Page 1

PROFIBUS POWER HUB

SEGMENT COUPLER

PROCESS AUTOMATION

MANUAL

HD2-GTR-4PA

Page 2

With regard to the supply of products, the current issue of the following document is applicable:

The General Terms of Delivery for Products and Services of the Electrical Industry, as published by

"

the Central Association of the „Elektrotechnik and Elektroindustrie (ZVEI) e.V.“,

including the supplementary clause „Extended reservation of title“.

We at Pepperl+Fuchs recognise a duty to make a contribution to the future.

For this reason, this printed matter is produced on paper bleached without the use of chlorine.

Page 3

PROFIBUS POWER HUB SEGMENT COUPLER

Table of Contents

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49-621-776-0 • USA +1-330-4253555 • Singapore +65-67-799091 • Internet www.pepperl-fuchs.com

3

1 Safety .........................................................................................................6

1.1 Validity ............................................................................................6

1.2 Symbols Used .................................................................................6

1.3 System Operator and Personnel ....................................................6

1.4 Pertinent Laws, Standards, Directives, and further Documentation 6

1.5 Delivery, Transport and Storage .....................................................7

1.6 Marking ...........................................................................................7

1.7 Intended Use ..................................................................................8

1.8 Mounting and Installation ................................................................8

1.8.1 Mounting Instructions for Power Hub ..................................8

1.8.2 Mounting instructions for HD2-GT* modules ....................... 9

1.8.3 Shield/Grounding .................................................................9

1.9 Housing ...........................................................................................9

1.10 Repair and Maintenance .................................................................9

1.11 Disposal ........................................................................................10

2 Specification .............................................................................................11

2.1 Overview .......................................................................................11

2.2 Coupling ........................................................................................12

2.3 Segment Supply ...........................................................................13

2.4 System Components ....................................................................13

2.4.1 Motherboards ....................................................................13

2.4.2 Modules for Coupling, Supply and Diagnosis .................... 14

2.5 Recommended System Combinations .........................................15

2.5.1 Case 1: Fully Redundant ...................................................15

2.5.2 Case 2: Redundant Coupling ............................................15

2.5.3 Case 3: Simplex ................................................................16

2.6 Component Identity .......................................................................17

2.7 Technical Data ..............................................................................19

2.8 Dimensions ...................................................................................21

3 Installation and Commissioning ...............................................................22

3.1 Mounting and Dismounting ...........................................................22

3.2 Shield/Grounding ..........................................................................23

3.3 Connections ..................................................................................25

3.3.1 Master Connection to a Redundant PROFIBUS

Power Hub System ............................................................27

4 Installation in Hazardous Areas ...............................................................28

4.1 Installation in Zone 2 Category 3G ...............................................28

Page 4

PROFIBUS POWER HUB SEGMENT COUPLER

Table of Contents

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49-621-776-0 • USA +1-330-4253555 • Singapore +65-67-799091 • Internet www.pepperl-fuchs.com

4

5 PROFIBUS Commissioning ..................................................................... 29

5.1 Assigning a Device Address ......................................................... 29

5.2 Commissioning of Cyclic Data Exchange ..................................... 29

5.2.1 Information on the GSD Conversion ................................. 31

5.2.2 Additional Information about Watchdog time .................... 33

5.2.3 Information about I/O Cycle Time ..................................... 34

5.2.4 Additional Information on Adjusting Retry ......................... 35

5.3 DTM Software Installation and Commissioning ............................ 35

6 Operation ................................................................................................. 40

6.1 Built-In-Slave (BIS) Description .................................................... 40

6.1.1 Cyclic Data Exchange ....................................................... 40

6.1.2 Parameterization Options (Channel Assignment) ............. 40

6.1.3 Diagnostics (Slave Diagnostics) ........................................ 41

6.2 Coupled Slaves ............................................................................ 43

6.3 Acyclic Data Exchange with BIS via DTM .................................... 43

6.3.1 Brief introduction to DTM with PACT

ware

TM

as an Example .................................................................. 44

6.3.2 Overview of the DTM User Interface ................................. 46

6.3.3 Structure Diagram ............................................................. 47

6.3.4 Watchdog Time in the DTM .............................................. 48

6.3.5 PA Retry Limit Setting ....................................................... 49

6.3.6 Restart Functions, Redundancy Switchover and Firmware Update 49

6.4 Redundant Operation ................................................................... 53

6.4.1 Redundancy Behavior ....................................................... 53

6.4.2 System Environment for Redundant Operation ................ 53

6.4.3 Applications with Redundant Operation ............................ 54

7 Advanced Diagnostics with the PROFIBUS Power Hub .......................... 56

7.1 Advanced Diagnostics Infrastructure ............................................ 56

7.1.1 Advanced Diagnostics Connection via PROFIBUS DP .... 56

7.1.2 Advanced Diagnostics Connection via Diagnostic Bus ..... 58

7.2 PROFIBUS Advanced Diagnostics Integration ............................ 61

7.2.1 Advanced Diagnostic Messages in the Gateway DTM ..... 62

8 Basic Principles ....................................................................................... 63

8.1 Redundancy Concepts ................................................................. 63

8.1.1 Overview ........................................................................... 63

8.1.2 Flying Redundancy ........................................................... 63

8.1.3 System Redundancy ......................................................... 64

9 Appendix 1 / Glossary .............................................................................. 65

Page 5

PROFIBUS POWER HUB SEGMENT COUPLER

Table of Contents

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49-621-776-0 • USA +1-330-4253555 • Singapore +65-67-799091 • Internet www.pepperl-fuchs.com

5

10 Parameter Reference List ........................................................................69

10.1 General Parameters .....................................................................69

10.1.1 PA Master Parameters ......................................................69

10.1.2 PA Segment Parameters ...................................................70

10.2 Diagnostic Parameters .................................................................70

10.2.1 Device Diagnostic Parameters ..........................................70

10.2.2 PA Segment Diagnostic Parameters .................................71

10.2.3 Redundancy Partner Parameters ...................................... 72

11 Troubleshooting .......................................................................................73

11.1 Faults Indicated via LEDs .............................................................73

11.2 Faults Indicated via DTM ..............................................................75

11.3 Faults Indicated via DCS ..............................................................77

11.4 Problems with Gateway Operation ...............................................79

Page 6

PROFIBUS POWER HUB SEGMENT COUPLER

Safety

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

6

Date of Issue 24.3.11

1 Safety

1.1 Validity

The chapter "Safety" is valid as operating instructions.

Specific process and instructions in this document require special pre-

cautions to guarantee the safety of personnel.

1.2 Symbols Used

1.3 System Operator and Personnel

The operator of the system is responsible in terms of planning, mounting, commissioning, operating and maintenance.

Assembly, commissioning, operation, maintenance and dismounting of

any devices may only be carried out by trained, qualified personnel who

have read and understood the instruction manual.

1.4 Pertinent Laws, Standards, Directives, and further

Documentation

Laws, standards, or directives applicable to the intended use must be

observed. In relation to explosive areas, Directive 1999/92/EC must be

observed.

This symbol indicates a warning about a possible danger.

In the event the warning is ignored, the consequences may range from

personal injury to death or from damage to equipment to destruction.

This symbol warns of a possible fault. Failure to observe the instructions

given in this warning may result in the device and any connected facilities

or systems to it develop a fault or fail completely.

This symbol brings important information to your attention.

This symbol marks an acting paragraph.

Warning

Attention

Note

Page 7

PROFIBUS POWER HUB SEGMENT COUPLER

Safety

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

7

Date of Issue 24.3.11

The corresponding data sheets, the declaration of conformity, the ECtype-examination certificate and applicable certificates (see data sheet)

are an integral part of this document. You can find this information under

www.pepperl-fuchs.com.

1.5 Delivery, Transport and Storage

Check the packaging and contents for damage.

Check if you have received every item and if the items received are the

ones you ordered.

Keep the original packaging. Always store and transport the device in

the original packaging.

Always store the device in a clean, dry environment. Note the permitted

storage temperature (see data sheet).

1.6 Marking

Gateway motherboards

Gateway module

MB-FB-GT

Pepperl+Fuchs GmbH

Gateway motherboard

Declaration of Conformity

TÜV 04 ATEX 2500X

•

Ex II 3G EEx nA IIC T4

MB-FB-GTR

Pepperl+Fuchs GmbH

Redundant gateway motherboard

Declaration of Conformity

TÜV 04 ATEX 2500X

•

Ex II 3G EEx nA IIC T4

HD2-GTR-4PA

Pepperl+Fuchs GmbH

Gateway module

Declaration of Conformity

TÜV 04 ATEX 2500X

•

Ex II 3G EEx nA IIC T4

Page 8

PROFIBUS POWER HUB SEGMENT COUPLER

Safety

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

8

Date of Issue 24.3.11

1.7 Intended Use

The PROFIBUS Power Hub Segment Coupler, as part of the Power Hub

System, serves as a Segment Coupler for connecting PROFIBUS PA

segments to PROFIBUS DP. Various Power Hub Power Supply solutions offer either simplex or redundant power to PROFIBUS PA segments. Power Hub Supplies for High-Power Trunk and the Fieldbus intrinsically safe concept DART are available.

The Segment Coupler ensures communication and galvanic isolation

between PROFIBUS PA and PROFIBUS DP. The Segment Coupler can

be used in all system environments in compliance with industry standard PROFIBUS DP Masters.

PROFIBUS PA is an extended version of the PROFIBUS DP that allows

for the physical transmission specifications of IEC 61158-2. Fieldbus

devices receive their electrical supply through the transmission lines.The combination of PROFIBUS Power Hub components makes it

possible to connect and supply four PROFIBUS PA segments per Gateway to the PROFIBUS DP.

The Segment Coupler may be installed in Zone 2 Category 3G hazardous areas. Types of protection are Ex nA (non-arcing) for Zone 2 Gas

Groups IIC, IIB, IIA.

The devices are only approved for appropriate and intended use. Ignoring these instructions will void any warranty and absolve the manufacturer from any liability.

The device must only be operated in the ambient temperature range

and at the relative humidity (non-condensing) specified.

1.8 Mounting and Installation

Prior to mounting, installation, and commissioning of the device you

should make yourself familiar with the device and carefully read the instruction manual.

The devices may be installed in a corrosive location acc. to ISA-S71.041985, severity level G3.

1.8.1 Mounting Instructions for Power Hub

The devices should be installed at least in an environment according

pollution degree 2.

Instructions for Zone 2

The devices may only be installed and operated in Zone 2 if they have

been mounted in an enclosure with degree of protection IP 54 acc.to

IEC/EN 60529. The enclosure must have a declaration of conformity according to 94/9/EC for at least category 3G.

Page 9

PROFIBUS POWER HUB SEGMENT COUPLER

Safety

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

9

Date of Issue 24.3.11

Connection or disconnection of energized non-intrinsically-safe circuits

is only permitted in the absence of a hazardous area.

Instructions for Zone 22

The devices may only be installed and operated in zone 22 if mounted

in an enclosure for which an EC-type-examination certificate acc. 94/9/

EG for at least category 3D exists.

1.8.2 Mounting instructions for HD2-GT* modules

The modules are intended for mounting on an appropriate Fieldbus Power Hub Gateway motherboard.

1.8.3 Shield/Grounding

Take care about good earthing practice and specific earthing requirements of your installation (see chapter “Shield/Grounding” on page 23).

Observe IEC 60079-14 for requirements of potential equalization.

1.9 Housing

The device must be mounted at least in protection category IP 54 in accordance with IEC 60529/EN 60529.

If additional housings are needed for installation in hazardous areas, the

following points must be considered / evaluated:

• Degree of protection as per IEC/EN 60529

• Light resistance as per IEC/EN 60079-0

• Impact strength as per IEC/EN 60079-0

• Chemical resistance as per IEC/EN 60079-0

• Heat resistance as per IEC/EN 60079-0

• Electrostatics as per IEC/EN 60079-0

To ensure the IP degree of protection:

• All seals must be undamaged and have been correctly fitted.

• All screws of the housing / housing cover must have been tightened with the appropriate torque.

• Only cable of the appropriate size must be used in the cable

glands.

• All cable glands must have been tightened with the appropriate

torque.

• All empty cable glands must have been sealed with sealing

plugs.

1.10 Repair and Maintenance

The devices may not be repaired, changed or manipulated. If there is a

defect, the product must always be replaced with an original part.

Page 10

PROFIBUS POWER HUB SEGMENT COUPLER

Safety

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

10

Date of Issue 24.3.11

1.11 Disposal

Devices, packaging material, and possibly contained batteries must be

disposed of in compliance with the applicable laws and guidelines of the

corresponding country.

Page 11

PROFIBUS POWER HUB SEGMENT COUPLER

Specification

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

11

Date of Issue 24.3.11

2 Specification

2.1 Overview

The Pepperl+Fuchs PROFIBUS Power Hub System has a modular design. It offers a number of possible combinations so it can be adapted

to the specific requirements of different explosion protection concepts or

the need for increased segment availability.

