Page 1

Manual

7500 Series

Bebco EPS® 7500 Series Type Z and

Ex pzc Purge and Pressurization System

Page 2

With regard to the supply of products, the current issue of

the following document is applicable: The General Terms

of Delivery for Products and Services of the Electrical

Industry, published by the Central Association of the

Electrical Industry (Zentralverband Elektrotechnik und

Elektroindustrie (ZVEI) e.V.) in its most recent version as

well as the supplementary clause: "Expanded reservation

of proprietorship."

Page 3

Table of Contents

1. Preface ......................................................................................................................................6

1.1 Information on This Manual ......................................................................................................6

1.2 Responsibility of the Operator and/or Installer ..........................................................................6

2. Safety ........................................................................................................................................7

2.1 Introduction ..............................................................................................................................7

2.1.1 Contents ................................................................................................................................7

2.1.2 Target Group, Personnel ........................................................................................................7

2.1.3 Symbols Used .......................................................................................................................8

2.1.4 Pertinent Laws, Standards, Directives, and Further Documentation ......................................8

2.1.5 Declaration of Conformity ......................................................................................................8

3. General Information on Purge and Pressurization ..............................................................9

3.1 Conditions of Safe Use .............................................................................................................9

4. 7500 Series System Components ........................................................................................10

4.1 Control Unit ............................................................................................................................10

4.1.1 Technical Data—Control Unit ..............................................................................................10

4.1.2 Terminal Connection Data ...................................................................................................13

4.1.3 Electrical Connections.........................................................................................................13

4.1.4 Dimensions—Control Unit ...................................................................................................14

4.1.5 Panel Cut-Out Dimensions ..................................................................................................14

4.1.6 Pressure Kit .........................................................................................................................15

4.1.7 Torque Requirements ..........................................................................................................15

4.1.8 Dimensions—7500-MTD* External/Panel Mount Systems ..................................................16

4.1.9 External/Panel Mount Illustration .........................................................................................20

4.2 EPV-7500 Vents ......................................................................................................................21

4.2.1 Technical Data—EPV-7500 Vents .......................................................................................21

4.2.2 Flow Rate Curves ................................................................................................................23

4.2.3 Dimensions—EPV-7500 Vents ............................................................................................25

4.3 7500-MAN-MV-01 Manual Manifold .......................................................................................26

4.3.1 Technical Data—7500-MAN-MV-01 .................................................................................... 26

4.2.2 Dimensions—7500-MAN-MV-01 ......................................................................................... 27

4.4 Automatic Manifolds ...............................................................................................................28

4.4.1 Technical Data—5500 Manifolds .........................................................................................29

4.4.2 Dimensions—5500 Manifolds .............................................................................................31

7500 Series Manual

5. Installation and Operation ....................................................................................................33

5.1 For Gas Atmospheres .............................................................................................................33

5.2 For Dust Atmospheres ............................................................................................................33

5.3 For Gas and Dust Atmospheres .............................................................................................33

5.4 Setting Up the System ............................................................................................................34

5.5 Operating the System .............................................................................................................34

6. Programming .........................................................................................................................35

6.1 LED Indication ........................................................................................................................36

6.2 Default Settings ......................................................................................................................36

6.3 Contrast and Back Light .........................................................................................................36

3

Page 4

7500 Series Manual

6.4 Menu Structure .......................................................................................................................37

6.5 Purge Programming Settings ..................................................................................................38

6.5.1 Program 1 ...........................................................................................................................38

6.5.2 Program 2 ...........................................................................................................................39

6.5.3 Program 3 ...........................................................................................................................40

6.5.4 Program 4 ...........................................................................................................................40

6.5.5 Program 5 ...........................................................................................................................41

6.5.6 Sequence of Events for All Programs ..................................................................................42

6.6 Purging Timer ........................................................................................................................42

6.7 Minimum Enclosure Pressure “P1” .........................................................................................43

6.8 Alarm Pressure “P2” ...............................................................................................................43

6.9 Purging Pressure “P3” .............................................................................................................43

6.10 Maximum Internal Pressure “P4”.............................................................................................43

6.11 Programming K2.....................................................................................................................45

6.12 Shutdown Timer for K1 ...........................................................................................................47

6.13 Bypass ...................................................................................................................................48

6.14 Units .......................................................................................................................................48

6.15 Change Password ..................................................................................................................49

7. Determining Purging Time ....................................................................................................50

8. User Parameter Setting Sheet ..............................................................................................51

9. Type Codes .............................................................................................................................52

10. Certifi cations ..........................................................................................................................54

11. Maintenance and Repair .......................................................................................................56

12. Troubleshooting .....................................................................................................................56

13. Dismantling and Decommissioning .....................................................................................56

4

Page 5

7500 Series Manual

This page left blank intentionally.

5

Page 6

7500 Series Manual

1 Preface

We are pleased that you have chosen a quality product from Pepperl+Fuchs.

This manual will help you meet the safety and protection requirements for systems with explosion

protection in equipment group II Zones 2 or 22, Class I or II, Division 2 when installing, commissioning,

and using the 7500 control unit and its components. This important information will help you use the 7500

purge and pressurization system safely and correctly.

We reserve the right to make technical changes.

Publisher with responsibility for content:

Pepperl+Fuchs GmbH

Lilienthalstraße 200

68307 Mannheim, Germany

1.1 Information on This Manual

Knowledge of the basic safety regulations and additional training and experience in the area of explosion

protection are essential for the safe handling and failure-free operation of the 7500 series purge and

pressurization system.

These operating instructions contain important data and information to ensure the safe use of the

7500 system in hazardous areas and to meet the requirements of Directive 2014/34/EU. This manual,

particularly the safety information, must be followed by all personnel who work on the system.

1.2 Responsibility of the Operator and/or Installer

The operator and/or installer undertake to ensure that only specialist, trained personnel work on the 7500

series purge and pressurization system and that they

are familiar with the occupational safety and accident prevention regulations and have been briefed

regarding handling of the unit.

have the additional knowledge of explosion protection that is required for work on explosion protected

components.

are familiar with the relevant rules and regulations for the installation, operation, and maintenance of

explosion-protected systems.

have read the safety section and warnings in this manual.

6

Page 7

2 Safety

2.1 Introduction

2.1.1 Contents

This document contains information that you need to use your product throughout the applicable stages of

the product life cycle. These can include the following:

Product identification

Delivery, transport, and storage

Mounting and installation

Commissioning and operation

Maintenance and repair

Troubleshooting

Dismounting and disposal

Warning!

Failure to follow these instructions may impair the safety protection and function of the equipment.

Note!

For complete information on the product, refer to the instruction manual and further documentation at

www.pepperl-fuchs.com.

7500 Series Manual

The documentation consists of the following parts:

Present document

Instruction manual

Datasheet

Additionally, the following parts may belong to the documentation, if applicable:

EU declaration of conformity

Certificates

Control drawings

Additional documents

2.1.2 Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation, maintenance, and dismounting lies with

the plant operator. In accordance with but not limited to IEC/EN 60079-14, only appropriately trained and

qualified personnel may carry out mounting, installation, commissioning, operation, maintenance, and

dismounting of the product. National laws and regulations must be observed and take precedence over

any aspects of IEC/EN 60079-14. The personnel must have read and understood the instruction manual

and any further documentation.

7

Page 8

7500 Series Manual

2.1.3 Symbols Used

This document contains symbols for the identification of warning messages and of informative messages.

Warning Messages

You will find warning messages in instances where danger may arise from your actions. You must observe

these warning messages for your personal safety and to avoid property damage. Depending on the risk

level, the warning messages are displayed in descending order as follows:

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants, or result in

their complete failure

Informative Symbols

Note!

This symbol brings important information to your attention.

Action

This symbol indicates a paragraph with instructions. You are prompted to perform an action or

a sequence of actions.

2.1.4 Pertinent Laws, Standards, Directives, and Further Documentation

NEC, CEC, and other national and local aws, standards, or Directives that are applicable to the intended

use and installation location must be observed. In relation to hazardous areas, Directive 1999/92/EC must

be observed.

The corresponding datasheets, EU Declaration of Conformity, EU Type Examination Certificates, NEC/

NFPA and CEC certificates, and control drawings, if applicable (see datasheet), are an integral part of this

document. You can find this information at www.pepperl-fuchs.com.

Due to constant revisions, documentation is always subject to change. Please refer only to the most up-todate version, which can be found at www.pepperl-fuchs.com.

2.1.5 Declaration of Conformity

All products were developed and manufactured under observance of the applicable European standards

and guidelines.

Note!

A declaration of conformity is included with these instructions and can be requested from the manufacturer

or obtained online at www.pepperl-fuchs.com.

8

Page 9

3 General Information on Purge and Pressurization

Purge and pressurization is one of the most versatile ignition protection classes. Purge and pressurization

systems are based on the principle that in Zone 2/Class I Division 2 (gas), the gas mixture in the ambient

atmosphere, which may ignite under certain circumstances, is removed from the housing by an initial purge

process. After the purge phase, sufficiently compressed inert gas, usually air, is supplied to compensate

for leaks in the housing and any installed equipment. This permanent overpressure prevents any potentially

explosive atmosphere in the ambient air from entering the housing. During the purge phase, an internal

pressure is achieved.

For applications in Zone 22/Class II Division 2 (dust), the purge process is omitted because purging would

raise explosive dust into a cloud, creating a possible hazard. Instead of pre-purging, the interior of the

housing is inspected for dust and cleaned manually if dust is present.

Purge and pressurization systems are particularly suitable for installed equipment that is not approved for use

in hazardous areas. The equipment can then be used directly in the hazardous area.

3.1 Conditions of Safe Use

1. The main control unit and the EPV vent are the only parts that have been evaluated for the system’s

certifications.

2. All unused entry points to the 7500 control unit shall be closed with a properly certified IECEx, ATEX,

or cULus device that is suitable for the installation location and has the necessary ingress protection.

3. For dust environments, the non-metallic window may pose an electrostatic discharge hazard. To clean

the device, use only a water-damp cloth and allow to air dry. Do not use or install in high chargeareas. See IEC60079-32-1 for more information.

7500 Series Manual

4. When the 7500 series purge and pressurization system is mounted to an enclosure, the complete

installation shall be evaluated to the appropriate standards and regulations that are applicable for

the final installation location. These include, but are not limited to NFPA 496, IEC 60079-2, and IEC

60079-14. These standards shall be available at the site of installation. See certificates for applicable

editions.

5. The purge control unit has a temperature class (T6, T5 or T4) that is dependent on ambient

temperature. This temperature shall be considered when mounted to an enclosure, or inside of an

enclosure. See details on the certificate.

