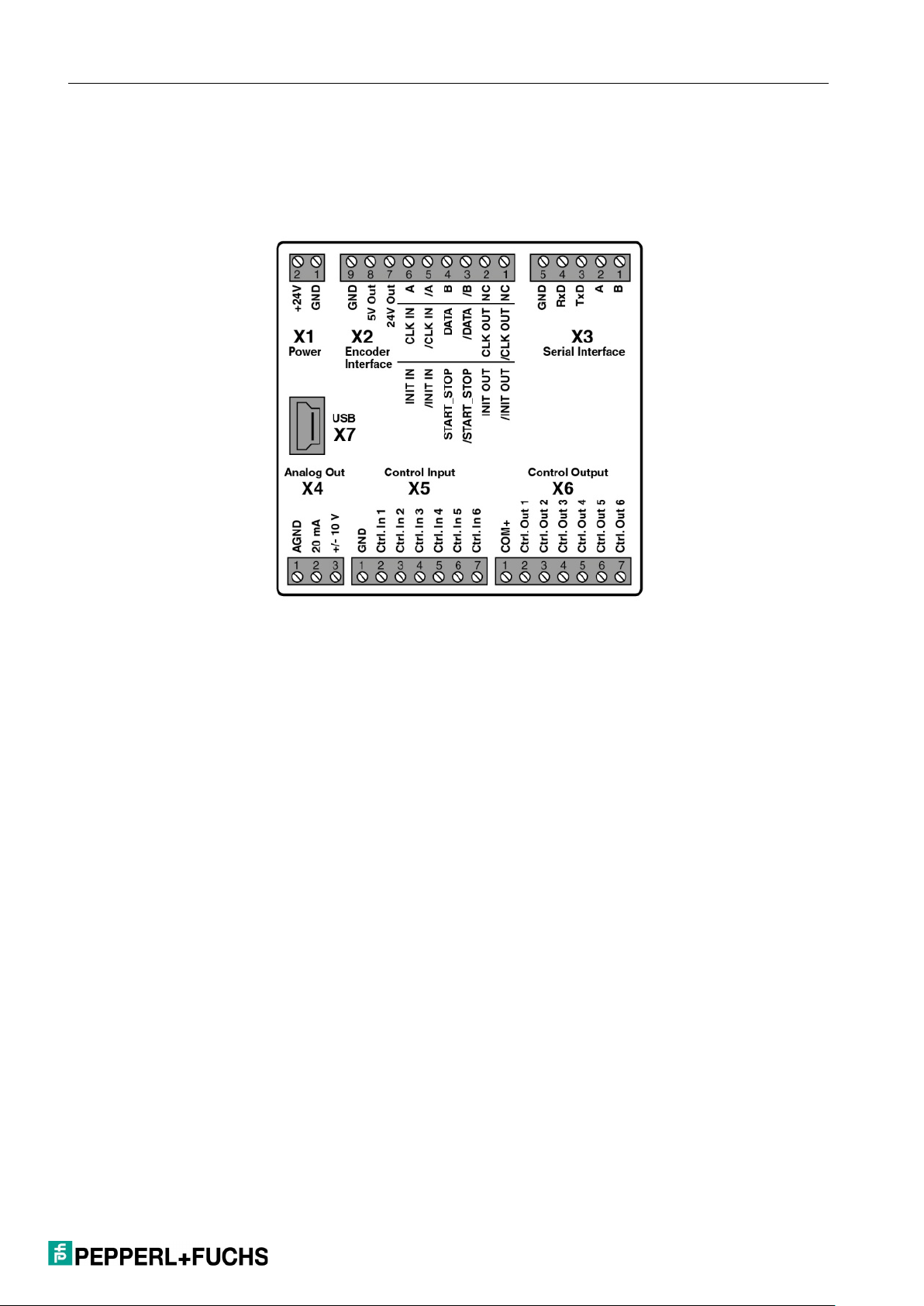

3. Electrical Connections

The terminals should be tightened with a slotted screwdriver (blade width 2 mm).

| ELECTRICAL CONNECTIONS

3.1 DC Voltage Supply (X1)

The device can be supplied with a DC voltage between 18 and 30 V DC via

terminal X1 pins 1 and 2. The current consumption depends, among other things,

on the level of the supply voltage and the settings and is approx. 50 mA, plus the

rotary encoder current taken from the auxiliary voltage output.

All GND connections are connected internally.

3.2 Auxiliary Voltage Output (X2)

Two auxiliary voltages 24 V DC and 5 V DC are available as encoder/sensor

supply at terminal X2 pins 7, 8, and 9. The 24-V DC output voltage depends on

the device supply (see Technische Daten).

9

Page 10

| ELECTRICAL CONNECTIONS

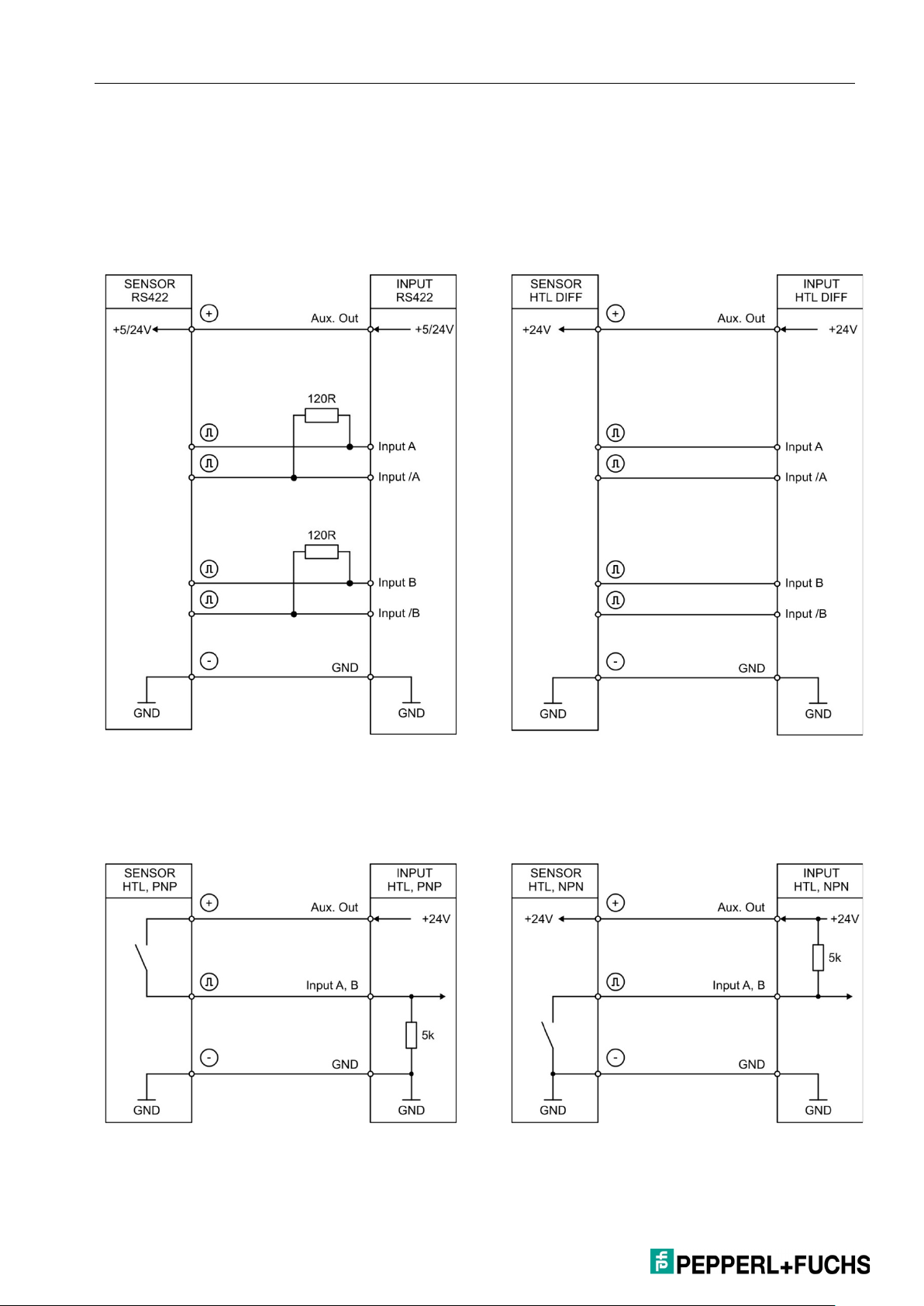

RS422

HTL DIFFERENTIAL

3.3 Incremental Rotary Encoder Input (X2)

A connection for various incremental signals is available at terminal X2 pins 3, 4,

5, and 6.

HTL PNP

HTL NPN

10

Page 11

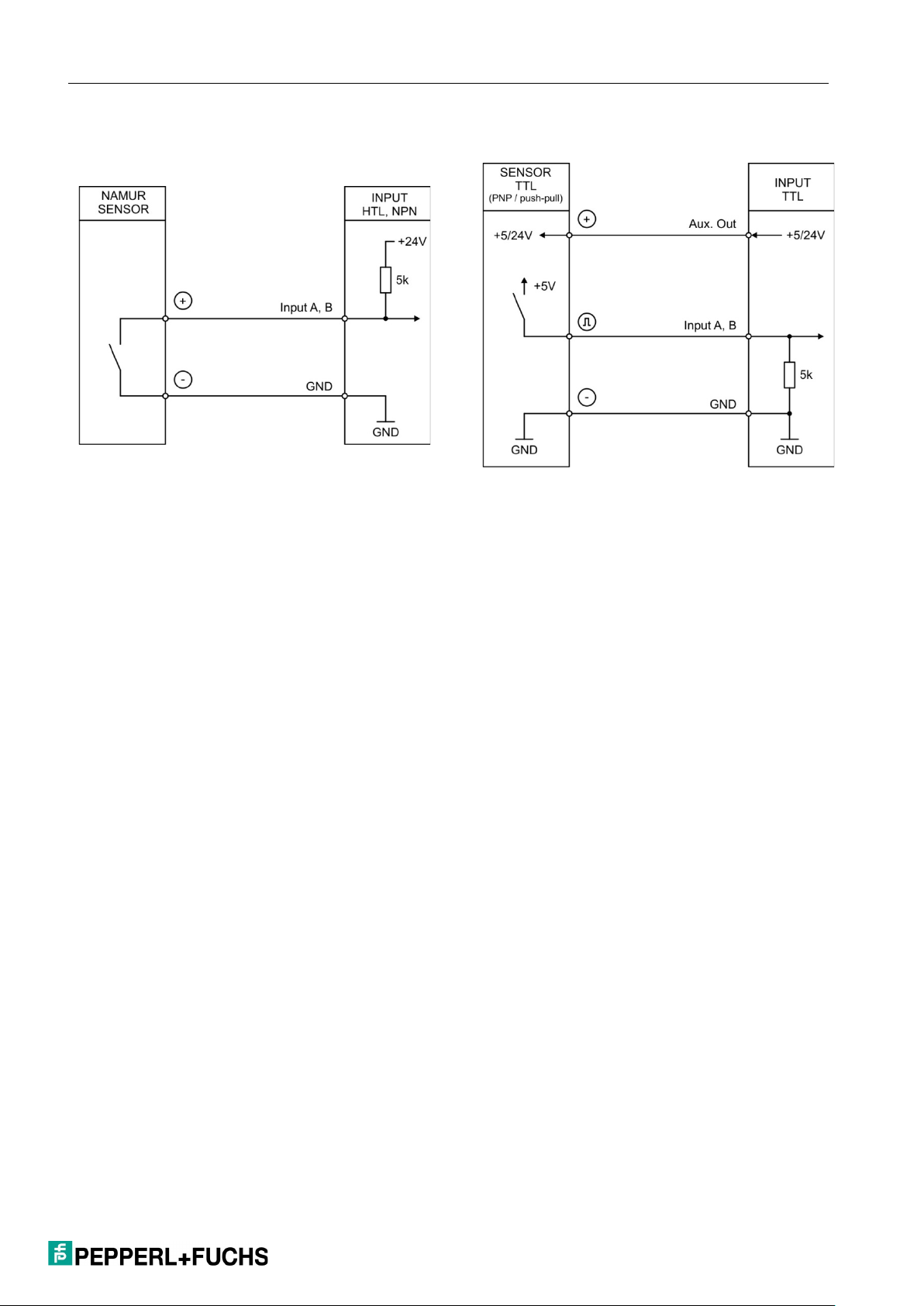

| ELECTRICAL CONNECTIONS

HTL NPN (NAMUR)

TTL (PNP)

In general, open PNP inputs are "LOW" and open NPN inputs are "HIGH."

The input stages are designed for electronic pulse generators.

Note for mechanical switching contacts:

If, in exceptional cases, mechanical contacts are to be used as a pulse source, a

commercially available external capacitor of approx. 10 µF must be installed at

the terminals between GND(-) and the corresponding input (+). This attenuates

the maximum input frequency to approximately 20 Hz and suppresses bouncing.

