Page 1

FACTORY AUTOMATION

MANUAL

ICDM-RX/MOD

Modbus Router User

Page 2

ICDM-RX/MOD User Manual

With regard to the supply of products, the current issue of the following document is applicable: The General Terms of

Delivery for Products and Services of the Electrical Industry, published by the Central Association of the Electrical Industry

(Zentralverband Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the supplementary

clause: "Expanded reservation of proprietorship".

Page 3

ICDM-RX/MOD User Manual

Table of Contents

Table of Contents

1. Overview ......................................................................................................................... 5

1.1. Introduction ....................................................................................................................................... 5

1.2. Terms and Definitions ...................................................................................................................... 5

1.3. What is Modbus? .............................................................................................................................. 7

1.3.1. Modbus/RTU .............................................................................................................................. 7

1.3.2. Modbus/ASCII ............................................................................................................................ 7

1.3.3. Modbus/TCP .............................................................................................................................. 8

1.4. Modbus Router Functionality .......................................................................................................... 9

1.5. Multiple Gateway Modbus Networks ........................................................................................... 13

1.6. Modbus/RTU and Modbus/ASCII To-Slaves Interface................................................................. 16

1.6.1. Communication Methodology................................................................................................... 17

1.6.2. Local Public Modbus Slave Device Search Methodology......................................................... 18

1.7. Alias Device ID and Device ID Offset Functionality..................................................................... 18

1.7.1. Alias Modbus Device ID Functionality ...................................................................................... 20

1.7.2. Device ID Offset Functionality .................................................................................................. 20

1.8. Modus Master/Slaves Serial Port Mode (Private Serial Bus) ..................................................... 21

1.8.1. Master/Slaves Message Routing.............................................................................................. 22

1.8.1.1. Forward Broadcasts From Master Option....................................................................... 22

1.8.1.2. Private Device ID Range Setting .................................................................................... 23

1.9. Shared Memory Functionality........................................................................................................ 23

1.10. Remote Modbus Routing Capabilities ........................................................................................26

1.10.1. Serial Modbus Master(s) to Modbus/TCP Slave(s) ................................................................ 26

1.10.2. Modbus over Ethernet TCP/IP Master(s) to Modbus/TCP Slave(s) ........................................ 27

1.10.3. Modbus/TCP Master(s) to Modbus/TCP Slave(s) .................................................................. 28

1.10.4. Device ID Mapping to IP Address/Port/Slave Device IDs ....................................................... 29

2. Configuration Overview...............................................................................................33

2.1. Prerequisites ................................................................................................................................... 33

2.2. Configuration Overview.................................................................................................................. 33

2.3. Modbus Router Home .................................................................................................................... 34

3. Serial Menus.................................................................................................................35

3.1. Serial Port Overview Page ............................................................................................................. 35

3.2. Serial Port Configuration Page ...................................................................................................... 35

4. Modbus Menus .............................................................................................................38

4.1. TCP/IP Configuration Pages .......................................................................................................... 38

4.1.1. Modbus over TCP Overview (not Modbus/TCP) Page ............................................................. 38

4.1.2. Modbus over TCP (not Modbus/TCP) Socket Configuration Page ........................................... 38

4.2. Modbus/TCP Configuration Page .................................................................................................. 39

4.3. Remote Modbus/TCP Device Configuration Page ....................................................................... 40

4.4. Modbus Alias Device ID Configuration Page ............................................................................... 41

4.5. Shared Memory Configuration Page............................................................................................. 41

3

Page 4

ICDM-RX/MOD User Manual

Table of Contents

5. Network Menu...............................................................................................................44

5.1. Network Configuration Page.......................................................................................................... 44

5.2. Password Page................................................................................................................................ 45

5.3. Security Page .................................................................................................................................. 45

5.4. Keys/Certs Page.............................................................................................................................. 46

6. Diagnostics Menu ........................................................................................................48

6.1. Serial Communication Statistics Page ......................................................................................... 48

6.2. Modbus RTU/ASCII over Ethernet TCP Statistics Page .............................................................. 49

6.3. Serial Interface Logs Page ............................................................................................................. 50

6.4. Known Modbus Slave Device List Page ....................................................................................... 50

6.5. Modbus/TCP and Serial Modbus Master Statistics Page ........................................................... 52

6.6. Modbus/TCP Connections Page.................................................................................................... 54

6.7. Modbus Alias Device ID Statistics Page ....................................................................................... 55

6.8. Shared Memory Contents Page..................................................................................................... 55

6.9. Shared Memory Contents Page - Shared Coil Blocks................................................................. 56

6.10. System Log Page .......................................................................................................................... 57

7. System Menu ................................................................................................................58

7.1. Update Firmware Page ................................................................................................................... 58

7.2. Configuration File Page.................................................................................................................. 58

7.2.1. Saving a Configuration File....................................................................................................... 59

7.2.2. Loading a Configuration File..................................................................................................... 59

7.3. Device Snapshot Page ................................................................................................................... 59

7.4. Restore Defaults Page .................................................................................................................... 59

7.5. Reboot Page .................................................................................................................................... 59

8. Troubleshooting and Technical Support...................................................................60

8.1. Troubleshooting Checklist ............................................................................................................ 60

8.2. General Troubleshooting ............................................................................................................... 61

8.3. Daisy-Chaining ICDM-RX/MOD Units With Dual Ethernet Ports................................................. 61

8.4. Technical Support........................................................................................................................... 62

2019-06

4

Page 5

ICDM-RX/MOD User Manual

Overview

1. Overview

1.1. Introduction

This guide discusses ICDM--RX/MOD Industrial Gateway configuration for the ICDM--RX/MOD running the

Modbus Router application.

The Modbus Router application provides enhanced connectivity from a wide variety of Modbus masters to a

wide variety of Modbus slaves, advanced Master-to-Master connectivity, and connectivity from private Modbus

serial networks to public Modbus networks.

Supported Modbus masters include:

• Modbus/TCP

• Modbus/RTU serial

• Modbus/ASCII serial

• Modbus/ RTU

• Modbus/ASCII over Ethernet TCP/IP

Supported Modbus slaves include:

• Modbus/TCP

• Public and private Modbus/RTU serial

• Public and private Modbus/ASCII serial

Connectivity can be easily achieved between any master(s) and any public slave(s) anywhere on an Ethernet

network. Combined with a ICDM-RX/MOD running the Modbus/TCP application, both serial and Ethernet TCP/

IP Raw/ ASCII devices can be accessed anywhere on a network from any Modbus master.

Modbus Router was designed to greatly enhance system maintenance capabilities. Included are

comprehensive device and port specific diagnostic web pages that display status, message response timing,

time-outs, other error counts, and overall message statistics. A serial log is also included to provide message

level diagnosis for serial devices.

1.2. Terms and Definitions

This subsection defines terms and definitions used in this guide.

Te r m D ef i ni t io n

Alias Device ID

Device ID

Device ID Offset

6/3/19

The device ID that the original received ID is changed to when an Alias Device ID is

configured.

The Modbus device identification number. Device IDs include:

0 = Broadcast

1-247 = Standard device IDs

248-255 = Reserved device IDs (generally used for vendor specific gateway functions)

An offset applied at the slave serial port interface that changes the message device

ID range to match the serial device(s) device ID range.

5

Page 6

ICDM-RX/MOD User Manual

Overview

Term Definition

Ethernet TCP/IP

Local Slave Device A local slave device is one that is connected directly to a serial port on the gateway.

Master (or Client)

Mode

Modbus/ASCII

Modbus/RTU

Modbus/TCP

Polling

Public Slave

Device

Private Slave

Device

Received Device

ID

Remote Slave

Device

Slave (or Server)

Mode

Sockets

A form of Ethernet connectivity that provides a level of guaranteed delivery and data

verification. This is used for many upper layer protocols such Modbus/TCP and can

be also used for transferring Modbus/RTU and Modbus/ASCII messages.

The method of operation when a PLC, a gateway, or an application is operating as a

Master or the message originator.

An ASCII, or character based, form of Modbus. The base message is the same as

Modbus/RTU, but the format is somewhat different.

The standard Modbus messages, in hexadecimal format, that are typically

transmitted over serial lines but can also be transmitted over other communication

methods such as wireless or Ethernet TCP/IP socket connections.

Note: Modbus/RTU over Ethernet TCP/IP is not the same as Modbus/TCP.

An Ethernet based form of Modbus communication. The base message is the same

as Modbus/RTU, but a special Modbus header is included for packet identification

and routing purposes.

The process where a PLC or Application requests data on a continual basis. In this

operation the Master sends the request messages while the Slave responds to the

messages.

A public slave device is one that can communicate to all master(s) on the Modbus

network.

Note: If a device is not specifically specified as a “public” or “private” slave device,

then it can be assumed to be a public device.

A private slave device is one that can only communicate to a master that is connected

on the same serial bus, such as RS-485 or RS-422. Private slave device cannot

communicate to other masters on the Modbus network.

The original device ID received in the Modbus message from a Modbus master.

A remote slave device is either a slave Modbus/TCP device or a serial slave device

attached to another gateway and accessed as a remote Modbus/TCP device.

The method of operation when a PLC, a gateway, or an application is operating as a

Slave or the message receiver.

The method used to communicate between devices while communicating over

Ethernet TCP/IP.

6/3/19

6

Page 7

ICDM-RX/MOD User Manual

Overview

1.3. What is Modbus?

This subsection discusses:

• Modbus/RTU

• Modbus/ASCII on Page 7

• Modbus/TCP on Page 8

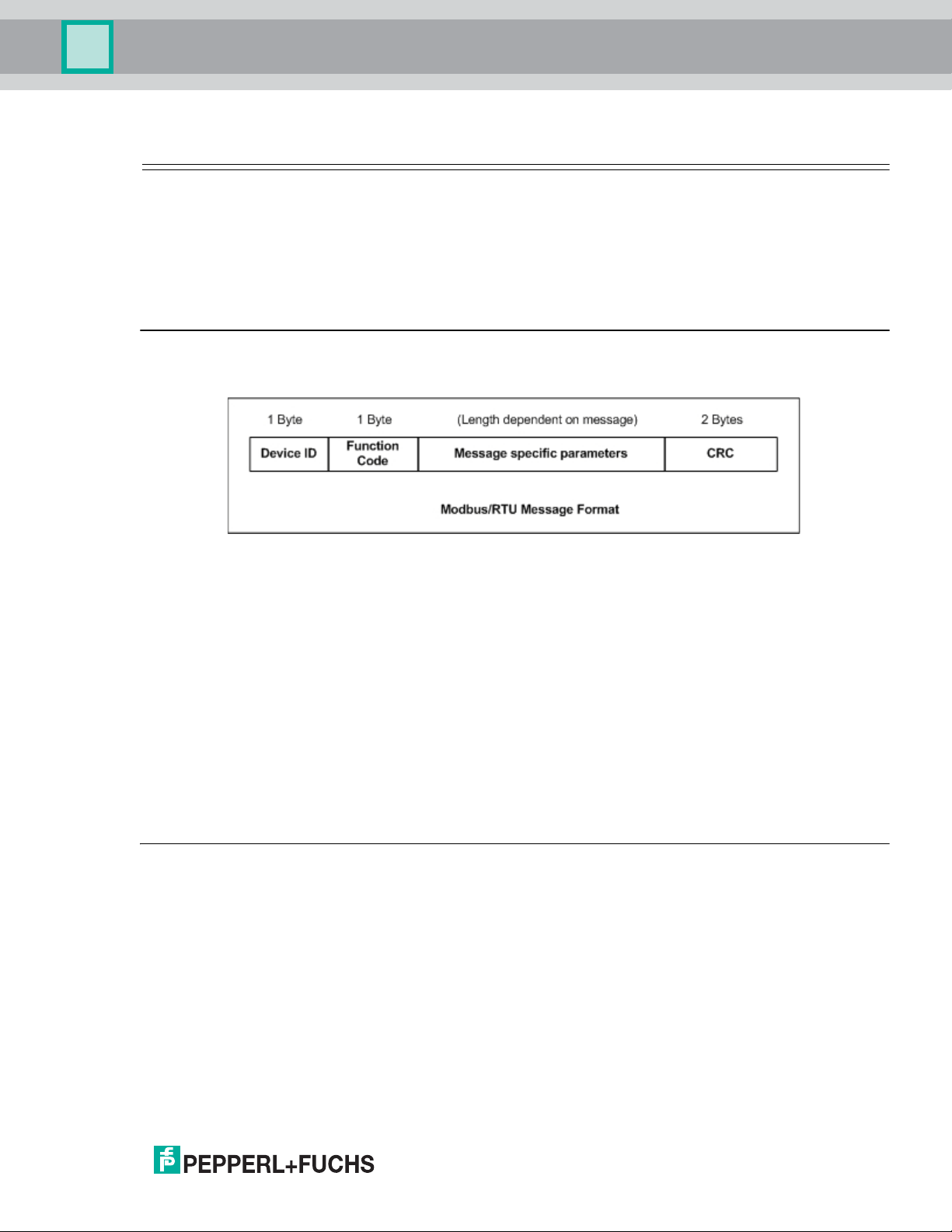

1.3.1. Modbus/RTU

Modbus/RTU is native Modbus in hexadecimal format. These are the base Modbus messages that contain

simple read and write requests. The format is as follows:

Where:

• The terms Master or Client are used to identify the sender of the message.