6. The bypass function shall only be enabled when the area is known to be non-hazardous.

7. In a hazardous dust environment, regularly remove dust from the unit to prevent excessive

temperature rise. See certificate for full information.

9

Page 10

7500 Series Manual

s

4 7500 Series System Components

The 7500 series system consists of a control unit, an enclosure protection vent, and manual or automatic

manifold. The control unit has a touch screen display that is menu driven and will easily guide the user in

selecting pre-programmed and user-selected variables. The 7500 can be used with a digital valve/manifold

system like the 5500-MAN-... unit to make a fully automatic system. The enclosure pressure and leakage can

be monitored and, in the event of a loss in enclosure pressure, the solenoid valve can engage to restore the

defined pressure settings and/or alarm for the pressure drop. An easy-to-see display also has 4 LEDs for

system condition indication from a distance.

4.1 Control Unit

The 7500 control unit is a control device for Type Z & Ex pz purge systems and is suitable for purge time

and pressure monitoring in Class I or II, Division 2, Zone 2 or 22. It controls the volume of purge gas flowing

into the explosion-protected control cabinet, and it maintains and monitors an overpressure relative to the

ambient air when purging is complete.

The 7500 control unit can be ordered as a stand-alone unit for panel mounting to your enclosure or mounted

to a panel with the 7500-MAN-MV-01 valve in a configuration.

Control Unit Components

7500 control unit

Mounting bracket, gasket, and screws for enclosure mounting

Manual

Warning!

The conduit hub extension, 7500-HUB-AA-01, can only be mounted once to the 7500 control unit. If

removed, it cannot be reinstalled. A new conduit unit must be purchased.

nent

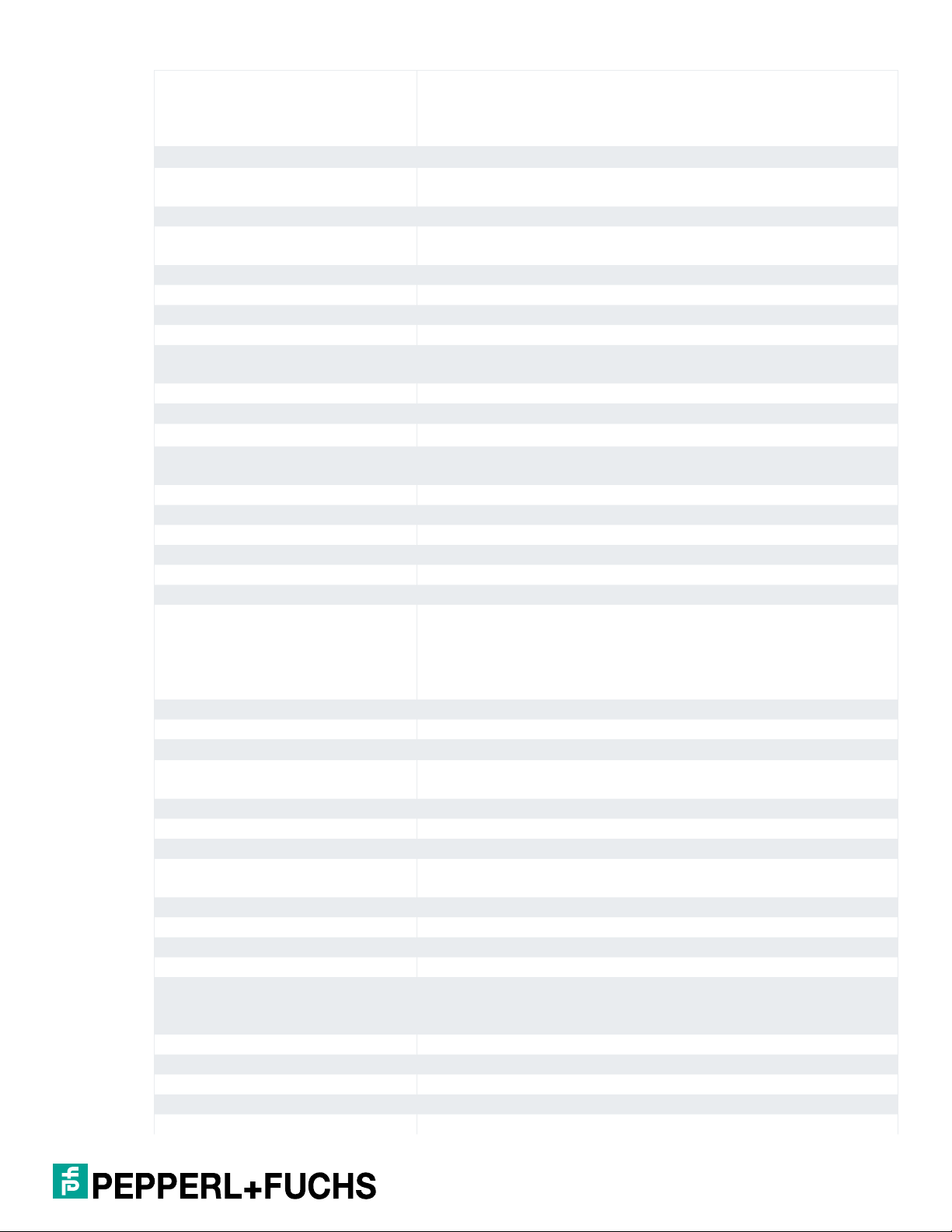

4.1.1 Technical Data—Control Unit

General specifications

Equipment architecture max. enclosure size 450 ft3 (12.7 m3)

Operating mode fully automatic (FA)

Series 7500

Hazardous environment gas or dust

Supply

10

Page 11

7500 Series Manual

Rated voltage U

r

20 ... 30 V DC at 0.1 A

90 ... 250 V AC, 50 ... 60 Hz at 0.04 A without solenoid valve

Supply voltage can be line-to-line or line-to-neutral, single phase

OVC II

Power consumption max. 2.7 W / 7.3 VA without valve

Accuracy pressure readings: ± 2 %

timers: ± 5 %

Electrical specifi cations

Connection screw terminals—see manual for specifi cations on wire size and

torque values

Output

Output I

Connection K1, terminals, 1 x NO

Output type enclosure power contacts

Contact loading 5 A at 250 V AC , 5 A at 30 V DC, relays must be externally fused

inrush current: 50 A

Output II

Connection K2, terminals, 1 x NO

Output type alarm and control contacts

Contact loading 5 A at 250 V AC , 5 A at 30 V DC, relays must be externally fused

inrush current: 50 A

Output III

Connection K3, terminals, L1 powered contact

Output type solenoid manifold, contact

Inrush current 5 A

Contact loading 0.5 A at 250 V AC , 0.5 A at 30 V DC, relays must be externally fused

Indicators/settings

LED indicator K1: Green - Contact K1 is energized (enclosure contacts)

K2: Amber - Contact K2 is energized (alarm/control contacts)

P/SV: Blue - Safe pressure P1 (minimum enclosure pressure)

P/SV: Amber - Solenoid manifold is energized (purging/pressure

compensation)

Pneumatic parameters

Protective gas supply compressed air or inert gas, 5 m fi lter, free from oil

Pressure requirement supply pressure: 20 ... 120 psig (1.4 ... 8.2 bar)

Safe pressure 0.38 in wc (0.95 mbar) for gas

0.8 in wc (2.0 mbar) for dust

Enclosure pressure 0 ... 10 in wc (0 ... 25 mbar)

Directive conformity

Electromagnetic compatibility

Directive 2014/30/EU EN 61326-1, FCC CFR 47, part 15, subpart B: 2017, Class A

ICES-003, Issue 6:2016, Class A ITE

RoHS

Directive 2011/65/EU (RoHS) EN 50581:2012

Conformity

Ambient conditions

Ambient temperature -40 ... 70 °C (-40 ... 158 °F) at T4 / T80°C

-40 ... 65 °C (-40 ... 149 °F) at T5 / T75°C

-40 ... 50 °C (-40 ... 122 °F) at T6 / T60°C

Storage temperature -40 ... 80 °C (-40 ... 176 °F)

Altitude max. 2000 m

Relative humidity 5 ... 90 %, non-condensing

Vibration resistance 5 ... 100 Hz , 1 g, 12 m/s

2

, all axes

Impact resistance 30 g, 11 ms, all axes

11

Page 12

7500 Series Manual

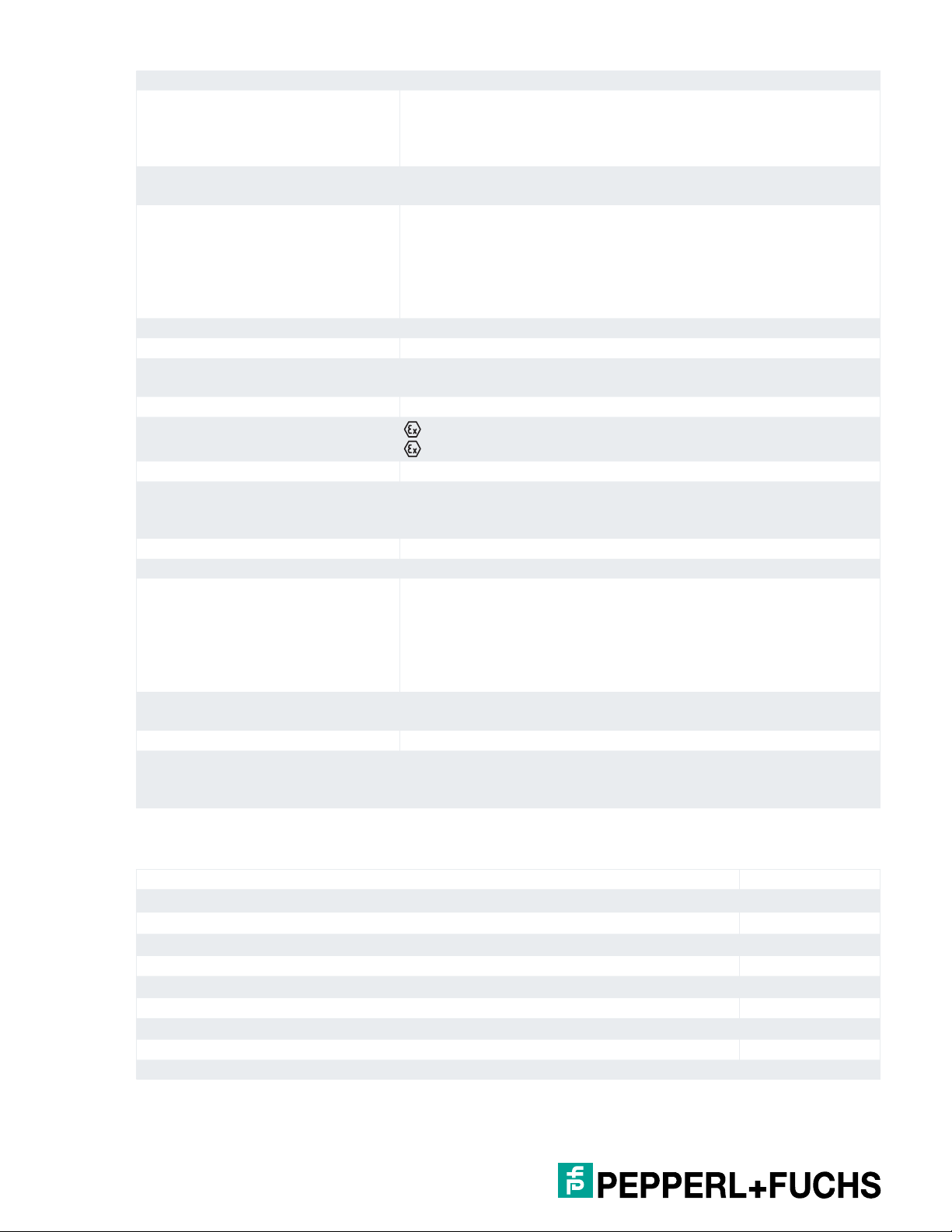

Mechanical specifi cations

Connection type electrical: 2 x 1/2 inch NPTF (open from factory)