11

Page 12

| ELECTRICAL CONNECTIONS

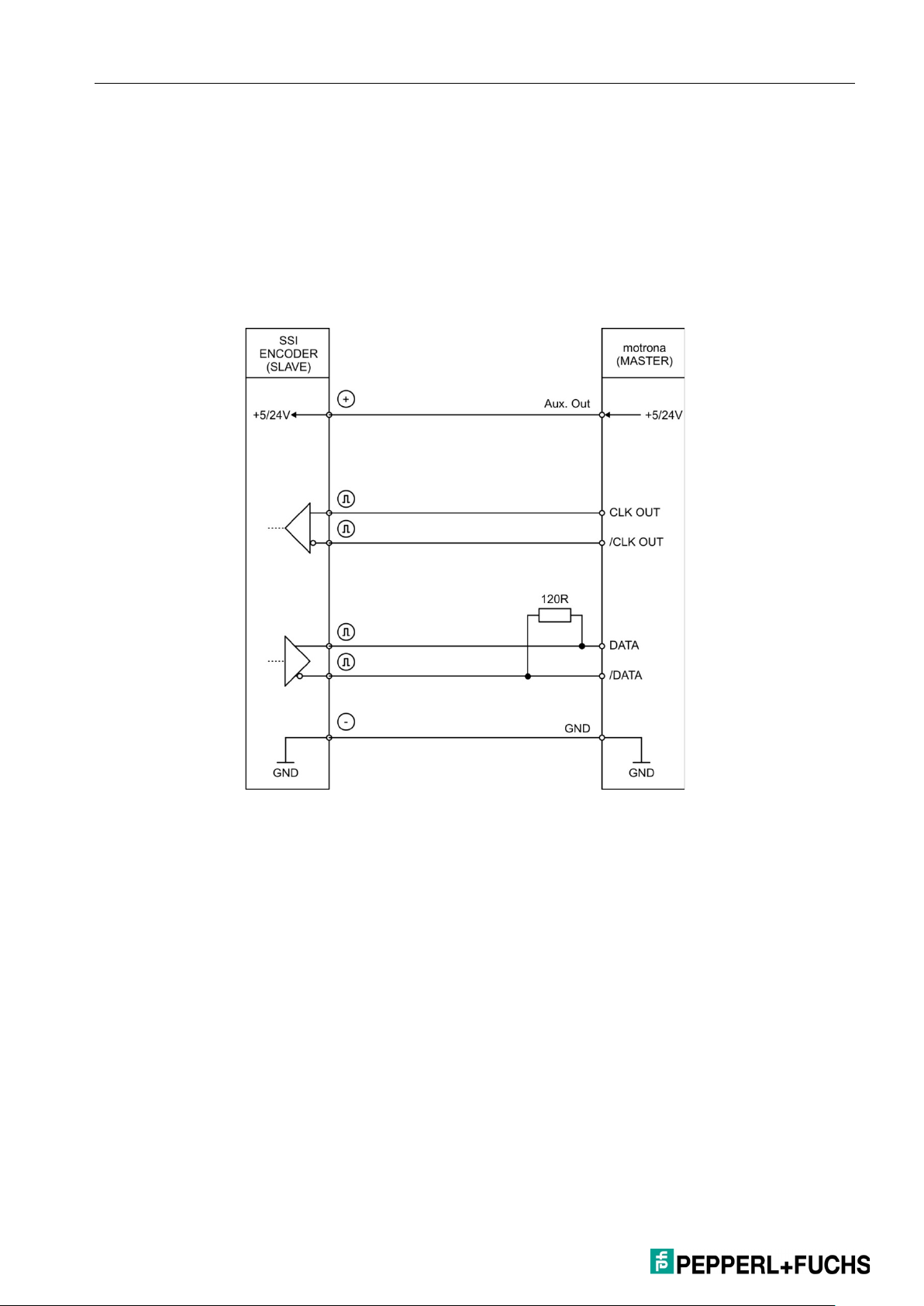

3.4 Absolute Rotary Encoder Input (X2)

The SSI connection is available for managing operation at terminal X2 pins 1, 2,

3, 4.

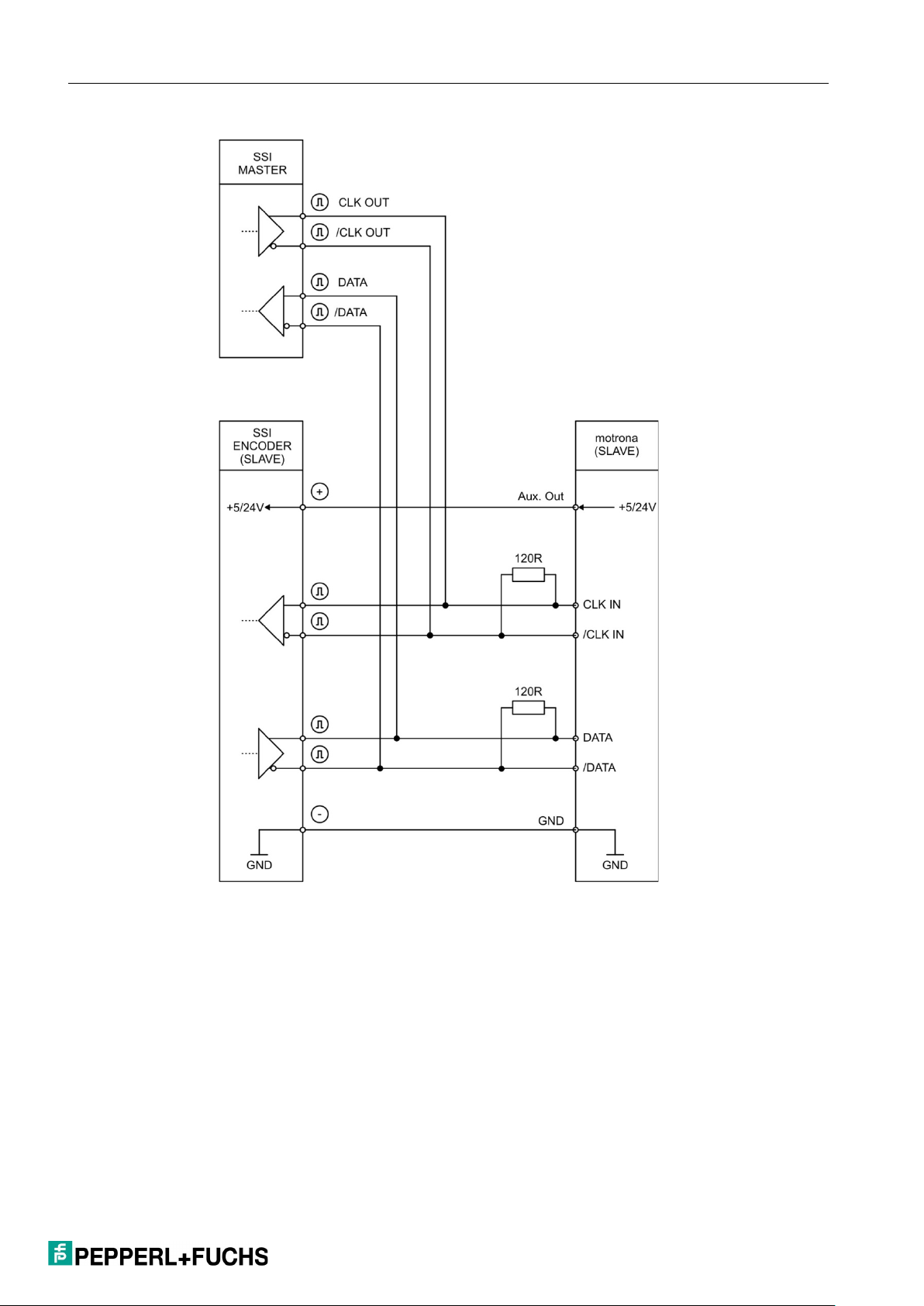

The SSI connection is available for managed operation at terminal X2 pins 3, 4, 5,

6.

Connection for managing operation:

12

Page 13

Connection for managed operation:

| ELECTRICAL CONNECTIONS

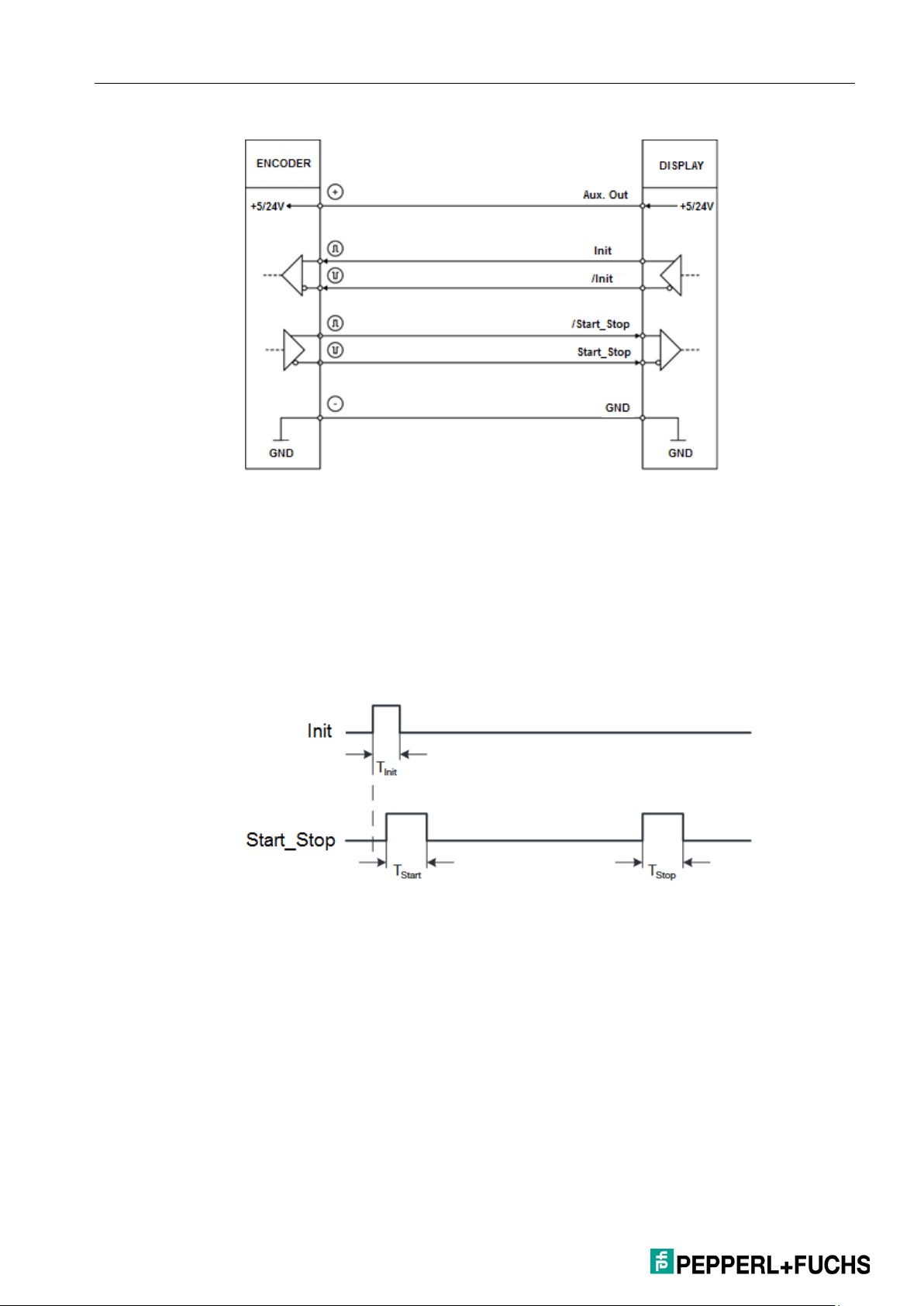

3.5 Start/Stop Encoder Inputs (X2)

The RS422 connection is available for the init pulse in managing operation at

terminal X2 pins 1+2. The device generates the init pulse.

The RS422 connection is available for the init pulse in managed operation at

terminal X2 pins 5+6. The init pulse is generated by an external device.

The RS422 connection is available for the Start/Stop pulse at terminal X2 pins

3+4.

13

Page 14

| ELECTRICAL CONNECTIONS

Connection of the RS422 signals

DPI measurement mode:

In managing operation, the init pulse is sent at regular intervals (=SAMPLING

TIME [ms]) on the init line to the displacement transducer, the rising edge of

which triggers a measurement.

The pulse duration of the init pulse can be set using the "INIT pulse TIME (µs)"

parameter.

T

: 1 µs … 9 µs (adjustable)

Init

T

: ~3 µs … 5 µs

Start

T

: ~3 µs … 5 µs

Stop

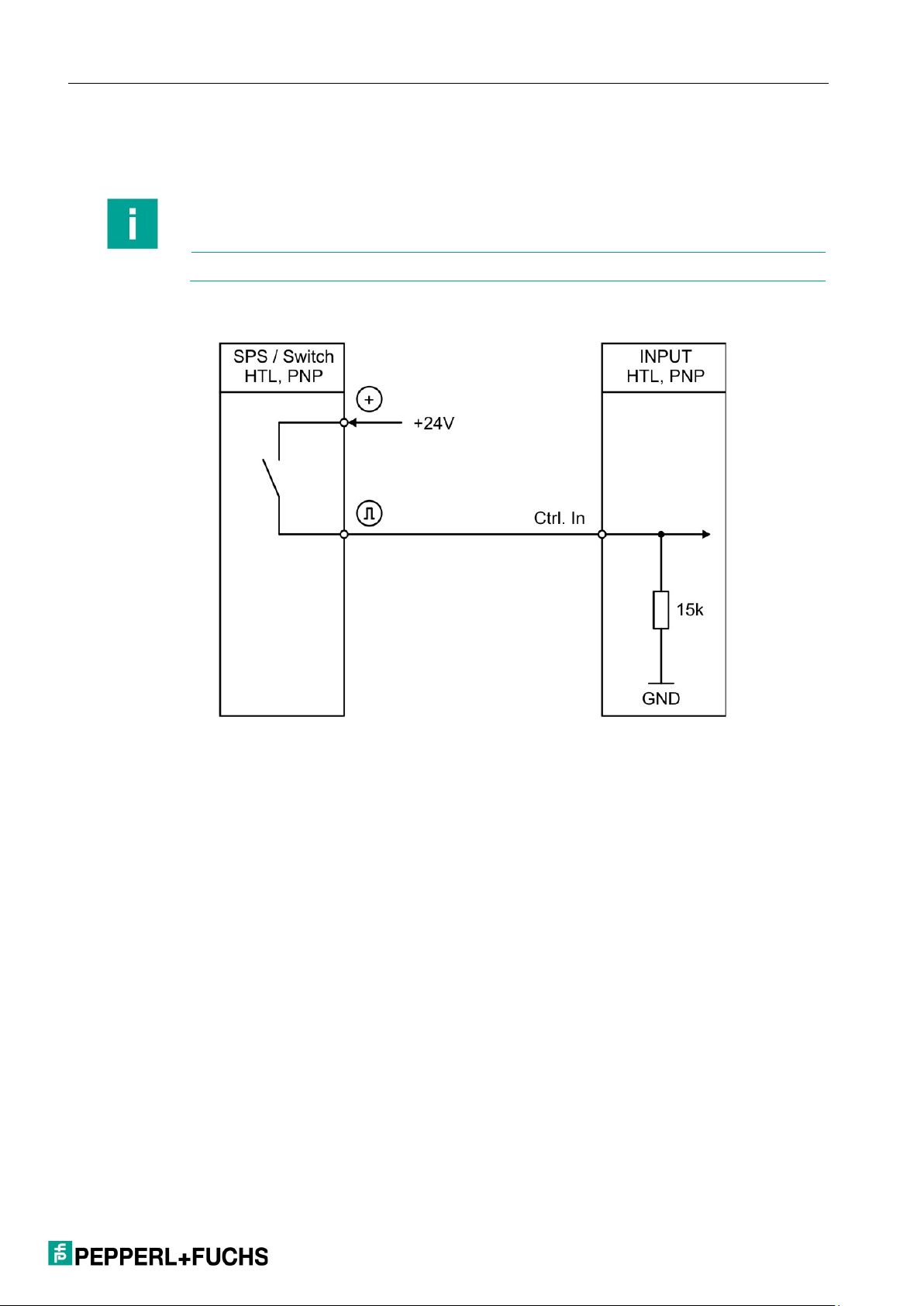

3.6 Control Inputs (X5)

Six control inputs with HTL-PNP characteristics are available at terminal X5 pins

2, 3, 4, 5, 6, and 7.

