Pepperl+Fuchs IPT FP, IDENT-I system P IPT FP Series, IDENT-I system P IPT1-FP, IDENT-I system P U-P6-B5-V Series Manual

Page 1

MANUAL

IPT*-FP WITH U-P6-B5

Read/write station with

INTERBUS interface

FACTORY AUTOMATION

Page 2

IPT*-FP WITH U-P6-B5

1 Introduction..................................................................4

2 Declaration of conformity ...........................................5

2.1 CE conformity ........................................................................................... 5

3 Safety............................................................................6

3.1 Symbols relevant to safety ...................................................................... 6

3.2 Intended use.............................................................................................. 6

3.3 General safety instructions...................................................................... 6

3.4 Operational reliability and monitoring.................................................... 7

4 Product description.....................................................8

4.1 Product family........................................................................................... 9

4.1.1 Code/data carrier ........................................................................................ 9

4.2 Range of application ...............................................................................10

4.3 Delivery package......................................................................................10

4.4 Device characteristics.............................................................................10

4.5 Display and controls ...............................................................................11

4.6 Diagnostic LEDs ......................................................................................11

4.7 Interfaces and connections ................................................................... 12

5 Installation..................................................................13

5.1 Storage and transport ............................................................................ 13

5.2 Unpacking ............................................................................................... 13

5.3 EMC concept ........................................................................................... 13

5.4 Device connection .................................................................................. 15

5.4.1 Voltage supply .......................................................................................... 15

5.4.2 Earth connection....................................................................................... 16

5.4.3 INTERBUS Ring termination .................................................................... 17

5.4.4 Cable lengths............................................................................................ 17

5.4.5 Cable ........................................................................................................ 17

5.4.6 Transfer rate changeover.......................................................................... 18

2

Page 3

IPT*-FP WITH U-P6-B5

6 Commissioning ......................................................... 19

6.1 Installation check ....................................................................................19

6.2 Preliminary considerations ....................................................................20

6.3 Self test ....................................................................................................20

7 Operation on the INTERBUS.................................... 21

7.1 General information on INTERBUS........................................................21

7.2 Outline of the commands and data on the INTERBUS ........................21

7.3 General command information ..............................................................21

7.3.1 Software information .................................................................................21

7.3.2 Command overview...................................................................................23

7.4 System commands..................................................................................25

7.5 Read/write commands ............................................................................29

7.5.1 Read data..................................................................................................29

7.5.2 Write data ..................................................................................................33

7.6 Read only code........................................................................................37

7.7 Special command modes .......................................................................41

7.7.1 IPC03 configuration...................................................................................41

7.7.2 Password mode with IPC03 ......................................................................51

7.7.3 Write fixed code IPC10 ..............................................................................54

7.8 Legend......................................................................................................58

7.9 Error/Status messages ...........................................................................59

8 Technical specifications .......................................... 60

8.1 Read/write station IPT*-FP......................................................................60

8.2 Read/write distances IPT*-FP.................................................................61

8.3 U-P6B5 lower section..............................................................................62

3

Page 4

IPT*-FP WITH U-P6-B5

Introduction

1 Introduction

Congratulations

You have chosen a device manufactured by Pepperl+Fuchs. Pepperl+Fuchs develops,

produces and distributes electronic sensors and interface modules for the market of

automation technology on a worldwide scale.

Before you install this device and put it into operation, please read the operating instructions

thoroughly. The instructions and notes contained in this operating manual will guide you stepby-step through the installation and commissioning to ensure the trouble-free usage of this

product. This is useful to you, because with this you:

• support the safe operation of the device

• can utilize the device’s entire range of functions

• reduce faulty operation and the associated errors

• reduce costs from downtime and incidental repairs

• increase the effectiveness and operating efficiency of your plant.

Store this operating manual somewhere safe in order to have it available for future work on the

device.

Directly after opening the packaging, please ensure that the device is intact and that the

package is complete.

Symbols used

The following symbols are used in this manual:

Note!

This symbol draws your attention to important information.

Handling instructions

You will find handling instructions beside this symbol

Contact

If you have any questions about the device, its functions, or accessories, please contact us at:

Pepperl+Fuchs GmbH

Lilienthalstraße 200

68307 Mannheim

Telephone: +49 621 776-4411

Fax: +49 621 776-274411

E-Mail: fa-info@pepperl-fuchs.com

102696 2009-03

4

Page 5

IPT*-FP WITH U-P6-B5

Declaration of conformity

2 Declaration of conformity

2.1 CE conformity

This product was developed and manufactured under observance of the applicable European

standards and guidelines.

Note!

A declaration of conformity can be requested from the manufacturer.

102696 2009-03

5

Page 6

IPT*-FP WITH U-P6-B5

Safety

3 Safety

3.1 Symbols relevant to safety

Danger!

This symbol indicates a warning about a possible danger.

In the event the warning is ignored, the consequences may range from personal injury to death.

Warning!

This symbol indicates a warning about a possible fault or danger.

In the event the warning is ignored, the consequences may course personal injury or heaviest

property damage.

Caution!

This symbol warns of a possible fault.

Failure to observe the instructions given in this warning may result in the devices and any

connected facilities or systems develop a fault or fail completely.

3.2 Intended use

Together, the devices IPT*-FP and U-P6-B5 of the inductive identification system IDENT-I

system P comprise a read/write station..

Always operate the device as described in these instructions to ensure that the device and

connected systems function correctly. The protection of operating personnel and plant is only

guaranteed if the device is operated in accordance with its intended use.

3.3 General safety instructions

Only instructed specialist staff may operate the device in accordance with the operating

manual.

Independent interventions and separate modifications are dangerous and will void the warranty

and exclude the manufacturer from any liability. If serious faults occur, stop using the device.

Secure the device against inadvertent operation. In the event of repairs, send the device to

Pepperl+Fuchs.

The connection of the device and maintenance work when live may only be carried out by a

qualified electrical specialist.

The operating company bears responsibility for observing locally applicable safety regulations.

Store the not used device in the original packaging. This offers the device optimal protection

against impact and moisture.

Note!

Electronic waste is hazardous waste. Observe local disposal regulations.

6

102696 2009-03

Page 7

IPT*-FP WITH U-P6-B5

Safety

3.4 Operational reliability and monitoring

The devices IPT*-FP and U-P6-B5 of the inductive identification system IDENT-I System P

operate on a microprocessor level. Device status is reported via LEDs on the front side on the

IPT*-FP read station and in the U-P6-B5 lower section terminal compartment.

In addition, the INTERBUS functionality can be tested by querying the status information or via

specific commands to test the device. Device error or the failure of a read/write station, for

example, can be recognized and reported by the INTERBUS master in this way.

102696 2009-03

7

Page 8

IPT*-FP WITH U-P6-B5

Product description

4 Product description

The brand name IDENT-I System P represents a complete identification system. The read/write

station consists of the read/write head IPT*-FP (standard version: IPT1-FP) and the lower

section U-P6-B5 with INTERBUS interface. With the use of 125 kHz technology, the system is

extensively open for the implementation of other components.

The lower section operates as a passive node (Slave). It is therefore restricted to use on the

cyclically read process data channel. The device assigns 5 words to each 16 bits (10 bytes).

The acyclically read parameter channel of the INTERBUS protocol is not assigned.

