Page 1

INSTRUCTION MANUAL

Door Interrupt System

With FYQLA1-140R-3

FACTORY AUTOMATION

Logic Amplier

Original Instructions

Page 2

Contents

Introduction ...................................................................................................... 3

Declaration of conformity .................................................................................. 4

Information regarding EC conformity ................................................................. 4

Document purpose ............................................................................................ 4

Scope ........................................................................................................... 4

Delivery ........................................................................................................ 4

Denitions ................................................................................................... 5

Symbols used ............................................................................................... 5

General statements ................................................................................. 5

Qualied personnel ...................................................................................... 5

Intended use ............................................................................................... 6

Safety system test ........................................................................................ 6

Product description ........................................................................................... 7

Features ....................................................................................................... 7

Functions ........................................................................................................... 7

Power-up sequence ....................................................................................... 7

Daily inspection ....................................................................................... 8

Safety inputs ............................................................................................... 10

Reset faulted state ....................................................................................... 10

Hardware ......................................................................................................... 10

Inputs ......................................................................................................... 10

Indicators .................................................................................................... 11

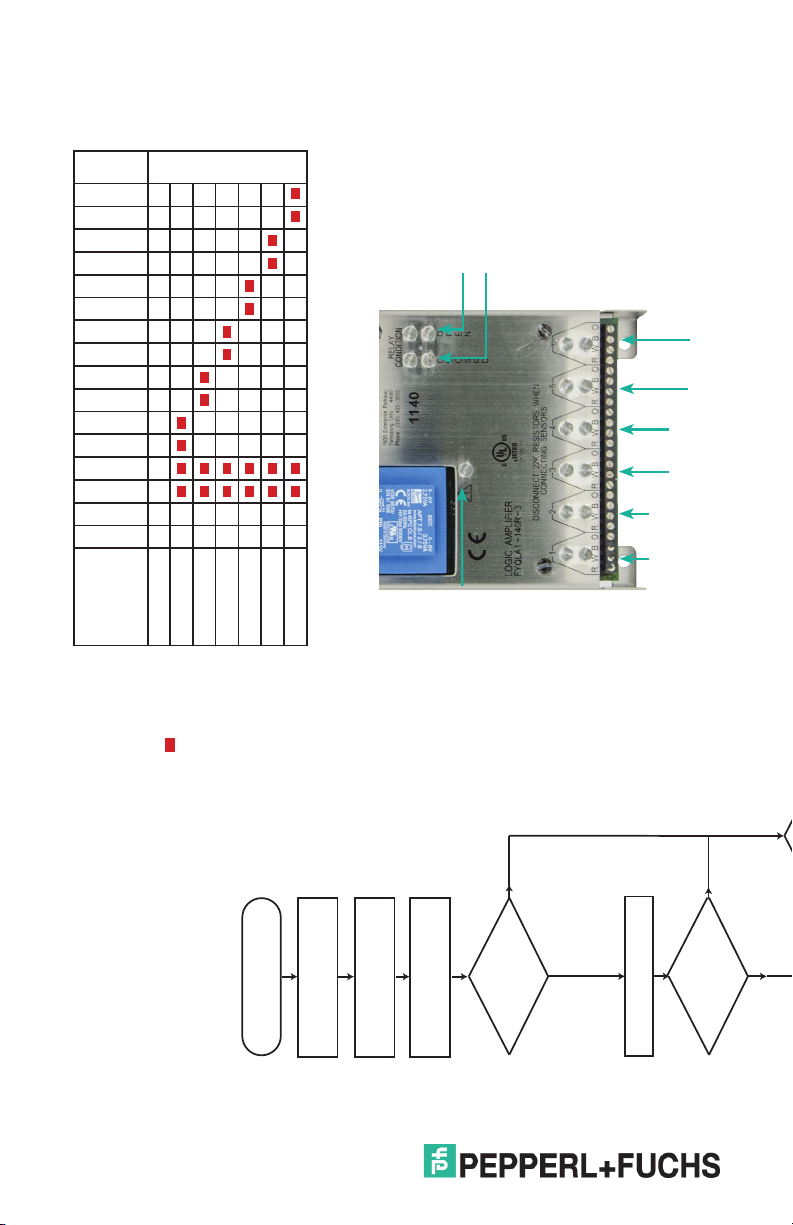

Indicator status table ................................................................................... 11

