Page 1

MANUAL

IC-KP-B7-V95

IDENTControl interface

with DeviceNet interface

FACTORY AUTOMATION

Page 2

IC-KP-B7-V95

With regard to the supply of products , the current issue of the following document is applicab le: The

General Terms of Delivery for Products and Services of the Electrical Industry, published by the

Central Association of the Electrical Industry (Zentralverband Elektrotechnik und Elektroindustrie

(ZVEI) e.V.) in its most recent version as well as the supplementary clause: "Expanded reservation

of proprietorship"

Page 3

IC-KP-B7-V95

Contents

1 Introduction......................................................................... 6

2 Declaration of conformity.................................................. 7

2.1 Declaration of conformity .............................................................................. 7

3 Safety................................................................................... 8

3.1 Symbols relevant to safety ............................................................................ 8

3.2 Intended use ................................................................................................. 8

3.3 General notes on safety.................................................................................8

3.4 Contact protection......................................................................................... 9

4 Product Description ......................................................... 10

4.1 Range of application ...................................................................................10

4.2 Device characteristics .................................................................................10

4.3 Product family .............................................................................................10

4.3.1 R/W heads ............................................................................................. 10

4.3.2 Code / Data carrier .................................................................................10

4.3.3 Handhelds ..............................................................................................11

4.4 Displays and controls ..................................................................................12

4.5 Interfaces and connections ......................................................................... 13

4.6 Delivery package ........................................................................................13

4.7 Connection accessories..............................................................................14

4.7.1 Connection cable for R/W heads and trigger sensors ............................14

4.7.2 Cable connectors for the power supply ..................................................14

5 Installation......................................................................... 15

5.1 Storage and transport ................................................................................. 15

5.2 Unpacking...................................................................................................15

5.3 EMC concept ..............................................................................................15

5.4 Device connection ......................................................................................16

5.4.1 Power supply ..........................................................................................16

5.4.2 Read/Write Head and Trigger Sensors ................................................... 17

5.4.3 Cable length between control interface and R/W heads .........................17

5.4.4 Ground connection ................................................................................. 17

5.4.5 DeviceNet connection guide...................................................................18

6 Commissioning................................................................. 19

6.1 Connection .................................................................................................19

6.2 Preliminary considerations ..........................................................................19

6.3 Device settings ........................................................................................... 19

6.3.1 Operating the device ..............................................................................21

6.4 Output of the contents of read data carriers on the display.......................... 22

2013-04

6.5 Setting the network parameters ..................................................................22

3

Page 4

IC-KP-B7-V95

Contents

7 Commands........................................................................ 23

7.1 Communication via DeviceNet ................................................................... 23

7.1.1 General information on communication via DeviceNet ........................... 23

7.1.2 Performance spectrum .......................................................................... 23

7.1.3 Electronic data sheet (EDS)................................................................... 23

7.1.4 Data/Command transfer......................................................................... 23

7.1.5 Mixed mode ........................................................................................... 23

7.1.6 Separated mode .................................................................................... 24

7.1.7 Data length ............................................................................................ 24

7.1.8 Assembly attributes ............................................................................... 25

7.1.9 Access administration............................................................................ 26

7.1.10 Heartbeat and ident status ..................................................................... 26

7.1.11 Data hold time ........................................................................................ 27

7.2 Command Execution.................................................................................. 27

7.2.1 Command examples.............................................................................. 29

7.3 Command types ......................................................................................... 30

7.4 Command overview ................................................................................... 31

7.4.1 System commands ................................................................................ 33

7.4.2 Standard read/write commands ............................................................. 39

7.4.3 Special command modes ...................................................................... 44

7.5 Legend ....................................................................................................... 65

7.6 Fault/Status messages ............................................................................... 66

8 Technical specifications .................................................. 68

8.1 Dimensions ................................................................................................ 68

8.2 General data ............................................................................................... 68

9 Troubleshooting ............................................................... 70

9.1 Fault location .............................................................................................. 70

10 ASCII table ........................................................................ 71

11 Appendix A ....................................................................... 72

11.1 Example 1 .................................................................................................. 72

11.2 Example 2 .................................................................................................. 77

4

2013-04

Page 5

IC-KP-B7-V95

Contents

12 Appendix B........................................................................ 88

12.1 Object model ..............................................................................................88

12.1.1 Identity object (01h)................................................................................88

12.1.2 Assembly object (04h) ............................................................................89

12.1.3 Output command object (instances 64h - 6) ...........................................94

12.1.4 Input command object (instances 65h - 6)..............................................95

12.1.5 Boot-up parameter object (instances 66h - 4).........................................96

12.1.6 Diagnostics object (instances 67h - 5)....................................................96

2013-04

5

Page 6

IC-KP-B7-V95

Introduction

1Introduction

Congratulations

You have chosen a device manufactured by Pepperl+Fuchs. Pepperl+Fuchs

develops, produces and distributes electronic sensors and interface modules for

the market of automation technology on a worldwide scale.

Before installing this equipment and put into operation, read this manual carefully.

This manual containes instructions and notes to help you through the installation

and commissioning step by step. This makes sure bring such a trouble-free use of

this product. This is for your benefit, since this:

■ ensures the safe operation of the device

■ helps you to exploit the full functionality of the device

■ avoids errors and related malfunctions

■ avoids costs by disruptions and any repairs

■ increases the effectiveness and efficiency of your plant

Keep this manual at hand for subsequent operations on the device.

After opening the packaging please check the integrity of the device and the

number of pieces of supplied.

Symbols used

The following symbols are used in this manual:

Note!

This symbol draws your attention to important information.

Handling instructions

You will find handling instructions beside this symbol

Contact

If you have any questions about the device, its functions, or accessories, please

contact us at:

Pepperl+Fuchs GmbH

Lilienthalstraße 200

68307 Mannheim

Telephone: +49 621 776-4411

Fax: +49 621 776-274411

E-Mail: fa-info@pepperl-fuchs.com

2013-04

6

Page 7

IC-KP-B7-V95

ISO9001

Declaration of conformity

2 Declaration of conformity

2.1 Declaration of conformity

This product was developed and manufactured under observance of the

applicable European standards and guidelines.

Note!

A Declaration of Conformity can be requested from the manufacturer.

The product manufacturer, Pepperl+Fuchs GmbH, D-68307 Mannheim, has a

certified quality assurance system that conforms to ISO 9001.

2013-04

7

Page 8

IC-KP-B7-V95

Safety

3Safety

3.1 Symbols relevant to safety

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

War ning !

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt devices and any connected facilities or systems,

or result in their complete failure.

3.2 Intended use

The IDENTControl IC-KP-B7-V95 is a control interface including a DeviceNet

interface for identification systems. The device can be used as a control cabinet

module or for field applications. Besides the DeviceNet connection, suitable

inductive R/W heads, microwave antennas or trigger sensors can be connected.

Wiring suitable for the system design must be used.

3.3 General notes on safety

Only instructed specialist staff may operate the device in accordance with the

operating manual.

User modification and or repair are dangerous and will void the warranty and

exclude the manufacturer from any liability. If serious faults occur, stop using the

device. Secure the device against inadvertent operation. In the event of repairs,

return the device to your local Pepperl+Fuchs representative or sales office.

The connection of the device and maintenance work when live may only be

carried out by a qualified electrical specialist.

The operating company bears responsibility for observing locally applicable

safety regulations.

Store the not used device in the original packaging. This offers the device optimal

protection against impact and moisture.

Ensure that the ambient conditions comply with regulations.

2013-04

8

Page 9

IC-KP-B7-V95

Read head IDENTControl

Compact

Safety

Note!

Disposal

Electronic waste is hazardous waste. When disposing of the equipment, observe

the current statutory requirements in the respective country of use, as well as local

regulations.

3.4 Contact protection

Our housings are manufactured using components made partly or completely

from metal to improve noise immunity.

Danger!

Electric shock

The metallic housing components are connected to ground to protect against

dangerous voltages that may occur in the event of a fault in the SELV power

supply!

See chapter 5.4.4

2013-04

9

Page 10

IC-KP-B7-V95

Product Description

4 Product Description

4.1 Range of application

The system is suited for the following applications:

■ Automation

■ Material flow control in production

■ Acquisition of operating data

■ Access control

■ Identification of storage vessels, pallets, work piece carriers, refuse

containers, tanks, containers, etc.

4.2 Device characteristics

■ Up to 4 R/W heads can be connected

■ Alternatively up to 2 R/W heads and 2 trigger sensors can be connected

■ LCD indicator with background illumination

■ Direct operation using 4 function keys

■ LED status indicator for bus communication and R/W heads

4.3 Product family

The IDENTControl brand name represents a complete identification system. The

system consists of an IDENTControl interface including bus interface, inductive

R/W heads (125 kHz and 13.56 MHz) and accompanying code and data carriers

in many different designs. The IDENTControl can be connected to other

identification systems.

The system is equally well suited for use in the switching cabinet and for field use

in IP67. The interface to the controlling fieldbus is integrated into the enclosure

and all connections are implemented as plugs. This enables simple installation

and quick, correct replacement in case of device failure. The consistent EMC

design (metal enclosure, grounding, shielded wires) offers a high degree of noise

immunity. Function buttons are available for parameterization and entering

commands directly into the IDENTControl.

4.3.1 R/W heads

There are different R/W heads available for the IDENTControl in different designs.

You can connect inductive R/W heads (125 kHz and 13.56 MHz) depending on

your particular application.

4.3.2 Code / Data carrier

Read only / read/write tag 125 kHz (inductive)

A wide range of read only and read/write tag designs are available for this

frequency range, from a 3 mm thin glass tube to a transponder 50 mm in diameter.

Read/write tags are available for temperatures up to 300 °C (max. 5 min) in

chemical-resistant housings for installation in metal and in degree of protection

IP68/IP69K. IPC02-... read only tags offer 40-bit read only codes. IPC03-...

read/write tags have a 928-bit freely programmable memory bank and an

unmodifiable 32-bit read only code. You can define 40-bit read only codes with

IPC11-... read only tags. You can use these as permanent read only codes or

continually redefine them.

10

2013-04

Page 11

IC-KP-B7-V95

Product Description

Read/write tag 13.56 MHz (inductive)

Read/write tags in this frequency range save larger quantities of data and offer a

considerably higher reading speed than read/write tags of the 125 kHz system.

IQH-* and IQH1-* read/write heads from Pepperl+Fuchs are compatible with most

existing read/write tags that comply with standard ISO 15693. With the IQH2-*

read/write heads you can use read/write tags that comply with standard ISO

14443A.

The 13.56 MHz technology even allows smart labels (read/write tags in the form

of adhesive labels with printed barcode). Currently available read/write tags have

a memory capacity of 64 bits of read only code and a maximum 2 KB of

programmable memory.

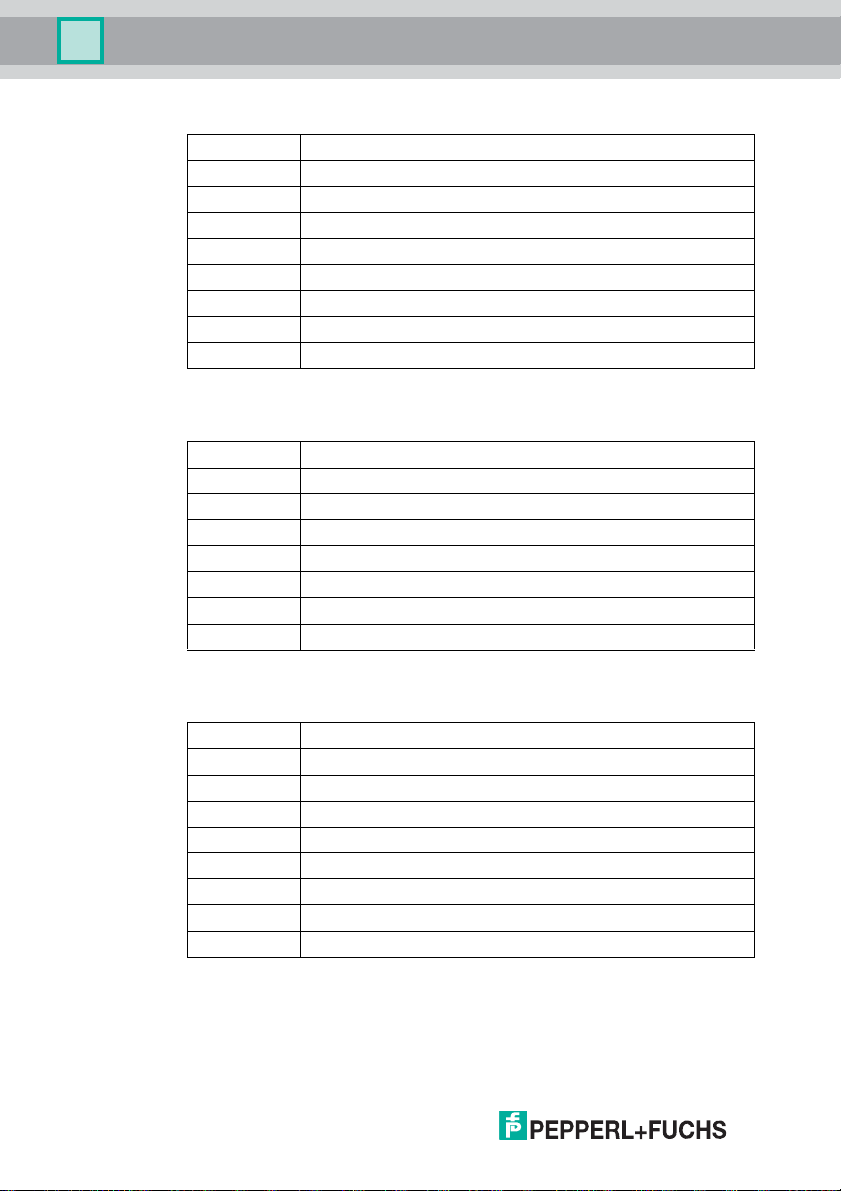

4.3.3 Handhelds

There are various handheld read/write devices available for controlling processes

(write/read functions, initialization of data carriers).