102696 2009-03

8

Page 9

IPT*-FP WITH U-P6-B5

2

1

3

Product description

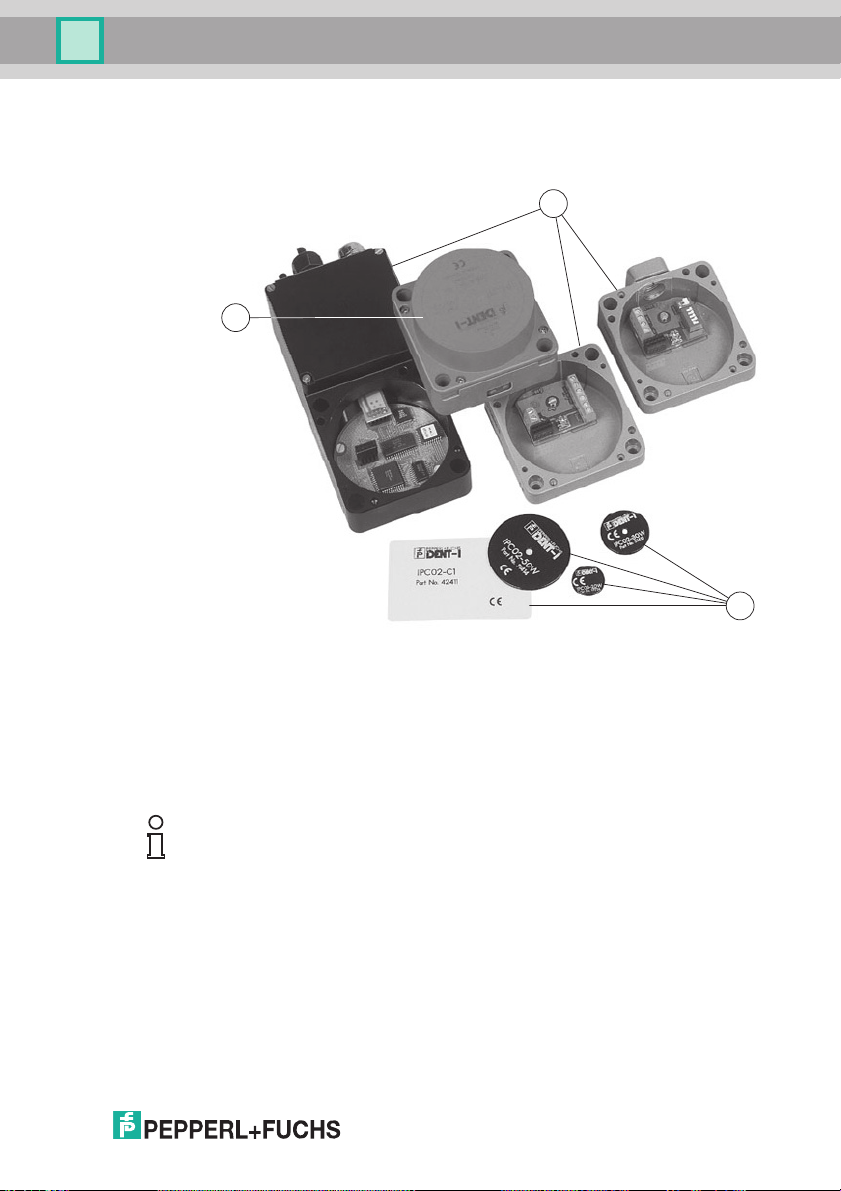

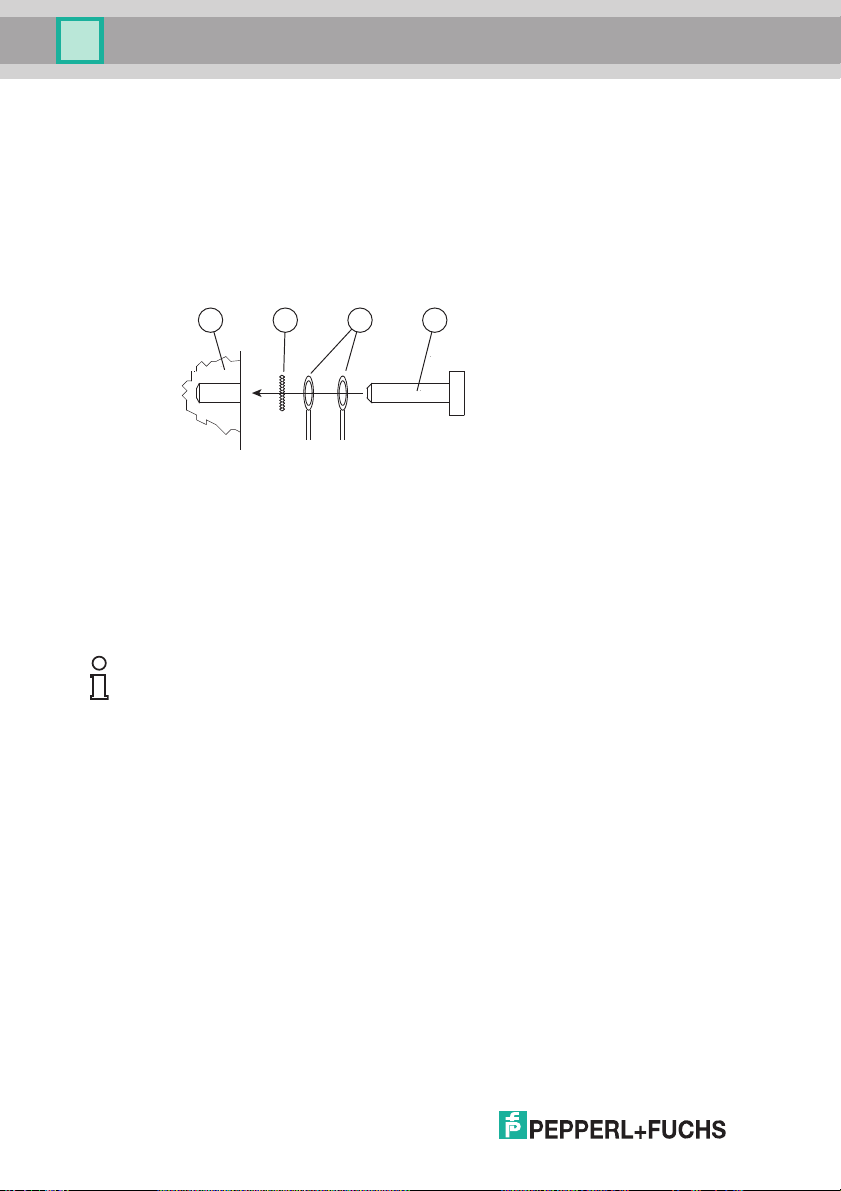

4.1 Product family

The inductive identification system IDENT-I system P from Pepperl+Fuchs offers various

possible combinations of individual components.

1 Read/write station

2 Lower sections

3 Code/data carrier

Note!

Detailed information on the components of the identification system IDENT-I system P can be

found in the sensor systems 1 catalog.

4.1.1 Code/data carrier

A wide assortment of designs is available for the inductive 125 kHz code and data carriers.

Data carriers are available for temperatures up to 300 °C (max. 5 min) in chemical-resistant

housings for installation in metal and in protection class IP68/IP69K. IPC02-... code carriers

offer 40-bit fixcode. IPC03-... data carriers have 928 bits of freely programmable memory and a

non-variable fixcode of 32 bits. The storage area of the IPC03-… can be protected against

unauthorized read and write. 40-bit fixcodes that can be freely determined can be generated

with IPC11-... code carriers. These fixcodes can be generated one time permanently or they

102696 2009-03

can be modifiable.

9

Page 10

IPT*-FP WITH U-P6-B5

Product description

4.2 Range of application

The system is suited for the following applications:

• Automation

• Material flow control in production

• Acquisition of operating data

• Access control

• Identification of e.g. storage vessels, pallets, work piece carriers, refuse containers, tanks,

containers, etc.

4.3 Delivery package

IPT*-FP contains:

• 1 Read/write head

• CD with documentation (incl. this manual)

1

U-P6-B5

contains:

• Lower section

• 1 cover

• 2 ring terminals

• 1 earthing screw

• 1 serrated lock washer

1 sticker

1

The lower section must be ordered separately.

4.4 Device characteristics

The lower section U-P6-B5 is the interface with the INTERBUS remote bus.

• Supply voltage with galvanic isolation

• Bus interfaces with functional isolation accordant with EN 50178.

• Connection of the field bus via EMV-PG9 and screw terminals

• Addressing by means of physical position of the station in the system

• Display LEDs (on the front of the read/write station IPT*-FP)

• Diagnostic LEDs

• The lower section operates as a passive node (Slave). It is therefore restricted to use on

the cyclically read process data channel. The device assigns 5 words to each 16 bits (10

bytes). The acyclically read parameter channel of the INTERBUS protocol is not assigned.

10

102696 2009-03

Page 11

IPT*-FP WITH U-P6-B5

2

1

3

Product description

4.5 Display and controls

The following displays and controls are located on the read/write head.

LED display

1 Bus error - red

2 IPC recognized - yellow,

command executed successfully (approx. 1 second)

3 Power on - green

4.6 Diagnostic LEDs

The following diagnostic LEDs are located in the terminal compartment of the lower section:

LED Color Meaning

US green "Power on"

RC green "Remote Check"

BA green "Bus Acitve"

RD yellow "Remotebus Disabled"

102696 2009-03

11

Page 12

IPT*-FP WITH U-P6-B5

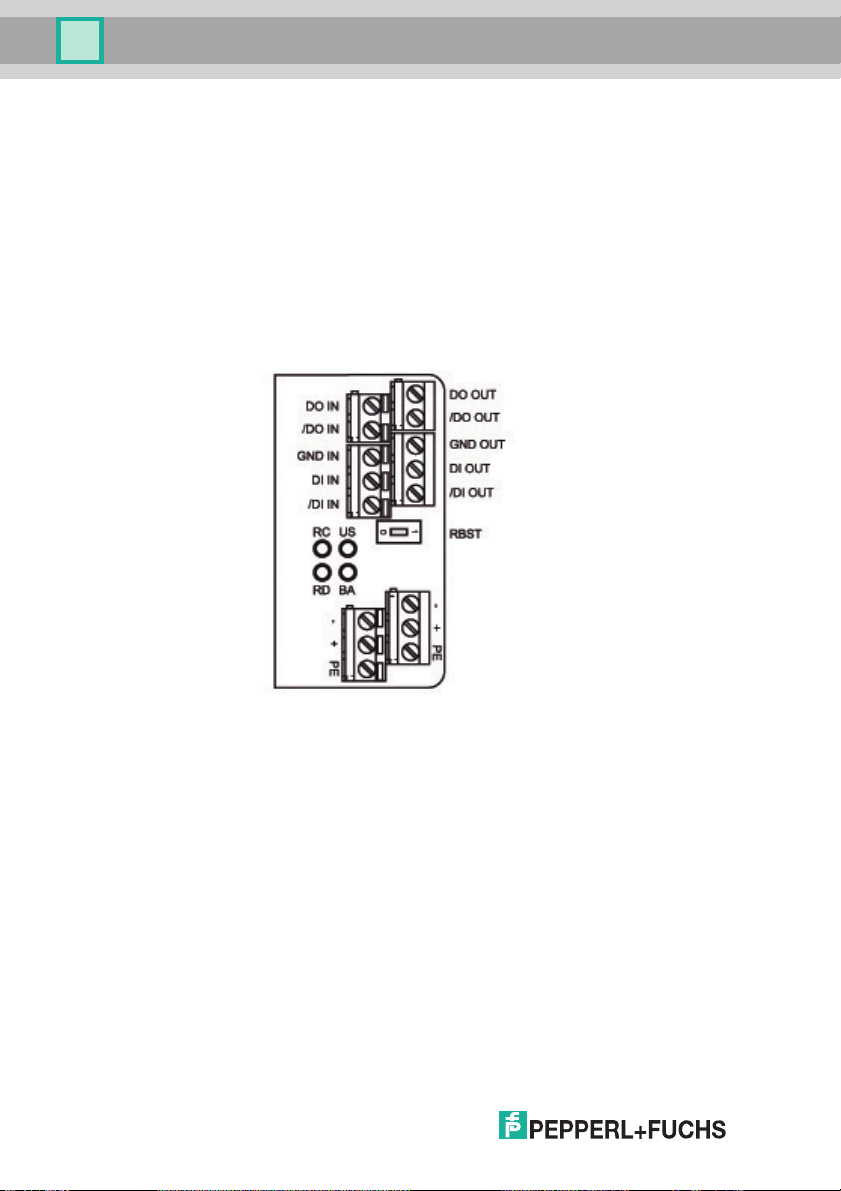

Product description

4.7 Interfaces and connections

The following interfaces and connections are located on the lower section U-P6-B5:

12

102696 2009-03

Page 13

IPT*-FP WITH U-P6-B5

Installation

5 Installation

5.1 Storage and transport

For storage and transport purposes, package the unit using shockproof packaging material and

protect it against moisture. The best method of protection it to package the unit using the

original packaging. Furthermore, ensure that the ambient conditions are within permissible

range.