Guided relays .............................................................................................. 12

Input devices ................................................................................................... 12

Magnetic switches ...................................................................................... 12

Nominal oset distances ............................................................................. 13

Device dimensions ...................................................................................... 13

Installation ...................................................................................................... 14

Installation requirements ............................................................................ 14

Clearance around the device ....................................................................... 14

General safety notes ...................................................................................... 14

Installation and testing ................................................................................ 14

Electrical installation ....................................................................................... 15

Powering the device .................................................................................... 15

Wiring requirements ................................................................................... 15

Wiring diagram ........................................................................................... 16

Electrical connection .................................................................................. 17

Commissioning and startup .............................................................................. 18

Validation of the application ....................................................................... 18

Diagnostics...................................................................................................... 19

Faults .................................................................................................... 19

Technical support ................................................................................... 19

Troubleshooting ................................................................................. 19

Fault diagnosis ................................................................................... 20

Approvals ............................................................................................... 20

Product specications ...................................................................................... 20

Dimensions ...................................................................................................... 23

Page 3

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

Introduction

Congratulations!

You have chosen a device manufactured by Pepperl+Fuchs. Pepperl+Fuchs

develops, produces and distributes electronic sensors and interface modules for

the market of automation technology on a worldwide scale.

Before you install this device and put it into operation, please read the instructions

thoroughly. The instructions and notes contained in this operating manual will

guide you step-by-step through the installation and commissioning procedures to

ensure trouble-free use of this product. By doing so, you:

• Can utilize the entire range of device functions

• Reduce costs from downtime

• Increase the eectiveness and operating eciency of your machine

Store this instruction manual somewhere safe in order to have it available for future

reference. Directly after opening the packaging, please ensure that the device is

intact and that the package is complete.

Copyright

Copyright © 2017 by Pepperl+Fuchs, Inc.

All rights reserved

The company Pepperl+Fuchs, Inc. claims copyright on this documentation. To

modify, extend, hand over to a third party, or copy this documentation without

written approval by the company, Pepperl+Fuchs, Inc. is expressly prohibited. Nor

is any liability assumed for damages resulting from the use of the information

contained herein. Further, this publication and features described herein are

subject to change without notice.

The publisher reserves the right to alter the information and data contained in

this manual without prior notice. Unless otherwise indicated, the company names

as well as other names and data used in the examples are purely ctitious. The

publisher may have registered patents or pending patent applications for subject

matter covered in the manual. This manual does not give you license to these

patents.

3

Page 4

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

Note

Contact

If you have any questions about the device, its functions, or accessories, please

contact your local Pepperl+Fuchs representative.

Declaration of conformity

The FYQLA1-140R-3 was developed and manufactured compliant with the

applicable standards and guidelines.

A corresponding declaration of conformity may be requested from the manufacturer.

Note

Information regarding EC conformity

Pepperl+Fuchs declares that the product described in this manual conforms with

EC Directives by providing the following information:

Manufacturer

Declaration of conformity www.pepperl-fuchs.com

Directives observed

Pepperl+Fuchs GmbH, Lilienthalstraße 200, 68307

Mannheim, Germany, www.pepperl-fuchs.com

2006/42/EC (Machinery Directive)

2014/30/EU (EMC Directive)

2014/35/EU (Low Voltage Directive)

Standards observed

Documentation ocer

EN ISO 13849-1:2015, EN 60664-1:2008,

EN 61326-1:2012, EN 61326-3-2:2008

Pepperl+Fuchs GmbH, Lilienthalstraße 200, D-68307

Mannheim, Germany

Document purpose

Scope

The purpose of this document is to give the user the required information to

properly apply and install the door interrupt system. The product model covered

under this document includes the FYQLA1-140R-3.

Delivery

Included in the delivery:

• 1 - FYQLA1-140R-3 logic amplier

• 10 - 22 k resistors

• 1 - Instruction manual

Must be used with approved devices that are sold separately.

See page 12.