Control input 1 (Ctrl. In 1) to control input 5 (Ctrl. In 5) are freely configurable in

the COMMAND menu and are used for externally triggered functions such as

releasing the self-locking mechanism, resetting the measurement result, or for

14

Page 15

| ELECTRICAL CONNECTIONS

Note

An HTL pulse (rising edge) at Ctrl. In 6 resets the device to factory settings.

teaching the preselection values or the analog output.

Control input 6 (Ctrl. In 6) is used exclusively for resetting the device parameters

to the "default" values and is therefore not freely configurable.

Connection of the control inputs:

Generally, open control inputs are "LOW."

The input stages are designed for electronic control signals.

Note for mechanical switching contacts:

With mechanical contacts as a pulse source, a commercially available external

capacitor of approx. 10 µF must be installed between GND(-) and the

corresponding input (+). This attenuates the maximum input frequency to

approximately 20 Hz and suppresses bouncing.

15

Page 16

| ELECTRICAL CONNECTIONS

CAUTION!

Parallel operation of voltage and current output is not permitted!

3.7 Analog Output (X4)

A 16-bit analog output is available at terminal X4.

This output can be configured and scaled in the ANALOG MENU.

The following configuration is possible:

Voltage output: -10 V … +10 V

Current output: 0 mA … 20 mA

Current output: 4 mA … 20 mA

The analog output is proportional to the measurement result and refers to AGND

potential.

AGND and device GND are connected internally.

3.8 Serial Interface (X3)

A serial interface (RS232 or RS485) is available at terminal X3.

This interface can be configured in the SERIAL MENU.

The RS232 or RS485 interface can be used as follows:

For parameterization of the device during commissioning

For changing parameters during operation

For reading out actual values via PLC or PC

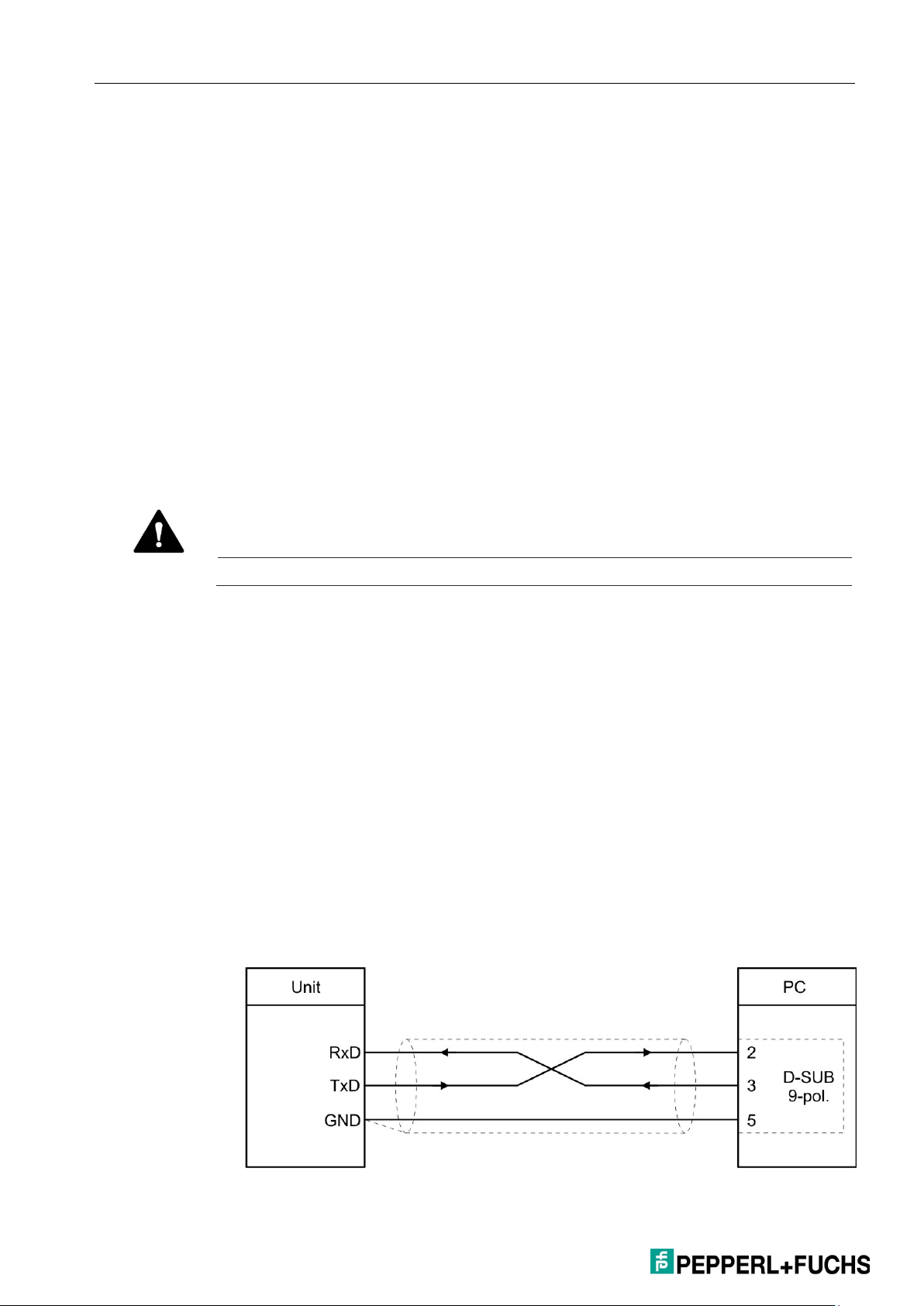

Connection of the RS232 interface:

16

Page 17

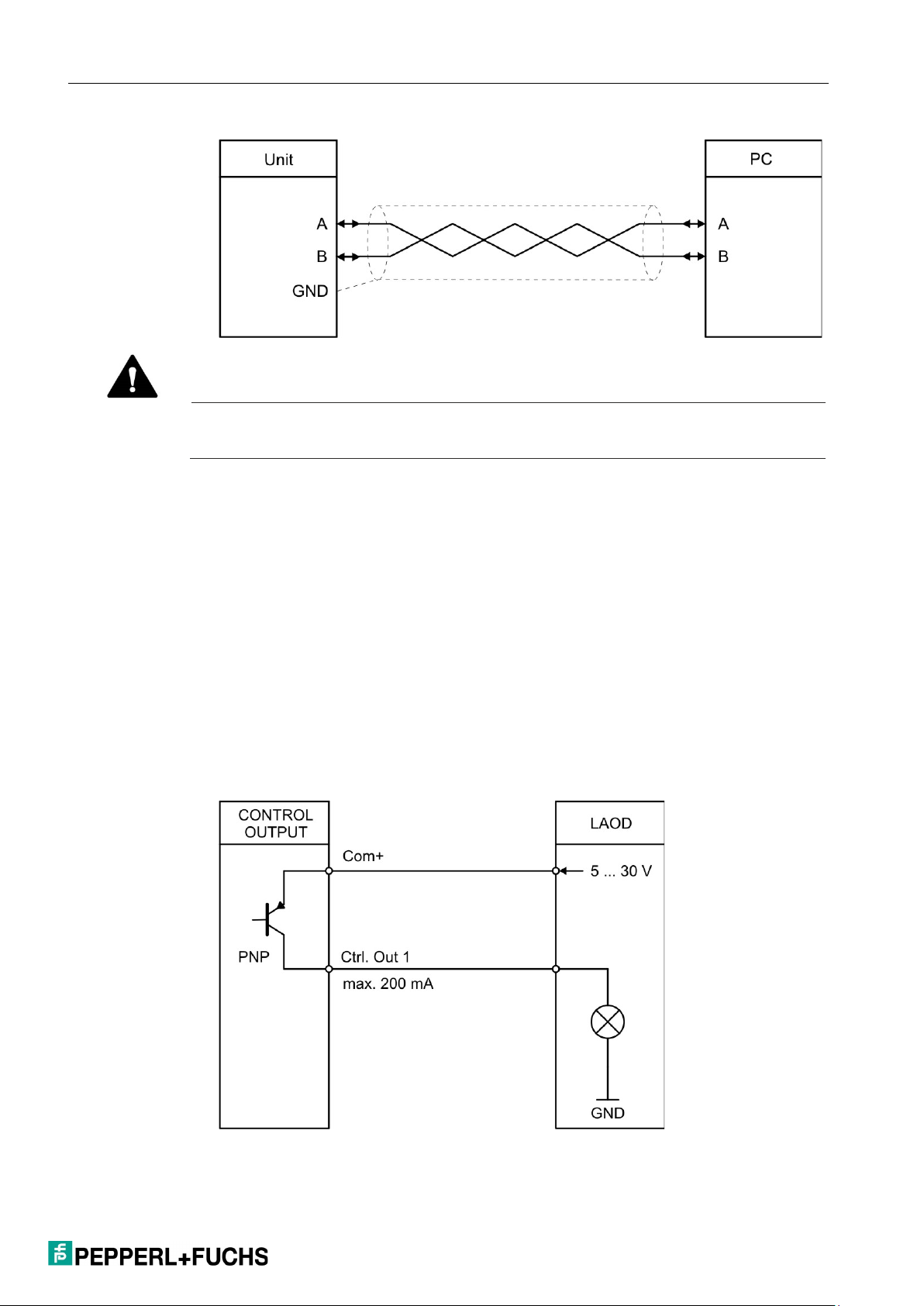

Connection of the RS485 interface:

CAUTION!

Parallel operation of RS232 and RS485 is not permitted!

Default values: 9600 baud, 7even1

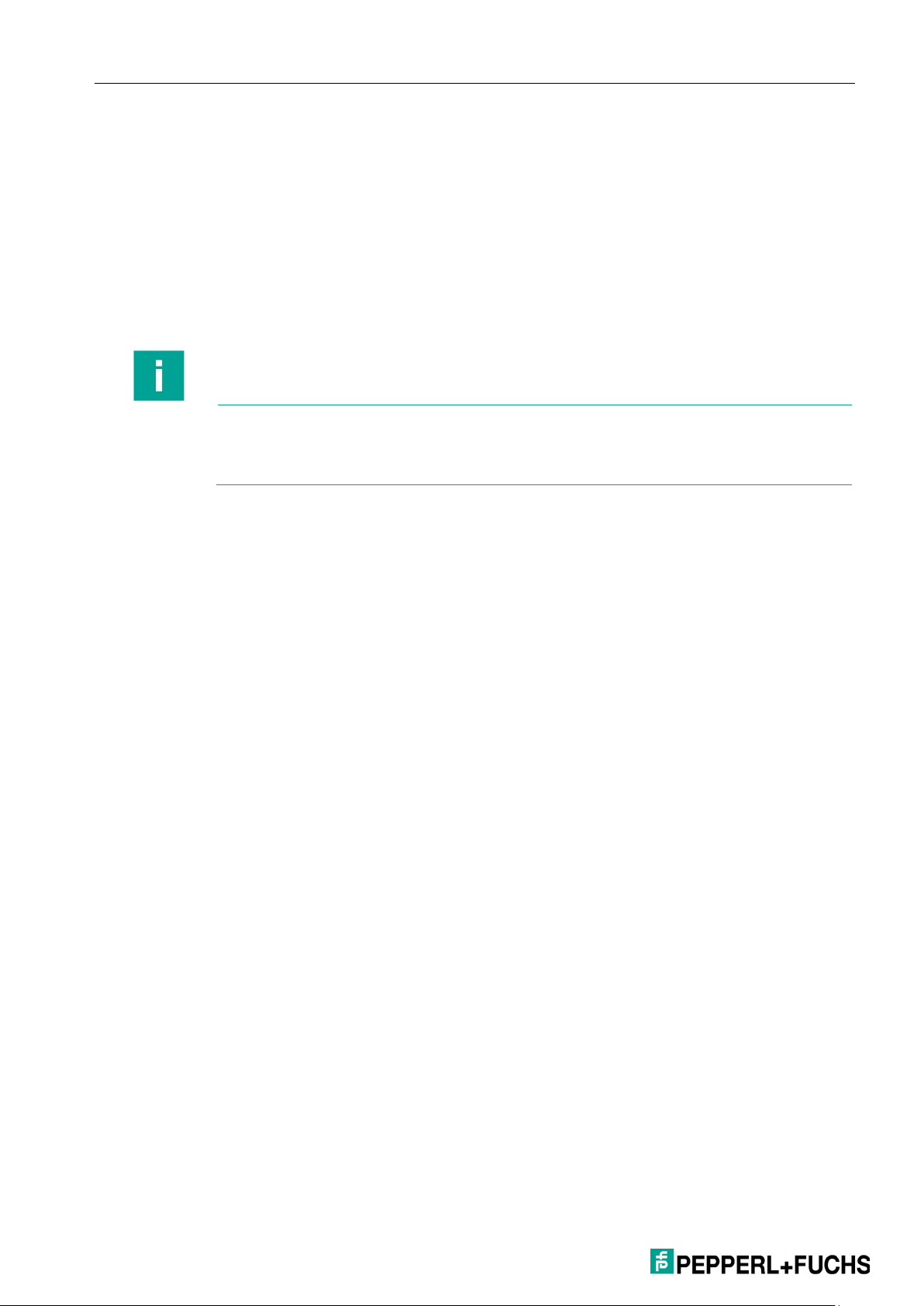

3.9 Control Outputs (X6)

| ELECTRICAL CONNECTIONS

Six control outputs are available at terminal X6 pins 2, 3, 4, 5, 6, and 7.

The switch conditions can be adjusted accordingly in the PRESELECTION

MENU.

Outputs Ctrl. Out 1–6 are quick PNP control outputs.

The switching voltage is determined by the voltage supplied to terminal X6 pin 1

(COM+).

External attenuation measures are recommended for switching inductive loads.

Connection of the control outputs:

17

Page 18

| ELECTRICAL CONNECTIONS

Note

The serial USB communication is carried out at a baud rate of "115200 baud" and a

serial data format of "

These values cannot be changed by the user!