5.2 Unpacking

Check the product for damages while unpacking. In the event of damage to the product, inform

the post office or parcel service and notify the supplier.

Check the package contents with your purchase order and the shipping documents for:

• Delivery quantity

• Device type and version in accordance with the type plate

• Accessories

• Manual/manuals

Retain the original packaging in case the device must be stored or shipped again at a later

date.

Should you have any questions, please direct them to Pepperl+Fuchs.

5.3 EMC concept

The screening of cables provides for the discharge of electromagnetic interference. When

screening a cable, both sides of the screen must be connected to the earth with low resistance

and low inductance.

Note!

If cables with double screening are used, e.g. wire meshing and metalized foil, the screens

must be connected together at the ends, with low resistance, when making up the cable.

Power supply cables are the source of much interference, e.g. the starting current of 3-phase

electric motors. For this reason, the parallel laying of power supply cables with data and signal

cables should be avoided, particularly in the same cable duct.

102696 2009-03

13

Page 14

IPT*-FP WITH U-P6-B5

1

2

3

Installation

Connect screening with the PG cable gland of the lower section

In order to connect the screening with the PG cable gland on the lower section and in so doing

satisfy the EMC requirements in accordance with DIN VDE 0871/6.78, the following steps must

be carried out:

1. Strip the outer sheathing of the cable end over a length of approx. 10 mm.

2. Lightly flare the screen (2).

3. Slide the screen (2) over the cone (3).

4. Pull the seal insert (1) over the screen (2) and cone (3).

5. Screw on the PG cable gland.

14

102696 2009-03

Page 15

IPT*-FP WITH U-P6-B5

rt ge gn

mP1

mP2

SU PI

OUT

IN

OUT

I P T-FP

U-P6-B5

IP C

20 ... 30 VDC

IN

PELV

3

U

s

RC

BA

RD

gn gn gn ge

5

5

RBST

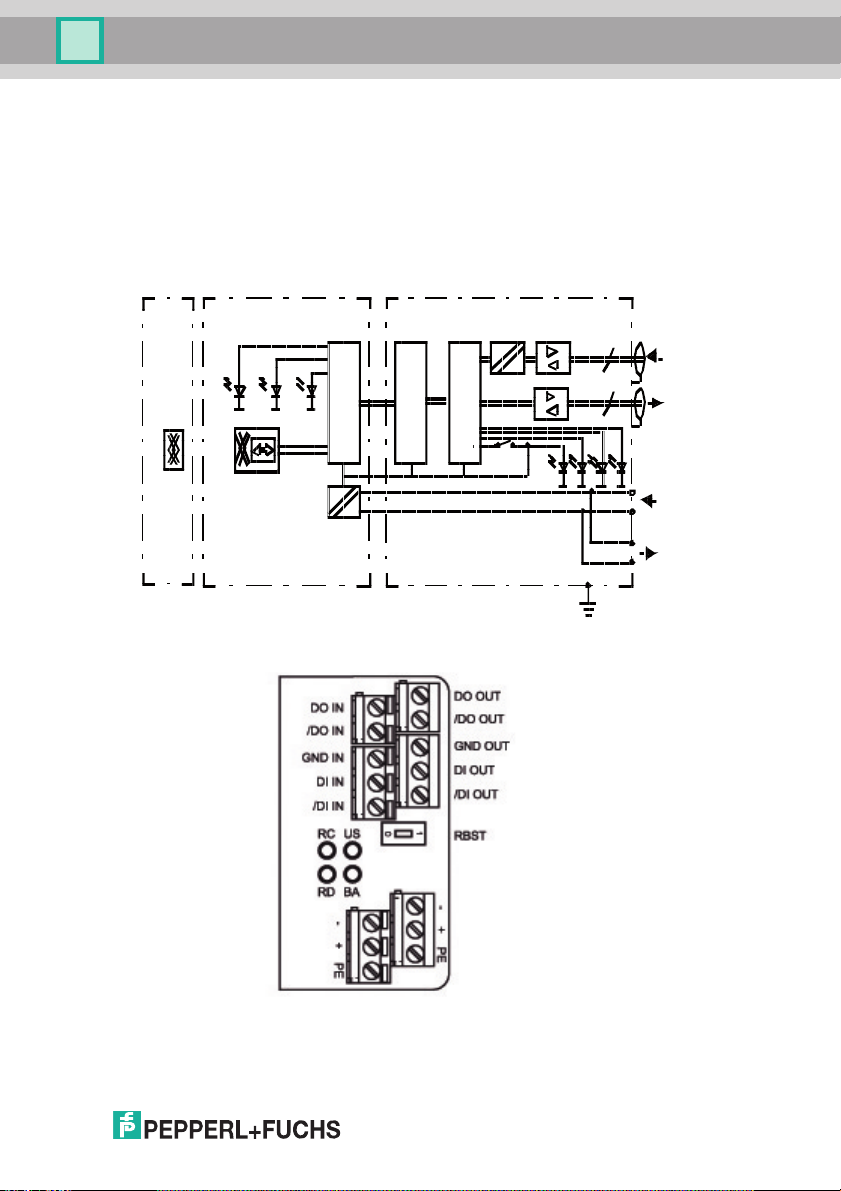

Installation

5.4 Device connection

5.4.1 Voltage supply

The electrical connection of the lower section is made via screw terminals. The maximum core

cross-section of the cable is 1.5 mm

Connect up the INTERBUS and the supply voltage as described in the connection diagram and

in the terminal assignment list.

2

.

102696 2009-03

15

Page 16

IPT*-FP WITH U-P6-B5

12 43

Installation

5.4.2 Earth connection

The internal PE connection of the lower section is conductively connected with the housing.

However, from the point of view of screening, connection to the outside of the housing is

preferable.

The external earth connection of the lower section is located lower left, adjacent to the cable

entries. The PE conductor is screwed to the housing with a crimp connector. In order to

guarantee safe earthing, the serrated washer must be mounted between the crimp connector

and the housing.

1 Housing

2 Serrated lock washer

3 Crimp connector

4 Lock screw

A cross-section of at least 4 mm

2

is recommended for the PE conductor lead.

Note!

The “CMD” manufacturer-independent program is available for planning, commissioning and

diagnosing INTERBUS networks.

Details of this program and information on the general theme of INTERBUS are available from:

INTERBUS-Club

Postfach 11 08

D-32817 Blomberg

Tel: +49 52 35/ 34 21 00

Fax: +49 52 35/ 34 12 34

16

102696 2009-03

Page 17

IPT*-FP WITH U-P6-B5

1

0

Bus not

terminated

Bus terminated

Installation

5.4.3 INTERBUS Ring termination

A characteristic of the INTERBUS system is its physical ring structure. Each connected device

lies in the bus between two other stations. If this is not the case, for example, at the end of a

branch with a bus terminal, then the ring line must be closed in the respective device.

The DIP switch for the ring termination, designated “RBST”, must be set to the correct position

(see Figure 5.3). The ring termination switch is located in the terminal compartment in the lower

section U-P6-B5.

Ring termination switch

Note!

The ring termination must only be activated if the device is positioned at the end of an open

branch! Otherwise all the following devices will be cut off from the communication.

5.4.4 Cable lengths

5.4.5 Cable

102696 2009-03

Depending on the type of cable used and the magnitude of the external interference, the

distance between two devices can be up to 400 meters. The total expansion of an INTERBUSSystem can be up to 12.8 kilometers. The number of devices connected to the bus is limited to

512.

The following INTERBUS remote bus cables should be used:

Parameter Standard Highly flexible

Cable construction Twisted pairs/i.e. 2-core, common screening

Conductor crosssection

Operating capacity 60 pF/m

Impedance 120 Ω at 64 KHz/100 Ω at 1 MHz

Use only screened cables constructed as twisted pairs. The best possible EMC interference

immunity can only be achieved by using screened cables.