4

Page 5

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

Denitions

• Input Device – Externally mounted dual-channel switching device

• Input – Dual channel, redundant monitoring port

• Qualied Personnel – Persons trained in the use of the product, machinery,

and system

Symbols used

This symbol warns of a danger.

Failure to observe this warning may result in personal injury or

Warning

death, property damage or destruction.

This symbol warns of a possible fault.

Failure to observe the instructions given in this warning may

Attention

result in the device and any facilities or systems connected to

it developing a fault or even failing completely.

This symbol draws your attention to important information.

Note

General statements

Qualied personnel

The door interrupt system is a safety product. However, just adding the door

interrupt system to a machine or process will not meet safety standards.

Functional Safety Management (FSM), considering a full lifecycle approach,

must be used to guarantee functional safety. Competence is essential in the

delivery of functional safety. The application must be planned by qualied

personnel that know how to apply the necessary standards and regulations.

The door interrupt system must be installed by qualied personnel who are

properly trained in the installation and usage of the FYQLA1-140R-3 product.

These persons must have access to all instructions and knowledge of all

required safety requirements regarding the application of such devices and

machinery equipment.

Requirements:

• Manual must be read by persons using this equipment

• Device users must be trained and qualied in the use of safety-rated

devices

• Users must learn and follow all the safety rules and operating principles in

this manual

• Users must follow all warnings, cautions, and other safety messages in this

manual

• Only original spare parts from Pepperl+Fuchs may be used for repairs

• The unit contains no user serviceable parts

5

Page 6

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

Warning

Warning

Warning

Note

Intended use

The door interrupt system monitors up to six input devices. The external devices

are individually wired to the system and the signals are evaluated to determine if

one of the input devices is in the open state.

The FYQLA1-140R-3 must be used in accordance with its intended

purpose. The system must be installed according to regulations for

safeguarding from hazardous locations or areas being entered, or as

a safety relay for safety components appropriate for the described

conditions. When used dierently, the intended function of the system

is not guaranteed. Appropriate measures should be taken such that

any forseeable misuse is prevented

Safety system test

Only a qualied trained person should perform this test. Any

problems detected as a result of this test must be repaired by

qualied personnel before operating the equipment! DO NOT operate

the equipment if problems are detected or serious injury could result!

The purpose of this test is to verify the function of each switch and

control component in the safety system. The person performing the

test should be familiar with the dierent guards and controls on the

equipment. This test should be performed daily. If the machine is not

in continuous operation, test before each use. See the Daily inspection

ow diagram, pages 8-9.

6

Regular maintenance testing

It is recommended to test the door interrupt system regularly to verify proper

operation on a daily schedule. These should be performed and documented by

qualied personnel. See test sequence, Daily inspection, pages 8-9.

This safety device and associated equipment should be tested

regularly by qualied personnel familiar with the principles and

procedures in this manual. If the testing indicates a problem with this

device or system, the equipment is not safe to operate. Call qualied

personnel immediately to locate and repair the fault.

This safety device and associated equipment should be tested when

any change or modication is done to the device and/or setup by

qualied personnel familiar with the principles and procedures in

this manual. If the testing indicates a problem with this device or

system, the equipment is not safe to operate. Call qualied personnel

immediately to locate and repair the fault.

Page 7

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

Product description

Features

The FYQLA1-140R-3 is a category 3 PL d( ISO 13849-1:2015) logic amplier.

The basic features of the FYQLA1-140R-3 include inputs for up to six individual

two-channel switches for monitoring door access or guarded/monitored functions.

Both channels are monitored and cross checked for proper operational switch

states. The safety function monitors all switches, and they must have closed state

conditions on both channels to allow the safety relay output to be energized.

• Monitored inputs (6)

• N.O. output relay contact

• Internal relay monitoring

• Screw terminals

• LED input indicators

• LED fault indicator

• LED relay status indicators

• LED relay power indicator

Together with the 50FY41 series sensors and 52FY31 series actuators, the

FYQLA1-140R-3 can be used to protect one or more points of hazardous areas.

Functions

Power-up sequence

After power is applied to the system, an internal system check is performed

verifying the functional logic and connected switch conditions. If any errors are

detected at power-up, the safety output relays will remain in the de-energized

state. Time to complete this internal verication is approximately two to three

seconds.