Figure 4.1

Handheld Frequency range

IPT-HH20 125 kHz

IST-HH20 250 kHz

IQT1-HH20 13.56 MHz

IC-HH20-V1 depending on the read/write head

2013-04

11

Page 12

IC-KP-B7-V95

1

PWR/

ERR

234

ESC

IC-KP-B7-V95

Part No. 130985

Module

Status

Network

Status

Com

Network

Pwr

Product Description

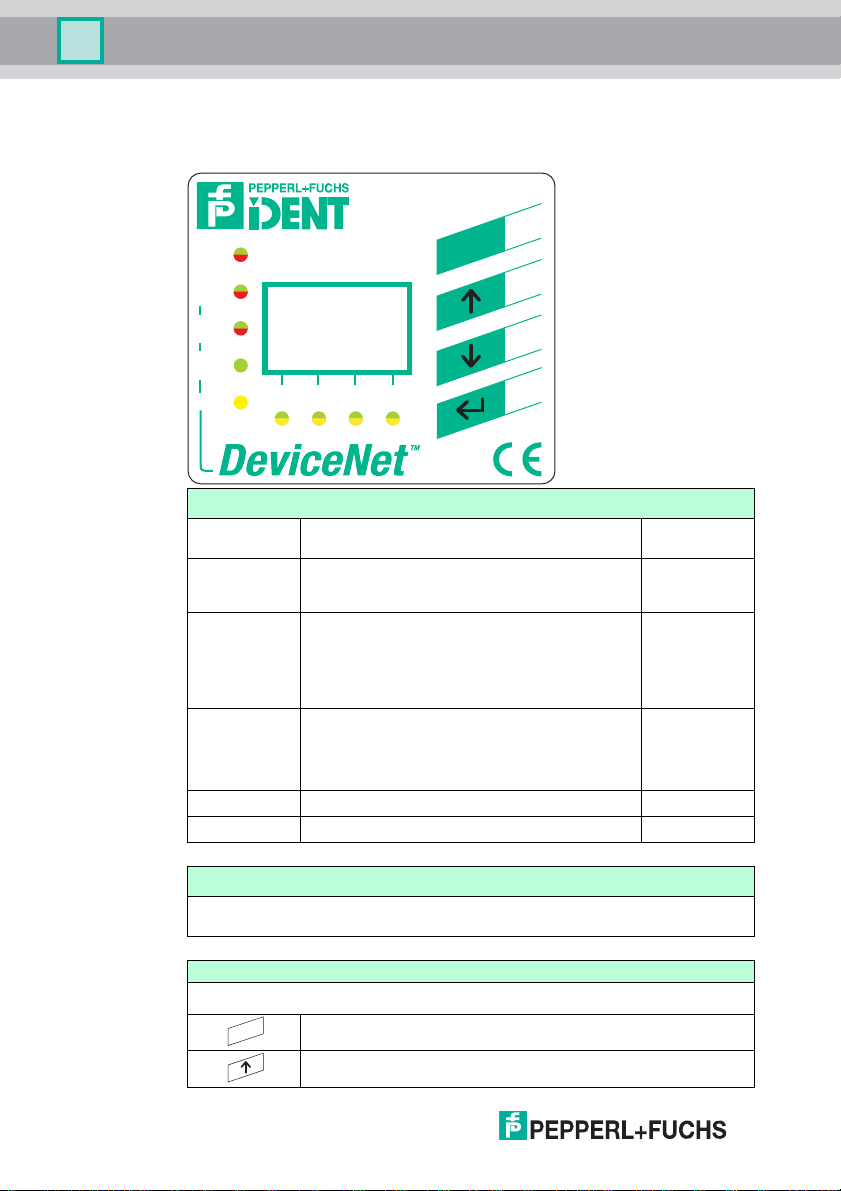

4.4 Displays and controls

The following displays and controls are located on the control interface.

LED indicators

PWR/ERR Power on

1, 2, 3, 4 Status display for R/W heads

Module status Device is operating in normal state

Network status Online, not connected

Network Pwr Network power supply available green

Com Data transfer (approx. 250 ms) Yel l ow

Hardware error

Command on R/W head is active

Command executed successfully (approx. 1 second)

Repairable errors (see chapter 9.1)

Irreparable errors – device must be replaced

Configuration requires modification (see chapter 9.1)

LED function test

Online, connected

Connection timeout

Critical connection error (duplicate MAC ID, bus

error)

green

red

green

yellow

green

red flashing

red

green flashing

red/green

flashing

green flashing

green

red flashing

red

12

Display

Two-line multifunction display with 12 characters per line for displaying different status and

operating information and four pictograms for displaying connected reading heads.

Push buttons

Push buttons are used for controlling the display and selecting commands when

programming the control interface.

ESC

Return to higher level

Up menu item

2013-04

Page 13

IC-KP-B7-V95

1

A

2

3

B

Product Description

Push buttons

Down menu item

RETURN (confirm input)

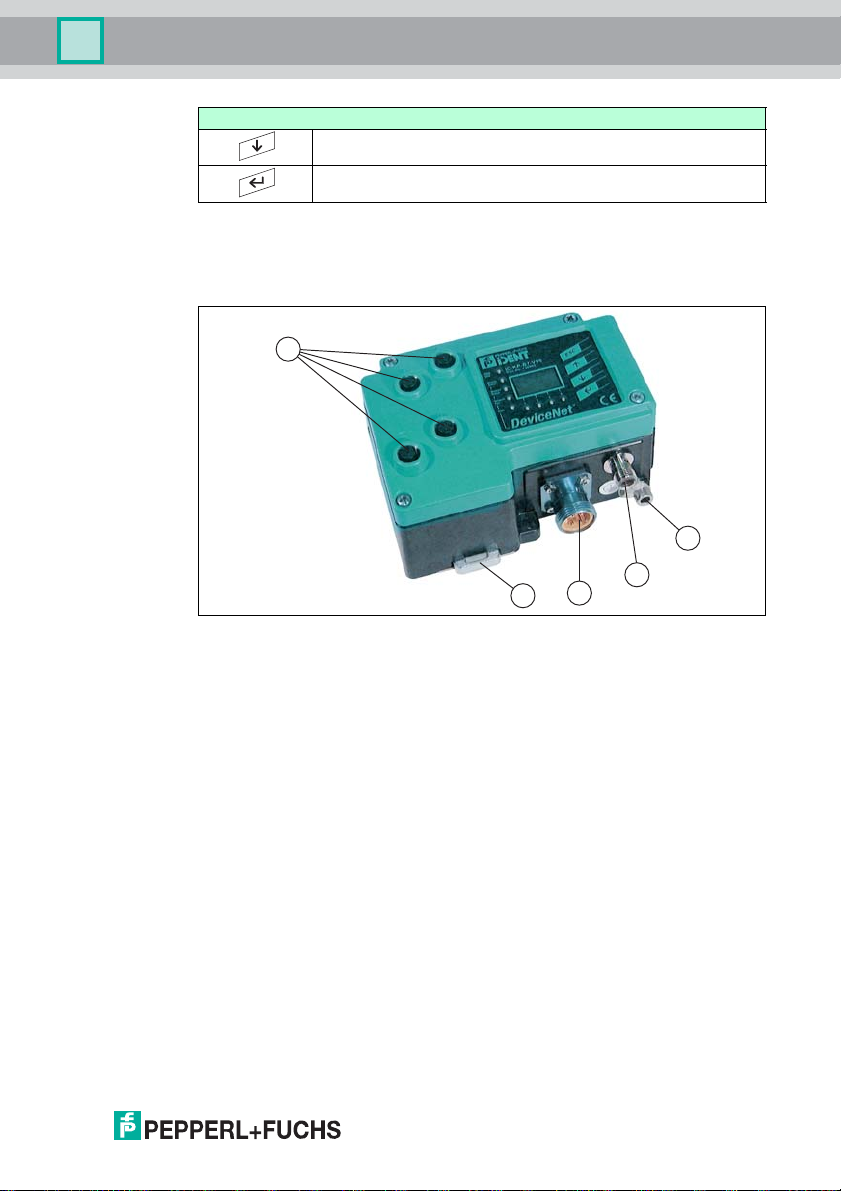

4.5 Interfaces and connections

The following interfaces and connections are located on the control interface ICKP-B7-V95.

Connections

1 M12 connector for R/W heads (sockets) - V1

2 M12 connector for power supply (plug) - V1

3 5-pin DeviceNet Ministyle connector

Other accessories

A Screw for gro und

B Metal latches for mounting the DIN rail

Accesso ries

Accessories see chapter 4.7.

4.6 Delivery package

The delivery package contains:

■ 1 IDENTControl control interface

■ 1 quick start guide

■ 1 grounding screw (already fitted)

■ 1 serrated lock washer (already fitted)

2013-04

■ 2 crimp connectors (already fitted)

13

Page 14

IC-KP-B7-V95

Product Description

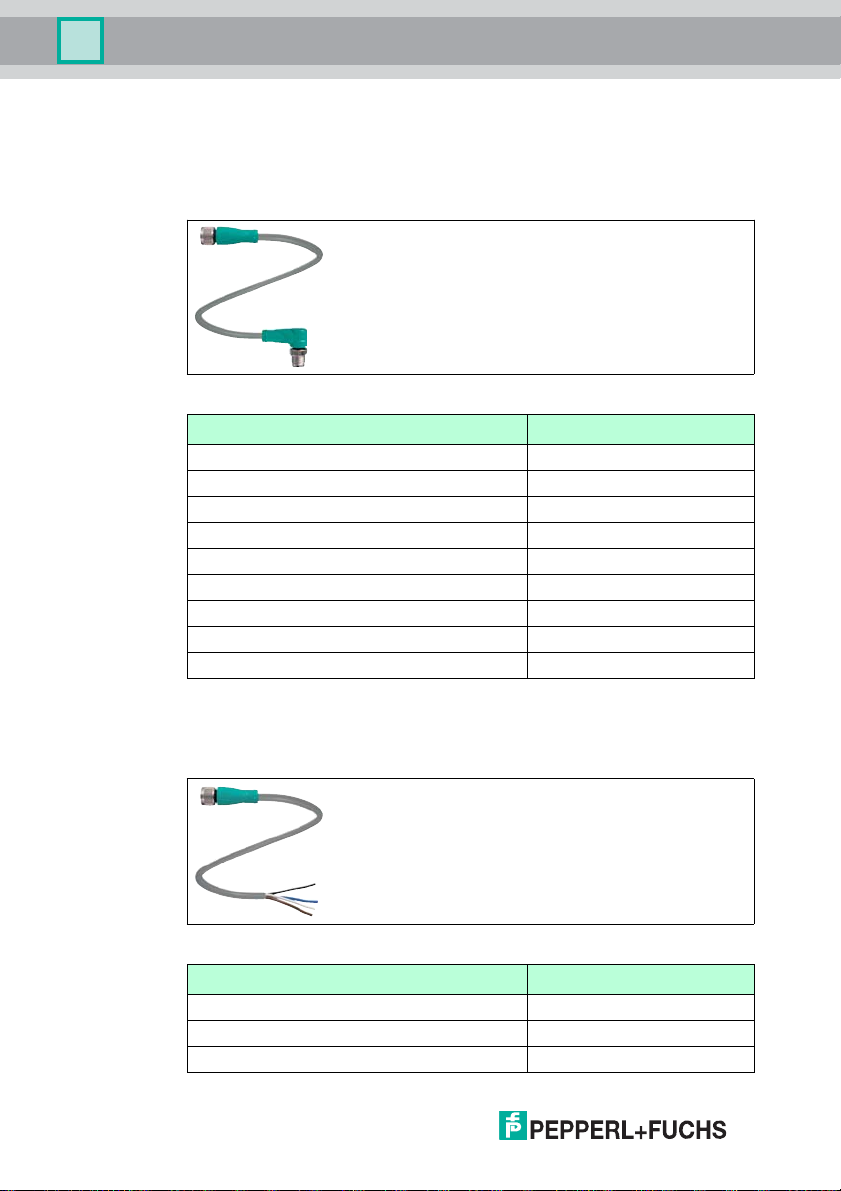

4.7 Connection accessories

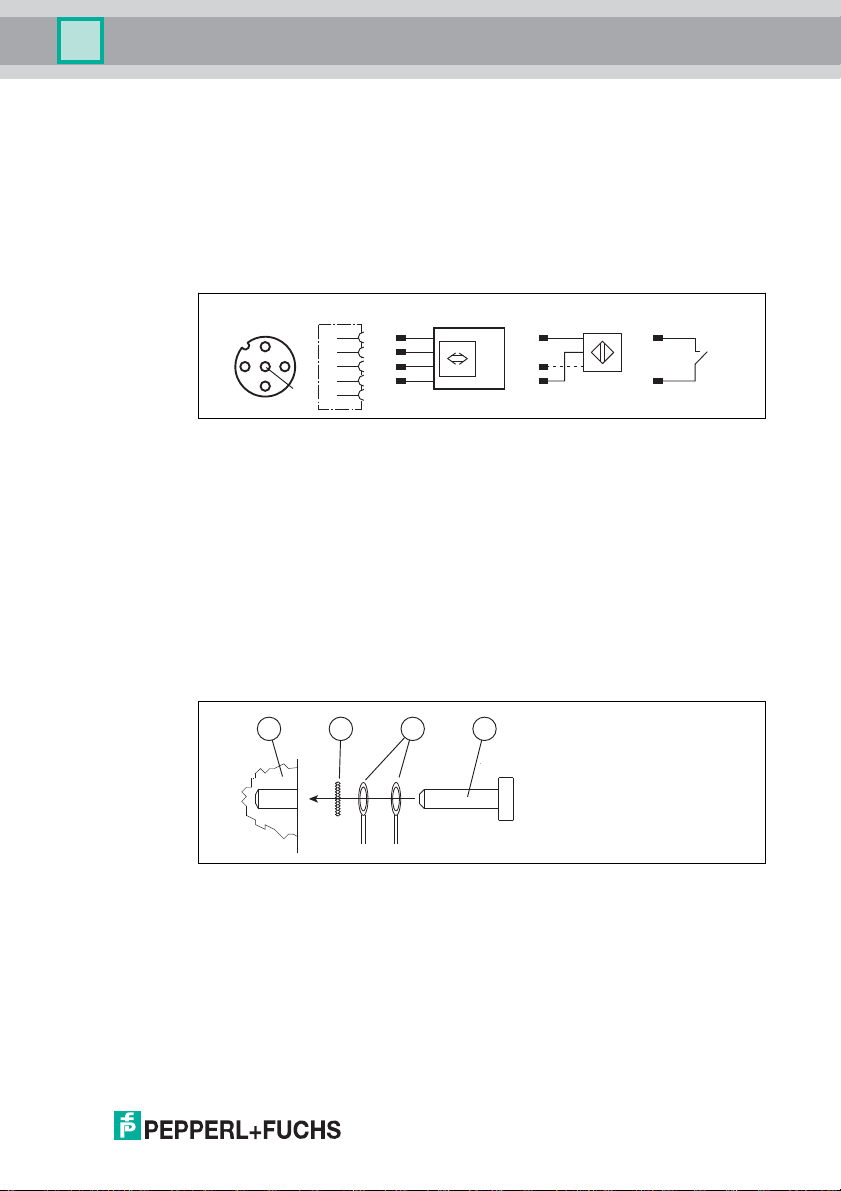

4.7.1 Connection cable for R/W heads and trigger sensors

Compatible connection cables with shielding are available for connecting the R/W

heads and trigger sensors.