3 x 2 x 0.22 mm

2

3 x 2 x 0.25 mm

Suitable for laying

underground

2

3 x 2 x 0.22 mm

2

17

Page 18

IPT*-FP WITH U-P6-B5

2 MBit/s

500 kBit/s

Installation

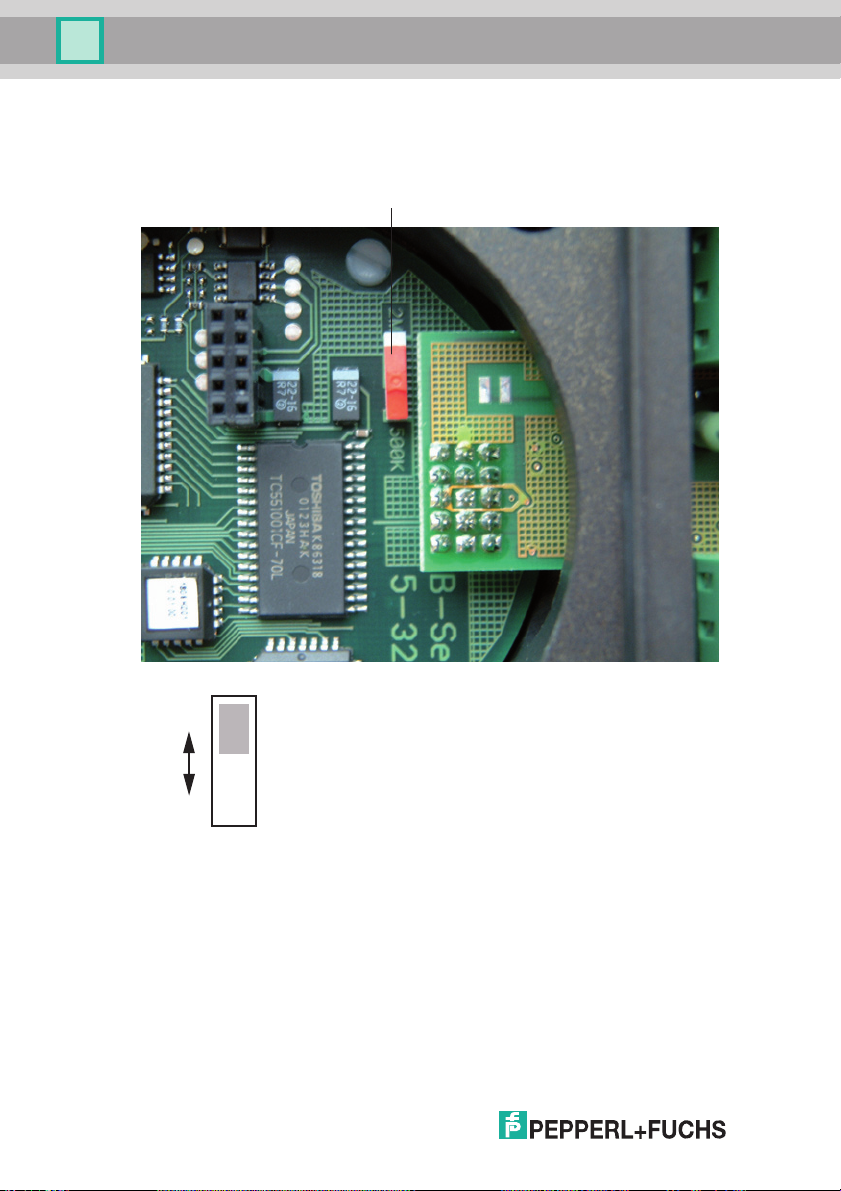

5.4.6 Transfer rate changeover

An internal slide switch enables the transfer rate to be adjusted to match that of the bus. This

allows the two values of 500 kbit/s and 2 Mbit/s to be set.

Schiebeschalter

The status is preset at 2 MBit/s on delivery.

102696 2009-03

18

Page 19

IPT*-FP WITH U-P6-B5

Commissioning

6 Commissioning

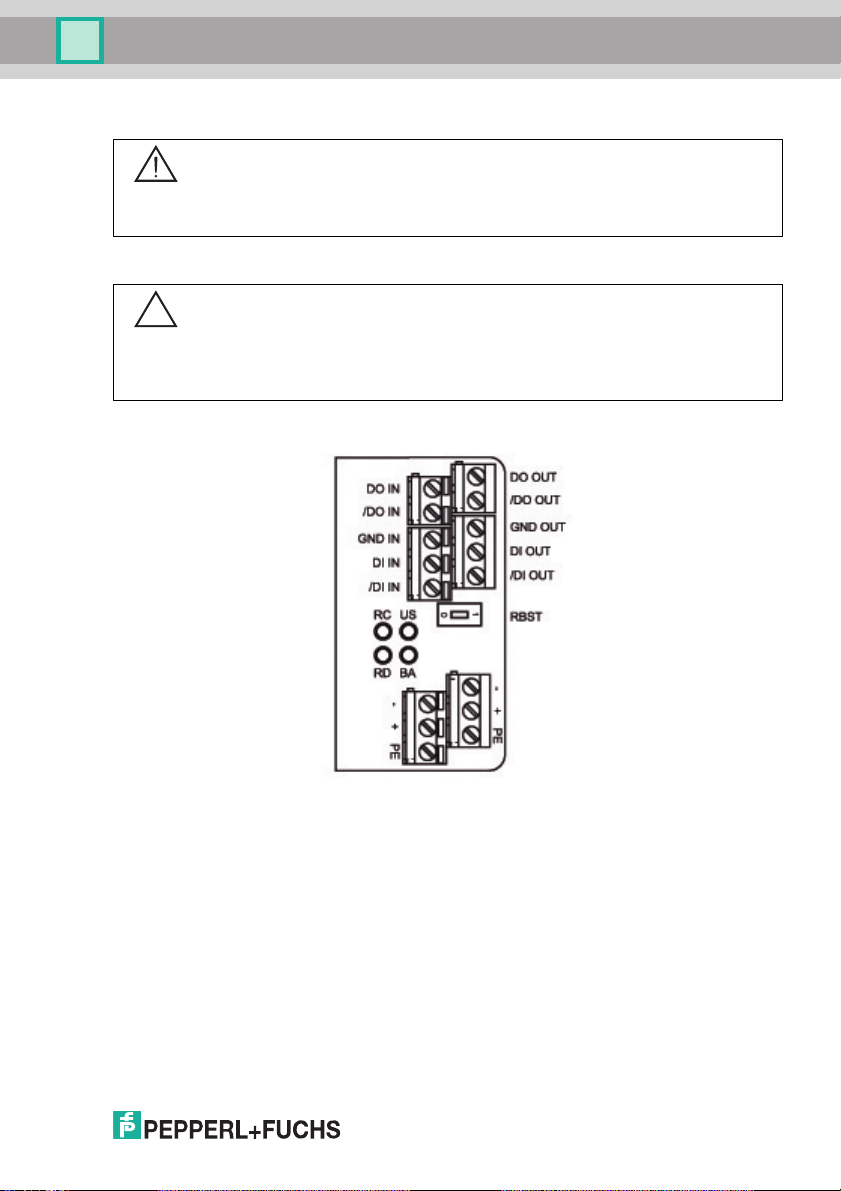

Warning!

Before commissioning, ensure that the plant is not in danger relating to device malfunction, e.g.

from uncontrollable triggered processes.

6.1 Installation check

Caution!

Before commissioning, check once again that the connections are correct.

Before commissioning, familiarize yourself with the system of communication between your

INTERBUS and the read/write station. Commissioning requires accurate knowledge of

INTERBUS and the programming of your master device.

After connecting the supply voltage the "power on" LED on the read station and the green "US"

LED on the lower section must light. Configure the read/write station with the described system

commands. “Autodetect” is set as the data carrier type.

The transfer speed on the INTERBUS is 500 kbit/s or 2 Mbit/s.

102696 2009-03

19

Page 20

IPT*-FP WITH U-P6-B5

Commissioning

6.2 Preliminary considerations

Due to the complexity of field bus programming with the INTERBUS it is very difficult to make

generally valid statements about commissioning.

A very important aspect of the operation of an inductive identification system with the lower

section on the INTERBUS is the time response of the overall system. The question, "How long

after the positioning of a data carrier in front of a read/write station will the read data be

available in my computer?" is answered with the aid of knowledge of the INTERBUS protocol

structure and the following formula:

= [182 + 1,5 x m] x t

t

ü

t

= Transfer time

ü

m = Number of remote bus stations

installed

= Bit duration t

t

B

it

= Soft ware run time

t

s

w

On large projects, or if you have little experience of programming an INTERBUS system, you

should, in any case, construct a laboratory set up of your application and test the data transfer

to the INTERBUS master before installing the system in the plant.

+ t

Bit

sw

=2μs corresponding to 500 kBit/s or

B

it

t

=0.5μs corresponding to 2 MBit/s

B

it

= 200 μs

t

s

w

Note!

The “CMD” manufacturer-independent program is available for planning, commissioning and

diagnosing INTERBUS networks.

Details of this program and information on the general theme of INTERBUS are available from:

INTERBUS-Club

Postfach 11 08

D-32817 Blomberg

Tel: +49 52 35/ 34 21 00

Fax: +49 52 35/ 34 12 34

6.3 Self test

When the power supply is switched on the device executes a self test in its internal memory. If

the error "RAM defect" or "ROM defect" occurs, the communication is not activated. If no error

occurs, then the connection to the INTERBUS master is established automatically.

Note!

When the bus connection with the device is established, the green "BA" LED illuminates and

remains on.

20

102696 2009-03

Page 21

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

7 Operation on the INTERBUS

7.1 General information on INTERBUS

The INTERBUS is a standardized field bus, which enables data exchange between PLCs, PCs,

operating and observation devices and also sensors and actuators.

For detailed information, reference should be made to the INTERBUS standard DIN 19258 and

to the current literature on the subject.

Note!

The INTERBUS Club publishes informational brochures and an INTERBUS product catalog.

7.2 Outline of the commands and data on the INTERBUS

The lower section assigns 5 words to each 16 bits (10 bytes) in the framework protocol of the

INTERBUS in both communication directions. It is restricted in this to the cyclic transfer of the

process data channel. This means:

• Even the instructions for the adjustment of the device are updated on every cycle.

• The parameter channel of the INTERBUS is not used.

• The control interface unit is designed as a remote bus station. The ID code is 03.

7.3 General command information

7.3.1 Software information

A command consists of the command code, a specified number of parameters, the toggle flag

and the data relating to the command. The command is entered in the output data field of the

master.

A response is read from the input data field of the master and consists of the echo of the

command code, a parameter, the toggle flag, the status, an execution counter and the read

data.

102696 2009-03

21

Page 22

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

A number of commands do not use all the parameter and data fields. These unused data fields

are then ignored by the device. The input and output fields are constructed as follows:

Output data field:

Byte 0 Command code

Byte 1 Parameter/Toggle flag

Byte 2 Parameter

Byte 3 Parameter

Byte 4 Write data

... ...

Byte N

(defined by module selection)

Input data field:

Byte 0 Command code (Echo)

Byte 1 Parameter/Toggle flag (Echo)

Byte 2 Status

Byte 3 Execution counter

Byte 4 Read data

... ...

Byte N

(defined by module selection)

Write data

Read data

22

In order to send a new command to the device, the INTERBUS master must write a command

in the output data field. The new command is executed when the data has changed relative to

the last read-in. If the same command is to be executed a number of times, the toggle flag must

be inverted, so that the device recognizes that a new command has to be processed.

Upon detection of a new command “Status” is set to FFh. In addition, the execution counter is

set to 00h and on every further execution of this command it counts up. If the execution counter

overruns, it starts again at 00h. An overrun exists when the execution counter reading is equal

to 00h and the status is not equal to FFh.

After the processing of commands by the identification system, the “Status” is output in

accordance with the Status/Fault signal table (see Section 7.8).