3.10 USB Interface (X7)

A serial USB interface (mini USB) is available at terminal X7.

The USB interface can be used as follows:

For parameterization of the device during commissioning

For changing parameters during operation

For reading out actual values via PC

8none1."

18

Page 19

| OPERATING SOFTWARE OS6.0 / OS10.0

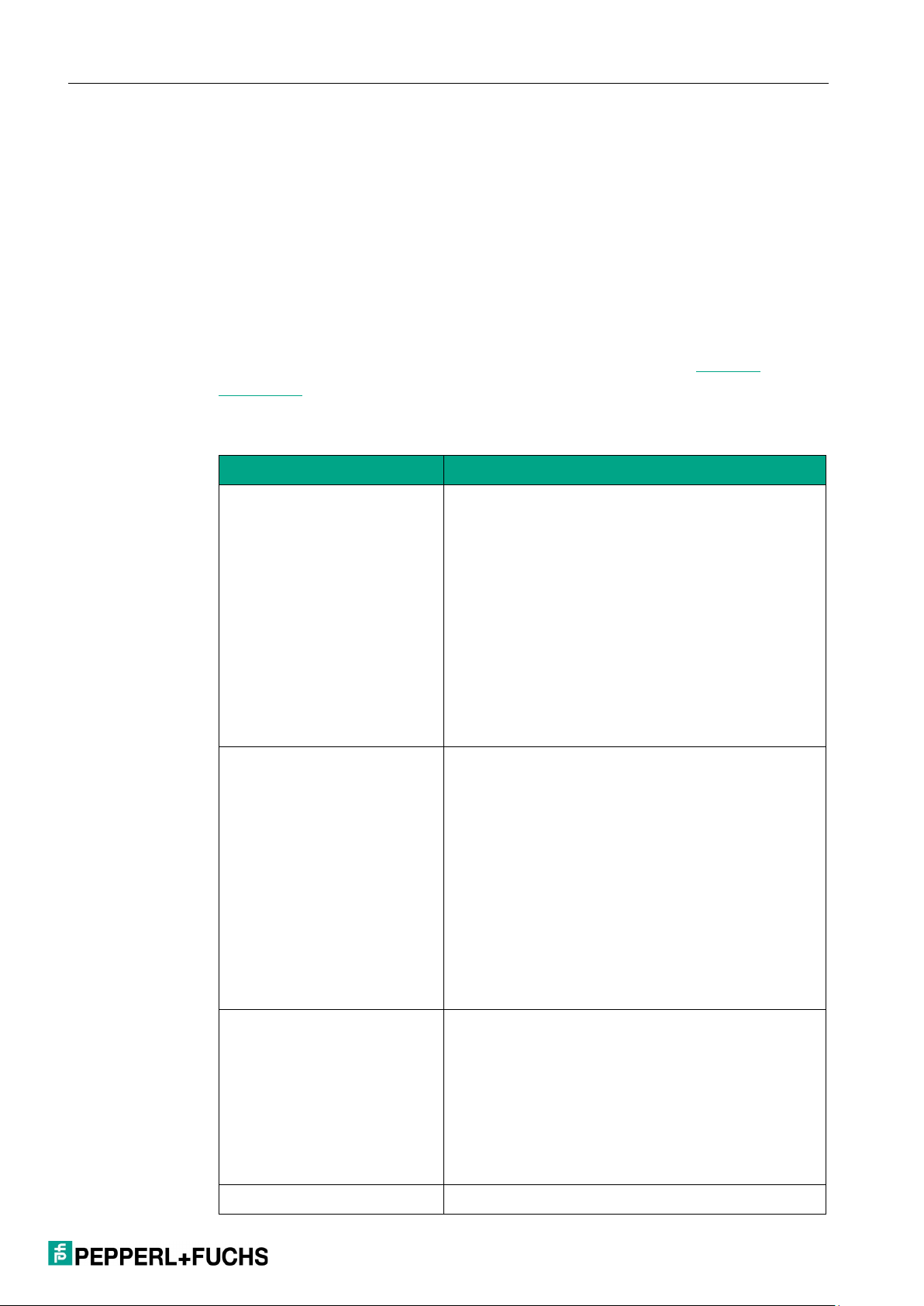

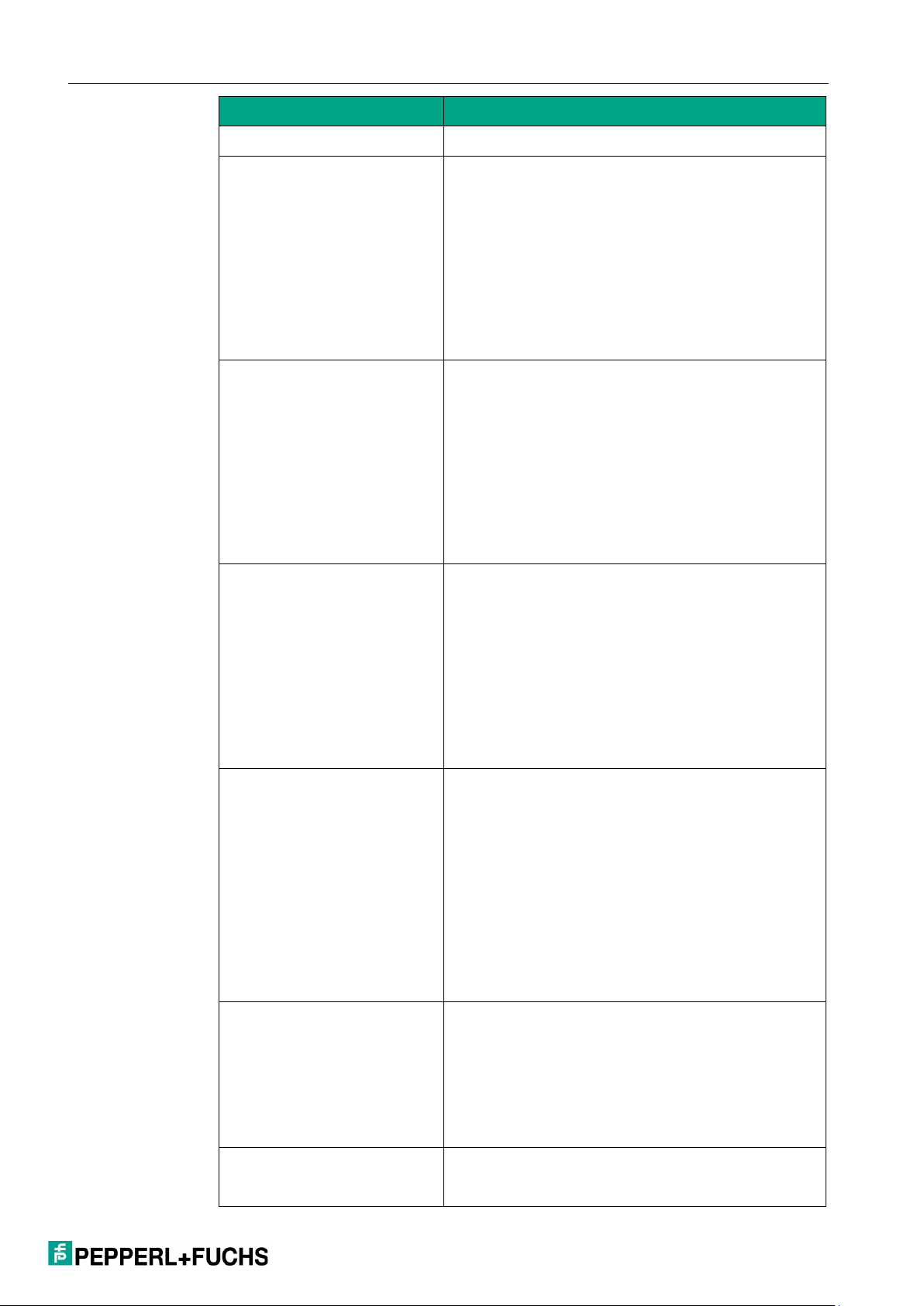

Menu

Parameter

GENERAL MENU

MODE

FACTORY SETTINGS

FREQUENCY MODE

FREQUENCY MODE

AVERAGE FILTER 2

COUNTER MODE

COUNT MODE

ROUND LOOP VALUE

SSI MODE

SSI MODE

4. Operating Software OS6.0 /

OS10.0

The device is parameterized:

via the serial interface using a PC and the OS6.0 operating software.

via the USB interface using a PC and the OS10.0 operating software.

The free operating software OS6.0 and OS10.0 can be found at

Fuchs.com

This section shows the overview of the individual menus and their parameters.

ENCODER PROPERTIES

ENCODER DIRECTION

FACTOR

DIVIDER

ADDITIVE VALUE

LINEARIZATION MODE

BACKUP MEMORY

FREQUENCY BASE

Pepperl-

SAMPLING TIME 1 (S)

WAIT TIME 1 (S)

STANDSTILL TIME 1 (S)

AVERAGE FILTER 1

SAMPLING TIME 2 (S)

WAIT TIME 2 (S)

FACTOR A

SET VALUE A

FACTOR B

SET VALUE B

19

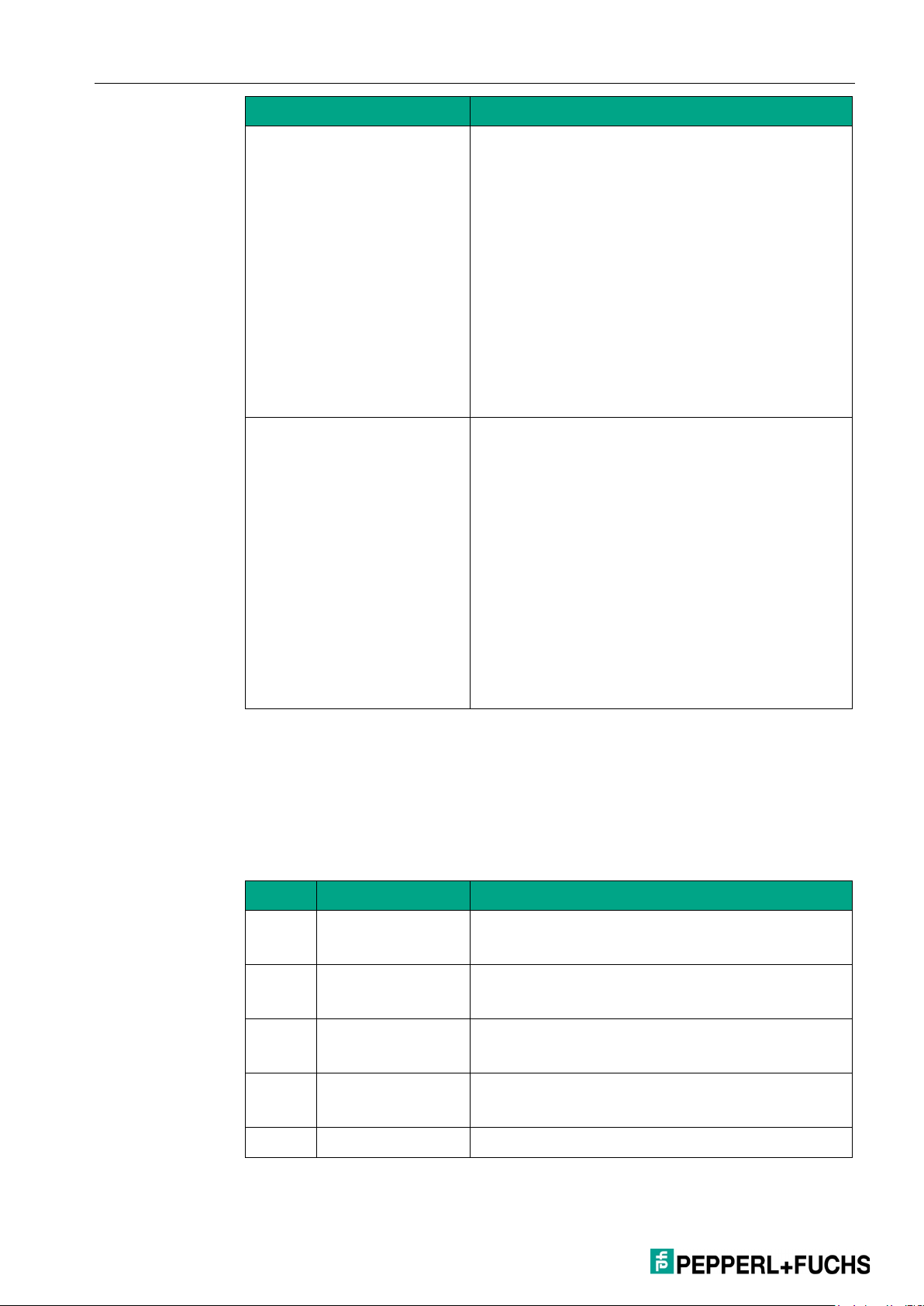

Page 20

| OPERATING SOFTWARE OS6.0 / OS10.0

Menu

Parameter

ENCODER RESOLUTION

ERROR POLARITY

PRESELECTION VALUES

PRESELECTION 1

PRESELECTION 6

PRESELECTION 1 MENU

MODE 1

STARTUP DELAY 1 (S)

PRESELECTION 2 MENU

MODE 2

PRESELECTION 3 MENU

MODE 3

DATA FORMAT

BAUD RATE

SSI ZERO

HIGH BIT

LOW BIT

SSI OFFSET

ROUND LOOP VALUE

SAMPLING TIME (S)

ERROR BIT

PRESELECTION 2

PRESELECTION 3

PRESELECTION 4

PRESELECTION 5

HYSTERESIS 1

PULSE TIME 1 (S)

OUTPUT TARGET 1

OUTPUT POLARITY 1

OUTPUT LOCK 1

HYSTERESIS 2

PULSE TIME 2 (S)

OUTPUT TARGET 2

OUTPUT POLARITY 2

20

OUTPUT LOCK 2

STARTUP DELAY 2 (S)

HYSTERESIS 3

PULSE TIME 3 (S)

