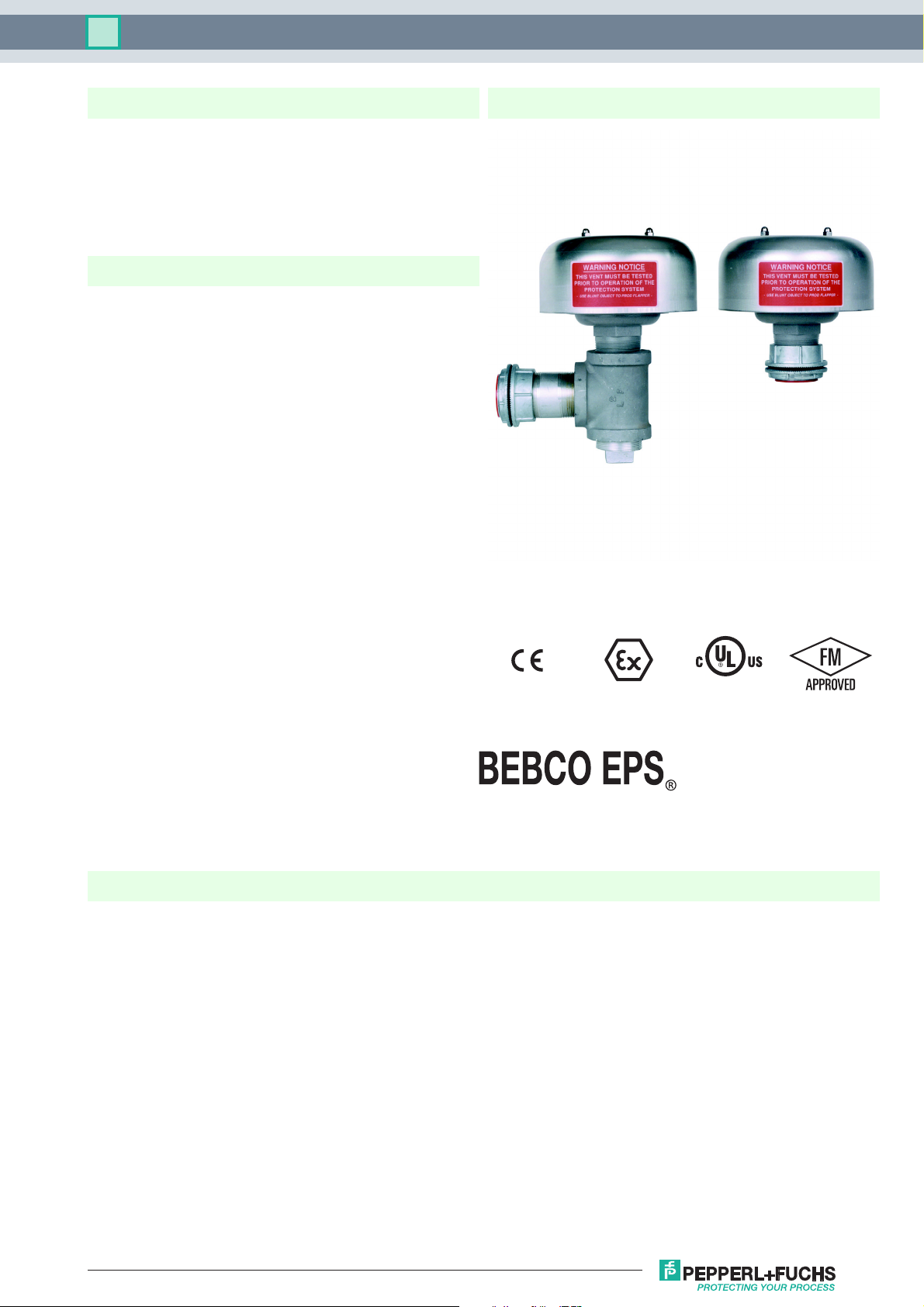

Enclosure protection vent

EPV-*-SA-*

Features

• Top or side mount configurations

• Seamless cap

• Friction free valve assembly

• Spark arresting exhaust

• Can only be purchased in conjunction with corresponding

Purge system or as a replacement

Function

The EPV (enclosure protection vents) are self-seating, gravity

controlled, low pressure relief valve designed to ventilate

excessive enclosure pressures created by the Rapid

Exchange

control devices.

Each vent features a seamless cap, a spark arresting (SA)

style exhaust element, a friction-free valve assembly, a base,

and a mounting hub. The mounting hub, along with associated

pipe fittings, permits direct mounting through a round cutout

on the top or side of a protected enclosure.

This device functions only in conjunction with Pepperl+Fuchs

Bebco EPS® purge systems, to reduce the hazardous

(classified) area rating within protected enclosure(s), in

accordance with the NEC - NFPA 70, Article 500, NFPA 496,

and ISA 12.4.

®

process, or the failure of the enclosure pressure

Assembly

Connection

Release date 2014-04-09 16:51 Date of issue 2014-04-09 515455_eng.xml

Refer to "General Notes Relating to Pepperl+Fuchs Product Information".