Figure 4.2

Accessories Description

2 m long (straight female, angled male) V1-G-2M-P UR-ABG-V1-W

5 m long (straight female, angled male) V1-G-5M-P UR-ABG-V1-W

10 m long (straight female, angled male) V1-G -10M-PUR-ABG-V1-W

20 m long (straight female, angled male) V1-G -20M-PUR-ABG-V1-W

Field attachable female connector, straight, shielded V1-G-A BG-PG9

Field attachable male connector, straight, shielded V1S-G-ABG-PG9

Field attachable female connector, angled, shielded V1-W-ABG-PG9

Field attachable male connector, angled, shielded V1S-W-ABG-PG9

Dummy plug M12x1 VAZ -V1 -B3

4.7.2 Cable connectors for the power supply

Compatible M12 sockets with an open cable end for connecting the

IDENTControl to a power supply are available in different lengths.

Figure 4.3

Accessories Designation

Length 2 m (straight socket) V1-G-2M-P UR

Length 5 m (straight socket) V1-G-5M-P UR

Length 10 m (straight socket) V1-G -10M-PUR

14

2013-04

Page 15

IC-KP-B7-V95

Installation

5 Installation

5.1 Storage and transport

For storage and transport purposes, package the unit using shockproof

packaging material and protect it against moisture. The best method of protection

is to package the unit using the original packaging. Furthermore, ensure that the

ambient conditions are within allowable range.

5.2 Unpacking

Check the product for damage while unpacking. In the event of damage to the

product, inform the post office or parcel service and notify the supplier.

Check the package contents with your purchase order and the shipping

documents for:

■ Delivery quantity

■ Device type and version in accordance with the type plate

■ Accessories

■ Quick start guide

Retain the original packaging in case you have to store or ship the device again at

a later date.

Should you have any questions, please contact Pepperl+Fuchs.

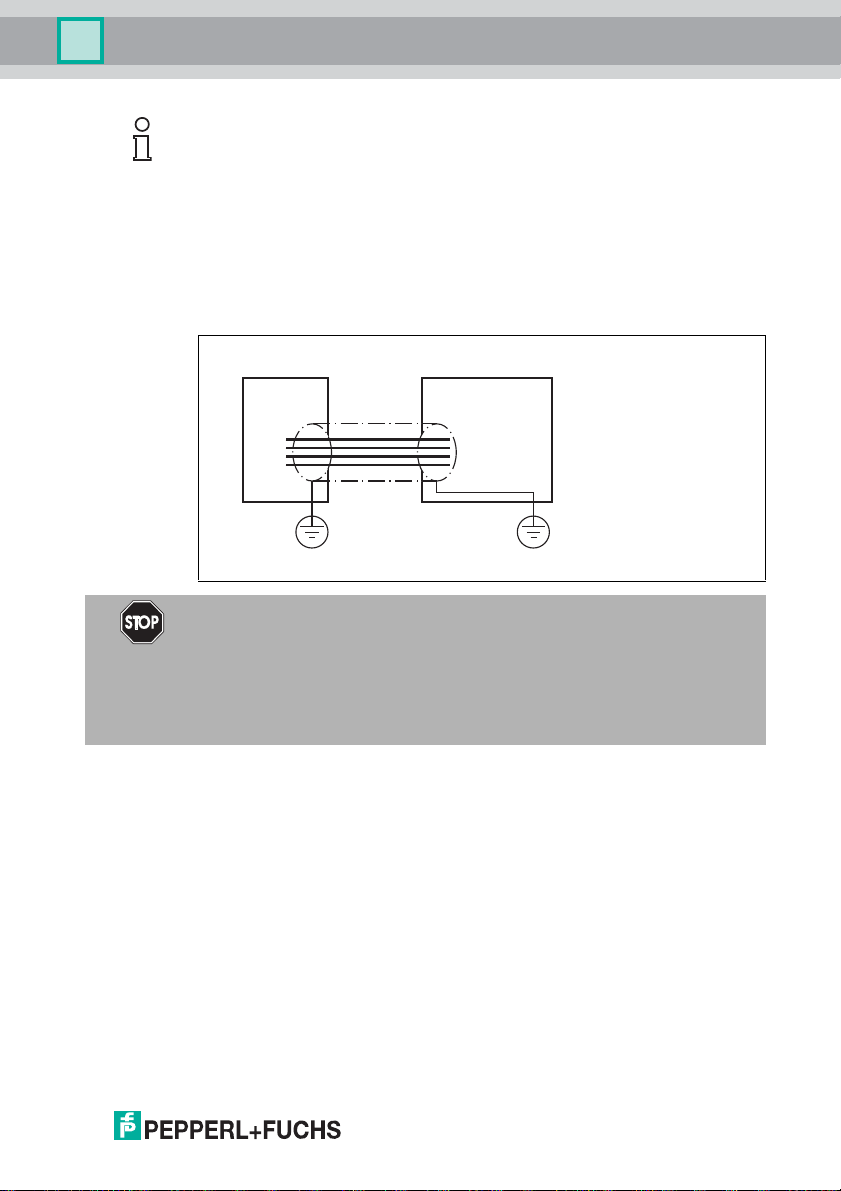

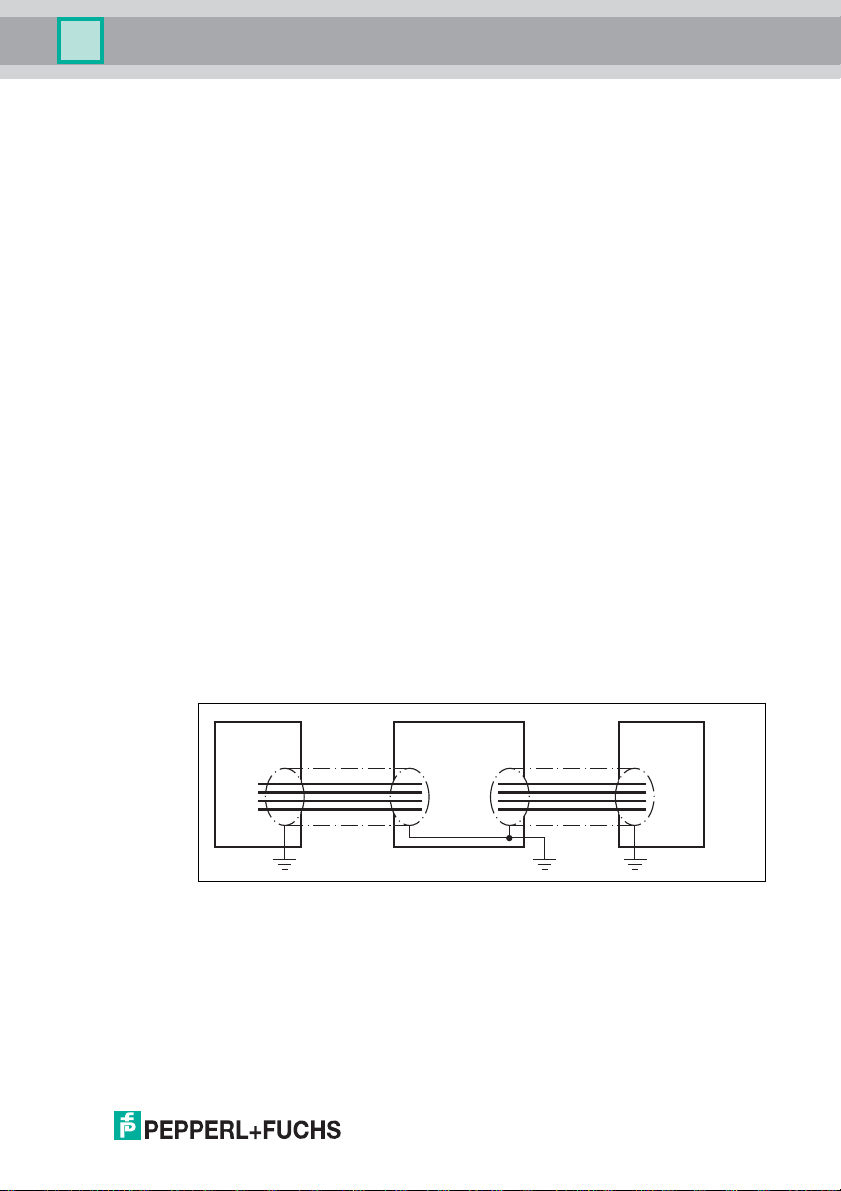

5.3 EMC concept

The outstanding noise immunity of the IDENTControl against emission and

immission is based on its consistent shielding design, which uses the principle of

the Faraday cage. Interference is caught in the shield and safely diverted via the

ground connections.

Read head ControlIDENTControl

DeviceNet

The cable shielding is used to discharge electromagnetic interference. When

shielding a cable, you must connect both sides of the shield to ground with low

resistance and low inductance.

2013-04

15

Page 16

IC-KP-B7-V95

4

13

2

Installation

Note!

If cables with double shields are used, e.g. wire mesh and metalized foil, the both

shields must be connected together, with low resistance, at the ends when

making up the cable.

Power supply cables are the source of much interference, e.g. from the supply

lines of 3-phase electric motors. For this reason, the parallel laying of power

supply cables with data and signal cables should be avoided, particularly in the

same cable duct.

The metal enclosure of the IDENTControl and the metal enclosure of the R/W

heads complete the consistent shielding concept.

The most important issue here is that the shields are connected to ground with

low resistance and low inductance. The metal enclosure ensures that the

shielding is not interrupted, i.e. the complete electronics system and all routed

cables are located within a Faraday cage.

Caution!

Due to the requirements in the DeviceNet specification, the shield on the bus

cable is connected to the device housing via an RC link.

5.4 Device connection

Electrical connection using plug connectors makes installation simple.

5.4.1 Power supply

Connect the power supply via an M12 connector with integrated voltage and

reverse polarity protection indicator (green: correct polarity, red: revers e polarity).

A plug with the following pin assignment is located on the housing:

1 + 24 V

2 NC

3 GND

4 NC

Compatible connecting cable see chapter 4.7.2.

16

2013-04

Page 17

IC-KP-B7-V95

trigger switch

trigger sensor

read/write head

signal

socket at housing

2

13

4

5

+

A

-

+

-

B

1

2

3

4

5

Installation

5.4.2 Read/Write Head and Trigger Sensors

A maximum of 4 read/write heads can be connected to the IDENTControl.

Instead of the read/write heads, a maximum of 2 trigger sensors can be

connected to sockets 3 and 4. A trigger sensor can be assigned to only one

read/write head. The trigger sensors must be PNP.

Connect the read/write heads and trigger sensors to the sockets on the top of the

enclosure using M12 connectors.

For details of compatible read/write heads, and of compatible connecting cables,

see chapter 4.7.1.

5.4.3 Cable length between control interface and R/W heads

The maximum cable length between the control interface and a connected R/W

head is 1000 meters. If you wish to attain the maximum possible cable length,

select a suitably large cable cross-section. See chapter 4.7.1

5.4.4 Ground connection

The ground connection of the IDENTControl is located at the lower right of the

connector array. The ground conductor is screwed to the housing with a crimp

connector. In order to guarantee safe grounding, the serrated washer must be

mounted between the crimp connector and the housing.

2013-04

12 43

1 Housing

2 Serrated lock washer

3 Crimp connector

4 Lock screw

A cross-section of at least 4 mm

2

is recommended for the ground conductor lead.

17

Page 18

IC-KP-B7-V95

2

4

1

3

5

Installation

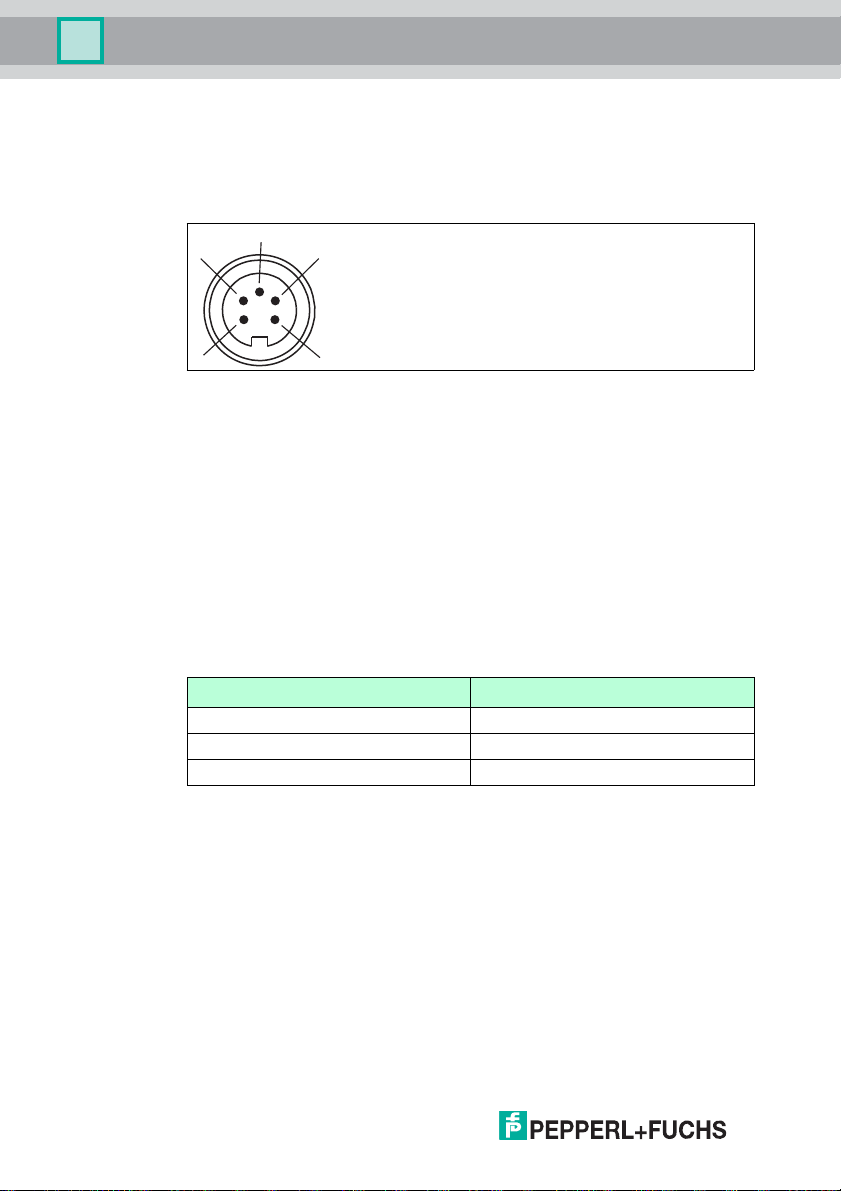

5.4.5 DeviceNet connection guide

Network connection

The network connection is established using a DeviceNet MiniStyle connector.