Degree of protection Type 4X, IP66

Material lens: Makrolon

Mass 710 g (1 lb 10 oz)

Dimensions 150 x 100 x 50 mm (5.9 x 4 x 2 in)

Data for application in connection

with hazardous areas

Certifi cate

Marking

Directive conformity

Directive 2014/34/EU IEC/EN 60079-0, IEC/EN 60079-2, IEC/EN 60079-7,

International approvals

UL approval

cULus Class I, Division 2, Groups A, B, C, D T4 (-40 °C Ta 70 °C)

IECEx approval Ex ec nC [pzc] IIC T6...T4 Gc

General information

Supplementary information Type Examination Certifi cate, Declaration of Conformity, and

1 x M12 opening (plugged from factory)

pneumatic: high-pressure port - 1/8 in NPTF, low-pressure port - 1/8

in NPTF

No ratings for mounting to enclosure for 7500-MTD-BX...

®

GP-V polycarbonate

screws: AISI 316 (1.4401), 304, or 18-8 stainless steel

housing: A380, A356, or 6061-T6 aluminum

mounting gasket: Bisco® HT-800 medium cellular silicone

mounting tabs: SAE 304 stainless steel

M12 plug: 6061-T6 aluminum

II 3 G Ex ec nC [pzc] IIC T6...T4 Gc

II 3 D Ex tc [pzc] IIIC T60 °C ... T80 °C Dc

IEC/EN 60079-15, IEC/EN 60079-31

Supplements: EN 61010-1:2010

Class I, Division 2, Groups A, B, C, D T5 (-40 °C Ta 65 °C)

Class I, Division 2, Groups A, B, C, D, T6 (-40 °C Ta 50 °C)

Class II, Division 2, Groups F, G T4 (-40 °C Ta 70 °C)

Class II, Division 2, Groups F, G T5 (-40 °C Ta 65 °C)

Class II, Division 2, Groups F, G T6 (-40 °C Ta 50 °C)

Ex tc [pzc] IIIC T60 °C ... T80 °C Dc

instructions have to be observed where applicable. For information

see www.pepperl-fuchs.com.

4.1.2 Terminal Connection Data

Conductor cross section solid max. 0.2 mm²

Conductor cross section solid max. 6 mm²

Conductor cross section fl exible min. 0.2 mm²

Conductor cross section fl exible max. 4 mm²

Conductor cross section fl exible, with ferrule without plastic sleeve min. 0.25 mm²

Conductor cross section fl exible, with ferrule without plastic sleeve max. 4 mm²

Conductor cross section fl exible, with ferrule with plastic sleeve min. 0.25 mm²

Conductor cross section fl exible, with ferrule with plastic sleeve max. 4 mm²

Conductor cross section AWG min. 24

Conductor cross section AWG max. 10

12

Page 13

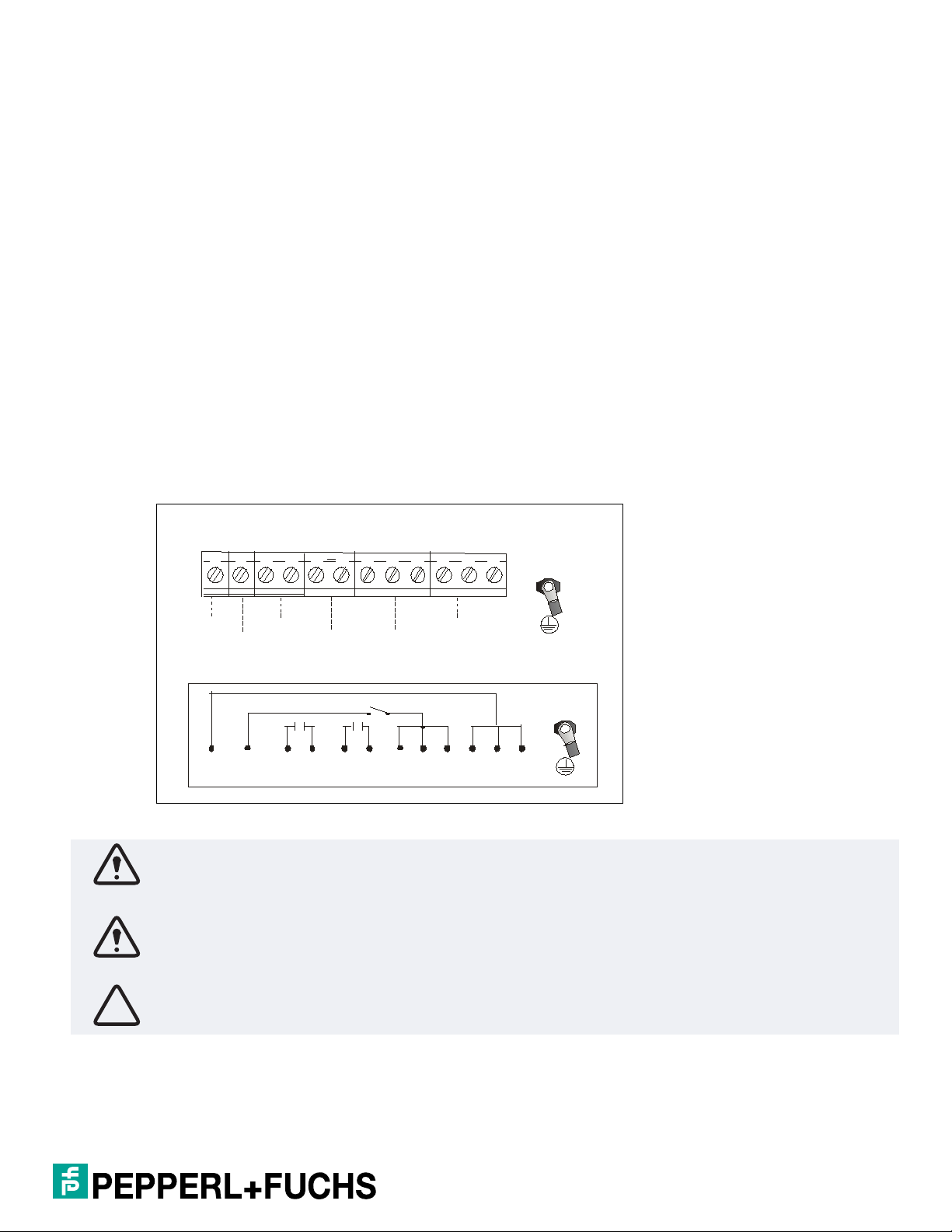

4.1.3 Wiring Requirements and Electrical Connections

Alarm/

Encl

Encl

Valve

L/L1/+

N/L 2/-N/L 2/-

Terminal Block Connections

Te rm in a l Bl o ck

L /L1/+ SV1 Alarm/Encl

K2

En c l

K1

N /L 2/-N /L2/-

Protective

earth

Wiring Requirements

1. All applicable local and national wiring codes must be followed when wiring the system.

See IEC 60079-14 for more information.

2. The power supply to this device shall have a separate disconnect. If placed in the hazardous area, it shall

be rated for the area in which it is being installed. Placing the disconnect into the purged enclosure is not

a "safe" area since power needs to be applied to the control unit before the purge cycle is complete.

3. The protective earth wire must be the same size as largest wire used to bring power into the enclosure.

Terminate using a ring lug that is properly crimped at the protective earth stud in the bottom of the

enclosure. The protective earth terminal torque is 12 in lb (1.36 Nm).

4. All wire shall be copper only, rated at a minimum of 80 °C.

5. The wire strip length into the fixed terminal block is 8 mm.

6. The terminal torque is 0.5 Nm to 0.6 Nm.

7. There shall be only one wire per terminal.

8. It is recommended to leave a bit of extra wire loop in the housing.

Electrical Connections

7500 Series Manual

Warning!

When connecting line-to-line power and K1 and K2 are used to switch the power, the alarm function is not

available. For more information, see chapter 6.11.

Warning!

When powering the system line-to-line, both lines are present if K3 is used. In this event, both sides of the

relay contacts must be fused.

Caution!

Use ferrules with all stranded wire types.