• The terms Slave or Server are used to identify the devices responding to the message.

Modbus/RTU is used primarily for:

• Serial port connectivity

RS-485 is the most common serial mode, but RS-232 and RS-422 are also widely used. Commonly used

by both Master and Slave devices.

• Ethernet TCP/IP socket connections

This is not the same as Modbus/TCP on Page 8, but does provide a very simple method of interfacing to

remote devices. It is used by many applications and some OPC servers.

Note: This communication method typically is not supported by PLCs.

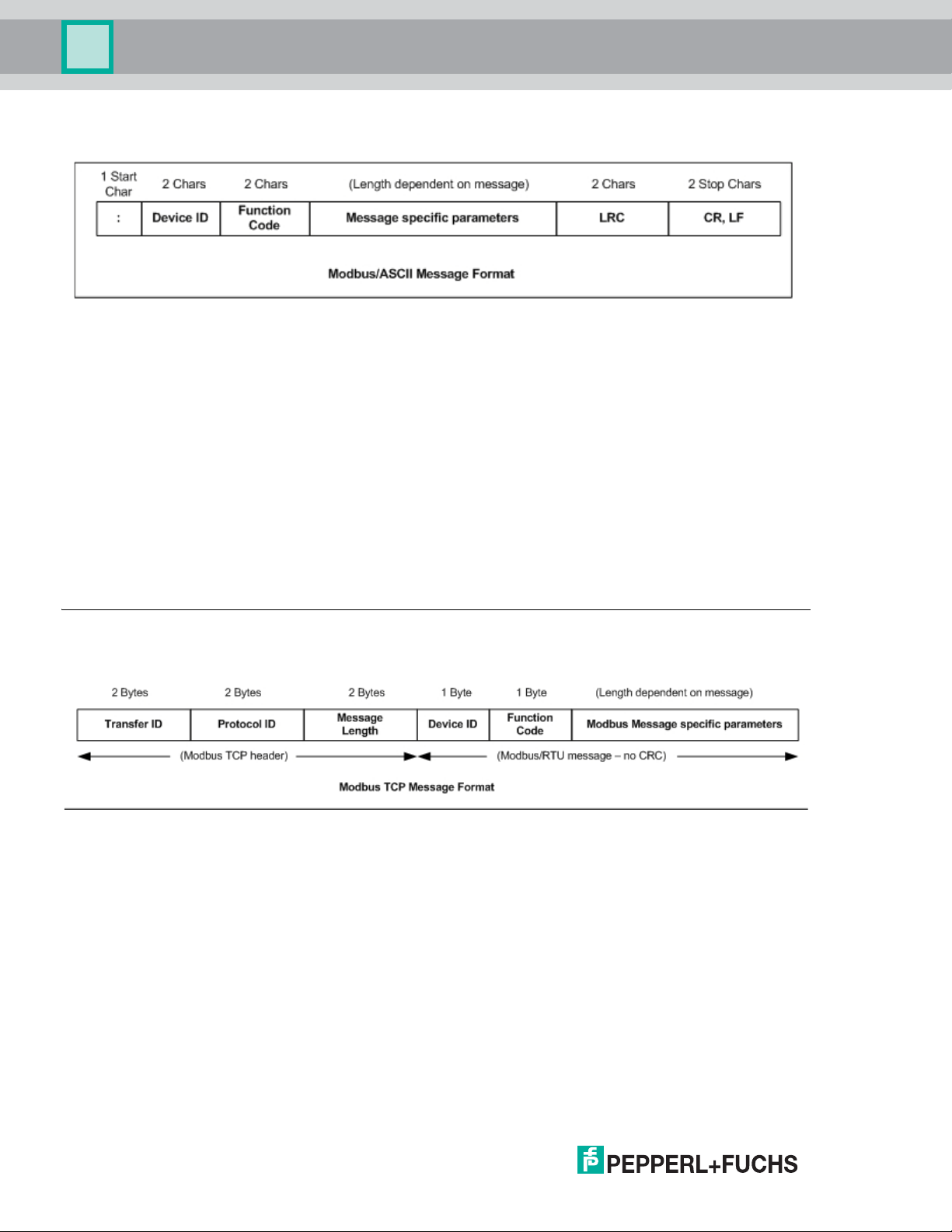

1.3.2. Modbus/ASCII

Modbus/ASCII is native Modbus in ASCII format. This protocol is used primarily by legacy devices and is no

longer supported as widely as Modbus/RTU.

Like Modbus/RTU, Modbus/ASCII contains the base Modbus messages that contain simple read and write

requests. The differences between Modbus/ASCII and Modbus/RTU are:

1. The message data is sent in ASCII format, so the message length is twice as long. It requires two ASCII

characters for each byte of data.

2. An 8-bit LRC is attached to verify the message instead of a 16-bit CRC. The LRC is also transmitted in

ASCII format.

3. There are defined starting and ending characters to determine a Modbus/ASCII messages.

6/3/19

7

Page 8

ICDM-RX/MOD User Manual

Overview

The format is as follows:

Where:

• The terms Master or Client are used to identify the sender of the message.

• The terms Slave or Server are used to identify the devices responding to the message.

Modbus/ASCII is used primarily for:

• Serial port connectivity

RS-485 is the most common serial mode, but RS-232 and RS-422 are also used. Used primarily by legacy

Slave devices.

• Ethernet TCP/IP socket connections

This is not the same as Modbus/TCP, but does provide a very simple method of interfacing to remote

devices. It is used by some applications and some OPC servers.

Note: This communication method typically is not supported by PLCs.

1.3.3. Modbus/TCP

Modbus/TCP is an Ethernet network based protocol that contains a Modbus/RTU message, with the exception

of the 2-byte CRC. The Modbus/TCP message contains a header with information designed to provide

message identification and routing information. The format is as follows:

Where:

• The terms Master or Client are used to identify the sender of the message.

• The terms Slave or Server are used to identify the devices responding to the message.

• Modbus/TCP messages are typically sent to and received on a defined Ethernet TCP/IP socket of 502.

• Modbus/TCP implementations provide more capability, but also require more processing than simpler

Modbus/RTU implementations.

Modbus/TCP is used for connecting advanced Ethernet based devices, such as PLCs, HMIs, SCADA Systems,

and most OPC Servers to:

• Other Ethernet devices supporting Modbus/TCP.

• Remote serial Modbus/RTU and/or Modbus/ASCII devices through gateways (such as the ICDM-RX/MOD

running the Modbus Router or Modbus/TCP applications).

• Remote serial or Ethernet TCP/IP ASCII devices (barcode scanners, printers, RFID readers, visions

systems, etc) through a gateway (such as the ICDM-RX/MOD running the Modbus/TCP application).

6/3/19

8

Page 9

ICDM-RX/MOD User Manual

Overview

1.4. Modbus Router Functionality

The Modbus Router application provides the following functionality:

• Provides robust connectivity from all supported master devices to all supported slave devices:

- Supported Masters:

- Modbus/TCP Master - accepts Modbus/TCP messages on up to eight TCP/IP ports. This includes

502 and seven configurable ports.

- Modbus/RTU Serial Master

- Modbus/ASCII Serial Master

- Modbus/RTU over Ethernet TCP/IP Master

- Modbus/ASCII over Ethernet TCP/IP Master

- Supported Slaves:

- Modbus/RTU Serial Slaves

- Modbus/RTU ASCII Slaves

- Remote Modbus/TCP Slaves (addressable to device ID and IP address/port)

- Remote Modbus/RTU Serial Slaves (via Modbus/TCP using another gateway)

- Remote Modbus/ASCII Serial Slaves (via Modbus/TCP using another gateway)

• Multiple ICDM-RX/MOD chassis can be used together to form a Modbus network.

• Supports up to 255 public Modbus devices per gateway and/or Modbus network. Both standard, (1-247),

and reserved, (248-255), device IDs are supported.

• All Modbus devices not configured remotely are assumed to be locally connected to the gateway.

• The locations of all local Modbus devices are determined automatically.

• Modbus Device ID Aliasing. Modbus message device ID can be aliased when messages are received from

a Modbus master.

• Device ID Offset. At the serial port interface, device IDs can have a positive or negative offset applied to

change the device ID range.

• Supports up to 96 Modbus/TCP connections. This can include any combination of slave and master

connections.

• Modbus/RTU and Modbus/ASCII over Ethernet TCP/IP Master specific:

- Can support up to six TCP/IP connections per serial port configuration.

- All messages received from any Ethernet TCP/IP Master connection enter the routing functionality and

can be routed to any local or remote device.

- Combined with a serial port redirector, such as the Pepperl+Fuchs Comtrol Secure Port Redirector, can

provide COM port functionality from a computer to the Modbus network.

• Supports connectivity to private Modbus serial buses, such as a serial master and slave(s) on a RS-485

loop:

- The Modbus master is provided connectivity to the public Modbus network.

- Only the master has direct access to the serial devices on the private serial network.

- Private slaves are protected from intrusion by other master(s).

- Both slave device specific and port level diagnostics are provided for private network communication.

• Advanced Master-to-Master connectivity is provided via the Shared Memory sub-system. Features are:

- Eight Holding Register blocks containing 200 registers each.

- Eight Coil blocks containing 160 coils each.

- Read access to all master(s) on the Modbus network.

6/3/19

9

Page 10

ICDM-RX/MOD User Manual

Overview

- Block-specific configurable write-access control. For each block, writes can be enabled for all

master(s) or restricted to a specific serial, Modbus/TCP, or Ethernet TCP/IP master.

- Web pages provide configuration, diagnostics, display of block contents and shared memory clearing

capabilities.

• Modbus specific message handling:

- CRC verification of all messages received on the TCP/IP and serial Modbus/RTU interfaces.

- LRC verification of all messages received on the TCP/IP and serial Modbus/ASCII messages.

- Timing out of responses from slave Modbus devices.

- Transfer ID verification of all remote Modbus/TCP messages.

- Parameter checking of all slave responses.

- Broadcast message handling.

• System monitoring to ensure gateway operation:

- Gateway busy.

- Application message time-outs

- Message validity checking.

• Advanced diagnostics web pages:

- Modbus device specific statistics, response timing, and status. Up to 255 Modbus devices, both

attached and remote, can be monitored simultaneously.

- Modbus/TCP diagnostics, connection(s) status, error messages

- Serial port specific statistics and status.

- Serial port message logging.