The pin assignment is taken from the drawing below.

1 Ground / uncoated

2 V+ / RD

3 V- / BK

4 CAN_H / WH

5 CAN_L / BU

Connecting cable

The device must always be connected using the "Thick" and "Thin" extension

cables described in the DeviceNet specification. Refer to the "Thick cable profile"

and "Thin cable profile" sections in the DeviceNet specification for more detailed

information.

Transfer rates and cable lengths

Baud rate Max. length of the transfer cable

125 kBits/s 500 m

250 kBits/s 250 m

500 kBits/s 100 m

2013-04

18

Page 19

IC-KP-B7-V95

Commissioning

6Commissioning

6.1 Connection

War ning !

Before commissioning, check once again that the connections are correct.

Before commissioning, familiarize yourself with the system of communication

between your DeviceNet control and the read/write station (see chapter 7).

Commissioning requires accurate knowledge of DeviceNet communication.

After the supply voltage is connected, the green LED in the voltage connector and

the PWR LED on the display panel must light up. If the LED in the connector lights

up red, the polarity of the power supply is reversed.

6.2 Preliminary considerations

A very important aspect of the operation of an extended identification system on

the DeviceNet is the time response of the overall system. The question "How long

after the positioning of a data carrier in front of a read/write station will the read

data be available in the computer or PLC?" cannot be answered universally.

The most important factors that determine the response time are:

■ Nature of the higher-level host system, e.g. PLC or PC

■ Communication between the client and server

■ Network utilization

■ Number and nature of connected read/write stations

■ Type of code/data carrier used

■ Nature of access to the communication objects of the read/write station

■ Nature of the commands to the read/write station

■ Structure of the user program

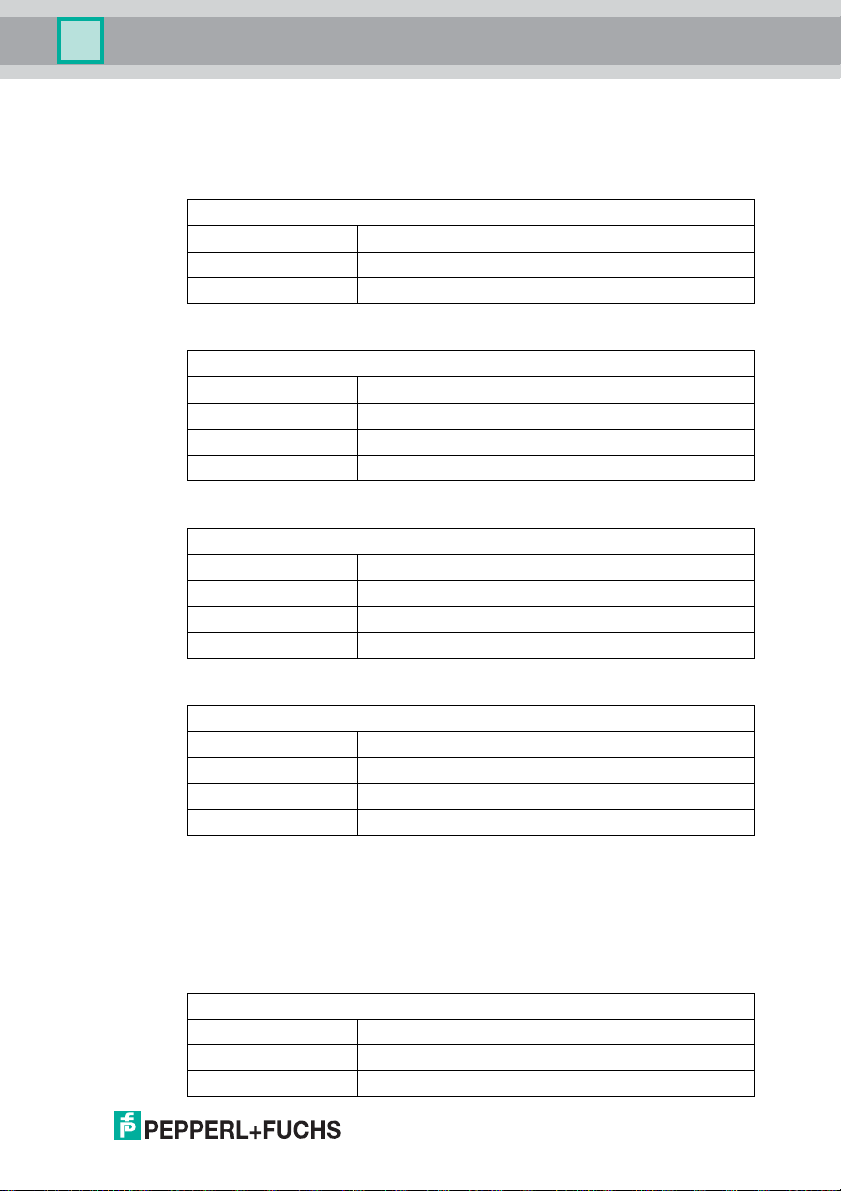

6.3 Device settings

War ning !

Device not configured or configured incorrectly

Configure the device prior to commissioning. A device that has not been

configured or configured incorrectly may lead to faults in the plant.

You must set the various parameters prior to commissioning.

The parameters are volatile and non-volatile parameters. Volatile parameters are

reset to their default setting when the system is switched off and on again.

2013-04

19

Page 20

IC-KP-B7-V95

Commissioning

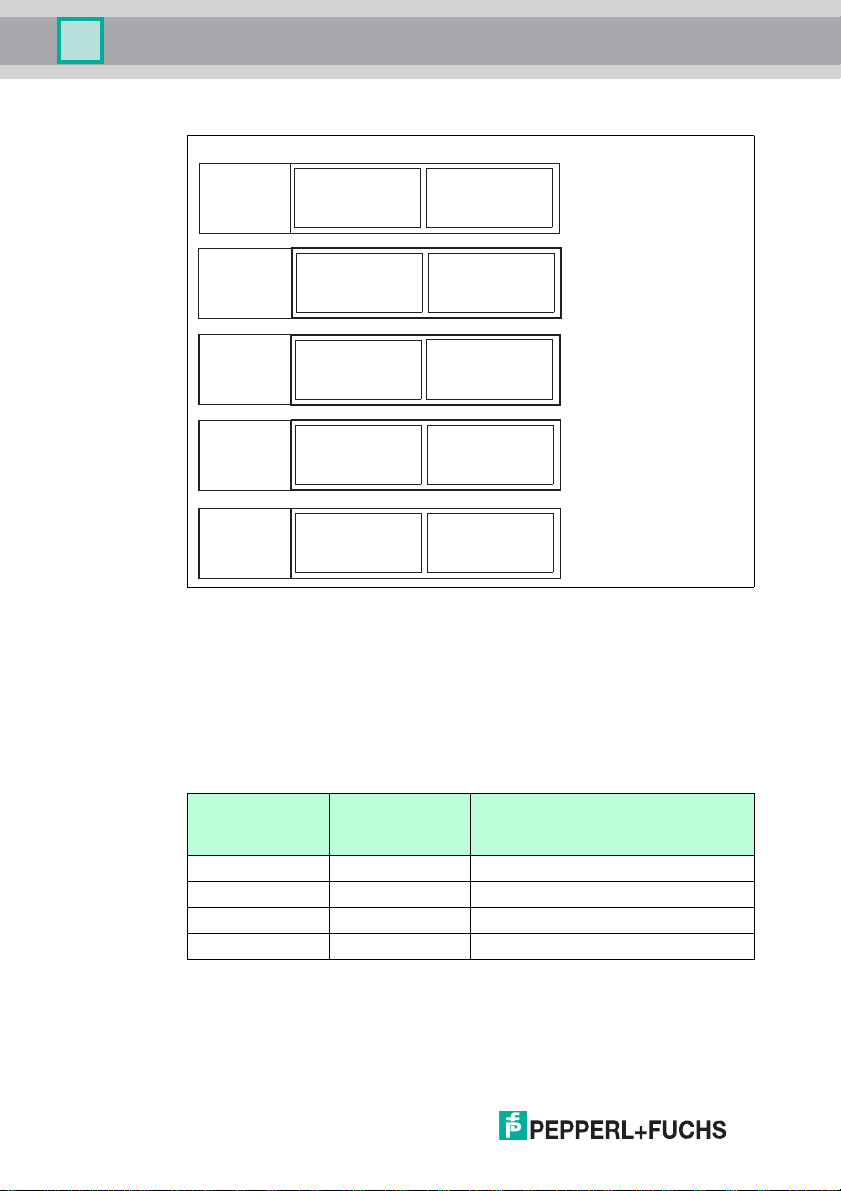

Non-volatile parameters

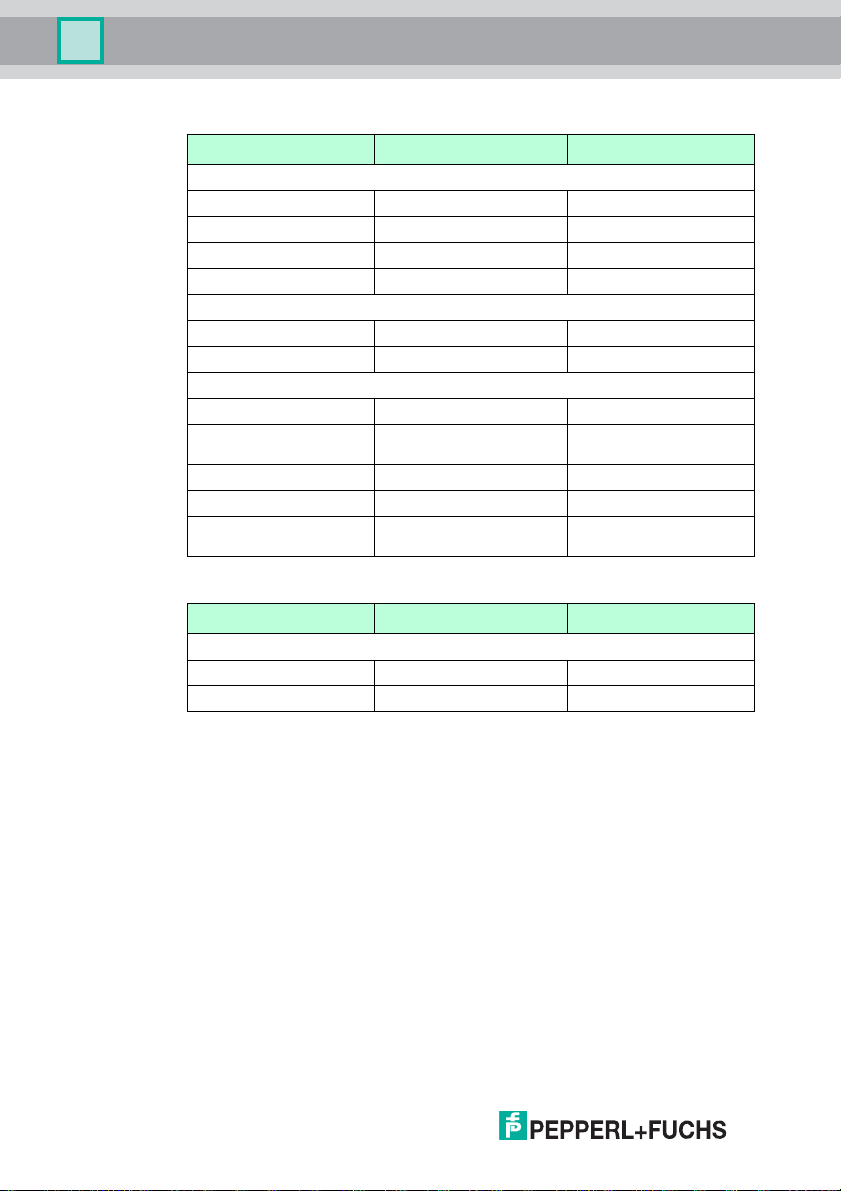

Par ame ter Default setting Value range

Ge n er a l

LCD c on trast 50 36 ... 71

LCD l ig ht On On / off

Language Eng lish English / German

Multiplex mode off On / off

R/W head

Trigger mode off On / off

Ta g t yp e 99 00 ... FF

DeviceNet interface

Network address 63d 00d ... 63d

Baud rate 125 kBit/s 125 kBit/s, 250 kBit/s,

Instance Out 100d 100d ... 112d

Instance In 150d 150d ... 162d

Data hold time 10 x 10 ms 000 x 10 ms ... 255d x 10

Volatile parameters

500 kBit/s

ms

20

Par ame ter Default setting Value range

R/W head

Password mode Off on / off

Password 00000000 00000000 ... FFFFFFFF

Configure the read/write station with the described system commands. "99" is

preset as the tag type.

2013-04

Page 21

IC-KP-B7-V95

Version

information

IPH1 IPH2 IPH3 IPH4

IDENTControl...

IPH1 IPH2 IPH3 IPH4

Config

IdentControl

IPH1 IPH2 IPH3 IPH4

Show Config

IdentControl

IPH1 IPH2 IPH3 IPH4

MultiplexM.

X

IPH1 IPH2 IPH3 IPH4

TagType

XX XX XX XX

IPH1 IPH2 IPH3 IPH4

TriggerMode

XXX

IPH1 IPH2 IPH3 IPH4

Triggerstate

H3:X H4:X

IPH1 IPH2 IPH3 IPH4

IdentGateway

IC-KP-B7-..

IPH1 IPH2 IPH3 IPH4

Reset

Config

IPH1 IPH2 IPH3 IPH4

Config

Channels

IPH1 IPH2 IPH3 IPH4

Aktivate

Command

IPH1 IPH2 IPH3 IPH4

Set Tag

(ChannelNo)

IPH1 IPH2 IPH3 IPH4

Version

ChannelNo:

IPH1 IPH2 IPH3 IPH4

EnhancedRead

Fixcode

IPH1 IPH2 IPH3 IPH4

ChannelNo: X

IPH1 IPH2 IPH3 IPH4

Enhanced

Read 1 Word

IPH1 IPH2 IPH3 IPH4

ChannelNo: X

IPH1 IPH2 IPH3 IPH4

Triggermode

...

