Page 1

R

PROCESS AUTOMATION

MANUAL

Multi-Input/Output

Device

F2D0-MIO-Ex12.PA.*

R8D0-MIO-Ex12.PA.*

Page 2

Multi-Input/Output Device

With regard to the supply of products, the current issue of the following document is ap-

plicable: The General Terms of Delivery for Products and Services of the Electrical Indus-

try, published by the Central Association of the Electrical Industry (Zentralverband

Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the

supplementary clause: "Expanded reservation of proprietorship"

Page 3

Multi-Input/Output Device

1 Introduction................................................................................. 7

1.1 Content of this Document ................................................................... 7

1.2 Target Group, Personnel...................................................................... 7

1.3 Symbols Used ...................................................................................... 7

2 Product Specifications............................................................... 9

2.1 Overview and Application ................................................................... 9

2.2 Modes of Operation ............................................................................. 9

2.3 Hazardous Area Installation and Use............................................... 12

3 Installation and Commissioning ............................................. 14

3.1 Mounting and Dismounting............................................................... 14

3.2 Hardware Installation......................................................................... 15

3.2.1 R8D0-MIO* Cable and Connection Information ............................... 15

3.2.2 F2 Housing Degree of Protection ..................................................... 19

3.2.3 Grounding and Shielding ................................................................. 21

3.2.4 DIP Switch Settings ......................................................................... 23

3.3 PROFIBUS Ident Number Setting ..................................................... 25

3.4 Requirements for Commissioning.................................................... 26

3.5 Parameterization and Configuration Procedure ............................. 26

4 Configuration ............................................................................ 27

4.1 Host System Integration .................................................................... 27

4.2 Configuration of Cyclic Communication ......................................... 27

4.3 Cyclic Communication Data Description......................................... 29

4.3.1 Valve Coupler Mode and FD0-VC Compatibility Mode Variables ..... 29

4.3.2 Sensor Input Mode and FD0-BI Compatibility Mode Variables ........ 34

4.4 Cyclic Communication Data Structure............................................. 36

4.4.1 Valve Coupler Mode and FD0-VC-Ex4.PA Compatibility Mode ........ 36

4.4.2 Example of a Typical Configuration in Valve Coupler Mode ............. 37

4.4.3 Sensor Input Mode and FD0-BI-Ex12.PA Compatibility Mode ......... 37

4.4.4 Example of a Typical Configuration in Sensor Input Mode ............... 38

3

Page 4

Multi-Input/Output Device

5 Parameterization in Cyclic Communication (Set_Prm)......... 39

5.1 Condensed Status and Diagnosis.....................................................39

5.2 FD0-BI-Ex12 Compatibility Mode ...................................................... 39

6 Troubleshooting and Diagnosis.............................................. 41

6.1 LED Status and Error Indication........................................................ 41

6.2 Device Internal Errors ........................................................................42

6.3 Diagnosis ............................................................................................ 42

6.4 Initialization Run (Valve Coupler Mode)........................................... 46

7 Device-Related Parameters ..................................................... 49

7.1 Device Identification........................................................................... 49

7.2 Device Documentation .......................................................................49

8 Channel-Related Parameters for the Valve Coupler Modes . 50

8.1 Use of Setpoint Variables SP_D and RIN_D..................................... 50

8.2 Modes of Operation............................................................................ 51

8.2.1 Device Maintenance Modes............................................................. 51

8.2.2 Operating Modes.............................................................................. 51

8.2.3 Operating Mode "Auto" in Case of Fault ........................................... 51

8.2.4 Operating Mode "Remote-Cascade (RCas)".................................... 52

8.3 Functional Parameters .......................................................................52

8.3.1 Actuator Fail Action .......................................................................... 52

8.3.2 Sensor Usage .................................................................................. 53

8.4 Diagnostic Parameters.......................................................................54

8.4.1 Wire Check ...................................................................................... 54

8.4.2 Stroke Counter ................................................................................. 54

8.4.3 Time Monitoring ............................................................................... 54

8.4.4 Cyclic Function Test (Partial Stroke Test) .......................................... 56

4

Page 5

Multi-Input/Output Device

9 Channel-Related Parameters for the Sensor Input Modes ... 57

9.1 Modes of Operation ........................................................................... 51

9.1.1 Device Maintenance Modes ............................................................ 57

9.1.2 Operating Modes ............................................................................. 57

9.1.3 Operating Mode "Auto" in Case of Fault ........................................... 57

9.2 Functional Parameters....................................................................... 52

9.2.1 Sensor Mode ................................................................................... 57

9.2.2 Sensor-On Time .............................................................................. 58

9.3 Diagnostic Parameters ...................................................................... 54

9.3.1 Sensor Wire Check.......................................................................... 58

10 PACTware Multi-Input/Output Device Type Manager ............ 59

10.1 DTM Software Installation and Commissioning .............................. 59

10.2 Device Type Manager (DTM) Dialogs ............................................... 60

10.2.1 Online Dialogs ................................................................................. 61

10.2.2 Offline Dialogs ................................................................................. 62

10.2.3 Multi-Input/Output Device Type Manager User Interface.................. 63

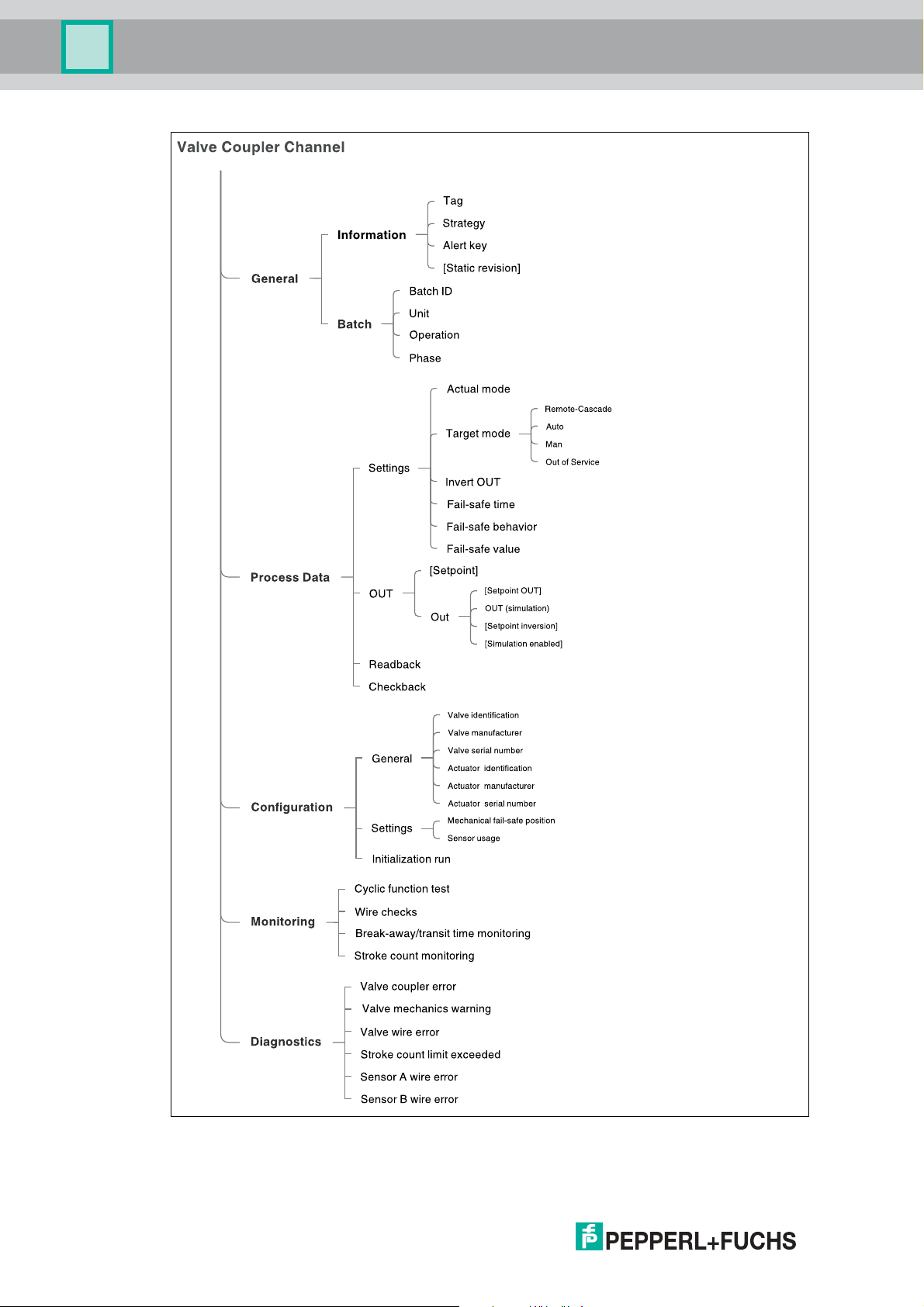

10.2.4 MIO DTM for Sensor Input Mode - Structural Diagram..................... 64

10.2.5 MIO DTM for Valve Coupler Mode - Structural Diagram................... 67

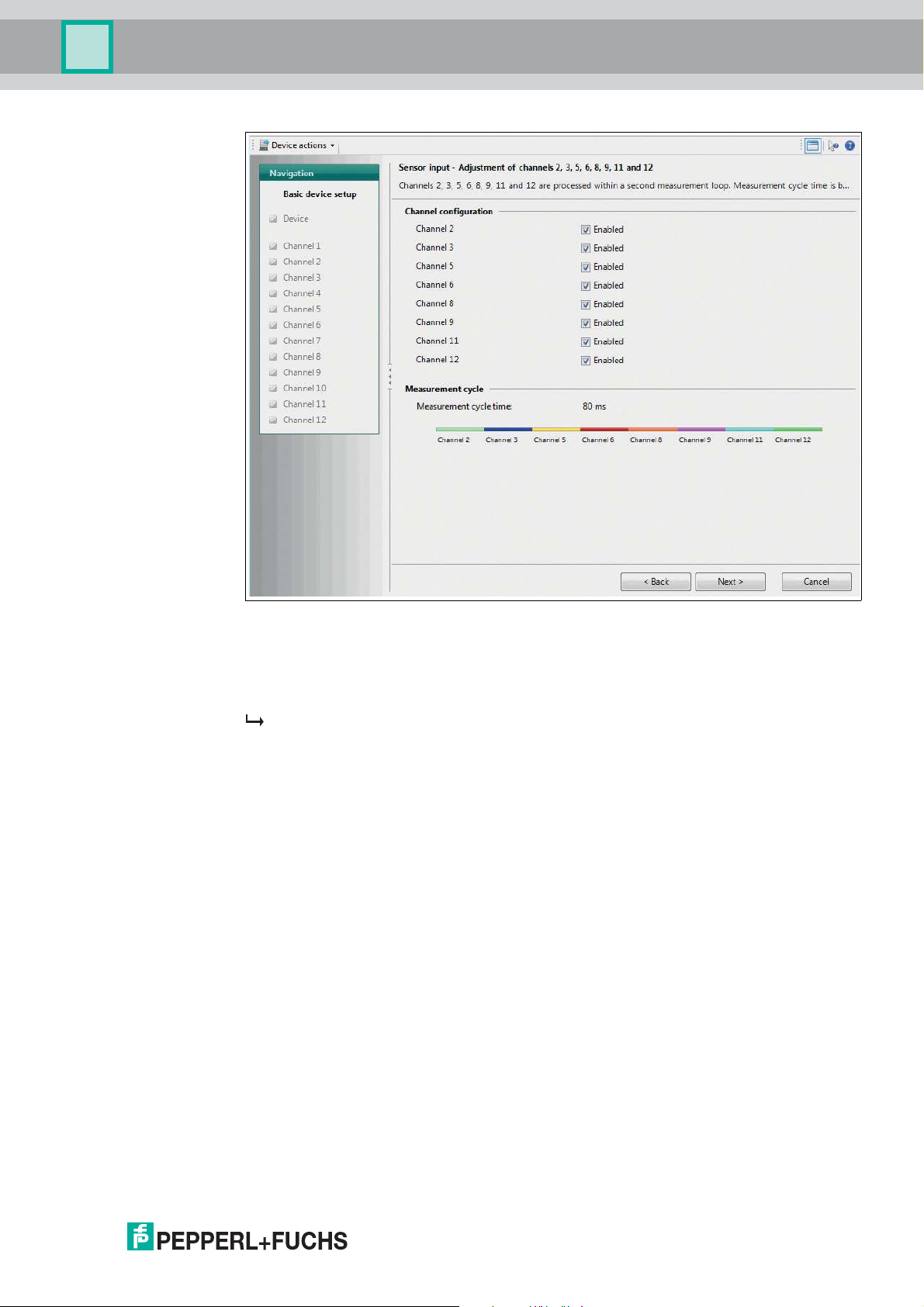

10.3 Basic Device Setup in Sensor Input Mode ...................................... 69

10.3.1 Tab "Device Information".................................................................. 74

10.3.2 Device Tab "Diagnostics" ................................................................. 75

10.3.3 Sensor Input Channels 1 ... 12......................................................... 77

10.3.4 Tab "General" ................................................................................... 78

10.3.5 Tab "Process Data" for a Binary Input............................................... 79

10.3.6 Tab "Process Data" for a Frequency Input ........................................ 81

10.3.7 Tab "Process Data" for a Counter..................................................... 83

10.3.8 Tab "Configuration" .......................................................................... 84

10.3.9 Channel Tab "Diagnostics"............................................................... 86

5

Page 6

Multi-Input/Output Device

10.4 Basic Device Setup in Valve Coupler Mode ..................................... 88

10.4.1 Tab "Device Information" .................................................................. 89

10.4.2 Device Tab "Diagnostics" ................................................................. 91

10.4.3 Valve Coupler Connections 1 ... 4 .................................................... 93

10.4.4 Tab "General".................................................................................... 93

10.4.5 Tab "Process Data"........................................................................... 95

10.4.6 Tab "Configuration"........................................................................... 98

10.4.7 Tab "Monitoring" ............................................................................. 100

10.4.8 Channel Tab "Diagnostics" ............................................................. 102

6

Page 7

Multi-Input/Output Device

Introduction

1 Introduction

1.1 Content of this Document

This document contains information that you need in order to use your product throughout the

applicable stages of the product life cycle. These can include the following:

■

Product identification

■

Delivery, transport, and storage

■

Mounting and installation

■

Commissioning and operation

■

Maintenance and repair

■

Troubleshooting

■

Dismounting

■

Disposal

Note!

This document does not substitute the instruction manual.

Note!

For full information on the product, refer to the instruction manual and further documentation on

the Internet at www.pepperl-fuchs.com.

The documentation consists of the following parts:

■

Present document

■

Instruction manual

■

Datasheet

Additionally, the following parts may belong to the documentation, if applicable:

■

EU-type examination certificate

■

EU declaration of conformity

■

Attestation of conformity

■

Certificates

■

Control drawings

■

Additional documents

1.2 Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation, maintenance, and

dismounting lies with the plant operator.

Only appropriately trained and qualified personnel may carry out mounting, installation,

commissioning, operation, maintenance, and dismounting of the product. The personnel must

have read and understood the instruction manual and the further documentation.

Prior to using the product make yourself familiar with it. Read the document carefully.

1.3 Symbols Used

This document contains symbols for the identification of warning messages and of informative

messages.

2018-07

7

Page 8

Multi-Input/Output Device

Introduction

Warning Messages

You will find warning messages, whenever dangers may arise from your actions. It is mandatory

that you observe these warning messages for your personal safety and in order to avoid

property damage.

Depending on the risk level, the warning messages are displayed in descending order as

follows:

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants, or result in

their complete failure.

Informative Symbols

Note!

This symbol brings important information to your attention.

Action

This symbol indicates a paragraph with instructions. You are prompted to perform an action or

a sequence of actions.

2018-07

8

Page 9

Multi-Input/Output Device

Product Specifications

2 Product Specifications

2.1 Overview and Application

The FieldConnex® Multi-Input/Output device (MIO) for PROFIBUS PA provides discrete inputs,

discrete outputs, 1 frequency input, or 1 counter to process control systems. The device is

suitable for DIN rail mounting and field installation with different housing options. The F2 type

housing is made of sturdy cast aluminum for installation in rough environments. Fieldbus and

sensor-actuator cable entries can be selected individually from a range of cable glands.

Optionally, either screw terminals or spring terminals can be chosen. Contact your

Pepperl+Fuchs representative for further information on housing options.

The device can be installed in hazardous areas Zones 1, 21, 2, 22, and Division 1, 2.

PROFIBUS PA and input/output sensor and actuator connections are rated intrinsically safe for

installation in Zone 0 and Division 1.

