5500 series vent

Features

• One design, three flow rate variants to support your design

requirements

• Anodized aluminum with an optional stainless steel cap

• Universal mounting

Application

The EPV-5500 vent works with the 5500 control unit and

manifold valve to form a certified purge and pressurization

system for enclosures. It can not be used alone.

Vents are a required component for all pressurized enclosure

systems. The EPV-5500 functions as a pressure relief device,

allowing the purge gas to exit the enclosure and includes a

spark arrestor. The vent also provides a seal when enclosure

is pressurized and operating.

The 5500 series purge and pressurization system has NEC,

CEC, ATEX and IECEx third part certifications for Class I,

II/Div. 2 and Zone 2/22.

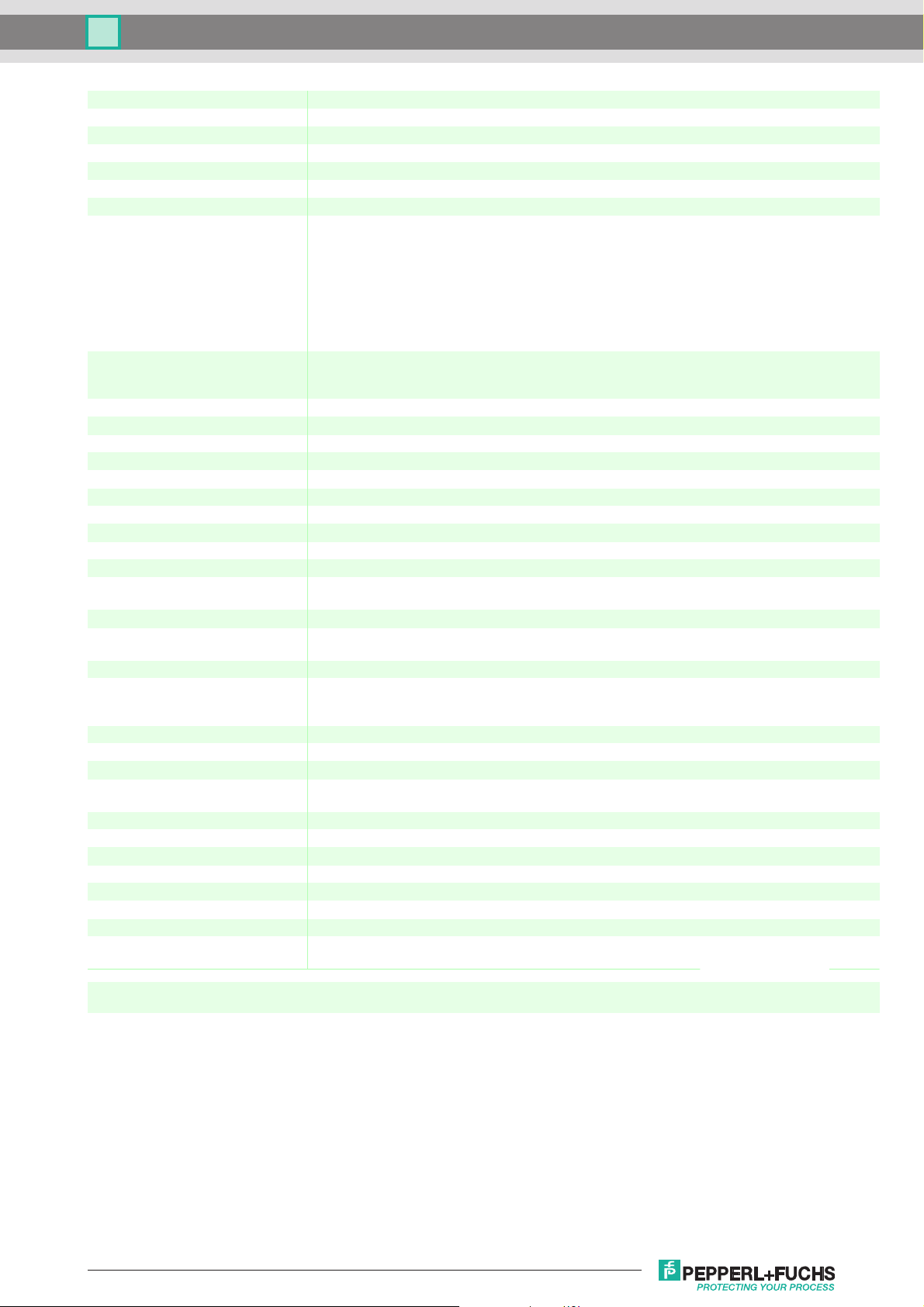

EPV-5500 Vent System

Dimensions

1 1/2 NPS thread

(3) Hex key 0.050" (included)