IPH1 IPH2 IPH3 IPH4

Sensor Ch.

-> X

IPH1 IPH2 IPH3 IPH4

Quit

Command

IPH1 IPH2 IPH3 IPH4

ChannelNo: X

IPH1 IPH2 IPH3 IPH4

Reset

Identcontrol

IPH1 IPH2 IPH3 IPH4

Word-Address

XXXX

IPH1 IPH2 IPH3 IPH4

ChannelNo: X

IPH1 IPH2 IPH3 IPH4

ChannelNo: X

IPH1 IPH2 IPH3 IPH4

Tag Type

XX

IPH1 IPH2 IPH3 IPH4

IXH-XXXX

XX.XX.XX

IPH1 IPH2 IPH3 IPH4

Display

config

IPH1 IPH2 IPH3 IPH4

Select

language

IPH1 IPH2 IPH3 IPH4

LCD-Light

on/off

IPH1 IPH2 IPH3 IPH4

Adjust

LCD-Contrast

IPH1 IPH2 IPH3 IPH4

Reset

Config

IPH1 IPH2 IPH3 IPH4

Language

english

IPH1 IPH2 IPH3 IPH4

LCD-Contrast

XX

IPH1 IPH2 IPH3 IPH4

IDENT

Gateway...

IPH1 IPH2 IPH3 IPH4

Multiplexed

XXX

IPH1 IPH2 IPH3 IPH4

Multiplexed

Mode...

IPH1 IPH2 IPH3 IPH4

Set

Defaults?

IPH1 IPH2 IPH3 IPH4

Ident Ch.

-> X

IPH1 IPH2 IPH3 IPH4

Triggermode

XXX

IPH1 IPH2 IPH3 IPH4

Restart?

X

IPH1 IPH2 IPH3 IPH4

stands for pressing

ESC

stands for pressing

stands for pressing

stands for pressing

Direction

Direction

Direction

Direction

IPH1 IPH2 IPH3 IPH4

IPH1 IPH2 IPH3 IPH4

IPH1 IPH2 IPH3 IPH4

IPH1 IPH2 IPH3 IPH4

IPH1 IPH2 IPH3 IPH4

IPH1 IPH2 IPH3 IPH4

IPH1 IPH2 IPH3 IPH4

IPH1 IPH2 IPH3 IPH4

Address... MAC ID:

00-63

Baudrate...

125kBit/s

250kBit/s

Assembly

Instance

Out

100-In 150

Out

101-In 151

Datahold

Time

Datahold

T

x

10ms

500kBit/s

Out

112-In 162

...

Baudrate:

dhcp gültig

ja / nein

IPH1 IPH2 IPH3 IPH4IPH1 IPH2 IPH3 IPH4

Restart?

X

dhcp gültig

ja / nein

IPH1 IPH2 IPH3 IPH4IPH1 IPH2 IPH3 IPH4

Restart?

X

dhcp gültig

ja / nein

IPH1 IPH2 IPH3 IPH4IPH1 IPH2 IPH3 IPH4

Restart?

X

dhcp gültig

ja / nein

IPH1 IPH2 IPH3 IPH4IPH1 IPH2 IPH3 IPH4

Restart?

X

Commissioning

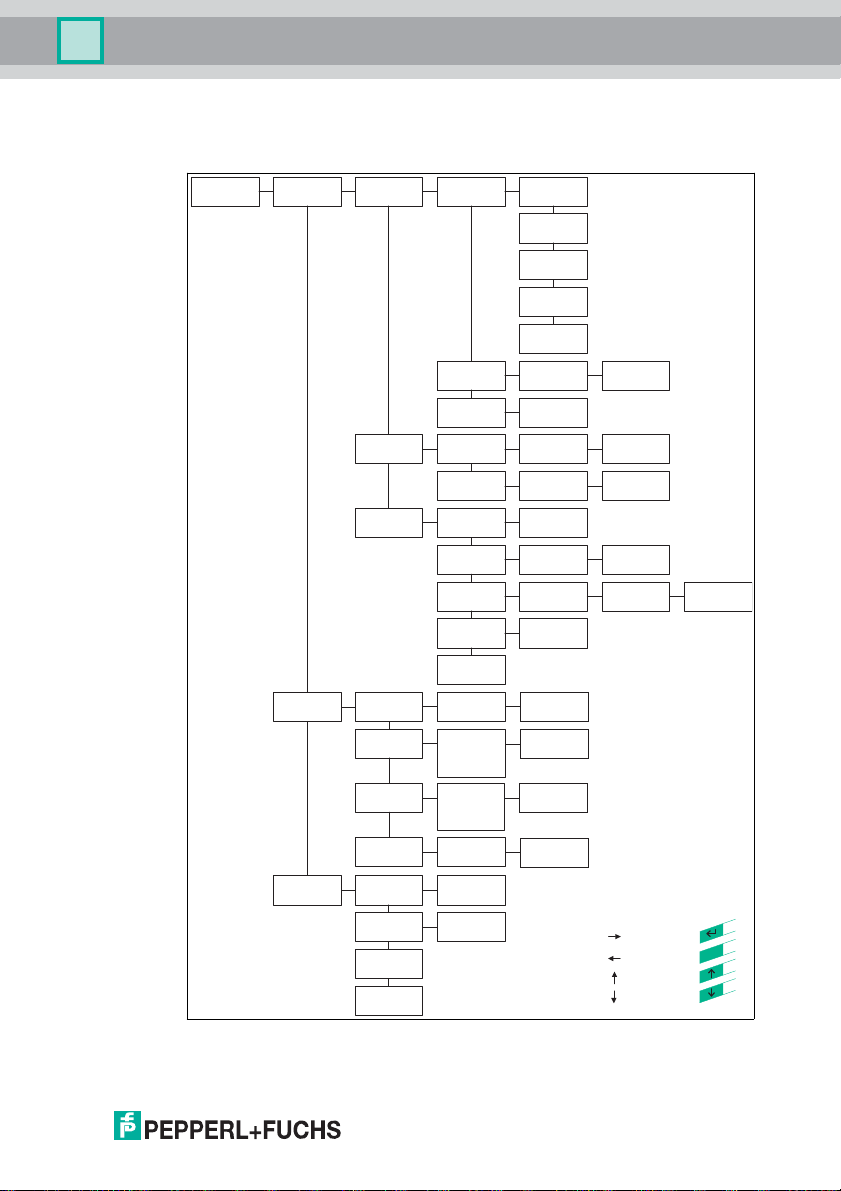

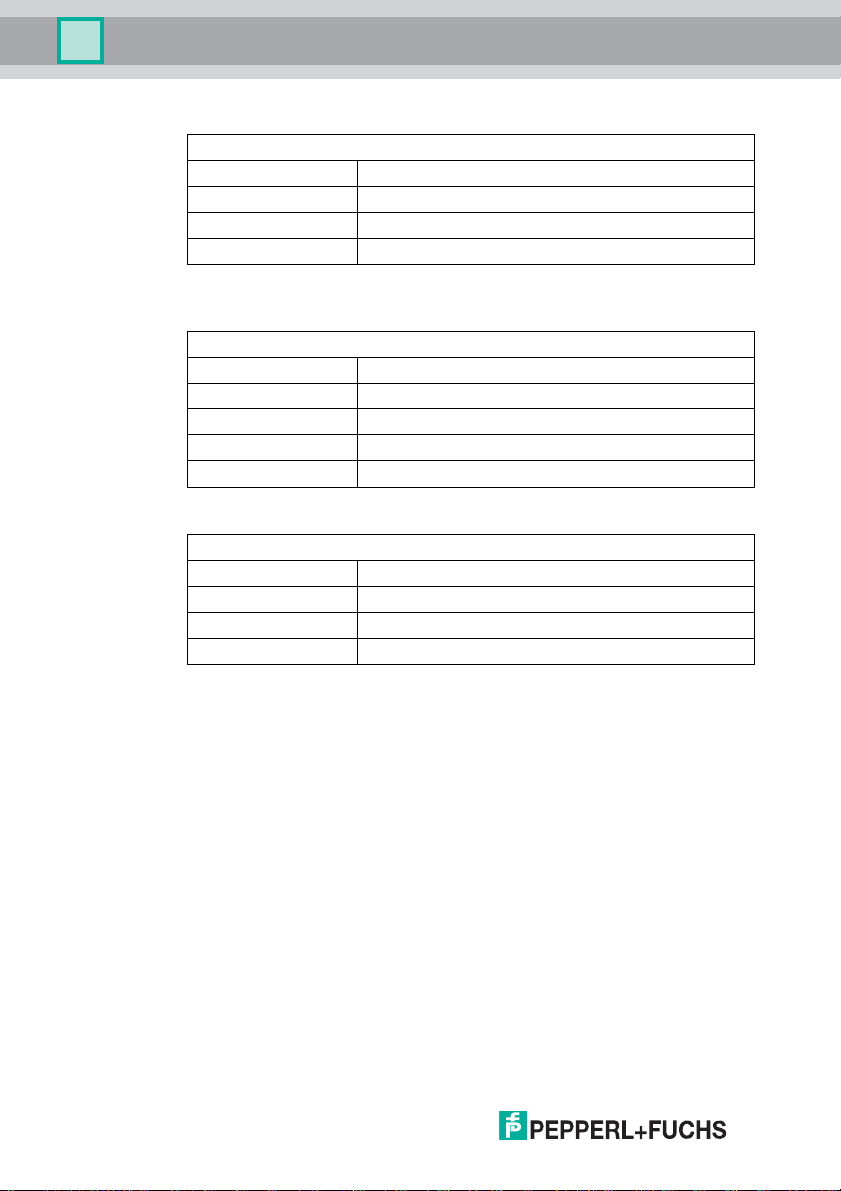

6.3.1 Operating the device

The following illustration shows how the device is operated directly:

2013-04

21

Page 22

IC-KP-B7-V95

Commissioning

6.4 Output of the contents of read data carriers on the display

In the first menu level, the IDENTControl shows the contents of read data carriers

on the display. Information messages of this kind are marked with a bell icon ( )

in the top right corner of the display to distinguish them from menu items.

A maximum of the first 12 characters of the read data set can be displayed. The

following characters may be excluded.

The view on the display can be toggled by pressing the arrow buttons. The

following display variants are available:

■ HEX (hexadecimal with decimal delimiter)

■ HEX2 (hexadecimal without decimal delimiter)

■ ASCII (ASC)

Note!

Data carrier content from commands that are activated manually on the

IDENTControl are always displayed, irrespective of the menu level that was just

displayed.

6.5 Setting the network parameters

The following parameters must be set manually via the display:

■ Bus address

■ Baud rate

■ Assembly instance

■ Data hold time

Caution!

Always use parameters that you know are compatible with your network.

Setting parameters

To set the parameters using the function buttons, proceed as follows:

1. Press return (confirm input).

2. Select IDENT gateway (down arrow button, return).

3. Press return to confirm the option Address ...

4. Enter the bus address using the arrow buttons.

5. Press return to save and exit the menu item.

6. Proceed with the options Baud rate, Assembly instance and Data hold time in

the same way.

7. Initiate a reset (menu) or disconnect the power supply to restart the device.

The settings only take effect after the reset.

2013-04

22

Page 23

IC-KP-B7-V95

Channel 1

Channel 2

Channel 3

Channel 4

Channel

IDENTControl

Class 64h

Instance 06 d

Attributes 1-4

1

Class 65h

Instance 06 d

Attributes 1-4

1

Input command objectOutput command object

Commands

7Commands

7.1 Communication via DeviceNet

7.1.1 General information on communication via DeviceNet

DeviceNet is an open fieldbus standard that enables data exchange between

programmable logic controllers (PLCs), personal computers (PCs), control and

monitoring systems as well as sensors and actuators. Please visit the ODVA

website at www.odva.org for more information about DeviceNet.

7.1.2 Performance spectrum

The DeviceNet has the following characteristics:

■ Group 2 only server

■ Data transfer via Poll I/O, change of state, cyclic I/O, explicit message

■ Supported transfer rates: 125 kBit/s, 250 kBit/s, 500 kBit/s

7.1.3 Electronic data sheet (EDS)

The device is supplied with an EDS file.

7.1.4 Data/Command transfer

The commands are transferred via DeviceNet/IP objects, i.e. objects from classes

04h, 64h, and 65h. There are always two different modes available, which may not

be confused: "Mixed mode" and "Separated mode".

7.1.5 Mixed mode

The five IDENT channels (four R/W heads, one configuration channel) are

addressed using an input and an output instance, with the advantage that the

controller requires less memory.

The different parameters of the IDENT telegram distinguish the channels.

2013-04

23

Page 24

IC-KP-B7-V95

Channel 1

Channel 2

Channel 3

Channel 4

Channel

Output command object Input command object

IDENTControl

Class 64h

Instance 03d

Attributes 1-4

1

Class 65h

Instance 03d

Attributes 1-4

1

Class 64h

Instance 05d

Attributes 1-4

1

Class 65h

Instance 05d

Attributes 1-4

1

Class 65h

Instance 01d

Attributes 1-4

1

Class 64h

Instance 02 d

Attributes 1-4

1

Class 65h

Instance 02 d

Attributes 1-4

1

Class 64h

Instance 04d

Attributes 1-4

1

Class 65h

Instance 04d

Attributes 1-4

1

Class 64h

Instance 01d

Attributes 1-4

1

Commands

7.1.6 Separated mode

Each IDENT channel is addressed using a separate input and separate output

instance. The advantage here is that data processing is simplified because

different IDENT channels do not have to process the data in the same memory

area.

7.1.7 Data length

Depending on the data length required, four different attributes with different

lengths are available for each input/output instance.

Class 64h and 65h, instance 1-6

Attribute ID Data length Maximum number of double words (4

Attributes 1-3 require fewer data bytes than attribute 4.