The device provides different configurable modes of operation.

The valve coupler mode allows connecting 4 low-power valves with 2 end position inputs per

valve.

The sensor input mode allows connecting up to 12 binary sensors. 4 sensor inputs are

designed to support vibrating forks for level control. One of these inputs is designed to support

a frequency or counter input.

The MIO is intended to be used as a replacement for Pepperl+Fuchs process interfaces FD0VC-Ex4.PA and FD0-BI-Ex12.PA.

For device configuration, a device type manager (DTM) for FDT-based frame applications is

available. Also, a device description (DD) for the Siemens Process Device Manager (PDM) is

available.

2.2 Modes of Operation

The device supports 12 hardware channels which can be configured as inputs and outputs.

The functional configuration of the channels is determined by selecting a dedicated mode of

operation.

Valve Coupler Mode

In the valve coupler mode, the channels 1, 4, 7, and 10 are used to control 4 low-power valves.

The channels 2, 3, 5, 6, 8, 9, 11, and 12 are used as valve position feedback inputs for

NAMUR proximity switches or mechanical switches. Condition monitoring functions like stroke

counter, partial stroke test, and travel time survey enable you to detect evolving faults, before

they become critical for the process control.

Refer to the technical data of the MIO for specification of compatible valves and sensors. A list

of compatible low-power valves and NAMUR sensors are available on the Pepper+Fuchs

website.

FD0-VC-Ex4.PA Compatibility Mode

This mode allows the use of *D0-MIO-Ex12.PA* in an existing installation as a replacement for

FD0-VC-Ex4.PA. In order to activate this mode, use the GSD file of FD0-VC-Ex4.PA. The mode

is activated during the start-up of cyclic data exchange. Use the device type manager or device

description of the *D0-MIO-Ex12.PA* to adjust the device parameters according to the

replaced FD0-VC-Ex4.PA.

PROFIBUS Profile 3.02 Valve Coupler Compatibility Mode

PROFIBUS PA profile 3.02 defines an interoperability mode for a 4-channel valve coupler. The

corresponding GSD file is available on the PROFIBUS International website. Use the device

type manager or device description of the *D0-MIO-Ex12.PA* in order to adjust the device

parameters.

2018-07

9

Page 10

Multi-Input/Output Device

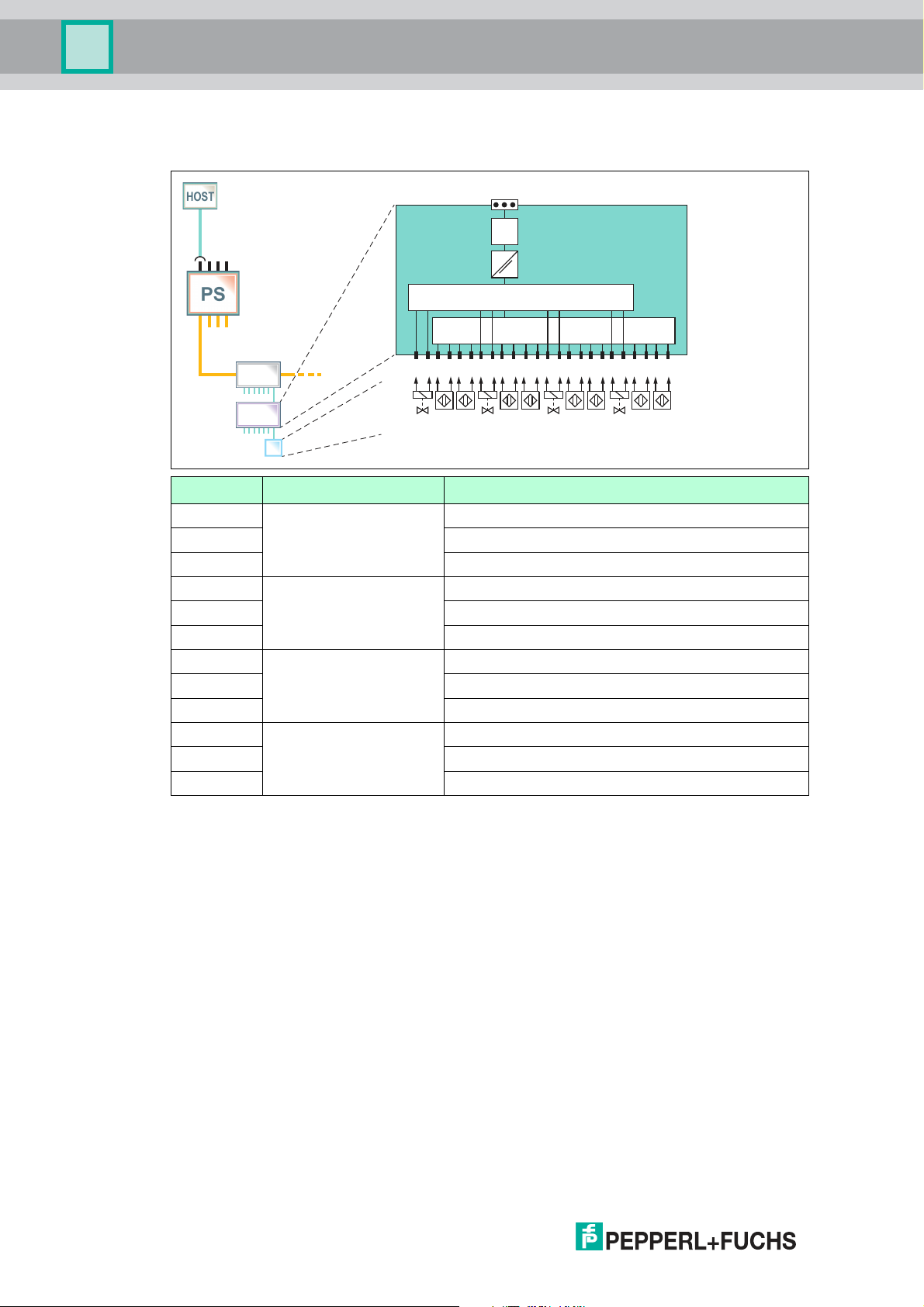

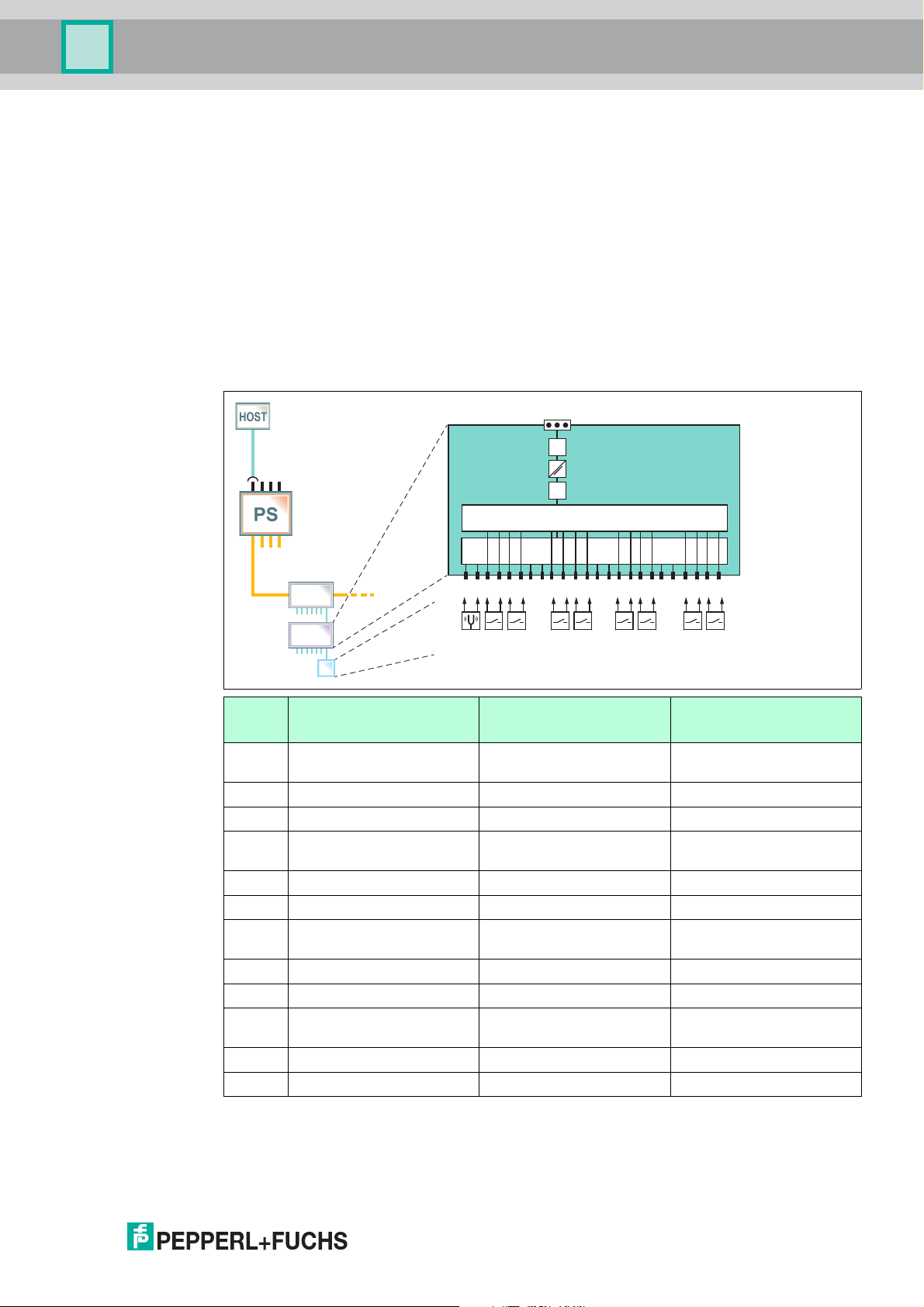

Zone 1

- +S

MAU

µC

CH1

+ - + - + - + - + - + - + - + - + -

CH4 CH7 CH10

A B A B A B A B

MUX

+

- + - + -

PI

FB/SP

Product Specifications

Modes: Valve Coupler, FD0-VC-Ex4.PA Compatibility, PA Profile 3.02 Valve Coupler

Compatibility

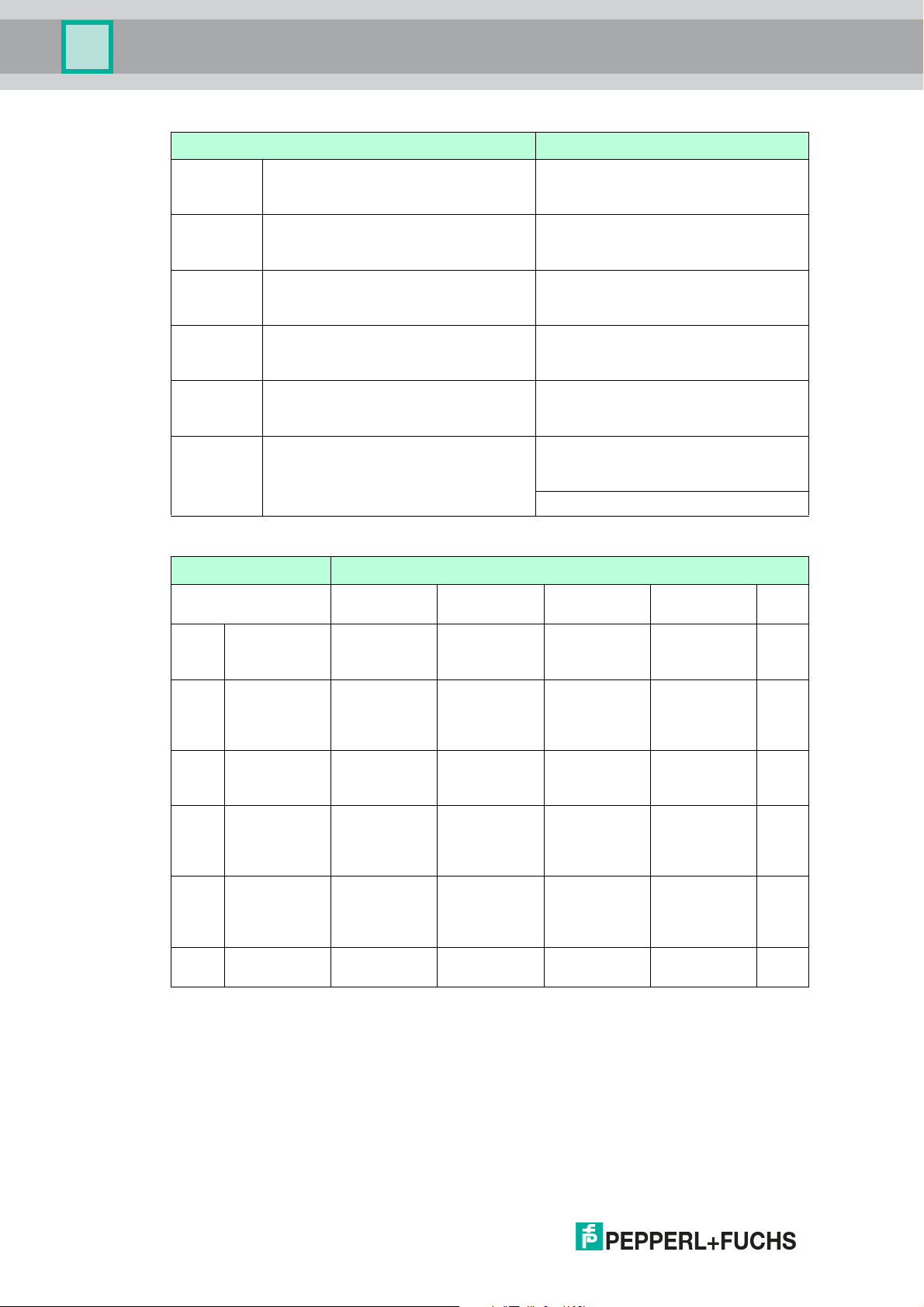

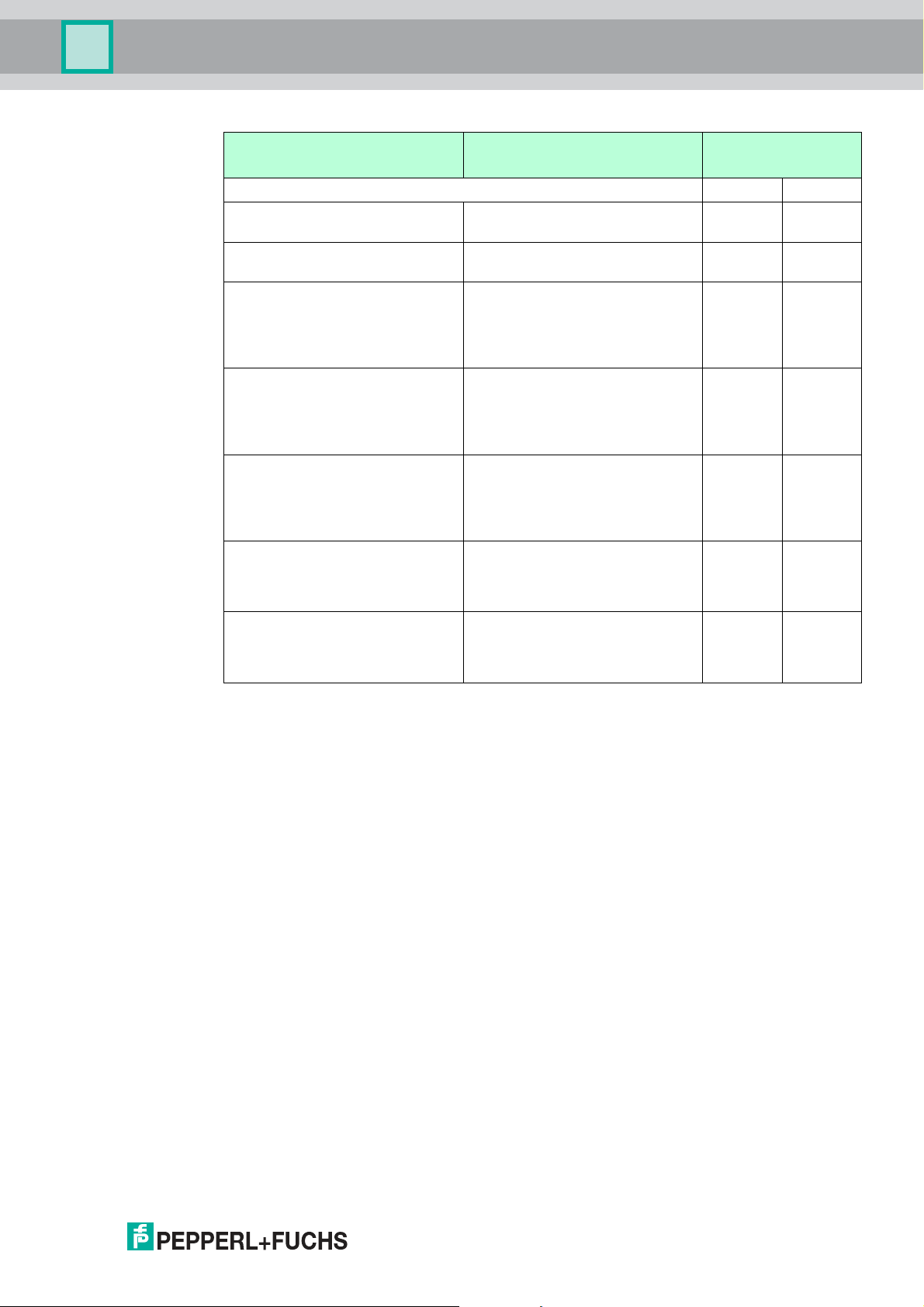

Channel Description Valve Coupler Mode

1 VC Channel 1,2,3 Output 1, low-power valve

2 Position feedback sensor/switch A for output 1

3 Position feedback sensor/switch B for output 1

4 VC Channel 4,5,6 Output 2, low-power valve

5 Position feedback sensor/switch A for output 2

6 Position feedback sensor/switch B for output 2

7 VC Channel 7,8,9 Output 3, low-power valve

8 Position feedback sensor/switch A for output 3

9 Position feedback sensor/switch B for output 3

10 VC Channel 10,11,12 Output 4, low-power valve

11 Position feedback sensor/switch A for output 4

12 Position feedback sensor/switch B for output 4

Sensor Input Mode

The device samples the inputs in 2 independent cycles. Channels 1, 4, 7, and 10 are intended

to be used for sensing multiplexed binary inputs as vibrating forks, NAMUR sensors, or

mechanical switches. Channel 1 can also be configured to be used as a frequency or counter

input. If the channel 1 frequency or counter input is activated, channels 4, 7, and 10 are

deactivated. In the device type manager, the ON-time of channel 1, 4, 7, and 10 can be

adjusted individually between 10 ms ... 10 000 ms.