13

Page 14

7500 Series Manual

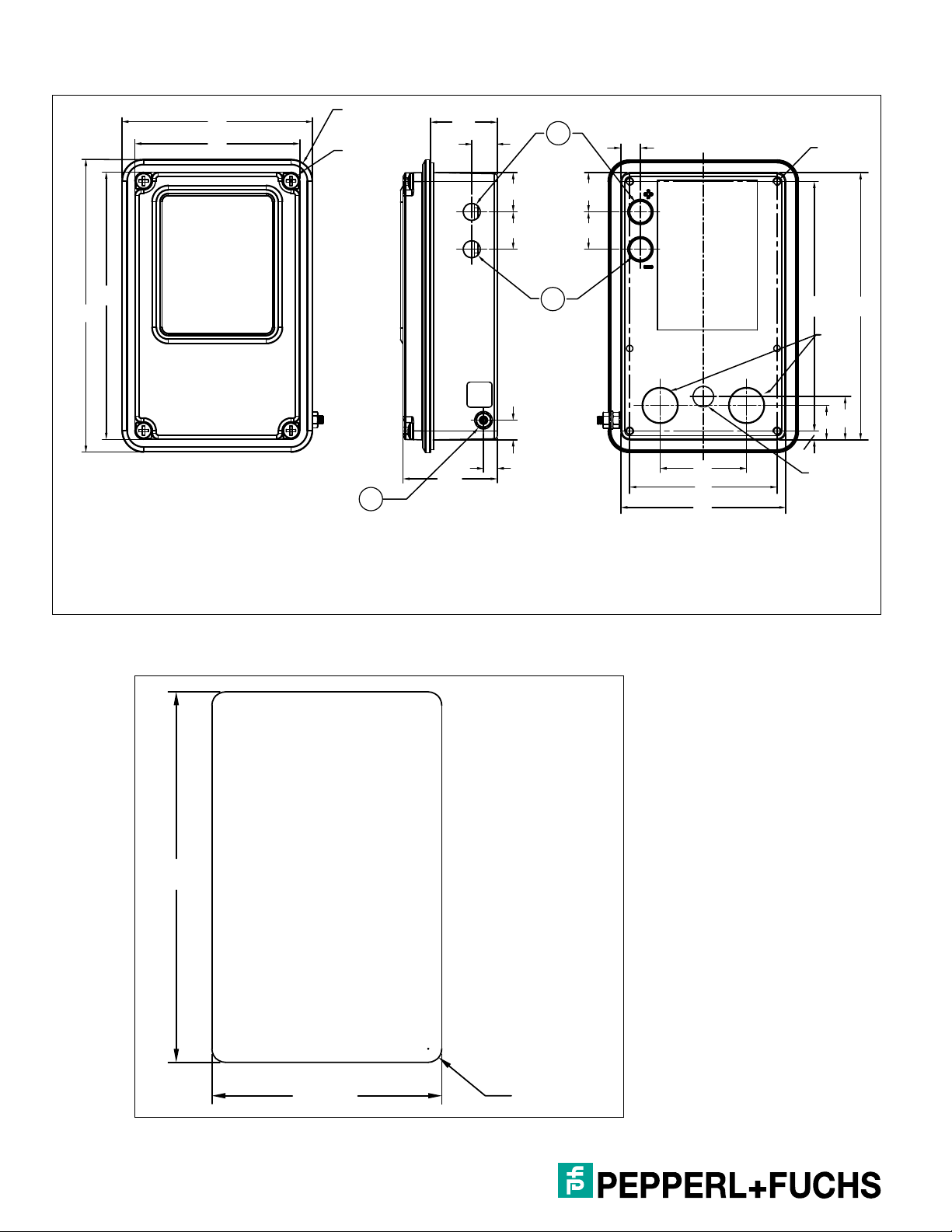

4.1.4 Dimensions—Control Unit

149

4 x

R11

4 x

R4.5

48

3

136

97

84

1. High-pressure port 1/8-27 NPT

2. Low-pressure port 1/8-27 NPT

3. Protective earth stud, torque 12 in lb (1.35 Nm)

34

13

20

19 19

10

7

1

2

20

10

44

75

84

127

4.5

M12 x 1.5

4 x

M4 x .7

1/2-14

NPT

17.5

136

22

4.1.5 Panel Cut-Out Dimensions

137 ± 0.5

85 ± 0.5 4 x R5 ± 1

14

Page 15

4.1.6 Pressure Kit

The included pressure kit contains the following components:

Bulkhead fitting

O-ring

Tubing

Tubing inserts

Straight connector

Sintered element for bulkhead fitting

7500 Series Manual

4.1.7 Torque Requirements

Hardware Torque

Main lid 12 in lb (1.36 Nm).

M4 screws for mounting bracket 12 in lb (1.36Nm).

Screws for mounting HUB 12 in lb (1.36 Nm).

M12 plug 15 in lb (1.70 Nm).

Panel mount bracket hardware Tighten evenly to a uniform gasket thickness of 1.3 mm to 1.7 mm

Set screws to mount control unit in panel Tighten until control unit is touching metal-to-metal around all

Manifold mounting hardware Tighten hardware until gasket is compressed 0.64 mm to 0.96 mm

edges

(use washers provided)