The first two bytes of the response correspond to the first two bytes of the command call-up.

Correspondingly, the toggle bit of the response is the same as the toggle bit of the command.

The commands buffered… and enhanced buffered… are executed repeatedly as long as the

commands remain in the output data field. The execution is terminated when a new command

is written in the data.

102696 2009-03

Page 23

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

7.3.2 Command overview

The commands in the list are described in detail on the following pages.

System commands

Command code Command description

2d 02h quit QU

4d 04h change tag CT

3d 03h version VE

Standard read/write commands

Fixcode

Command code Command description

1d 1h single read fixcode SF

8d 8h auto read fixcode AF

9d 9h buffered read fixcode BF

29d 1Dh enhanced buffered read fixcode EF

Read data

Command code Command description

16d 10 h single read words SR

32d 20h auto read words AR

48d 30h buffered read words BR

25d 19h enhanced buffered read words ER

Write data

Command code Command description

64d 40h single write words SW

80d 50h auto write words AW

96d 60h buffered write words BW

26d 1Ah enhanced buffered write words EW

Abbrevi

ation

Abbrevi

ation

Abbrevi

ation

Abbrevi

ation

102696 2009-03

23

Page 24

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Special command modes

Password mode with IPC03

Command code Command description

24d 18h password mode PM

65d 41h password change PC

66d 42h password set PS

IPC03 configuration

Command code Command description

18d 12 h single write configuration SC

19d 13 h auto write configuration AC

20d 14h buffered write configuration BC

102d 66h enhanced buffered write configuration EC

97d 61h single get configuration SG

98d 62h auto get configuration AG

99d 63h buffered get configuration BG

104d 68h enhanced buffered get configuration EG

Abbrevi

ation

Abbrevi

ation

24

Write fixcode

Commands for the IPC10 and IPC11

Command code Command description

31d 1Fh single write fixcode SX

100d 64h auto write fixcode AX

101d 65h buffered write fixcode BX

36d 24h enhanced buffered write fixcode EX

Abbrevi

ation

102696 2009-03

Page 25

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

7.4 System commands

Quit

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command

code

Byte 1 Reserved/

Toggle bit

Byte 2 not

relevant

.

.

.

.

.

.

Byte 9 not

relevant

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command

code

Byte 1 Reserved/

Toggle bit

Byte 2 Status <Status>

Byte 3 Execution

counter

Byte 4 not

relevant

.

.

.

.

.

.

Byte 9 not

relevant

0 0 0 0 0 0 1 0

- - - - - - - T

- - - - - - - -

- - - - - - - -

- - - - - - - -

0 0 0 0 0 0 1 0

- - - - - - - T

<ExecCounter>

- - - - - - - -

- - - - - - - -

- - - - - - - -

The running buffered, enhanced-buffered or auto command of the specified read/write head is

interrupted.

102696 2009-03

25

Page 26

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Change Tag

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command

code

Byte 1 Reserved/

Toggle bit

Byte 2 Data

carrier

type in

ASCII

Byte 3 Data

carrier

type in

ASCII

Byte 4 not

relevant

.

.

.

.

.

.

Byte 9 not

relevant

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command

code

Byte 1 Reserved/

Toggle bit

Byte 2 Status <Status>

Byte 3 Execution

counter

Byte 4 not

relevant

.

.

.

.

.

.

Byte 9 not

relevant

0 0 0 0 0 1 0 0

- - - - - - - T

<TagType> (High Byte)

<TagType> (Low Byte)

- - - - - - - -

- - - - - - - -

- - - - - - - -

0 0 0 0 0 1 0 0

- - - - - - - T

<ExecCounter>

- - - - - - - -

- - - - - - - -

- - - - - - - -

26

This command tells the read head which code or data carrier to communicate with. The read

head status on delivery is type “00”.

102696 2009-03

Page 27

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

The following code and data carriers are currently supported:

TagType

Description Chip Access

0 0 Autodetect

0 2 IPC02 μEM V4001 Fixcode 32

0 3 IPC03 μEM V4050/64 R/W 00...1D 928

1 0 IPC10 Nova R/W 0 96

With <TagType> = “00”, mixed operation of different code and data carriers is possible. Since

the read head for the autodetect requires a significantly longer time, only static read and write is

practical in this mode.

<WordA

ddr>

BitsHigh Byte Low Byte

102696 2009-03

27

Page 28

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Version

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 0 0 0 1 1

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Parameter <Parameter>

Byte 3 not relevant - - - - - - - -

.

.

.

.

.

.

Byte 9 not relevant - - - - - - - -

Response

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 0 0 0 1 1

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Status <Status>

Byte 3 Execution counter <ExecCounter>

Byte 4 Data 00 ... FF

.

Data 00 ... FF

.

.

Byte 9 Data 00 ... FF

h

h

h

- - - - - - - -

<VersionData> section 1

<VersionData> section ...

<VersionData> section 6

28

This command transfers the software version. The complete software version message cannot

be transferred with one command due to its length. The individual parts of the software version

message are transferred by repeated execution of the command with the appropriate

parameters.

<Parameter> Meaning <VersionData> Beispiel

0; > 8 Incorrect parameter, Status “04h” Data = 0 000000

1 Identification system - Type IPT*-FP

2 Identification system - Part number 095725

3 Identification system - software number 01I040

4 Identification system - software date 170399

5 Bus system - type U-P6B5

6 Bus system - part number 099100

7 Bus system - software number 01K034

8 Bus system - software date 170399

102696 2009-03

Page 29

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

7.5 Read/write commands

7.5.1 Read data

Single Read Words

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 1 0 0 0 0

Byte 1 Word count/Toggle bit <WordNum> - - - T

Byte 2 Word address <WordAddr> (High Byte)

Byte 3 Word address <WordAddr> (Low Byte)

Byte 4 not relevant - - - - - - - -

.

.

.

Byte 9 not relevant - - - - - - - -

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 1 0 0 0 0

Byte 1 Word count/Toggle bit <WordNum> - - - T

Byte 2 Status <Status>

Byte 3 Execution counter <ExecCounter>

Byte 4

Byte 5

Byte 6

Byte 7

Byte 8 not relevant - - - - - - - -

Byte 9 not relevant - - - - - - - -

.

.

.

ID-Code 00 ... FF

ID-Code 00 ... FF

ID-Code 00 ... FF

ID-Code 00 ... FF

- - - - - - - -

a)

h

a)

h

a)

h

a)

h

<Data3>

<Data2>

<Data1>

<Data0>

One attempt is made to read a 32-bit word (<WordNum> = “0001”) from the address

<WordAddr>.

102696 2009-03

29

Page 30

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Auto Read Words

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 1 0 0 0 0 0

Byte 1 Word count/Toggle bit <WordNum> - - - T

Byte 2 Word address <WordAddr> (High Byte)

Byte 3 Word address <WordAddr> (Low Byte)

Byte 4 not relevant - - - - - - - -

.

.

.

.

.

.

Byte 9 not relevant - - - - - - - -

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 1 0 0 0 0 0

Byte 1 Word count/Toggle bit <WordNum> - - - T

Byte 2 Status <Status>

Byte 3 Execution counter <ExecCounter>

Byte 4

Byte 5

Byte 6

Byte 7

ID-Code 00 ... FF

ID-Code 00 ... FF

ID-Code 00 ... FF

ID-Code 00 ... FF

a)

h

a)

h

a)

h

a)

h

Byte 8 not relevant - - - - - - - -

Byte 9 not relevant - - - - - - - -

- - - - - - - -

<Data3>

<Data2>

<Data1>

<Data0>

30

Repeated attempts are made until a 32-bit word (<WordNum> = “0001”) is read from the

address <WordAddr>.

102696 2009-03

Page 31

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Buffered Read Words

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 1 0 0 0

Byte 1 Word count/Toggle bit <WordNum> - - - T

Byte 2 Word address <WordAddr> (High Byte)

Byte 3 Word address <WordAddr> (Low Byte)

Byte 4 not relevant - - - - - - - -

.

.

.

.

.

.

- - - - - - - -

Byte 9 not relevant - - - - - - - -

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 1 0 0 0

Byte 1 Word count/Toggle bit <WordNum> - - - T

Byte 2 Status <Status>

Byte 3 Execution counter <ExecCounter>

Byte 4

Byte 5

Byte 6

Byte 7

ID-Code 00 ... FF

ID-Code 00 ... FF

ID-Code 00 ... FF

ID-Code 00 ... FF

a)

h

a)

h

a)

h

a)

h

Byte 8 not relevant - - - - - - - -

Byte 9 not relevant - - - - - - - -

0 1

0 1

<Data3>

<Data2>

<Data1>

<Data0>

An attempt is made to read a 32-bit word (<WordNum> = “0001”) from the address until

successful <WordAddr>. Only changed data is transferred via the interface, i.e. when the next

data carrier is read, or if previously no data carrier was found in the read range, the new data

carrier.

102696 2009-03

31

Page 32

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Enhanced buffered Read Words

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 1 1 0 0 0 1

Byte 1 Word count/Toggle bit <WordNum> - - - T

Byte 2 Word address <WordAddr> (High Byte)

Byte 3 Word address <WordAddr> (Low Byte)

Byte 4 not relevant - - - - - - - -

.

.

.

.

.

.

Byte 9 not relevant - - - - - - - -

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 1 1 0 0 0 1

Byte 1 Word count/Toggle bit <WordNum> - - - T

Byte 2 Status <Status>

Byte 3 Execution counter <ExecCounter>

Byte 4

Byte 5

Byte 6

Byte 7

ID-Code 00 ... FF

ID-Code 00 ... FF

ID-Code 00 ... FF

ID-Code 00 ... FF

a)

h

a)

h

a)

h

a)

h

Byte 8 not relevant - - - - - - - -

Byte 9 not relevant - - - - - - - -

- - - - - - - -

<Data3>

<Data2>

<Data1>

<Data0>

32

An attempt is made to read a 32-bit word (<WordNum> = “0001”) from the address until

successful <WordAddr>. Only changed data is transferred via the interface. When a data

carrier leaves the read range, the status “05h” is output.