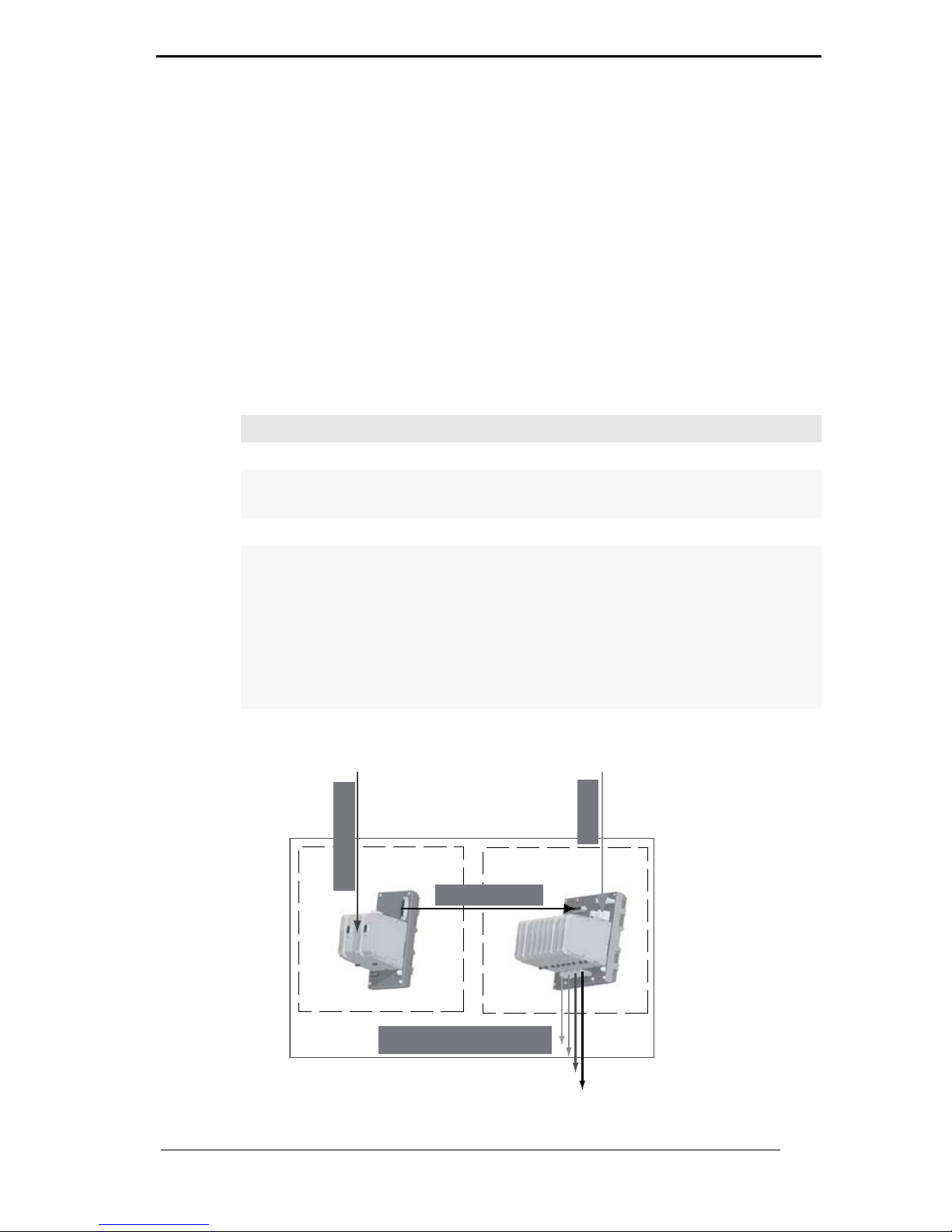

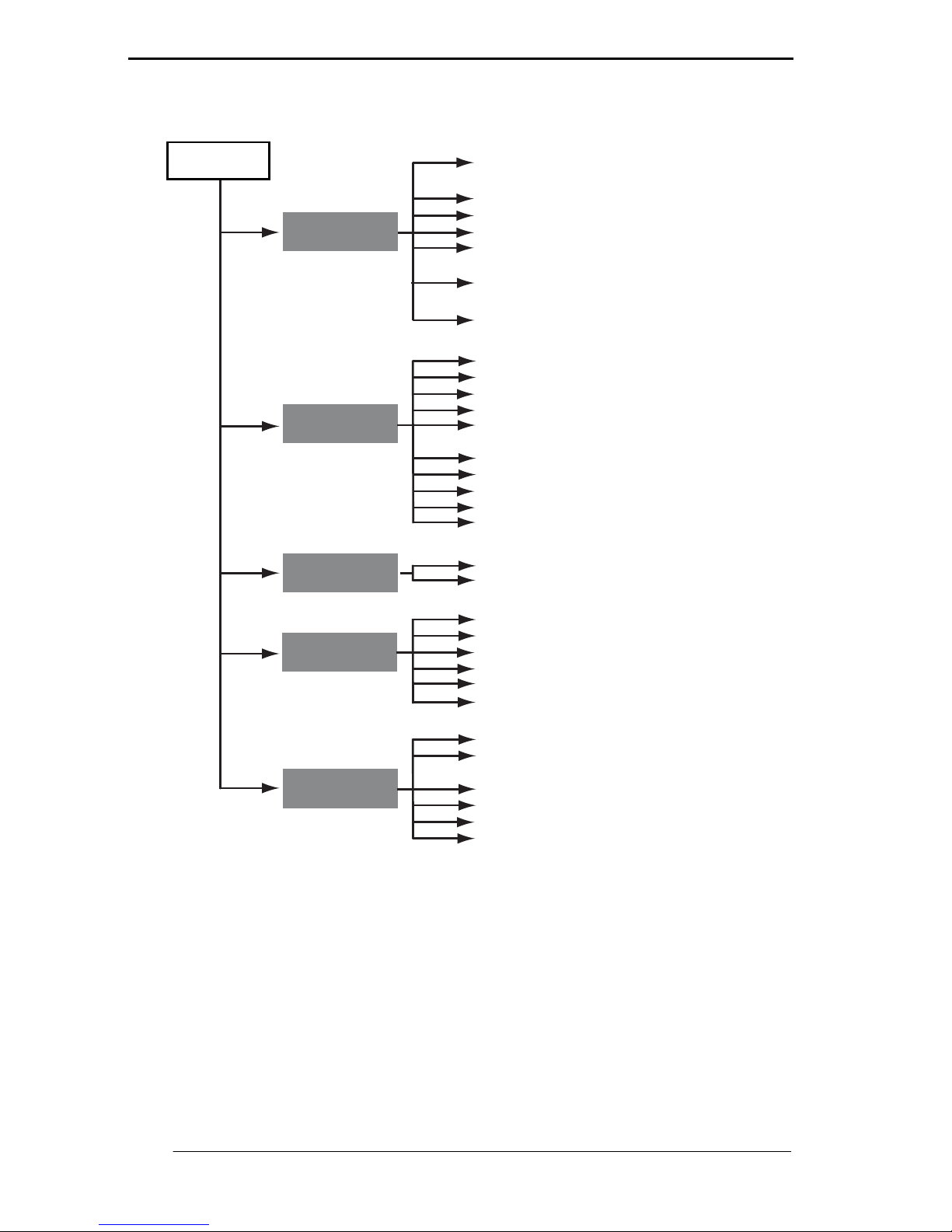

Functionally, the system may be divided into two component groups:

• Coupling (described in this manual)

• Segment supply (described in the Power Hub manuals)

Modules and Motherboards are assigned to these groups as shown:

•

Figure 2.1: Coupling and Supply for the PROFIBUS Power Hub System

Coupling: Segment supply:

Modules:

Gateway Module HD-2-GTR-4.PA Power Hub Modules HD2-FB*

HD2-DM* Diagnostic Modules

Motherboards:

Gateway Motherboard simplex:

MB-FB-GT

Gateway Motherboard redundant:

MB-FB-GTR

Power Hub Motherboards simplex

or redundant:

MB-FB*.GEN

MBHD-FB*.GEN

DART Power Hub Motherboard

redundant:

MBHD-FB-D-4R.GEN

PROFIBUS DP

PROFIBUS PA

Energy

4 x PA-Fieldbus trunk

Coupling

Supply

Profibus Power Hub system

Page 12

PROFIBUS POWER HUB SEGMENT COUPLER

Specification

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

12

Date of Issue 24.3.11

Various Power Hub power supply solutions offer either simplex or redundant power to PROFIBUS PA segments. The Power Hub consists of

a motherboard with sockets for plug-in modules.

• One power supply module per segment in simplex mode or, alternatively, two power supply modules per segment in redundant mode.

• A physical layer diagnostic module HD2-DM*.

The Power Hub feeds fieldbus segments following the High-Power

Trunk concept for explosion protection. High energy level on the trunk

line is fed to the field instruments via couplers like FieldBarriers or Segment Protectors. A dedicated version of the Power Hub (DART) supports the intrinsically safe concept for fieldbus.

A plug-in Advanced Diagnostic Module for fieldbus is available. This module monitors the physical layer online and in real time enabling detection of degradation and faults during operation. Measurement data and

alarms are transmitted to the control room thus bringing visibility to the

fieldbus physical layer, which can now be treated as active component

in Plant Asset Management systems. Operators are enabled to decide

on proactive measures to avoid unwanted situations while the plant is

running smoothly.

2.2 Coupling

Coupling involves a Gateway Motherboard and one or, in the case of

redundant coupling, two Gateway Modules.

The purpose of coupling is to adjust the physical transmission properties on the DP side (RS 485) to those of the PROFIBUS PA (in conformity with IEC 61158-2). The coupling provides a baudrate of 31.25 kbit/

s on the PA side. In addition, the coupling creates galvanic isolation between PROFIBUS DP and PROFIBUS PA. The DP/PA coupling of the

PROFIBUS Power Hub System is functionally compatible with the Pepperl+Fuchs SK 2 System, which is well established on the market.

The coupling of the PROFIBUS PA slave to the PROFIBUS DP is transparent. This means that all PA slaves appear on the DP bus and are interpreted by the Host as DP slaves. A DP address is also assigned to

the Gateway itself for diagnostic and parameterization purposes.

Although segment supply is part of the PROFIBUS Power Hub System,

it is not described in this manual (only where needed for better understanding). Please refer to the respective „Generic Power Hub“ manuals

for detailed information on segment supply.

Note

Page 13

PROFIBUS POWER HUB SEGMENT COUPLER

Specification

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

13

Date of Issue 24.3.11

Cyclic data exchange can be connected redundantly to the DP line by

using the redundant Gateway Motherboard MB-FB-GTR and two

HD2-GTR-4PA Gateways.

The Gateway Module HD2-GTR-4PA supports PROFIBUS

"Flying Redundancy“ (chapter “Redundancy Concepts” on page 63) as

well as all non-redundant DP Masters.

In summary, the Gateway is responsible for the following tasks:

• Conversion of the PROFIBUS DP physical layout to that of the

PROFIBUS PA

• Adjusting the DP transmission rate to the PA transmission rate

• Galvanic isolation between PROFIBUS DP and PA

• Elementary functional diagnostics via LEDs

• Ensuring increased availability through redundant coupling of

cyclic data exchange (with redundant layout)

• Acyclic Parameterization of Gateway parameters by

FDT/DTM

• Redundancy diagnostics (with redundant layout)

2.3 Segment Supply

Power is supplied to the field devices through Power Hub Modules on a

Power Hub Motherboard (simplex: 4 Power Hub connection slots, redundant: 8 connection slots) and via bus lines to the individual segments.

PA segments can receive redundant power supply if the redundant Power Hub Motherboard is used along with two Power Hub Modules for

each segment.

In summary, the supply is responsible for the following tasks:

• Power supply of field devices: power and communication signal

• Redundant supply for high system availability

• Elementary diagnostic information via LEDs

• Advanced Physical Layer Diagnostics via the HD2-DM* Diagnostic Module and the FDT/DTM software package (see corresponding documentation).

2.4 System Components

2.4.1 Motherboards

Gateway motherboard simplex MB-FB-GT

The gateway motherboard simplex MB-FB-GT allows the connection of

the Fieldbus Power Hub motherboards MB-FB*.GEN or MBHDFB*.GEN using a standard cable. A socket will hold the DP/PA Gateway

HD2-GTR-4PA. The Built-In Slave of the HD2-GTR-4PA can be addressed using the DIP switch on the motherboard.

Page 14

PROFIBUS POWER HUB SEGMENT COUPLER

Specification

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

14

Date of Issue 24.3.11

Gateway motherboard redundant MB-FB-GTR

The gateway motherboard redundant MB-FB-GTR allows the connection of the Fieldbus Power Hub motherboards MB-FB*.GEN or MBHDFB*.GEN with a standard cable. Two sockets will hold two DP/PA Gateways HD2-GTR-4PA. The Built-In Slaves of the HD2-GTR-4PA modules

can be addressed using the DIP switch on the motherboard.

