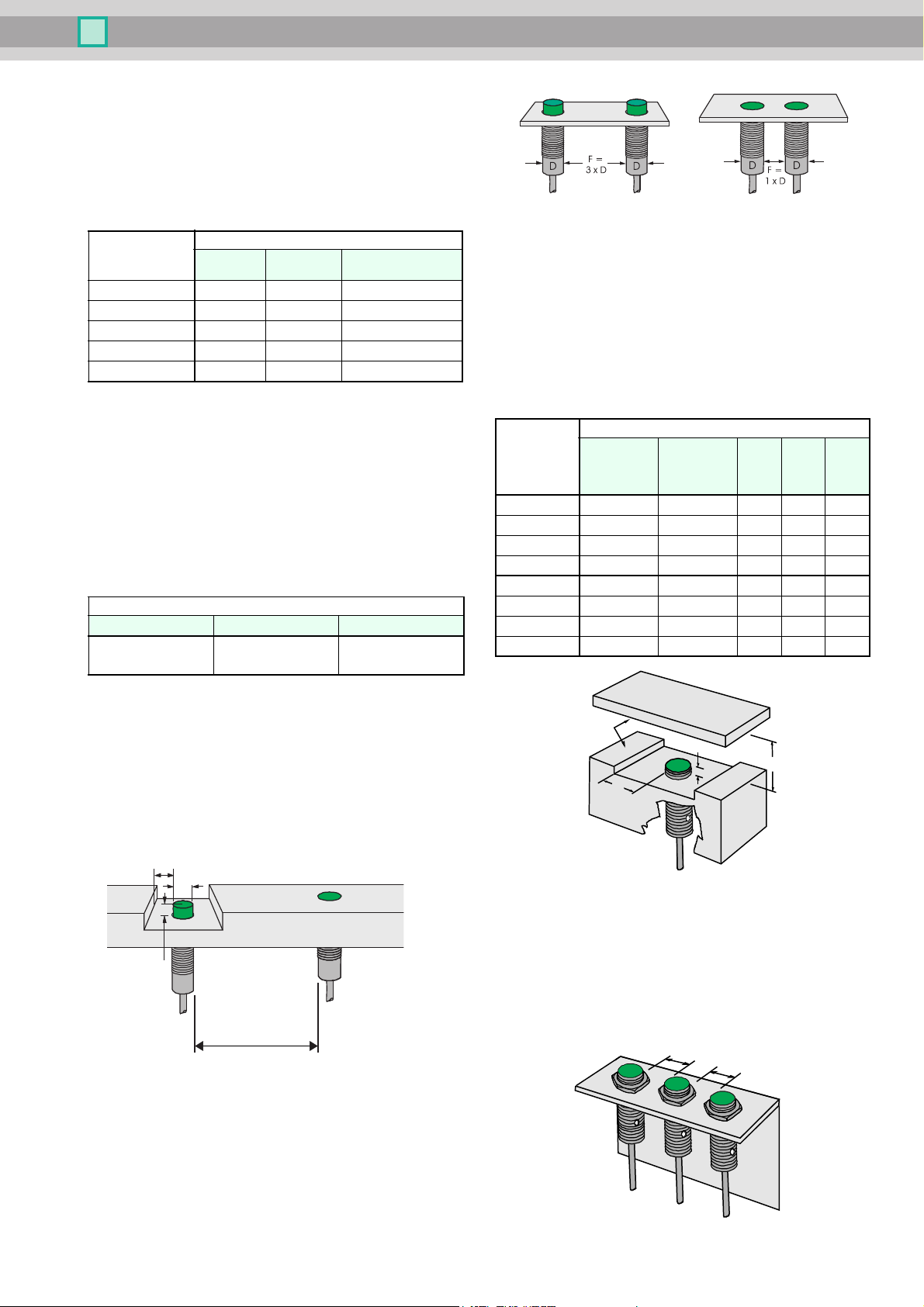

Installation conditions for inductive sensors

D

F

A

B

Non-flush proximity

switches, properly

installed

Flush proximity

switches,

properly installed

B = diameter D

A = 2 x switching distance

Non-flush installed proximity

sensors, F must be 3 times the

housing diameter

Flush installed proximity sensors, F must be equivalent to

the housing diameter

A

C

B

Metal

F

F

Installation condition

The given values are minimum values. They cause changes of the

sensing range less than 10%.

Cylindrical proximity switches

Devices with the same diameter may have different switching distances. The following table shows typical examples:

Diameter

[

mm]

6.5 2 3 3

8 2 3 3

12 2 4 6

18 5 8 12

30 10 15 22

flush not flush

Proximity switches that are installed non-flush

The largest possible switching distance (relative to the diameter) is

chieved by proximity switches that are installed non-flush. An in-

a

ductive proximity switch utilizes coils for generating the electromagnetic field. To achieve a particular direction of the field these coils

are wound in an encapsulated core. Nonetheless, some of this field

will radiate sideways.

To avoid these products with a large range to be already attenuated

by the environment, a clear space must be created around the sensor element complying with the minimum values in the following table.

Dimensions [mm]

A B F

2 x S

n

Switching distance

B = D

increased switching

distance, flush

flush F = D

not flush

F = 3 x D

Sensors with increased switching distance

These sensors with extremely increased switching distance cannot

b

e installed fully flush in metal. They are described as semi-flush in-

stalled.

Distance [mm]

Type

NEB 3-6,5... 1,0 0 6 9 16

NEB 6-12... 2,0 1,0 6 18 18

NEB 12-18... 4,0 1,5 12 36 26

NEB 22-30... 6,0 1,5 22 66 50

NEN 6-8... 8 8 8 18 20

NEN 10-12... 12 12 12 30 30

NEN 20-18... 22 22 22 60 60

NEN 40-30... 40 40 40 120 120

A

(steel, nonfer-

rous heavy

metal)

A

(stainless

steel)

B C F

Proximity switches that are installed flush

Flush installed inductive proximity switches can be used without

earance (A = 0). An advantage is that they are thus mechanically

cl

better protected and less sensitive to erroneous effects than nonflush installed types. The required reduction of the lateral field is

achieved by a special internal shielding. This is at the expense of the

range; these proximity switches only achieve approx. 60 % of the

switching distance of designs for non-flush installation.

Mutual interference

The minimum distances F specified in the table above must be kept

o prevent any mutual interference. If these distances cause prob-

t

lems with the application, then proximity switches with offset frequencies are available upon request. These can then be installed

directly adjacent.

If in doubt please enquire.

Date of issue 2018-02-13

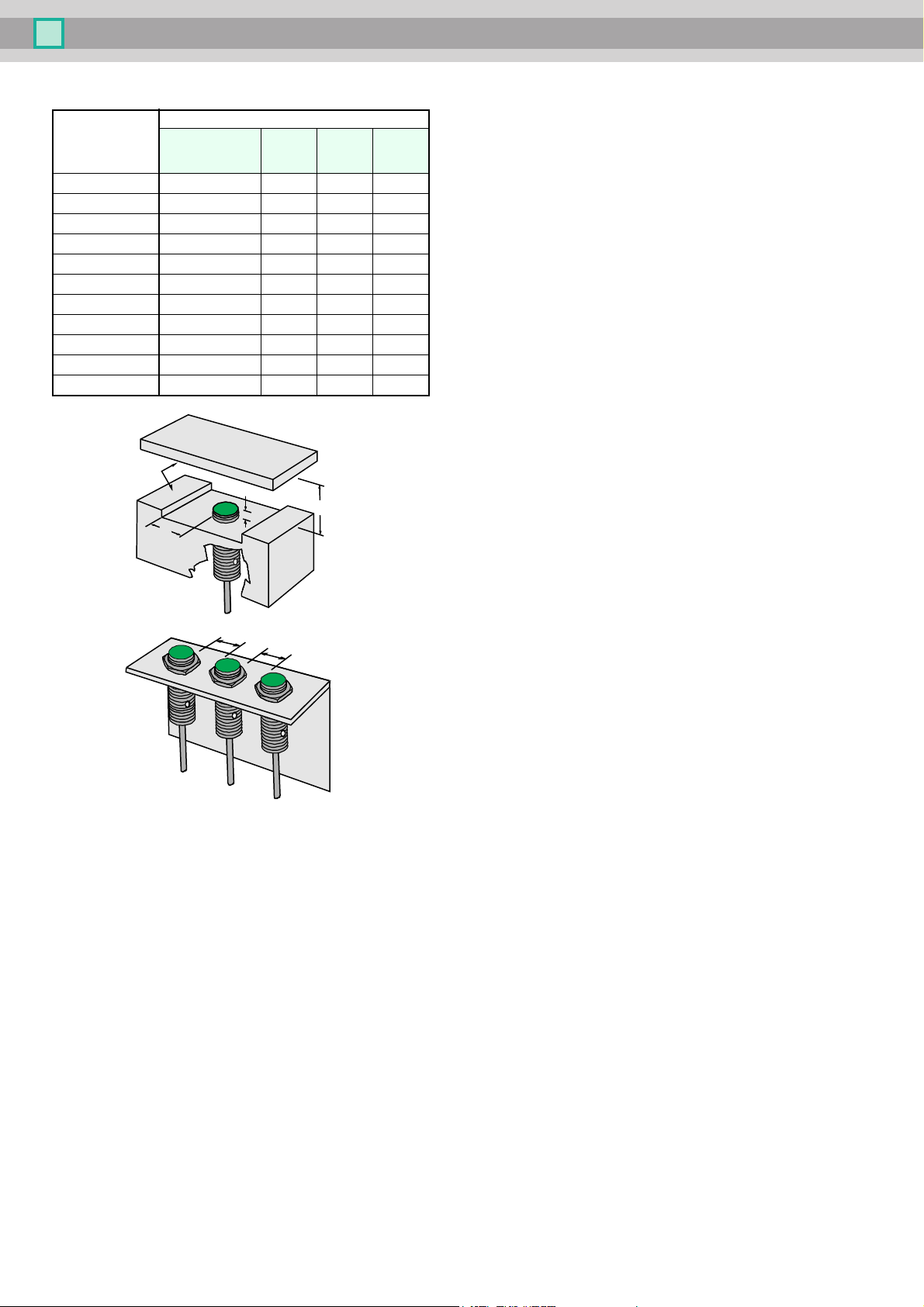

Mutual interference

To prevent the mutual interference between two similar sensors the

inimum distances specified in these tables must be kept.

m

For applications where these distances cannot be maintained proximity switches with offset frequencies are available upon request.

These can then be installed directly adjacent.

Please talk to our product specialist.

1

Sensors with Reduction Factor 1

A

C

B

mild steel

F

F

Distance [mm]

Type

NRB2-6,5… 0 5 10 20

NRN6-6,5… 10 20 20 30

NRB2-8G… 0 5 10 15

NRN6-8G… 10 20 20 25

NRB4-12G… 0 5 15 15

NRN10-12G… 20 30 30 50

NRB8-18G… 0 5 15 20

NRB12-18G… 5 15 20 20

NRN15-18G… 25 30 40 60

NRB15-30G… 0 15 20 35

NRN30-30G… 30 45 80 160

A

(for installation in

mild steel)

B C F

Date of issue 2018-02-13

2

Loading...

Loading...