10

As a parameter, the ON-time of channel 1, 4, 7, and 10 can be adjusted individually between

10 ms ... 11 000 ms.The total cycle time is the sum of the 4 individual ON-times.

Channels 2, 3, 5, 6, 8, 9, 11, and 12 are intended to be used for sensing multiplexed binary

inputs as NAMUR sensors and mechanical switches. The sampling time of 10 ms is not

adjustable. The total cycle time is calculated as follows: number of used channels * 10 ms

(minimum 50 ms). If all 8 sensors are used, the total cycle time is 80 ms.

Refer to the technical data of the MIO for the specification of compatible sensors. A list of

compatible NAMUR sensors is available on the Pepperl+Fuchs website.

2018-07

Page 11

Multi-Input/Output Device

MUX

Zone 1

-

+S

MAU

µC

MUX

CH1

+ -

+ - + - + - + -

+ -

+ - + - + - + -

+ - + -

CH4 CH7 CH10

CH2 CH3 CH5 CH6 CH8 CH9 CH11 CH12

PI

FB/SP

Product Specifications

FD0-BI-Ex12 Compatibility Mode

This mode allows the use of *D0-MIO-Ex12.PA* in an existing installation as a replacement for

FD0-BI-Ex12.PA. In order to activate this mode, use the GSD file of FD0-BI-Ex12.PA. The

configuration of the FD0.BI-Ex12.PA takes place during the start-up of the cyclic data

exchange. The device type manager allows read-only access to the configuration data. No

further adjustments are required to update an existing installation with *D0-MIO-Ex12.PA*.

PROFIBUS Profile 3.02 Sensor Input Compatibility Mode

PROFIBUS PA profile 3.02 defines an interoperability mode for a 12-channel sensor input. Use

the device type manager or device description of the *D0-MIO-Ex12.PA* in order to adjust the

device parameters.

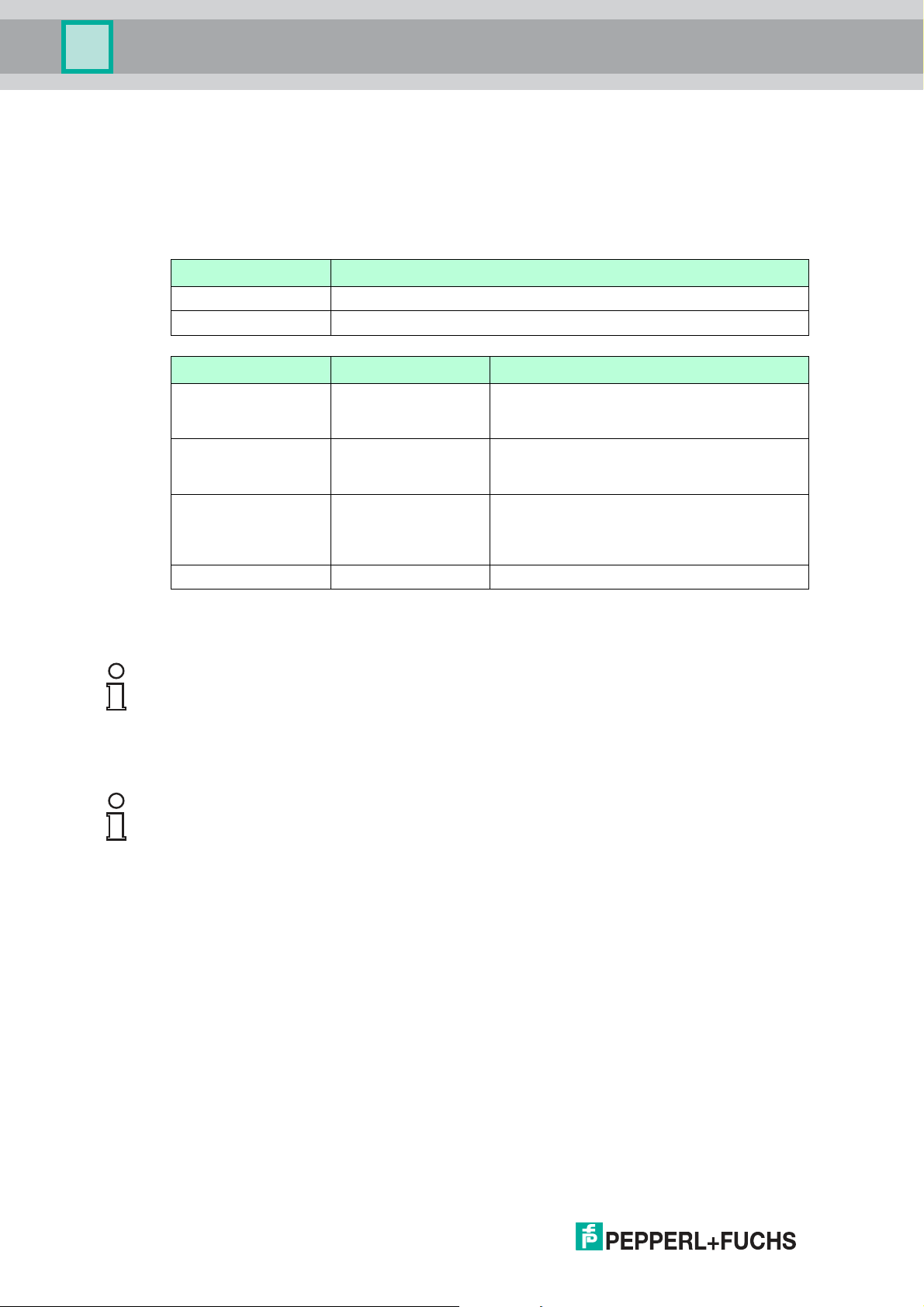

Modes: Sensor Input, FD0-BI-Ex12.PA Compatibility, PA Profile 3.02 Sensor Input

Compatibility

Chann

el Sensor Input Modes Frequency Input Mode Counter Input Mode

1 Vibration fork or

Frequency input Counter input

sensor/switch

2 Sensor/switch Sensor/switch Sensor/switch

3 Sensor/switch Sensor/switch Sensor/switch

4 Vibration fork or

Disabled Disabled

sensor/switch

5 Sensor/switch Sensor/switch Sensor/switch

6 Sensor/switch Sensor/switch Sensor/switch

7 Vibration fork or

Disabled Disabled

sensor/switch

8 Sensor/switch Sensor/switch Sensor/switch

9 Sensor/switch Sensor/switch Sensor/switch

10 Vibration fork or

sensor/switch

11 Sensor/switch Sensor/switch Sensor/switch

Disabled Disabled

12 Sensor/switch Sensor/switch Sensor/switch

2018-07

11

Page 12

Multi-Input/Output Device

Product Specifications

2.3 Hazardous Area Installation and Use

The device may be operated in Zone 1.

For applications in Zone 1, the type of protection must be Ex i according to Entity or FISCO.

The device may be installed in Zone 2.

The type of protection for the trunk interface is Ex ec or Ex ic according to Entity or FISCO.

Independent of the type of protection of the fieldbus interface, the inputs/outputs remain

intrinsically safe and may be installed in Zone 1.

Zone 2

Danger!

Explosion hazard from live wiring of non-intrinsically safe circuits

If you connect or disconnect energized non-intrinsically safe circuits in a potentially explosive

atmosphere, sparks can ignite the surrounding atmosphere.

Only connect or disconnect energized non-intrinsically safe circuits in the absence of a

potentially explosive atmosphere.

Type of Protection "Ex i"

Danger!

Explosion hazard from wrong separation distances

Non-observance of the separation distances between circuits can result in added currents or

voltages. This can result in a current/voltage flashover generating sparks. The sparks can ignite

the surrounding potentially explosive atmosphere.

Ensure you observe the compliance of the separation distances according to

IEC/EN 60079–14.

Danger!

Explosion hazard from wrong calculation of verification of intrinsic safety

If you do not consider the maximum permissible peak values of all components when

connecting intrinsically safe devices with intrinsically safe circuits of associated apparatus, this

can lead to added currents or voltages. This, in return, can result in a current/voltage flashover

generating sparks. The sparks can ignite the surrounding potentially explosive atmosphere.

Ensure you observe IEC/EN 60079-14 and IEC/EN 60079-25 for the verification of intrinsic

safety.

Type of Protection "Ex ec"

Danger!

Explosion hazard from pollution

12

An excessively polluted surface of the device can become conductive and consequently ignite

a surrounding potentially explosive atmosphere.

Ensure that you install the device only in environments with a pollution degree 2 or better

according to IEC/EN 60664–1.

2018-07

Page 13

Multi-Input/Output Device

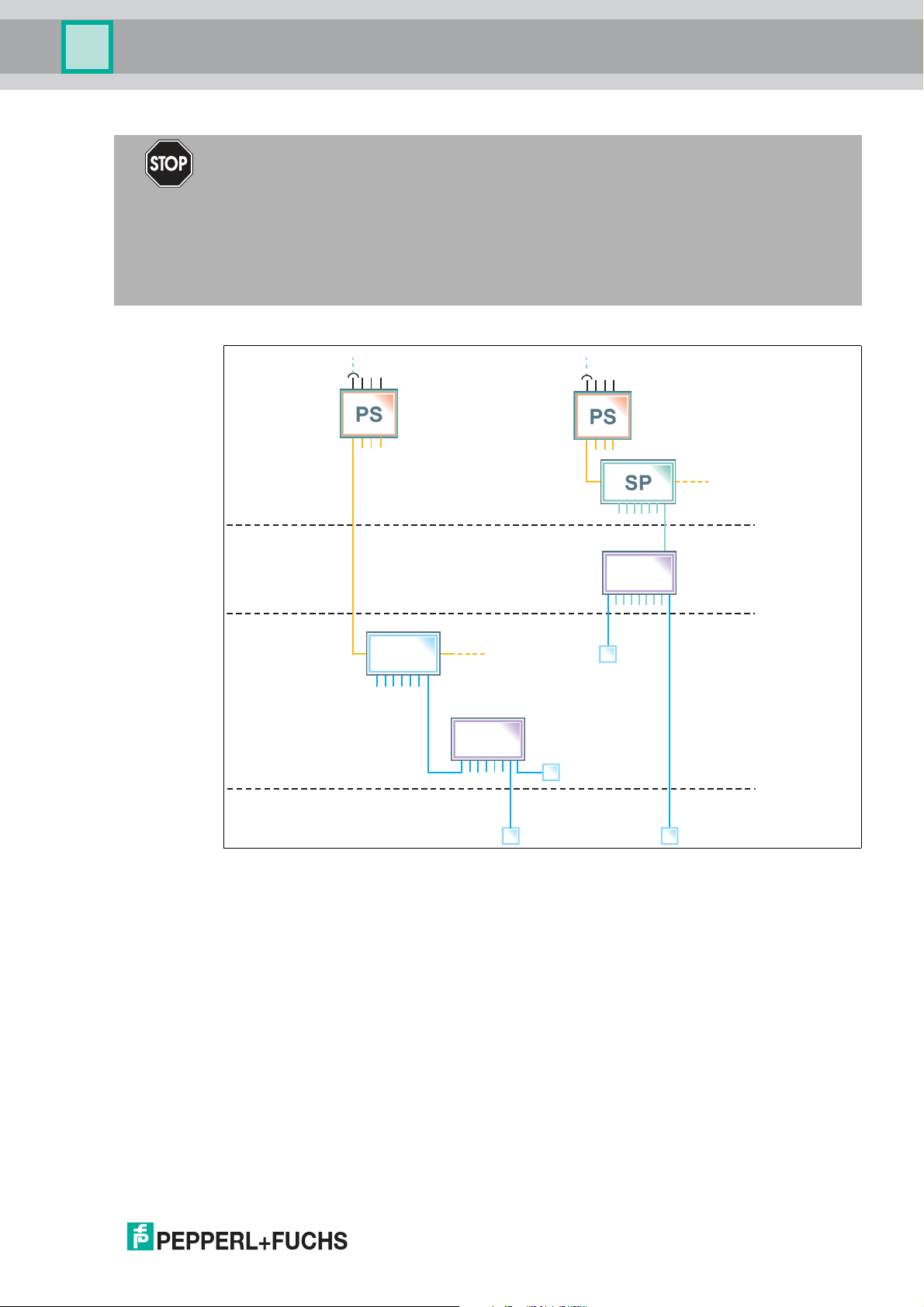

Zones 2, 22

Zone 0

Zones 1, 21

Non-Explosion

Hazardous

Area

Ex ic FISCO/

Ex ec

Ex i

Ex ia

FISCO

PI

*MIO-Ex12*

PI

*MIO-Ex12*

FB

Product Specifications

Danger!

Explosion hazard from exposure to potentially explosive gas atmosphere

If the device is installed in Zone 2 without mounting it in a sufficiently suitable enclosure, gas,

dust, water or other external interferences can cause the live device to spark. The sparks can

ignite the surrounding potentially explosive atmosphere.

Only mount the device in an enclosure with degree of protection IP54 according to

IEC/EN 60529. The enclosure must have an EU declaration of conformity according to the

ATEX Directive for at least equipment category 3G.

Hazardous Area Installation Options

Figure 2.1 Installation options for the multi-input/output device in the hazardous area

Observe the EC-type-examination certificate or the statement of conformity. Pay particular

attention to any "special conditions" that may be indicated.

2018-07

13

Page 14

Multi-Input/Output Device

2

3

4

1

Installation and Commissioning

3 Installation and Commissioning

In the following section you find information on how to install and commission the multiinput/output (MIO) device in your fieldbus topology.

Danger!

Danger to life from using damaged or repaired devices.

Using a defective or repaired device can compromise its function and its electrical safety.

■

Do not use a damaged or polluted device.

■

The device must not be repaired, changed or manipulated.

■

If there is a defect, always replace the device with an original device from Pepperl+Fuchs.

Danger!

Explosion hazard from damaged electronic components

Premature wear of electronic components in a device that was previously used in a general

electrical installation can cause sparks that can ignite the surrounding potentially explosive

atmosphere.

Never install devices that have already been operated in general electrical installations in

electrical installations used in combination with hazardous areas!