Power Hub motherboard simplex MB-FB-4.GEN

The MB-FB-4.GEN allows the supply of four Fieldbus segments as well

as the direct connection of the PROFIBUS DP/PA Gateway Motherboards MB-FB-GT or MB-FB-GTR with a standard cable. Four sockets

hold the Power Modules. The modules are available for different explosion protection concepts and with various isolation levels. A further sokket holds a Diagnostic Module

Power Hub motherboards redundant MB*-4R.GEN

The MB*-4R.GEN motherboards allow the redundant supply of four

fieldbus segments as well as the direct connection of the PROFIBUS

DP/PA Gateway Motherboards MB-FB-GT or MB-FB-GTR with a standard cable. Eight sockets hold the power supply modules, two power

supply modules supplying each of the four segments redundantly. The

modules are available for different explosion protection concepts and

with various isolation levels. A further socket holds a Diagnostic Module.

DART Power Hub motherboard redundant MBHD-FB-D-4R.GEN

The MBHD-FB-D-4R.GEN motherboard allows for the redundant supply of four intrinsically safe Ex ib fieldbus segments as well as the direct

connection of the PROFIBUS DP/PA Gateway Motherboards MB-FBGT or MB-FB-GTR with a standard cable. Eight sockets hold the power

supply modules, two power supply modules supplying each of the four

segments redundantly. A further socket holds a Diagnostic Module.

2.4.2 Modules for Coupling, Supply and Diagnosis

Gateway module HD2-GTR-4.PA

The Gateway module provides the connection of four PROFIBUS PA

segments to a PROFIBUS DP. In conjunction with Fieldbus Power Modules, PA segments are supplied directly via Fieldbus lines. Coupling is

transparent, so each PA device is addressed and configured as a PROFIBUS DP device.

The HD2-GTR-4PA module includes four full-featured PA masters, who

perform data exchange time independently.

The FDT/DTM based PC software package allows the parameterization

of the Gateway and offers several status and diagnostic functionalities.

Used in connection with the corresponding motherboard, two Gateways

Page 15

PROFIBUS POWER HUB SEGMENT COUPLER

Specification

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

15

Date of Issue 24.3.11

provide redundant coupling. The HD2-GTR-4PA supports PROFIBUS

„Flying Redundancy“ as well as all non-redundant masters.

Power modules HD2-FB*

Power Modules supply electrical power to segments. They couple the

supply current to the two-wire Fieldbus cable while maintaining the highest signal quality.

Diagnostic modules HD2-DM*

Diagnostic modules are divided into the Basic Diagnostic Module HD2DM-B and the Advanced Diagnostic Module HD2-DM-A. The diagnostic

modules provide various system diagnostics.

2.5 Recommended System Combinations

2.5.1 Case 1: Fully Redundant

In the fully redundant system, both coupling of PROFIBUS DP to

PROFIBUS PA and the supply of the four segments are designed redundantly. The fully redundant PROFIBUS Power Hub consists of the following components:

• Gateway motherboard MB-FB-GTR

• Power Hub motherboard MB*-4R.GEN

• 2 x HD2-GTR-4PA

• 8 x Power Modules

• 1 x Diagnostic Module

• 1 x Sub-D cable to connect motherboards

The fully redundant system offers the highest protection against individual failures or failure of all PA segments of PROFIBUS.

2.5.2 Case 2: Redundant Coupling

In this case, coupling is designed redundantly, but there is only one

supply per segment (simplex). The redundantly coupled system consists of the following components:

• Gateway motherboard MB-FB-GTR

• Power Hub motherboard MB-FB-4.GEN

• 2 x HD2-GTR-4PA

• 4 x Power Modules

• 1 x Diagnostic Module

• 1 x Sub-D cable to connect motherboards

Redundant coupling ensures communication of the four PA segments.

Failure of one segment has no effect on the other three segments.

Page 16

PROFIBUS POWER HUB SEGMENT COUPLER

Specification

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

16

Date of Issue 24.3.11

2.5.3 Case 3: Simplex

In the simplex system, both the coupling of DP to PA and the supply of

the four segments are single (simplex). The simplex system consists of

the following components:

• Gateway motherboard MB-FB-GT

• Power Hub motherboard MB-FB-4.GEN

• 1 x HD2-GTR-4PA

• 4 x Power Modules

• 1 x Diagnostic Module

• 1 x Sub-D cable to connect motherboards

Combining a simplex Gateway Motherboard and a redundant Power Hub

Motherboard also makes a fourth combination possible. Pepperl+Fuchs

does not recommend using this arrangement. Since a fault in the coupling of DP to PA results in failure of all four segments together, but the

failure of a single segment does not have any effect on the remaining

segments, increased segment availability can be achieved most easily

with redundant coupling (as described in case 1 and case 2).

Note

Page 17

PROFIBUS POWER HUB SEGMENT COUPLER

Specification

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

17

Date of Issue 24.3.11

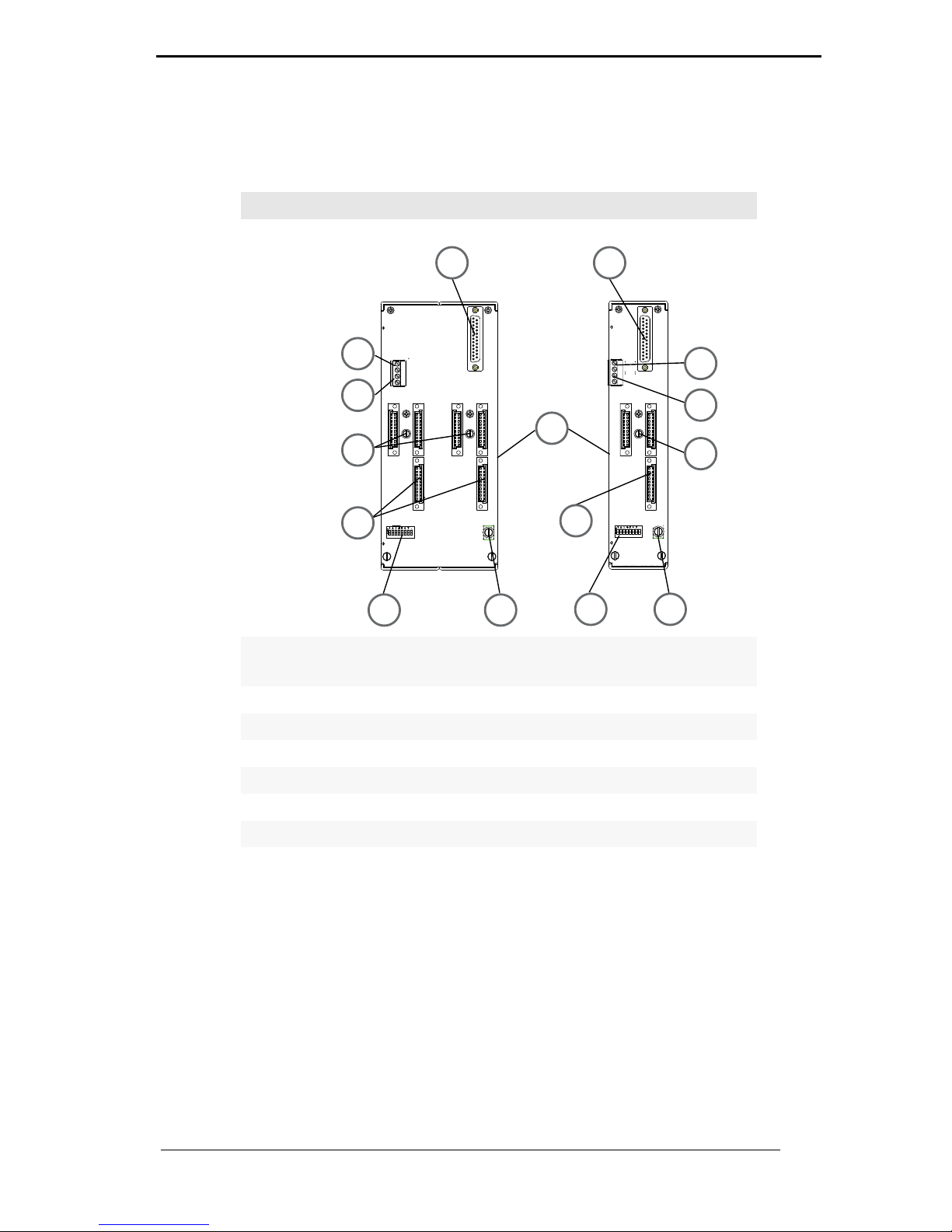

2.6 Component Identity

MB-FB-GTR MB-FB-GT

1 Sub-D connection to Power Hub mother

board

2 VFC alarm contact

3 Diagnostic bus contact

4 Slots for DP/PA Gateway Modules

5 DIP Switch for BIS address

6 Screen/ground connection clamp

7 Motherboard fastening screws

8 DIN rail slot

1

4

5

1

4

5

6

6

8

3

2

3

2

7

7

Page 18

PROFIBUS POWER HUB SEGMENT COUPLER

Specification

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

18

Date of Issue 24.3.11

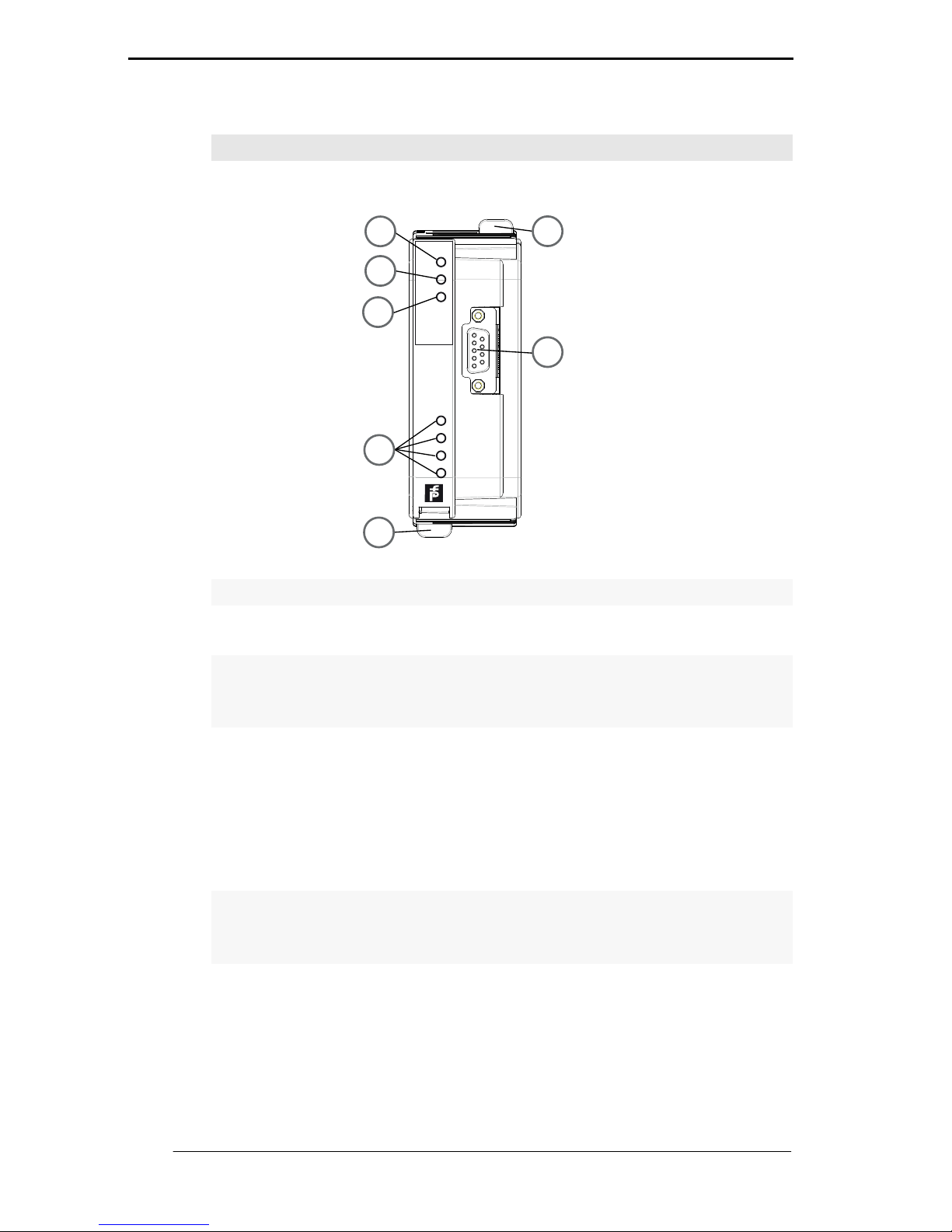

HD2-GTR-4PA

1 Quick Lok Bar

2 LED „PWR“

• Green: Device in operation

3 LED „DP/ERROR“

• Red, flashing with 2 Hz: DP error.

• Red: Hardware error

4 LED Redundancy

• Yellow: Redundant operation (this Gateway Module is the primary

device)

• Yellow, flashing with 2 Hz: Synchronisation or Redundancy not

available (this Gateway Module is the primary device)

• LED is off: simplex operation; in redundant mode, this Gateway Modul is the secondary device

5 Segment status LEDs

• LED segments 1...4. Red, flashing with 2 Hz: PA error

• Segment LED and LED „DP/ERROR“ on: MAU hardware error

6 PROFIBUS DP connection

PROFIBUS

DP/P

A

Gateway

HD2GTR4P A

Seg4

Seg3

Seg2

Seg1

PW R

DP/

ERR

Red.