10

6/3/19

Page 11

ICDM-RX/MOD User Manual

Overview

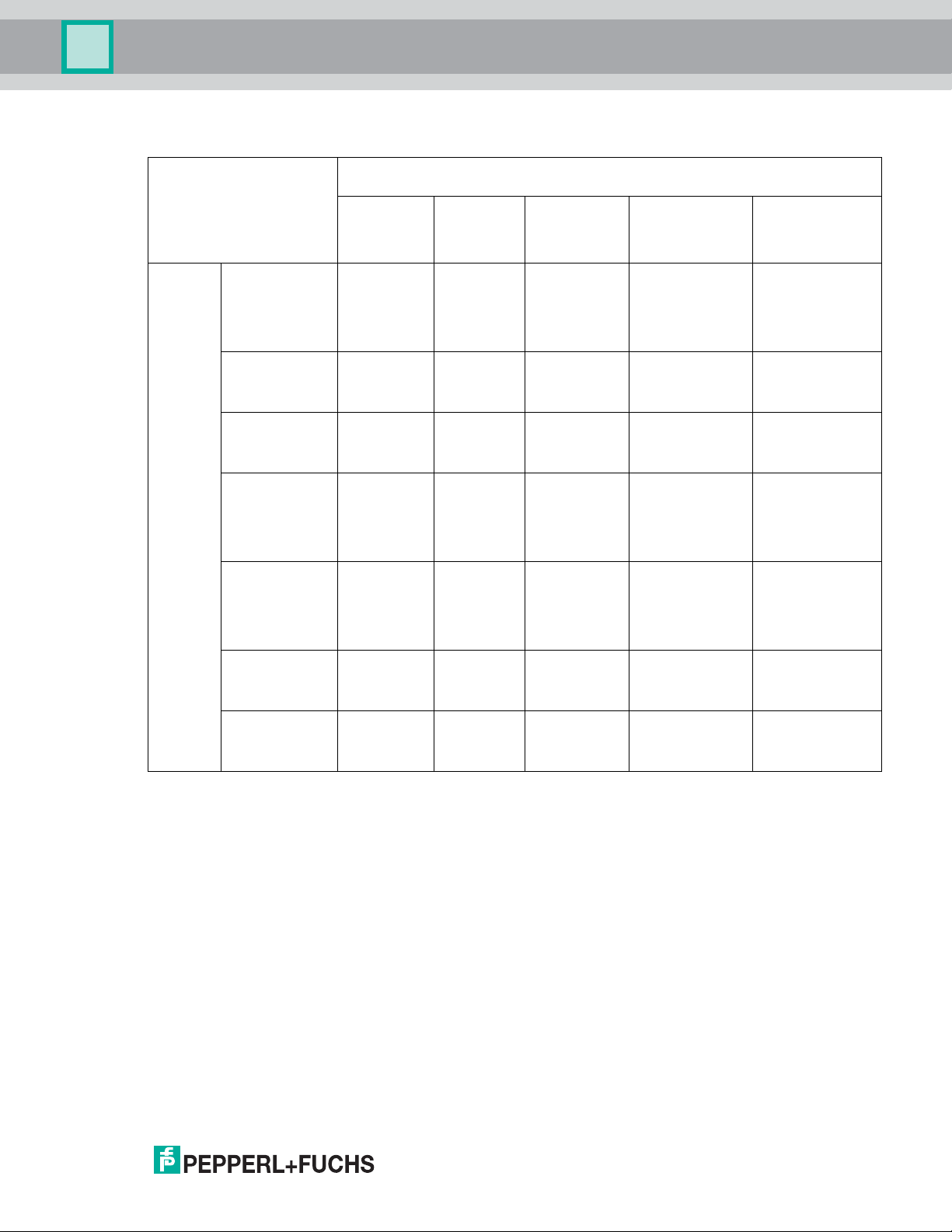

Supported Connectivity includes:

Modbus Router

Connectivity Grid

Modbus/TCP

Slave (remote

gateway or

slave Modbus/

TCP device)

Local Public

Modbus/RTU

Serial Slave

Local Public

Modbus/ASCII

Serial Slave

Remote

Slave

Devices

Modbus/RTU

Serial Slave (via

remote

gateway)

Modbus/

TCP Master

XX X X X

XX X X X

XX X X X

XX X X X

Modbus/

RTU Serial

Master

Masters

Modbus/

ASCII Serial

Master

Modbus/RTU

Master over

Ethernet TCP/IP

Modbus/ASCII

Master over

Ethernet TCP/IP

Remote

Modbus/ASCII

Serial Slave (via

remote

gateway)