Pepperl+Fuchs Group

1

Technical data EPV-*-SA-*

General specifications

Series EPV

Hazardous environment gas or dust

Pneumatic parameters

Protective gas supply Instrument grade air or inert gas

Pressure requirement 2" ...5" wc (50.8 mm ... 127 mm wc)

Maximum pressure 5" ... 7" wc (127 mm ... 177 mm wc)

Breaking pressure 0.65" wc (16.5 mm wc)

Ambient conditions

Ambient temperature -29 ... 49 °C (-20.2 ... 120.2 °F)

Relative humidity 5 ... 95 %, noncondensing

Mechanical specifications

Material Body:

Exhaust elements:

Valve assembly:

Mass EPV-1-SA-00: 3 lb (1.36 kg)

EPV-1-SA-90: 4 lb (1.81 kg)

EPV-2-SA-00: 3 lb (1.36 kg)

EPV-2-SA-00: 4 lb (1.81 kg)

EPV-3-SA-00: 4 lb (1.81 kg)

EPV-3-SA-90: 5 lb (2.27 kg)

EPV-4-SA-00: 7 lb (3.18 kg)

EPV-4-SA-00: 9 lb (4.08 kg)

EPV-5-SA-00: 10 lb (4.54 kg)

EPV-5-SA-00: 12 lb (5.44 kg)

Mounting -00: top mount

-90: side mount

General information

Supplementary information EC-Type Examination Certificate, Statement of Conformity, Declaration of Conformity, Attestation of

Conformity and instructions have to be observed where applicable. For information see www.pepperlfuchs.com.

cap - 3003 drawn aluminum

base - A.S.E. 306, 308 cast aluminum

mounting hub - zinc plated steel

pipe fittings - schedule 40 3003 aluminum

nameplates - Lexan®

hardware - 316 SS

spark arrestor - 316 SS

element cap - 6061 aluminum

base - 14 Ga. machined 316 ss

seat disc - 14 Ga. machined 316 SS

hinge - Zytel® 8018, 14% glass fill

pin & rivets - 316 SS

disc adhesive - urethane epoxy

Vents are only certified for use with Pepperl+Fuchs Bebco EPS® purge and pressurization systems.

See specific purge and pressurization system for associated certifications.

Release date 2014-04-09 16:51 Date of issue 2014-04-09 515455_eng.xml

Refer to "General Notes Relating to Pepperl+Fuchs Product Information".

Pepperl+Fuchs Group

2

Technical data EPV-*-SA-*

Vent Compatibility & Flow Rate Chart

Vent model Required use Optional use SCFH (l)/hr @ 3"

(76.2 mm)

EPV-1-SA 11, 1011, 1001A &

568 (16086) 1044 (29566)

2001A

EPV-2-SA 1012, 1002 & 2002 685 (19399) 122 (34041)

EPV-3-SA 1003, 2003, 3003

1001C & 201B 1143 (32370) 1971 (55819)

& 4004

EPV-4-SA 1004, 2004, 3004,

1001C & 2001C 2510 (71083) 4387 (124240)

& 4004

EPV-5-SA 1005 & 2005 4280 (121210) 4479 (126845)

Normal SCFH measured with enclosure pressure @ 3" (76.2 mm) of water

Max SCFH measured @ 7" (177.8 mm) of water

Overall Vent Dimensions [inches (mm)]

Vent model EPV-1 EPV-2 EPV-3 EPV-4 EPV-5

Hub size 1/2" 3/4" 1 - 1/4" 1 - 1/2" 2"

A 4.75 (120.70) 4.88 (123.8) 5.25 (133.4) 7 (177.8) 7 (177.8)

B 7 (177.8) 7.36 (187.3) 8 (203.2) 11 (279.4) 11.5 (292.1)

C 4 (101.6) 4.63 (117.5) 5 (127) 8 (203.2) 8 (203.2)

D 0.88 (22.2) 1.13 (28.6) 1.75 (44.5) 2 (50.8) 2.5 (63.5)

E 4.25 (108) 5.25 (133.4) 5.5 (139.7) 9 (228.6) 9 (228.6)

F 2.75 (69.9) 2.75 (69.9) 2.75 (69.9) 3.75 (95.3) 3.75 (95.3)

Hub Size indicates standard trade conduit size. All vents require 4" to 7" (101.6 mm to 177.8 mm) underside clearance for

testing.

SCFH (l)/hr @ 7"

(177.8 mm)

C

F

A

D

EPV-*-SA-00 EPV-*-SA-90

F

B

C

D

E

Release date 2014-04-09 16:51 Date of issue 2014-04-09 515455_eng.xml

Refer to "General Notes Relating to Pepperl+Fuchs Product Information".

Pepperl+Fuchs Group

3

Technical data EPV-*-SA-*

Type code/model number

-+

EPV – 1 –SA– 0 0

Mounting configuration

00 To p m ou nt

90 Side mount

SA Spark arrestor included

Ven t si ze

1 1/2" (12.5 mm)

2 3/4" (19.0 mm)

3 1 - 1/4" (32.0 mm)

4 1 - 1/2" (38.0 mm)

5 2" (51.0 mm)

Release date 2014-04-09 16:51 Date of issue 2014-04-09 515455_eng.xml

Refer to "General Notes Relating to Pepperl+Fuchs Product Information".

Pepperl+Fuchs Group

4

Loading...

Loading...