Power-up state (output relay energized):

• All internal function checks were veried and all input switch states are in the

closed position

Power-up state safety function (output relay de-energized):

• All internal function checks were veried, but one or more input switch states

are in the open position

• One or more internal function checks fail

7

Page 8

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

Are the 2 green relay

LEDs lit?

Are only the 2 red

input LEDs for the open

door lit?

No

Yes

Yes

Open or remove first

guard/door equipped with

the 50FY41 switch

No

Description

Fault LEDs

Input 6b LED

Input 6a LED

Input 5b LED

Input 5a LED

Input 4b LED

Input 4a LED

Input 3b LED

Input 3a LED

Input 2b LED

Input 2a LED

Input 1b LED

Input 1a LED

SR2 Red LED

SR1 Red LED

SR2 Grn LED

SR1 Grn LED

p p

All guards closed

Green LED

p

Only input 1 open

Red LED

Only input 2 open

Only input 3 open

Only input 4 open

Only input 5 open

momentarily at power up

O at all times other than

Only input 6 open

SR1, SR2 LEDs

Red relay status

Red fault LED

Green relay status

5A, 5B 6A, 6B

3A, 3B 4A, 4B

1A, 1B 2A, 2B

Input

status

LEDs

Daily inspection

Power off

No

Yes

Reapply power

Wait 3 -5 seconds

switches are closed

Ensure that all door guard

LEDs on?

Are any red input

Verify all doors are closed

No

Yes

LEDs on?

Are any red input

8

Page 9

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

the 50FY41 switch

Open or remove next

guard/door equipped with

No

Yes

been tested?

Have all inputs

Close open guard/door

Yes

LEDs lit?

Are the 2 red relay

No

Yes

Wait 3 -5 seconds

door lit?

Are only the 2 red

input LEDs for the open

No

Yes

Yes

LEDs lit?

Are the 2 green relay

No

the 50FY41 switch

Open or remove first

guard/door equipped with

Is the red fault LED

Document results in

No

lit or blinking?

inspection records

Done / Passed

Yes

Shut down machine &

contact repair technician

9

Page 10

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

System inputs

The six device inputs allow the user to monitor up to six functional switch devices.

Each device must have two channels of output, one sourcing output and one

sinking output. These outputs must operate in tandem for a valid switch function

to be recognized by the FYQLA1-140R-3. If the output channels of the switches are

not functioning in a synchronized manner the amplier will not accept the switch

closure as a valid. The allowable timing between closure of switch channel A and

channel B is approximately one second. If any given pair of switch channels does

not transition to the proper state in the minimum time, then the monitor will issue a

fault on that switch channel and prevent the output from closing.

Reset faulted state

If an invalid door switch sequence is detected by the Channel A and Channel B

synchronization, the output safety relays will open and red fault LED will blink.

Reset is accomplished by a power down/power up sequence.

Actuator Switch

Channel A

Channel B

Monitor input

Channel A

Output relays to de-energize equipment

When an invalid input condition is recognized by the door interrupt

system, the output safety relay will be de-energized. This will cause the

relay contact pair to open. Be sure to verify the contact power ratings

Attention

when applying these relay outputs to energize/de-energize associated

equipment.

Hardware

Inputs

• Six switch inputs compatible with dual channel devices

▸ Pepperl+Fuchs’ 50FY41 series magnetic sensors

Channel B

Minimum time

between transitions

10

Page 11

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

Indicators

The FYQLA1-140R-3 has indicators on front of the device for the following

functions:

• State of the connected input switches

▸ Two indicators per switch input (channel A & channel B)

▸ Indicator is illuminated (on) when the switch state is open

• Relay output status

▸ Two indicators available, one per relay state:

Red indicator illuminated when de-energized

Green indicator illuminated when energized

• Fault Indicator

▸ Fault indicator ashes under the following conditions:

Input switch sequence error (channel A and channel B timing)

▸ Output relay contact monitor fault

Indicator status table

Switch Status Relay 1 Status Relay 2 Status

1

2

2

2

Green LED ON

p

Red LED ON

Red

Channel

1 LED

Condition

Door

Sensor

Open

Door

Normal

Operation

Sensor

Closed

Door

Sensor

Fault

Relay 1

Welded

Contact

Fault

Faults

Relay 2

Welded

Contact

Fault

Internal

Relay

Fault

Power O

1) Indicator status changes to fault 1-2 seconds after input sequence fault is detected

2) Fault may require the next operational cycle to start before fault is indicated

Red

Channel

2 LED

Red

Open

LED

Green

Closed

Red

BLINKING

OFF

Red

Green

Open

LED

Closed

LED

p p

p

LED

p

OPEN

CLOSED

Red

Fault

LEDs

SR1

Contact

Status

11

Page 12

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

Guided relays

The door interrupt system incorporates two force-guided safety relays that are

monitored for proper operation and generate a redundant output for application

use.

Input devices

Magnetic switches

The 50FY41 series hall eect door switches are a noncontact, magnetic actuation

system consisting of a sensor and a magnetically keyed actuator. The sensor

contains two hall-eect integrated circuits that are connected independently.

When exposed to this magnetic actuator and properly aligned, the sensor

responds with an output.

Approved devices

• 50FY41 series Hall eect door interrupt sensor

• 52FY31 series Keyed hall eect magnetic-actuator

NOTE: These are the only approved devices that should be used.

50FY41 sensor alignment

12

Attention

Cable length

Attention

Ensure the alignment of the sensor and magnetic actuator are correct

for proper operation. A 10 mm (0.39 in) separation distance between

sensor and actuator will cause an OFF condition, independent of axial

oset distance.

Sensor cable length must not exceed 25 m (80 ft).

Page 13

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

Nominal oset distances

Sensing distance mm (in)

Oset Max. Actuator

O Distance

Distance

0 (zero) 2.5 (0.1) 10 (0.4)

3.8 (0.15) 1.3 (0.05) 10 (0.4)

7.5 (0.3) 0 (zero) 10 (0.4)

Offset

Hall effect sensor

Device dimensions

(for reference only—dimensions in mm)

39

25.4 12.7

39

25.4 12.7

Magnet actuator

Distance

25.4

39

2 x ø5

50FY41 hall eect sensor

Cable Length

25.4

39

52FY31 magnet actuator

2 x ø5

13

Page 14

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

Note

Installation

Installation requirements

Panel mounted inside an enclosure using the four mounting feet in the stainless

steel housing. The FYQLA1-140R-3 is intended to be installed in a clean and dry

environment. A control cabinet must be used to guarantee that the unit is exposed to

no worse than an IP20 environment. The unit is designed to meet the requirements for

industrial environments. Suitability for other environments cannot be ensured.

Clearance around device

Adequate clearance should be provided around the device to allow for proper

cooling and ventilation of the control unit.

General safety notes

Installation and testing

After installation, the FYQLA1-140R-3 and all connected devices must be tested to

ensure proper wiring and operation. All wiring should be veried before applying

power to the unit. Once power is applied, each door switch should be opened to

verify proper operation of the system.

Periodic inspection and testing of the door interrupt system is

recommended. The device must be cycled and safety operation veried

once per day, or between equipment usage cycles. During this time,

proper operation of the safety switches and the correct response

of output safety relays must be veried. Inspection records of the

performed inspections must be maintained.

14

Page 15

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

Warning

Warning

Warning

Electrical installation

Switch the main machine power OFF prior to installation!

The machine could inadvertently start during installation.

The door interrupt system fullls the EMC requirements in accordance

with EN/IEC 61326-3-2:2008 for safety related systems.

Powering the device

The FYQLA1-140R-3 is to be powered only with 120 VAC with

a supply tolerence of no greater than 15% and a frequency of

45-65 Hz.

All connected downstream devices and wiring/installation must

correspond to the required category according to

ISO 13849-1:2015.

Wiring requirements

• GREEN terminal block: Input supply power/Relay contact output

• BLACK terminals: CH1 ... CH 6, 50FY41 switch inputs

Improper installation

This product is designed to conform to the technical requirements of

ISO 13849-1:2015. To ensure compliance with these requirements,

50FY41 series sensors and 52FY31 series actuators MUST be used

with the FYQLA1-140R-3.

Consult with the local safety agency and its requirements when

designing a machine control system, interface, and all control

elements that aect safety. Strictly adhere to all installation

instructions. Failure to comply with these instructions could result in

death or serious injury.