102696 2009-03

Page 33

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

7.5.2 Write data

Single Write Words

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 0 0 0 0 0 0

Byte 1 Word count/Toggle bit <WordNum> - - - T

Byte 2 Word address <WordAddr> (High Byte)

Byte 3 Word address <WordAddr> (Low Byte)

Byte 4 Data 00 ... FF

Byte 5 Data 00 ... FF

Byte 6 Data 00 ... FF

Byte 7 Data 00 ... FF

Byte 8 not relevant - - - - - - - -

Byte 9 not relevant - - - - - - - -

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 0 0 0 0 0 0

Byte 1 Word count/Toggle bit <WordNum> - - - T

Byte 2 Status <Status>)

Byte 3 Execution counter <ExecCounter>

Byte 4 not relevant - - - - - - - -

.

.

.

.

.

.

Byte 9 not relevant - - - - - - - -

h

h

h

h

- - - - - - - -

<Data 3>

<Data 2>

<Data 1>

<Data 0>

One attempt is made to write a 32-bit word (<WordNum> = “0001”) from the address

<WordAddr>. A maximum of 1 word = 4 bytes can be written.

102696 2009-03

33

Page 34

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Auto Write Words

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 0 1 0 0 0 0

Byte 1 Word count/Toggle bit <WordNum> - - - T

Byte 2 Word address <WordAddr> (High Byte)

Byte 3 Word address <WordAddr> (Low Byte)

Byte 4 Data 00 ... FF

Byte 5 Data 00 ... FF

Byte 6 Data 00 ... FF

Byte 7 Data 00 ... FF

h

h

h

h

<Data 0>

Byte 8 not relevant - - - - - - - -

Byte 9 not relevant - - - - - - - -

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 0 1 0 0 0 0

Byte 1 Word count/Toggle bit <WordNum> - - - T

Byte 2 Status <Status>)

Byte 3 Execution counter <ExecCounter>

Byte 4 not relevant - - - - - - - -

.

.

.

.

.

.

- - - - - - - -

Byte 9 not relevant - - - - - - - -

<Data 3>

<Data 2>

<Data 1>

34

Repeated attempts are made until a 32-bit word (<WordNum> = “0001”) is written from the

address <WordAddr>. A maximum of 1 word = 4 bytes can be written.

102696 2009-03

Page 35

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Buffered Write Words

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 1 0 0 0 0 0

Byte 1 Word count/Toggle bit <WordNum> - - - T

Byte 2 Word address <WordAddr> (High Byte)

Byte 3 Word address <WordAddr> (Low Byte)

Byte 4 Data 00 ... FF

Byte 5 Data 00 ... FF

Byte 6 Data 00 ... FF

Byte 7 Data 00 ... FF

h

h

h

h

Byte 8 not relevant - - - - - - - -

Byte 9 not relevant - - - - - - - -

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 1 0 0 0 0 0

Byte 1 Word count/Toggle bit <WordNum> - - - T

Byte 2 Status <Status>)

Byte 3 Execution counter <ExecCounter>

Byte 4 not relevant - - - - - - - -

.

.

.

.

.

.

- - - - - - - -

Byte 9 not relevant - - - - - - - -

<Data 3>

<Data 2>

<Data 1>

<Data 0>

An attempt is now made to write a 32-bit word (<WordNum> = “0001”) from the address

<WordAddr>. After successfully writing, the response is sent and then continuous reading

ensues. Then the same carrier data is read, until the data carrier has left the read/write range

or a new data carrier appears in front of the read/write head. The command then starts again

with write attempts.

A maximum of 1 word = 4 bytes can be written.

102696 2009-03

35

Page 36

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Enhanced Buffered Write Words

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 1 1 0 0 1

Byte 1 Word count/Toggle bit <WordNum> - - - T

Byte 2 Word address <WordAddr> (High Byte)

Byte 3 Word address <WordAddr> (Low Byte)

Byte 4 Data 00 ... FF

Byte 5 Data 00 ... FF

Byte 6 Data 00 ... FF

Byte 7 Data 00 ... FF

h

h

h

h

Byte 8 not relevant - - - - - - - -

Byte 9 not relevant - - - - - - - -

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 1 1 0 0 1

Byte 1 Word count/Toggle bit <WordNum> - - - T

Byte 2 Status <Status>)

Byte 3 Execution counter <ExecCounter>

Byte 4 not relevant - - - - - - - -

.

.

.

.

.

.

- - - - - - - -

Byte 9 not relevant - - - - - - - -

<Data 3>

<Data 2>

<Data 1>

<Data 0>

36

An attempt is now made to write a 32-bit word (<WordNum> = "0001“) from the address

<WordAddr> . After successfully writing, the response is sent and then continuous reading

ensues. Then the same carrier data is read, until the data carrier has left the read/write range

or a new data carrier appears in front of the read/write head. The command then starts again

with write attempts. The status “05h” is output if the data carrier leaves the read range.

A maximum of 1 word = 4 bytes can be written.

102696 2009-03

Page 37

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

7.6 Read only code

Single Read Fixcode

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 0 0 0 0 1

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 not relevant - - - - - - - -

.

.

.

Byte 9 not relevant - - - - - - - -

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 0 0 0 1 0

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Status <Status>

Byte 3 Execution counter <ExecCounter>

Byte 4

Byte 5

Byte 6

Byte 7

Byte 8

Byte 9 not relevant - - - - - - - -

.

.

.

ID-Code 00 ... FF

ID-Code 00 ... FF

ID-Code 00 ... FF

ID-Code 00 ... FF

ID-Code 00 ... FF

- - - - - - - -

a)

h

a)

h

a)

h

a)

h

a)

h

<ID-Code 4>a)/<ID-Code 3>

<ID-Code 3>a)/<ID-Code 2>

<ID-Code 2>a)/<ID-Code 1>

<ID-Code 1>a)/<ID-Code 0>

<ID-Code 0>

a)

a) only with IPC02

A fixed code is read once.

102696 2009-03

37

Page 38

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Auto Read Fixcode

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 0 1 0 0 0

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 not relevant - - - - - - - -

.

.

.

.

.

.

Byte 9 not relevant - - - - - - - -

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 0 1 0 0 0

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Status <Status>

Byte 3 Execution counter <ExecCounter>

Byte 4

Byte 5

Byte 6

Byte 7

Byte 8

ID-Code 00 ... FF

ID-Code 00 ... FF

ID-Code 00 ... FF

ID-Code 00 ... FF

ID-Code 00 ... FF

a)

h

a)

h

a)

h

a)

h

a)

h

Byte 9 not relevant - - - - - - - -

- - - - - - - -

<ID-Code 4>a)/<ID-Code 3>

<ID-Code 3>a)/<ID-Code 2>

<ID-Code 2>a)/<ID-Code 1>

<ID-Code 1>a)/<ID-Code 0>

<ID-Code 0>

a)

38

a) only with IPC02

An attempt is made to read until a fixed code has been read.

102696 2009-03

Page 39

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Buffered Read Fixcode

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 0 1 0 0 1

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 not relevant - - - - - - - -

.

.

.

.

.

.

Byte 9 not relevant - - - - - - - -

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 0 1 0 0 1

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Status <Status>

Byte 3 Execution counter <ExecCounter>

Byte 4

Byte 5

Byte 6

Byte 7

Byte 8

ID-Code 00 ... FF

ID-Code 00 ... FF

ID-Code 00 ... FF

ID-Code 00 ... FF

ID-Code 00 ... FF

a)

h

a)

h

a)

h

a)

h

a)

h

Byte 9 not relevant - - - - - - - -

- - - - - - - -

<ID-Code 4>a)/<ID-Code 3>

<ID-Code 3>a)/<ID-Code 2>

<ID-Code 2>a)/<ID-Code 1>

<ID-Code 1>a)/<ID-Code 0>

<ID-Code 0>

a)

a) only with IPC02

The fixcode continues to be read. Only changed data is transferred via the interface.

102696 2009-03

39

Page 40

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Enhanced Buffered Read Fixcode

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 1 1 1 0 1

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 not relevant - - - - - - - -

.

.

.

.

.

.

Byte 9 not relevant - - - - - - - -

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 1 1 1 0 1

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Status <Status>

Byte 3 Execution counter <ExecCounter>

Byte 4

Byte 5

Byte 6

Byte 7

Byte 8

ID-Code 00 ... FF

ID-Code 00 ... FF

ID-Code 00 ... FF

ID-Code 00 ... FF

ID-Code 00 ... FF

a)

h

a)

h

a)

h

a)

h

a)

h

Byte 9 not relevant - - - - - - - -

- - - - - - - -

<ID-Code 4>a)/<ID-Code 3>

<ID-Code 3>a)/<ID-Code 2>

<ID-Code 2>a)/<ID-Code 1>

<ID-Code 1>a)/<ID-Code 0>

<ID-Code 0>

a)

40

a) only with IPC02

The fixcode continues to be read. Only changed data is transferred via the interface. If the code

or data carrier leaves the read range, the status “05h” is output.

102696 2009-03

Page 41

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

7.7 Special command modes

7.7.1 IPC03 configuration

Note!

These commands can only be used when data carrier type 03 (IPC03) is set. They cannot be

used in the autodetect mode (mixed operation, data carrier type 00)!

The storage of a type IPC03 data carrier is organized by word. Every “word” is made up of 32

bits. For the normal data range, 29 words from addresses 3 through 31 (<WordAddr> = 00

) are available.

1C

h

The storage of the data carrier IPC03 is constructed in the following way:

Address Meaning <WordAddr> <ConfAddr> Note

Word 0 Password - - Write on ly

Word 1 Protection word - "1" Read/write

Word 3 Control word - "2" Read/write

Word 3...31 Data range "00"..."1C" - Read/write

Word 32 Device Serial

Word 33 Device

Number

identification

"1D" - Read only

"1E" - Read only

…

h

The IPC03 has one “protection word” and one “control word”. With the “protection word”, a read-

protected and a write-protected range can be defined. For this, each start and end of a readprotected and a write-protected range can be defined. With the “control word”, various operating

modes and the read range for the “default read” operating mode are set. Both words can only

be accessed with the correct password.

The bits of the individual words have the following meaning:

Control word

Bit Meaning Byte

0...7 Read range start 0

8 ... 15 Read range end 1

16 Password protection on/off 2

17 “Read after write” operating

18 ... 23 Open

24 ... 31 Open 3

102696 2009-03

mode on/off

41

Page 42

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Protection word

Bit Meaning Byte

0 ... 7 First read-protected word 0

8 ... 15 Last read-protected word 1

16 ... 23 First write-protected word 2

24 ... 31 Last write-protected word 3

With the control and protection word, it should be noted that when communicating a word, the

highest value byte is transferred first and the lowest value byte last. With the entry of the read

and write-protected words, the words are counted as follows:

00 Password

01 Protection word

02 Control word

03 1. Data word

04 2. Data word

... ...

1F 29. Data word

IPC03 password mode

It is possible to protect the control word and the protection word from being overwritten. Then

the configuration can no longer be changed. The password mode serves this purpose.

With password mode active in the data carrier, the data range of a data carrier can only be read

or written after the correct password is sent to the data carrier from the read/write head. The

following must apply for this:

• The correct password is set once with the command PS “set password” and

• the password mode is activated with the command PM “set password mode”.

The password in the read/write head and on the data carrier can be changed with the

command PC.

42

If the password mode is deactivated, every word on the data carrier can be read and written as

necessary.

In the factory default condition of the read heads and the data carrier IPC03, the password is

00000000

IPC03 in a non-volatile manner.

"Default read"

In the “default read” operating mode 1 or 2, words can be read very quickly, because the

memory to be read is already defined on the data carrier and does not need to be

communicated to the data carrier from the read/write head first.

. In the read head, the password is stored in a volatile manner and in the data carrier

h

102696 2009-03

Page 43

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

The start and end of the read range are stored in the bytes 0 and 1 of the "control word". As

soon as the data carrier is supplied with energy the data carrier sends out the data from the

data range, which is defined by the read range start and end. The data range between read

range start and end can be read with the read commands SR (single read words) and ER

(enhanced buffered read words) when <WordAddr> is set to 0000h and <WordNum> is set to

00h.

The advantages of the “default read” operating mode lie in the readout speed. The readout of

one data word (4 bytes) is twice as fast in this mode. The readout of 2 words takes approx. 1/3

less time. Starting at 3 data words there is no more time advantage since this mode is only

intended for the reading of a maximum of 2 words (=8 bytes). Reading larger data ranges can

lead to error messages when the read head does not respond within the planned reaction time.

Single Write Configuration

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 1 0 0 1 0

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 not relevant - - - - - - - -

Byte 3 Address in the configuration

Byte 4 Data 00 ... FF

Byte 5 Data 00 ... FF

Byte 6 Data 00 ... FF

Byte 7 Data 00 ... FF

range

h

h

h

h

Byte 8 not relevant - - - - - - - -

Byte 9 not relevant - - - - - - - -

<RegAddr>

<Data>

<Data>

<Data>

<Data>

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 1 0 0 1 0

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Status <Status>

Byte 3 Execution counter <ExecCounter>

Byte 4 not relevant - - - - - - - -

.

.

.

.

.

.

- - - - - - - -

Byte 9 not relevant - - - - - - - -

One attempt is made to write a word in the configuration range from the address <RegAddr>. In

order to write in the configuration range, the password mode must be active.

102696 2009-03

43

Page 44

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Auto Write Configuration

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 1 0 0 1 1

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 not relevant - - - - - - - -

Byte 3 Address in the

configuration range

Byte 4 Data 00 ... FF

Byte 5 Data 00 ... FF

Byte 6 Data 00 ... FF

Byte 7 Data 00 ... FF

h

h

h

h

Byte 8 not relevant - - - - - - - -

Byte 9 not relevant - - - - - - - -

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 1 0 0 1 1

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Status <Status>

Byte 3 Execution counter <ExecCounter>

Byte 4 not relevant - - - - - - - -

.

.

.

.

.

.

- - - - - - - -

Byte 9 not relevant - - - - - - - -

<RegAddr>

<Data>

<Data>

<Data>

<Data>

44

An attempt is made to write a word in the configuration range from the address until successful.

<RegAddr>. In order to write in the configuration range, the password mode must be active.

102696 2009-03

Page 45

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Buffered Write Configuration

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 1 0 1 0 0

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 not relevant - - - - - - - -

Byte 3 Address in the

configuration range

Byte 4 Data 00 ... FF

Byte 5 Data 00 ... FF

Byte 6 Data 00 ... FF

Byte 7 Data 00 ... FF

h

h

h

h

Byte 8 not relevant - - - - - - - -

Byte 9 not relevant - - - - - - - -

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 1 0 1 0 0

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Status <Status>

Byte 3 Execution counter <ExecCounter>

Byte 4 not relevant - - - - - - - -

.

.

.

.

.

.

- - - - - - - -

Byte 9 not relevant - - - - - - - -

<RegAddr>

<Data>

<Data>

<Data>

<Data>

One attempt is made to write a word in the configuration range from the address <RegAddr> .

After each successful write, the response is sent and the system waits until a new data carrier

is within the detection range. The command then starts again from the beginning. In order to

write in the configuration range, the password mode must be active.

102696 2009-03

45

Page 46

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Enhanced Buffered Write Configuration

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 1 0 0 1 1 0

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 not relevant - - - - - - - -

Byte 3 Address in the

configuration range

Byte 4 Data 00 ... FF

Byte 5 Data 00 ... FF

Byte 6 Data 00 ... FF

Byte 7 Data 00 ... FF

h

h

h

h

Byte 8 not relevant - - - - - - - -

Byte 9 not relevant - - - - - - - -

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 1 0 0 1 1 0

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Status <Status>

Byte 3 Execution counter <ExecCounter>

Byte 4 not relevant - - - - - - - -

.

.

.

.

.

.

- - - - - - - -

Byte 9 not relevant - - - - - - - -

<RegAddr>

<Data>

<Data>

<Data>

<Data>

46

One attempt is made to write a word in the configuration range from the address <RegAddr>.

After each successful write, the response is sent and the system waits until a new data carrier

is within the detection range. The command then starts again from the beginning. In order to

write in the configuration range, the password mode must be active. When the data carrier

leaves the read range, the status “05

” is output.

h

102696 2009-03

Page 47

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Single Get Configuration

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 1 0 0 0 0 1

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Reserved 0 0 0 0 0 0 0 0

Byte 3 Register address <RegAddr>

Byte 4 not relevant - - - - - - - -

.

.

.

Byte 9 not relevant - - - - - - - -

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 1 0 0 0 0 1

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Status <Status>

Byte 3 Execution character <ExecCounter>

Byte 4 Data 00 ... FF

Byte 5 Data 00 ... FF

Byte 6 Data 00 ... FF

Byte 7 Data 00 ... FF

Byte 8 not relevant - - - - - - - -

Byte 9 not relevant - - - - - - - -

.

.

.

h

h

h

h

- - - - - - - -

<Data>

<Data>

<Data>

<Data>

One attempt is made to read a word in the configuration range (“protection word” or “control

word”) from the address <RegAddr>.

102696 2009-03

47

Page 48

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Auto Get Configuration

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 1 0 0 0 1 0

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Reserved 0 0 0 0 0 0 0 0

Byte 3 Register address <RegAddr>

Byte 4 not relevant - - - - - - - -

.

.

.

.

.

.

Byte 9 not relevant - - - - - - - -

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 1 0 0 0 1 0

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Status <Status>

Byte 3 Execution character <ExecCounter>

Byte 4 Data 00 ... FF

Byte 5 Data 00 ... FF

Byte 6 Data 00 ... FF

Byte 7 Data 00 ... FF

h

h

h

h

Byte 8 not relevant - - - - - - - -

Byte 9 not relevant - - - - - - - -

- - - - - - - -

<Data>

<Data>

<Data>

<Data>

48

Repeated attempts are made until successful, to read a word in the configuration range from

the address <RegAddr> .

102696 2009-03

Page 49

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Buffered Get Configuration

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 1 0 0 0 1 1

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Reserved 0 0 0 0 0 0 0 0

Byte 3 Register address <RegAddr>

Byte 4 not relevant - - - - - - - -

.

.

.

.

.

.

Byte 9 not relevant - - - - - - - -

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 1 0 0 0 1 1

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Status <Status>

Byte 3 Execution character <ExecCounter>

Byte 4 Data 00 ... FF

Byte 5 Data 00 ... FF

Byte 6 Data 00 ... FF

Byte 7 Data 00 ... FF

h

h

h

h

Byte 8 not relevant - - - - - - - -

Byte 9 not relevant - - - - - - - -

- - - - - - - -

<Data>

<Data>

<Data>

<Data>

An attempt is made to write a word in the configuration range from the address until successful.

<RegAddr>. Only changed data is transferred via the interface.

102696 2009-03

49

Page 50

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Enhanced Buffered Get Configuration

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 1 0 1 0 0 0

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Reserved 0 0 0 0 0 0 0 0

Byte 3 Register address <RegAddr>

Byte 4 not relevant - - - - - - - -

.

.

.

.

.

.

Byte 9 not relevant - - - - - - - -

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 1 0 1 0 0 0

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Status <Status>

Byte 3 Execution character <ExecCounter>

Byte 4 Data 00 ... FF

Byte 5 Data 00 ... FF

Byte 6 Data 00 ... FF

Byte 7 Data 00 ... FF

h

h

h

h

Byte 8 not relevant - - - - - - - -

Byte 9 not relevant - - - - - - - -

- - - - - - - -

<Data>

<Data>

<Data>

<Data>

50

An attempt is made to write a word in the configuration range from the address until successful.

<RegAddr>. Only changed data is transferred via the interface. When the data carrier leaves

the read range, the status “05h” is output.

102696 2009-03

Page 51

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

7. 7. 2 P a s s w o r d m od e w i t h I P C 0 3

Note!