1

5

1

4

6

3

2

Page 19

PROFIBUS POWER HUB SEGMENT COUPLER

Specification

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

19

Date of Issue 24.3.11

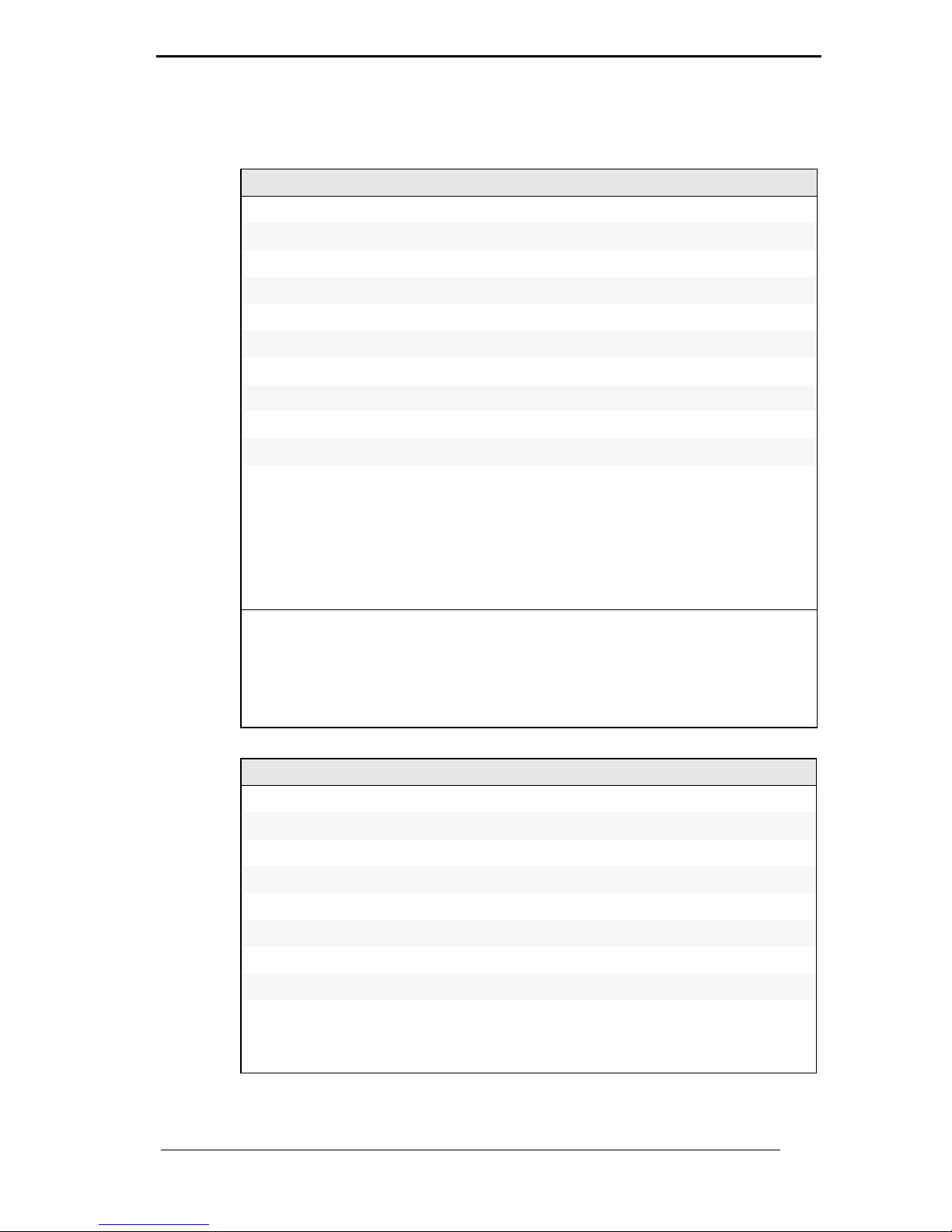

2.7 Technical Data

System overview

Ambient conditions:

Ambient temperature -40..60 °C

Storage temperature -40..85 °C

Relative humidity <95% non-condensing

Shock resistance 15 g 11 ms

Vibration resistance 1 g, 58 to 150 Hz

Mechanical data:

Protection degree IP 20 acc. to EN 60529

Motherboard mounting Mounting rail, 35 mm

Conformity to standards:

Shock resistance

Vibration resistance

Fieldbus standard

EMV

DIN EN 60068-2-27

DIN EN 60068-2-6

IEC 61158

Namur NE 21

EN 61326

Installation in hazardous areas:

Approvals: Zone 2

II 3 G Ex nA II T4

Class 1

Division 2

Gas groups IIC, IIB, IIA

HD2-GTR-4PA

Supply:

Rated voltage 19.2 to 35 V DC

Rated current 160... 90 mA

Power dissipation 3W

Fieldbus interface/PROFIBUS DP:

Connection SUB-D-socket, 9-pin

Protocol PROFIBUS DP V1

Galvanic isolation:

PROFIBUS DP/CH

PROFIBUS DP/supply

All circuits/FE

Functional isolation per IEC 62103,

rated isolation voltage 50 V

eff

Page 20

PROFIBUS POWER HUB SEGMENT COUPLER

Specification

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

20

Date of Issue 24.3.11

Gateway Motherboards MB-FB-GT / MB-FB-GTR

Supply:

Rated voltage 19.2 to 35 V DC

Rated current 16 A

Display/control elements:

Error message VFC alarm output via connections

DIP switch:

MB-FB-GT PROFIBUS address 0...125

MB-FB-GTR PROFIBUS address 0...61

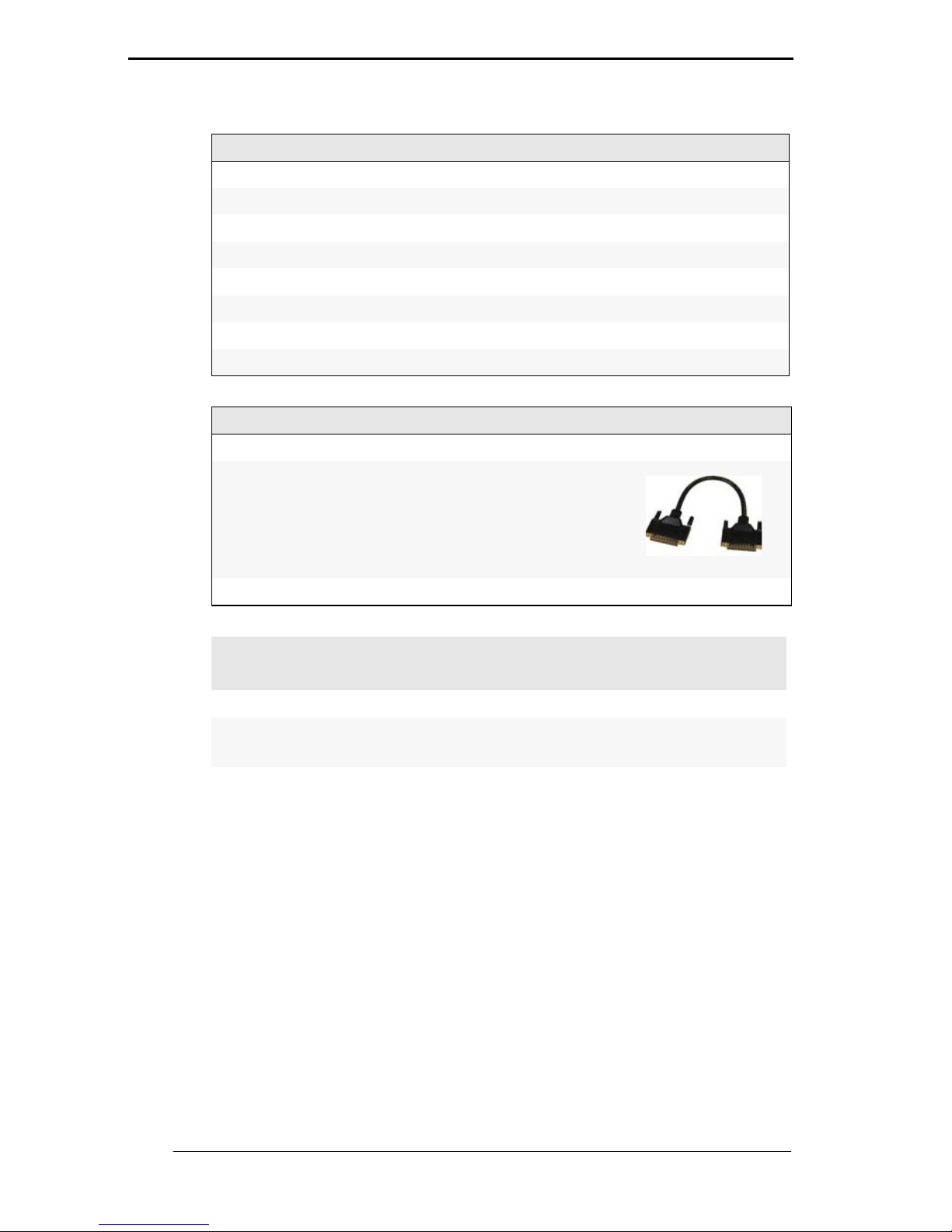

Accessories

Description Part number Special feature

Sub-D cable,

9-pin*

ACC-MB-HGC For connecting

the Gateway

Motherboard

and Power Hub

Motherboard

•

*comes with the Gateway Motherboards

Overview of ordering information

Designation Description

HD2-GTR-4PA Gateway Module for 4 PA segments

MB-FB-GT Gateway Motherboard for a HD2-GTR-4PA (Sub-D

cable included)

MB-FB-GTR Redundant Gateway Motherboard for two HD2-

GTR-4PAs (Sub-D cable included)

Page 21

PROFIBUS POWER HUB SEGMENT COUPLER

Specification

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

21

Date of Issue 24.3.11

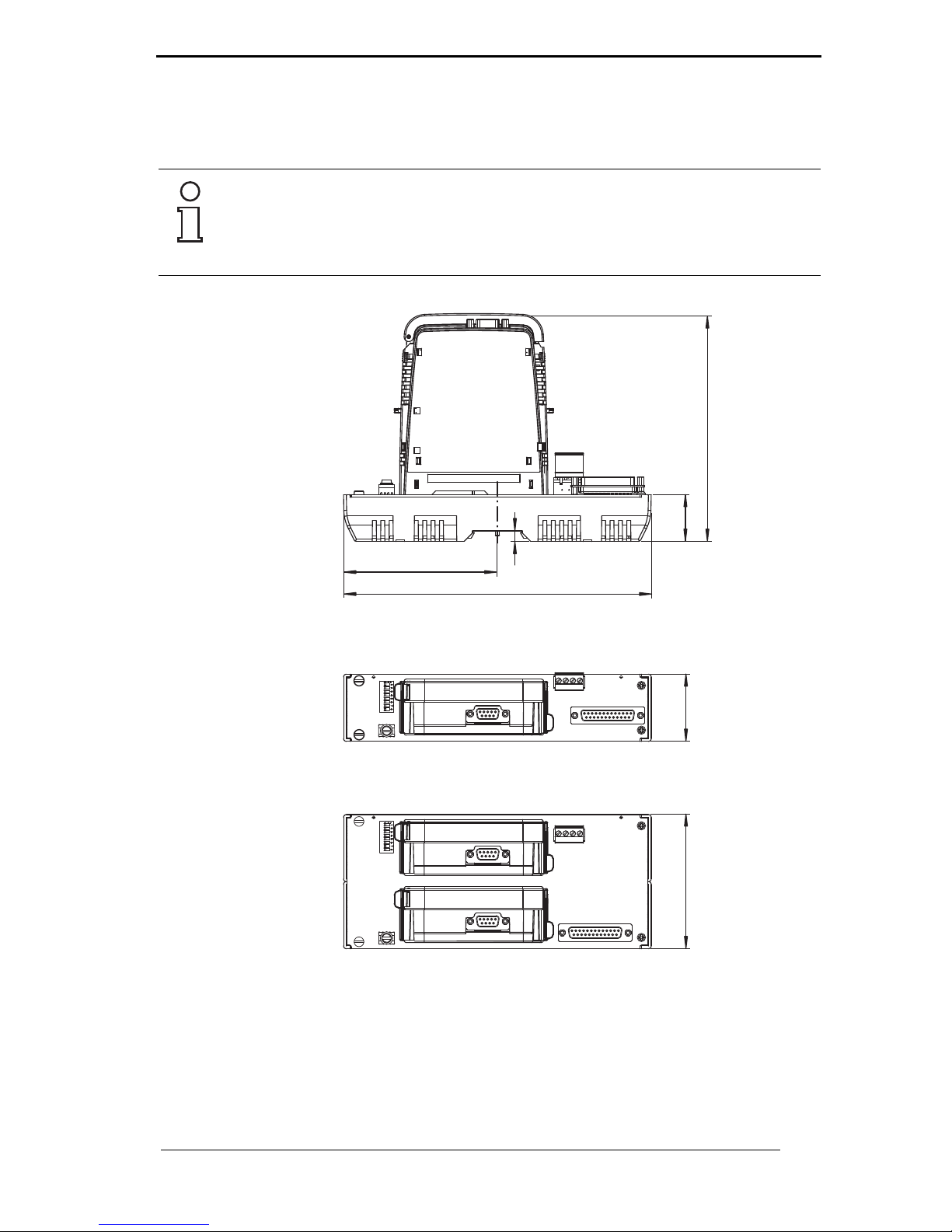

2.8 Dimensions

•

All dimensions in millimeters and inches (values in brackets) and without

tolerance indication.