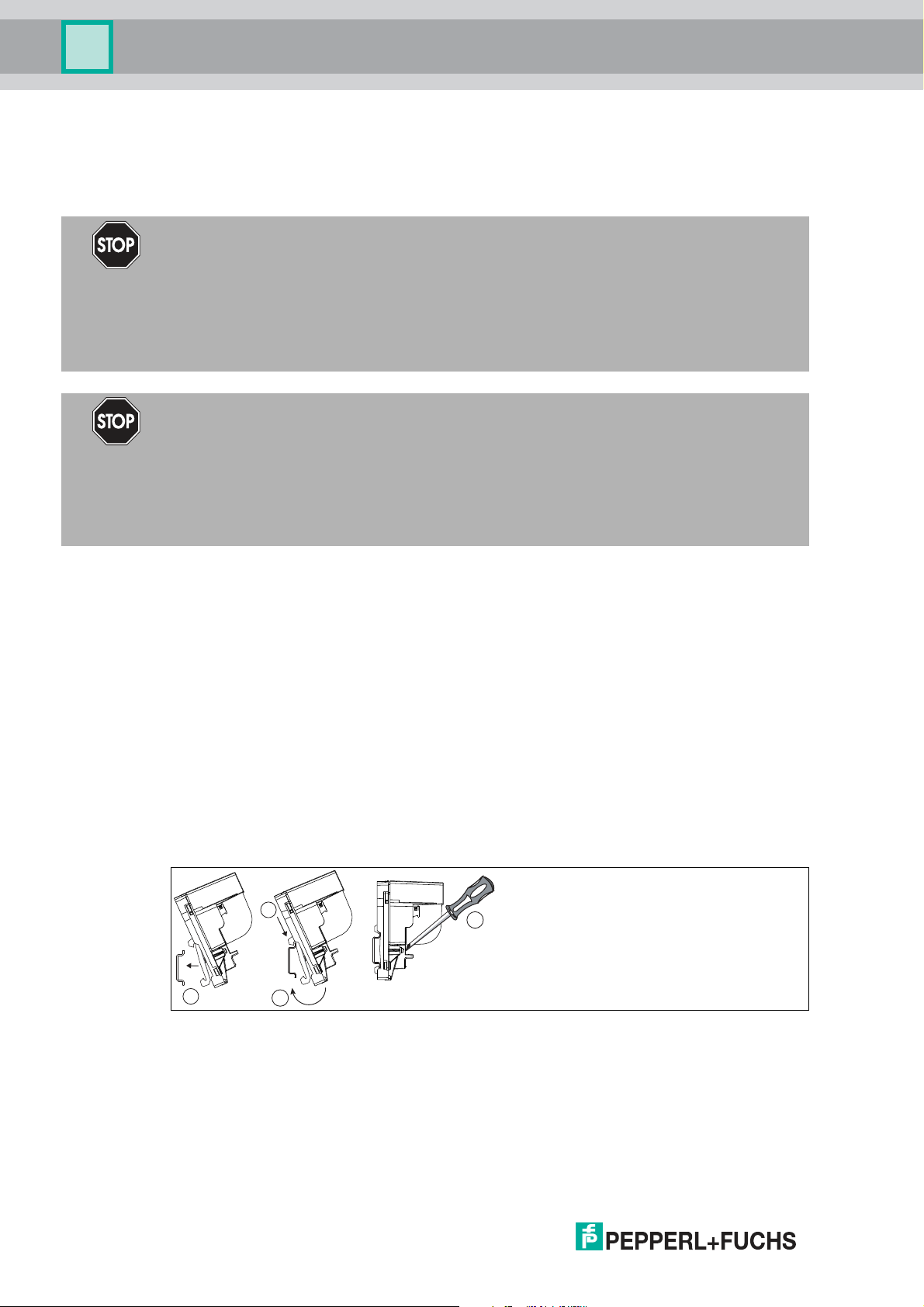

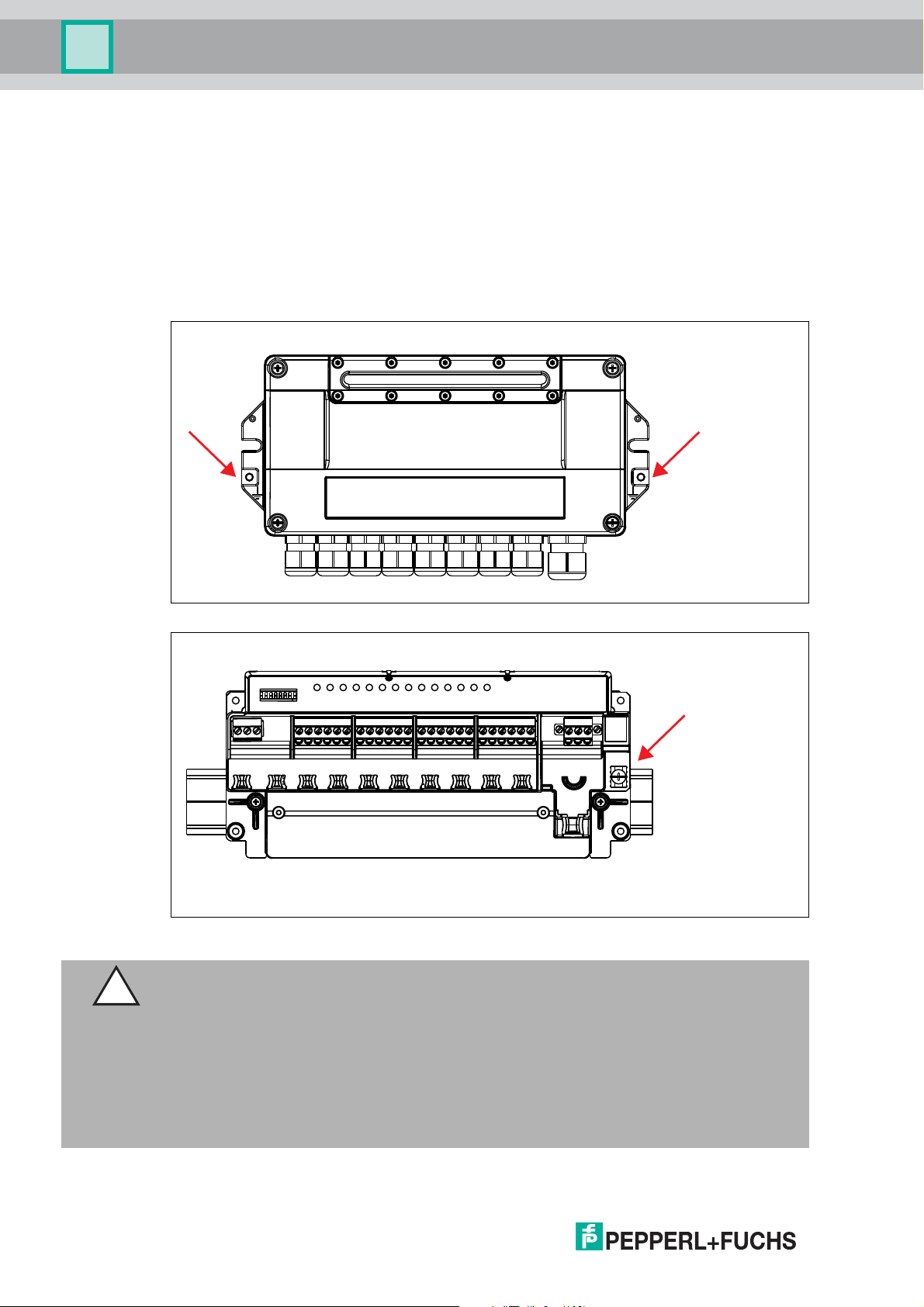

3.1 Mounting and Dismounting

Mounting/Dismounting F2D0-MIO*

F2D0-MIO* is designed for panel (wall) mounting.

■

Select mounting material that is suitable for the sub-surface (the wall).

■

Ensure that the mounting material guarantees secure fastening.

■

To attach the device: use 2 fixing screws with a diameter of 6 mm.

■

To dismount the device: Undo the fixing screws and take the device off the wall.

Mounting/Dismounting R8D0-MIO*

R8D0-MIO* is designed for mounting on a 35 mm DIN mounting rail in accordance with

EN 50022.

Mounting the R8D0-MIO* Electronics onto the DIN Mounting Rail

1 Place the R8D0-MIO* on the DIN mounting rail.

2 Use the top hook in order to hook the electronics onto the DIN mounting rail.

3 Move the bottom hook over the lower end of the DIN mounting rail.

4 Tighten the 2 fastening screws to attach the electronics on the DIN mounting rail.

Tightening torque: 0.4 Nm

To dismount the device: Take off the device in reverse order.

2018-07

14

Page 15

Multi-Input/Output Device

Installation and Commissioning

R8D0-MIO* Installation

Depending on the application, the R8D0-MIO* must be mounted in a suitable environment.

If mounted in Zone 2 for an Ex ec application, the environment (housing or enclosure) must

ensure the following:

■

IP54 in accordance with IEC 60529 for hazardous area Zone 2

■

Pollution degree 2 or better according to IEC/EN 60664-1

3.2 Hardware Installation

3.2.1 R8D0-MIO* Cable and Connection Information

Danger!

Explosion hazard from insufficient insulation

Insufficient dielectric strength of insulators between intrinsically safe circuits may lead to

interferences and to charge transfers that cause sparks. These sparks can ignite a potentially

explosive atmosphere.

Ensure that the dielectric strength of the insulation between intrinsically safe circuits is at least

500 V according to IEC/EN 60079–14.

Danger!

Explosion hazard or danger to life from inadequate installation of cables and connection lines

If you do not install cables and connection lines according to the instructions given in the

instruction manual, this can generate sparks that can ignite the surrounding potentially

explosive atmosphere. Furthermore, insufficient installation practice can result in electric

shock.

Ensure you carry out any cable gland installations in accordance with the instructions given in

the instruction manual.

Danger!

Explosion hazard from connection damage

Manipulating connections outside of the specified ambient temperature range can lead to

material damage, resulting in an unwanted failure of the connection. This could result in an

increased explosion hazard in potentially explosive atmospheres.

Only manipulate connections in the specified ambient temperature range.

Temperature range: -5 C° ... +70 C°

Danger!

Danger to life from incorrect installation

Incorrect installation of cables and connection lines can compromise the function and the

electrical safety of the device.

■

Observe the permissible core cross section of the conductor.

■

When using stranded conductors, crimp wire end ferrules on the conductor ends.

■

Use only one conductor per terminal.

■

When installing the conductors the insulation must reach up to the terminal.

■

Observe the tightening torque of the terminal screws.

The following section describes the different connection details of the multi-input/output with

particular reference to the torques required for a safe installation.

2018-07

15

Page 16

Multi-Input/Output Device

Installation and Commissioning

For any terminal connections, observe the following cable and connection information.

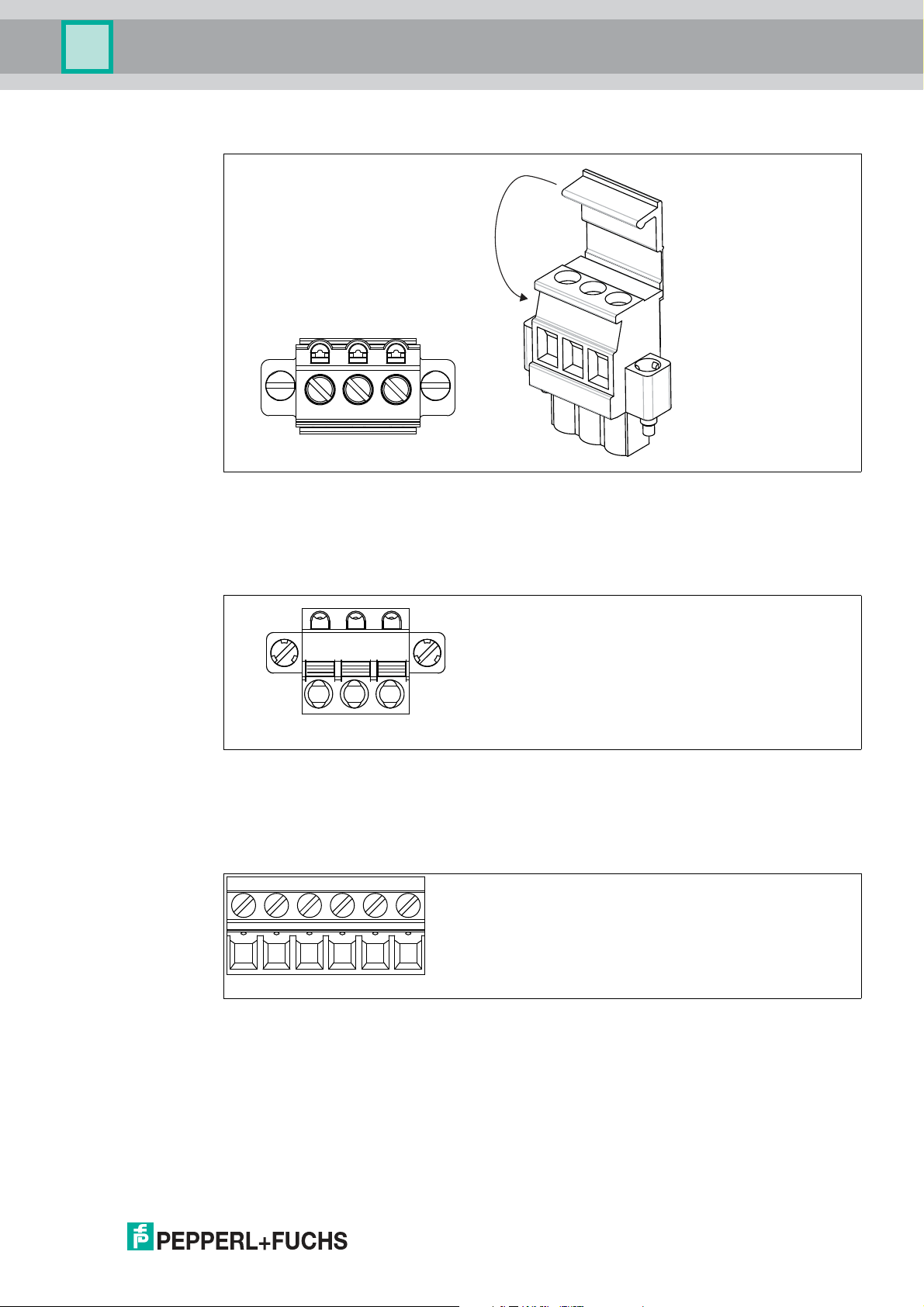

Screw Terminals: Cable and Connection Information

■

Permissible core cross section:

• Screw terminals with flexible or rigid wires: 0.2 mm2... 2.5 mm

■

Insulation stripping length: 7 mm

■

If you use stranded connectors: Crimp on wire end ferrules

■

Ensure that connectors are mechanically locked

■

Torque required for tightening terminal screws: 0.5 Nm ... 0.6 Nm

Spring Terminals: Cable and Connection Information

■

Permissible core cross section:

• Spring terminals with flexible or rigid wires: 0.5 mm2... 2.5 mm

■

Insulation stripping length: 10 mm

■

Ensure that connectors are mechanically locked

■

Torque required for tightening terminal screws: 0.5 Nm ... 0.6 Nm

2

2

Tip

Double-check that the correct torques are used when un- and reinstalling the terminal during

wiring activities!

Connecting the Trunk

The multi-input/output is connected to the trunk line via designated screw or spring terminals.

Danger!

Explosion hazard from open or missing trunk terminal cover

If the device is installed Zone 2 and powered by a non-intrinsically safe power source, carrying

out hot work on the input/output terminals with an uncovered trunk terminal can lead to contact

with solid particles or tools. This can cause the live device to spark. The sparks can ignite the

surrounding potentially explosive atmosphere.

Ensure that the trunk terminal cover is present and correctly snapped onto the connector

housing to guarantee IP30 rating.

16

2018-07

Page 17

Multi-Input/Output Device

Click!

−+ S

−+ S

+ –

+ –

+ –

Installation and Commissioning

Trunk Connection with Covered Screw Terminal

+ Segment +

- Segment -

S Shield connection

Trunk Connection with Spring Terminal

+ Segment +

- Segment -

S Shield connection

Multi-Input/Output Screw Terminal

2018-07

6-pin screw terminal for multi-inputs/outputs

+ Input/output +

- Input/output -

17

Page 18

Multi-Input/Output Device

+ –

+ –

+ –

PWRCOM/

ERR

21

3

4

6

5

7

8 91011 12

ERR

CH

Configuration

ON

1 2 3 4 5 6 7 8

T G R

Extension

+ -1+ -2+ -3+ -

4

+ -

5

+ -6+ -7+ -

8

+ -

9

+ -

10

+ -

11

+ -

12

+ - S

Bus

Installation and Commissioning

Multi-Input/Output Spring Terminal

6-pin spring terminal for multi-inputs/outputs

+ Input/output +

- Input/output -

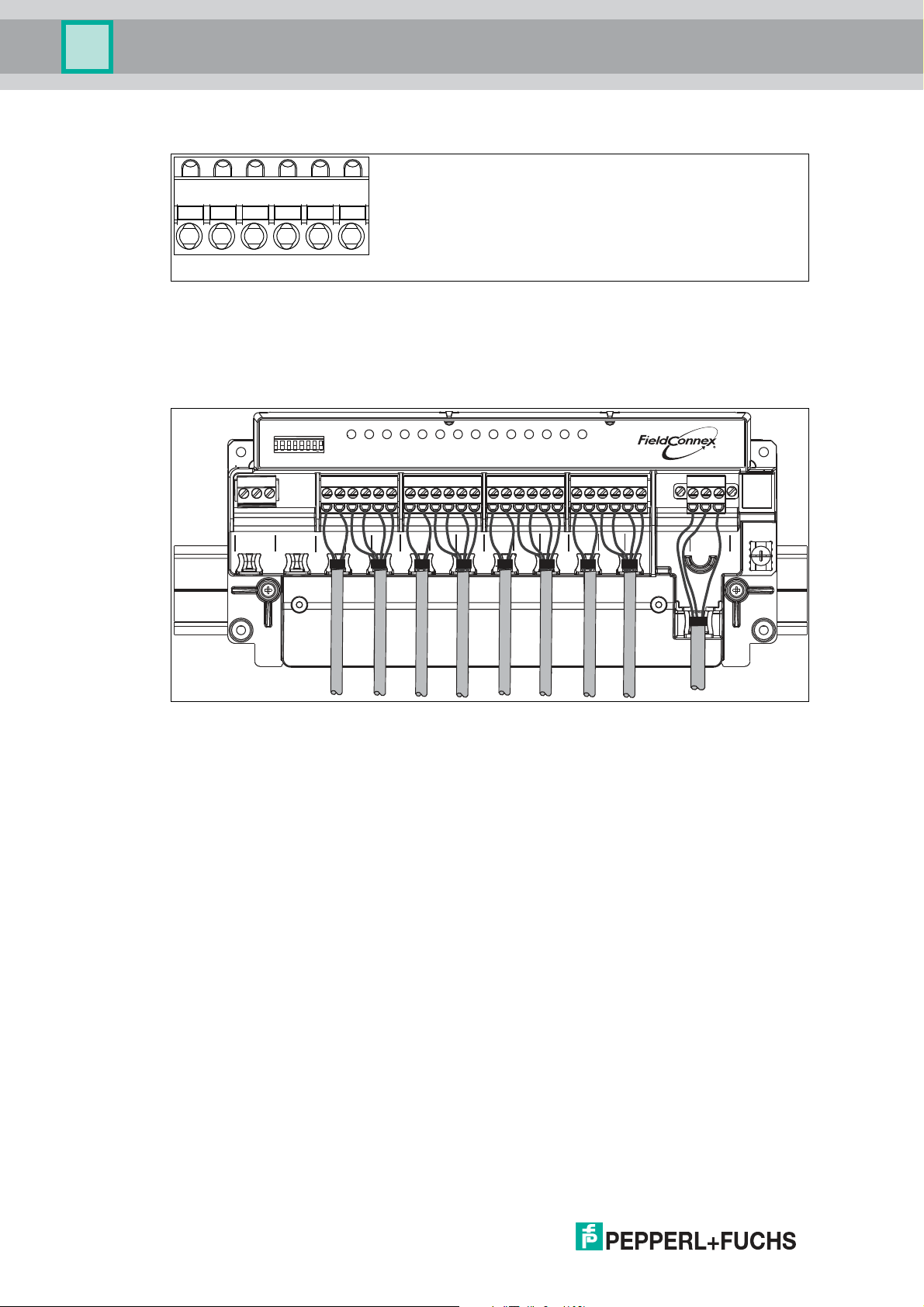

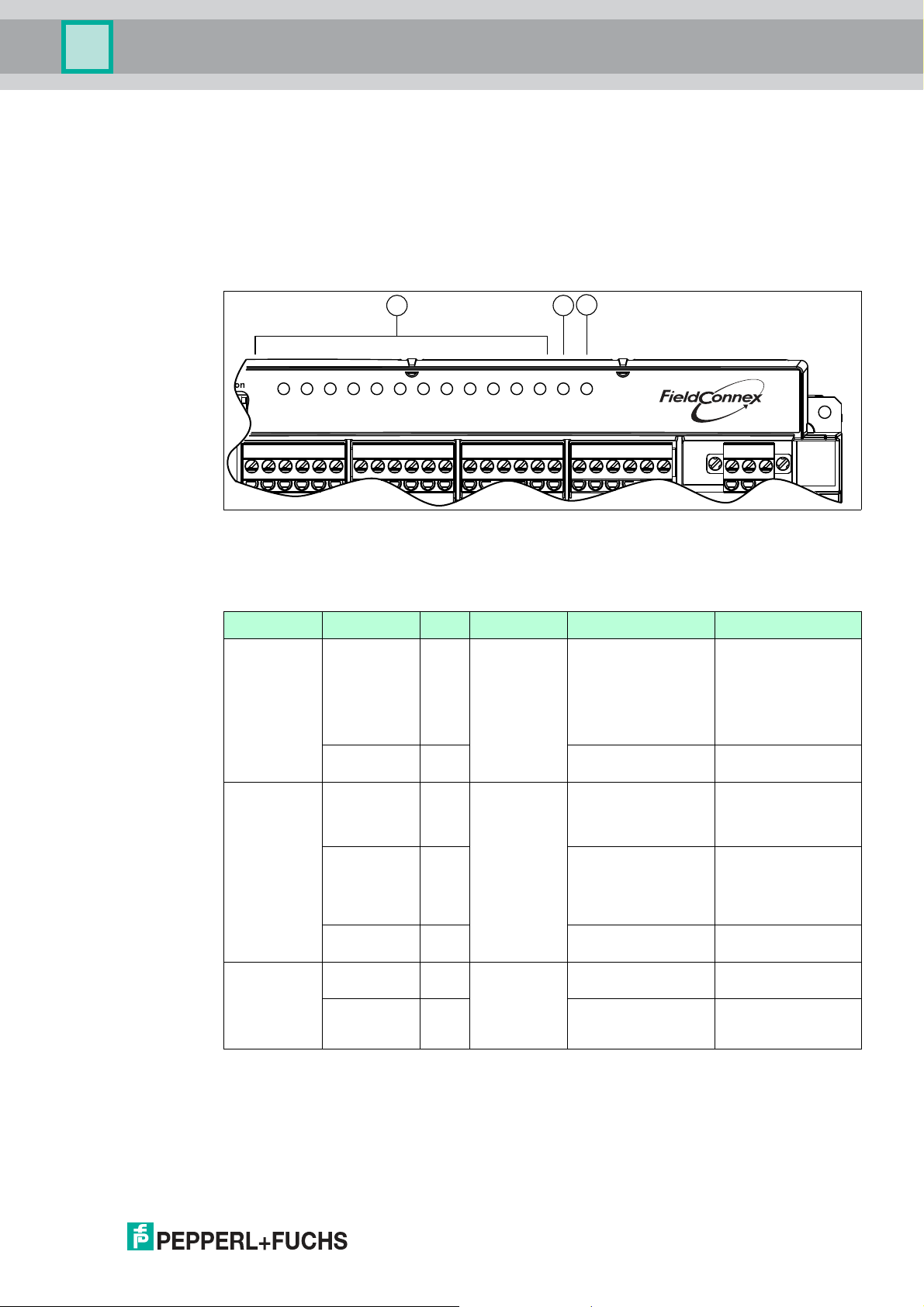

R8D0-MIO* Sample Connection Diagram

The connection diagram shows the sample connection of the multi-input/output as a valve

coupler

Cable Position Fixture

The R8D0-MIO* electronics provides special fixtures for cable ties. To keep the cabling in a

safe position, use the fixtures with cable ties.

Cable tie width: up to 4 mm

Using Mechanical Switches

If mechanical contacts are used as valve final position feedbacks, observe the following. The

lead breakage and short circuit monitoring can be used after adding series and parallel

resistors in the lead. In this case the prerequisites are:

■

1 x 1-kOhm series resistance for monitoring short circuit

■

1 x 10-kOhm parallel resistance for lead breakage detection

18

2018-07

Page 19

Multi-Input/Output Device

Installation and Commissioning

3.2.2 F2 Housing Degree of Protection

The following section contains information concerning the installation and sealing of the cable

glands and the housing cover.

Danger!

Explosion hazard or danger to life from inadequate installation of cable glands

If you do not install cable glands according to the instructions given in the instruction manual,

this can generate sparks that can ignite the surrounding potentially explosive atmosphere.

Furthermore, insufficient installation practice can result in electric shock.

Ensure you carry out any cable gland installations in accordance with the instructions given in

the instruction manual.

Fixing the Housing Cover

Before closing the housing cover: Visually inspect the housing for any visible signs of damage

on the cover seal. If damaged, replace the seal with an original seal wear part.

Tightening torque for the screws of the housing cover: 2.5 Nm

General Information on the Installation of Cable Glands

When installing cable glands, observe the following:

■

Only insert permanently laid cables and wires into the cable glands.

• Ensure that the cables laid do not execute any strain on the cable glands.

• For permissible cable diameters, refer to the respective datasheet.

■

Use an appropriate strain relief clamp, e.g., a suitable cable clamp.

■

Seal unused cable glands with a suitable plug or replace them with appropriate screw

plugs. Observe the required degree of protection IP66.

• For a choice of stop plugs and screw plugs, refer to the respective datasheets.

• Note that the ambient temperature range can be restricted by the stopping plug.

■

Protect plastic cable glands against mechanical hazard.

■

Ensure you use the correct tightening torques when installing cable glands or plugs. For

detail see tables with torque information below.

The specific technical data may vary depending on the type of cable gland or plug you use for

your installation. The following cable glands or plug types are documented and information is

available at www.pepperl-fuchs.com:

2018-07

19

Page 20

Multi-Input/Output Device

Installation and Commissioning

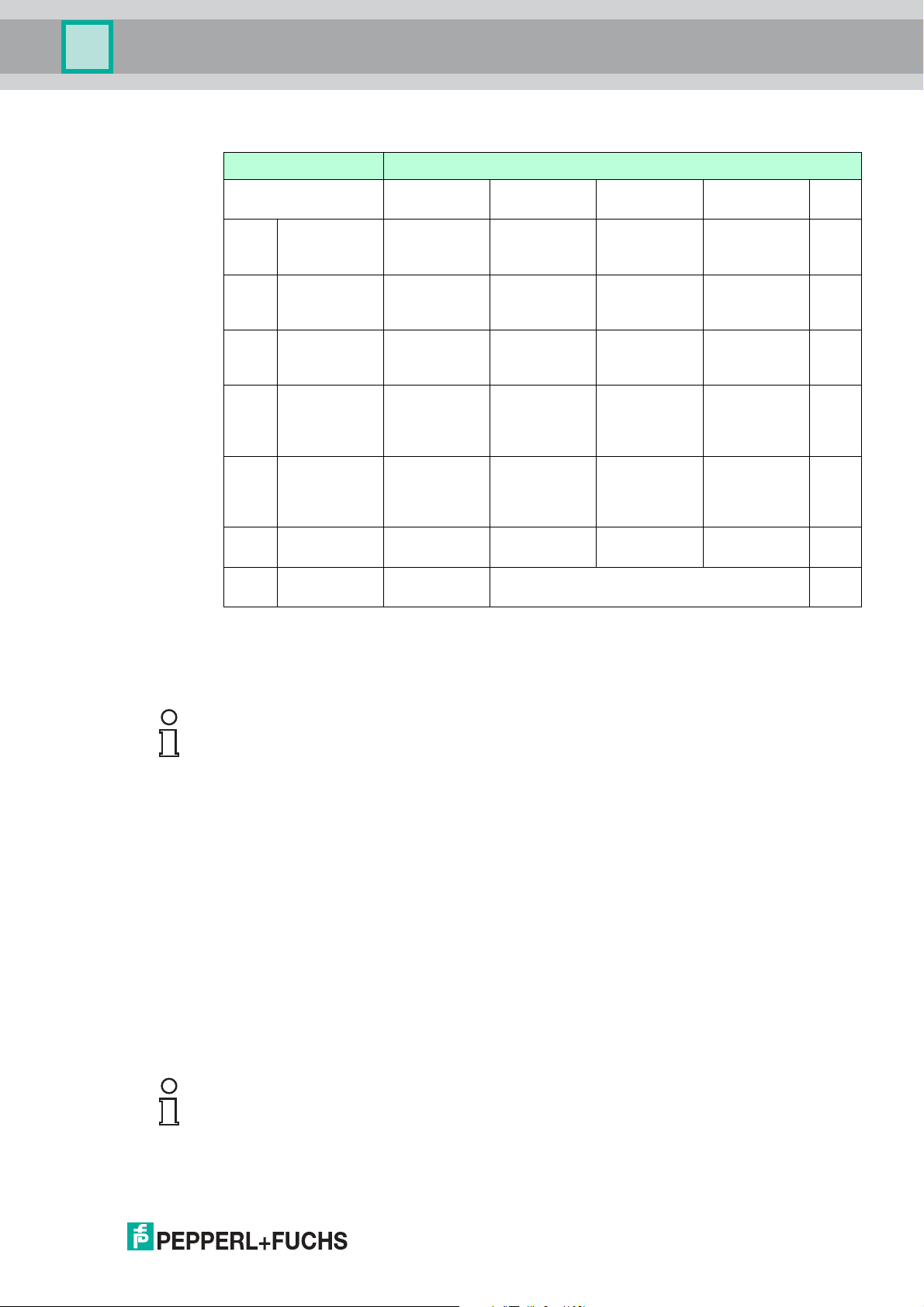

Cable Entry Option Cable Gland or Plug Type

00 Sealing plug plastic:

1 x M20,

8 x M16

01 Sealing plug stainless steel:

1 x M20,

8 x M16

02 Cable glands plastic:

1 x M20,

8 x M16

03 Cable glands nickel plated brass:

1 x M20,

8 x M16

04 Cable glands stainless steel:

1 x M20,

8 x M16

05 Cable glands plastic

5 x M20 CG.PEDS.M20.PA.C.10

SP.PE.M20.PA.C

SP.PE.M16.PA.C

SP.MD.M20.SS.C

SP.MD.M16.SS.C

CG.PEDS.M20.PA.C.10

CG.PIDS.M16S.PA.C.10

CG.NA.M20S.BN.C

CG.NA.M16.BN.C

CG.NA.M20S.SS.C

CG.NA.M16.SS.C

CG.PIDS.M20.PA.C.10

SP.PE.M20.PA.C

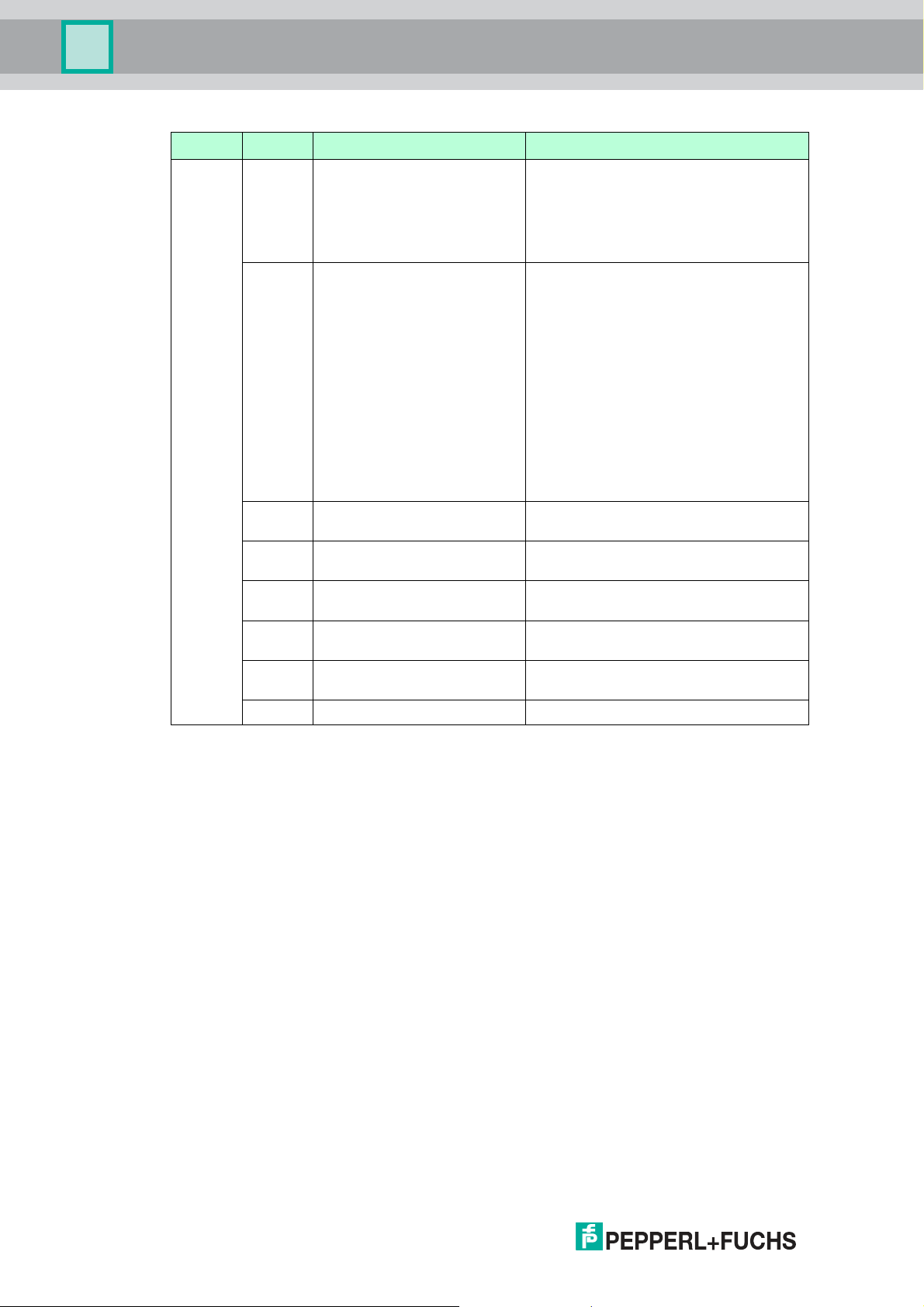

F2D0-MIO* Input/Output Cable Glands

Sensor Entries Clamping Ranges: Torques

Cable Entry Option CG or Plug

00 1 x M20, 8 x

M16 sealing

plug plastic

01 1 x M20, 8 x

M16 sealing

plug stainless

steel

02 1 x M20, 8 x

M16 cable

glands plastic

03 1 x M20, 8 x

M16 cable

glands nickel

plated brass

04 1 x M20, 8 x

M16 cable

glands

stainless steel

05 5 x M20 cable

glands plastic

Table 3.1 The torques that are actually required depend on the clamping range. This range is

determined by the diameter of the cable and the resulting seal combinations (S1+S2+S3,

S1+S2, S1) used with the cable gland or plug. For details see the documentation on the

cable gland or plug type available at www.pepperl-fuchs.com.

Type

SP.PE.M16.PA.C- - - 1.5

SP.MD.M16.S

S.C

CG.PIDS.M16

S.PA.C.10

CG.NA.M16.B

N.C

CG.NA.M16.S

S.C

CG.PIDS.M20

.PA.C.10

S1+S2+S3 S1+S2 S1 Body

- - - 4 Nm

- 4 … 5 mm:

4 … 6 mm:

20 Nm

4 … 6 mm:

20 Nm

- 6 … 8.5 mm:

3.5 Nm

6 … 9 mm:

18 Nm

6 … 9 mm:

18 Nm

5 Nm

5 … 8 mm:

4 Nm

9 … 12 mm:

15 Nm

9 … 12 mm:

15 Nm

7 … 12 mm:

5 Nm

Nm

1.5

Nm

4 Nm

4 Nm

2 Nm

20

2018-07

Page 21

Multi-Input/Output Device

Installation and Commissioning

F2D0-MIO* Fieldbus Cable Gland

Cable Entry Option CG or Plug

00 1 x M20, 8 x

M16 blind plug

plastic

01 1 x M20, 8 x

M16 blind plug

stainless steel

02 1 x M20, 8 x

M16 cable

glands plastic

03 1 x M20, 8 x

M16 cable

glands nickel

plated brass

04 1 x M20, 8 x

M16 cable

glands

stainless steel

05 5 x M20 cable

glands plastic

05 5 x M20 cable

glands plastic

Table 3.2 The torques that are actually required depend on the clamping range. This range is

determined by the diameter of the cable and the resulting seal combinations (S1+S2+S3,

S1+S2, S1) used with the cable gland or plug. For details see the documentation on the

cable gland or plug type available at www.pepperl-fuchs.com.

Fieldbus Entries Clamping Ranges: Torques

S1+S2+S3 S1+S2 S1 Body

Type

SP.PE.M20.PA.C- - - 2 Nm

SP.MD.M20.S

S.C

CG.PEDS.M2

0.PA.C.10

CG.NA.M20S.

BN.C

CG.NA.M20S.

SS.C

CG.PEDS.M2

0.PA.C.10

- - - 5.5

Nm

- 6 … 8.5 mm:

5 Nm

4 … 6 mm:

20 Nm

4 … 6 mm:

20 Nm

6 … 9 mm:

18 Nm

6 … 9 mm:

18 Nm

- 6 … 8.5 mm:

5 Nm

7 … 12 mm:

5 Nm

9 … 12 mm:

15 Nm

9 … 12 mm:

15 Nm

7 … 12 mm:

5 Nm

2 Nm

5.5

Nm

5.5

Nm

2 Nm

SP.PE.M20.PA.CUnused thread 2 Nm

Note!

Careful when tightening cap nuts!

■

The cap nuts must be securely tightened. Tightening the cap nuts too much or not enough

both can affect the degree of protection.

■

The tightening torques of cap nuts vary, depending on the cable type used. For exact

details refer to the documentation of your cable manufacturer.

3.2.3 Grounding and Shielding

Equipotential Bonding of Devices in F2* Metal Housings

For electronic components in F2* metal housings in hazardous areas, suitable equipotential

bonding in accordance with IEC/EN 60079 is required. Therefore, the device is designed as

follows:

■

The shield (terminal S) of the intrinsically safe fieldbus trunk is internally connected to the

F2* metal housing.

■

The housing has a grounding point with a grounding screw. The grounding connection

must be secured against loosening and corrosion, e. g., by using tinned cable plates.

Note!

Ensure potential equalization of F2 Metal Housings

Ensure that the housing is connected properly to the potential equalization.

2018-07

21

Page 22

Multi-Input/Output Device

Installation and Commissioning

Shielding of the Fieldbus Trunk Using the R* Electronic Component in

Intrinsically Safe Segments

The shield (terminal S) of the fieldbus trunk is internally connected to the grounding point.

Grounding and Shielding *D0-MIO-Ex12*

Shielded cables for the valve or sensor are not required.

The device provides a grounding terminal for connecting to an equipotential bonding.

F2D0-MIO-Ex12* Grounding Points

R8D0-MIO-Ex12* Grounding Point

Connection to Equipotential Bonding System

Caution!

Risk of electric shock or property damage from inadequate grounding

If you fail to connect all metal parts of the device to protective local earth correctly, this could

result in potential equalization currents. These currents could hurt operating personnel or

cause property damage.

22

The grounding terminal is not a safety earth: Do not use the grounding terminal to ground

exposed metal parts.

Ground exposed metal parts of the device separately. Ensure that a correct grounding is

guaranteed at all times.

All shield connections are internally connected to the "Shield/Screen GND" grounding terminal.

2018-07

Page 23

Multi-Input/Output Device

1

2

3

4

2

Installation and Commissioning

Connecting the Ground Connection Cable

Note!

Use a cable with a minimum cross section of 4 mm².

1. Connect the ground cable to a cable lug.

2. Position the cable lug over the grounding terminal with the cable pointing downwards.

3. Screw the cable lug to the grounding terminal with 2 toothed lock washers inserted between

screw, lug, and terminal as illustrated:

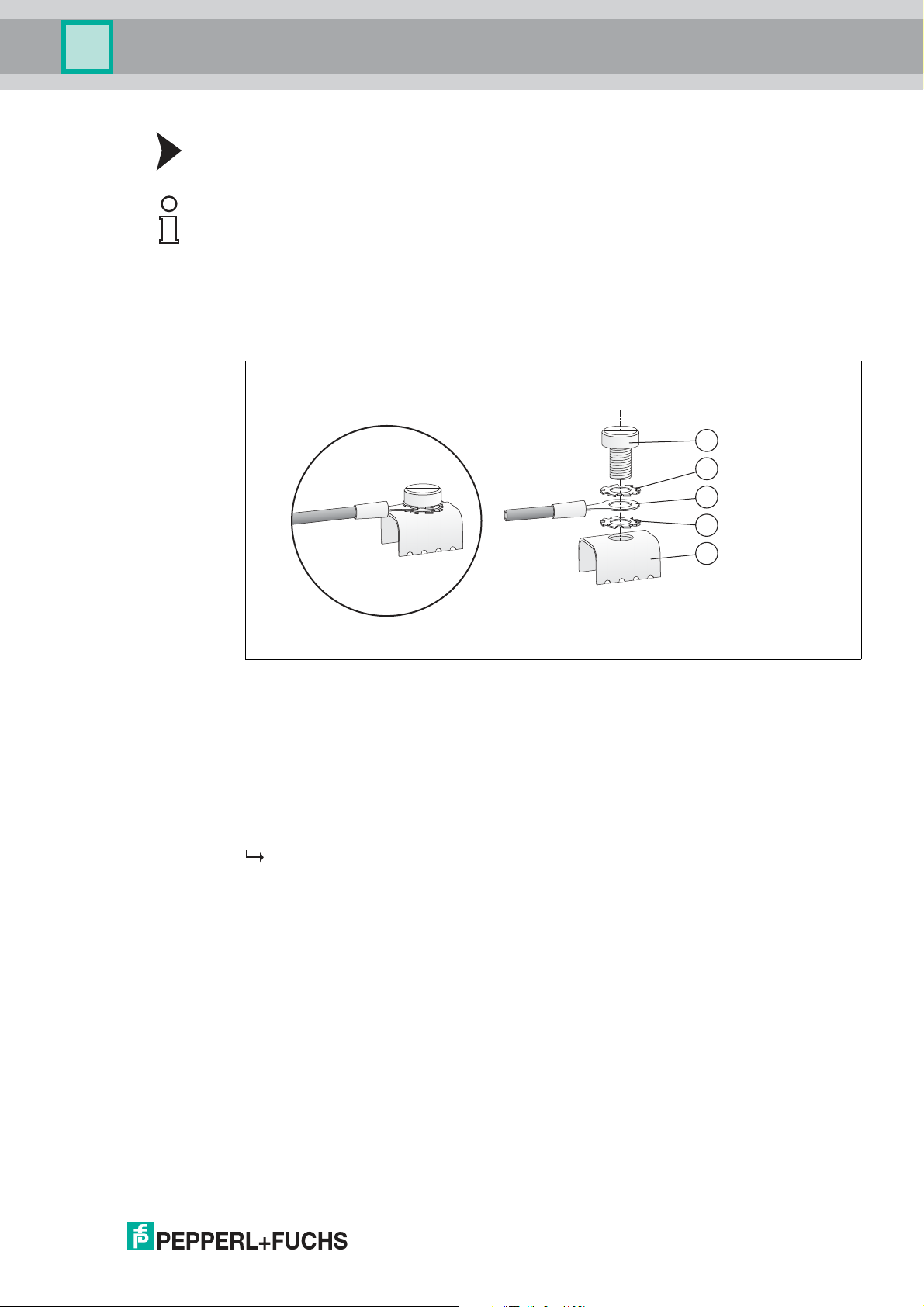

Figure 3.1 Connecting the ground connection cable

1 Screw

2 Toothed lock washer

3 Cable lug

4 Grounding terminal on motherboard

4. Tighten the screw with a torque of 1.5 Nm.

The cable lug is properly attached and cannot come loose.

Connect the "Shield/Screen GND" grounding terminal to an equipotential bonding system.

3.2.4 DIP Switch Settings

The device has 8 DIP switches:

■

DIP switches S1 ... S7: Address setting and binary coding

■

DIP switch 8: Write protection settings

Address Settings

You can assign the PROFIBUS address 0 … 125 in 2 ways. Use the hardware DIP switches of

the device or the device type manager (DTM) software.

In order to assign an address to the mulit-input/output (MIO) device in the range of 0 ... 125 as

PROFIBUS address, use the DIP switches S1 ... S7.

2018-07

23

Page 24

Multi-Input/Output Device

PROFIBUS

address setting

Position ON = logical 1

Position OFF = logical 0

1 2 3 4 5 6 7

8

Hardware

write

protection

ON

Installation and Commissioning

Any subsequent attempt to change this address via the DTM software is rejected. In this case,

the hardware DIP switch settings have priority. To change a hardware address setting again,

use the DIP switches.

After modifying the address DIP switches, the device must be rebooted in order to use the new

setting. Either disconnect the device from the fieldbus and then reconnect it, or restart the

device via the DTM.

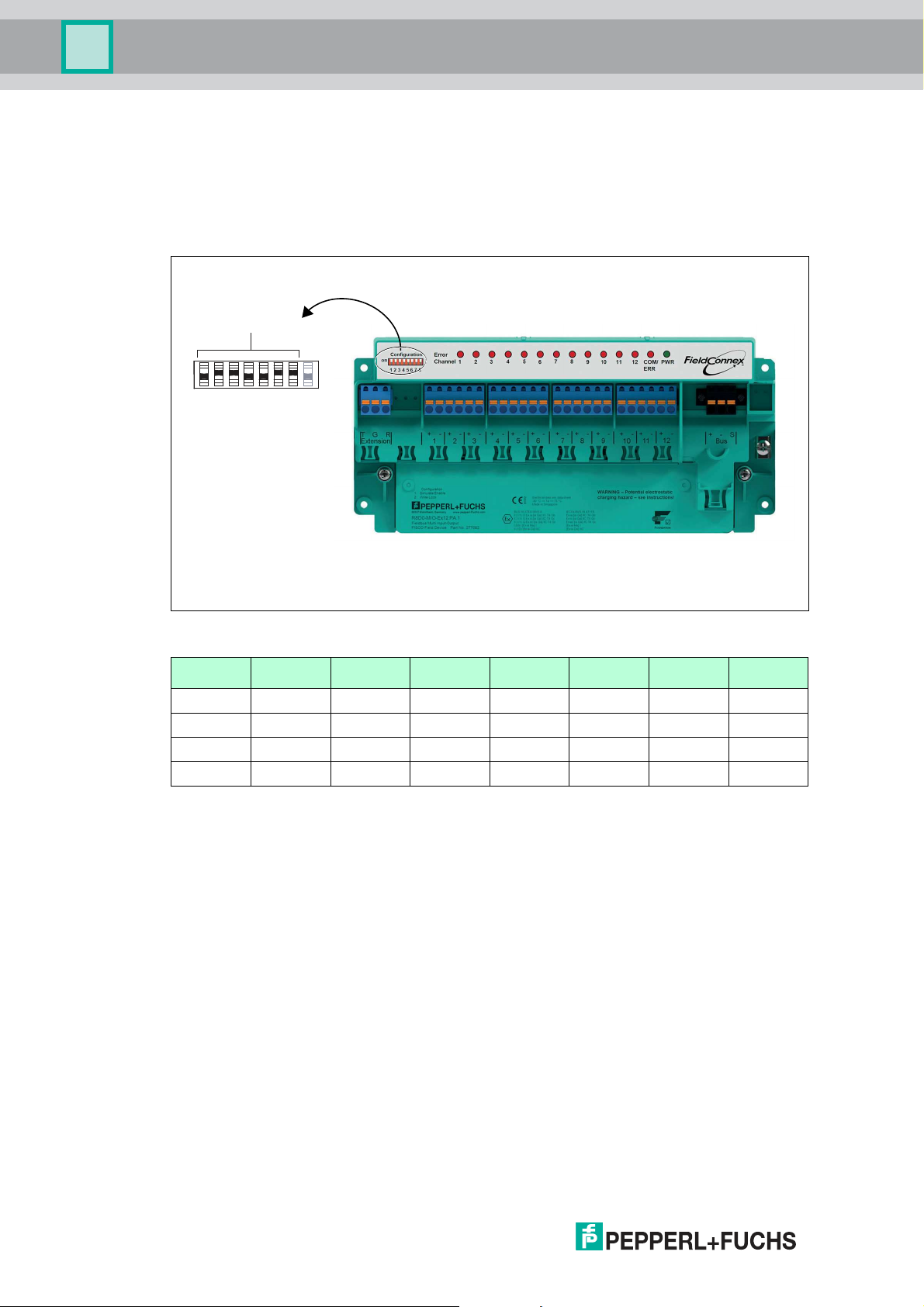

Figure 3.2 DIP switches to set the PROFIBUS address on the device

Address S1 (20) S2 (21) S3 (22) S4 (23) S5 (24) S6 (25) S7 (26)

0 OFF OFF OFF OFF OFF OFF OFF

1 ON OFF OFF OFF OFF OFF OFF

...

126 ON ON ON ON ON ON ON

■

By default, the MIO device is delivered with the address set to 126, with the DIP switches

S1 ... S7 set to ON. This enables the modification of the address via the bus.

■

An address set via the bus remains active, even if the device has been temporarily

disconnected from the bus.

■

If an address in the range of 1 ... 125 is set via the DIP switches, this address overrules an

address previously set via the bus.

Assigning a PROFIBUS Address via the Device Type Manager

In order to enable software address setting of the MIO device, set the DIP switches either to

126 or 127. For details on how to change the address via the fieldbus, refer to the

documentation of your configuration tool.

When the address is changed, the device automatically reboots, using the new address

afterwards.

Write Protection Settings

To protect the parameters from modification you can use write protection.

Write protection has the following effects:

24

■

Acyclic write access is blocked

2018-07

Page 25

Multi-Input/Output Device

Position ON = Active

Position OFF = Not active (default setting)

PROFIBUS

address setting

1 2 3 4 5 6 7

8

OFF

ON

Hardware

write

protection

Installation and Commissioning

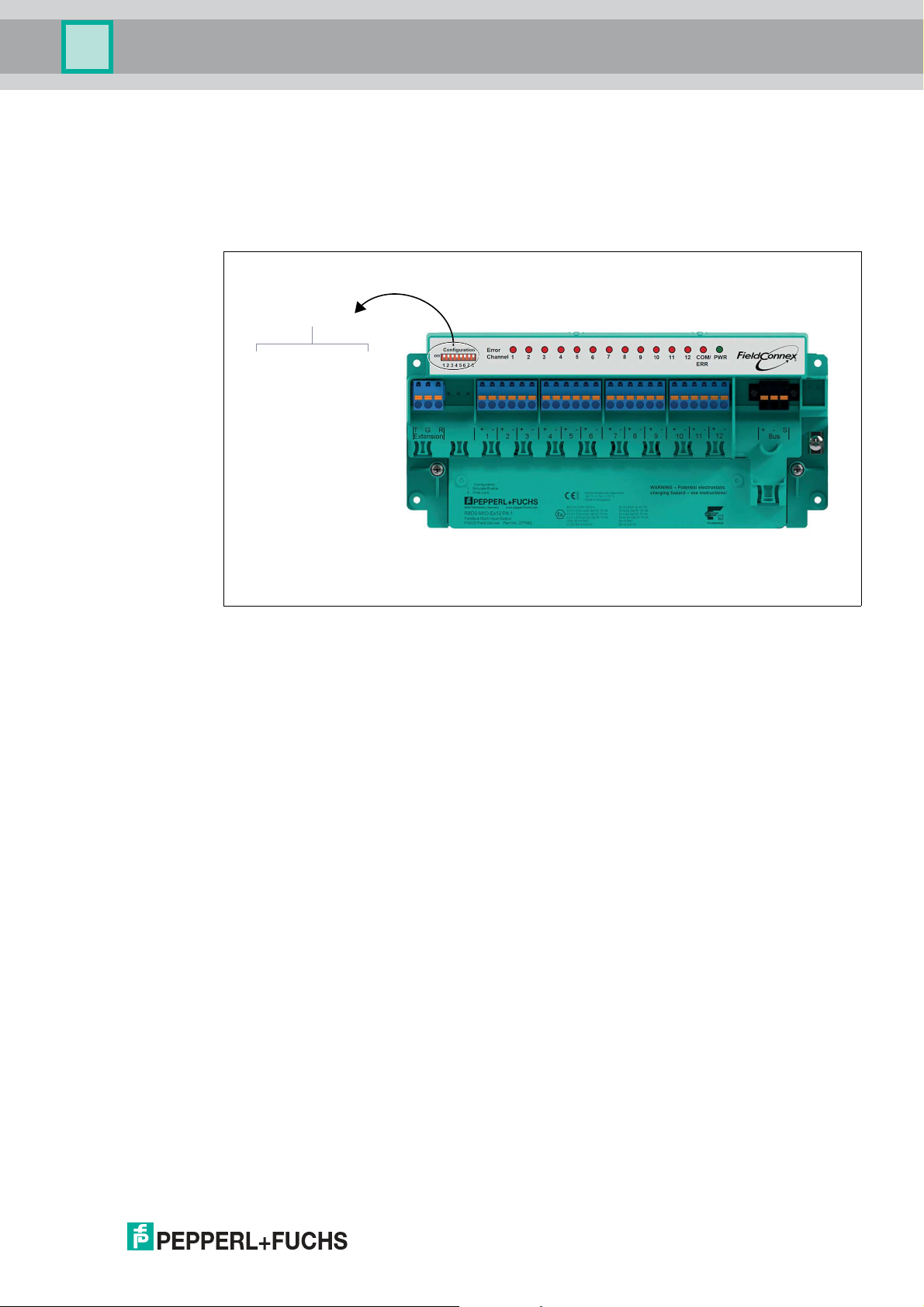

Activate write protection in either of the following ways:

■

Hardware write protection: Use DIP switch 8 on the device (see below).

■

Software write protection: Activate the respective parameter in the DTM software. For

more information see description of user interface no. 8, see chapter 10.2.3.

Activating Write Protection via the DIP Switch

Figure 3.3 DIP switch 8 to activate the hardware write protection

Both write protection methods work the same way, regardless of which one is activated.

3.3 PROFIBUS Ident Number Setting

For each PROFIBUS field device type of each manufacturer at least 1 unique PROFIBUS ident

number is assigned for device identification. *D0-MIO-Ex12.PA support different ident numbers

and thus, different GSD files, to configure the required mode of operation.

Depending on the required mode of operation of the device, select the ident number in the

device type manager (DTM) software. Use the PROFIBUS Ident Number parameter.

For setting the PROFIBUS ident number, see chapter 10.4 and see chapter 10.3.

Manufacturer-Specific MIO Mode Ident Number

■

Manufacturer-specific MIO mode ident number: 0x0F8B

For selecting the corresponding device mode in the DTM, see chapter 10.4 and see chapter

10.3.

FD0-VC-Ex4.PA Compatible Mode Ident Number

■

FD0-VC-Ex4.PA compatible mode ident number: 0x0841

FD0-BI-Ex12.PA Compatible Mode Ident Number

■

FD0-BI-Ex12.PA compatible mode ident number: 0x0461

PROFIBUS Profile 3.02 Valve Coupler Mode Ident Number

■

PROFIBUS profile 3.02 valve coupler mode ident number: 0x9733

PROFIBUS Profile 3.02 Sensor Input Mode Ident Number

■

PROFIBUS profile 3.02 sensor input mode ident number: 0x972B

2018-07

25

Page 26

Multi-Input/Output Device

Installation and Commissioning

Note!

Automatic Mode

By default, the device is set to "Automatic" mode: In the process of establishing cyclic

communication, the device checks if one of the supported ident numbers is set. If so, the

device automatically uses that number.

3.4 Requirements for Commissioning

Before commissioning the multi-input/output device (MIO), ensure that the following

requirements are met:

■

For acyclic communication/parameterization: A suitable FDT frame application is in place

in order to parameterize the MIO via a PROFIBUS DP master. The device type manager

(DTM) needed to run in the FDT frame application can be downloaded from Internet under

www.pepperl-fuchs.com. Refer to the release notes of the DTM for information on the

frameworks that are supported. The release notes are included in the FieldConnex® DTM

package.

■

For cyclic communication/configuration: A process control system (PCS) is prepared to

configure cyclic user data exchange via a PROFIBUS DP Master Class I.

■

The PROFIBUS master is connected to a PROFIBUS DP segment. No DP slaves need to

be available at the DP segment.

■

A PROFIBUS PA segment is connected via a Segment Coupler.

■

The bus terminations at both ends of the PROFIBUS PA segment are mounted or

switched ON.

■

A MIO device is installed at the PROFIBUS PA segment.

3.5 Parameterization and Configuration Procedure

Use the FDT frame application with the device type manager (DTM) to parameterize the

device. Parameterization is an "acyclic" communication, i. e., read/write data is read from or

stored on the device as needed. This also means that once set in the DTM, the parameters are

kept even if the device is put into operation at a later point.

Use the following checklist when commissioning the device. Skip those steps you have already

completed. For detailed information on how to proceed, refer to the chapters mentioned.

Parameterization (hardware and software):

1. Set a fixed valid PROFIBUS address 0 ... 125 via the DIP switch of the device or set the

address 126 (default setting) for assignment of the address via the configuration or parameterization tool. For more information, see chapter 3.2.4 or see chapter 10.3, and see

chapter 10.4.

2. Set the parameters for the devices in your project, e. g., PROFIBUS ident number, description parameters. For more information see chapter 3.3 and see chapter 10.3/see

chapter 10.4.

3. Set channel-related parameters. For more information, see chapter 8.

4. If needed, activate the hardware or software write protection to protect the parameters

from overwriting. For more information, see chapter 3.2.4 or description of user interface

no. 8, see chapter 10.2.3.

Configuration:

26

1. Log on to the DP master.

2. Select the GSD file to be used (manufacturer-specific, profile-specific). For more information, see chapter 3.2.

If necessary, install the respective GSD file.

2018-07

Page 27

Multi-Input/Output Device

Configuration

4 Configuration

4.1 Host System Integration

The configuration of the device in a PROFIBUS network requires a GSD file. The file describes

the details of communication capabilities and structures of cyclic data. For the *D0-MIOEx12.PA, different GSD files are available to support different modes of operation.

Mode of operation Ident number GSD file

MIO 0x0F8B PF00F8B.gsd

FD0-VC-Ex4.PA compatibility 0x0841 PF00841.gsd

FD0-BI-Ex12.PA compatibility 0x0461 PF00461.gsd

PROFIBUS profile 3.02 valve coupler 0x9733 PA09733.gsd

The manufacturer-specific GSD files for MIO mode of operation offer the full functionality of the

devices. The GSD file is available on the Internet under www.pepperl-fuchs.com.

The profile-specific GSD files are defined by the PROFIBUS PA profile 3.02. The GSD files

offer a limited, standardized functionality that guarantees interoperability between devices of

different manufacturers. Profile-specific GSD files are available on the Internet under

www.pepperl-fuchs.com.

The FD0-VC-Ex4.PA and FD0-BI-Ex12.PA GSD files are used if in an existing installation of a

device has to be replaced. The GSD files of preceeding Pepperl+Fuchs process interfaces are

available on the Internet under www.pepperl-fuchs.com.

4.2 Configuration of Cyclic Communication

Prerequisite: The GSD file is installed in your process system. For more information, see

chapter 4.1.

During cyclic data exchange, "user data" is exchanged in regular intervals between the master

and the slave or bus, e. g., between a process control system and a field device. User data

includes, e. g., measurement values, limit position feedback, and output data, etc. The bus

cycle time depends on the number of nodes and the amount of data that is transmitted.

The cyclic data is represented in so called “modules” which are mapped to slots. For each

hardware channel a module can be selected. The module data consists of a combination of

input and output data of different variables. Modules of the different operation modes are not

allowed to be mixed other than stated below. The supported types of modules are described in

the specific GSD files.

Module types for the valve coupler mode and the FD0-VC-Ex4.PA compatibility mode In the

valve coupler mode the following variables for cyclic communication are available:

■

Empty module: Used if a channel is not used for cyclic communication.

■

OUT_D: Input value and status of position feedback monitor.

■

SP_D: Specified setpoint value of valve position in the "Auto" mode.

■

RB_D: Feedback of valve position and the states of the position feedback inputs and their

line fault condition.

■

CB_D: Detailed status, alarm, and fault condition of the valve.

■

RIN_D: Specified setpoint value of host in the "RCas" mode of operation.

■

ROUT_D: Setpoint value feedback to host in the "RCas"mode of operation.

2018-07

27

Page 28

Multi-Input/Output Device

Configuration

Modules (combination of

variables) Description Byte length

EMPTY_MODULE Empty module. Used if a channel

OUT_D Input value and status of sensor

SP_D Setpoint value of the valve 2 0

SP_D+RB_D Setpoint value + position feedback 2 2

SP_D+CB_D Setpoint value + diagnostics 2 3

SP_D+RB_D+CB_D Setpoint value + position feedback

RIN_D+ROUT_D Setpoint value host 2 2

RIN_D+ROUT_D+CB_D Setpoint value host + diagnostics 2 5

SP_D+RB_D+RIN_D+ROUT_D+

CB_D

is not used.

input

+ diagnostics

Setpoint value host + final position

feedback (PFC) + diagnostics

Input Output

0 0

2 0

2 5

4 7

In the valve coupler mode, up to 12 modules per *D0-MIO-Ex12.PA are supported.

Module types for the sensor input mode and FD0-BI-Ex12.PA compatibility mode In the sensor

input mode, the following variables for cyclic communication are available:

■

Empty module: Used if a channel is not used for cyclic communication.

■

OUT_D: Value of the sensor input and the corresponding status information.

■

OUT: Value for frequency input with the corresponding status. Not applicable to the FD0BI-Ex12.PA compatibility mode.

■

OUT long: Value for frequency input with the corresponding status. Module description in

long format. Not applicable to the FD0-BI-Ex12.PA compatibility mode.

■

OUT short: Value for frequency input with the corresponding status. Module description in

short format. Not applicable to the FD0-BI-Ex12.PA compatibility mode.

■

OUT_C: Value for counter input with corresponding status. Not applicable to the FD0-BIEx2.PA compatibility mode.

■

OUT_C_RESET: 1 output byte used to reset the sensor input and the corresponding

status information.

28

2018-07

Page 29

Multi-Input/Output Device

Configuration

Modules (combination of

variables) Description Byte length

EMPTY_MODULE Empty module. Used if a channel

OUT_D Input value and status of the input

OUT Input value and status of the input

OUT long OUT long: Value for frequency

OUT short OUT short: Value for frequency

OUT_C Input value and status of the input

OUT_C + OUT_C_RESET Counter input value and

Input Output

0 0

is not used.

2 0

if binary sensors are used.

5 0

if configured in frequency mode.

Not applicable to the

FD0–BI–Ex12.PA compatibility

mode.

5 0

input with the corresponding

status. Module description in long

format. Not applicable to the FD0BI-Ex12.PA compatibility mode.

5 0

input with the corresponding

status. Module description in short

format. Not applicable to the FD0BI-Ex12.PA compatibility mode.

5 0

if configured in counter mode. Not

applicable to the FD0–BI–Ex12.PA

compatibility mode.

5 1

corresponding status in

combination with counter reset

value.

4.3 Cyclic Communication Data Description

The following sections describe the device variables involved in cyclic communication. Most of

these variables contain a data part and a status byte. The status supports 2 different sets of

coding: the classic status and the condensed status. The condensed status offers gradual

prioritized information which is the most suitable to support you with process control and

maintenance tasks. Whereas the classic status follows a fixed mapping between failure cause

and status message, the condensed status can be configured depending on available failure

causes. For more information, refer to the device type manager description on diagnostic and

status mapping.

4.3.1 Valve Coupler Mode and FD0-VC Compatibility Mode Variables

The following section offers information on the following valve coupler mode variables:

■

SP_D

■

RIN_D

■

RB_D

■

ROUT_D

■

CB_D

■

OUT_D

2018-07

29

Page 30

Multi-Input/Output Device

Configuration

SP_D

The status of SP_D influences the control of the valve. The SP_D variable consists of 2 bytes:

1. The first byte represents the setpoint value of the valve for the “auto” mode of operation of

the function block.

2. The second byte represents the status.

Value Description

0 Set position “closed”

1 ... 255 Set position “open”

Classic Status Value Mnemonic Description

0xA0 GOOD (NC)-IFS (Initiate fail-safe.)

0x80 GOOD (NC)-OK Valid setpoint value.

>= 0x40 UNCERTAIN

GOOD (C)

GOOD (NC)

<= 0x3F BAD All values 00 h ... 3 Fh.

Command for control to change to the

fail–safe state.

Recommended to be used as the default

value for "GOOD".

Valid setpoint valueAll values 40h ... BFh

except A0h.

Value 80h recommended to be used

preferably.

The setpoint value is only valid if the value of the status byte (second byte) is "GOOD" (NC)OK" (80h).

Note!

Controlling the Valve

The setpoint value is not the control value of the valve. Which value opens or closes a valve,

depends on the setting of the "invert setpoint" parameter. For more information, see chapter

8.1.

Example!

Setting the Invert Setpoint Parameter

If the Invert Setpoint parameter is set to "OFF", the setpoint value is not inverted. The setpoint

value "0" controls the valve in the "closed" position. Any other setpoint value from 1 ... 255

controls the valve in the "open" position.

If the Invert Setpoint parameter is set to "ON", the coding of the setpoint value is inverted. That

means, the setpoint value "0" controls the valve in the "open" position. Any other setpoint value

from 1 ... 255 controls the valve in the "closed" position.

30

2018-07

Page 31

Multi-Input/Output Device

Configuration

RIN_D

The variable RIN_D contains the specified setpoint value of the valve position in the "RCas"

mode. Coding is identical to SP_D.

The relevant status values are:

Classic Status Value Mnemonic Description

0xC0 GOOD (C)-OK Valid setpoint value.

0xC1 GOOD (C)-IA (Initialization acknowledgment.)

0xE0 GOOD (C)-IFS (Initiate fail-safe.)

< 0xC0 GOOD (NC)

UNCERTAIN

BAD

Clearance from control system to change to

the RCas mode.

Command for channel to change to the Auto

mode.

Invalid setpoint value.

Change to Auto mode.

Example!

Setting the Valve Position

If the variable RIN_D is 0 with the Invert Setpoint" parameter set to "OFF", the setpoint value is

not inverted. The setpoint value "0" controls the valve in the "closed" position. Any other

setpoint value from 1 ... 255 controls the valve in the "open" position.

If RIN_D is 0 with the Invert Setpoint parameter set to "ON", the coding of the setpoint value is

inverted. The setpoint value "0" controls the valve in the "open" position. Any other setpoint

value from 1 ... 255 controls the valve in the "closed" position.

RB_D

The variable RB_D gives the feedback of the valve position, the states of the position inputs,

and their lead faults. The variable consists of 2 bytes: the first byte represents the readback and

the second byte represents the status.

The coding of the readback is as follows:

Bit Description

0+1 Valve position 0 = unknown, 1 = closed, 2 = open, 3 = intermediate

2 Position feedback A 0 = actuated, 1 = not actuated

3 0 = no lead short circuit, 1 = lead short circuit

4 0 = no lead breakage, 1 = lead breakage

5 Position feedback B 0 = actuated, 1 = not actuated

6 0 = no lead short circuit, 1 = lead short circuit

7 0 = no lead breakage, 1 = lead breakage

position

2018-07

31

Page 32

Multi-Input/Output Device

Configuration

The coding of the status is as follows:

Classic Status Value Mnemonic Description

0x80 GOOD (NC)-OK Feedback value valid.

0x84 GOOD (NC)-UE (Update event.)

0x0C BAD (NC)-DF (Device failure.)

0x10 BAD (NC)-SF Position feedback sensor combination not

0x11 BAD (NC)-SF Lead short circuit

0x12 BAD (NC)-SF Lead breakage

ROUT_D

The variable ROUT_D consists of 2 bytes providing the setpoint value of the valve which is retransferred by RIN_D for monitoring and the status. This setpoint value does not include

information of the states of the position feedback sensors. The status is mainly used to control

the sequence of module change in case of failure.

10-s message for parameter changes.

Electric hardware fault. Send the device to

Pepperl+Fuchs for repair.

allowed.

The coding of the status is as follows:

Classic Status Value Mnemonic Description

0xC0 GOOD (C)-OK Valid setpoint value.

0xC2 GOOD (C)-IR (Initialization request.)

0xCC GOOD (C)-NI (Not invited.)

0x0C BAD-DF (Device failure.)

0x1C BAD-OS (Out of service.)

Clearance request from slave to master in

order to change to the RCas mode.

RCas is not set as the target mode.

Electric hardware fault. Send device to

Pepperl+Fuchs for repair.

Is set in the OoS mode.

32

2018-07

Page 33

Multi-Input/Output Device

Configuration

CB_D

The variable CB_D provides detailed status, alarm, and fault signals of the valve. The variable

consists of 3 bytes.

The information is bit-coded as follows:

Bit Description

0 The valve is set to fail-safe state.

1 Unused

2 Unused

3 Unused

4 After a correct switching operation, the valve has left the appropriate end

5 Lead breakage of the valve.

6 Lead short circuit of the valve.

7 Unused

8 Valve is in the process of opening.

9 Valve is in the process of closing.

10 Update event. 10-s message while changing the parameters of this

11 The channel is in simulation mode.

12 Unused

13 Unused

14 Valve moved into the mechanical safety position.

position or the PFCs show an invalid position.

channel.

■

In case of fault if fault states = Actuator Fail Action.

■

In Manual mode if status of manual setpoint of valve is BAD.

15 A cyclic functional test is currently carried out.

16 The limit value for the stroke counter has been exceeded.

17 The breakaway time OPEN-CLOSED including tolerance has been

18 The breakaway time CLOSED-OPEN including tolerance has been

19 A fault occurred during the cyclic function test of the valve.

20 The transit time OPEN-CLOSED including tolerance has been

21 The transit time CLOSED-OPEN including tolerance has been

22 Actuating drive or valve mechanically blocked.

23 Unused

exceeded/fallen below.

exceeded/fallen below.

exceeded/fallen below.

exceeded/fallen below.

2018-07

33

Page 34

Multi-Input/Output Device

Configuration

OUT_D

The variable OUT_D consists of 2 bytes. The first byte contains the process value of the

sensor, the second byte contains the status of the data.

The structure of the first byte, i. e., the process value of the sensor input, is as follows:

Bit 0 Value of the sensor input 0: low current

Bit 1 … 7 na Not used

The structure of the second byte, containing the status of the data, is as follows:

Classic Status Value Mnemonic Description

0x80 GOOD-OK No error, the input value is valid.

0x12 BAD-SF (Sensor failure.)

0x11 BAD-SF (Sensor failure.)

0x0C BAD-DF (Device failure.)

0x1C BAD-OS (Out of specification.)

1: high current

Lead breakage.

Lead short circuit.

Hardware fault.

No valid value of the sensor has been read

(after power-up of the device).

The values of the position feedback sensors in the MIO valve coupler mode can be transmitted

individually to calculate e. g. the position of a valve in the process control system.

4.3.2 Sensor Input Mode and FD0-BI Compatibility Mode Variables

The following section offers information on the following sensor input mode variables:

■

Discrete Input Variables

■

Frequency and Counter Variables

Discrete Input Variables

The variable OUT_D consists of 2 bytes. The first byte contains the process value of the

sensor, the second byte contains the status of the data.

The structure of the first byte, i. e., the process value of the sensor input, is as follows:

Bit 0 Value of the sensor input 0: low current

Bit 1 … 7 na Not used

1: high current

34

2018-07

Page 35

Multi-Input/Output Device

Configuration

The structure of the second byte, containing the status of the data, is as follows:

Classic Status Value Mnemonic Description

0x80 GOOD-OK No error, the input value is valid.

0x12 BAD-SF (Sensor failure.)

0x11 BAD-SF (Sensor failure.)

0x0C BAD-DF (Device failure.)

0x1C BAD-OS (Out of specification.)

Frequency Input Variables

The OUT variable consists of 5 bytes. The first 4 bytes contain the process value of the

frequency or counter. The 5th byte contains the status of the process value.

Lead breakage.

Lead short circuit.

Hardware fault.

No valid value of the sensor has been read

(after power-up of the device).

The OUT long variable represents the value for the frequency input with the corresponding

status. Module description in long format. Not applicable to the FD0-BI-Ex12.PA compatibility

mode.

The OUT short variable represents the value for the frequency input with the corresponding

status. Module description in short format. Not applicable to the FD0-BI-Ex12.PA compatibility

mode.

For the frequency input, the sensor value is formatted in float format according to IEEE 754.

The structure of the 5th byte, containing the input status, is as follows:

Classic Status Value Mnemonic Description

0x80 GOOD-OK No error, the input value is valid.

0x12 BAD-SF (Sensor failure.)

Lead breakage.

0x11 BAD-SF (Sensor failure.)

Lead short circuit.

0x0C BAD-DF (Device failure.)

0x1C BAD-OS (Out of specification.)

Hardware fault.

No valid value of the sensor has been read

(after power-up of the device).

2018-07

35

Page 36

Multi-Input/Output Device

Configuration

Counter Input Variables

The OUT_C variable consists of 5 bytes. The first 4 bytes contain the process value of the

frequency or counter. The 5th byte contains the status of the process value.

For the counter input the sensor value is formatted in unsigned 32.

The structure of the 5th byte, containing the input status, is as follows:

Classic Status Value Mnemonic Description

0x80 GOOD-OK No error, the input value is valid.

0x12 BAD-SF (Sensor failure.)

0x0C BAD-DF (Device failure.)

0x1C BAD-OS (Out of specification.)

Counter Output Variable OUT_C_RESET

Lead breakage.

Hardware fault.

No valid value of the sensor has been read

(after power-up of the device).

The variable OUT_C_RESET contains the reset value in counter mode.

■

= 0: Counter is in normal operation.

■

> 0: Counter is in reset mode. As long as the counter is in reset mode, the following

applies:

• OUT_C variable = 0

• OUT_C.status = 0x4F (uncertain-initial value-const.)

4.4 Cyclic Communication Data Structure

In the following section explains the order of the module data transmitted in the cyclic data

exchange.

4.4.1 Valve Coupler Mode and FD0-VC-Ex4.PA Compatibility Mode

The length of the module data depends on the module type. For more information, see chapter

4.2.

Byte 1 ... n

Module

data+status

CH 1/ output 1

If an “empty” module is used instead of a module containing data, no data is transferred during

the data exchange for the corresponding channel.

Module

data+status

CH 4/ output 2

Module

data+status

CH 7/ output 3

Module data+status CH 10/ output 4

36

Note!

Discrete Input Modules

Discrete input (DI) modules are supported in the MIO mode for valve couplers only. These are

the OUT_D variables of the position feedback sensors. These variables work as described in

the section "Discrete Input Variables", see chapter 4.3.2.

2018-07

Page 37

Multi-Input/Output Device

Configuration

4.4.2 Example of a Typical Configuration in Valve Coupler Mode

Out of 4 available valves, valve 2 and valve 3 are assigned.

Lead monitoring is activated both valves: CB_D

For the valve 3, an additional final position feedback and monitoring is required: RB_D

The mode of operation for valve 2 is Auto and for valve 3 it is RCas.

In this setup, the list of the modules used should have the following structure:

Pos. Module Use

1 EMPTY_MODULE Valve 1: Empty module as the valve is

2 SP_D+CB_D Valve 2: Specified setpoint value of

3 SP_D+RB_D+RIN_D+ROUT_D+CB_D Valve 3: Specified setpoint value of

4 EMPTY_MODULE or no specification Valve 4: Empty module or no

not used

valve with fault feedback in Auto mode.

valve with fault feedback and final

position monitoring (likewise with fault

feedback) in RCas mode. The identifier

must contain the RB_D variable for the

final position feedback.

assignment as the valve is not used

and no used channels follow.

The length of the user data transferred to the device (output data) is: 0 + 2 + 4 + 0 = 6 bytes

The length of the user data transferred from the device (input data) is: 0 + 3 + 7 + 0 = 10 bytes

4.4.3 Sensor Input Mode and FD0-BI-Ex12.PA Compatibility Mode

Example: Binary sensor input only, channels 1 … 12:

■

Channels 1, 4, 7, 10: sensor measurement group 1

■

Channels 2, 3, 5, 6, 8, 9, 11, 12: sensor measurement group 2

Byte 1 2 3 4 5 6 7 8 9 10 11 12 ... 23 24

Content

Data CH1

Status CH1

Data CH4

Status CH4

Data CH7

Status CH7

Data CH10

Status CH10

Data CH2

Status CH2

Data CH3

Status CH3

Example:

Combined frequency or counter and sensor input:

■

Channel 1: frequency or counter input

■

Channels 2, 3, 5, 6, 8, 9, 11: sensor inputs

Note: Channels 4, 7, and 10 are empty modules and cannot receive data.

Byte 1 ... 4 5 6 7 8 9 10 ... 18

...

Data CH12

Status CH12

Content

If an “empty” module is used instead of a module containing data, no data is transferred during

2018-07

the data exchange for the corresponding channel.

Data CH1

Status CH1

Data CH2

Status CH2

Data CH3

Status CH3

Data CH5

...

Status CH11

37

Page 38

Multi-Input/Output Device

Configuration

4.4.4 Example of a Typical Configuration in Sensor Input Mode

Out of 4 available vibrating forks, fork 1 and fork 3 are used.

Out of the 8 available sensors, sensor 2 and sensor 3 are used.

Settling time of the vibrating forks that is set: 4 s.

In this setup, the list of the modules used should have the following structure:

Pos. Module Use

1 OUT_D Vibrating fork 1

2 EMPTY_MODULE Vibrating fork 2 is not used

3 OUT_D Vibrating fork 3

4 EMPTY_MODULE Vibrating fork 4 is not used

5 EMPTY_MODULE Sensor 1 is not used

6 OUT_D Sensor 2

7 OUT_D Sensor 3

8 ... 12 EMPTY_MODULE Sensor 4 ... 8 is not used

A typical parameterization string is, e. g.: 00 00 00 53 01 02 01 03 02 01

Explanation

00 00 00 53 01 02 03 03 02 01

3 bytes =

always "0"

At maximum, 5 more bytes could follow for the sensors 4 ... 8.

During the cyclic user data exchange, the following 8 bytes are transferred:

1. Byte 2. Byte 3. Byte 4. Byte 5. Byte 6. Byte 7. Byte 8. Byte

Data

Fork1

Configuration byte

for fork 1,

Status

Fork1

incl. settling

time setting

Fork 2,

deactivated

Data

Fork3

Fork 3,

deactivated

Status

Fork3

Fork 4,

deactivated

Data

Sens2

Sensor 1,

deactivated

Status

Sens2

Sensor 2

Data

Sens3

Sensor 3

Status

Sens3

38

2018-07

Page 39

Multi-Input/Output Device

Parameterization in Cyclic Communication (Set_Prm)

5 Parameterization in Cyclic Communication (Set_Prm)

5.1 Condensed Status and Diagnosis

The device supports the classic and condensed status and diagnostic messages. For more

information, see chapter 6.3. During parameterization it is possible to switch between the

modes. The PRM_COND parameter defines whether the condensed status and diagnostic

status are enabled or disabled.

Note!

Compatibility Modes

The FD0-VC-Ex4.PA and FD0-BI-Ex12 compatibility modes only support the classic status!

5.2 FD0-BI-Ex12 Compatibility Mode

In the FD0-BI-Ex12 compatibility mode, the device can be configured by using the PRM_DATA

PROFIBUS parameterization string. For each of the 12 sensor inputs/modules 1 byte is

transmitted. The first byte contains the lead breakage and lead short circuit option and the

settling time for CH1, CH4, CH7, and CH10. The following bytes contain the lead breakage and

lead short circuit option for the CH2 … CH12.

Content of the first parameterization byte:

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Settling for the sensor inputs of the hardware

channels, 1, 4, 7, and 10

Coding of the lead breakage/lead short circuit settings (bit 0 … 4):

0: Lead breakage + short circuit check (LB and SC checks are activated)

1: Lead breakage check (LB check is activated)

2: Short circuit check (SC check is activated)

3: No check (LB is deactivated)

Coding of the settling time settings (bit 5 … 7):

0: 1 s (default)

1: 250 ms

2: 500 ms

3: 2 s

4: 3 s

5: 4 s

Lead breakage, lead short circuit settings

6: 5 s

2018-07

39

Page 40

Multi-Input/Output Device

Parameterization in Cyclic Communication (Set_Prm)

The parameterization bytes 2 … 12 have the following content:

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Not used Lead breakage, lead short circuit settings

Coding of the lead breakage/lead short circuit settings (low nibble):

0: Lead breakage + short circuit check (LB and SC checks are activated)

1: Lead breakage check (LB check is activated)

2: Short circuit check (SC check is activated)

3: No check (LB check is deactivated)

For sensors that are configured as empty modules, the lead breakage and lead short circuit

checks are deactivated independently of the content of their parameterization byte.

40

2018-07

Page 41

Multi-Input/Output Device

PWRCOM/

ERR

21

3

4

6

5

7

8 9

10

11 12

ERR

CH

®

1 2 3

Troubleshooting and Diagnosis

6 Troubleshooting and Diagnosis

The following information helps you to identify problems with the multi-input/output device and

interpret diagnostic issues.

6.1 LED Status and Error Indication

The device is providing LED indication for each channel, the communication status and the

fieldbus voltage.

1 LED CH ERR 1 ... 12 for indicating channel errors

2 LED COM ERR for indicating communication errors

3 LED PWR for indicating operation

LED Indication Color Information Reason Remedy

CH ERR Flashing Red Status of the