The password is a 32-bit word that is set to "0" before a new IPC03 data carrier leaves the

factory. The password cannot be read. In order to write the passwords for the "Control Word"

and the "Protection Word", the processing must always be in password mode.

Password Mode

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 1 1 0 0 0

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Mode (on:<F>=1, off:<F>=0) 0 0 0 0 0 0 0 <F>

Byte 3 not relevant - - - - - - - -

.

.

.

Byte 9 not relevant - - - - - - - -

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 1 1 0 0 0

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Status <Status>

Byte 3 not relevant - - - - - - - -

.

.

.

Byte 9 not relevant - - - - - - - -

.

.

.

.

.

.

- - - - - - - -

- - - - - - - -

Activates (Mode <F> = “1”) and deactivates (Mode <F> = “0”) the password mode of the read

head. In the password mode, the password is transferred to the data carrier before each

read/write access. If a data carrier is addressed with the wrong password, then even the data

range, for which no password protection is set, cannot be accessed.

102696 2009-03

51

Page 52

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Password Change

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 0 0 0 0 0 1

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Old password 00 ... FF

Byte 3 Old password 00 ... FF

Byte 4 Old password 00 ... FF

Byte 5 Old password 00 ... FF

Byte 6 New password 00 ... FF

Byte 7 New password 00 ... FF

Byte 8 New password 00 ... FF

Byte 9 New password 00 ... FF

h

h

h

h

h

h

h

h

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 0 0 0 0 0 1

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Status <Status>

Byte 3 not relevant - - - - - - - -

.

.

.

.

.

.

- - - - - - - -

Byte 9 not relevant - - - - - - - -

<PSW 3>

<PSW 2>

<PSW 1>

<PSW 0>

<PSW 3>

<PSW 2>

<PSW 1>

<PSW 0>

52

Changes the password in a data carrier. Here, first the old and then the new password has to

be entered. If the password has been successfully written, then the password in the read/write

head is also changed. The command “password set” is no longer necessary. The IPC03

password can also be changed when the password mode is deactivated.

102696 2009-03

Page 53

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Password Set

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 0 0 0 0 1 0

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 not relevant - - - - - - - -

Byte 3 not relevant - - - - - - - -

Byte 4 Password 00 ... FF

Byte 5 Password 00 ... FF

Byte 6 Password 00 ... FF

Byte 7 Password 00 ... FF

h

h

h

h

Byte 8 not relevant - - - - - - - -

Byte 9 not relevant - - - - - - - -

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 0 0 0 0 1 0

Byte 1 Reserved/Toggle bit - - - - - - - T

Byte 2 Status <Status>

Byte 3 not relevant - - - - - - - -

.

.

.

.

.

.

- - - - - - - -

Byte 9 not relevant - - - - - - - -

<PSW 3>

<PSW 2>

<PSW 1>

<PSW 0>

Sets the password, which the read/write head communicates to the data carrier in the

password mode.

102696 2009-03

53

Page 54

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

7.7.3 Write fixed code IPC10

Single Write Fixcode

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 1 1 1 1 1

Byte 1 FixLen/Toggle bit <FixLen> - - - T

Byte 2 Fixtype <FixType> (High Byte)

Byte 3 Fixtype <FixType> (Low Byte)

Byte 4 Data 00 ... FF

.

.

.

Byte 9 Data 00 ... FF

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 0 1 1 1 1 1

Byte 1 FixLen/Toggle bit <FixLen> - - - T

Byte 2 Status <Status>

Byte 3 Execution counter <ExecCounter>

Byte 4 not relevant - - - - - - - -

.

.

.

Byte 9 not relevant - - - - - - - -

Data 00 ... FF

.

.

.

h

h

h

<Data>

<Data>

<Data>

- - - - - - - -

54

One attempt is made to write a fixed code. This <FixType> is always “02” and <FixLen> “05

since 5 bytes must always be written.

”,

h

102696 2009-03

Page 55

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Auto Write Fixcode

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 1 0 0 1 0 0

Byte 1 FixLen/Toggle bit <FixLen> - - - T

Byte 2 FixType <FixType> (High Byte)

Byte 3 FixType <FixType> (Low Byte)

Byte 4 Data 00 ... FF

.

Data 00 ... FF

.

.

Byte 9 Data 00 ... FF

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 1 0 0 1 0 0

Byte 1 FixLen/Toggle bit <FixLen> - - - T

Byte 2 Status <Status>

Byte 3 Execution counter <ExecCounter>

Byte 4 not relevant - - - - - - - -

.

.

.

.

.

.

Byte 9 not relevant - - - - - - - -

h

h

h

- - - - - - - -

<Data>

<Data>

<Data>

An attempt is made to write a fixcode until successful.

102696 2009-03

55

Page 56

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Buffered Write Fixcode

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 1 0 0 1 0 1

Byte 1 FixLen/Toggle bit <FixLen> - - - T

Byte 2 FixType <FixType> (High Byte)

Byte 3 FixType <FixType> (Low Byte)

Byte 4 Data 00 ... FF

.

Data 00 ... FF

.

.

Byte 9 Data 00 ... FF

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 1 1 0 0 1 0 1

Byte 1 FixLen/Toggle bit <FixLen> - - - T

Byte 2 Status <Status>

Byte 3 Execution counter <ExecCounter>

Byte 4 not relevant - - - - - - - -

.

.

.

.

.

.

Byte 9 not relevant - - - - - - - -

h

h

h

- - - - - - - -

<Data>

<Data>

<Data>

56

One attempt is made to write a fixcode. After each successful write, the response is sent and

the system waits until a new data carrier is within the detection range. The command then

starts again from the beginning.

102696 2009-03

Page 57

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

Enhanced buffered write fixed code; write ID code

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 1 0 0 1 0 0

Byte 1 FixLen/Toggle bit <FixLen> - - - T

Byte 2 Fixtype <FixType> (High Byte)

Byte 3 Fixtype <FixType> (Low Byte)

Byte 4 Data 00 ... FF

.

Data 00 ... FF

.

.

Byte 9 Data 00 ... FF

h

h

h

Response:

Byte Content B7 B6 B5 B4 B3 B2 B1 B0

Byte 0 Command code 0 0 1 0 0 1 0 0

Byte 1 FixLen/Toggle bit <FixLen> - - - T

Byte 2 Status <Status>

Byte 3 Execution counter <ExecCounter>

Byte 4 not relevant - - - - - - - -

.

.

.

.

.

.

- - - - - - - -

Byte 9 not relevant - - - - - - - -

<Data>

<Data>

<Data>

One attempt is made to write a fixcode. After each successful write, the response is sent and

the system waits until a new data carrier is within the detection range. The command then

starts again from the beginning. When the data carrier leaves the read range, the status “05

output.

102696 2009-03

” is

h

57

Page 58

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

7.8 Legend

<ConfAddr> : Word start address in the configuration range of the data

<Data> : <WordNum> times 4 Bytes. When communicating a word,

<ExecCounter> : 1 byte

<FixLen> : 4 Bits

<FixType> : 2 ASCII characters, for example: for IPC02 “02” (32h 30h)

<IDCode> : 4 bytes for IPC03

Mode <F> : 1 ASCII character “0” or “1”.

<Parameter>: : 1 Byte, range of values 01h to 08h

<PSW> : 4 Bytes, password

<RegAddr>: : 4 Bytes

<Status> : 1 byte

<T> : 1 Bit 0 (0b); 1(1b)

<TagType> : 2 ASCII characters, for example: '02' for IPC02

<VersionData> : 6 ASCII characters, software version message

<WordAddr> : 4 Bytes

<WordNum> : 4 Bits

carrier.

1 ASCII character range from "0" to "F", depending on data

carrier type.

The following applies for IPC03:

"1" = Protection Word

"2" = Control Word

the highest value byte is transferred first and the lowest

value byte last.

5 bytes for IPC02 and IPC11

Word start address in the data carrier, range from "0000"

to "FFFF", depending on data carrier type.

Number of words to be read or written, 01h (“0001”) is used

as number of words.

The following applies for IPC03:

The number of words 00h is used with the word address

“0000” to read the preset data range on the data carrier.

58

102696 2009-03

Page 59

IPT*-FP WITH U-P6-B5

Operation on the INTERBUS

7.9 Error/Status messages

Status Meaning

00h The command has been executed without error.

FFh The command is processing.

Error messages which triggered the identification system

Status Meaning

02h Switch-on message. Reset has been executed.

03h Reserved

04h Incorrect or incomplete command or parameter not in the valid

05h Read/write error. No data carrier in the detection range.

06h Hardware error,

07h Internal device error.

08h Reserved

09h Reserved

0Ah Reserved

0Bh Reserved

0Ch Reserved

0Dh Reserved

0Eh Reserved

0Fh Reserved

range.

e.g. error on self test or read head defect.

Error messages, which triggered the lower section U-P6-B5*

Status Meaning

10h Reserved

20h Reset has been executed.

40h Incorrect or incomplete command or parameter not in the valid

60h Hardware error,

70h Internal device error.

102696 2009-03

range.

e.g. no communication with the identification system.

59

Page 60

IPT*-FP WITH U-P6-B5

Technical specifications

8 Technical specifications

8.1 Read/write station IPT*-FP

IPT*-FP

General data

Operating frequency 125 kHz

Transfer rate 2 kBit/s

Operating distance max. 100 mm

Display/controls

LED green Power on

LED yellow IPC recognized

LED red Bus error (with the use of field bus

Electrical data

Rated operating voltage U

Power consumption P

Galvanic isolation

e

0

interfaces)

20 ... 30 V DC, ripple 10 %SS, PELV

max. 5 W, in connection with lower section

60

Operating voltage/Interface Functional isolation in accordance with DIN

Interface

Physical Interface type depends on the lower section

Ambient conditions

Ambient temperature -25 ... 70 °C (248 ... 343 K)

Storage temperature -40 ... 85 °C (233 ... 358 K)

Mechanical data

Degree of protection IP67 in accordance with IN 60529, in

Housing material PBT (Polybutylene terephthalate)

EN 50178, rated isolation voltage 50 V

used

connection with lower section

eff

102696 2009-03