Local Private

Modbus/RTU

Serial Slave

Local Private

Modbus/ASCII

Serial Slave

XX X X X

X

X

6/3/19

11

Page 12

ICDM-RX/MOD User Manual

Overview

12

6/3/19

Page 13

ICDM-RX/MOD User Manual

Overview

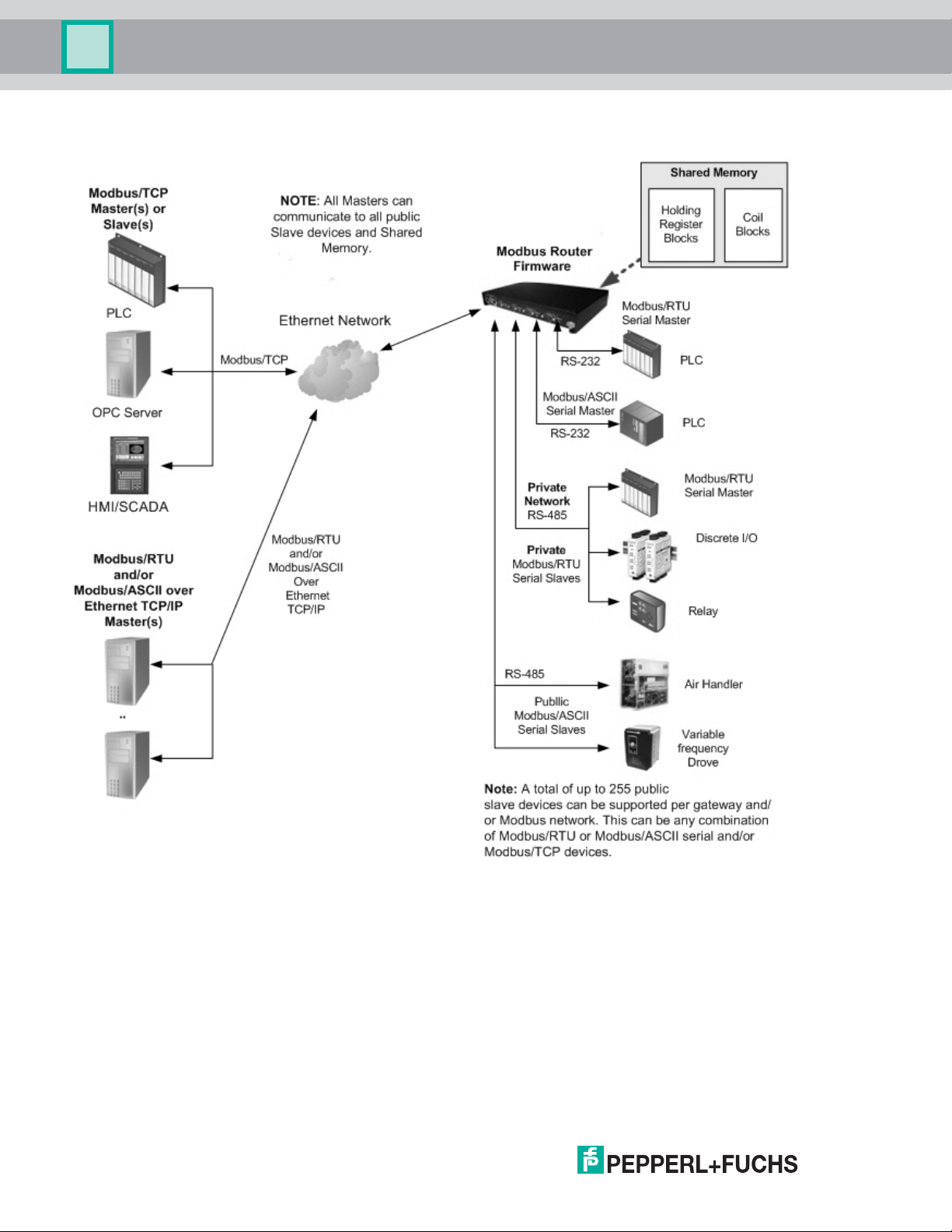

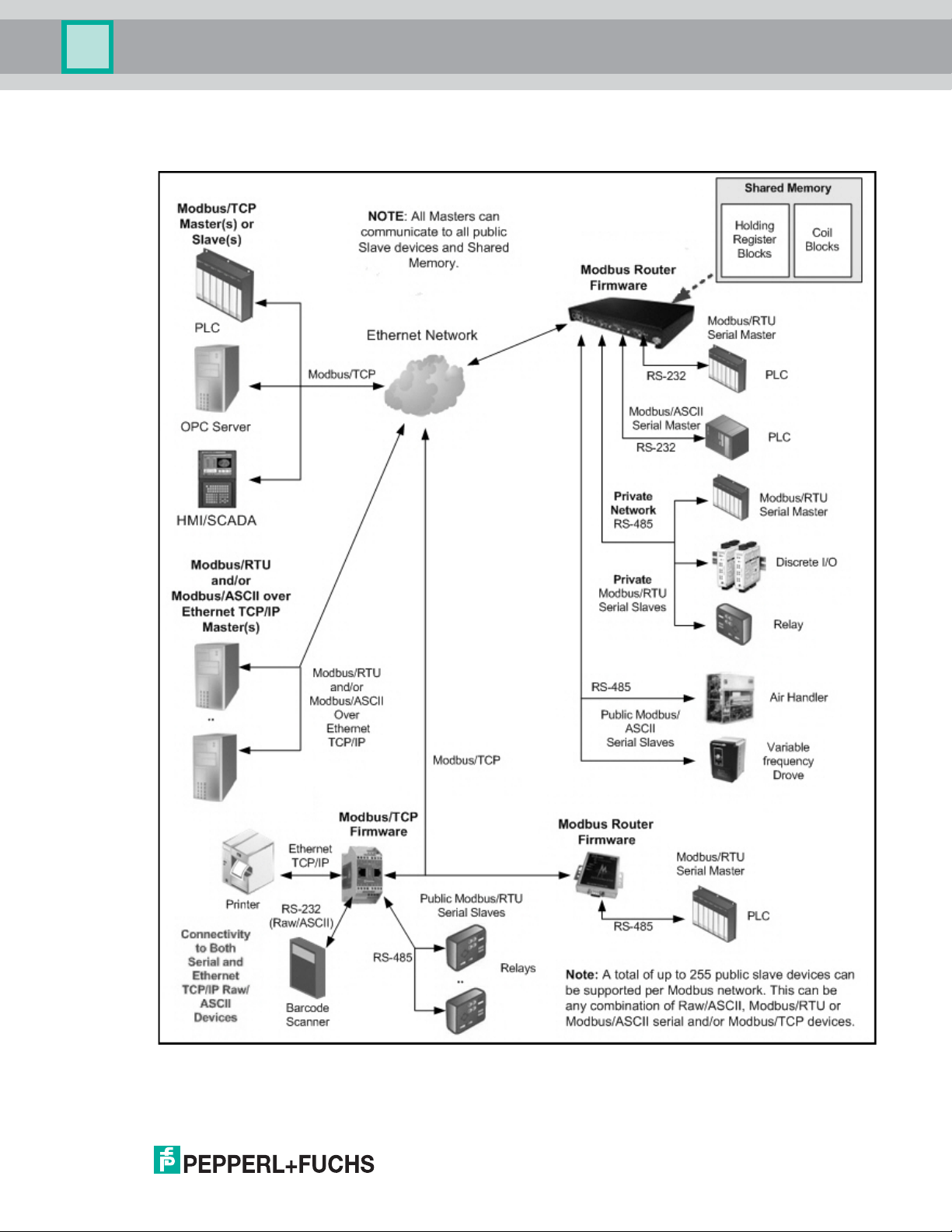

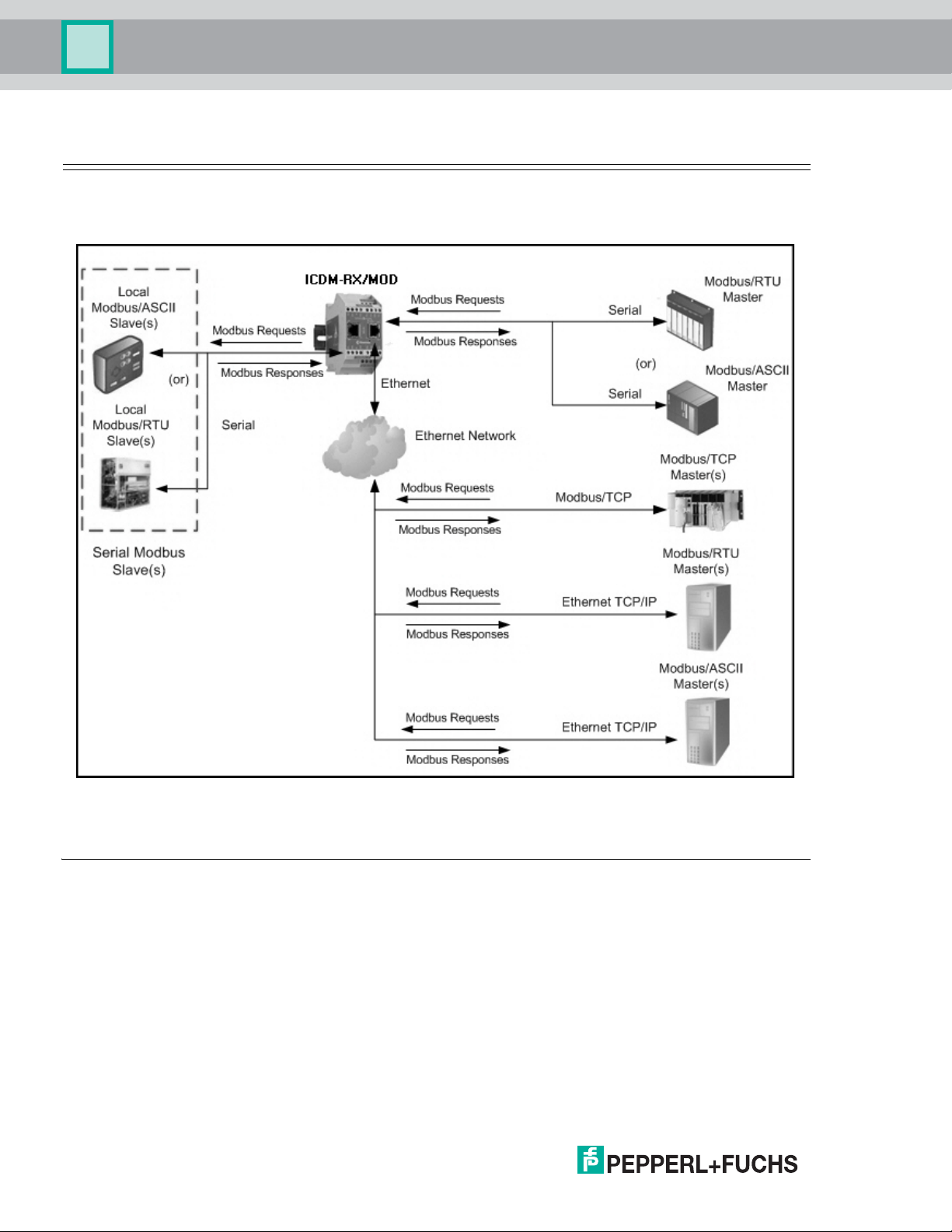

1.5. Multiple Gateway Modbus Networks

A multiple gateway Modbus Network is created by combining two or more Modbus slave(s) and master(s) with

two or more ICDM-RX/MODs running the Modbus Router and/or Modbus/TCP firmware applications.

• Typically, at least one chassis will be running the Modbus Router firmware application.

• The Modbus/TCP application can provide connectivity to local or remote serial and Ethernet TCP/IP Raw/

ASCII devices such as barcode scanners, RFID readers, printers, vision systems, and weigh scales.

• All Modbus masters connected to a ICDM-RX/MOD running Modbus Router can communicate to all public

slaves.

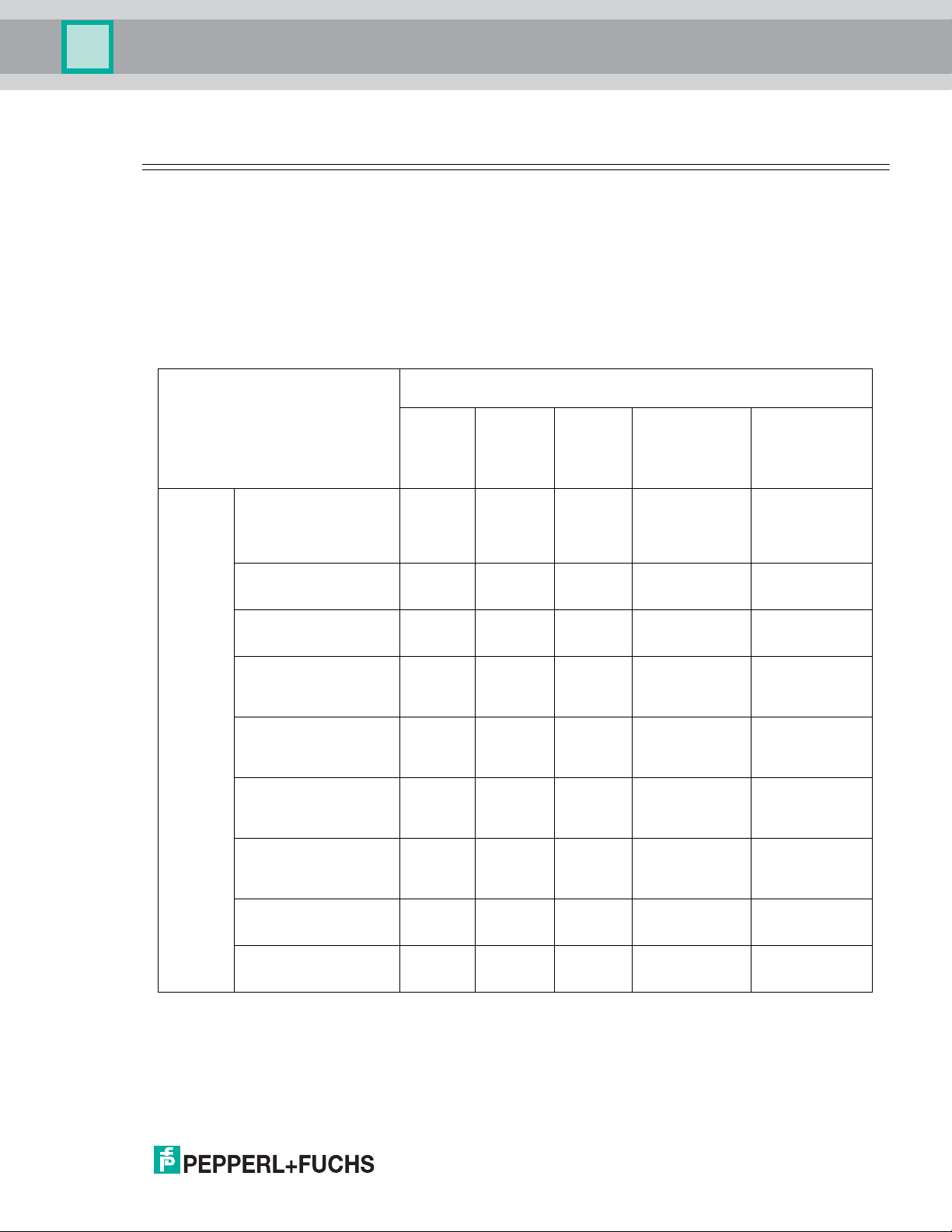

The following connectivity can be provided in a Modbus network when using multiple ICDM-RX/MOD chassis

with Modbus Router and Modbus/TCP firmware applications:

Masters

Modbus Network Connectivity

Slave

Devices

Grid

Modbus/TCP Slave

(remote gateway or

slave Modbus/TCP

device)

Local Public Modbus/

RTU Serial Slave

Local Public Modbus/

ASCII Serial Slave

Remote Modbus/RTU

Serial Slave (via remote

gateway)

Remote Modbus/ASCII

Serial Slave (via remote

gateway)

Serial Raw/ASCII

Devices (remote or

local)

Ethernet TCP/IP Raw/

ASCII Devices (remote

or local)

Modbus

/TCP

Master

XXX X X

XXX X X

XXX X X

XXX X X

XXX X X

XXX X X

XXX X X

Modbus/

RTU

Serial

Master

Modbus/

ASCII

Serial

Master

Modbus/RTU

Master over

Ethernet TCP/

IP

Modbus/ASCII

Master over

Ethernet TCP/

IP

Local Private Modbus/

RTU Serial Slave

Local Private Modbus/

ASCII Serial Slave

6/3/19

X

X

13

Page 14

ICDM-RX/MOD User Manual

Overview

The following diagram demonstrates a multiple gateway Modbus network utilizing Modbus Router firmware.

14

6/3/19

Page 15

ICDM-RX/MOD User Manual

Overview

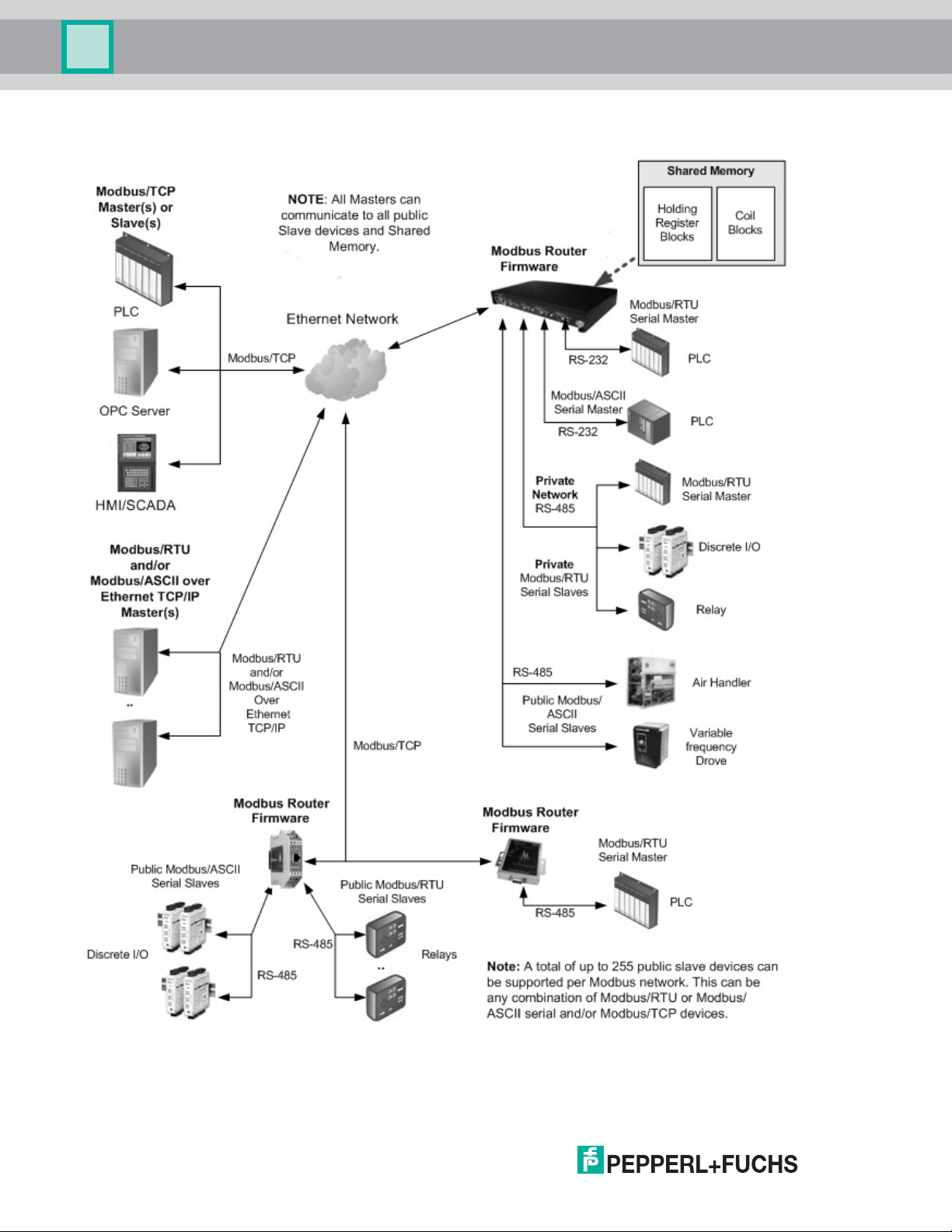

The following diagram demonstrates a multiple gateway Modbus network utilizing both Modbus Router and

Modbus/TCP firmware.