Note

50 (1.9)

35 (1.3)

162 (6.3)

8

110 (4.3)

220 (8.6)

95 (3.7)

MB-FB-GT

MB-FB-GTR

Page 22

PROFIBUS POWER HUB SEGMENT COUPLER

Installation and Commissioning

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

22

Date of Issue 24.3.11

3 Installation and Commissioning

3.1 Mounting and Dismounting

Mounting Motherboards on a DIN rail

To mount a motherboard, proceed as follows:

1. Place the motherboard on the DIN rail.

2. Tighten the fastening screw in the middle of the motherboard to attach the motherboard to the DIN rail.

The motherboard is mounted. Dismounting is performed in the reverse

order.

•

Mounting of HD2-* modules on the Motherboard

To install a new module on the motherboard, proceed as follows.

1. Carefully center the polarisation holes and mate the two connectors, then gently press down the module.

2. Push down the red Quick Lok bars on each side of the module to

fix it to the panel (no tools required).

The new module is installed.

•

Page 23

PROFIBUS POWER HUB SEGMENT COUPLER

Installation and Commissioning

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

23

Date of Issue 24.3.11

Dismounting of HD2-* modules from the Motherboard

To dismount a module from the motherboard, proceed as follows:

Push the red Quick Lok bars upwards and gently lift off the entire

module.

The module is removed.

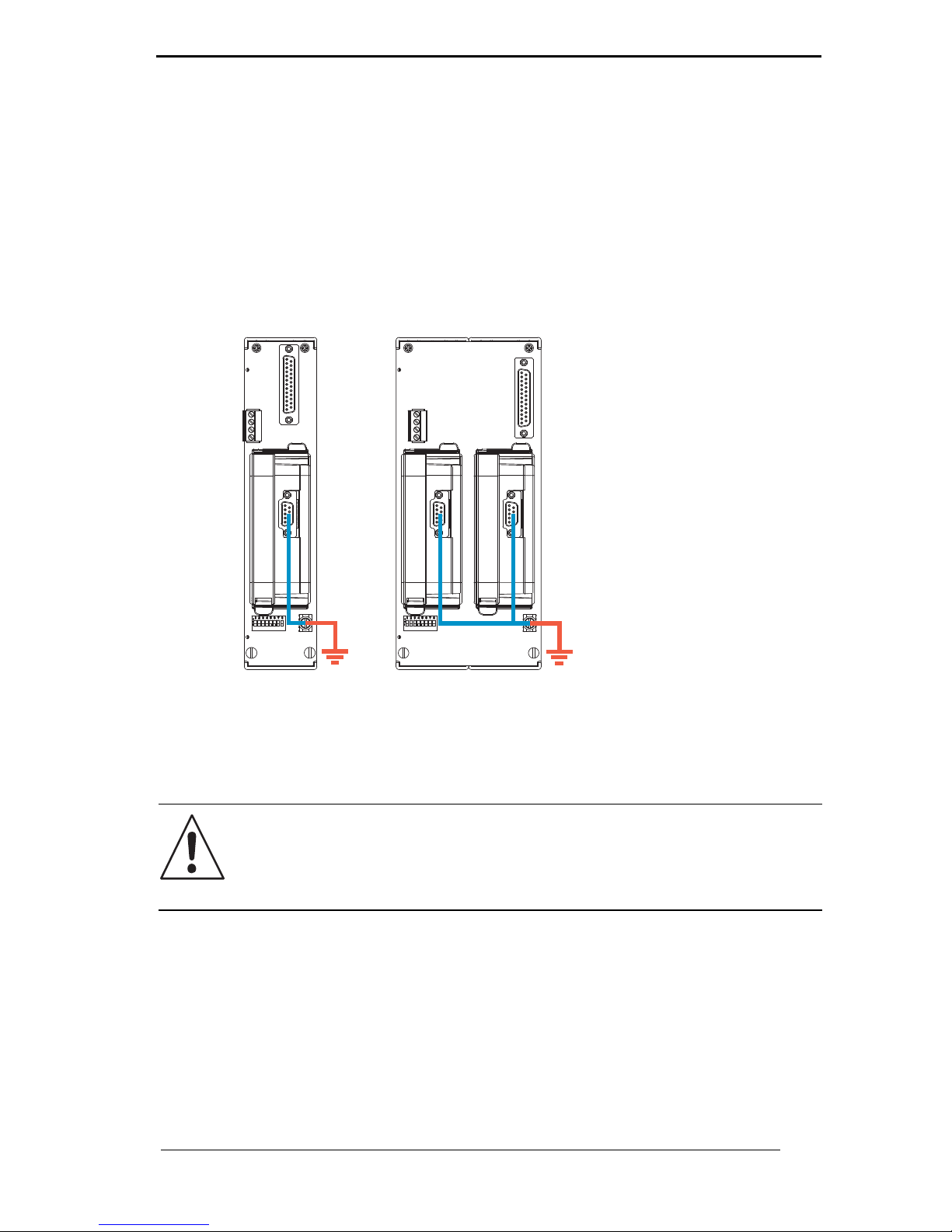

3.2 Shield/Grounding

•

The screen/shield of the Profibus cable on the HD2-GTR-4PA is connected directly to the screen/ground connection clamp of the motherboard.

If the Profibus DP cable leads into a hazardous area the screen/ground

connection clamp has to be connected to safety earth.

There might be a requirement to earth all exposed metal parts as a matter of course.

•

Earth Connection

Take care about good earthing practice and ensure a clean earth at all

times.

MB-FB-GT

MB-FB-GTR

Attention

Page 24

PROFIBUS POWER HUB SEGMENT COUPLER

Installation and Commissioning

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

24

Date of Issue 24.3.11

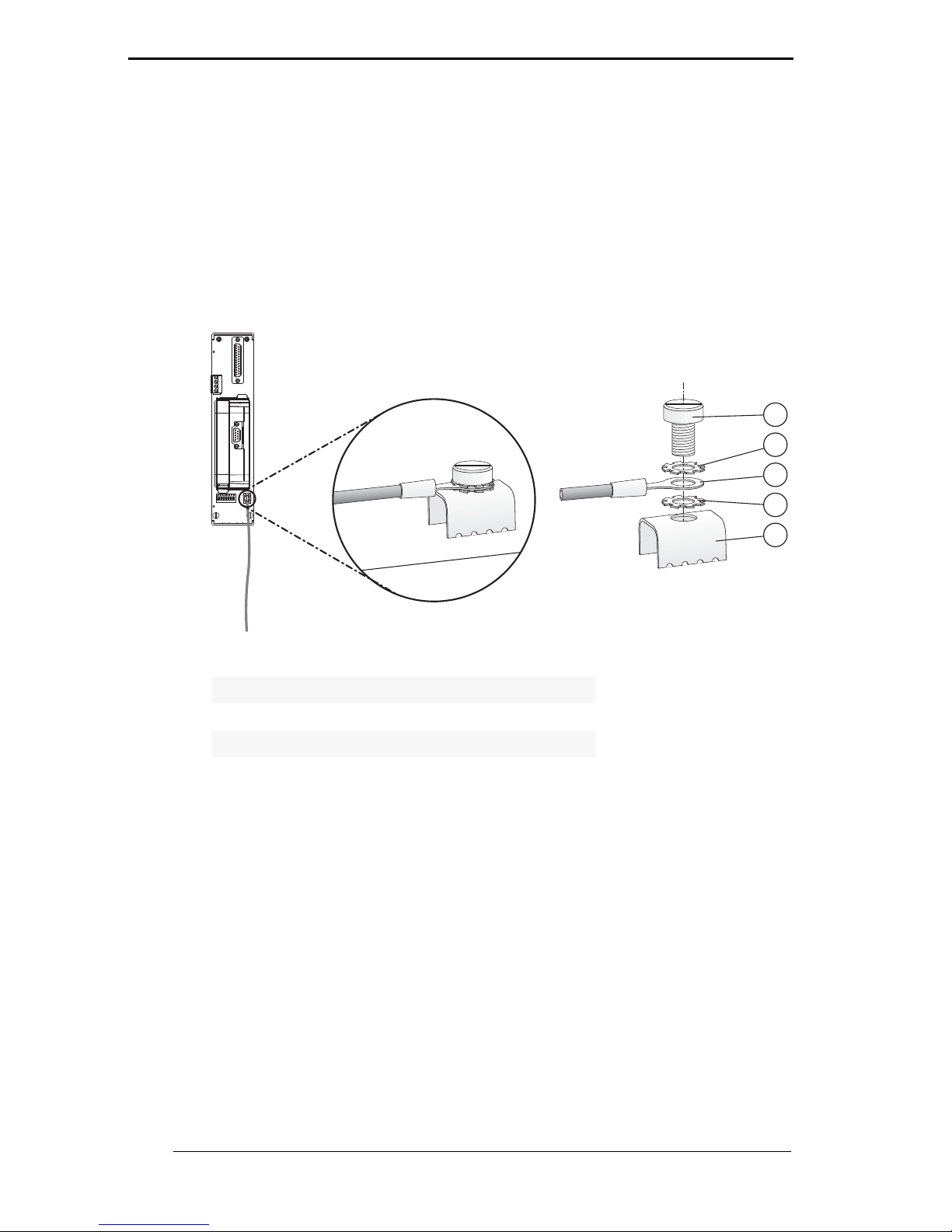

Connecting the ground connection cable

1. Connect the ground cable to a cable lug.

2. Position the cable lug over the ground connection clamp so that

the cable points downwards.

3. Screw the cable lug to the ground connection clamp using two toothed lock washers.

4. Tighten the screw so that the cable lug can not move.

•

1Screw

2 Toothed lock washer

3Cable lug

4 Ground connection clamp on motherboard

1

2

3

4

2

Page 25

PROFIBUS POWER HUB SEGMENT COUPLER

Installation and Commissioning

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

25

Date of Issue 24.3.11

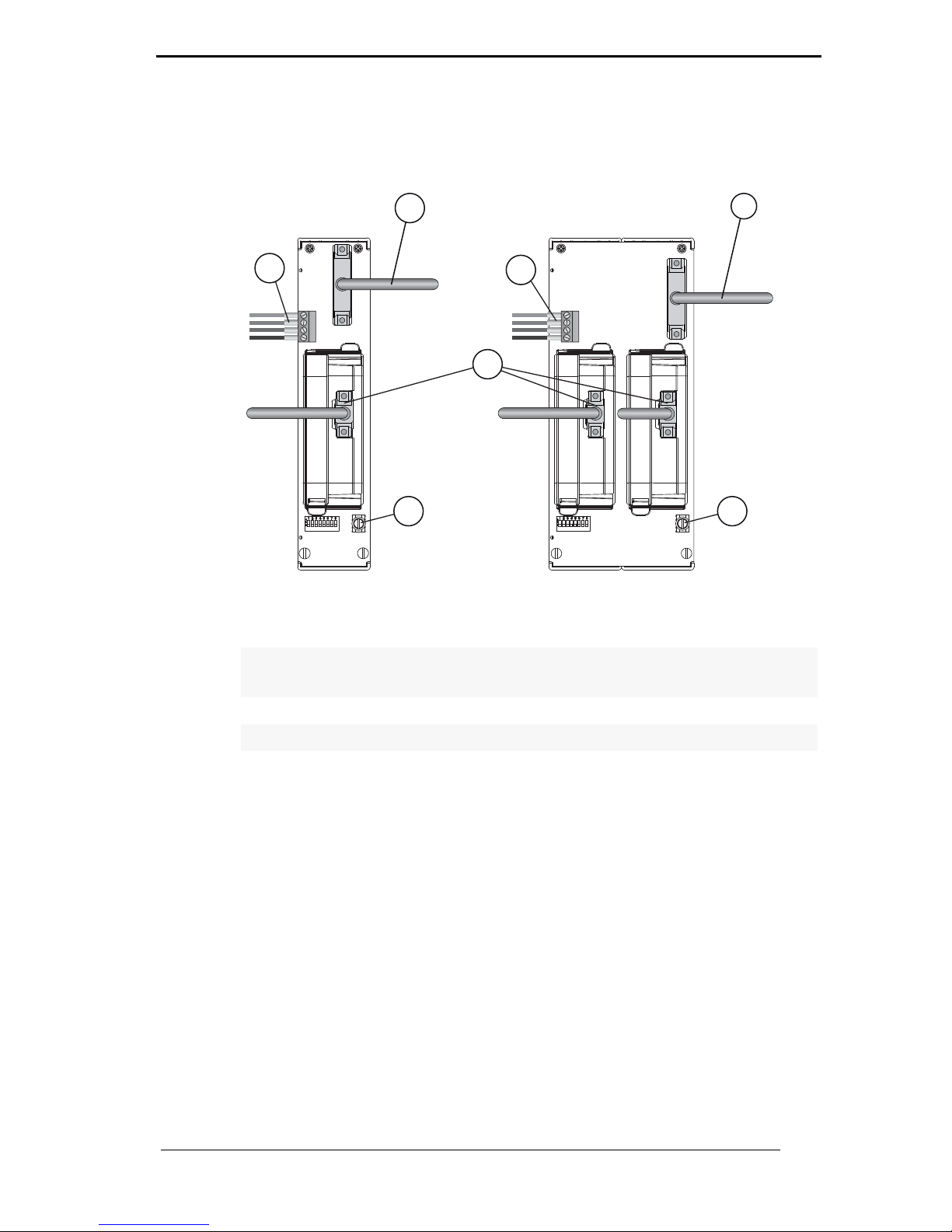

3.3 Connections

•

1 Sub-D connection to Power Hub motherboard MB*-FB*.GEN using

ACC-MB-HGC link cable

2 Diagnostics coupling to neighboring Power Hub motherboard using

ACC-MB-HDC link cable (optional, see also next page)