1 8 1

2 12 2

3 32 7

4 60 14

bytes) that can be read/written at any one

time

24

2013-04

Page 25

IC-KP-B7-V95

attribute 4

attribute 3

attribute 2

attribute

1

Commands

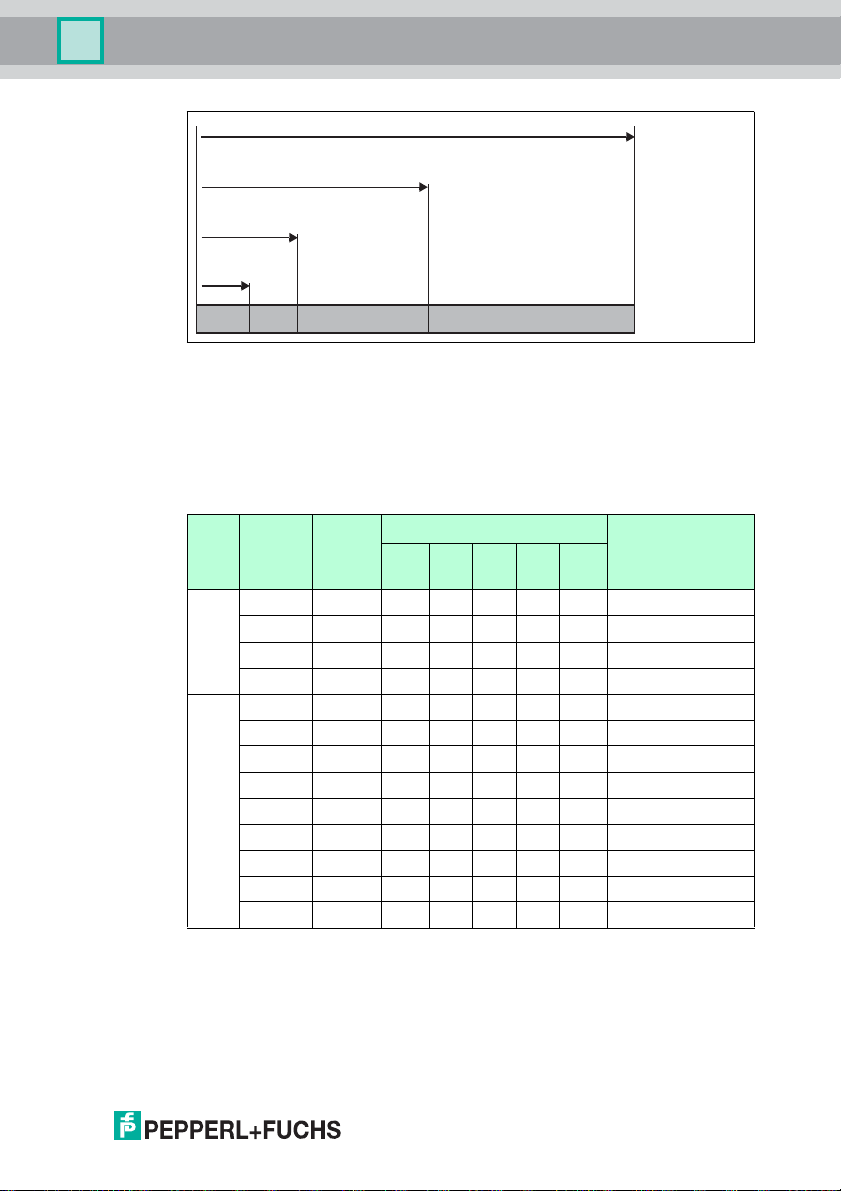

7.1.8 Assembly attributes

The attributes of the output object (class 64h) and the input objects (class 65h)

appear in different combinations in the assembly object. 26 assembly instances

can be used in pairs for implicit communication and so there are 13 possible

combinations. These combinations can be selected either via the device display,

the attribute 100 from instance 0 of the assembly object or by specifying the

combination on the PLC (Forward Open).

Mixed

mode

Sepa-

rated

mode

Output

instance

100d 150d 8* 8 / 8

101d 151d 12* 12 / 12

102d 152d 32* 32 / 32

103d 153d 60* 60 / 60

104d 154d 8 8 8 8 32 / 32

105d 155d 12 12 12 12 48 / 48

106d 156d 32 32 32 32 128 / 128

107d 157d 60 60 60 60 240 / 240

108d 158d 8 8 8 8 8 40 / 40

109d 159d 12 12 12 12 8 56 / 56

110d 160d 32 32 32 32 8 136 / 136

111d 161d 60 60 60 60 8 248 / 248

112d 162d 0 / 10 0 / 10

Input

instance

Channel size Required/Generated

1 2 3 4 5

(conf.)

size

Output/Input byte

* access to mixed mode instance for input/output command object

The following comparison shows the relationship between input and output

instances: Input instance = output instance + 50d.

A combination of the "heartbeat" and the ident status forms the output instance

112 and input instance 162. Refer to appendix B for a more detailed view of the

2013-04

object model.

25

Page 26

IC-KP-B7-V95

Commands

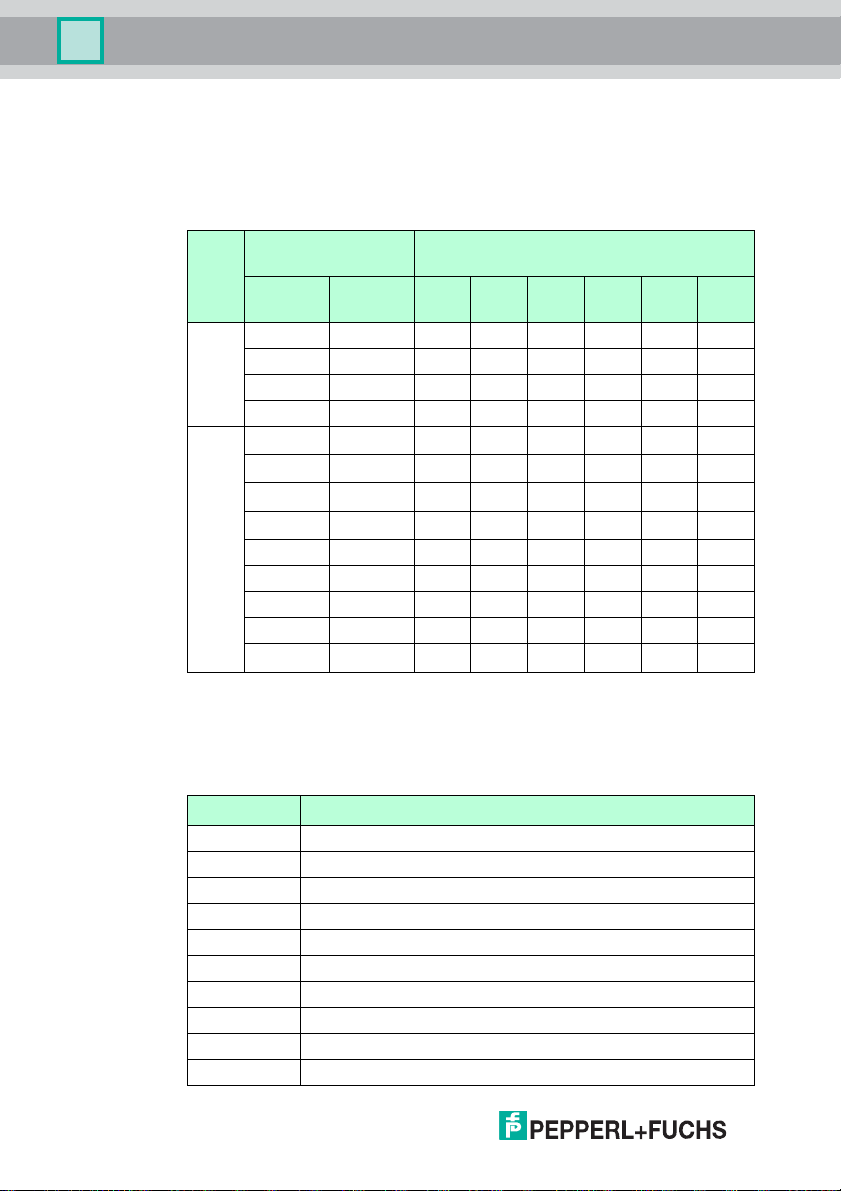

7.1.9 Access administration

The assembly object is a collection of attributes from classes 64h and 65h (input

and output). Both implicit and explicit access to these objects is possible (via the

assembly object). Simultaneous access is regulated as follows to prevent the

attributes from overwriting one another.

Implicit data

exchange

Mixed

mode

Sepa-

rated

mode

Output

instance

100d 150d x x x x x x

101d 151d x x x x x x

102d 152d x x x x x x

103d 153d x x x x x x

104d 154d x x x x x

105d 155d x x x x x

106d 156d x x x x x

107d 157d x x x x x

108d 158d x x x x x x

109d 159d x x x x x x

110d 160d x x x x x x

111d 161d x x x x x x

112d 162d x

Input

instance

7.1.10 Heartbeat and ident status

If instance 112d and 162d of the assembly object are selected, the size of the

output field is 0 bytes and the size of the input that contains the status and reply

counter is 10 bytes.

Byte status Description

00 Status of the IDENTControl

01 Reply counter of the IDENTControl

02 Status of channel 1

03 Reply counter from channel 1

04 Status of channel 2

05 Reply counter from channel 2

06 Status of channel 3

07 Reply counter from channel 3

08 Status of channel 4

09 Reply counter from channel 4

26

Explicit access

Instances from input/o utput commands

1 2 3 4 5

(conf.)

6

2013-04

Page 27

IC-KP-B7-V95

Commands

The advantage of this procedure is that only a few data bytes are transferred via

the bus. Ident commands are transferred as the ident system as explicit

commands. A new ident response can be read as soon as the value on the reply

counter changes.

7.1.11 Data hold time

All responses from the device are present in the input field for a specific time.

Make sure that the controller reads all responses before they are overwritten by a

new response. The data hold time indicates how long an IDENT telegram of this

kind remains in the input field. The data hold time can be adjusted via the display

or the boot-up object (see chapter 12.1). Values between 0 and 2.55 seconds can

be preset in 10 ms increments. The default value is 100 ms. Make sure that the

data hold time is greater than the maximum cycle time of the whole system

(including data storage to the PLC). However, the data hold time should not be

much longer than necessary for the following reasons:

1. The reaction time of the device will increase if several responses arrive in

quick succession.

2. The maximum possible number of response telegrams per time unit de-

creases when the data hold time is increased. A memory overflow may occur. The State LED then flashes green.

7.2 Command Execution

The controller initiates an identification command. If the data has changed since

the last read-out, the c ontrol interface executes the new command If the control

interface is scheduled to execute a command a number of times, the toggle bit

must be inverted. Only then does the device detect that the command has to be

executed again.

If the control interface detects a new command, it sets the status in the input field

to FFh. The reply counter value increases by 1. The status is displayed () after the

control interface has executed the commands.

The toggle bit of the response is the same as the toggle bit of the command.

When new data becomes available, the previous data is overwritten. The reply

counter value increases by 1. In the event of an overflow, the reply counter is reset

to its start value (01h).

New commands may only be sent to an output field after the response from the

previous command is read.

For an overview of supported commands, .

2013-04

27

Page 28

IC-KP-B7-V95

Commands

Command:

Byte 0* Telegram length, high byte

Byte 1* Telegram length, low byte

Byte 2 Command code

Byte 3 Channel/toggle bit = 0

Byte 4 Parameters

Byte 5 Parameters

Byte 6 Data to be written

... ...

Byte N Data to be written

Table 7.1 * This byte is only used with the TCP/IP and MODBUS TCP/IP protocol.

Confirmation (with MODBUS/TCP, no confirmation is sent)

Byte 0* Telegram length, high byte

Byte 1* Telegram length, low byte

Byte 2 Command code (echo)

Byte 3 Channel/toggle bit (echo) = 0

Byte 4 Status FFh

Byte 5 Reply cou nter

... 00h

Byte N 00h

Table 7.2 * This byte is only used with the TCP/IP and MODBUS TCP/IP protocol.

28

Response:

Byte 0* Telegram length, high byte

Byte 1* Telegram length, low byte

Byte 2 Command code (echo)

Byte 3 Channel/toggle bit (echo) = 0

Byte 4 St atu s

Byte 5 Reply cou nter

Byte 6 Read data

... ...

Byte N Read data

Table 7.3 * This byte is only used with the TCP/IP and MODBUS TCP/IP protocol.

2013-04

Page 29

IC-KP-B7-V95

Commands

7.2.1 Command examples

Example: Define tag type

Command: Change tag type on channel 1 to IPC03

04:02:30:33 (hexadecimal format)

04 Command code CT (change tag)

02 Reserved/Channel (1), toggle bit 0b

30:33 tag type (IPC03)

Confirmation

04:02:FF:01

04 Repeat command code CT (change tag)

02 Reserved/Channel (1), toggle bit 0b

FF Status FFh (processing command)

01 Rep ly counter

Response: Type IPH-... read/write head on channel 1

04:02:00:02

04 Repeat command code CT (change tag)

02 Reserved/Channel (1), toggle bit 0b

00 Status 0 (command executed without error)

02 Rep ly counter

Alternative response: No read/write head on channel 1

04:02:06:02

04 Repeat command code CT (change tag)

02 Reserved/Channel (1), toggle bit 0b

06 Status 6 (hardware error)

02 Rep ly counter

Example: Read tag

Prerequisites:

■ The tag type IPC03 is set.

■ One type IPH-… read/write head is connected to channel 1.

Command: Read two double words starting from address 0 on channel 1

10:22:00:00

10 Command code SR (single read words)

22 Number of double words (2) / channel (1), toggle bit

2013-04

00:00 Address of double words (0000)

29

Page 30

IC-KP-B7-V95

Commands

Confirmation

10:22:FF:01

10 Repeat command code SR (single read words)

22 Number of double words (2) / channel (1), toggle bit

FF Status FFh (processing command)

01 Rep ly counter

Response: Type IPC03 tag is located in front of the read/write head, the

highlighted part depends on the content of the tag

10:22:00:02:31:32:33:34:35:36:37:38

10 Repeat command code SR (single read words)

22 Number of double words (2) / channel (1), toggle bit

00 Status 0 (command executed without error)

02 Rep ly counter

31:32:33:34:35:36:37:38 Data

Alternative response: No tag in front of read/write head

10:02:05:02

10 Repeat command code SR (single read words)

02 Number of double words (0) / channel (1), toggle bit

05 Status 5 (no tag in the detection range)

02 Rep ly counter

7.3 Command types

When using commands, a distinction is always made between the two command

types single mode and enhanced mode.

Single mode

The command is executed once. A response is issued immediately.

Enhanced mode

The command remains permanently active until it is interrupted by the user or by

an error message. A response is issued immediately.

The command remains active after the response is issued. Data is only

transferred if read/write tags change. Read/write tags are not read twice. If a

read/write tag leaves the read range, the status '5' is output.