6/3/19

15

Page 16

ICDM-RX/MOD User Manual

Overview

1.6. Modbus/RTU and Modbus/ASCII To-Slaves Interface

The ICDM-RX/MOD provides access to serial Modbus/RTU and Modbus/ASCII slave devices. Modbus master

messages are translated to appropriate Modbus slave messages, public slave devices are automatically

located, and appropriate responses are returned to the Modbus master.

Modbus Master(s) to Public Modbus Slave(s)

1.6.1. Communication Methodology

The ICDM-RX/MOD translates various Modbus formats and forwards them to public slave devices attached to

the Modbus To-Slaves configured serial ports. Each Modbus message is transmitted and a response is

expected. The ICDM-RX/MOD times out the Modbus messages if there is no response returned within the

configured timeout period.

The following diagram displays the Modbus message transfer. The following apply to Modbus To-slaves serial

ports.

• All valid Modbus messages are translated to the appropriate format for serial port or Modbus/TCP

transmission.

• Local public Modbus slave devices are automatically located on a ICDM-RX/MOD 2-port or 4- port.

• Local and remote public Modbus slave devices can be accessed from a Modbus master as if they were of

that master’s protocol type.

• Messages are timed out if no response is returned within the configured timeout period.

16

6/3/19

Page 17

ICDM-RX/MOD User Manual

Overview

• Appropriate Modbus responses are returned to the Modbus master.

• Broadcast Modbus messages, those with a unit identifier of zero, are transmitted out all Modbus To-slaves

serial ports on the ICDM-RX/MOD. Depending on the remote device configuration(s), remote slave devices

may or may not receive broadcast messages.

From a message routing standpoint, all local and remote public Modbus slave devices attached to a ICDM-RX/

MOD gateway (1, 2, or 4-port) must be addressed with unique Unit Identifiers. Valid Unit Identifiers are 1 to 255

and the Broadcast Identifier is zero. However, the Device ID Offset functionality can be configured to change

the addressing of serial connected slave devices to allow multiple slave devices with the same unit ID to be

connected to the same gateway, but addressed differently. For more information, see section on Alias and

Device ID Offset functionality.

To communicate to local Modbus slave device(s) through a ICDM-RX/MOD, perform the following steps.

1. Select the Serial menu and then select the appropriate port.

2. Under Serial Configuration, configure the serial port parameters such as the Mode, Baud rate, Data Bits,

and so forth.

3. Under Modbus Settings, set the Serial Port Protocol to Modbus/RTU-To-Slaves or Modbus/ASCII-To-

Slaves.

4. Under Modbus Slaves To-Slaves Settings, set the Response Timeout to the desired value.

Note: 2- and 4-Port only: Set the Lost Device Search Enable setting. See Local Public Modbus Slave

Device Search Methodology.(below) for more information.

5. If desired, configure the Device ID Offset Mode and Device ID Offset.

To communicate to remote Modbus slave device(s) through a ICDM-RX/MOD, perform the following steps.

1. Select the Modbus menu and then the Remote Modbus Configuration page.

2. Click the Add Remote Configuration button.

3. Configure each remote device as needed and click Save.

To enable the Alias Device ID capability for one or more device Ids, perform the following steps.

1. Select the Modbus menu and then the Alias Configuration page.

2. Click the Add Alias Configuration button.

3. Configure each alias device ID as needed and click Save.

1.6.2. Local Public Modbus Slave Device Search Methodology

Locating a local Modbus slave device on a ICDM-RX/MOD 1-port is relatively simple. Either the Modbus slave

device is connected to the port or it is not. However, if more than one port is configured for Modbus To-Slaves

on a ICDM-RX/MOD 2- or 4-port, the device must be found. The following is an explanation of how the search

algorithm works on a ICDM-RX/MOD 2- or 4-port.

Locating a Local Modbus slave device after a reboot or port reset: When the ICDM-RX/MOD receives a

message for a public Modbus slave device for the first time since reboot or port initialization, it will transmit the

Modbus message out all Modbus To-Slaves serial ports and wait for a response to be returned. Once the

response is returned, the device port is known and all messages sent to the device will be routed through the

serial port.

Lost Devices: Lost devices, or devices that time out, are a special case. The ICDM-RX/MOD provides two

methods for handling lost devices via the Lost Device Search Enable option on the web page.

• Disabling this option on a Modbus To-Slaves port:

- Prevents the ICDM-RX/MOD from searching for a lost device on other Modbus To-Slaves ports.

- Prevents lost devices known to have been on other ports from being searched for on this port.

Note: This is the recommended setting whenever it is desired to prevent timeout delays on other Modbus

To-Slaves ports in the event that a device times out.

• Enabling this option on a Modbus To-Slaves port:

6/3/19

17

Page 18

ICDM-RX/MOD User Manual

Overview

- Allows the ICDM-RX/MOD to search for lost devices on all Modbus To-Slaves ports with the Lost

Device Search Enable option turned on.

- This will cause timeout delays on all Modbus To-Slaves ports with the Device Search Enable option

turned on until the device is found.

Note: This can be useful for locating devices if a device has been moved onto another port by moving the

serial cable or, perhaps, by moving the device onto a different Modbus To-Slaves serial bus.

1.7. Alias Device ID and Device ID Offset Functionality

One of the most common challenges people face when setting up Modbus systems are the problems caused

by the limited device ID range. The Alias Device ID and Device ID Offset functionality have been developed to

help solve those problems.

The Modbus specification has the following limitations:

• Requires all public devices attached to gateway to be addressed by a device ID.

• Allows only 256 device IDs with a range of 0 to 255.

• Not all device IDs can be used for addressing devices.

- Device ID 0 is reserved for broadcast messages

- 1-247 are for device addressing

- 248 to 255 are reserved for such things as gateway functions. Depending on your environment, these

device IDs may or may not be available for assignment to devices.

The following are common problems that can occur as a result of the device ID limitations:

• A gateway must route Modbus messages based on the device ID. Therefore, it cannot route to multiple

Modbus devices with the same device ID.

• It is not always possible or practical to change the device ID of serial Modbus slave devices.

• Serial and Ethernet TCP/IP Modbus RTU/ASCII masters with one connection may need to access multiple

devices with the same device ID. Furthermore, these devices may be located locally or remotely.

• It is not always possible or practical to modify the device IDs on existing Modbus master programs. This is

often true when adding a SCADA system to an existing PLC controlled system.

The Alias Modbus Device ID and Device ID Offset functionality has been developed to solve these problems.

18

6/3/19

Page 19

ICDM-RX/MOD User Manual

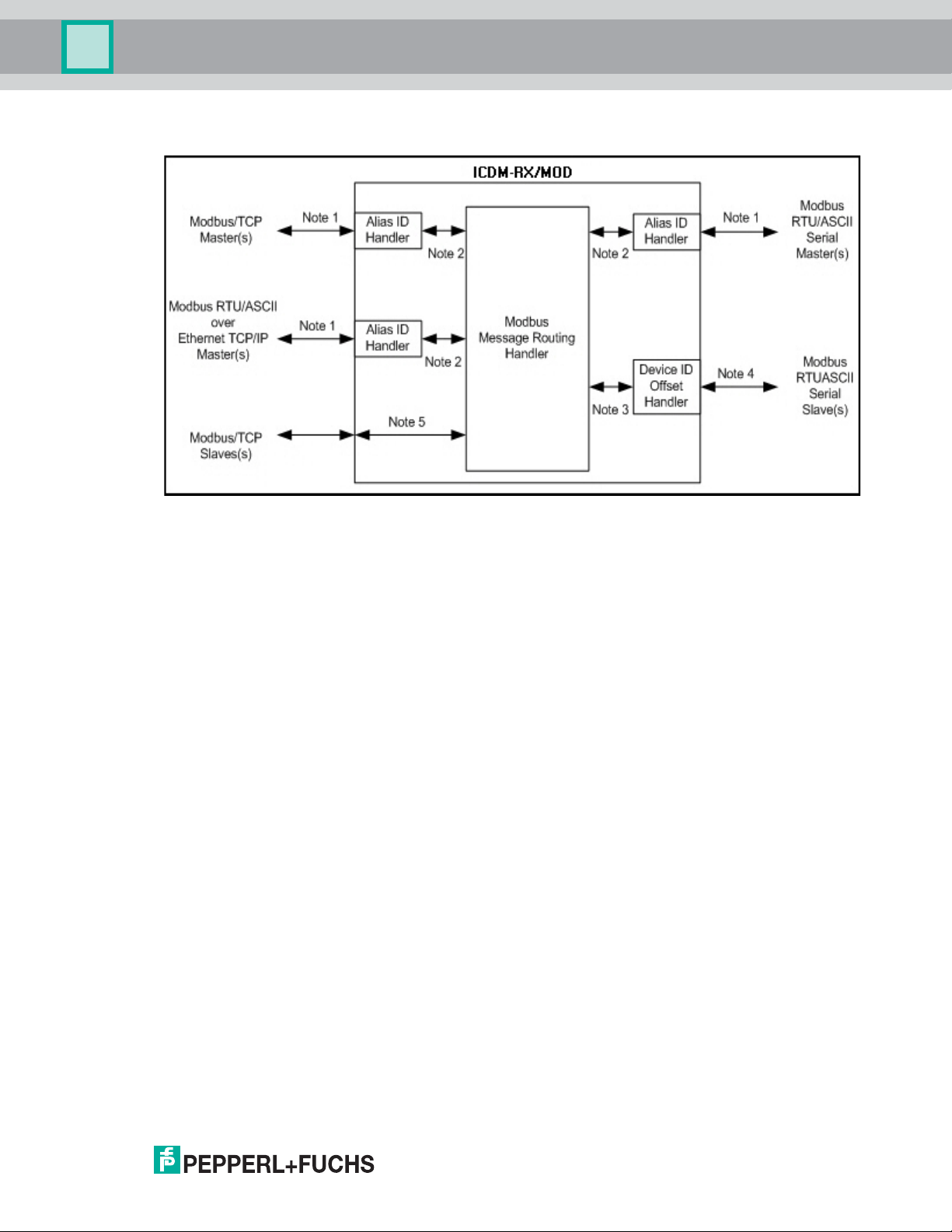

Alias Device ID and Device ID Functionality

Overview

This functionality is described in the following diagram:

Note 1:Originally received Modbus messages. All responses will be returned with the original device ID.

Note 2:Modbus messages sent to and responses received from Modbus Message Routing Handler.

Note 3:Modbus messages received from the Modbus Message Routing Handler. Depending on the Alias

Note 4:Modbus messages sent to Modbus serial slaves. Depending on the Device ID Offset configuration

Note 5:Modbus messages received from the Modbus Message Routing Handler. Depending on the Alias

Depending on the Alias ID configuration, these messages may contain the originally received

device ID or the alias device ID.

ID configuration, these messages may contain the originally received device ID from the Modbus

master or the alias device ID. All responses contain the device ID as received from the Modbus

Message Routing Handler.

for the serial port, these messages may be the same as those received from the Modbus Message

Routing Handler or have a device ID that has been either incremented or decremented to match

the serial device ID range.

ID configuration, these messages may contain the originally received device ID from the Modbus

master or the alias device ID. Device ID Offset functionality does not apply to Modbus/TCP

slaves.