57.2

57.2

127

23.4

Exhaust port Inlet port

49.5

73.2

98.5

Release date 2018-09-13 22:35 Date of issue 2018-09-13 t169761_eng.xml

Refer to "General Notes Relating to Pepperl+Fuchs Product Information".

Pepperl+Fuchs Group

1

Technical data EPV-5500 Vent System

General specifications

Series 5500

Hazardous environment gas or dust

Pneumatic parameters

Protective gas supply instrument grade air or inert gas

Maximum pressure depends on the integrity of the enclosure (strength)

Purge flow rate See graphs

Flow rate for leakage compensation EPV-5500....-01:

Breaking pressure EPV-5500....-01: 0.8" w.c. (2.0 mbar)

Conformity

Degree of protection EN 60529

Shock resistance EN 60068-2

Ambient conditions

Ambient temperature -20 ... 60 °C (-4 ... 140 °F)

Storage temperature -20 ... 60 °C (-4 ... 140 °F)

Relative humidity 5 ... 90 %, non-condensing

Vibration resistance 5 ... 100 Hz , 1 g, 12 m/s2, all axes

Impact resistance 30 g, 11 ms, all axes

Mechanical specifications

Degree of protection EPV-5500....-01/02: mounting only Type 4X

Material

Housing EPV-5500-AA... body and cap: 6061T6 aluminum

Spark arrestor 316L, (1.4404) stainless steel

Installation - any orientation to enclosure

Mass approx. 1005 g (2.2 lb)

Dimensions see dimensions

Mounting mounting hole 1.5 in NPT knockout (50.8 mm) hole sealing nut (provided)

Data for application in connection

with hazardous areas

Directive conformity

Directive 2014/34/EU part of DEMKO 14 ATEX 1282X

International approvals

UL approval

cULus UL File E184741

IECEx approval part of IECEx UL 14.0019X

General information

Supplementary information Type Examination Certificate, Statement of Conformity, Declaration of Conformity, Attestation of Conformity

approx. 21 scfh (593 l/hr) @ 0.25" w.c. (0.63 mbar)

approx. 58 scfh (1640 l/hr) @ 0.75" w.c. (1.9 mbar)

EPV-5500....-02:

approx. 14 scfh (395 l/hr) @ 0.25" w.c. (0.63 mbar)

approx. 34 scfh (961 l/hr) @ 0.75" w.c. (1.9 mbar)

EPV-5500....-03:

approx. 9.2 scfh (260 l/hr) @ 0.25" w.c. (0.63 mbar)

approx. 22 scfh (622 l/hr) @ 0.75" w.c. (1.9 mbar)

EPV-5500....-02: 1.4" w.c. (3.5 mbar)

EPV-5500....-03: 1.5" w.c. (3.8 mbar)

EPV-5500....-03: Type 4X

EPV-5500-SS... body: 6061T6 aluminum, cap: 316L stainless steel

- not gravity dependent

- internal and external mounting possible

and instructions have to be observed where applicable. For information see

Flow Rate Curves

If you are using the EPV-5500…-01 you will use one of the following three curves to determine your flow rate. The size of your

enclosure will determine what curve to use. The first curve is for an enclosure up to 5 cubic feet, the second curve is for an

enclosure between 5-15 cubic feet and the third curve is for an enclosure 15 cubic feet and larger. Once you determine which

curve matches your application you can determine your flow rate from the pressure reading.

Release date 2018-09-13 22:35 Date of issue 2018-09-13 t169761_eng.xml

Refer to "General Notes Relating to Pepperl+Fuchs Product Information".

Pepperl+Fuchs Group

2

Loading...

Loading...