3 PROFIBUS DP connection

4 Ground connection clamp

MB-FB-GT

MB-FB-GTR

2

3

4

1

1

2

4

Page 26

PROFIBUS POWER HUB SEGMENT COUPLER

Installation and Commissioning

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

26

Date of Issue 24.3.11

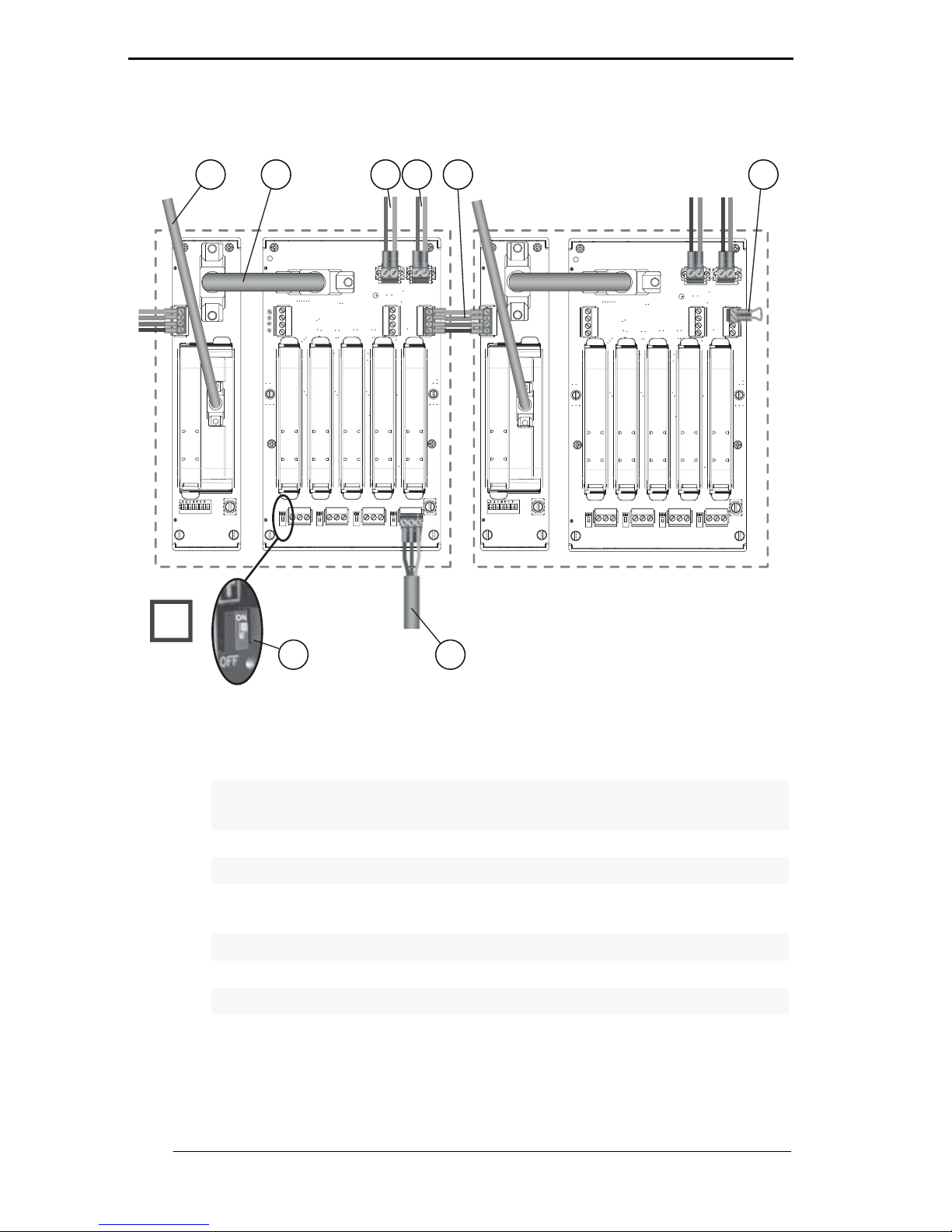

•

Figure 3.1: Connections of the PROFIBUS Power Hub system

1

PROFIBUS DP connection

2 ACC-MB-HGC link cable connecting Gateway motherboard and

Power Hub motherboard

3 Primary power supply connection

4 Secondary power supply connection

5 ACC-MB-HDC diagnostic link cable connecting neighboring Power

Hubs (optional, read following note)

6 Final motherboard link (optional, read following note)

7Trunk

8 Terminator

T

2

3 4

5

6

7

1

8

Page 27

PROFIBUS POWER HUB SEGMENT COUPLER

Installation and Commissioning

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

27

Date of Issue 24.3.11

3.3.1 Master Connection to a Redundant PROFIBUS Power Hub System

•

Normally, diagnostic information from the diagnostic module HD2-DM* is

transmitted via the gateway. You do not need to connect neighboring Power Hubs.

Alternatively, you may bypass the gateway and transmit the diagnostic information via a separate bus. Only in this case do you need to connect

neighboring power hubs using the ACC-MB-HDC diagnostic link cable.

The last Power Hub in a row has to be fitted with a final motherboard link

(see figure 3.1).

Note

*Flying Redundancy

Master 1

Master 2*

Page 28

PROFIBUS POWER HUB SEGMENT COUPLER

Installation in Hazardous Areas

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

28

Date of Issue 24.3.11

4 Installation in Hazardous Areas

4.1 Installation in Zone 2 Category 3G

The PROFIBUS Power Hub Segment Coupler may be installed in

Zone 2 Category 3G. The protection class is EEx nA C (non-arcing) gas

group IIC, IIB, IIA. Depending on the type of Power Modules used, different topologies and Zone 2 installations can be implemented.

The Fieldbus trunk is always categorized as EEx nA for Zone 2 applications. Connecting the PROFIBUS Power Hub with the Pepperl+Fuchs

Segment Protector (SPs) allows hot swapping of field devices.

Special safety instructions

EC type examination certificates and EC Certificates of Conformity and/

or the manufacturer’s Declaration of Conformity must be observed. It is

especially important to observe the "Special Conditions" included in

these documents.

•

Connections of non-energy-limited circuits under voltage may only be

made or disconnected during installation or maintenance or for repair

purposes.

•

If it is mounted in the hazardous area of Zone 2 Category 3G, the device

must be mounted in a housing, corresponding to at least protection class

IP 54 in accordance with EN 60529 and suitable for this type of installation.

•

The possibility of an explosive atmosphere occurring during installation,

maintenance or repairs is evaluated as improbable in Zone 2.

•

Devices that have been operated in general electrical plants must not be

used again after that in electrical plants that are connected to hazardous

areas.

Warning

Warning

Warning

Warning

Page 29

PROFIBUS POWER HUB SEGMENT COUPLER

PROFIBUS Commissioning

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

29

Date of Issue 24.3.11

5 PROFIBUS Commissioning

5.1 Assigning a Device Address

After the module is mounted, a slave address must be assigned to the

Built-In-Slave of Gateway HD2-GTR-4PA. This assignment is performed

only via the DIP switch on the Motherboard.

The DIP switch consists of 8 switches positioned next to each other.

They can be used to assign addresses from 0 to 255 in binary form

(2

8

=256).

Assigning the Built-In-Slave Address

To assign an address to the Built-In-Slave of the Gateway HD2-GTR4PA, follow these steps:

1. Place the eight individual switches of the DIP switch in the correct positions to generate the desired address of the Built-InSlave as the sum of powers of two from left to right (see the label on the Gateway Module).

2. Restart the Gateway by disconnecting it from the power supply or

by unplugging the Gateway Module and reconnecting it.

The Built-In-Slave address is assigned.

5.2 Commissioning of Cyclic Data Exchange

An appropriate configuration tool is required to configure cyclic data exchange (defining the slave, effective data, etc.) with a PROFIBUS-DP

Master Class 1.

In non-redundant operation, Built-In-Slave addresses are permitted in

the range from 0-125; in redundant operation, addresses between 0 and

61 are permitted.

Assigning an invalid address for the type of operation in question causes

the Built-In-Slave to be deactivated.

In redundant operation, an address must be assigned to the Built-InSlave.

In the case of redundant coupling, both Gateways need to be restarted

at the same time.

Note

Note

Note

Page 30

PROFIBUS POWER HUB SEGMENT COUPLER

PROFIBUS Commissioning

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

30

Date of Issue 24.3.11

Commissioning of Simplex System and Redundant System

The following section describes communication start-up of the

HD2-GTR-4PA:

1. If necessary, convert existing GSD files of PA slaves with the

P+F-GSD converter and then integrate them into the configuration tool

2. Integrate the GSD file of the HD2-GTR-4PA into the configuration

tool

3. Add Built-In-Slave (BIS) of the HD2-GTR-4PA to the DP bus configuration

4. Assign the BIS address set on the Motherboard DIP switch to the

HD2-GTR-4PA on the DP bus

5. Adjust the Watchdog. Rough value: 5 seconds (see chapter “Additional Information about Watchdog time” on page 33)

Additional steps for Redundant Coupling

The following additional steps are required for redundant coupling:

1. Add the Built-In-Slave (BIS) of the second DP/PA Gateway to

the DP bus configuration

2. Assign the BIS address set on the DP bus (the address of the first

BIS + 64) to the second DP/PA Gateway on the DP bus.

Additional steps for use of fiber-optical zones

If Coupling is designed redundantly and the DP bus uses optical fiber

as a communication medium, the following additional steps must be

performed:

Adjust the retry limit according to the baudrate (see chapter “Additional Information on Adjusting Retry” on page 35).

Because the DP/PA-Gateway is already a DP slave, its device GSD does

not need to be converted. The GSD file of the HD2-GTR-4PA is available

for download at www.pepperl-fuchs.com.

•

PA slaves do not take part in cyclic data exchange

The Built-In-Slave (BIS) of the first DP/PA Gateway must take part in cyclic data exchange. If it does not the connected PA slaves will also not

enter into cyclic data exchange.

Add the BIS of the Gateway to the DP bus configuration!

Note

Attention

Page 31

PROFIBUS POWER HUB SEGMENT COUPLER

PROFIBUS Commissioning

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

31

Date of Issue 24.3.11

5.2.1 Information on the GSD Conversion

Because coupling is transparent, PROFIBUS PA nodes are treated like

PROFIBUS DP slaves by the PROFIBUS DP Master. This also applies

to start-up and configuration.

The GSD file must be integrated in a configuration tool before it can be

used to configure and operate a PROFIBUS PA slave.

The following distinctions are important to recognize in GSD files for

PROFIBUS PA slaves:

• Is the file a profile GSD or a manufacturer-specific GSD?

• is the GSD designed for communication via the RS 485 interface (DP-GSD) or by the interface in conformity with

IEC 61158-2 (PA-GSD)?

If a profile GSD is being used, the filename indicates whether it is a DPGSD or a PA-GSD. For example, file PA039733.gsd is the profile GSD

for 4 binary outputs. The "PA“ in the filename means it is a PROFIBUS

PA slave. The following "0“ indicates it is a DP-GSD. The filename of the

PA-GSD for the same profile is PA139733. The "1“ after the PA abbreviation identifies it as a PA-GSD.

If manufacturer-specific GSDs are used, for example to make use of

functionality that falls outside the profile, the following convention identifies whether it is a DP-GSD or PA-GSD:

• If you have not done so already, integrate the GSD into your

configuration tool.

• Check in your configuration tool what baud rates are supported.

If a baudrate of 31.25 kBd is supported, the file is a PA-GSD. Normally

only baudrates of 31.25 kBd, 45.45 kBd and 93.75 kBd are supported

by the PA-GSD.

If transmission rates in accordance with the PROFIBUS specification

are used (IEC 61158), i.e. baudrates of 9.6 kBd to 1.5 MBd or 12 MBd,

the file is a DP-GSD. Some PROFIBUS PA field device manufacturers

do not offer any PROFIBUS DP-GSDs. In this case the existing PROFIBUS PA-GSD must be converted. The conversion software (GSD converter) is available at no cost from www.pepperl-fuchs.com. The purpose of this conversion software is exclusively to enter missing

transmission rates and to set specific bus parameters to values that allow for problem-free operation of the PROFIBUS DP.