6/3/19

19

Page 20

ICDM-RX/MOD User Manual

Overview

1.7.1. Alias Modbus Device ID Functionality

The Alias Modbus Device ID functionality allows modification of device IDs only when messages are received

from Modbus masters. When configured, a Modbus message from a master with the specified device ID is

converted to the alias device ID, the message is then routed internally using the alias device ID. All responses

are returned to the master with the original received message device ID.

The following table demonstrates several device ID aliasing examples:

Received

Device ID

110 10

50 5 5

100 254 254

10 10 10

Alias Device IDRouted Message

Device ID

Description

Convert messages with received device ID 1 to 10.

Route message with device ID 10.

Convert messages with received device ID 50 to 5.

Route message with device ID 5.

Convert messages with received device ID 100 to 254.

Route message with device ID 254.

Invalid configuration attempt. No change to device ID is

performed.

1.7.2. Device ID Offset Functionality

The Device ID Offset functionality allows modification of device IDs when messages are transmitted to serial

Modbus slave devices. When configured, the Device ID Offset functionality will modify the device ID received in

the message to match the actual device ID range of the serial device(s). The device ID range is effectively either

increased or decreased depending on the serial port Device ID Offset configuration.

The following table demonstrates several Device ID Offset examples:

Device ID Offset

Mode

Off 0 1-255 1-255

Add-to-Msg-ID 50 1-205 51-255

Subtract-from-Msg-ID 100 101-255 1-155

Device ID

Offset

Valid Message

Device ID

Range

Valid Serial

Device ID

Range

Description

Default mode. Device IDs are

unchanged.

Increase device ID range by 50.

Examples:

Device ID 1 is converted to 51

Device ID 10 is converted to 60

Device ID 120 is converted to 170

Decrease device ID range by 100.

Examples:

Device ID 101 is converted to 1

Device ID 150 is converted to 50

Device ID 225 is converted to 125

It is highly recommended to take great care when configuring the Device ID Offset functionality. Verify the

following when configuring the Device ID Offset:

• Check for Device ID overlaps. Be certain that no two devices can have same device ID as recognized by the

internal Modbus Message Routing Handler.

• Check for conflicts with the Alias device ID configuration. The Device ID Offset configuration must coincide

with any Alias device ID configurations.

20

6/3/19

Page 21

ICDM-RX/MOD User Manual

Overview

• Verify the valid device ID ranges are sufficient to address all serial devices.

1.8. Modus Master/Slaves Serial Port Mode (Private Serial Bus)

As of Modbus Router v5.10, Modbus masters and slave(s) can be connected together on the same serial port.

This provides the following benefits:

1. A serial Modbus master can communicate to slaves on its’ own private serial bus as well as public slaves on

a Modbus network. In this configuration, a serial master can communicate to:

a. Modbus RTU/ASCII slave(s) on its own serial bus.

b. Public Modbus RTU/ASCII serial slave(s) connected to the same ICDM-RX/MOD.

c. Modbus/TCP slaves.

d. Remote public Modbus RTU/ASCII serial slave(s) via an Ethernet attached Modbus gateway.

e. All other Modbus master(s) on the Modbus network via the Shared Memory functionality.

2. The Modbus slaves on the serial bus are

a. The slave device(s) are affectively protected from all other Modbus masters on the Modbus network.

b. The master has total control of communication to the slaves on its own serial bus.

c. The master can provide data to/from the slave(s) to the Modbus network, and other Modbus masters,

via the Shared Memory functionality.

3. Deployment can be greatly simplified.

a. An existing serial bus can be left intact, thusly reducing the rewiring effort.

b. The only wiring change is to attach the ICDM-RX/MOD to the bus anywhere there is access.

4. The system can be more fault-tolerant.

a. In the event the ICDM-RX/MOD is powered off, the master and slaves on the serial bus can still

communicate.

b. By preventing other masters from communicating to the slave devices on the serial bus:

• Other masters cannot cause disruptions in communications between the master and slaves on the

serial bus by overloading the gateway.

• Message latency time between the master and slaves is minimized.

5. Maintenance and downtime costs can be minimized with detailed diagnostics web pages provided by the

ICDM-RX/MOD.

private to the master on that serial bus.

6/3/19

21

Page 22

ICDM-RX/MOD User Manual

Overview

The following diagram demonstrates the To-Master/Slaves mode compared to the To-Master and To-Slaves

modes.

1.8.1. Master/Slaves Message Routing

On a serial port configured to Master/Slaves, only the master on the private serial bus has access to the serial

slaves on that serial bus. However, the master can also communicate to public devices and shared memory

anywhere on the Modbus network.

The Serial Interface Configuration web page contains two configuration settings that determine how the serial

bus routing is controlled.

1.8.1.1. Forward Broadcasts From Master Option

If this option is selected, all broadcast messages received on this port will be forwarded to the Modbus network.

If this option is not selected, all broadcast messages received on this serial port will be dropped and only the

private slave devices will receive them.

Note: Make sure that broadcasts should be forwarded before selecting this option. If this option is selected, all

public slave devices on the local Modbus network will receive the broadcast messages and that may

cause unpredictable results.

22

6/3/19

Page 23

ICDM-RX/MOD User Manual

Overview

1.8.1.2. Private Device ID Range Setting

This range defines the expected private slave device ID range on the serial bus.

• Modbus request messages received on this port that are within this device ID range will not be forwarded to

the Modbus network.

• All communication to device(s) in that range must occur between the Modbus master and slave(s) on that

serial bus.

• The private device ID range must not include public device(s) addressed by the serial master. Loss of

communication errors will result if this occurs. It is recommended to use either the Alias and/or the Device

ID Offset functionality to address those cases where a public device ID falls into the private device ID range.

• All received Modbus request messages that are not within the private device ID range or have been

previously detected on the serial bus, will be forwarded to the Modbus network via the ICDM-RX/MOD.

• Responses, including error messages such as timeouts, received from the Modbus network will be

forwarded to the serial master.

• The ICDM-RX/MOD has a built-in auto-detect algorithm for detecting private slave device(s) with ID(s) not

defined within the private device ID range. If a response from such a device is received on the serial bus,

the ICDM-RX/MOD will add that device ID to the private device list and will no longer route those messages

to the Modbus network.

Note: There is a potential race condition if a slave device ID is not within the private device ID range and exists

both as a public device on the Modbus network and as a private device on the serial bus. If this situation

occurs and the public device responds before the private serial device, the master would receive two

responses for that request, with the first response coming from the public device. If the public and

private device responded at the same time, the Modbus master could detect a corrupted response.

However, once the private slave device responds with a valid response, the auto-detect algorithm will

prevent forwarding of additional requests to the Modbus network.

1.9. Shared Memory Functionality

The Shared Memory functionality has been added to provide a simple and robust method for master-to-master

communication.

• The Shared Memory interface contains eight 200 Holding Register blocks and eight 160 Coil blocks.

• All Modbus masters, (Modbus/TCP, serial Modbus RTU/ASCII, and Modbus RTU/ASCII over Ethernet TCP/

IP), can read the contents of the Shared Memory blocks.

• Write access can be controlled to each Holding Register and Coil block. Each block can be configured to

provide all masters write access or be restricted to a port-specific serial master, a Modbus/TCP master or

an Ethernet TCP/IP master.

• The Shared Memory contents can be displayed and cleared via the embedded web pages.

• Diagnostics for each block include read, write and blocked write message counts.

• Blocked write messages are recorded in the Write Violation Log.

This table displays the supported Holding Register Block Function Codes.

Function Code Description

3 Read Holding Registers

6Write Single Register

16 Write Multiple Registers

22 Write Mask Register

23 Read Write Registers

6/3/19

23

Page 24

ICDM-RX/MOD User Manual

Overview

This table shows the supported Coil Block Function Codes.

Function Code Description

1 Read Coils

5 Write Single Coil

15 Write Multiple Coils

24

6/3/19

Page 25

ICDM-RX/MOD User Manual

Overview

Modbus Router Shared Memory Functionality

6/3/19

25

Page 26

ICDM-RX/MOD User Manual

Serial Modbus Masters to Modbus/TCP Slaves

Overview

1.10. Remote Modbus Routing Capabilities

The Modbus Router firmware provides a wide variety of routing options. Combining those options for a specific

installation requires proper configuration of the ICDM-RX/MOD and a thorough understanding of the Modbus

master(s) and slave(s) communication capabilities and requirements.

1.10.1. Serial Modbus Master(s) to Modbus/TCP Slave(s)

This routing configuration provides serial Modbus master(s) connectivity to Modbus/TCP slave(s). This is

applicable when Modbus master(s) are limited to serial port connectivity and require connectivity to Modbus/

TCP slave(s) or remote Modbus serial slave(s).

1.10.2. Modbus over Ethernet TCP/IP Master(s) to Modbus/TCP Slave(s)

The Modbus router application provides Modbus RTU/ASCII over Ethernet TCP/IP master(s) connectivity to

Modbus/TCP slave(s). This is especially useful when deploying Modbus masters, such as many SCADA, HMI

or OPC servers, that do not support Modbus/TCP.

Modbus over Ethernet TCP/IP Masters to Modbus/TCP Slaves

6/3/19

26

Page 27

ICDM-RX/MOD User Manual

Overview

1.10.3. Modbus/TCP Master(s) to Modbus/TCP Slave(s)

This involves providing Modbus/TCP master(s) connectivity to Modbus/TCP slave(s). This is especially useful

when:

• Modbus/TCP master(s), that can open only one or a very limited number of Modbus/TCP connections,

requires connectivity to multiple Modbus/TCP slaves.

• Multiple Modbus/TCP masters require connectivity to Modbus/TCP slave(s) that can accept only one or a

very limited number of Modbus/TCP connections.

• Modbus/TCP master(s), that can send messages only to the standard Modbus/TCP port of 502, require

connectivity to Modbus/TCP slave(s) that accept messages on non-standard port(s), such as 503, 504,

505, or 506.

Modbus/TCP Masters to Modbus/TCP Slaves (with Non-Standard Ports)

Modbus/TCP Masters to Modbus/TCP Slaves (Single Connection Devices)

6/3/19

27

Page 28

ICDM-RX/MOD User Manual

Overview

1.10.4. Device ID Mapping to IP Address/Port/Slave Device IDs

Combining the Alias and Remote Modbus/TCP configurations can provide connectivity between Modbus

master(s) that address slave(s) based on device ID(s) to Modbus/TCP slave(s) which require specific IP

addresses, port numbers and/or alternate device ID(s). This is especially useful when:

• There are multiple Modbus/TCP slaves with the same device ID.

• A Modbus/TCP slave has multiple internal applications that are addressable through:

- Different IP addresses, same port, same device ID

- Different IP addresses, different ports, same device ID

- Same IP address, different ports, same device ID

The following example depicts a typical installation requiring Device ID mapping:

28

Modbus Master Device ID to Slave Modbus/TCP Device Mapping Example

6/3/19

Page 29

ICDM-RX/MOD User Manual

Overview

To implement this Device ID Mapping example, the following web page configuration entries are required on the

Modbus Alias Device ID Configuration page, which is accessed by clicking Modbus | Alias Configuration.

Where:

Parameter Type Description

Rx Device

Alias Device ID

Modbus/TCP Master

Modbus Serial Master

Modbus over TCP Master

Configuration

(1-255)

Configuration

(1-255)

Configuration (yes/

no)

Configuration (yes/

no)

Configuration (yes/

no)

The original, or pre-alias, device ID received from Modbus

master(s). Required.

The corresponding slave device ID. Required.

Enables the Alias conversion from Modbus/TCP masters.

Must be enabled if Modbus/TCP master(s) are present.

Enables the Alias conversion from serial Modbus masters.

Must be enabled if serial Modbus master(s) are present.

Enables the Alias conversion from Modbus over Ethernet

TCP/IP masters. Must be enabled if Modbus over Ethernet

TCP/IP master(s) are present.

6/3/19

29

Page 30

ICDM-RX/MOD User Manual

Overview

Access the Remote Modbus/TCP Device Configuration page, by clicking Modbus | Remote Modbus

Configuation and the following configuration entries are required.

Slave Device 1 Slave Device 2 Slave Device 3 Slave Device 4 Slave Device 5

Device ID (Can be

pre-alias as

received from

master)

Message Device ID

(can be aliased)

Remote IP Address 192.168.0.10 192.168.0.11 192.168.0.12 192.168.0.12 192.168.0.12

Remote IP Port 502 502 502 503 504

Timeout

Dedicated

Connection

Send Writes First No (configurable)

Disable Broadcasts No (configurable)

Route on Pre-Alias

Device ID

12345

1(not aliased) 1 1 1 1

1000 ms

configurable)

No (configurable)

Yes (See note

below)

1000 ms

(configurable)

No

(configurable)

No

(configurable)

No

(configurable)

No (N/A) No (N/A) No (N/A) No (N/A)

1000 ms

(configurable)

No

(configurable)

No

(configurable)

No

(configurable)

1000 ms

(configurable)

No

(configurable)

No

(configurable)

No

(configurable)

1000 ms

(configurable)

No

(configurable)

No

(configurable)

No

(configurable)

If the following conditions are all met then the routing configuration for the pre-alias device ID will be applied to

the message. This includes the Remote IP Address, Remote IP Port, Dedicated Connection, Send Writes First

and Disable Broadcasts options.

1. The Route on Pre-Alias Device ID is enabled in the remote message device ID configuration in this example:

device ID 1.

2. The message device ID has been aliased, or changed from the original device ID.

3. There is a valid remote device configuration entry for the original, or pre-alias, device ID.

30

6/3/19

Page 31

ICDM-RX/MOD User Manual

Overview

The routing decision making process is depicted in the following diagram:

6/3/19

31

Page 32

ICDM-RX/MOD User Manual

Overview

32

6/3/19

Page 33

ICDM-RX/MOD User Manual

Configuration Overview

2. Configuration Overview

This section provides an overview of how to configure the ICDM-RX/MOD and discusses the Home page.

2.1. Prerequisites

Before you can configure Modbus Router on the ICDM-RX/MOD, you must have previously performed the

following steps:

• Installed the hardware.

• Installed PortVision DX.

• Configured the ICDM-RX/MOD IP address using PortVision DX.

Note: If necessary, refer to the ICDM-RX/MOD Hardware Installation and Configuration Guide for the above

procedures.

2.2. Configuration Overview

The following overview shows how to access the ICDM-RX/MOD Router Configuration embedded web pages.

If you have not configured the network information into the ICDM-RX/MOD during initial setup, you must

configure the network information before configuring serial/socket port characteristics. See the PortVision DX

help system for help configuring the network settings.

1. From PortVision DX, highlight the ICDM-RX/MOD that you want to configure and select Webpage.

Note: Optionally, enter the IP address of the device in the Address box of your web browser.

2. Select the appropriate procedure for your environment.

Serial Modbus Master, Slave, or Master/Slaves

a. Click the Serial tab, which defaults to the Serial Port Overview page.

b. Click the port that you want to configure.

c. Change and save the serial port configuration properties as required for your installation.

Ethernet TCP/IP Modbus Master

a. Click the Modbus tab, which displays the Modbus over TCP Overview (not Modbus/TCP) page.

b. Click the socket that you want to configure.

c. Change and save the Ethernet TCP/IP configuration properties as required for the interface.

Modbus/TCP Device

a. Click the Modbus tab, which displays the Modbus over TCP Overview (not Modbus/TCP) page.

b. Click the Modbus/TCP Configuration sub-menu.

c. Change and save the Modbus/TCP configuration properties as required for the device.

Remote Modbus/TCP Device

a. Click the Modbus tab, which displays the Modbus over TCP Overview (not Modbus/TCP) page.

b. Click the Remote Modbus/TCP Device Configuration sub-menu.

6/3/19

33

Page 34

ICDM-RX/MOD User Manual

Configuration Overview

c. Update and save the remote Modbus/TCP configuration properties as required for the device.

Alias Modbus Device ID

a. Click the Modbus tab, which displays the Modbus over TCP Overview (not Modbus/TCP) page.

b. Click the Alias Configuration sub-menu.

c. Click Add Alias Configuration.

d. Configure and save the Alias Modbus Device IDs as required.

Shared Memory

a. Click the Modbus tab, which displays the Modbus over TCP Overview (not Modbus/TCP) page.

b. Click the Shared Memory sub-menu.

c. Configure and save the Shared Memory blocks as required.

3. Remember to click Save to commit the changes and repeat for each interface that requires configuration.

Note: You may want to back up your ICDM-RX/MOD configuration using PortVision DX. Refer to the

PortVision DX help system for information or the appropriate installation document.

2.3. Modbus Router Home

Access the ICDM-RX/MOD Modbus Router Home page from PortVision DX or enter the IP address of the

ICDM-RX/MOD in the Address box of your web browser.

The Home page displays the software version and current network configuration for the ICDM-RX/MOD.

Modbus Router Home Page

Firmware Modbus Router firmware version currently running on the ICDM-RX/MOD.

Device Name

Serial Number The ICDM-RX/MOD serial number.

MAC Address

System Uptime

IP Config Type of IP configuration currently in use (static or DHCP).

IP Address, IP Netmask, IP

Gateway

You can enter a Device Name in the Network | Configuration page, which will

display in this field.

This is the MAC address of this ICDM-RX/MOD, which is located on the

compliance label on the ICDM-RX/MOD.

Displays how long this ICDM-RX/MOD has been on-line since powered on or

rebooted.

IP address, netmask, and gateway configured in the ICDM-RX/MOD.

34

6/3/19

Page 35

ICDM-RX/MOD User Manual

Serial Menus

3. Serial Menus

This section discusses the Serial Port Overview Page and Serial Port Configuration Page on Page 35, which are

located under the Serial menu.

3.1. Serial Port Overview Page

The Serial Port Overview page displays information about the configured serial settings for each port.

Valid Rcvd Msg Device ID Range (1-255) – (1-255): Displays the valid received message device ID range.

Messages with other valid device IDs will not be transmitted out this port. (Informational only.)

Valid On Port Device ID Range (1-255) – (1-255): Displays the valid device ID range for slave devices

connected to the serial port. Slave devices with other device IDs will not be accessible on this port.

(Informational only.)

For additional diagnostic information, see the Diagnostics Menu on Page 48.

3.2. Serial Port Configuration Page

To access the Serial Port Configuration page, click Serial | Port x.

The following tables provide information about serial configuration settings.

Serial Configuration Page

Serial Configuration

Port Name (Default =

blank)

Port Mode (Default =

RS-232)

Baud Rate (Default =

38400)

User-definable string used to describe the serial interface. Valid characters include

a-z, A-Z, 0-9, underscores, spaces and dashes. All other characters are

discarded. The Port Name supports up to an 80 character ASCII string.

All panel or rack mount models:

• RS-232 (default)

• RS-485

• RS-422

All DIN rail models:

• RS-232 (default)

• RS-422

• RS-485_2-wire

• RS-485_4-wire_Master

• RS-485_4-wire_Slave

300, 600, 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200, and 230400

6/3/19

35

Page 36

ICDM-RX/MOD User Manual

Serial Menus

Serial Configuration Page (Continued)

Parity

(Default = None)

Data Bits (Default = 8) 5, 6, 7, 8

Stop Bits (Default = 1) 1 or 2

Flow Control (Default =

None)

Terminating Resistor

(Only displays on

applicable models)

DTR Mode (Default =

Off)

Rx Timeout Between

Packets (ms) (Default =

200)

Discard Rx Packets With

Errors (Default = On)

None

Even

Odd

RTS/CTS

XON /XOF F

Half Duplex

To ensure the best signal integrity on a long distance high-speed RS-422 or RS485 network, sometimes it is required to place a 120Ω termination resistor

between each of the transmit differential pair or receive differential pair. Signal

reflection is reduced and a reliable communication is ensured by placing the 120Ω

termination resistor. Using the software, you can place 120Ω termination resistors

between the signals shown below:

• RS-422 Mode

- Between TxD+ and TxD- (Pin 5 and 7)

- Between RxD+ and RxD- (Pin 4 and 2)

• RS-485 - Between TxD/RxD+ and TxD/RxD- (Pin 5 and 7)

0=Off

1=On

Receive time-out (0-65535) between packets in msec. This is the maximum

spacing between received bytes allowed before the received Modbus serial

message is expected to be complete.

On or Off: If selected, the ICDM-RX/MOD drops all packets received with parity,

framing, or overrun errors.

Note: Modbus/RTU messages with invalid CRCs and Modbus/ASCII messages

without correct start and end of transmission characters are always

discarded independent of this setting.

Modbus Settings

Serial Port Protocol

(Default = Modbus/RTUto-Slaves)

36

The Modbus Protocol, setting for this serial port:

• Modbus/RTU-to-Slaves – Configures the serial port to communicate to

Modbus/RTU slaves.

• Modbus/ASCII-to-Slaves – Configures the serial port to communicate to

Modbus/ASCII slaves.

• Modbus/RTU-to-Master – Configures the serial port to communicate to a

Modbus/RTU master.

• Modbus/ASCII-to-Master – Configures the serial port to communicate to a

Modbus/ASCII master.

• Modbus/RTU-to-Master/Slaves – Configures the serial port to communicate to

a serial bus with a Modbus/RTU master and Modbus/RTU slave(s).

• Modbus/ASCII-to-Master/Slaves – Configures the serial port to communicate

to a serial bus with a Modbus/ASCII master and Modbus/ASCII slaves.

6/3/19

Page 37

ICDM-RX/MOD User Manual

Serial Menus

Serial Configuration Page (Continued)

Modbus To-Slaves Settings

Response Timeout

(Default = 1000 msec)

Lost Device Search

Enable

Not supported: 1-port

(Default = Off)

Inactivity Wait Time

Before Tx (ms) (Default

= 0 ms)

Send Write Messages

First (Default = Off)

Disable Writes (Read

Only) (Default = Off)

Device ID Offset Mode

(Default = Off)

Device ID Offset

Modbus To-Master Settings

The maximum allowable time (0 to 65535 msec.) for a slave device to respond to a

message before the message is considered timed out.

If selected, lost devices that were on this port are searched for on other Modbus/

RTU and Modbus/ASCII slave ports that also have this option set.

The minimum time (0 to 65535 msec.) that the ICDM-RX/MOD waits after

receiving a response or transmitting a Modbus request before transmitting the next

request.

If selected, it transmits any write messages before transmitting any read messages

that may have already been queued for transmission.

If selected, it disables transmission of all standard Modbus write messages.

• Off disables Device ID Offset functionality.

• Add-to-Msg-ID adds the Device Offset to the message device ID.

• Subtract-from-Msg-ID subtracts the Device ID Offset from the message device

ID.

• 0 = disables Device ID Offset functionality.

• 1-254 = dependent on the Device ID Offset Mode, is added to or subtracted

from the message device ID before the Modbus message is transmitted out

the serial port.

Discard Modbus Errors

(Default = Off)

Modbus Master/Slave Settings

Forward Broadcasts

from Master (Default =

Off)

Private Slave Device ID

Range (Default: Min = 1,

Max =1)

6/3/19

If selected, all broadcast messages from the serial master will be forwarded to the

Modbus network through the ICDM-RX/MOD.

If selected, all broadcast messages from the serial master will be forwarded to the

Modbus network through the ICDM-RX/MOD.

This range (1-255) defines the expected slave device ID range on the serial bus.

Modbus request messages received on this port within this device ID range will not

be forwarded to the Modbus network.

Note: The ICDM-RX/MOD has a built-in auto-detect algorithm for detecting

For a more complete discussion, refer to Modus Master/Slaves Serial Port Mode

(Private Serial Bus) on Page 21.

Note: The minimum value must be less than or equal to the maximum value.

private slave device(s) with ID(s) not defined within the private device ID

range.

37

Page 38

4. Modbus Menus

This section discusses the Modbus configuration pages:

• TCP/IP Configuration Pages on Page 38

• Modbus/TCP Configuration Page on Page 39

• Remote Modbus/TCP Device Configuration Page on Page 40

• Modbus Alias Device ID Configuration Page on Page 41

• Shared Memory Configuration Page on Page 41

4.1. TCP/IP Configuration Pages

This subsection discusses the Modbus over TCP Overview (not Modbus/TCP) Page and Modbus over TCP (not

Modbus/TCP) Socket Configuration Page for the Ethernet TCP/IP interface.

Each Ethernet TCP/IP interface provides connectivity to either Modbus/RTU or Modbus/ASCII masters. All request

messages received from the Ethernet TCP/IP interface are forwarded to the routing process which, in turn, forwards

the messages to either local or remote Modbus slave devices.

Note: The Ethernet TCP/IP interfaces are not directly tied to a serial port. All messages received over the Ethernet

TCP/IP interface receive the same local and remote routing capabilities as messages received over the

Modbus/TCP or serial Master interfaces.

4.1.1. Modbus over TCP Overview (not Modbus/TCP) Page

Access the Modbus over TCP Overview (not Modbus/TCP) page by clicking Modbus | TCP/IP Configuration and the

following page appears. This page provides an overview of the settings for each socket.

4.1.2. Modbus over TCP (not Modbus/TCP) Socket Configuration Page

Access the Modbus over TCP (not Modbus/TCP Socket Configuration page by clicking Modbus | TCP/IP

Configuration | Socket x. The following table provides information about each configuration setting.

Modbus over TCP (not Modbus/TCP) Socket Configuration Page

TCP Configuration

• Modbus/RTU-to-Master – Configures the TCP/IP connection(s) to

Connect To Mode

Enable (Default = Off) If selected, this TCP/IP socket interface will be enabled.

Listen (Default = Off)

communicate to Modbus/RTU master(s).

• Modbus/ASCII-to-Master – Configures the TCP/IP connection(s) to

communicate to Modbus/ASCII master(s).

If selected, the TCP/IP socket interface will listen for a connection at the specified

Listen Port.

Modbus Menus ICDM-RX/MOD User Manual: DOCT-6444 Rev. A - 38

Page 39

ICDM-RX/MOD User Manual

Modbus Menus

Modbus over TCP (not Modbus/TCP) Socket Configuration Page (Continued)

The Listen Port values are 1-65535.

Listen Port

(Defaults:

Port 1=8000

Port 2=8001

Port 3=8002

Port 4=8003)

Connect to Mode (Default

= Never)

Connect Port (Default = 0)

Connect IP Address

(Default = 0)

Disconnect Mode (Default

= Never)

Idle Timer (Default = 0)

Rx Timeout Between

Packets (Default = 100)

If Enable and Listen are both selected, allows acceptance of:

• Up to six connections from external applications if there is no active Connect-

to connection.

• Up to five connections if there is an active Connect-to connection.

Note: The defined Modbus/TCP socket port of 502 will not be accepted as valid

configuration data.

• If Enable is selected, this setting determines how to connect to an

application.

• If Never: Do not attempt to make a connection.

• If Connect-Always: Always attempt to maintain a connection to the

application at Connect IP Address and Connect Port.

Socket port to connect to (1 to 65535). Used in conjunction with Connect to Mode

and Connect IP Address.

IP Address of application to create a connection. Used in conjunction with

Connect to Mode and Connect Port.

Note: The IP Address of this ICDM-RX/MOD will not be accepted as valid

configuration data.

Mode on which to disconnect from the application.

• Never – Will not disconnect when connection(s) are idle.

• Idle – Utilizes the Idle Timer to determine when to close the connection.

If the Disconnect Mode is set to Idle, the idle or inactivity time (1 to 65535 ms)

when the connection(s) will be closed.

Receive timeout (0-65565) between packets in msec. This is the maximum

spacing between received bytes allowed before the received Modbus message

is expected to be complete.

4.2. Modbus/TCP Configuration Page

Access the Modbus/TCP Interface Configuration page by clicking Modbus | Modbus/TCP Configuration. The

following table provides information about each configuration setting.

Modbus/TCP Configuration Page

Modbus TCP/IP Port 1

Enabled Always enabled. Cannot be disabled.

TCP/IP Port The standard Modbus TCP/IP port of 502. This port is always enabled.

Modbus TCP/IP Ports 2 to 16

Enabled

(Default: No)

6/3/19

If selected, the ICDM-RX/MOD will listen for Modbus/TCP requests on the

configured TCP/IP port.

39

Page 40

ICDM-RX/MOD User Manual

Modbus Menus

Modbus/TCP Configuration Page (Continued)

TCP/IP Port

Default Port 2 = 503

Default Port 3 = 505

Default Port 4 = 506

Default Port 5 = 507

Default Port 6 = 508

Default Port 7 = 509

Default Port 8 = 510

The specified TCP/IP port(1-65535) that the ICDM-RX/MOD will listen for Modbus/

TCP requests on.

Default ports are the first seven unassigned ports, as determined by the Internet

Assigned Numbers Authority after the standard Modbus/TCP port of 502.

Note: TCP/IP ports 0, 22, 23, 80, 443, 4606 and 4607 are not allowed. Enabling

TCP/IP ports other than the defaults may cause disruptions on your

network. Please verify any configuration changes with your IT department.

4.3. Remote Modbus/TCP Device Configuration Page

All Modbus devices not configured remotely are assumed to be local, or connected to this gateway. The

location of all local Modbus devices is determined automatically. Access the Remote Modbus/TCP Device

Configuration page by clicking Modbus | Remote Modbus Configuration. Click the Add Remote Configuration

button to add additional remote devices.

The following table provides details about configuration options.

Remote Modbus/TCP Device Configuration Page

Device ID #

Remote IP Address

Remote Modbus/TCP

Port (Default = 502)

Timeout (ms)

(Default = 1000 msec)

Dedicated Connection

(Default = Off)

Send Writes First

(Default = Off)

Disable Broadcast

Messages (Default =

Off)

The Device ID (also often called the unit ID) of the remote device must be unique.

The Device ID range is 1-255. 0 means that it is not configured.

IP address of the Modbus/TCP device. All 0s means that it is not configured.

Note: The IP address of the ICDM-RX/MOD will not be accepted as valid

configuration data.

The TCP/IP port (1-65535) to connect to on the remote device.

The maximum allowable time (0 to 65535 msec) for a slave device to respond to a

message before the message is considered timed out.

If selected, a dedicated Modbus/TCP connection will be used to connect to this

remote device.

Note: This is most commonly used when connecting to another gateway, multiple

devices are being accessed, and maximum bandwidth is desired.

If selected, will forward write messages before forwarding any pending read

messages.

Note: This is most commonly used when multiple messages may be outstanding

for the remote device(s) and low latency for write messages is desired.

If selected, will disable broadcasts to this remote device.

Note: If multiple remote devices are accessed through another gateway, then

this option must be selected for all remote devices configured to that

gateway to prevent broadcast messages from being sent to those devices.

40

6/3/19

Page 41

ICDM-RX/MOD User Manual

Modbus Menus

Remote Modbus/TCP Device Configuration Page (Continued)

This setting only applies to a Modbus message if the following two statements are

true:

• The Modbus message device ID has been aliased, or changed, as a result of a

corresponding Alias Device ID configuration via the Modbus Alias Id

Route on Pre-Alias

Device ID (Default = Off)

Delete If enabled, that Device ID or IDs are deleted when you click the Save button.

Configuration page.

• A Remote Modbus/TCP Device configuration exists for the pre-aliased, or

original, device ID.

If selected and all requirements are true, then the Remote Device ID configuration

for the pre-aliased device ID will be applied to the Modbus message. This includes

the IP address/port, timeout and control flags.

4.4. Modbus Alias Device ID Configuration Page

You can configure up to four alias device IDs at one time.

Access the Modbus Alias Device ID Configuration page by clicking Modbus | Alias Configuration.

The following configuration options apply:

Modbus Alias Device ID Configuration Page

Rx Device ID

Alias Device ID

Modbus/TCP Master

(Default = Off)

Modbus Serial Master

(Default = Off)

Modbus over TCP Master

(Default = Off)

The device ID (also often called the unit ID) of the received

message from a master. Device IDs range from 1 to 255.

The alias device ID to convert the received device ID to. Alias

Device IDs range from 1 to 255.

If selected, this applies the alias device ID configuration to

messages received from Modbus/TCP masters.

If selected, this applies the alias device ID configuration to

messages received from serial Modbus masters.

If selected, this applies the alias device ID configuration to

messages received from Modbus RTU/ASCII over Ethernet TCP/IP

masters.

4.5. Shared Memory Configuration Page

Access the Shared Memory Configuration page by clicking Modbus | Shared Memory.

The following table displays the supported Holding Register Block function codes.

Holding Register Block Function Codes

3 Read Holding Registers

6Write Single Register

16 Write Multiple Registers

22 Write Mask Register

23 Read Write Registers

6/3/19

41

Page 42

ICDM-RX/MOD User Manual

Modbus Menus

This shows the supported Coil Block function codes.

Coil Block Function Codes

1 Read Coils

5 Write Single Coil

15 Write Multiple Coils

The following table provides details about the configuration options. Click the Display button to view detailed

information about a specific block or coil.

Shared Memory Configuration Page

Enable Shared Memory

(Default = Off)

Shared Memory Device

ID (Default = 252)

Holding Register Start

Address (Base 1)

(Default = 400001)

Coil Block Start Address

(Base 1) (Default = 1)

Shared Holding Registers

Block Specifies the block number.

Address Range Specifies the block address range.

Accept Broadcast

Messages (Default = No)

Write Master(s) (Default

= All)

Serial Port / IP Address

Description

If selected, enables the Shared Memory functionality.

The Device ID (also often called the unit ID) of the Shared Memory must be

unique within the public Modbus network. The Device ID range is 1 to 255.

Specifies the starting address of the Shared Memory Holding Register

blocks. The range is 400001 to 463935.

Specifies the starting address of the Shared Memory Coil blocks. The range

is 1 to 64255.

If selected, the Shared Memory block(s) will accept broadcast messages

addressed to their memory block(s).

Indicates which master(s) have write access to the Shared Memory block.

• All – All masters have write access to the block

• Port specific serial master:

- Port-1

- Port-2 (2-port and 4-port models only)

- Port-3 (4-port models only)

- Port-4 (4-port models only)

• Ethernet based masters:

- Modbus/TCP - Modbus/TCP master(s) at a specified IP address

- Ethernet TCP/IP – Ethernet TCP/IP master(s) at a specified IP

address

IP address of the Modbus/TCP or Ethernet TCP/IP master. Zeros indicate

that there is no configuration.

Note: Does not apply to All or port-specific serial masters.

User-defined description of the Shared Memory block. ASCII string with a

maximum of 80 characters in length.

Shared Coils

Block Specifies the block number.

Coil Range Specifies the coil range.

42

6/3/19

Page 43

ICDM-RX/MOD User Manual

Modbus Menus

Shared Memory Configuration Page (Continued)

Accept Broadcast

Messages (Default = No)

Write Master(s) (Default

= All)

Serial Port / IP Address

Description

If selected, the Shared Memory block(s) will accept broadcast messages

addressed to their memory block(s).

Indicates which master(s) have write access to the Shared Memory block.

• All – All masters have write access to the block

• Port specific serial master:

- Port-1

- Port-2 (2-port and 4-port models only)

- Port-3 (4-port models only)

- Port-4 (4-port models only)

• Ethernet based masters:

- Modbus/TCP - Modbus/TCP master(s) at a specified IP address

- Ethernet TCP/IP – Ethernet TCP/IP master(s) at a specified IP

address

IP address of the Modbus/TCP or Ethernet TCP/IP master. Zeros indicate

that there is no configuration.

Note: Does not apply to All or port-specific serial masters.

User-defined description of the Shared Memory block. ASCII string with a

maximum of 80 characters in length.

6/3/19

43

Page 44

ICDM-RX/MOD User Manual

Network Menu