15

Page 16

7500 Series Manual

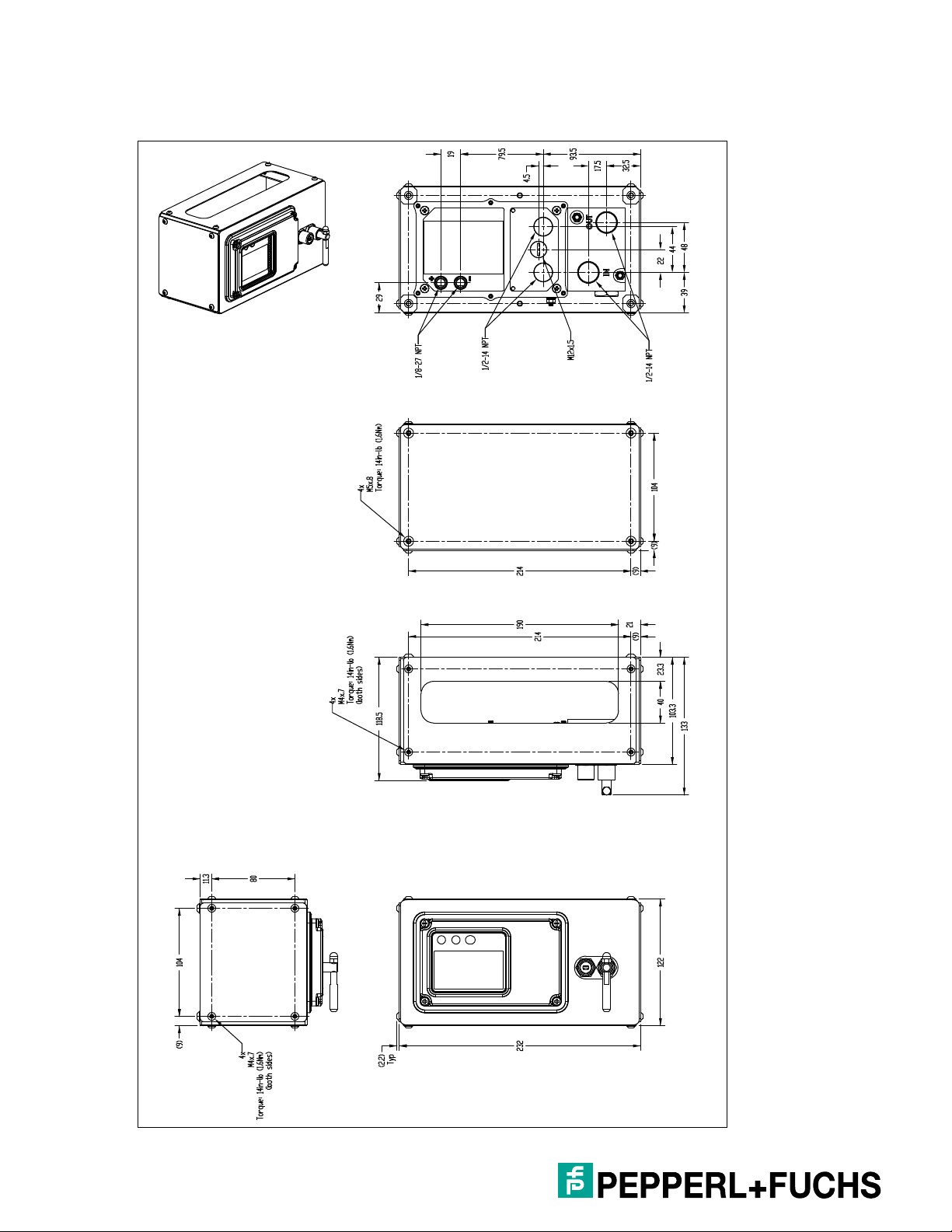

4.1.8 Dimensions—7500-MTD-* External/Panel Mount Systems

7500-MTD-BXRW-01 Rectangular External Mount with Control Unit and Manifold

16

Page 17

7500 Series Manual

7500-MTD-PMRW-01 Rectangular Panel Mount with Control Unit and Manifold

17

Page 18

7500 Series Manual

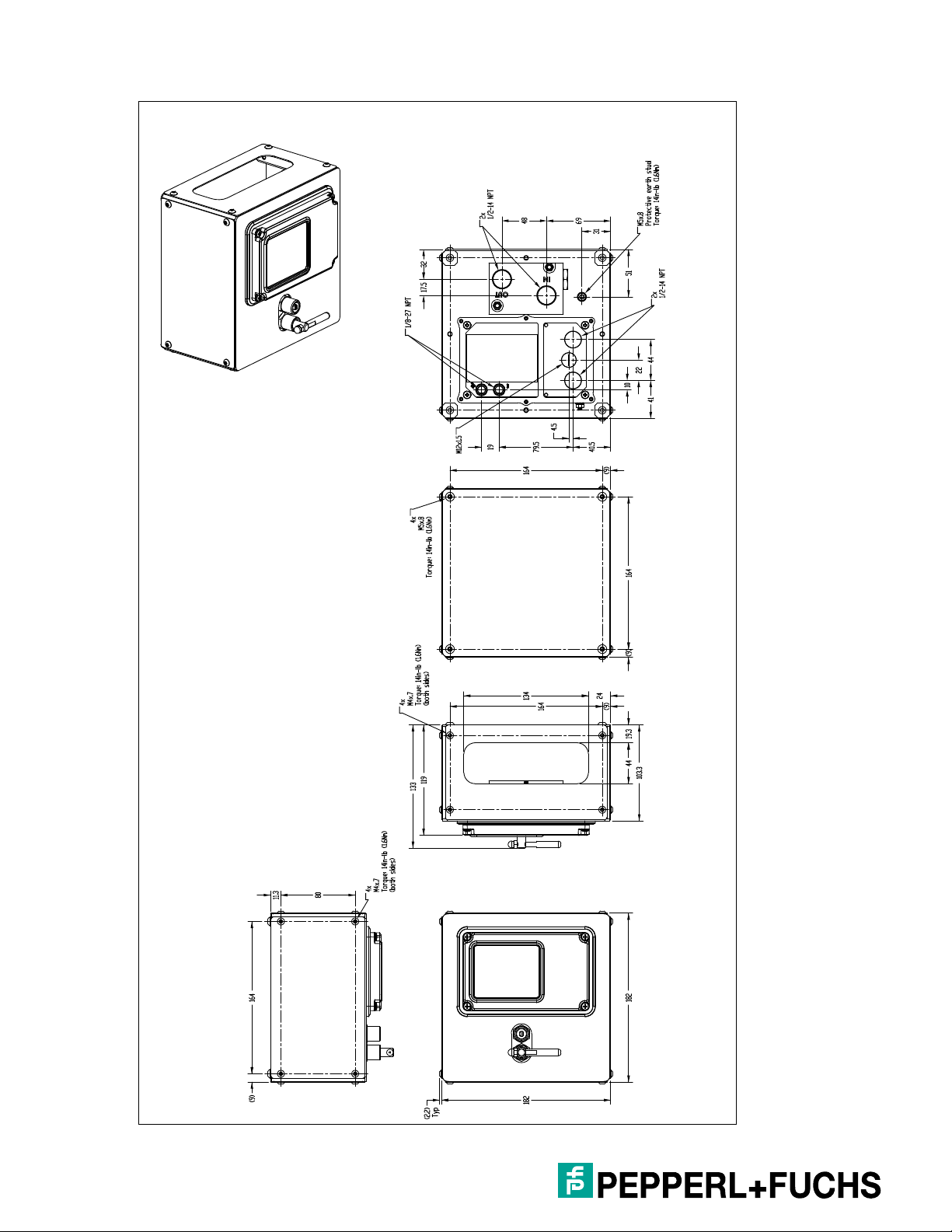

7500-MTD-BXSW-01 Square External Mount with Control Unit and Manifold

18

Page 19

7500-MTD-PMSW-01 Square Panel Mount with Control Unit and Manifold

7500 Series Manual

19

Page 20

7500 Series Manual

4.1.9 External/Panel Mounting Illustration

20

Page 21

4.2 EPV-7500 Vents

EPV-7500 vents work with the 7500 control unit and manifold to provide a functional, certifiable purge and

pressurization system for enclosures. As required by all pressurized enclosure systems, the EPV-7500 vent

functions as a pressure relief device and allows the purge gas to exit the enclosure, yet provides a seal

when the enclosure is pressurized and operating. The vent also has a spark arrestor, which is required for

hazardous areas.

EPV-7500-...-01/02/03 EPV-7500-PY-04

7500 Series Manual

EPV-7500 Components

EPV-7500 vent with spark arrestor

Sealing washer and nut for internal or external mounting

Hex key for removing, attaching, and rotating the vent cap

4.2.1 Technical Data—EPV-7500 Vents

General specifications

Equipment architecture max. enclosure size 450 ft3 (12.7 m3)

Series 7500

Hazardous environment gas or dust

Pneumatic parameters

Protective gas supply compressed air or inert gas, 5 m fi lter, free from oil

Maximum pressure depends on the integrity of the enclosure (strength)

Purge fl ow rate See tables

Flow rate for leakage compensation EPV-7500....-01:

Breaking pressure EPV-7500....-01: 0.8 in wc (2.0 mbar)

approx. 25 scfh (707 l/hr) at 0.25 in wc (0.63 mbar)

approx. 65 scfh (1838 l/hr) at 0.75 in wc (1.9 mbar)

EPV-7500....-02:

approx. 20 scfh (565 l/hr) at 0.25 in wc (0.63 mbar)

approx. 48 scfh (1357 l/hr) at 0.75 in wc (1.9 mbar)

EPV-7500....-03 and EPV-7500-PY-04:

approx. 15 scfh (424 l/hr) at 0.25 in wc (0.63 mbar)

approx. 25 scfh (707 l/hr) @ 0.75 in wc (1.9 mbar)

EPV-7500-...-02: 1.4 in wc (3.5 mbar)

EPV-7500-...-03: 1.5 in wc (3.8 mbar)

EPV-7500-PY-04: 1.4 in wc (3.5 mbar)

21

Page 22

7500 Series Manual

Directive conformity

Electromagnetic compatibility

Directive 2014/30/EU EN 61326-1, FCC CFR 47, part 15, subpart B: 2017, Class A

RoHS

Directive 2011/65/EU (RoHS) EN 50581:2012

Conformity

Degree of protection Directive conformity: see Declaration of Conformity

Ambient conditions

Ambient temperature -40 ... 70 °C (-40 ... 158 °F) (AA and SS versions)

Storage temperature -40 ... 80 °C (-40 ... 176 °F) (AA and SS versions)

Relative humidity 5 ... 90 %, non-condensing

Vibration resistance 5 ... 100 Hz , 1 g, 12 m/s

Impact resistance 30 g, 11 ms, all axes

Mechanical specifi cations

Degree of protection EPV-7500....-01/02: mounting only Type 4X

Material EPV-7500-AA...: body and cap 6061T6 aluminum

Housing EPV-7500-AA... body and cap 6061T6 aluminum body and cap:

Spark arrestor 304 stainless steel

Installation - any orientation to enclosure

Mass approx. 1005 g (2.2 lb)

Dimensions See dimensions in chapter 4.2.3

Mounting EPV-7500-...-01/02/03: mounting hole 1.5 in NPT knockout (50.8

Data for application in connection

with hazardous areas

Certifi cate

Marking ATEX: part of 18ATEX2025X

International approvals

cULus Part of the cULus classifi ed 7500 purge system

ICEx approval Part of IECEx UL 18.0022X

ICES-003, Issue 6:2016, Class A ITE

-20 ... 60 °C (-4 ... 140 °F) (PY versions)

-20 ... 60 °C (-4 ... 140 °F) (PY versions)

2

, all axes

EPV-7500....-03: Mounting and unit Type 4X

EPV-7500-SS...: body: 6061T6 aluminum, cap: AISI 316 (1.4401)

stainless steel

EPV-7500-PY...: body and cap: polyoxymethylene (POM)

Spark arrestor: AISI 316L (1.4404) stainless steel

6061T6 aluminum

EPV-7500-SS... body: 6061T6 aluminum, cap: AISI 316L (1.4404)

stainless steel

EPV-7500-PY... body and cap: polyoxymethylene (POM)

- not gravity dependent

- internal and external mounting possible

mm) hole sealing nut (provided)

EPV-7500-PY-04: mounting hole 37 mm with sealing nut (provided)

22

Page 23

4.2.2 Flow Rate Curves

The enclosure pressure vs. flow rate curves below represent the EPV-7500....-01, 02, 03, and 04 vents. This

corresponds to the enclosure pressure and is independent of the valve used, provided the valve can deliver

the flow rate that is required.

The vent flow tables represent the flow rate and enclosure pressure for each vent with a safety margin

attached to the values. Enclosure pressure may be less than the tables below for actual measured value.

The values below do not take into account leakage from the enclosure; they represent a perfectly sealed

enclosure. In most applications, the enclosure will have leakage, which will require higher flow rate into

the enclosure to achieve the correct reading. This extra flow will depend on the leakage throughout the

enclosure.

There is no restriction of enclosure size for each vent, but leakage rate, flow rate, enclosure pressure, and

the 7500 maximum purge time of 254:59 should be considered when applying these vents.

The EPV-7500-…-01 is usually used on large enclosures because it has a higher flow rate and lower back

pressure within the enclosure than the other versions. This can reduce the purging time while keeping the

enclosure pressure low, which is important for a large enclosure. However, this vent leaks more pressure

through its flow control mechanism.

The EPV-7500-…-02 provides a better seal at the vent than the EPV-7500-…-01. The flow rate for purging is

less for the same enclosure pressure of the ‘-01’ version.

7500 Series Manual

The EPV-7500-…03 provides the best seal for pressurization and should be selected for a smaller enclosure,

bottled air, or inert gas sources, and for increased conservation of the protective gas source. The flow rate is

less than the ‘-01’ and ‘-02’ versions but provides very low leakage.

The EPV-7500-PY-04 is similar to the EPV-7500-…03 vent and is used in the same applications, but it

is made out of polyoxymethylene and is lower in cost. The flow rate and enclosure pressure are slightly

different. See the tables below for exact values.

EPV-75000-...-01 Vent Flow vs. Enclosure Pressure

ft3/m Inches of water l/m mbar

5 1.41 141 3.49

7 1.57 198 3.89

10 1.77 282 4.39

12 1.93 339 4.78

15 2.23 424 5.53

17 2.43 480 6.02

20 2.66 565 6.59

25 3.08 707 7.63

30 3.63 848 9

35 4.28 990 10.62

23

Page 24

7500 Series Manual

EPV-7500-...-02 Vent Flow vs. Enclosure Pressure

ft3/m Inches of water l/m mbar

5 2.28 141 5.7

7 2.48 198 6.2

10 2.78 282 6.95

12 2.98 339 7.45

15 3.28 424 8.2

17 3.48 480 8.7

20 3.78 565 9.45

25 4.38 707 10.95

30 4.88 848 12.2

35 5.38 990 13.45

EPV-7500-...-03 Vent Flow vs. Enclosure Pressure

ft3/m Inches of water l/m mbar

4 2.13 113 5.32

6 2.33 170 5.82

8 2.53 226 6.32

10 2.83 282 7.07

12 3.63 339 9.07

14 4.78 396 11.95

16 6.23 452 15.57

EPV-7500-...-04 Vent Flow vs. Enclosure Pressure

ft3/m Inches of water l/m mbar

3 2.63 85 6.53

4 2.88 113 7.15

5 3.23 141 8.02

6 3.53 170 8.77

7 3.93 198 9.76

8 4.33 226 10.76

9 4.73 254 11.75

10 5.13 283 12.75

11 5.63 311 13.99

12 6.23 339 15.48

13 6.93 368 17.22

14 7.83 396 19.45

24

Page 25

4.2.3 Dimensions—EPV-7500 Vents

EPV-7500-...-01/02/03

1 1/2 NPS thread

(3) Hex key 0.050" (included)

7500 Series Manual

57.2

57.2

EPV-7500-PY-04

55.0 mm (2.15")

28.0 mm (1.10")

127

23.4

Exhaust port Inlet port

49.5

73.2

98.5

41.0 mm (1.60")

30.0 mm (1.20")

70.0 mm (2.75")

111.0 mm (4.35")

9.0 mm (0.35")

41.0 mm (1.60")

25.0 mm (1.00")

28.0 mm (1.10")

55.0 mm (2.15")

57.0 mm (2.25")

25

Page 26

7500 Series Manual

4.3 7500-MAN-MV-01 Manual Manifold

The 7500-MAN-MV-01 combines in one device a ball valve for purging and a needle valve for pressurizing

an enclosure. The ball valve has a handle for easy actuation. To provide security and prevent tampering, the

needle valve requires a slot-head screwdriver to set the enclosure pressure.

Note!