15

Page 16

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

Wiring diagram

16

FYQLA1-140R-3

Page 17

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

Warning

Electrical connection

Monitor terminals 50FY41 Unused inputs

R (positive) RED - positive

W (normally open, sourcing) WHITE - output

B (negative) BLACK - ground

O (normally open, sinking) ORANGE - output

Use two, 22 K

resistors

(included)

50FY41

Red

White

Black

Orange

x1

R

x2

W

x3

B

x4

O

If less than six sensors are connected to the safety monitor, install two, 22 K

resistors (one between R-W and one between B-O) into the unused inputs.

R W B O

Do not connect or remove wires with power applied.

17

Page 18

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

Warning

Warning

Commissioning and startup

Do not commission without a check by qualied safety personnel!

The door interrupt system must be installed by qualied personnel

who are properly trained in the installation, application, and usage of

the FYQLA1-140R-3 product.

You must ensure that no one is located in the hazardous area before

commissioning!

Check the hazardous area and secure it so that people cannot enter.

For example, set up warning signs, attach blocking ropes or similar.

Observe the relevant laws and local regulations.

Validation of the application

You may commission the system only if all pretests were successful. Validation may

be performed only by qualied personnel. The general acceptance comprises the

following tests:

• Check whether the components used correspond to the required Performance

Level in accordance with EN ISO 13849-1:2015.

• Check that the devices connected to the door interrupt system are in

accordance with this user manual.

• Clearly mark all connection cables and plugs.

• Perform a complete verication of the safety functions of the system in each

operating mode and error simulation. Observe the response times of the

system in response to tested functions.

18

Page 19

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

Diagnostics

Faults

The door interrupt system has multiple LEDs mounted on the top of the device to

provide diagnostic and troubleshooting assistance. LEDs are provided for each

switch input pair, indicating the status of the individual channel. Also provided are

output LEDs indicating the status of each of the safety relays. In addition, a fault

LED provides indication of when an input switch error has occurred, resulting in a

fault condition and opening of the safety relay. Fault conditions can be cleared only

upon power down-power up, of the door interrupt system.

Technical support

Troubleshooting

Problem Probable cause Remedy

No supply power Verify incoming power is present

No LEDs illuminated

Fault LED is ashing

and single LED is lit

for a sensor input

while actuated or

de-actuated

Blown internal fuse

Misaligned sensor and

actuator

Input screw terminal loose Fully install screw terminal

Defective sensor

Internal failure in door switch

monitor

Verify input power is within spec,

and then replace fuse

Check alignment and realign as

needed

See Fault diagnosis (next page)

to help determine problems

All inputs activated

(all input LEDs are o)

and the relays do not

activate

Defective unit Replace unit

19

Page 20

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

Fault diagnosis

If fault LED ashes and no sensor alignment problem can be found:

• Turn o power

• Unwire sensors from input terminals

• Power up unit

•

If fault LED begins to ash repeatedly after 2-3 seconds, the system needs to be

replaced. If the fault LEDs do not begin to ash:

• Remove power, then wire one sensor (R,W,B,O) connection at a time. Apply

power, waiting 2-3 seconds. Repeat sequence with all sensors until fault

LED begins to ash. This will be the sensor/actuator that is generating

the fault condition. Reevaluate alignment and terminal connections. If no

problem is found, replace the sensor and/or actuator in question

Approvals

UL508

Product specications

Input specications

FYQLA1-140R-3 120 VAC ± 15% <0.25A @ 45 to 65 Hz

Input devices (6) dedicated noncontact hall eect door

Switch voltage input 12 VDC (2 channel, sink/source)

Typical response time 20 ms (switch open to contact open)

Power up time 3 s

Output specications

Contact material AgCuNi + 0.2 um Au

Continuous current 5 mA to 5 A (N.O. contact)

Relay type 1 relay output, force guided connection,

Inrush current (max) 30 A for 20 ms

Maximum switching

characteristics

(Determined acc. to

EN60947-4-1/EN60947-5-1)

External fusing should be added

to protect the application and unit

from unforseen circumstances

sensors (50FY41 series)

normally open contacts

AC-1: 250 V/5 A (100,000 cycles)

AC-15: 230 V/3 A (150,000 cycles)

DC-1: 24 V/5 A (100,000 cycles)

DC-13: 24 V/1 A /0.1 Hz (100,000 cycles)

20

Page 21

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

Product specications (cont.)