30

2013-04

Page 31

IC-KP-B7-V95

Commands

7.4 Command overview

The commands in the list are described in detail on the following pages.

System commands

Command

code

4d 04h See "Change tag (CT):" on page 33 CT

2d 02h See "Quit (QU):" on page 36 QU

22d 16h See "Reset (RS):" on page 36 RS

155d 9Bh See "Set multiplexed mode (MM):" on page 37 MM

156d 9Ch See "Set trigger mode (TM):" on page 38 TM

Standard read/write commands

Fixcode

Command

code

1d 01h See "Single read read only code (SF):" on page 39 SF

29d 1Dh

Read data

Command description

Command description

See "Enhanced buffered read read only code (EF):" on page 40

Abbre

viation

Abbre

viation

EF

Command

code

16d 10h See "Single read words (SR):" on page 41 SR

25d 19h See "Enhanced buffered read words (ER):" on page 42 ER

Command description

Abbre

viation

Write data

Command

code

64d 40h See "Single write words (SW):" on page 43 SW

26d 1Ah See "Enhanced buffered write words (EW):" on page 44 EW

Command description

Abbre

viation

Special command modes

Password mode with IPC03

Command

code

24d 18h See "Set password mode (PM):" on pag e 47 PM

65d 41h See "Change password (PC):" on page 48 PC

66d 42h See "Set password (PS):" on page 49 PS

2013-04

Command description

Abbre

viation

31

Page 32

IC-KP-B7-V95

Commands

IPC03 configuration

Command

code

97d 61h See "Single get configuration (SG):" on page 50 SG

104d 68h See "Enhanced buffered get configuration (EG):" on page 51 EG

18d 12h See "Single write configuration (SC):" on page 52 SC

102d 66h

Extended commands for tag type IPC11 and IDC-...-1K

Command

code

31d 1Fh See "Single write read only code (SX):" on page 54 SX

36d 24h

188d BCh See "Set tag ID code (TI)" on page 56 TI

170d AAh See " Fill data carrier (S#)" on page 57 S#

Extended commands for tag type IDC-...-1K

Command

code

10d 0Ah See "Single read special f ixcode (SS)" on page 58 SS

113d 71h See "Enhanced read special fixcode (ES)" on page 59 ES

13d 0Dh See "Single program special fixcode (SP)" on page 60 SP

117d 75h See "Enhanced program special fixcode (EP)" on page 61 EP

107d 6Bh See "Initialize data carrier (SI):" on page 62 SI

Command description

See "Enhanced buffered write configuration (EC):" on page 53

Command description

See "Enhanced buffered write read only code (EX):" on page 55

Command description

Abbre

viation

EC

Abbre

viation

EX

Abbre

viation

32

Extended commands for IQH2-... read/write heads

Command

code

190d BEh See "read param (RP)" on page 63 RP

191d BFh See "write param (WP)" on page 64 WP

Command description

Abbre

viation

2013-04

Page 33

IC-KP-B7-V95

Commands

7.4.1 System commands

Change tag (CT):

Byte Contents Bit no.

7 6 5 4 3 2 1 0

Byte 0 Command code (04h) 0 0 0 0 0 1 0 0

Byte 1

Byte 2 Tag ty p e i n A S CI I <TagType> (high byte)

Byte 3 Tag ty p e i n A S CI I <TagType> (low byte)

Response:

Byte Contents Bit no.

Byte 0 Command code (04h) 0 0 0 0 0 1 0 0

Byte 1

Byte 2 Status <Status>

Byte 3 Reply counter <ReplyCounter>

This command tells the read/write head on the relevant channel which tag type to

communicate with. This setting is stored in the non-volatile memory on the unit.

S u p po rte d Ta g Ty p e s

Ta g ty pe P+F

High

byte

'0' '2' IPC02 Unique, EM4102 (EM

'0' '3' IPC03 EM4450 (EM

'1' '1' IPC11 Q5 (Sokymat) Read/write 5 - 125 kHz

'1' '2' IPC12 P+F FRAM Read/wr ite

'2' '0'

'2' '1' IQC21 I-Code SLI (NXP) Read/wr ite

'2' '2' IQC22 Tag-it HF-I Plus (Texas

2013-04

Low

byte

designation

IQC20

Reserved/Ident channel/Toggle bit

Reserved/Ident channel/Toggle bit

Chip type Access Writable

microelectronic)

microelectronic), Titan

1)

All ISO 15693 compliant

read/wri te tags

Instruments)

0 0 0 0 <Channel> <T>

7 6 5 4 3 2 1 0

0 0 0 0 <Channel> <T>

Read only

code

Read/write

read onl y

code

read onl y

code

Read/write

read onl y

code

read onl y

code

Read/write

read onl y

code

memory

[bytes]

116 4 125 kHz

8k 4 125 kHz

112 8 13.56 MHz

250 8 13.56 MHz

Read

only

code

length

[byte]

5 5 125 kHz

8 8 13.56 MHz

Fre quenc y

range

33

Page 34

IC-KP-B7-V95

Commands

Ta g ty pe P+F

High

byte

Low

byte

designation

'2' '3' IQC23 my-D SRF55V02P

'2' '4' IQC24 my-D SRF55V10P

'3' '1' IQC31 Tag -i t HF - I Sta nd ar d

'3' '3'

IQC33

'3' '4' IQC34 FRAM MB89R119

'3' '5' IQC35 I-Code SLI-S (NXP) Read /write

'4' '0' IQC40 All ISO 14443A compliant

'4' '1' IQC41 Mifare UltraLight MF0 IC

'4' '2'

'4' '3'

IQC42

IQC43

'5' '0' IDC-...-1K P+F Read/write

'5' '2' ICC-... P+F Read only

'7' '2'

'7' '3'

'7' '4'

'7' '5'

'7' '6'

IUC72

IUC73

IUC74

IUC75

IUC76

Chip type Access Writable

(Infinion)

(Infinion)

(Texas Instruments)

2)

FRAM MB89R118

(Fujitsu)

(Fujitsu)

read/wri te tags

U1 (NXP)

3)

Mifare Classic MF1 IC

S50 (NXP)

3)

Mifare Classic MF1 IC

S70 (NXP)

Read/write

read onl y

code

Read/write

read onl y

code

Read/write

read onl y

code

Read/write

read onl y

code

Read/write

read onl y

code

read onl y

code

Read only

code

Read/write

read onl y

code

Read/write

read onl y

code

Read/write

read onl y

code

read onl y

code

code

4)

UCode-EPC-G2XM

(NXP)

4)

4)

4)

4)

Higgs-2 (Alien) Read only

UCode-EPC-G2 (NXP) Read/write

Monza 2.0 (Impinj) Read only

Higgs-3 (Alien) Read/wr ite

Read/write

read onl y

code

code

read onl y

code

code

read onl y

code

memory

[bytes]

Read

only

code

length

[byte]

Fre quenc y

range

224 8 13.56 MHz

928 8 13.56 MHz

32 8 13.56 MHz

2k 8 13.56 MHz

29 8 13.56 MHz

160 8 13.56 MHz

-

4/7

6)

13.56 MHz

48 7 13.56 MHz

752

3440

4/7

4/7

6)

6)

13.56 MHz

13.56 MHz

125 4 250 kHz

28 7 250 kHz

64 8 868 MHz

- 96 868 MHz

28 96 868 MHz

- 96 868 MHz

56 240 868 MHz

34

2013-04

Page 35

IC-KP-B7-V95

Commands

Ta g ty pe P+F

High

byte

'8' '0' All Class 1 Gen 2 compliant read/write

'9' '9'

1)

IQC20 is not an actual tag type as such, but is used to read the UID (read only code) of all ISO 15693

compliant read/write tags.

2)

Read/write tag IQC33 can only be used in combination with a IQH1-... read/write head. The memory is

divided into 8-byte blocks (instead of 4-byte blocks). You must enter a continuous initial address for write

commands SR, ER, SW and EW.

<WordNum> specifies the number of 8-byte blocks (here, max. 7) and must be an even number.

3)

Read/write tags I QC40–IQC43 can only be used in combination with a IQH2-... read/write head.

<WordNum> specifies the number of 16-byte blocks and must be a multiple of 4.

The memory can be encrypted for each sector (1 sector = 4 blocks of 16 bytes).

The default key in the tag and reader is FF FF FF FF FF FF

using the Read param command and written using the Write para m command (see System

Commands). The key is only changed in the reader during this process and not in the tag!

The key in the reader is stored in the non-volatile memory.

4)

IUC7* type read/write tags can only be used with read/write head IUH-F117-V1 in combination with

certain control interfaces.

5)

The tag type configured in the read/write head as the default is selected.

6)

Read/write tags can have 4-byte (older versions) or 7-byte UIDs. IQC42 and IQC43 type read/write tags

from Pepperl+Fuchs generally have 7-byte UIDs.

Low

byte

designation

Chip type Access Writable

tags

Depends on the reader

5)

- - Max. 96 868 MHz

- - - -

memory

[bytes]

. The key in the reader can be read

ASCII

Read

only

code

length

[byte]

Fre quenc y

range

Note!

In a plant where only one tag type is used, it is advantageous to permanently

configure that tag type so that the read/write head detects the tag quicker.

Default tag type:

In the factory default condition, the tag type 99 is preset in the IDENTControl

(depending on the reading head type), thus the tag type preset on the reading

head is used.

Recommendation:

For operation in an automated plant, permanently preset the data carrier type in

use via a command.

2013-04

35

Page 36

IC-KP-B7-V95

Commands

Quit (QU):

Byte Contents Bit no.

Byte 0 Command code (02h) 0 0 0 0 0 0 1 0

Byte 1

Response:

Byte Contents Bit no.

Byte 0 Command code (02h) 0 0 0 0 0 0 1 0

Byte 1

Byte 2 Stat us <Status>

Byte 3 Reply counter <ReplyCounter>

The command running on this channel is interrupted.

Reset (RS):

Byte Contents Bit no.

Byte 0 Command code (16h) 0 0 0 1 0 1 1 0

Byte 1 Reserved/Channel/Toggle bit 0 0 0 0 0 0 0 <T>

Reserved/Ident channel/Toggle bit

Reserved/Ident channel/Toggle bit

7 6 5 4 3 2 1 0

0 0 0 0 <Channel> <T>

7 6 5 4 3 2 1 0

0 0 0 0 <Channel> <T>

7 6 5 4 3 2 1 0

36

This command terminates all active commands. The device settings are reloaded

from the non-volatile memory.

This confirmation is issued for this command (status FFh) instead of a response.

The device resets the hardware and then restarts.

2013-04

Page 37

IC-KP-B7-V95

Commands

Set multiplexed mode (MM):

Byte Contents Bit no.

Byte 0 Command code (9Bh) 1 0 0 1 1 0 1 1

Byte 1 Reserved/Toggle bit 0 0 0 0 0 0 0 <T>

Byte 2 Multiplex mode 0 0 0 0 0 0 0 <F>

Response:

Byte Contents Bit no.

Byte 0 Command code (9Bh) 1 0 0 1 1 0 1 1

Byte 1 Reserved/Toggle bit 0 0 0 0 0 0 0 <T>

Byte 2 Stat us <Status>

Byte 3 Reply counter <ReplyCounter>

This command switches multiplex mode on and off. In multiplex mode, the R/W

heads are controlled according to the time multiplex process, i.e. only one R/W

head is active. The procedure minimizes mutual interference between R/W

heads, allowing two R/W heads to be mounted side by side.

Each IDENT channel sends a response in reply to an MM command.

7 6 5 4 3 2 1 0

7 6 5 4 3 2 1 0

Multiplex mode <F>='0': Mode off

<F>='1': Mode on

If a R/W head is not connected to a channel, the response telegram receives the

status "06h" (hardware fault) from this channel.

2013-04

37

Page 38

IC-KP-B7-V95

Commands

Set trigger mode (TM):

Byte Contents Bit no.

Byte 0 Command code (9Ch) 1 0 0 1 1 1 0 0

Byte 1

Byte 2 Trigger mode <Trigger mode>

Response:

Byte Contents Bit no.

Byte 0 Command code (9Ch) 1 0 0 1 1 1 0 0

Byte 1

Byte 2 Stat us <Status>

Byte 3 Reply counter <ReplyCounter>

Permitted parameters:

<Sensor channel> 3 (011b), 4 (100b)

<Ident channel> 1 (0001b), 2 (0010b), 3 (0011b), 4 (0100b)

<Trigger mode> 0 (00000000b): Trigger mode off

Ident chan nel/sen sor channel /toggle bit

Reserved/sensor channel/toggle bit

(but not <Sensor channel>)

1 (00000001b): Trigger mode on

2 (00000010b): Trigger mode inverted

7 6 5 4 3 2 1 0

0 <Ident channel> <Sensor channel> <T>

7 6 5 4 3 2 1 0

0 0 0 0 <Sensor channel> <T>

38

2013-04

Page 39

IC-KP-B7-V95

Commands

7.4.2 Standard read/write commands

Single read read only code (SF):

Byte Contents Bit no.

Byte 0 Command code (01h) 0 0 0 0 0 0 0 1

Byte 1 Reserved/Channel/Toggle bit 0 0 0 0 <Channel> <T>

Response:

Byte Contents Bit no.

Byte 0 Command code (01h) 0 0 0 0 0 0 0 1

Byte 1 Reserved/Channel/Toggle bit 0 0 0 0 <Channel> <T>

Byte 2 Stat us <Status>

Byte 3 Re ply c ounter <ReplyCounter>

Byte 4 ID code 00h ... FFh <ID code>

Byte 5 ID code 00h ... FFh <ID code>

... ID code 00h ... FFh <ID code>

1)

Byte N

ID code 00h ... FFh <ID code>

1. N = <FixLen> + 3

7 6 5 4 3 2 1 0

7 6 5 4 3 2 1 0

The R/W head makes only one attempt to read a read only code.

The length of the read only code that is output depends on the tag type. See table

"Supported Tag Types" on page 33.

2013-04

39

Page 40

IC-KP-B7-V95

Commands

Enhanced buffered read read only code (EF):

Byte Contents Bit no.

Byte 0 Command code (1Dh) 0 0 0 1 1 1 0 1

Byte 1 Reserved/Ichannel/Toggle bit 0 0 0 0 <Channel> <T>

Response:

Byte Contents Bit no.