OUTPUT TARGET 3

OUTPUT POLARITY 3

OUTPUT LOCK 3

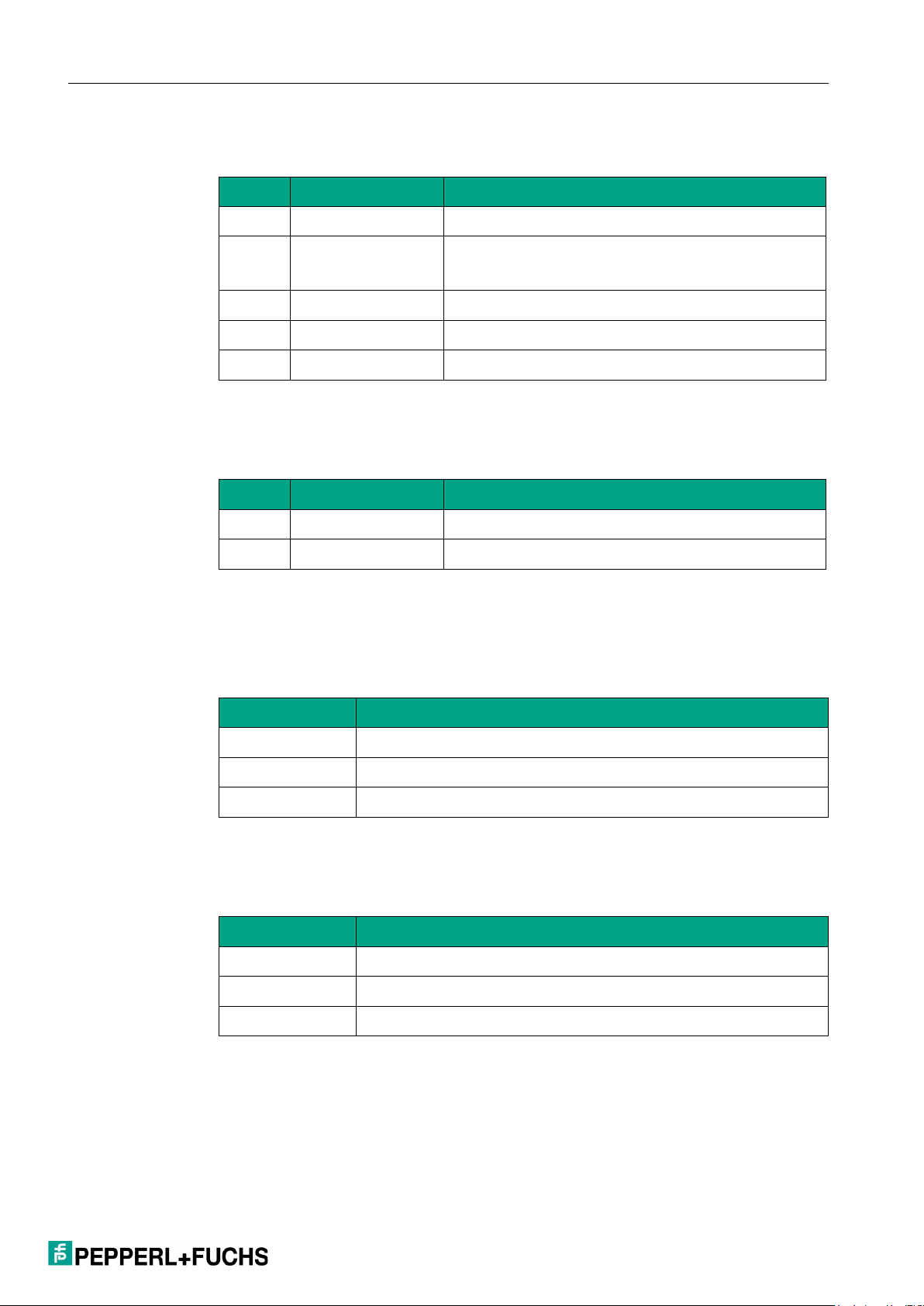

Page 21

| OPERATING SOFTWARE OS6.0 / OS10.0

Menu

Parameter

STARTUP DELAY 3 (S)

PRESELECTION 4 MENU

MODE 4

STARTUP DELAY 4 (S)

PRESELECTION 5 MENU

MODE 5

STARTUP DELAY 5 (S)

PRESELECTION 6 MENU

MODE 6

STARTUP DELAY 6 (S)

SERIAL MENU

UNIT NUMBER

MODBUS

ANALOG MENU

ANALOG FORMAT

COMMAND MENU

INPUT 1 ACTION

HYSTERESIS 4

PULSE TIME 4 (S)

OUTPUT TARGET 4

OUTPUT POLARITY 4 (S)

OUTPUT LOCK 4

HYSTERESIS 5

PULSE TIME 5 (S)

OUTPUT TARGET 5

OUTPUT POLARITY 5

OUTPUT LOCK 5

HYSTERESIS 6

PULSE TIME 6 (S)

OUTPUT TARGET 6

OUTPUT POLARITY 6

OUTPUT LOCK 6

SERIAL BAUD RATE

SERIAL FORMAT

SERIAL INIT

SERIAL PROTOCOL

SERIAL TIMER (S)

SERIAL VALUE

ANALOG START

ANALOG END

ANALOG GAIN (%)

ANALOG OFFSET (%)

INPUT 1 CONFIG

21

Page 22

| OPERATING SOFTWARE OS6.0 / OS10.0

Menu

Parameter

INPUT 2 ACTION

LINEARIZATION MENU

P1(X)

Value

Designation

Function

0

NOT DEFINED

Operating mode: Not defined, modulation and

measurement results are zero

1

FREQUENCY

Operating mode: Frequency converter,

2

COUNTER

Operating mode: Counter, incremental signals

3

SSI

Operating mode: Absolute value converter, SSI

4

START/STOP

Operating mode: Start/Stop interface converter

INPUT 2 CONFIG

INPUT 3 ACTION

INPUT 3 CONFIG

INPUT 4 ACTION

INPUT 4 CONFIG

INPUT 5 ACTION

INPUT 5 CONFIG

INPUT 6 ACTION (FACTORY SETTINGS)

INPUT 6 CONFIG (RISING EDGE)

P1(Y)

P2(X)

4.1 General Menu

MODE (operating mode)

This parameter defines which measurement function (operating mode/mode) the

device should fulfill.

P2(Y)

…

…

P23(X)

P23(Y)

P24(X)

P24(Y)

22

incremental signals (replaces FU252)

(replaces ZU252)

signals (replaces IV251)

Page 23

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Designation

Function

0

RS422

RS422 standard

HTL

DIFFERENTIAL

2

HTL PNP

PNP (switching to +)

3

HTL NPN

NPN (switching to -)

4

TTL PNP

TTL PNP (switching to +)

Value

Designation

Function

0

FORWARD

Forward

1

REVERSE

Backward

Value

Function

-99999999

Smallest value

1

Default value

99999999

Largest value

Value

Function

-99999999

Smallest value

1

Default value

99999999

Largest value

ENCODER PROPERTIES

This parameter defines the characteristics of the incremental input.

1

HTL differential

ENCODER DIRECTION

This parameter reverses the direction of counting and/or travel.

FACTOR (multiplication factor)

This parameter defines the factor by which the measurement result is

multiplied.

DIVIDER (division factor)

This parameter defines the divisor by which the measurement result is divided.

23

Page 24

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Function

-99999999

Smallest value

0

Default value

99999999

Largest value

Value

Designation

Function

0

OFF

No linearization

1

1 QUADRANT

Linearization in the first quadrant

2

4 QUADRANT

Linearization in all four quadrants

Value

Designation

Function

0

NO

No retentive memory

1

YES

Retentive memory active. Stores the actual

Value

Designation

Function

0

NO

The factory settings are not loaded

1

YES

The factory settings are loaded

ADDITIVE VALUE (additive constant)

This parameter defines an additive constant, which is added to the

measurement result.

LINEARIZATION MODE

This parameter defines the linearization function. Note the information in

the appendix!

BACKUP MEMORY (retentive memory)

FACTORY SETTINGS

value of the counter readings in the event of a

power failure and "counter" mode is switched on.

24

Page 25

4.2 Frequency Mode

Value

Designation

Function

0

A ONLY

Single-channel frequency measurement (only for

channel A).

1

RATIO

Frequency ratio of both channels (channel B /

decimal places in the format +/- x.xxxx

2

PERCENT

Percentage deviation from channel B to channel

places in the format +/- xxx.xx %

3

A + B

Frequency addition of both channels (channel A

+ channel B)

4

A - B

Frequency subtraction of both channels

(channel A - channel B)

5

A/B x 90°

Frequency measurement with A/B x 90° signal.

monitoring)

Value

Function

0

1 Hz

(Interpretation of result in format: xxxxxxxx Hz)

1

1/10 Hz

(Interpretation of result in format: xxxxxxx.x Hz)

2

1/100 Hz

(Interpretation of result in format: xxxxxx.xx Hz)

3

1/1000 Hz

(Interpretation of result in format: xxxxx.xxx Hz)

In this menu, the operation is defined as a frequency converter (incremental

signals). Depending on the operating mode set, only channel A or both channels

(channel A and channel B) are active.

FREQUENCY MODE

This parameter determines which operating mode of the frequency measurement

is desired.

| OPERATING SOFTWARE OS6.0 / OS10.0

channel A).

Note: Interpretation of the result with four

A.

Note: Interpretation of the result with two decimal

(Forward/backward—rotation direction

FREQUENCY BASE

Sets the desired base for frequency measurement (resolution).

25

Page 26

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Function

0.001

Minimum measuring time in seconds

0.1

Default value

9.999

Maximum measuring time in seconds

Value

Function

0.01

Frequency = 0 Hz for frequencies less than 100 Hz

1.00

Default value

79.99

Frequency = 0 Hz for frequencies less than ~ 0.01 Hz

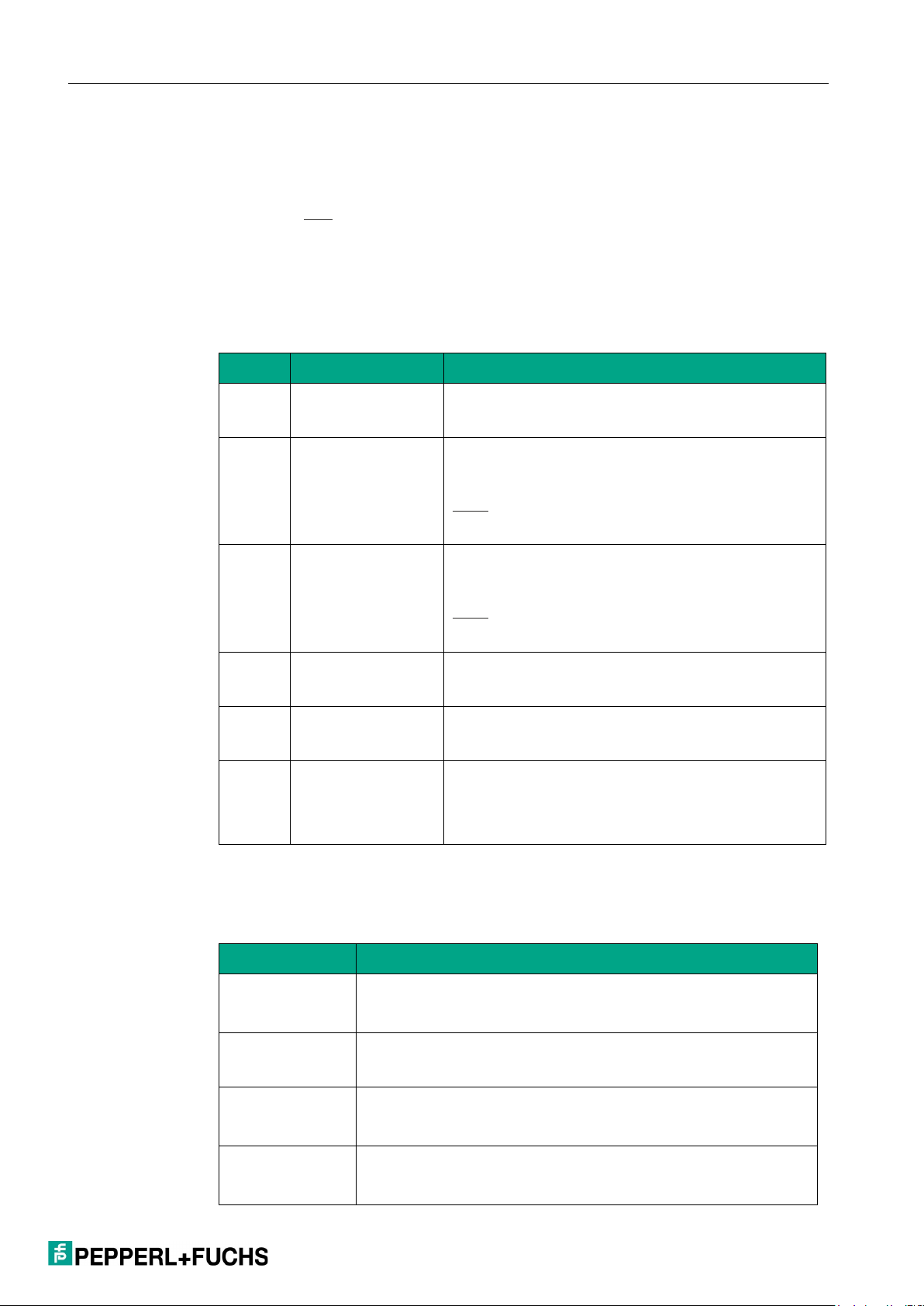

SAMPLING TIME 1 (S)

The set value is the minimum measuring time (for channel A) in seconds. The

sampling time acts as a filter for irregular frequencies. This parameter directly

affects the reaction time of the device.