Functional safety related parameters*

Safety function

Safe state

Standards/regulations ISO 13849-1 :2015/UL 508

Performance level acc. to ISO 13849-1 PL d

Structure acc. to ISO 13849-1 Category 3

MTTFd (years)

DC

d

PFH 2.06 x 10E

CCF

TM (years)

Pollution degree

Over-voltage category

Rated insulation voltage 250 V

Protection degree IP20, Class 1 “indoor use only”

Housing material 304 stainless steel

Internal hardware diagnostic fault

detection

Relay output closed only when sensors activated by

appropriate target

Relay output open

75850

98.6 %

-7

5 %

20

2

(OC) II

< 4 s

*The following assumptions were made during the failure modes, eects, and diagnostic analysis (FMEDA) of the

FYQLA1-140R-3:

• Failure rates are constant, wear out mechanisms are not included.

• Failure rates are based on the Siemens standard SN29500.

• Power supply failures are not included in the FMEDA, a loss of power introduces the safe state.

• It was assumed that the appearance of a safe error (e. g., output in safe state) would be repaired within 8

hours (e. g., remove sensor burnout).

• During the absence of the device for repairing, measures have to be taken to ensure the safety function (for

example: substitution by an equivalent device).

• The stress levels are average for an industrial environment and can be compared to the Ground Fixed

Classication of MIL-HDBK-217F. Alternatively, the assumed environment is similar to IEC 60654-1 Class C

(sheltered location) with temperature limits within the manufacturer’s rating and an average temperature over

a long period of time of 40 °C. Humidity levels are assumed within manufacturer’s rating. For a higher average

temperature of 60 °C, the failure rates should be multiplied with an experience based factor of 2.5. A similar

multiplier should be used if frequent temperature uctuation must be assumed.

21

Page 22

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

Product specications (cont.)

Ambient conditions

Operating temperature -25 °C to +70 °C noncondensing

Storage temperature -25 °C to +70 °C noncondensing

Terminal block - power and relays

Conductor cross section capacity 0.2 mm² to 2.5 mm² (22 to 14 AWG) Cu

Tightening torque 0.5 Nm (4.5 lb-in)

Strip length 7 mm

Connection method Terminal block - screw connection

Terminal block - sensor inputs

Conductor cross section capacity 0.5 mm² to 2.5 mm² (22 to 14 AWG) Cu

Tightening torque 0.5 to 0.6 Nm (4.5 to 5.3 lb-in)

Strip length 6 mm

Connection method Terminal block - screw connection

General data

Dimensions - FYQLA1-140R-3 203.0 mm H x 135.0 mm W x 58.0 mm D

Mechanical service life (approx.) > 1,000,000 operations

Indicators

Sensor status

Relay status

Fault status

LED red, one per channel / two per input

LED green (2), red (2)

LED red, ashing

(See indicator status table, pg 11, for indication

denitions)

22

Page 23

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

Dimensions

(for reference only—dimensions in mm)

4X Ø 5.56

L2

R1 R1

L1

V

120

1/8 A SLOW BLOW

250 VAC

203

1/8A

190

5A 250VAC

!

Twinsburg, Ohio 44087

Phone: (330)425–3555

.630 A 250 VAC

RELAY

CONDITION

CLOSED

OPEN

37

58

LOGIC AMPLIFIER

FYQLA1-140R-3

DISCONNECT 22K RESISTORS WHEN

1

2

R W B 0

R W B 0

LISTED

IND. CONT. EQ.

1EA5

CONNECTING SENSORS

3

R W B 04R W B 05R W B 06R W B 0

108

135

23

Page 24

North/Central American Headquarters

Pepperl+Fuchs Inc.

Twinsburg · Ohio · USA

Tel. +1 330 486 0002

E-Mail: fa-info@us.pepperl-fuchs.com

Subject to modifications • Copyright Pepperl+Fuchs • Printed in USA • TDOCT-B1Z0_ENG 09/18

Loading...

Loading...