Converting the GSD file imposes the following functional restrictions if

that was previously supported by the original GSD file:

• FREEZE and SYNC functionality is deactivated. These

functions are used in PROFIBUS DP for synchronization of sensors/actuators. Since work is possible on the PROFIBUS DP

Page 32

PROFIBUS POWER HUB SEGMENT COUPLER

PROFIBUS Commissioning

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

32

Date of Issue 24.3.11

side (Host side) at transmission speeds of up to 12 MBd and on

the PROFIBUS PA side (field side) at a rate of 31.25 MBd, problem-free operation cannot be guaranteed.

Some PROFIBUS functions are not currently supported. If the field device is intended to support one or more of the following functions, a

warning will point out that this will no longer be the case after the conversion. This affects the following functions:

• Master class 1 acyclic access

The following functions of PROFIBUS DP V2:

• Data Exchange Broadcast (Publisher/Subscriber)

• Isochronous mode, i.e. cycle-synchronous transmission

Using the Pepperl+Fuchs GSD converter

To convert GSD files, follow these steps:

1. Start program PFGSDCX.EXE

The following dialog appears:

•

2. Select the directory that contains the GSD files you wish to convert.

3. Select the GSD files you wish to convert.

The Advisory Board of the PROFIBUS User Organization has agreed

that certified GSD files changed by the Pepperl+Fuchs GSD converter

software will not lose their certificate.

Note

Page 33

PROFIBUS POWER HUB SEGMENT COUPLER

PROFIBUS Commissioning

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

33

Date of Issue 24.3.11

4. Select the directory where you would like to store the converted

GSD files.

5. Convert the GSD files by clicking on the "Process GSD -->“ button

Another window appears with information about the result of the conversion process.

5.2.2 Additional Information about Watchdog time

PROFIBUS devices can activate a mechanism that monitors each time

interval in the cyclic data exchange process (also referred to as user

data exchange) to ensure that the PROFIBUS master is still active. The

time is measured in the PROFIBUS slave.

If the response monitor is active and the time (TWD) since the last cyclic

polling process has expired, the device stops the cyclic data exchange,

reverts to its original status (Wait_prm) and secures the status of the

outputs.

The time value TWD and the signal for activating the response monitor

are transmitted from the PROFIBUS master to the PROFIBUS slave in

the parameter telegram at start-up (transmitted during the cyclic data

exchange). The time T

WD

is generally defined specific to the user (not

device-specific, not in the GSD). Lesser values are limited by the cycle

times.

The time TWD is usually entered via the configuration tool. The watchdog setting in the DP/PA gateway is transparent. On some configuration

tools, the response monitor is preset once for the PROFIBUS master.

You can select one or more files for conversion by pressing the CTRL or

SHIFT keys. Files preceded by a "+" symbol are the result of a previous

conversion. These files cannot be converted again and an error message

appears if an attempt is made to do so. Files beginning with a "-" symbol

have not been converted and can be if required. Double-click to open and

view or edit a file.

•

Watchdog reprogramming during cyclic communication!

DPV1 slaves leave cyclic communication because the DPV1 standard

does not permit any Watchdog change during operation.

The BIS of the DP/PA Gateway performs diagnostics in the DTM and cyclically to determine whether the Watchdog time (TWD) is sufficient.

Note

Warning

Note

Page 34

PROFIBUS POWER HUB SEGMENT COUPLER

PROFIBUS Commissioning

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

34

Date of Issue 24.3.11

While on other tools, the response monitor is preset individually for each

PROFIBUS PA participant. The response monitor value does not change in any way.

Many tools calculate the time TWD automatically with a corresponding

baud rate based on the cycle time of the master.

If the baud rates at the PROFIBUS DP end are high (e.g. 12 MBd), the

cycle times of the PA end may be 300 times longer. If a PROFIBUS PA

device has been programmed directly with a time TWD calculated at a

higher master baud rate (DP), this is usually shorter than the PA cycle

and the device does not exchange data.

The following bus parameters should be used to ensure the DP/PA gateway operates reliably:

• only one watchdog time T

WD

is programmed for the entire

PROFIBUS system. The longest delay period must be determined in order to define T

WD

• one watchdog time TWD is programmed for each individual slave.

The preset (parameterized) time TWD must be greater than the maximum occurring delay period T

V_max

.

Two types of Watchdogs can be configured on the HD2-GTR-4PA in cyclic or acyclic data exchange (chapter “Watchdog Time in the DTM” on

page 48):

• Transparent Watchdog: The Watchdog time on the DP side is

the same as on the PA side (= default setting).

• Fixed Watchdog: A Watchdog time is set on the HD2-GTR-4PA

for the PA side that is different than the DP side.

5.2.3 Information about I/O Cycle Time

The overall I/O data cycle time from a DP master via HD2-GTR-4PA to

a PA slave can be approximated as follows:

T

Cycle_IO_Data

= T

Cycle_DP

+ T

Cycle_PA_Channel

where:

T

Cycle_PA_Channel

= Cycle time of the PROFIBUS PA channel

T

Cycle_DP

= Cycle time of the PROFIBUS DP

The HD2-GTR-4PA measures the current cycle time of each PA segment

and generates a diagnostic message if the Watchdog time is too short.

Then the Watchdog time must be increased. The Gateway diagnostics

are based on the following formula: 2 x T

Cycle_PA_Channel

+ 500 ms

Note

Page 35

PROFIBUS POWER HUB SEGMENT COUPLER

PROFIBUS Commissioning

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

35

Date of Issue 24.3.11

The PA cycle time T

Cycle_PA_Channel

depends on:

• the number n of nodes on a channel

• the effective data length L

The effective data length L is a unitless variable calculated as the sum

of input and output effective data quantity (in bytes) of all devices.

The cycle time is calculated approximately as follows:

Nonredundant system:

T

Cycle_PA_Channel

= (0.256 ms * L) + (n * 12 ms) + 40 ms

Redundant system:

T

Cycle_PA_Channel

= (0.256 ms * L) + (n * 12 ms) + 100 ms

5.2.4 Additional Information on Adjusting Retry

If the coupling from DP to PA is designed redundantly and the DP bus

uses optical fiber as a communication medium, Pepperl+Fuchs recommends increasing the retry limit of the DP master.

Recommended retry limits corresponding to various baudrates:

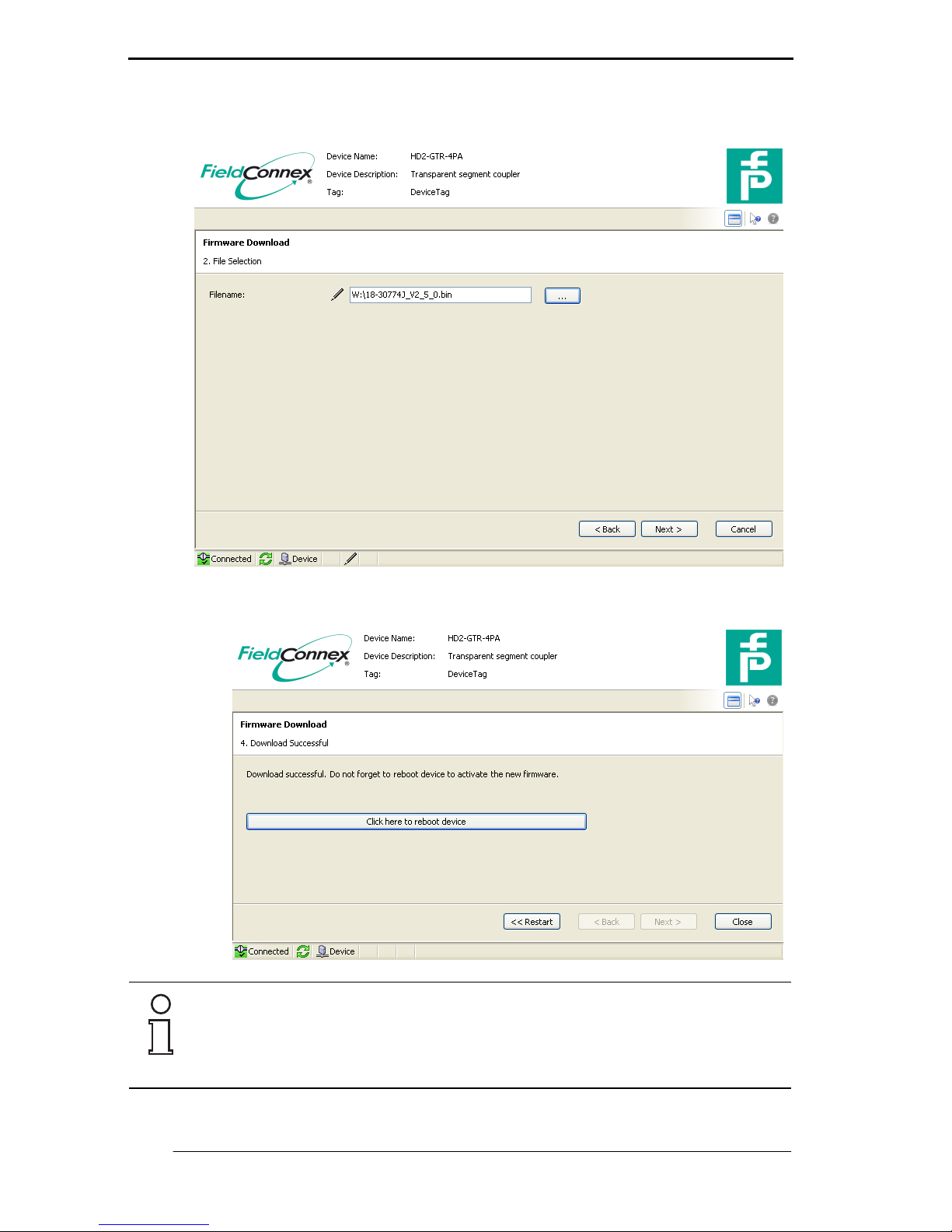

5.3 DTM Software Installation and Commissioning

System requirements for installation, commissioning and operation of

the DP/PA Gateway DTM:

• Hardware requirements based on your frame FDT

• FDT frame application (FDT specification 1.2)

• Latest version of HD2-GTR-4PA-DTM

•

Cycle time discrepancy in real application

This is the basic cycle time for ideal conditions. In reality acyclic communication, retries and diagnosis data can increase the cycle time so an additional safety margin has to be added. For the calculation of a overall

cycle time (Change of a measured signal until reaction of an Actuator)

additional parameters like the measurement cycle time of the PROFIBUS

PA devices and IO Processing cycle of the controller must be considered.

Baudrate Retry limit

45.45 kBd 2

93.75 kBd 2

187.5 kBd 2

1.5 MBd 2

3 MBd 4

6 MBd 6

12 MBd 7

Attention

Page 36

PROFIBUS POWER HUB SEGMENT COUPLER

PROFIBUS Commissioning

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

36

Date of Issue 24.3.11

• 40 MB free hard drive storage

Installation of DTM Package with PACTware

TM

as an Example

To install the DTM package on your system, follow these steps:

1. Install the P+F-FieldConnex

R

DTM package

2. Start the PACT

ware

TM

program

3. Update the device catalog

•

The Create New Device Catalog window appears:

•

4. Confirm with YES

The DTM is installed and ready for operation.

Create the project tree

To create the project tree, proceed as follows:

1. Start PACT

ware

TM

2. Open the appropriate project or create a new one

3. Open the device catalog (View/Device Catalog or press F3)

Make sure that all PACT

ware

TM

projects are closed.

Make sure the latest DTM version is installed and that the device catalog

is updated.