The 7500-MAN-MV-01 manifold can be used with 7500 series or 5500 series purge and pressurization

systems.

4.3.1 Technical Data—7500-MAN-MV-01 Manifold

General specifications

Equipment architecture max. enclosure size 450 ft3 (12.7 m3)

Series 7500

Hazardous environment gas or dust

Pneumatic parameters

Protective gas supply compressed air or inert gas, 5 m fi lter, free from oil

Pressure requirement 10 ... 120 psig (0.7 ... 8.2 bar)

Purge fl ow rate pressurization valve : Cv (fl ow coe cient) = 0.4

purging valve : Cv (fl ow coe cient) = 1.4

Connections inlet/outlet : 1/2 inch NPTF

Ambient conditions

Ambient temperature -40 ... 70 °C (-40 ... 158 °F)

Storage temperature -40 ... 80 °C (-40 ... 158 °F)

Mechanical specifi cations

Degree of protection Type 4X

Material Gasket material : Bisco® HT-800 medium cellular

Mass < 1.8 kg (4 lb)

Dimensions see dimensions in chapter 4.3.2

26

Page 27

4.3.2 Dimensions—7500-MAN-MV-01 Manifold

7500 Series Manual

55

2 x

1/2-14 NPT

56

48

14

2 x

5.5 ø thru-hole

41.5

17.5

17.5

4.5

9

Ball valve

closed

55

18.25

32.5 40

20

17.5

Ball valve

open

35

42.5

17

80

Needle valve

5

27

Page 28

7500 Series Manual

4.4 Automatic Manifolds

Pepperl+Fuchs 5500 series automatic manifolds can be used with the 7500 system because the area

classification is the same for both systems. The 7500 system is certified with the control unit and the EPV7500 vents and does not include the manifolds. The 5500 manifolds have their own certification from the

manufacturers.

Note!

Different manifolds are available for different certification requirements.

5500-MAN…. manifold valves include a solenoid valve for purging and a needle valve for pressurization in

one manifold design. When the valve is energized, the solenoid valve is open and allows a high flow rate

of protective gas into the enclosure. The amount of flow is controlled by the regulated pressure supply of

the protective gas to the manifold. When the valve is de-energized, the flow is through the internal needle

valve and is adjustable with the included hex key (for CDUL valve) or slot-head screwdriver (EX01 and

CD01 valves). The solenoid valve is used for purging and leakage compensation, with signals from the

7500 control unit that will have these set points set up by the user.

Mounting hardware includes 3/8 inch tube compression fittings mounted on the manifold for input and

output flow, 3/8 inch tube compression bulkhead fitting for getting flow into the enclosure, and sealing

washers that are certified by UL with bolts to mount the manifold to the enclosure.

Also included is 1 meter of 3/8 inch poly tubing with 3/8 inch poly tube stiffener inserts that allow users to

connect plastic tubing to compression fittings without collapsing the tubing. Stainless steel tubing can be

used with existing fittings.

For NEC, ATEX, and IECEx applications, see the type code for the correct model. The 5500 valve system

works with the 5500 and 7500 control unit as well as EPV-5500 and EPV-7500 vents. The 7500 control

system is certified by UL for Class/Division installation.

Users can also use their own pneumatic system or the 7500-MAN-MV-01 manual manifold. These valves

are not part of the evaluation of the certification of the 7500 control unit and EPV-7500... vent.

1 Solenoid coil for purging

2 1/8 inch hex key adjustment for pressurization (included)

28

Page 29

7500 Series Manual

Tubing kit included mounting hardware included

5500 manifolds include the solenoid and manual needle valve

3/8 inch compression ferrule fittings for inlet and outlet protective gas source

3/8 inch compression ferrule bulkhead fitting that attaches to enclosure—for protective gas to inside

enclosure

3/8 inch poly tubing, length: 2 m

Inserts for poly tubing to ferrule fitting connection. If stainless steel tubing is used, inserts are not

required.

Hex key for pressurization valve included with 5500-MAN-CDUL version

Note!

When ordering, note the supply voltage of the 7500 control unit. Order the manifold valves accordingly.

Voltages are 24 V DC, 120 V AC, and 220 V AC. 5500 MAN-CDUL manifold valves are only available with

60 Hz operation.

4.4.1 Technical Data—5500 Manifolds

General specifications

Operation mode For automatic purging

Series 5500 and 7500

Hazardous environment gas or dust

Supply

Rated power equipment 5500-MAN-CDUL

24 V DC 5.6 W

120 V AC 7.2 VA, 60 Hz

230 V AC 7.2 VA, 60 Hz

Rated power equipment 5500-MAN-CD01

24 V DC 4.6 W

120 V AC 6.8 VA, 60 Hz

230 V AC 6.8 VA, 60 Hz

Rated power equipment 5500-MAN-EX01

24 V DC 2.6 W

120 V AC 3.1 VA, 50 ... 60 Hz

230 V AC 3.0 VA, 50 ... 60 Hz

Voltage tolerance ±10 %

Fuse rating on 5500 control unit

DC voltage 500 mA

AC voltage 80 mA

29

Page 30

7500 Series Manual

Pneumatic parameters 5500-MAN-CDUL (only 60 Hz for AC version)

Protective gas supply 5 m fi ltered air or inert gas

Pressure requirement 20 psi (1.4 bar) to 120 psi (8.2 bar)

Purge fl ow rate (solenoid valves) Cv (fl ow coe cient) = 1.4

Pressurization fl ow (needle valve) Cv (fl ow coe cient) = 0.24

Pneumatic parameters 5500-MAN-CD01

Protective gas supply 5 m fi ltered air or inert gas

Pressure requirement 20 psi (1.4 bar) to 120 psi (8.2 bar)

Purge fl ow rate (solenoid valves) Cv (fl ow coe cient) = 1.4

Pressurization fl ow (needle valve) Cv (fl ow coe cient) = 0.24

Pneumatic parameters 5500-MAN-EX01

Protective gas supply 5 m fi ltered air or inert gas

Pressure requirement 25 psi (1.7 bar) to 115 psi (8.0 bar)

Purge fl ow rate (solenoid valves) Cv (fl ow coe cient) = 1.4

Pressurization fl ow (needle valve) Cv (fl ow coe cient) = 0.24

Mechanical specifi cations

Degree of protection (connector) Type 7 and 9

Mass 2.8 lb (1250 g)

Dimensions See dimension drawings

Material

Housing Anodized aluminum

3/8 inch compression fi ttings AISI 316L (1.4404) stainless steel

Pressure ports 3/8 inch NPTF

Bulkhead fi tting AISI 316L (1.4404) stainless steel

Mounting bolts ¼-20, 316 stainless steel

Sealing washers

Pneumatic connection type Pneumatic

Input port 3/8 inch tube compression fi tting

Output port 3/8 inch tube compression fi tting

Electrical connection

5500-MAN-CD 1/2 inch NPTF thread connection with 24 inch (0.61 m) fl ying leads

5500-MAN-EX01 3 m cable

30

Warning!

Incoming power must be fused. If power is line-to-line, both must be fused. See chapter 4.1.3 for more

information.

Page 31

4.4.2 Dimensions—5500 Manifolds

5500-MAN-CDUL

27

32

118

30

70.7

7500 Series Manual

95.3

50.8

31.8

5500-MAN-EX01

41.4

1/2"-14 NPT

45.8

ø6.5 (4x)

24.1

14.6

61.5

12.7

82.3

50.373.2

3/8" NPT (2x)

7.1

69

81.4

38.1 22.2

12.7 22.2

22.2

1/4-20UNC

9.5 (4x)

38.1

38.1 14.8

1/4-20UNC

8 (4x)

10.7

45.2

30

72.2

53.3

75

27

23

73

23

73

31

Page 32

7500 Series Manual

5500-MAN-CD01

24.1

14.6

3/8" NPT (2x)

61.5

38.1 22.2

56.6

12.7 22.2

22.2

1/4-20UNC

0.375 (4x)

38

38.1 14.8

1/4-20UNC

9.5 (4x)

50.5

10.9

23

30

76.2

53.3

73

73

32

Page 33

5 Installation and Operation

The 7500 series control unit, vent, and manifold can be universally mounted to the customer enclosure. The

7500-01-AA-STD-UNV-PNO is panel-mounted to the enclosure. An included bracket provides a Type 4X /

IPX6 mounting. The7500-MTD-PM... includes the 7500-01... control unit and 7500-MAN-MV-01 mounted

onto a flat panel that is then panel-mounted to the enclosure with the included bracket and gasket for a Type

4X / IPX6 mounting. The 7500-MTD-BX... includes the 7500-01.. control unit and 7500-MAN-MV-01 mounted

onto an enclosure that can then mount externally to the main enclosure. The EPV-7500 vent can be externally

or internally mounted with just the cap showing for exhaust of pressure.

The 7500 system is designed to allow the enclosure to be located in Zone 2 or 22, Class I or II, Division 2

hazardous locations to operate safely by first making them safe internally. This is done either by purging out

the hazardous gas or manually cleaning out the dust hazard and then pressurizing the enclosure so that the

internal pressure prevents the hazardous atmosphere from entering. The 7500 control unit has a differential

pressure sensor within the unit that is pneumatically connected to the protective enclosure to provide

pressure for evaluation of the enclosure pressure and the flow through the enclosure during purging. If

pressure is lost, then power can remain on. An indication by an alarm or display has to notify the operator of

the condition. If the pressurized enclosure has been opened or a positive pressure has not been maintained,

then purging for hazardous gas or cleaning the enclosure out for dust atmospheres is required. The flow

measurement is evaluated by using the pressure in the enclosure and the known measured flow in the tables

through one of the vents selected.

5.1 For Gas Atmospheres

7500 Series Manual

If the protective enclosure has been opened or has been subjected to the hazardous atmosphere, purging

is required to flush out the hazardous gas that may be inside the protective enclosure. A protective gas is

introduced into the enclosure so that the pressure builds up and is exhausted through the enclosure. The

measurement of flow is achieved by the 7500 control unit pressure sensor measuring enclosure pressure

and using that pressure for the flow tables of the vent selected and enclosure size. Each vent has an

enclosure pressure vs. flow table for enclosure size that can be used to determine flow rate. This flow rate is

used to determine the purge time required to make the protective enclosure safe.

Note!

The flow rate tables generated for each vent are measured on a completely sealed enclosure with no

leakage from the enclosure. In real applications, there will be some leakage from the enclosure, which will

depend on the integrity of the seals and door windows, etc. As the enclosure pressure increases, the leakage

may also increase. Always plan on more flow from the protective gas to achieve enclosure pressure because

of the leakage.