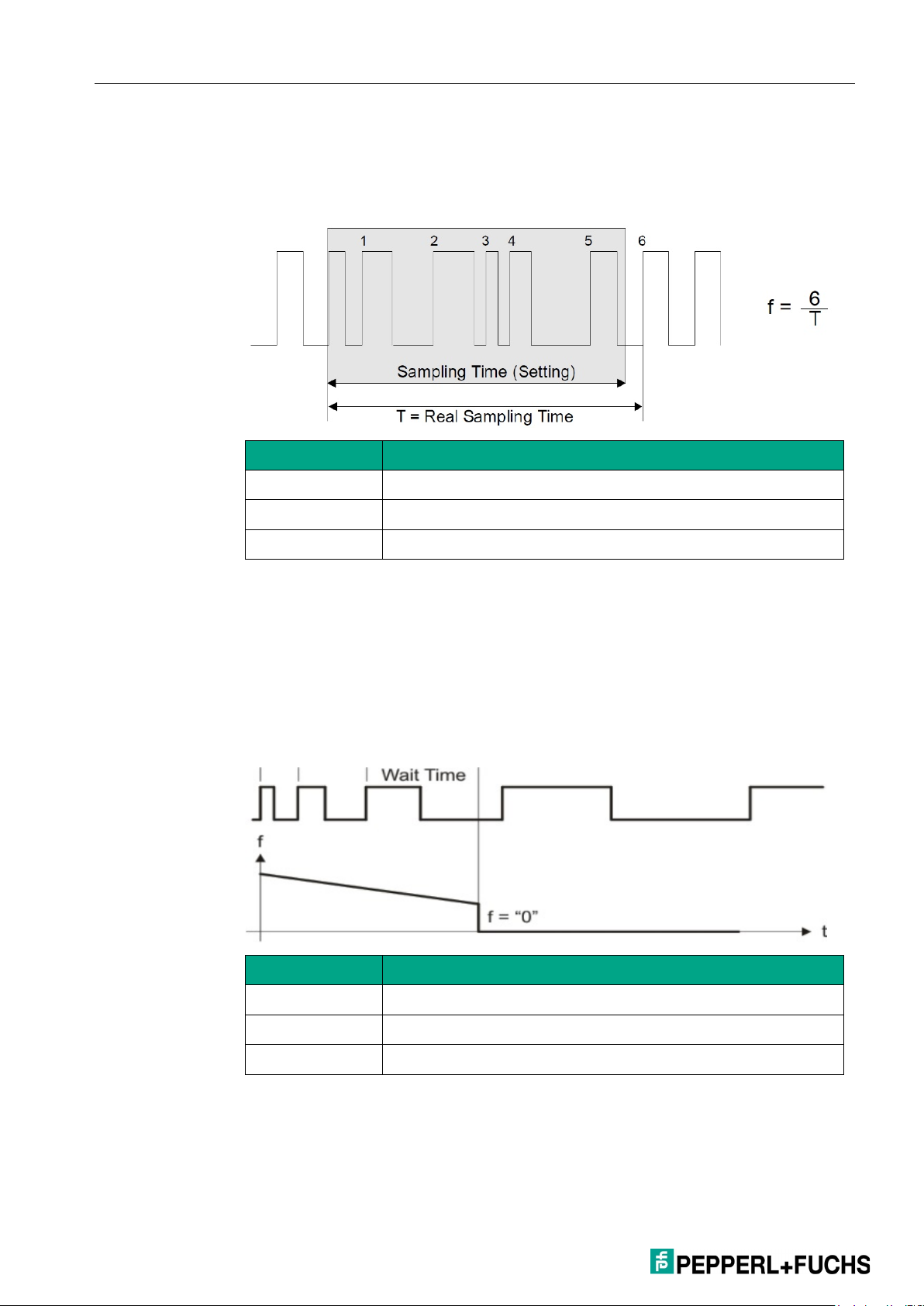

WAIT TIME 1 (S)

The set value is the zero setting time. This parameter defines the duration

of the lowest frequency, or the waiting time between two rising edges on

channel A, at which the device detects the 0 Hz frequency. Frequencies

with a duration greater than the set WAIT TIME 1 are evaluated as

frequency = 0 Hz.

26

Page 27

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Function

0.01

Shortest delay time in seconds

… 99.99

Longest delay time in seconds

Value

Function

0

No average determination

(quick response to any change)

1

Flowing average determination with two cycles

2

Flowing average determination with four cycles

3

Flowing average determination with eight cycles

4

Flowing average determination with 16 cycles

5

Exponential filter, T (63 %) = 2x SAMPLING TIME

6

Exponential filter, T (63 %) = 4x SAMPLING TIME

7

Exponential filter, T (63 %) = 8x SAMPLING TIME

8

Exponential filter, T (63 %) = 16x SAMPLING TIME

9

Exponential filter, T (63 %) = 32x SAMPLING TIME

10

Exponential filter, T (63 %) = 64x SAMPLING TIME

11

Exponential filter, T (63 %) = 128x SAMPLING TIME

12

Exponential filter, T (63 %) = 256x SAMPLING TIME

13

Exponential filter, T (63 %) = 512x SAMPLING TIME

14

Exponential filter, T (63 %) = 1024x SAMPLING TIME

15

Exponential filter, T (63 %) = 2048x SAMPLING TIME

STANDSTILL TIME 1 (S)

This parameter defines the downtime. If frequency = 0 Hz is detected at

channel A, a downtime is signaled after xx.xx seconds and the startup

override is reactivated. Downtime monitoring can be set in the

PRESELECTION menu.

AVERAGE FILTER 1 (average determination)

Switchable average determination or filter function at unstable frequencies at

input A for smoothing the analog signal. If the filter is set to 5 … 16, the device

uses an exponential function. The time constant T (63 %) corresponds to the

number of sampling cycles.

For example, SAMPLING TIME = 0.1 s and AVERAGE FILTER = exponential

filter,

T (63 %) = 2 x sampling time.

This means that after 0.2 s, 63 % of the jump height is reached.

27

Page 28

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Function

16

Exponential filter, T (63 %) = 4096x SAMPLING TIME

(very slow reaction)

CAUTION!

Maximum permissible frequency

When using the exponential filter, the maximum permissible frequencies at the input

must not be exceeded otherwise a data type overflow will follow!

If the frequency is

permissible value with the corresponding setting for further calculation and an error is

output. The LED flashes and the analog output modulates 0

maximum permissible frequencies are listed below for the corresponding settings.

FREQUENCY BASE

[0] – 1 Hz

[1] – 1/10 Hz

[2] – 1/100 Hz

[3] – 1/1000 Hz

AVERAGE FILTER 1+2

[5] - 2x

1,073,741,823 Hz

107,374,182.3 Hz

10,737,418.23 Hz

1,073,741.823 Hz

[6] - 4x

536,870,911 Hz

53,687,091.1 Hz

5,368,709.11 Hz

536,870.911 Hz

[7] - 8x

268,435,455 Hz

26,843,545.5 Hz

2,684,354.55 Hz

268,435.455 Hz

[8] - 16x

134,217,727 Hz

13,421,772.7 Hz

1,342,177.27 Hz

134,217.727 Hz

[9] - 32x

67,108,863 Hz

6,710,886.3 Hz

671,088.63 Hz

67,108.863 Hz

[10] - 64x

33,554,431 Hz

3,355,443.1 Hz

335,544.31 Hz

33,554.431 Hz

[11] - 128x

16,777,215 Hz

1,677,721.5 Hz

167,772.15 Hz

16,777.215 Hz

[12] - 256x

8,388,607 Hz

838,860.7 Hz

83,886.07 Hz

8388.607 Hz

[13] - 512x

4,194,303 Hz

419,430.3 Hz

41,943.03 Hz

4194.303 Hz

[14] - 1024x

2,097,151 Hz

209,715.1 Hz

20,971.51 Hz

2097.151 Hz

[15] - 2048x

1,048,575 Hz

104,857.5 Hz

10,485.75 Hz

1048.575 Hz

[16] - 4096x

524,287 Hz

52,428.7 Hz

5242.87 Hz

524.287 Hz

still exceeded, the frequency is replaced by the maximum

V or 0/4 mA. The

28

Page 29

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Function

0.001

Minimum measuring time in seconds

0.1

Default value

9.999

Maximum measuring time in seconds

Value

Function

0.01

Frequency = 0 Hz for frequencies less than 100 Hz

1.00

Default value

79.99

Frequency = 0 Hz for frequencies less than ~ 0.01 Hz

SAMPLING TIME 2 (S)

The set value is the minimum measuring time (for channel B) in seconds. The

sampling time acts as a filter for irregular frequencies. This parameter directly

affects the reaction time of the device.

WAIT TIME 2 (S)

The set value is the zero setting time. This parameter defines the duration

of the lowest frequency, or the waiting time between two rising edges on

channel B, at which the device detects the 0 Hz frequency. Frequencies

with a duration greater than the set WAIT TIME 2 are evaluated as

frequency = 0 Hz.

29

Page 30

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Function

0

No average determination

(quick response to any change)

1

Flowing average determination with two cycles

2

Flowing average determination with four cycles

3

Flowing average determination with eight cycles

4

Flowing average determination with 16 cycles

5

Exponential filter, T (63 %) = 2x SAMPLING TIME

6

Exponential filter, T (63 %) = 4x SAMPLING TIME

7

Exponential filter, T (63 %) = 8x SAMPLING TIME

8

Exponential filter, T (63 %) = 16x SAMPLING TIME

9

Exponential filter, T (63 %) = 32x SAMPLING TIME

10

Exponential filter, T (63 %) = 64x SAMPLING TIME

11

Exponential filter, T (63 %) = 128x SAMPLING TIME

12

Exponential filter, T (63 %) = 256x SAMPLING TIME

13

Exponential filter, T (63 %) = 512x SAMPLING TIME

14

Exponential filter, T (63 %) = 1024x SAMPLING TIME

15

Exponential filter, T (63 %) = 2048x SAMPLING TIME

16

Exponential filter, T (63 %) = 4096x SAMPLING TIME

(very slow reaction)

AVERAGE FILTER 2 (average determination)

Switchable average determination or filter function at unstable frequencies at

input B for smoothing the analog signal. If the filter is set to 5 … 16, the device

uses an exponential function. The time constant T (63 %) corresponds to the

number of sampling cycles.

E.g., SAMPLING TIME = 0.1 s and AVERAGE FILTER = exponential filter,

T (63 %) = 2 x sampling time.

This means that after 0.2 s, 63 % of the jump height is reached.

30

Page 31

CAUTION!

Maximum permissible frequency

When

must not be exceeded otherwise a data type overflow will follow!

If the frequency is still exceeded, the frequency is replaced by the maximum

permissible value with the corresponding setting for further calculation and an error is

output. The LED flashes and the analog output modulates 0

maximum permissible frequencies have already been listed in the AVERAGE

FILTER 1 parameter and can be taken from there.

Value

Designation

Function

0

A SINGLE

Input A is the counter input.

"LOW" = forward / "HIGH" = backward

1

A + B

Total: Counts A pulses + B pulses

2

A - B

Difference: Counts A pulses - B pulses

3

A/B 90 x1

Incrementing/decrementing counter for pulses with

(Single edge evaluation x1)

4

A/B 90 x2

Incrementing/decrementing counter for pulses with

(Double edge evaluation x2)

5

A/B 90 x4

Incrementing/decrementing counter for pulses with

(Quadruple edge evaluation x4)

using the exponential filter, the maximum permissible frequencies at the input

4.3 Counter Mode

In this menu, the operation is defined as a position converter for incremental

signals (pulse, sum, difference, incrementing, or decrementing counter.) Input A

and B are active.

| OPERATING SOFTWARE OS6.0 / OS10.0

V or 0/4 mA. The

COUNT MODE

Selecting the counter configuration

Input B determines the counting direction:

2x90° offset

2x90° offset

2x90° offset

31

Page 32

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Function

0.00001

Smallest value

1

Default value

99.99999

Largest value

Value

Function

-99999999

Smallest value

0

Default value

99999999

Largest value

Value

Function

0.00001

Smallest value

1

Default value

99.99999

Largest value

Value

Function

-99999999

Smallest value

0

Default value

99999999

Largest value

FACTOR A

Pulse scaling factor for input A.

Example: if set to 1.23456, the device displays the value 123456 after 100,000

input pulses.

SET VALUE A

In the case of a "RESET/SET COUNTER A" command (via control input), the

counter of input A is set to the value set here.

FACTOR B

Pulse scaling factor for input B.

Example: if set to 1.23456, the device displays the value 123456 after 100,000

input pulses.

SET VALUE B

In the case of a "RESET/SET COUNTER B" command (via control input), the

counter of input B is set to the value set here.

32

Page 33

ROUND LOOP VALUE

Value

Function

0

No concentricity

… 99999999

Number of steps for the concentricity function

Value

Designation

Function

0

PRIMARY

Managing operation: Clock pulse for SSI rotary

encoder is generated by the device.

1

SECONDARY

Managed operation: Clock pulse for SSI rotary

encoder comes from external control.

Value

Function

10

Smallest value

25

Default value

32

Largest value

Value

Designation

Function

0

GRAY CODE

Gray SSI code

1

BINARY CODE

Binary SSI code

Defines the number of encoder steps if a concentricity function is desired. (Only

for COUNT MODE: A SINGLE and A/B x 90)

4.4 SSI Mode

In this menu, the operation is defined as an absolute value converter (SSI

signals).

SSI MODE

SSI setting of the operating mode: Managing or managed

Depending on the SSI MODE, different terminals must be used for the SSI CLK:

| OPERATING SOFTWARE OS6.0 / OS10.0

Managing operation: Terminal X2—pins 1 and 2

Managed operation: Terminal X2—pins 5 and 6)

ENCODER RESOLUTION

Resolution of the SSI rotary encoder (total number of all bits)

DATA FORMAT

Setting of the SSI code (binary or gray)

33

Page 34

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Designation

Function

0

2 MHZ

N.A.

1

1.5 MHZ

N.A.

2

1 MHZ

Clock frequency 1 MHz

3

500 KHZ

Clock frequency 500 kHz

4

250 KHZ

Clock frequency 250 kHz

5

100 KHZ

Clock frequency 100 kHz

Value

Function

0

Smallest value

…

999999999

Largest value

Value

Function

01

Smallest value

25

Default value

32

Largest value

Value

Function

01

Smallest value

… 32

Largest value

BAUD RATE

Clock frequency of the SSI messages

SSI ZERO

In the event of a "ZERO POSITION" command (via control input), the current SSI

position of the rotary encoder is transferred to the "SSI ZERO" parameter and the

actual rotary encoder zero point is shifted accordingly. (rotary encoder zero point

shift)

HIGH BIT (for bit suppression)

Defines the highest bit (MSB) to be evaluated of the bit suppression.

If all bits are to be evaluated, HIGH BIT must be set to the specified total bit

number.

LOW BIT (for bit suppression)

Defines the lowest bit (LSB) to be evaluated of the bit suppression.

If all bits are to be evaluated, LOW BIT must be set to "01."

34

Page 35

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Function

0

Smallest value

…

999999999

Largest value

Value

Function

0

No concentricity

… 99999999

Number of steps for the concentricity function

Value

Function

0.001

Minimum measuring time in seconds

0.010

Default value

9.999

Maximum measuring time in seconds

SSI OFFSET

In the case of a "RESET/SET VALUE" command (via control input or PC user

interface), the as yet unscaled position value currently being recorded (after bit

suppression and any rotary encoder zero point shift) is transferred to the "SSI

OFFSET" parameter and the measurement result is reset to zero. From the new

zero point, it is now possible to move in the positive and negative directions,

depending on the direction of rotation.