Note

Note

Page 37

PROFIBUS POWER HUB SEGMENT COUPLER

PROFIBUS Commissioning

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

37

Date of Issue 24.3.11

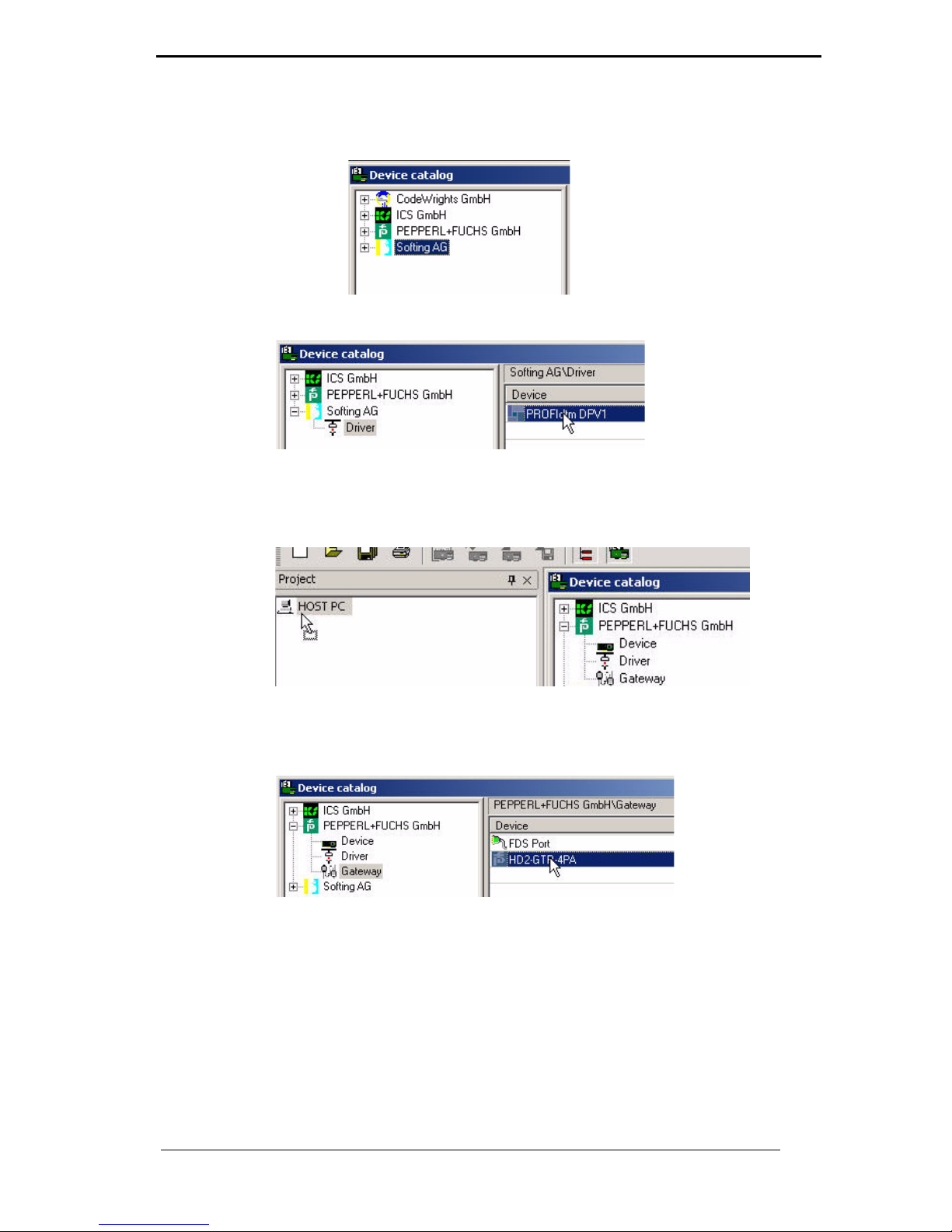

4. Open the menu entry Softing AG

•

5. Select the entry Drivers/PROFIBUS Driver

•

6. Drag and drop the PROFIBUS Driver to your project window/Host

PC

•

7. In the Device Catalog, open menu item Pepperl+Fuchs GmbH/

Device/HD2-GTR-4PA

•

Page 38

PROFIBUS POWER HUB SEGMENT COUPLER

PROFIBUS Commissioning

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

38

Date of Issue 24.3.11

8. Drag the HD2-GTR-4PA into the project window into the PRO-

FIdtm DPV1 node. The window Add station address will appear.

•

9. Enter the station address (BIS address of the Gateway) and confirm with OK.

Your project tree should now look like this:

•

Enter assigned BIS address in the DTM

To enter the BIS address (which has been assigned on the Gatewaymotherboard) into the DTM, proceed as follows:

1. Rightclick on PROFIdtm DPV1 in the project tree and choose

Additional Functions/Edit DTM Station Addresses.

2. Enter the BIS address set on the Gateway Motherboard and confirm with Apply:

•

In rare cases, the FDT application may not immediately display the

address change in the project window even though the change has been

made.

In that case, save the project once to update the display.

Note

Page 39

PROFIBUS POWER HUB SEGMENT COUPLER

PROFIBUS Commissioning

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

39

Date of Issue 24.3.11

Advanced Diagnostic Module Engineering

To integrate an Advanced Diagnostic Module HD2-DM-A via

PROFIBUS PA, proceed as follows:

1. In the device catalog, open

PEPPERL+FUCHS GmbH/Device/HD2-DM-A

2. Drag&Drop HD2-DM-A into the project window’s HD2-GTR-4PA

node

Your project tree should now look as follows:

•

3. To assign a tag to the Advanced Diagnostic Module, open the offline dialog of HD2-GTR-4PA.

4. Enter a device description into the field ADM Tag and confirm with

Enter

•

•

Data loss

The Advanced Diagnostic Module can be engineered in both the offline

and the online dialog. Make sure to load the data from the device or to

the device after engineering.

The ADM address is being detected automatically and is displayed symbolically by „999“. There is no need to assign an address.

Attention

Note

Page 40

PROFIBUS POWER HUB SEGMENT COUPLER

Operation

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

40

Date of Issue 24.3.11

6 Operation

In PROFIBUS, two types of communication exist:

• cyclic and

• acyclic data exchange.

In cyclic data exchange, user data is exchanged between the Master

(Process Control System) and Slave (field device) at regular intervals.

User data includes measurement values, limit position feedback and

output data, etc. The bus cycle time depends essentially on the number

of nodes and the amount of data being transmitted.

In acyclic data exchange, "service" data, for example device parameterization or diagnostic information, is transmitted.

A number of parameters of the HD2-GTR-4PA Gateway Module can be

adjusted both through acyclic parameterization (using the DTM) and via

the Process Control System. The advantage of parameterization via the

Process Control System is the simplification of device replacement

since no additional effort is required in addition to replacing the physical

device.

6.1 Built-In-Slave (BIS) Description

The Gateway has an integrated slave (Built-In-Slave or "BIS“) with a DP

address that can be configured with the DIP switch on the Motherboard.

As a device participating in cyclic data exchange, the BIS returns

function monitoring and diagnostic data to the Master.

6.1.1 Cyclic Data Exchange

The BIS is a modular DPV1 slave with one slot. Two modules are available, each with a one-byte input and one-byte output. The input provides a combined status message for the Gateway. The status message

is coded as a PA Profile Status Byte (0x00: Bad unspecific, 0xA4: Good

Maintenance Required, 0x80: Good). For the actual value of the byte

under certain diagnosis conditions, please refer to table “Device Diagnosis Parameters” on page 42. If multiple diagnosis events are present,

the priority is as follows: Bad (highest priority), Good Maintenance required, Good (lowest priority). A dummy byte (0x00) must be sent as an

output data item.

6.1.2 Parameterization Options (Channel Assignment)

The three configuration modules Default, PA-BUS Configuration and

PA-BUS Configuration + Diag allow the parameterization of the following values:

Page 41

PROFIBUS POWER HUB SEGMENT COUPLER

Operation

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

41

Date of Issue 24.3.11

6.1.3 Diagnostics (Slave Diagnostics)

The BIS returns the following of the diagnostic blocks described in the

GSD:

• Device Diagnosis

• 0- 4 x Segment Diagnosis (Channel Diagnosis)

• RedState-Block

Device Diagnosis provides specific diagnostic information about the Gateway. This information is parsed directly by the Process Control System

and displayed for the user. In redundant configuration, all diagnosis information is also available for the redundancy partner. Device Diagnosis

includes:

Default

none

PA-BUS Configuration

Watchdog Time

PA Retry limits

Number of activated PA segments

PA-BUS Configuration + Diag

Watchdog time

PA Retry limits

Number of activated PA segments

Diagnosis (ADM Alarm Observer)

If the PA bus configuration module is set, values that are set with this module cannot be changed with acyclic access during cyclic communication.

Note

Page 42

PROFIBUS POWER HUB SEGMENT COUPLER

Operation

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

42

Date of Issue 24.3.11

All Device Diagnostic parameters marked with „Yes“ in the EXT_DIAG

column cause the EXT_DIAG to be set in the slave diagnosis. The Process Control System then marks that slave as defective.

Device Diagnosis

Parameters

EXT_DIAG InputData

Gateway primary device

No GOOD

Redundancy not operative

Ye s BAD

Redundancy is

syncronizing

Ye s B A D

Redundancy gateway

missing

Ye s BAD

Hardware error

detected

Ye s B A D

Redundancy link

error

Ye s BAD

No baudrate detected Yes BAD

BuiltIn-Slave

not in data exchange

No

GOOD

Firmware version

mismatch

Ye s B A D

Firmware updated,

need reboot

Ye s BAD

A PA Masters not in

token ring

Ye s B A D

PABus parameters

write locked

No GOOD

Segment MAU error Yes BAD

ADM error

or module missing

Ye s BAD

ADM: system maintenance required

Yes GOOD Maintenance

required

ADM: system out of

specification

Ye s BAD

ADM: segment

maintenance required

Yes GOOD Maintenance

required

ADM: segment out of

specification

Ye s BAD

Page 43

PROFIBUS POWER HUB SEGMENT COUPLER

Operation

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

43

Date of Issue 24.3.11

Channel Diagnostics returns specific diagnostic information about each

individual segment. These error messages are prioritized and set to

preferred by the BIS depending on their ranking. The following table represents diagnostic information according to its ranking.

The RedState Block is a standardized diagnostic block, it is inserted

when the slave receives a PRM command.

6.2 Coupled Slaves

This section applies to coupled slaves on non-redundant Masters and

to Flying Redundancy Masters.

All coupled PA slaves behave as non-redundant DP slaves after the

GSD conversion, so that every PA slave appears directly on the DP bus.

The PA slaves are not merged to one single slave.

Both cyclic and acyclic communication is coupled.

As many C2 connections are coupled to the slaves as they support, al-

together a maximum of 500.

From the Master's point of view, redundancy switching of the Gateway

has no effect on PA slaves. They do not drop out of communication.

The FREEZE and SYNC modes are coupled, but because DP commu-

nication and PA communication are incompatible in terms of time, they

are not relevant for practical purposes.

Identification & Maintenance (I&M) Functions are supported.

6.3 Acyclic Data Exchange with BIS via DTM

The BIS supports four acyclic connections. Three dialogs are available

in acyclic mode via the DTM (Device Type Manager):

• the Offline Dialog

• the Online Dialog

• the Diagnostics Dialog

Channel Diagnostic parameters

Hardware Error

No slave in live list

DP Watchdog time too short

Duplicate slave address

PA master not in token ring

ADM: segment out of specification

ADM: segment maintenance required

Page 44

PROFIBUS POWER HUB SEGMENT COUPLER

Operation

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

44

Date of Issue 24.3.11

In the Offline dialog, all parameters can be set locally without having any

direct effect on communication or the device. Data can be written to the

device after all settings have been made. Current parameters can also

be read in from the device, processed and saved.

In the Online Dialog, you directly effect device parameters. Your entry is

written to the device immediately, as soon as you press the Return key.

The Online Dialog additionally offers diagnostic information about the

Gateway and the PA-segments connected to the Power Hub.

The Diagnostic Dialog shows the current device parameters and

diagnostic information, changes to the data cannot be made in this dialog.

•

Figure 6.1: Functional overview of dialogs

6.3.1 Brief introduction to DTM with PACTwareTM as an Example

Connect DTM to the HD2-GTR-4PA

Make sure all settings have been made correctly (the device address,

etc.)

1. Right click in the project tree on HD2-GTR-4PA

2. Select Connect

A rhomb (#) next to the device icon in the project tree indicates that the

connection exists.

•

Data Loss

Settings made in the Online Dialog are not automatically transferred to

the Offline Dialog.

To save online settings, load the data into the

Offline Dialog (function: Read Data from Device).

Attention

Field device

Offline

dialog

Online

dialog

Upload

Download

Direct connection

Diagnosis

dialog

Diagnosis only

Page 45

PROFIBUS POWER HUB SEGMENT COUPLER

Operation

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

45

Date of Issue 24.3.11

Open Offline Dialog

To open the Offline Dialog:

1. Right click in the project tree on HD2-GTR-4PA

2. Select Parameters/Offline Parameterization

Open Online Dialog

Make sure the HD2-GTR-4PA is connected.

To open the Online Dialog:

1. Right click in the project tree on HD2-GTR-4PA

2. Select Parameters/Online Parameterization

Open Diagnosis Dialog

Make sure the HD2-GTR-4PA is connected.

To open the Diagnosis Dialog:

1. Right click in the project tree on HD2-GTR-4PA

2. Select Diagnostics

Print Diagnostic Information

To print Diagnosis information:

1. Open the Diagnosis or the Online Dialog (see above)

2. Press the "Print Button“ in the DTM header

•

The diagnostic report Print Preview window appears

3. Click Print in the footer of the Print Preview window

•

The Printer Driver Selection menu appears

4. Select your printer and confirm the print job

Page 46

PROFIBUS POWER HUB SEGMENT COUPLER

Operation

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

46

Date of Issue 24.3.11

6.3.2 Overview of the DTM User Interface

1 Identification area

2 Navigation area

3 Work area

4 Quick start

Page 47

PROFIBUS POWER HUB SEGMENT COUPLER

Operation

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

47

Date of Issue 24.3.11

6.3.3 Structure Diagram

•

Figure 6.2: DTM structure - Offline Dialog

PA Master

HD2-GTR-4PA

Offline

Tag

Location

Descriptor

Signature

Segment Tags 1 ... 4

Activated PA segments

ADM Settings

ADM Alarm Observer

PA Retry Limit

Watchdog Mode

Installation Date

Device Settings

ADM Tag

PA Master Settings

Watchdog Time

PA Segment Tags

Slave Bus Parameter Set

Modul Configuration

Modul Configuration

Slave Bus Parameter Set

System

Settings

Channel

Assignment

Page 48

PROFIBUS POWER HUB SEGMENT COUPLER

Operation

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany