Multiturn absolute encoder ESM58-PN

Technical data

General specifications

Detection type photoelectric sampling

Device type Multiturn absolute encoder

Functional safety related parameters

MTTFd 120 a

Mission Time (TM) 20 a

L

1.9 E+11 at 6000 rpm and 20/40 N axial/radial shaft load

10h

Diagnostic Coverage (DC) 0 %

Electrical specifications

Model Number

ESM58-PN

Features

• Industrial standard

housing Ø58 mm

• PROFINET IRT

• 30 Bit multiturn

• Recessed hollow shaft

• Network loop through by means of

integrated 2 port switch (IRT capable)

• IP address resettable

• No DIP switches for address setting

• Mechanical compatibility with all

major encoders with fieldbus interface

• Status LEDs

Description

In addition to the CANopen-, DeviceNet-, PROFIBUS- and AS-Interface encoders, we have

broadened our product line of bus-capable absolute encoders with the ESM58 for Ethernet.

Absolute multiturn rotary encoders deliver an

absolute step value for each angle setting.

This device has a maximum basic resolution of

65536 steps per revolution (16 bits) and codes

up to 16384 revolutions (14 bits). Thus the overall resolution amounts to 30 bits. On account of

the high number of measuring steps resulting

(more than 1 billion), this type of encoder can be

used to divide very long linear distances into

small measuring steps.

The Ethernet interface of this absolute encoder

supports the Profinet protocol. The integrated

webserver provides Java applets, which allow

the whole parameterisation of the encoder via

any web browser. In addition to various

functions like resolution adjustment, e-mail-services, change of the IP address and many

others, the following operation modes can be

selected:

• Polled Mode

• Cyclic Mode

• Change of State Mode

The device is mounted directly onto the application shaft, without any coupling. Rotation of the

absolute encoder is prevented by a torque rest.

Operating voltage U

Power consumption P

Linearity ± 0.5 LSB (12 Bit) ,

Output code binary code

Code course (counting direction) programmable,

R

Interface

Interface type PROFINET IO

Resolution

Single turn up to 16 Bit

Multiturn 14 Bit

Overall resolution up to 30 Bit

Physical Ethernet

Transfer rate 100 MBit/s

Cycle time ≤ 1 ms (IRT) ; ≤ 10 ms (RT)

Connection

Connector Ethernet: 2 sockets M12 x 1, 4-pin, D-coded

Standard conformity

Degree of protection DIN EN 60529,

Climatic testing DIN EN 60068-2-3, no moisture condensation

Emitted interference EN 61000-6-4:2007

Noise immunity EN 61000-6-2:2005

Shock resistance DIN EN 60068-2-27, 100 g, 6 ms

Vibration resistance DIN EN 60068-2-6, 10 g, 10 ... 2000 Hz

Ambient conditions

Operating temperature -40 ... 85 °C (-40 ... 185 °F)

Storage temperature -40 ... 85 °C (-40 ... 185 °F)

Mechanical specifications

Material housing: powder coated aluminum

Combination 1 housing: powder coated aluminum

Combination 2 (Inox) housing: stainless steel 1.4305 / AISI 303

Mass approx. 360 g (combination 1)

Rotational speed max. 12000 min

Moment of inertia 30 gcm

Starting torque ≤ 3 Ncm (version without shaft seal)

Tightening torque, fastening screws max. 1.8 Nm

Shaft load

Angle offset ± 0.9 °

Axial offset static: ± 0.3 mm, dynamic: ± 0.1 mm

Radial offset static: ± 0.5 mm, dynamic: ± 0.2 mm

Approvals and certificates

UL approval cULus Listed, General Purpose, Class 2 Power Source

B

0

10 ... 30 V DC

max. 4 W

cw ascending (clockwise rotation, code course ascending)

cw descending (clockwise rotation, code course

descending)

Supply: 1 plug M12 x 1, 4-pin, A-coded

shaft side: IP64 (without shaft seal)/IP66 (with shaft seal)

housing side: IP65

Stainless steel version (INOX): completely IP67

flange: aluminum

shaft: stainless steel

flange: aluminum

shaft: stainless steel

flange: stainless steel 1.4301 / AISI 304

shaft: stainless steel 1.4305 / AISI 303

approx. 910 g (combination 2)

-1

2

Release date: 2014-07-10 15:44 Date of issue: 2016-01-26 t37194_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

1

Multiturn absolute encoder ESM58-PN

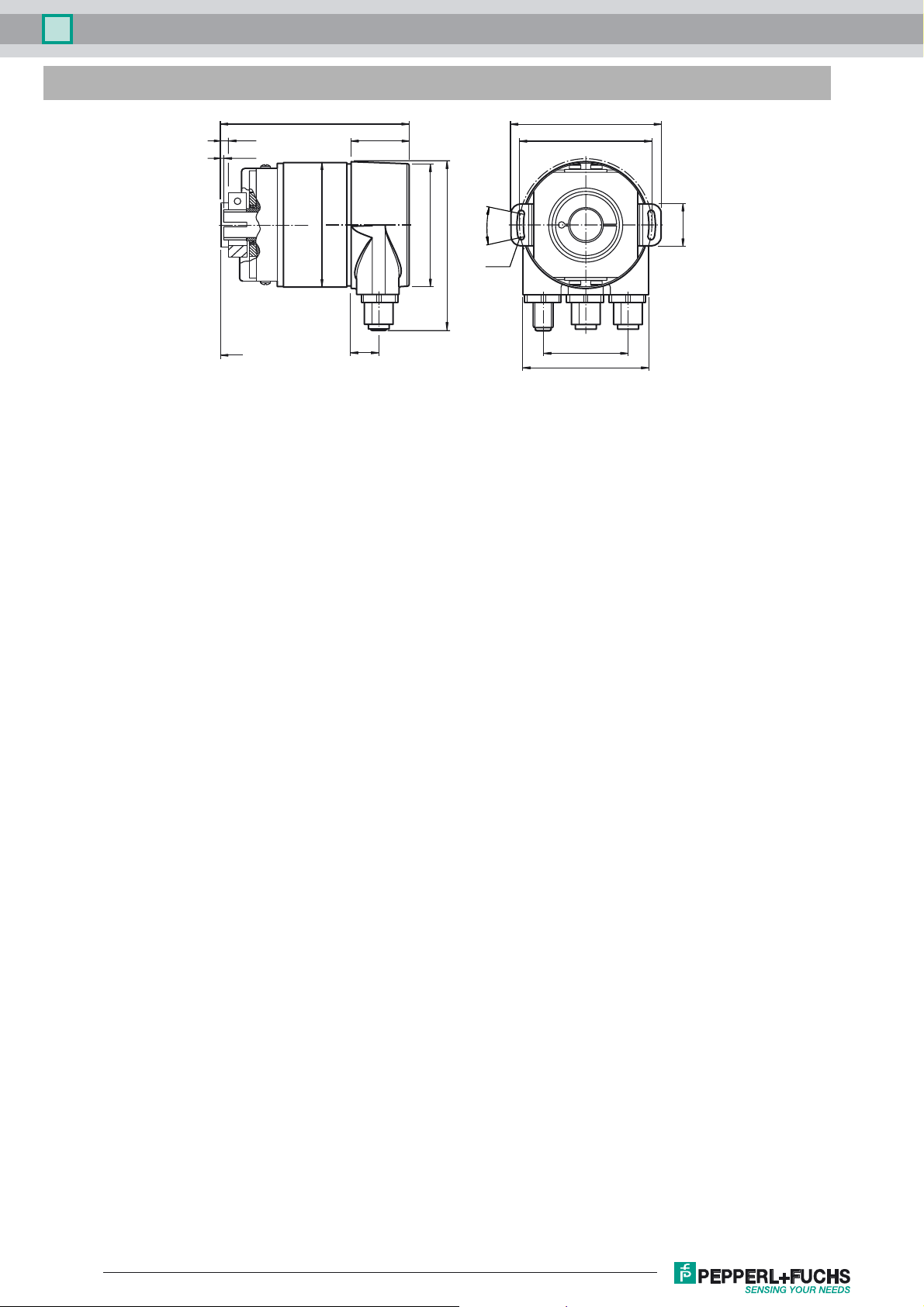

Dimensions

1.5

max. insertion

depth = 30

min. insertion

Lay-on edge

torque rest

depth = 15

L

4

ø 59

12.7

27.5

L: Singleturn = 87

Multiturn = 98

ø 58

75.9

20°

R 1.6

72

ø 63

20

40

60

Release date: 2014-07-10 15:44 Date of issue: 2016-01-26 t37194_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Multiturn absolute encoder ESM58-PN

Electrical connection

Pin

1 Supply voltage +U

2- Rx +

30 V Tx -

4- Rx -

Male connector M12 x 1,

4-pin, A-coded

B

1

2

4

3

Female connector M12 x 1,

Indicators

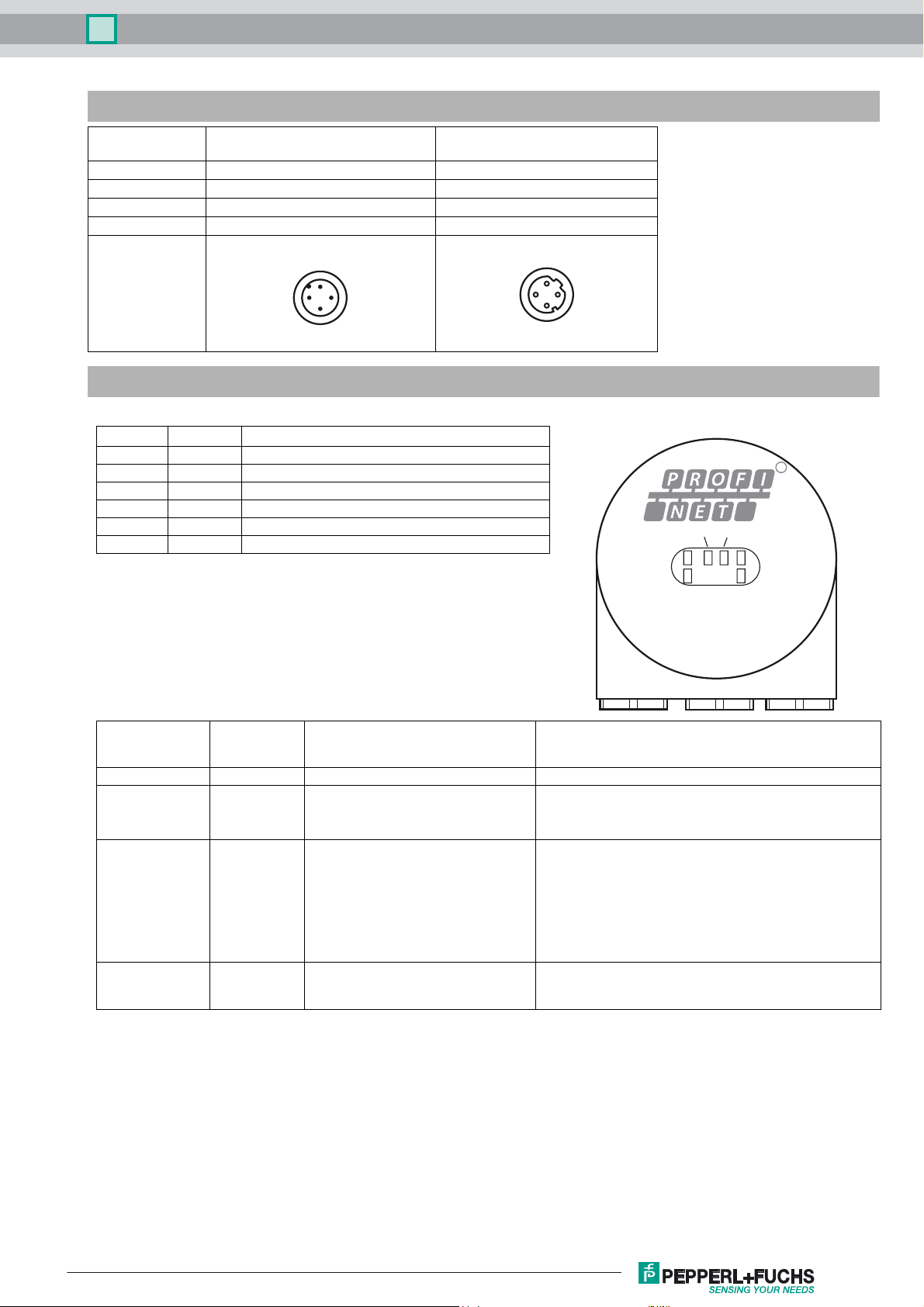

Diagnostic LEDs

LED Color Description for LED = ON

Active1 Yellow Incoming and outgoing data traffic for port 1

Link1* Green Connection to other Ethernet devices on port 1

Active2 Yellow Incoming and outgoing data traffic for port 2

Link2* Green Connection to other Ethernet devices on port 2

Stat1 Green Status 1, details see table below

Stat2 Red Status 2, details see table below

* flashes with 2 Hz if engineering identification call is activated and link connection is

available

4-pin, D-coded

Tx +

1

4

3

2

R

Stat1 Stat2

Active 2

Link 2

Active 1

Link 1

Stat1 (green) Stat2 (red)

Meaning Cause

bus failure

off off No power

on on No connection to another device

Criteria: no data exchange

on flashes

on off Data exchange.

1) flashing frequency 0.5 Hz for at least 3 seconds

1)

Parameterization fault, no data

exchange

Criteria: data exchange correct.

However, the slave did not switch to the

data exchange mode.

Slave and operation ok.

Port2 PWRPort1

• bus disconnected

• Master not available / switched off

• Slave not configured yet or wrong configuration

• Wrong station address assigned (but not outside

the permitted range)

• Actual configuration of the slave differs from the

nominal configuration

Release date: 2014-07-10 15:44 Date of issue: 2016-01-26 t37194_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

3

Multiturn absolute encoder ESM58-PN

Order code

ESM58 – PNR0BN–

Number of bits singleturn

13 8192 (standard)

16 65536

Number of bits multiturn

12 4096 (standard)

14 16384

Temp.

N normal

Output code

B binary

Option

0 none

Exit position

R radial

Connection type / protocol

PN Profinet protocol, 1 female connector/1 male connector, M12 x 1

Shaft dimensions

F1A Recessed hollow shaft Ø10 mm x 30 mm

F2A Recessed hollow shaft Ø12 mm x 30 mm

F3A Recessed hollow shaft Ø15 mm x 30 mm

Housing material

N Aluminium, powder coated

W Aluminium, powder coated with shaft seal

I Stainless steel

Function principle

M Multiturn

Shaft version

S Recessed hollow shaft

Data format

E Ethernet

Release date: 2014-07-10 15:44 Date of issue: 2016-01-26 t37194_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

4

Loading...

Loading...