After purging, the flow into the enclosure can be reduced so that just a small flow is used for leakage

compensation for pressurization of the enclosure.

5.2 For Dust Atmospheres

If the protective enclosure has been opened or has been subjected to the hazardous atmosphere, the

enclosure must be manually cleaned of all combustible dust, closed, and pressurized before supplying power

to the enclosure. For dust atmospheres, a higher pressure is required for pressurization and is reflected in the

pressure range within the 7500 programming setup.

5.3 For Gas and Dust Atmospheres

Danger!

EN and IEC 60079-2 standards do not state these requirements. Special consideration is needed, and a

proper certification body or authority having jurisdiction must be consulted.

33

Page 34

7500 Series Manual

5.4 Setting Up the System

1. Ensure that the system meets all electrical, mechanical, and pneumatic connections before operation.

Refer to this manual and standards for explanation of requirements.

2. Apply power to the 7500 series system.

3. Program the 7500 system using the user-interface display on the front of the 7500 control unit. See

chapter 6 for instructions.

Note!

This step is for initial setup of the 7500 system. This procedure can be skipped if the 7500 control unit has

been programmed for the application in which it will be used.

4. Make sure the control valve is closed before applying pressure to the system.

5. Use a regulated pressure source to the valve. Set the regulated pressure to 30 psig (2 bar) or lower. Do

not exceed the maximum pressure for the valve and tubing that is being used.

6. The pressure should be below 0.38 in wc (0.95 mbar). Slowly open the needle valve on the control valve

system so that the pressure is above P1. If one of the automatic manifolds, 5500-MAN, is being used,

the solenoid valve will energize either before P1 or after. This depends on the purge program being used.

See chapter 6.5.

7. Check the EPV vent to make sure air is coming out of it. If not, check for any obstructions or improper

installation

8. The system is ready to operate.

5.5 Operating the System

1. Follow the preceding instructions for setting up the system.

2. For Programs 1 through 4 (hazardous gas environments), purging is required.

a. Seal the pressurized enclosure.

b. Set enclosure pressure to a value above P1.

c. When using the 5500-MAN… manifod, the manifold valve is connected to the SV1 output. When the

enclosure pressure is greater than P1, SV1 energizes the solenoid valve for purging. When using the

7500-MAN... or other manual valves, initiate the purging valve.

d. Adjust the regulated pressure so that enclosure pressure is above P3 (purging starts).

e. For the 5500-MAN or 7500-MAN manifold, after purging, the needle valve can be re-adjusted to the

user’s desire, but it must be above P1 value.

3. For Program 5 (hazardous dust environment), purging is not required.

a. The inside of the enclosure must be cleaned of all combustible dust.

b. The enclosure is sealed.

c. Adjust the enclosure pressure above P1. The minimum for P1 is 0.8 in wc (2.0 mbar) for hazardous

dust environments.

4. If enclosure pressure is above P1, power to the enclosure will be energized.

5. If enclosure pressure drops below P1, power must be disconnected. If power is to remain on, an alarm

must be initiated and located near an operator.

6. To energize the pressurized enclosure again, repeat the above sequence.

Danger!

All 7500 pressurization systems require EPV-7500... vents for pressure relief.

34

Danger!

When accessing the user-interface display, the area must be free of hazardous gas and/or combustible dust.

The lid to the 7500 housing must be attached and propertly tightened for operation in a hazardous area.

Note!

At ambient temperatures below -20 °C, the display of the 7500 control unit may not be visible. However, the

unit and LED indicators will still function properly.

Page 35

6 Programming

Use the touch screen on the front of the 7500 control unit to program the system:

7500 Series Manual

Portrait View Landscape View

P ur gin g time: % co mple te / Time l eft

Enc losure P ress ure

X.XX in H O

0.35

P2

P1

X.XX

inH O

2

2

3

0.80

0.30

6.00

3.00

0:300%

10

Enclosure Pressure

0 to 10” w.c. range

P4

P3

CONTRAST

Bar Graph

Enclosure Pressure

To enter Purge Setup or Contrast

pres s and hold finger on the display

in position for 5 sec onds. To

SETUP

CONTRAST

enter Contrast push at location

shown

To en t er Pu rg e Setu p o r Co n trast

pres s and hold finger on the display

in position for 5 sec onds. To

enter Contrast push at location

shown

2

0.80

3.00 6.00

P2

P3

P1

P4

SETUP

P ur gin g time: % co mple te / Time l eft

0:300%

3

2

Pur ging Progr am

0 to 2” w.c. range

0 to 10” w.c. range

10

Bar Graph

Enc losure P ress ure

Program settings are saved on non-volatile memory within the CPU, and settings are unaffected by powerdown and reset function.Default values are stored and can be restored.

Note!

To save settings and exit setup mode, hold the set button to return to normal mode. Changes to settings take

effect immediately. Entering the incorrect password will exit setup mode.

Warning!

Do not change program settings in hazardous areas.

35

Page 36

7500 Series Manual

6.1 LED Indication

LED Color Description

K1 Green Contact K1 is energized

K2 Amber Contact K2 is energized

P/SV Blue/amber Blue: safe pressure

6.2 Default Settings

The following table shows all the possible parameters and their default values:

Display Description Default values

PASSWORD / SET Enter password to access

PURGE / PROGRAM Up to 5 programs to select 3

PURGE / TIME Time required for purging 00:30

ENCLOSUR / PRESS P1 Enclosure pressure P1 0.38 inch (gas), 0.8 in

ENCLOSUR / PRESS P2 Enclosure pressure P2 0.8 inch (2.0 mbar)

ENCLOSUR / PRESS P3 Enclosure pressure P3 2.5 inch (6.22 mbar)

ENCLOSUR / PRESS P4 Enclosure pressure P4 4.5 inch (11.20 mbar)

LEAKAGE / HYST Compensates for leakages 0.2 inch H20 (0.5 mbar)

PROGRAM / K2 Various parameters to acti-

SHUT-OFF / DELAY Delay in turning K1 o when

UNITS / M I M for metric units, I for im-

CHANGE / PASSWORD Change existing password

RESTORE DEFAULTS Factory restore

DISPLAY ROTATION Landscape or portrait Portrait

CYCLE POWER Power o then on O

Amber: valve on

0000

purge settings

(dust)

0.95 mbar (gas), 2.0 mbar

(dust)

K1*

vate K2 contacts

0 sec

P<P1

I

perial units

* Warning!

K1 is not an alarm output. See chapter 6.11 for programming details on what controls K2.

6.3 Contrast and Back light

Adjusting the Contrast

To adjust the contrast, push on the display in the area marked “contrast.” The up and down arrows adjust the

contrast level—up increases and down decreases.

LCD Back Light

The LCD back light is always on. It cannot be turned off or adjusted.

36

Page 37

6.4 Menu Structure

7500 Series Manual

Power On

SET

5 sec.

PASSWORD

PURGE

PROGRAM

Purge

Time

ENCLOSUR

PRESS P1

ENCLOSUR

PRESS P2

ENCLOSUR

PRESS P3

LEAKAGE

HYST

PROGRAM

K2

SHUT-OFF

DELAY

BYPASS

UNITS

MI

CHANGE

PASSWORD

RESTORE

DEFAULT

DISPLAY

ROTATION

At any time during

purge settings

SET

5 sec.

ENCLOSUR

PRESS P4

CYCLE

POWER

PASSWORD

ENCLOSUR

PRESS

37

Page 38

7500 Series Manual

6.5 Purge Programming Settings

There are 5 program selections for system operation. Programs 1 through 4 are for hazardous gas

environments and require purging. The fifth program is for hazardous dust environments that require cleaning

the enclosure, then pressurizing.

6.5.1 Program 1

Program 1 is used in hazardous gas atmospheres.

Pre-Purge

The purge valve (SV) is immediately energized regardless of enclosure pressure

If enclosure pressure goes above P4 during purging, SV will shut off but will energize when below P4.

Oscillation of SV may be noticed.

Setting the pressurization valve on the manifold must be done after purging, or the power to SV will have

to be interrupted to set this pressure. The solenoid valve on the manifold is immediately energized before

this pressure can be set.

The purge timer begins counting down when the enclosure pressure is greater than P3. Enclosure

pressure must remain greater than P3 to purge successfully. If the pressure drops below P3 at any

time, or for any length of time, the purge timer is reset and will not begin counting down until pressure is

greater than P3.

Operation Mode

After the purge timer counts down, the SV shuts off and K1 is energized.

If enclosure pressure drops below P2, the SV is energized and will stay energized for the value of HYST

(%, leakage compensation). If HYST is set to 0, leakage compensation is turned off.

If enclosure pressure drops below P1, K1 remains on and an alarm shall be implemented. K2 can be set

to P- or Alarm to indicate below safe or operating pressure.

If enclosure pressure goes above P4, K1 remains. If K2 is set up as Alarm, K2 will energize.

38

Page 39

Warning!

If K1 is used to energize power to the enclosure, K1 will remain energized if pressure is below P1 during

system operation. An alarm is required and must be located such that an operator will be notified of the

alarm.

6.5.2 Program 2

Program 2 is used in hazardous gas atmospheres.

Pre-Purge

The purge valve (SV) is energized when enclosure pressure is greater than P1.

If enclosure pressure goes above P4 during purging, the SV shuts off but will energize when below P4.

Oscillation of SV may be noticed.

Setting the pressurization valve on the manifold has to be done after purging, or the power to SV will

have to be interrupted to set this pressure. The solenoid valve is energized once enclosure pressure

is above P1. Adjusting the pressurization valve before the solenoid valve is energized will allow the

enclosure pressure to be above P1 when purging is completed. Fine adjustment of P1 can be achieved

after purging when the solenoid valve is off.

The purge timer begins counting down when enclosure pressure is greater than P3 and must remain

greater than P3 to purge successfully. If the pressure drops below P3 at any time, or for any length of

time during purging, the purge timer is reset and will not begin counting down until pressure is greater

than P3.

7500 Series Manual

Operation Mode

After the purge timer counts down, the SV shuts off and K1 is energized.

If enclosure pressure drops below P2, the SV is energized and will stay energized for the value of HYST

(%, leakage compensation). If HYST is set to 0, leakage compensation is turned off.

If enclosure pressure drops below P1, K1 remains on, and an alarm shall be implemented. K2 can be set

to P- or Alarm to indicate below safe or operating pressure.

If enclosure pressure goes above P4, K1 remains. If K2 is setup as Alarm, K2 will energize.

Warning!

If enclosure pressure is below P1 when K1 is used to provide power to the enclosure during operation, K1

will remain energized. An alarm is required and must be located such that an operator will be notified of the

alarm.