(Display zero point shift)

ROUND LOOP VALUE

Defines the number of rotary encoder steps if a concentricity function is desired.

SAMPLING TIME (S)

Determines the read-in cycle for the SSI signal in the managing operation

35

Page 36

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Function

0

No error bit present.

…

32

Position of the error bit to be evaluated.

Checks that the connected rotary encoder is switched on.

Value

Function

0

Bit is low in the event of a fault

1

Bit is high in the event of a fault

Note

SSI values

To process SSI values, see Linearisierung and SSI-Wert einlesen in the Anhang

Value

Designation

Function

0

PRIMARY

Managing operation: Init pulse is generated by the

device

1

SECONDARY

Managed operation: Init pulse is generated

externally

ERROR BIT

Defines the rotary encoder monitoring and the error bit

ERROR POLARITY

Defines the polarity of the error bit in the event of a fault

Checks that the connected rotary encoder is switched off.

4.5 Start/Stop Mode

In this menu, the operation is defined as a start/stop interface converter.

INIT MODE

Managing or managed operation

Depending on the selected INIT MODE, different terminals must be used for the

init pulse.

Managing operation: Terminal X2—pins 1 and 2

Managed operation: Terminal X2—pins 5 and 6

36

Page 37

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Function

00.200

Minimum measuring time

04.000

Default value

16.000

Maximum measuring time

Value

Function

1

Smallest value

2

Default value

9

Largest value

Value

Function

0001.00

Smallest value

2800.00

Default value

9999.99

Largest value

Value

Designation

Function

0

POSITION

Distance measurement

1

ANGLE

Angle measurement

2

SPEED

Velocity measurement

Note

For more information on the different "OPERATIONAL MODES" and interpretation of

the respective measurement results, see Chapter 6.7)

SAMPLING TIME (ms)

Duration between two init pulses in milliseconds. Corresponds to the time after

which a new measurement is started and directly affects the reaction time of the

device.

INIT PULSE TIME (µs)

This parameter defines the pulse duration of the init pulse in

microseconds.

VELOCITY (m/s)

Waveguide velocity of the encoder used in m/s.

OPERATIONAL MODE

This parameter determines which type of measurement the device is to perform.

37

Page 38

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Function

-99999999

Smallest value

0

Default value

99999999

Largest value

Note

Only for OPERATIONAL MODE: "ANGLE"

Note

Only for OPERATIONAL MODE: "ANGLE"

Value

Function

1

Smallest value

360

Default value

99999999

Largest value

Value

Function

00000.001

Smallest value

01000.000

Default value

99999.999

Largest value

OFFSET

In the event of a "Reset/Set Value" command via the control input or the PC user

interface, the current position of the rotary encoder is transferred

in a non-volatile manner to the "OFFSET" parameter. (= zero point shift)

CIRCUMFERENCE (mm)

Sets the reference quantity in mm for an angle measurement.

The distance traveled, e.g., the extent to which to generate the subsequent

ROUND LOOP VALUE, must be set here.

ROUND LOOP VALUE

Sets the desired data to be generated when the previous reference quantity

CIRCUMFERENCE is reached.

38

Page 39

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Function

0

No average determination

1

Flowing average determination with two cycles

2

Flowing average determination with four cycles

3

Flowing average determination with eight cycles

4

Flowing average determination with 16 cycles

Value

Function

0

No average determination

1

Flowing average determination with two cycles

2

Flowing average determination with four cycles

3

Flowing average determination with eight cycles

4

Flowing average determination with 16 cycles

Value

Function

0.01

Shortest delay time in seconds

…

99.99

Longest delay time in seconds

AVERAGE FILTER—POSITION

(filter for average determination)

Switchable average determination for preventing position fluctuations.

STANDSTILL TIME(s)

This parameter defines the downtime. When downtime is detected, a downtime

signal is signaled after xx.xx seconds and the startup override is reactivated.

Downtime monitoring can be set in the PRESELECTION MENU.

AVERAGE FILTER—SPEED (filter for average determination)

Switchable average determination for preventing velocity fluctuations.

39

Page 40

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Function

-99999999

Smallest preselection value

1000

Default value

99999999

Largest preselection value

Value

Function

-99999999

Smallest preselection value

2000

Default value

99999999

Largest preselection value

Value

Function

-99999999

Smallest preselection value

3000

Default value

99999999

Largest preselection value

Value

Function

-99999999

Smallest preselection value

4000

Default value

99999999

Largest preselection value

4.6 Preselection Values

In this menu, the preselection values or switch points are set. The switch points

always refer to the scaled measurement result "Measurement Result."

PRESELECTION 1

Preselection / switch point 1

PRESELECTION 2

Preselection / switch point 2

PRESELECTION 3

Preselection / switch point 3

PRESELECTION 4

Preselection / switch point 4

40

Page 41

PRESELECTION 5

Value

Function

-99999999

Smallest preselection value

5000

Default value

99999999

Largest preselection value

Value

Function

-99999999

Smallest preselection value

6000

Default value

99999999

Largest preselection value

Value

Designation

Function

0

|RESULT|>=|PRES|

Amount of measurement result greater than or

HYSTERESIS 1 OFF

1

|RESULT|<=|PRES|

Amount of measurement result less than or

HYSTERESIS 1 OFF

Preselection / switch point 5

PRESELECTION 6

Preselection / switch point 6

| OPERATING SOFTWARE OS6.0 / OS10.0

4.7 Preselection 1 Menu

MODE 1

Switch condition for preselection 1. Output switches according to the following

condition:

equal to amount of PRESELECTION 1

With HYSTERESIS 1 not equal to 0, the

following switch condition results:

Measurement result >= PRESELECTION 1

ON,

Measurement result < PRESELECTION 1 –

equal to amount of PRESELECTION 1

(Startup override STARTUP DELAY

recommended)

With HYSTERESIS 1 not equal to 0, the

following switch condition results:

Measurement result <= PRESELECTION 1

ON,

Measurement result > PRESELECTION 1+

41

Page 42

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Designation

Function

2

|RESULT|=|PRES|

Amount of measurement result equals amount

3

RESULT>=PRES

Measurement result greater than or equal to

HYSTERESIS 1 OFF

4

RESULT<=PRES

Measurement result less than or equal to

HYSTERESIS 1 OFF

5

RESULT=PRES

Measurement result equals PRESELECTION 1.

HYSTERESIS 1 OFF

6

RESULT=0

Display value equal to 0 (downtime duration

STANDSTILL TIME 1[s]),

of PRESELECTION 1. In conjunction with

hysteresis, a frequency band (preselection +/½ hysteresis) can be defined and monitored.

With HYSTERESIS 1 not equal to 0, the

following switch condition results:

Measurement result > PRESELECTION 1 + ½

HYSTERESIS 1 OFF,

Measurement result < PRESELECTION 1 – ½

HYSTERESIS 1 OFF

preselection 1, e.g., overspeed

With HYSTERESIS 1 not equal to 0, the

following switch condition results:

Measurement result >= PRESELECTION 1

ON,

Measurement result < PRESELECTION 1 –

preselection 1, e.g., underspeed

(Startup override STARTUP DELAY

recommended)

With HYSTERESIS 1 not equal to 0, the

following switch condition results:

Measurement result <= PRESELECTION 1

ON,

Measurement result > PRESELECTION 1+

In conjunction with HYSTERESIS 1, a

frequency band (preselection +/- ½ hysteresis)

can be defined and monitored.

With HYSTERESIS 1 not equal to 0, the

following switch condition results:

42

Measurement result > PRESELECTION 1 + ½

HYSTERESIS 1 OFF,

Measurement result < PRESELECTION 1 – ½

Page 43

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Designation

Function

e.g., downtime monitoring. (Only in

FREQUENCY operating mode).

7

RES>=PRES TRAIL

Trailing preselection 1:

PRESELECTION 1

8

ERROR SET

Common alarm for device faults

Value

Function

0

No switching hysteresis

… 99999

Switching hysteresis of 99,999

Value

Function

0.000

No one-shot pulse (static signal)

… 60.000

Pulse duration of 60 seconds

Value

Designation

Function

0

NO

No assignment

1

CTRL OUT 1

Assignment of the switch condition to Ctrl. Out 1

2

CTRL OUT 2

Assignment of the switch condition to Ctrl. Out 2

3

CTRL OUT 3

Assignment of the switch condition to Ctrl. Out 3

4

CTRL OUT 4

Assignment of the switch condition to Ctrl. Out 4

5

CTRL OUT 5

Assignment of the switch condition to Ctrl. Out 5

6

CTRL OUT 6

Assignment of the switch condition to Ctrl. Out 6

Measurement result greater than or equal to

PRESELECTION 1 – PRESELECTION 4

PRESELECTION 4 is the trailing preselection of

HYSTERESIS 1

Hysteresis for defining the switch-off point for the switch condition of preselection

1.

PULSE TIME 1 (S)

Duration of the one-shot pulse for the switch condition of preselection 1

OUTPUT TARGET 1

Assignment of an output for the switch condition of preselection 1.

If multiple switch conditions are assigned to a single output, the output is active

as soon as one of the switch conditions is met.

43

Page 44

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Designation

Function

0

ACTIVE HIGH

Active "HIGH"

1

ACTIVE LOW

Active "LOW"

Value

Designation

Function

0

NO

No self-locking

1

YES

Self-locking

Value

Function

0.000

No startup override

… 59,999

Startup override in seconds

60,000

Automatic startup override

OUTPUT POLARITY 1

Switch state for the switch condition of preselection 1.

OUTPUT LOCK 1

Self-locking for the switch condition of preselection 1.

STARTUP DELAY 1 (S)

Startup override for the switch condition of preselection 1.

Time frame until the monitoring function is focused.

This setting only applies for switch conditions |RESULT|<=|PRES| or

RESULT<=PRES and only for operating mode "FREQUENCY" MODE – channel

A.

STARTUP DELAY is set at a frequency of 0 Hz to the parameter set here and

started. The monitoring function remains deactivated until the set time has

elapsed.

A setting of "60,000" activates automatic startup override. This means that the

monitoring function remains deactivated until the preselection value / switch point

is exceeded for the first time.

44

Page 45

4.8 Preselection 2 Menu

Value

Designation

Function

See PRESELECTION 1 MENU

6

RES>=PRES TRAIL

Trailing preselection 2:

PRESELECTION 2

Value

Designation

Function

0

NO

No assignment

1

CTRL OUT 1

Assignment of the switch condition to Ctrl. Out 1

2

CTRL OUT 2

Assignment of the switch condition to Ctrl. Out 2

3

CTRL OUT 3

Assignment of the switch condition to Ctrl. Out 3

4

CTRL OUT 4

Assignment of the switch condition to Ctrl. Out 4

5

CTRL OUT 5

Assignment of the switch condition to Ctrl. Out 5

6

CTRL OUT 6

Assignment of the switch condition to Ctrl. Out 6

MODE 2

Switch condition for preselection 2, see PRESELECTION 1 MENU (except

for trailing preselection).

HYSTERESIS 2

| OPERATING SOFTWARE OS6.0 / OS10.0

Display value greater than or equal to

PRESELECTION 2 – PRESELECTION 5

PRESELECTION 5 is the trailing preselection of

Switching hysteresis for the switch condition of preselection 2. See

PRESELECTION 1 MENU.

PULSE TIME 2 (S)

Duration of the one-shot pulse for the switch condition of preselection 2. See

PRESELECTION 1 MENU.

OUTPUT TARGET 2

Assignment of an output for the switch condition of preselection 2.

45

Page 46

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Designation

Function

See PRESELECTION 1 MENU

6

RES>=PRES TRAIL

Trailing preselection 3:

PRESELECTION 3

OUTPUT POLARITY 2

Switch state for the switch condition of preselection 2. See PRESELECTION 1

MENU.

OUTPUT LOCK 2

Self-locking for the switch condition of preselection 2. See PRESELECTION 1

MENU.

STARTUP DELAY 2 (S)

Startup override for the switch condition of preselection 2. See PRESELECTION

1 MENU.

4.9 Preselection 3 Menu

MODE 3

Switch condition for preselection 3, see PRESELECTION 1 MENU (except for

trailing preselection).

Display value greater than or equal to

PRESELECTION 3 – PRESELECTION 6

PRESELECTION 6 is the trailing preselection of

HYSTERESIS 3

Switching hysteresis for the switch condition of preselection 3. See

PRESELECTION 1 MENU.

PULSE TIME 3 (S)

Duration of the one-shot pulse for the switch condition of preselection 3. See

PRESELECTION 1 MENU.

46

Page 47

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Designation

Function

0

NO

No assignment

1

CTRL OUT 1

Assignment of the switch condition to Ctrl. Out 1

2

CTRL OUT 2

Assignment of the switch condition to Ctrl. Out 2

3

CTRL OUT 3

Assignment of the switch condition to Ctrl. Out 3

4

CTRL OUT 4

Assignment of the switch condition to Ctrl. Out 4

5

CTRL OUT 5

Assignment of the switch condition to Ctrl. Out 5

6

CTRL OUT 6

Assignment of the switch condition to Ctrl. Out 6

Value

Designation

Function

See PRESELECTION 1 MENU

6

RES>=PRES TRAIL

Trailing preselection 4:

PRESELECTION 4

OUTPUT TARGET 3

Assignment of an output for the switch condition of preselection 3.

OUTPUT POLARITY 3

Switch state for the switch condition of preselection 3. See PRESELECTION 1

MENU.

OUTPUT LOCK 3

Self-locking for the switch condition of preselection 3. See PRESELECTION 1

MENU.

STARTUP DELAY 3 (S)

Startup override for the switch condition of preselection 3. See PRESELECTION

1 MENU.

4.10 Preselection 4 Menu

MODE 4

Switch condition for preselection 4, see PRESELECTION 1 MENU (except for

trailing preselection).

Display value greater than or equal to

PRESELECTION 4 – PRESELECTION 1

PRESELECTION 1 is the trailing preselection of

47

Page 48

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Designation

Function

0

NO

No assignment

1

CTRL OUT 1

Assignment of the switch condition to Ctrl. Out 1

2

CTRL OUT 2

Assignment of the switch condition to Ctrl. Out 2

3

CTRL OUT 3

Assignment of the switch condition to Ctrl. Out 3

4

CTRL OUT 4

Assignment of the switch condition to Ctrl. Out 4

5

CTRL OUT 5

Assignment of the switch condition to Ctrl. Out 5

6

CTRL OUT 6

Assignment of the switch condition to Ctrl. Out 6

HYSTERESIS 4

Switching hysteresis for the switch condition of preselection 4. See

PRESELECTION 1 MENU.

PULSE TIME 4 (S)

Duration of the one-shot pulse for the switch condition of preselection 4. See

PRESELECTION 1 MENU.

OUTPUT TARGET 4

Assignment of an output for the switch condition of preselection 4.

OUTPUT POLARITY 4

Switch state for the switch condition of preselection 4. See PRESELECTION 1

MENU.

OUTPUT LOCK 4

Self-locking for the switch condition of preselection 4. See PRESELECTION 1

MENU.

STARTUP DELAY 4 (S)

Startup override for the switch condition of preselection 4. See PRESELECTION

1 MENU.

48

Page 49

4.11 Preselection 5 Menu

Value

Designation

Function

See PRESELECTION 1 MENU

6

RES>=PRES TRAIL

Trailing preselection 5:

Value

Designation

Function

0

NO

No assignment

1

CTRL OUT 1

Assignment of the switch condition to Ctrl. Out 1

2

CTRL OUT 2

Assignment of the switch condition to Ctrl. Out 2

3

CTRL OUT 3

Assignment of the switch condition to Ctrl. Out 3

4

CTRL OUT 4

Assignment of the switch condition to Ctrl. Out 4

5

CTRL OUT 5

Assignment of the switch condition to Ctrl. Out 5

6

CTRL OUT 6

Assignment of the switch condition to Ctrl. Out 6

MODE 5

Switch condition for preselection 5, see PRESELECTION 1 MENU (except for

trailing preselection).

| OPERATING SOFTWARE OS6.0 / OS10.0

Display value greater than or equal to

PRESELECTION 5 – PRESELECTION 2

PRESELECTION 2 is the trailing preselection of

PRESELECTION 5

HYSTERESIS 5

Switching hysteresis for the switch condition of preselection 5. See

PRESELECTION 1 MENU.

PULSE TIME 5 (S)

Duration of the one-shot pulse for the switch condition of preselection 5. See

PRESELECTION 1 MENU.

OUTPUT TARGET 5

Assignment of an output for the switch condition of preselection 5.

49

Page 50

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Designation

Function

See PRESELECTION 1 MENU

6

RES>=PRES TRAIL

Trailing preselection 3:

PRESELECTION 6

OUTPUT POLARITY 5

Switch state for the switch condition of preselection 5. See PRESELECTION 1

MENU.

OUTPUT LOCK 5

Self-locking for the switch condition of preselection 5. See PRESELECTION 1

MENU.

STARTUP DELAY 5 (S)

Startup override for the switch condition of preselection 5. See PRESELECTION

1 MENU.

4.12 Preselection 6 Menu

MODE 6

Switch condition for preselection 6, see PRESELECTION 1 MENU (except for

trailing preselection).

Display value greater than or equal to

PRESELECTION 6 – PRESELECTION 3

PRESELECTION 3 is the trailing preselection of

HYSTERESIS 6

Switching hysteresis for the switch condition of preselection 6. See

PRESELECTION 1 MENU.

PULSE TIME 6 (S)

Duration of the one-shot pulse for the switch condition of preselection 6. See

PRESELECTION 1 MENU.

50

Page 51

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Designation

Function

0

NO

No assignment

1

CTRL OUT 1

Assignment of the switch condition to Ctrl. Out 1

2

CTRL OUT 2

Assignment of the switch condition to Ctrl. Out 2

3

CTRL OUT 3

Assignment of the switch condition to Ctrl. Out 3

4

CTRL OUT 4

Assignment of the switch condition to Ctrl. Out 4

5

CTRL OUT 5

Assignment of the switch condition to Ctrl. Out 5

6

CTRL OUT 6

Assignment of the switch condition to Ctrl. Out 6

Value

Function

11

Smallest address without zero

… 99

Largest address without zero

OUTPUT TARGET 6

Assignment of an output for the switch condition of preselection 6.

OUTPUT POLARITY 6

Switch state for the switch condition of preselection 6. See PRESELECTION 1

MENU.

OUTPUT LOCK 6

Self-locking for the switch condition of preselection 6. See PRESELECTION 1

MENU.

STARTUP DELAY 6 (S)

Startup override for the switch condition of preselection 6. See PRESELECTION

1 MENU.

4.13 Serial Menu

The default settings for the serial interface are defined in this menu.

UNIT NUMBER

This parameter can be used to set serial device addresses. The devices can be

assigned addresses between 11 and 99. Addresses that contain a "0" are not

allowed since these are used as group or collective addresses.

51

Page 52

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Designation

Function

0

9600

9600 baud

1

19,200

19,200 baud

2

38,400

38,400 baud

Value

Designation

Function

0

7-EVEN-1

7 data Parity even 1 stop

1

7-EVEN-2

7 data Parity even 2 stops

2

7-ODD-1

7 data Parity odd 1 stop

3

7-ODD-2

7 data Parity odd 2 stops

4

7-NONE-1

7 data No parity 1 stop

5

7-NONE-2

7 data No parity 2 stops

6

8-EVEN-1

8 data Parity even 1 stop

7

8-ODD-1

8 data Parity odd 1 stop

8

8-NONE-1

8 data No parity 1 stop

9

8-NONE-2

8 data No parity 2 stops

Value

Designation

Function

0

NO

The initialization values are transferred at 9600

by the user

1

YES

The initialization values are transmitted at the baud

the value set by the user

SERIAL BAUD RATE

This parameter is used to set the serial baud rate.

SERIAL FORMAT

This parameter sets the bit data format.

SERIAL INIT

This parameter determines the baud rate at which the initialization values are

transferred to the PC user interface. When set to greater than 9600 baud, the

duration of the initialization can be shortened.

baud. The device then works again at the value set

rate set by the user in the SERIAL BAUD RATE

parameter. The device then continues to work at

52

Page 53

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Function

Transmission protocol = unit no., +/-, data, LF, CR

1 1 +/- X X X X X X X LF

CR

Transmission protocol = +/-, data, LF, CR

+/- X X X X X X X LF

CR

Value

Function

0.000

Cyclical transmission is switched off and the device only

request via request protocol

… 60.000

Time cycle in seconds.

Value

Code

Function

0

:0

Measurement_Result (result after linking, scaling,

filter, etc.)

1

:1

Analog_Out_Voltage (analog output modulation [in

mV])

2

:2

Frequency (measured frequency—channel A)

3

:3

Frequency_2 (measured frequency—channel B)

4

:4

Counter (total counter reading after linking without

5

:5

Counter_A (counter reading—channel A)

6

:6

Counter_B (counter reading—channel B)

SERIAL PROTOCOL

Specifies the string for command-controlled or timed transmissions

(xxxxxxx = SERIAL VALUE).

At default 1, the unit no. is omitted and the transmission starts directly with the

measured value, which enables a quicker transmission cycle.

0

1

SERIAL TIMER (S)

Adjustable time cycle in seconds for automatic (cyclical) transmission of the

SERIAL VALUE via the serial interface.

In the event of a request via the request protocol, the cyclical transmission is

interrupted for 20 seconds.

sends SERIAL PRINT on command via a control input or

SERIAL VALUE

The parameter determines which value is transmitted.

scaling, filter, etc.)

53

Page 54

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Code

Function

7

:7

SSI_Data (read-in + any converted binary SSI

value)

8

:8

SSI_Calc_Result (SSI value incl. SSI zero and SSI

offset without scaling, filter, etc.)

9

:9

Minimum_Value (minimum value of

Measurement_Result)

10

;0

Maximum_Value (maximum value of

11

;1

Analog_Out_Current (analog output modulation [in

yA])

12

;2

Analog_Out_Percentage (analog output

(Measurement result in xxx.x %)

Value

Function

0

Serial interface uses the Lecom protocol

1 … 247

Serial interface uses the Modbus RTU protocol

The set value is the Modbus address of the device.

Value

Designation

Function

0

-10…10V

-10 V … +10 V

1

0…20MA

0 mA … 20 mA

2

4…20MA

4 mA … 20 mA

MODBUS

Measurement_Result)

modulation percentage)

This parameter enables the Modbus protocol to be activated and the Modbus

address to be set.

(For details on communication with the Modbus + protocol, see Modbus RTU

Schnittstelle)

4.14 Analog Menu

In this menu, the default settings for the analog output are defined.

ANALOG FORMAT

This parameter defines the output characteristics.

In the output format (-10 V … +10 V), the polarity of the output follows the sign of

the measurement result. The analog output is proportional to the measurement

result.

54

Page 55

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Function

-99999999

Smallest start value

0

Default value

99999999

Largest start value

Value

Function

-99999999

Smallest end value

10000

Default value

99999999

Largest end value

Value

Function

0.00

Smallest modulation

100.00

Default value

110.00

Largest modulation

ANALOG START

This parameter is used to set the start value of the analog modulation.

The start value specifies the measurement result at which the analog output

modulates 0 V or 0/4 mA

.

ANALOG END

This parameter is used to set the end value of the analog modulation. The end

value specifies the measurement result at which the analog output modulates its

max. value (+/-) 10 V or 20 mA.

ANALOG GAIN (%)

This parameter is used to set the maximum modulation. The ANALOG GAIN

indicates the maximum modulation of the analog output in % relative to (+/-) 10 V

or 20 mA.

Example 1: 102.00 corresponds to a modulation of 10.2 V / 20.4 mA, once the

ANALOG END value is reached.

Example 2: 95.00 corresponds to a modulation of 9.5 V / 18 mA, once the

ANALOG END value is reached.

ANALOG OFFSET (%)

This parameter is used to set the zero point shift of the output.

Example: 0.20 corresponds to a modulation of 0.02 V / 0.04 mA, when the

ANALOG START value is reached.

55

Page 56

| OPERATING SOFTWARE OS6.0 / OS10.0

Value

Function

-99.99

Smallest zero point shift

0

Default value

+99.00

Largest zero point shift

Value

Designation

Function

0 NO

No function.

1

RESET/SET

Transfers the currently recorded position

and B—only in "COUNTER" mode

(d)

2

FREEZE

Freezes the current measurement result

(s)

3

TEACH ANALOG

START

Transfers the current measurement result

to the "Analog Start" parameter

(d)

4

TEACH ANALOG

END

Transfers the current measurement result

to the "Analog End" parameter

(d)

5

TEACH

Transfers the current measurement result

(d)

6

TEACH

Transfers the current measurement result

(d)

7

TEACH

Transfers the current measurement result

(d) 8 TEACH

Transfers the current measurement result

(d) 9 TEACH

Transfers the current measurement result

(d)

10

TEACH

PRESELECTION 6

Transfers the current measurement result

to the "Preselection 6" parameter

(d)

4.15 Command Menu

INPUT 1 ACTION (function input 1)

This parameter determines the control function of the input "Ctrl. In 1."

(s) = stat. switching characteristics (level modulation) INPUT CONFIG must be

set to ACTIVE LOW/HIGH.

(d) = dyn. switching characteristics (edge modulation) INPUT CONFIG must

be set to RISING/FALLING EDGE.

VALUE

PRESELECTION 1

PRESELECTION 2

value (after bit suppression and any rotary

encoder zero point shift) to the "SSI offset"

parameter (display zero point shift)—only

in "SSI" mode

Resets/sets both counter values (channels

A and B) to the set values in SET VALUE A

to the "Preselection 1" parameter

to the "Preselection 2" parameter

(s)

56

PRESELECTION 3

PRESELECTION 4

PRESELECTION 5

to the "Preselection 3" parameter

to the "Preselection 4" parameter

to the "Preselection 5" parameter

Page 57

Value

Designation

Function

11

RESET MIN/MAX

Resets the minimum/maximum value

(d)

(s)

12

LOCK RELEASE

Releases the self-locking of all outputs

(d)

13

SERIAL PRINT

Sends the serial data (see "Serial Print"

parameter)

(d)

14

ACTIVATE DATA

N.A.

15

STORE DATA

N.A.

16

TESTPROGRAM

N.A.

17

CLEAR LOOP

TIME

Resets the maximum loop time

(d)

18

RESET/SET

Resets/sets the counter value of channel A

"COUNTER" mode

(d)

19

RESET/SET

Resets/sets the counter value of channel B

"COUNTER" mode

(d)

20

LOCK COUNTER

Counter (channel a) is disabled and does

"COUNTER" mode

(s)

21

LOCK COUNTER

Counter (channel B) is disabled and does

"COUNTER" mode

(s)

22

ZERO POSITION

Transfers the current SSI position to the

(d)

23

FACTORY

SETTINGS

The device is reset to its factory settings.

(d)

Value

Designation

Function

0

ACTIVE LOW

Activates at "LOW" (static)

1

ACTIVE HIGH

Activates at "HIGH" (static)

2

RISING EDGE

Activates at rising edge (dynamic)

3

FALLING EDGE

Activates at falling edge (dynamic)

| OPERATING SOFTWARE OS6.0 / OS10.0

COUNTER A

COUNTER B

A

B

to the set values in SET VALUE A—only in

to the set value in SET VALUE B—only in

not count any further pulses as long as this

command is present. —only in

not count any further pulses as long as this

command is present. —only in

"SSI Zero" parameter (rotary encoder zero

point shift)—only in "SSI" mode

(s)

(s)

(s)

PUT 1 CONFIG

This parameter determines the switching characteristics for "Ctrl. In 1."

57

Page 58

| OPERATING SOFTWARE OS6.0 / OS10.0

INPUT 2 ACTION

This parameter determines the control function of the input "Ctrl. In 2"

See function assignment for parameter INPUT 1 ACTION

INPUT 2 CONFIG

This parameter determines the switching characteristics for "Ctrl. In 2."

See activation assignment for parameter INPUT 1 CONFIG

INPUT 3 ACTION

This parameter determines the control function of the input "Ctrl. In 3"

See function assignment for parameter INPUT 1 ACTION

INPUT 3 CONFIG

This parameter determines the switching characteristics for "Ctrl. In 3."

See activation assignment for parameter INPUT 1 CONFIG

INPUT 4 ACTION

This parameter determines the control function of the input "Ctrl. In 4."

See function assignment for parameter INPUT 1 ACTION

INPUT 4 CONFIG

This parameter determines the switching characteristics for "Ctrl. In 4."

See activation assignment for parameter INPUT 1 CONFIG

INPUT 5 ACTION

This parameter determines the control function of the input "Ctrl. In 5"

See function assignment for parameter INPUT 1 ACTION

INPUT 5 CONFIG

This parameter determines the switching characteristics for "Ctrl. In 5."