Byte 0 Command code (1Dh) 0 0 0 1 1 1 0 1

Byte 1

Byte 2 Stat us <Status>

Byte 3 Reply counter <ReplyCounter>

Byte 4 ID code 00h ... FFh <ID code>

Byte 5 ID code 00h ... FFh <ID code>

... ID code 00h ... FFh <ID code>

Byte N

7 6 5 4 3 2 1 0

7 6 5 4 3 2 1 0

Reserved/Ident channel/Toggle bit

1)

ID code 00h ... FFh <ID code>

0 0 0 0 <Channel> <T>

1. N = <FixLen> + 3

40

The R/W head makes attempts until successful to read a read only code. Only

data that changes is transferred via the interface, i.e. the R/W head transfers data

whenever it reads a new read/write tag or whenever it reads a read/write tag

where there was previously no read/write head within the detection range.

The status '05h' (read command) is output whenever a read/write tag leaves the

detection range.

The length of the read only code that is output depends on the tag type. See table

"Supported Tag Types" on page 33.

2013-04

Page 41

IC-KP-B7-V95

Commands

Single read words (SR):

Byte Contents Bit no.

Byte 0 Command code (10h) 0 0 0 1 0 0 0 0

Byte 1

Byte 2 Word address <WordAddr>(high byte)

Byte 3 Word address <WordAddr> (low byte)

Response:

Byte Contents Bit no.

Byte 0 Command code (10h) 0 0 0 1 0 0 0 0

Byte 1

Byte 2 Status <Status>

Byte 3 Reply counter <ReplyCounter>

Byte 4 Data 00h ... FFh < Data>

Byte 5 Data 00h ... FFh < Data>

Byte 6 Data 00h ... FFh < Data>

Byte 7 Data 00h ... FFh < Data>

... Data 00h ... FFh <Data>

Byte N

7 6 5 4 3 2 1 0

Word number/Channel/Toggle bit

Word number/Ident channel/Toggle bit

1)

Data 00h ... FFh <Data>

<WordNum> <Channel> <T>

7 6 5 4 3 2 1 0

<WordNum> <Channel> <T>

1. N = 4 x <WordNum> + 5; Ethernet/IP: N = 4 x <WordNum> + 3

The R/W head makes one attempt to read <WordNum> 32-bit words from the

address<WordAddr>.

2013-04

41

Page 42

IC-KP-B7-V95

Commands

Enhanced buffered read words (ER):

Byte Contents Bit no.

Byte 0 Command code (19h) 0 0 0 1 1 0 0 1

Byte 1

Byte 2 Word address <WordAddr>(high byte)

Byte 3 Word address <WordAddr> (low byte)

Response:

Byte Contents Bit no.

Byte 0 Command code (19h) 0 0 0 1 1 0 0 1

Byte 1

Byte 2 Status <Status>

Byte 3 Reply counter <ReplyCounter>

Byte 4 Data 00h ... FFh < Data>

Byte 5 Data 00h ... FFh < Data>

Byte 6 Data 00h ... FFh < Data>

Byte 7 Data 00h ... FFh < Data>

... Data 00h ... FFh <Data>

Byte N

7 6 5 4 3 2 1 0

Word number/Ident channel/Toggle bit

Word number/Ident channel/Toggle bit

1)

Data 00h ... FFh <Data>

<WordNum> <Channel> <T>

7 6 5 4 3 2 1 0

<WordNum> <Channel> <T>

1. N = 4 x <WordNum> + 5; Ethernet/IP: N = 4 x <WordNum> + 3

42

The R/W head makes attempts until successful, to read <WordNum> 32-bit words

from the address <WordAddr>. Only modified data is transferred via the interface.

When a read/write tag leaves the detection range, the status '05h' (read

command) is output.

2013-04

Page 43

IC-KP-B7-V95

Commands

Single write words (SW):

Byte Contents Bit no.

Byte 0 Command code (40h) 0 1 0 0 0 0 0 0

Byte 1

Byte 2 Word address <WordAddr>(high byte)

Byte 3 Word address <WordAddr> (low byte)

Byte 4 Data 00h ... FFh < Data>

... Data 00h ... FFh <Data>

Byte N

Response:

Byte Contents Bit no.

Byte 0 Command code (40h) 0 1 0 0 0 0 0 0

Byte 1

Byte 2 Status <Status>

Byte 3 Reply counter <ReplyCounter>

7 6 5 4 3 2 1 0

Word number/Ident channel/Toggle bit

1)

Data 00h ... FFh <Data>

<WordNum> <Channel> <T>

1. N = 4 x <WordNum> + 5; Ethernet/IP: N = 4 x <WordNum> + 3

7 6 5 4 3 2 1 0

Word number/Ident channel/Toggle bit

<WordNum> <Channel> <T>

The R/W head makes one attempt to write <WordNum> 32-bit words from the

address<WordAddr>.

2013-04

43

Page 44

IC-KP-B7-V95

Commands

Enhanced buffered write words (EW):

Byte Contents Bit no.

Byte 0 Command code (1Ah) 0 0 0 1 1 0 1 0

Byte 1

Byte 2 Word address <WordAddr>(high byte)

Byte 3 Word address <WordAddr> (low byte)

Byte 4 Data 00h ... FFh < Data>

... Data 00h ... FFh <Data>

Byte N

Response:

Byte Contents Bit no.

Byte 0 Command code (1Ah) 0 0 0 1 1 0 1 0

Byte 1

Byte 2 Status <Status>

Byte 3 Reply counter <ReplyCounter>

7 6 5 4 3 2 1 0

Word number/Ident channel/Toggle bit

1)

Data 00h ... FFh <Data>

<WordNum> <Channel> <T>

1. N = 4 x <WordNum> + 5; Ethernet/IP: N = 4 x <WordNum> + 3

7 6 5 4 3 2 1 0

Word number/Ident channel/Toggle bit

<WordNum> <Channel> <T>

The read/write head repeatedly attempts to write <WordNum> 32-bit words from

the address <WordAddr> until successful. After each successful write, the head

sends the response and then switches to continuous read. The read/write head

then reads the same tag until the tag has left the detection range or a new tag

appears within the detection range. At this point, the read/write head again starts

write attempts.

The status '05h' is only output when a tag leaves the detection range or is not yet

within the detection range.

If two tags enter the read range one immediately after the other, the status '05h' is

not issued between the two readings.

7.4.3 Special command modes

Note!

You can only use the commands in this section for the data carrier type '03'

(IPC03).

IPC03 Configuration

The storage of a data carrier IPC03 is organized by word. A data word is defined

with a length of 32 bits. For the normal data range, 29 words from addresses 3

through 31 (<WordAddr> = 00h ... 1Ch) are available.

44

2013-04

Page 45

IC-KP-B7-V95

Commands

Address Meaning <WordAddr> <ConfAddr> Note

Word 0 Password - - Write only

Word 1 Protection word - 1 Read/wr ite

Word 2 Control word - 2 Read/wr ite

Word 3 ...31 Data range 00h ... 1Ch - Read /write

Word 32 Device Serial Number 1Dh - Read only

Word 33 Device identification 1Eh - Read onl y

Word 0 contains the password. The password can only be w ritten.

With word 1, the "Protection Word", you can define a read-protected and a writeprotected range. The "Protection Word" can only be read and written with the

correct password.

With word 2, the "Control Word", you can set various operating modes and the

read range for the operating mode "Default Read". The "Control Word" can only

be read and written with the correct password.

If you would like to use the "Protection Word" and the "Control Word", you must

first activate the password mode.

The individual bits have the following meanings:

Protection word

Bit Meaning Byte

0 ... 7 First read-p rotected word 0

8 ... 15 Last read-protected word 1

16 ... 23 First write-protected word 2

24 ... 31 L ast write-protected word 3

Control word

Bit Meaning Byte

0 ... 7 Read range start 0

8 ... 15 Read range end 1

16 Password mode on/off 2

17 "Read after write" operating mode

18 ... 23 Open

24 ... 31 Open 3

on/off

IPC03 password mode

If the password mode in the data carrier is activated, the data range of the data

carrier is read and write-protected and can only be read or written if the R/W head

2013-04

sends the correct password to the data carrier.

45

Page 46

IC-KP-B7-V95

Commands

If the password mode in the data carrier is deactivated, every data word on the

data carrier can be read or written.

The default password of the R/W heads and the data carrier is 00000000h. In the

R/W head, the password is stored in the volatile memory and in the data carrier,

the password is stored in the non-volatile memory.

To read or write the "Protection Word" and the "Control Word", you must first enter

the password in the password mode (see the commands SC or EC).

You can also limit access to the data carriers by defining the start and end of a

read-protected and a write-protected range in the Protection Word.

Setting the password

1. Enter the correct password once with the command PS (set password).

2. Activate the password mode with the command PM (set password mode).

The password in the R/W head and on the read/write tag can be changed with the

command PC.

If the password mode is deactivated, every data word on the read/write tag can be

read and written as necessary.

To read and write the words 1 “Protection Word” and 2 “Control Word”, the correct

password is always required and therefore the password mode must be active

(see the commands SC or EC).

In addition, the access to the read/write tag can be limited via read- and writeprotected ranges. To achieve this, each mutually independent start and end of a

read-protected and a write-protected range can be defined in the "Protection

Word ".

In the factory default condition of the reading heads and the read/write tag IPC03,

the password is 00000000h. In the reading head, the password is stored in a

volatile manner and in the read/write tag IPC03 in a non-volatile manner.

46

2013-04

Page 47

IC-KP-B7-V95

Commands

Set password mode (PM):

Byte Contents Bit no.

Byte 0 Command code (18h) 0 0 0 1 1 0 0 0

Byte 1

Byte 2 Password mode 0 0 0 0 0 0 0 <P>

Response:

Byte Contents Bit no.

Byte 0 Command code (18h) 0 0 0 1 1 0 0 0

Byte 1

Byte 2 Stat us <Status>

Activates and deactivates the password mode of the relevant channel. In the

password mode, the password is transferred to the read/write tag before each

read/write access. If a data carrier is addressed with the wrong password, then

even the other data ranges can no longer be accessed.

Reserved/Ident channel/Toggle bit

Reserved/Ident channel/Toggle bit

7 6 5 4 3 2 1 0

0 0 0 0 <Channel> <T>

7 6 5 4 3 2 1 0

0 0 0 0 <Channel> <T>

2013-04

47

Page 48

IC-KP-B7-V95

Commands

Change password (PC):

Byte Contents Bit no.

Byte 0 Command code (41h) 0 1 0 0 0 0 0 1

Byte 1

Byte 2 Old password 00h ... FFh <PSW> (byte 3)

Byte 3 Old password 00h ... FFh <PSW> (byte 2)

Byte 4 Old password 00h ... FFh <PSW> (byte 1)

Byte 5 Old password 00h ... FFh <PSW> (byte 0)

Byte 6 New password 00h ... FFh <PSW> (byte 3)

Byte 7 New password 00h ... FFh <PSW> (byte 2)

Byte 8 New password 00h ... FFh <PSW> (byte 1)

Byte 9 New password 00h ... FFh <PSW> (byte 0)

Response:

Byte Contents Bit no.

Byte 0 Command code (41h) 0 1 0 0 0 0 0 1

Byte 1

Byte 2 Stat us <Status>

Reserved/Ident channel/Toggle bit

Reserved/Ident channel/Toggle bit

7 6 5 4 3 2 1 0

0 0 0 0 <Channel> <T>

7 6 5 4 3 2 1 0

0 0 0 0 <Channel> <T>

48

The command PC changes the password in a tag. Enter the old and then the new

password <PSW> here. If the password has been successfully written, the

password in the read/write head also changes and the set password command

is no longer required. The password of the IPC03 can also be changed if the

password mode is deactivated.

2013-04

Page 49

IC-KP-B7-V95

Commands

Set password (PS):

Byte Contents Bit no.

Byte 0 Command code (42h) 0 1 0 0 0 0 1 0

Byte 1

Byte 2 Re served 0 0 0 0 0 0 0 0

Byte 3 Re served 0 0 0 0 0 0 0 0

Byte 4 Password 00h ... FFh <PSW> (byte 3)

Byte 5 Password 00h ... FFh <PSW> (byte 2)

Byte 6 Password 00h ... FFh <PSW> (byte 1)

Byte 7 Password 00h ... FFh <PSW> (byte 0)

Response:

Byte Contents Bit no.

Byte 0 Command code (42h) 0 1 0 0 0 0 1 0

Byte 1

Byte 2 Stat us <Status>

Reserved/Ident channel/Toggle bit

Reserved/Ident channel/Toggle bit

7 6 5 4 3 2 1 0

0 0 0 0 <Channel> <T>

7 6 5 4 3 2 1 0

0 0 0 0 <Channel> <T>

The command PSsets the password, which the R/W head communicates to the

data carrier in password mode.

Operating mode “Default Read”

In "default read" operating mode, 1 or 2 words are read extremely quickly. The

area of memory earmarked for reading is already specified on the tag. The R/W

head does not have to identify the memory area for the tag.

The start and end of the read range are stored in the bytes 0 and 1 of the control

word. As soon as power is supplied to the tag, it sends data from the data range

defined by the start and end of the read range. The data range between read

range start and end is read with the read commands SR (Single read words) and

ER (enhanced buffered read words) when <WordAddr> is set to 0000h and

<WordNum> to 00h.

The advantage of "default read" operating mode is the readout speed. The

readout of one data word (4 bytes) is twice as fast in this mode as the other

modes. The readout of two words takes approx. 1/3 less time. No more time

advantages can be gained after three data words because "default read" mode is

designed to read a maximum of two words (= 8 bytes). Reading larger data

ranges can lead to error messages if the reading head does not respond within

the planned reaction time.

2013-04

49

Page 50

IC-KP-B7-V95

Commands

Setting "Default Read"

1. Activate the password mode.

2. Write the read range start and end into the "Control Word".

3. Deactivate the password mode.

4. Read the data range with address designation 0000h and word count 0h.

IPC03 configuration

Single get configuration (SG):

Byte Contents Bit no.

Byte 0 Command code (61h) 0 1 1 0 0 0 0 1

Byte 1

Byte 2 Reserved 0 0 0 0 0 0 0 0

Byte 3

Response:

Byte Contents Bit no.

Byte 0 Command code (61h) 0 1 1 0 0 0 0 1

Byte 1

Byte 2 Stat us <Status>

Byte 3 Reply counter <ReplyCounter>

Byte 4 Data 00h ... FFh <Data>

Byte 5 Data 00h ... FFh <Data>

Byte 6 Data 00h ... FFh <Data>

Byte 7 Data 00h ... FFh <Data>

Reserved/Ident channel/Toggle bit

Address in the configuration range

Reserved/Ident channel/Toggle bit

7 6 5 4 3 2 1 0

0 0 0 0 <Channel> <T>

<ConfAddr>