39

Page 40

7500 Series Manual

6.5.3 Program 3

Program 3 is used in hazardous gas atmospheres.

Pre-Purge

The purge valve (SV) is energized when enclosure pressure is greater than P1.

If enclosure pressure goes above P4 during purging, the SV will shut off but will energize when below P4.

Oscillation of SV may be noticed.

Setting the pressurization valve on the manifold has to be done after purging, or power to SV will have to

be interrupted to set this pressure. The solenoid valve is energized once enclosure pressure is above P1.

Adjusting the pressurization valve before the solenoid valve is energized allows the enclosure pressure to

be above P1 when purging is completed. Fine adjustment of P1 can be achieved after purging, when the

solenoid valve is off.

Operation Mode

After the purge timer counts down, SV shuts off and K1 is energized.

If enclosure pressure drops below P2, the SV is energized and will stay energized for the value of HYST

(%, leakage compensation). If HYST is set to 0, leakage compensation is turned off.

If enclosure pressure drops below P1, K1 turns off immediately or after the Shutdown delay timer times

out. K1 remains off until the enclosure goes through a successful purging.

If enclosure pressure goes above P4, K1 remains. If K2 is set up as Alarm, K2 will energize

6.5.4 Program 4

Program 4 is used in hazardous gas atmospheres.

Pre-Purge

The purge valve (SV) is immediately energized regardless of enclosure pressure.

If enclosure pressure goes above P4 during purging, the SV shuts off but will energize when below P4.

Oscillation of SV may be noticed.

Setting the pressurization valve on the manifold has to be done after purging, or power to SV will have to

be interrupted to set this pressure. The solenoid valve on the manifold is immediately energized before

this pressure can be set.

The purge timer begins counting down when enclosure pressure is greater than P3, and it has to remain

greater than P3 to purge successfully. If the pressure drops below P3 at any time, or for any length of

time during purging, the purge timer is reset and will not begin counting down until pressure is greater

than P3.

Warning!

If enclosure pressure is below P1 when K1 is used to provide power to the enclosure during operation, K1

will remain energized. An alarm is required and must be located such that an operator will be notified of the

alarm.

40

Page 41

Operation Mode

After the purge timer counts down, SV shuts off and K1 is energized.

If enclosure pressure drops below P3, the SV is energized and will stay energized for the value of HYST

(%, leakage compensation). If HYST is set to 0, leakage compensation is turned off. However, Program 4

is usually used when a continuous purging through the enclosure is required during operation mode.

If enclosure pressure drops below P1, K1 remains on and an alarm will sound. K2 can be set to P- or

Alarm to indicate below safe or operating pressure.

If enclosure pressure goes above P4, K1 remains. If K2 is setup as Alarm, K2 will energize.

6.5.5 Program 5

Program 5 is used in combustible dust atmospheres.

Pre-Purge

The purge valve (SV) does not come on during this operation. In a dust atmosphere, purging is not

required. Instead, the enclosure must be cleaned of all combustible dust and then pressurized.

The menu screen will show "CLEAN ENCLOSURE." The enclosure should be cleaned and then

pressurized before pressing the SET button.

The enclosure pressure has to be above P1 (minimum 0.8 in wc (1.99 mbar) for dust atmospheres)

for the SET button to work.

7500 Series Manual

Operation Mode

After cleaning out and pressurizing the enclosure, the menu shows "CLEAN ENCLOSURE." To see the

enclosure pressure, press the Down or Up button. Pressing the SET button will energize K1.

If enclosure pressure drops below P2, the SV is energized and will stay energized for the value of HYST

(%, leakage compensation). If HYST is set to 0, leakage compensation is turned off. Compensation for

leakages is allowed in a dust atmosphere because the enclosure is safe at this point.

If enclosure pressure drops below P1, K1 remains on and an alarm will sound. K2 can be set to P- or

Alarm to indicate below safe or operating pressure.

If enclosure pressure goes above P4, K1 remains. If K2 is setup as Alarm, then K2 will energize.

Warning!

If enclosure pressure is below P1 when K1 is used to provide power to the enclosure during operation, K1

will remain energized. An alarm is required and must be located such that an operator will be notified of the

alarm.

41

Page 42

7500 Series Manual

6.5.6 Sequence of Events for All Programs

Program 1 2 3 4 5

Purging K1 SV K1 SV K1 SV K1 SV K1 SV

P<P1 o on o o o o o on o o

P1<P<P2 o on o on o on o on o o

P2<P<P3 o on o on o on o on o o

P3<P<P4 o on o on o on o on o o

P>P4 o o o o o o o o o o

After purging

P<P1 on on on on o o on o on o

P1<P<P2 on on on on on on on on on on

P2<P<P3 on o on o on o on on on o

P3<P<P4 on o

P<P4 on o on o on o on o on o

Note!

Shutdown timer and bypass affect the status of K1 and SV. See the explanation for each to determine effects

on K1 and SV.

on o on o on o on o

Clean activates

above P1

6.6 Purging Timer

MIN:SEC

000:00

To program the purging timer, proceed as follows:

Calculate the purging time using the formulas and examples in chapter 7.

Enter the purging time using the UP and DOWN buttons and SET.

To change purging time by 1 second increments, press the UP or DOWN button once.

To make purging time faster, hold down the button continuously. Purging time will advance faster, the

longer you hold the button down (in 5 seconds, 1 min, 5 min steps).

Maximum purge time is 254:59.

42

Page 43

6.7 Minimum Enclosure Pressure “P1”

In accordance with the applicable standards and tolerances on the 7500 pressure sensor, the minimum

operating pressures are as follows:

Gas environments: 0.38 in wc (0.95 mbar)

Dust environments: 0.8 in wc (1.99 mbar)

When enclosure pressure drops below P1 during operation mode, the power has to be interrupted. If not, an

alarm has to be generated to address the problem.

6.8 Alarm Pressure “P2”

If enclosure pressure drops below P2 during operation mode, the solenoid valve will energize until pressure

goes above P2+HYST. Therefore, leakage compensation has to be implemented.

If leakage compensation is not used, the P2 can sound an alarm to indicate that pressure is dropping.

P2 can be adjusted to above P1 and Below P3 values.

6.9 Purging Pressure “P3”

7500 Series Manual

The purging timer starts when enclosure pressure is above P3. If the pressure is above P3, purging will start

and finish uninterrupted. If the enclosure pressure is below P3, the purging timer will not start. If the pressure

drops below P3 during purging, the purging timer will immediately reset to its beginning time and will not start

timing down until pressure is above P3. P3 can be adjusted to above P2 and below P4 values.

6.10 Maximum Internal Pressure “P4”

If enclosure pressure is above P4, the display will read ‘MAX’ to indicate that maximum pressure has been

achieved. Regardless of the action of the solenoid valve (purging, leakage compensation), the solenoid valve

will de-energize and will not come on until enclosure pressure goes below P4. This action may cause the

solenoid valve to oscillate on and off. If this happens, it should be noted as a maximum pressure problem.

If K1 was on before P4 was reached, it will remain on after enclosure pressure is above P4. P4 is adjusted

above P3. Maximum setting is 9.99 in wc (24.86 mbar).

43

Page 44

7500 Series Manual

Leakage Compensation Hysteresis “HYST”

In operation mode, there may be excess leakage of pressure from the enclosure because a seal or gasket

has caused a drop in regulated line pressure (protective gas source). The leakage compensation option

allows the SV to turn on to compensate for these unintentional leakages. Depending on the purge program

being used, the SV will energize when below P2 and will de-energize when it is above P2 + hysteresis.

Note!

If leakage compensation is not required, set HYST to ‘0.’

Values for hysteresis HYST

Inches of wc mbar

00

0.2 0.5

0.4 1.0

0.6 1.5

0.8 2.0

1.0 2.5

1.2 3.0

1.4 3.5

1.6 4.0

1.8 4.5

2.0 5.0

Example

Units are in mbar, hysteresis = 15, then SV is on at P2 and turns off at P2 + 1.5

The HYST unit of measurement is the units being used.

If HYST = 1.5, then this is 1.5 mbar.

44

Page 45

6.11 Programming K2

The K2 contact output can be programmed for various settings that are chosen by the user.

For Type Z and Ex pz systems, power to the pressurized enclosure can remain on if pressure goes below the

minimum allowed pressure, but an audible and/or visual alarm must be generated to notify the operator of a

problem.

K2 can be used to generate the signal for the alarm when properly configured. Alarm function based on any

pressure point (P1 to P4 is not available when K2 is mapped to K1, purging or bypass. Additionally, the K2/

ALARM LED indication is not an alarm indication when K2 is mapped to these functions.

When K2 is mapped to a function that is not an alarm for loss of safe pressure, the power to the enclosure

must be removed, or an external method of alarming is required.

Users-Selectable Settings for K2

K1 Switches simultaneously with K1*

P1+ Switches on when pressure exceeds P1

P1- Switches o when pressure falls below P1

P2+ Switches on when pressure exceeds P2

P2- Switches o when pressure falls below P2

P3+ Switches on when pressure exceeds P3

P3- Switches o when pressure falls below P3

P4+ Switches on when pressure exceeds P4

P4- Switches o when pressure falls below P4

Purging Switches on when purge timer starts and shuts o at the end of

Bypass Switches on when the bypass function is activated

All Alarms Comes on when P1-, P4, Bypass

7500 Series Manual

purging

*This mode is intended for use when the system is controlling a line-to-line power source into the protected

enclosure and both power lines need to be switched.

45

Page 46

7500 Series Manual

46

Page 47

6.12 Shutdown Timer for K1

The shutdown timer is used in the operation mode and allows K1 to remain on for the duration of this setting

when enclosure pressure drops below the minimum setting of P1. If the pressure goes above P1 during the

countdown, the timer is reset. If the pressure remains below P1 for the duration of the countdown, K1 will

shut off.

The shutdown timer is effective only for Program 3, in which K1 de-energizes when enclosure pressure is

below P1. The other programs allow power to the enclosure to remain on when pressure is below P1, with an

alarm generated to the operator.

The default value is 0 seconds. The range is 0 to 300 seconds.

7500 Series Manual

47

Page 48

7500 Series Manual

6.13 Bypass

The Bypass mode allows power to the enclosure to be energized when the enclosure pressure is below the

minimum pressure P1. This can be useful in commissioning the enclosure or working on the enclosure when

it is open.

The Bypass option has two modes of operation to choose from.

Mode Description

N No Bypass is not enabled.

Y Yes Bypass is implemented using the purge settings menu. By select-

Danger!

Bypass should only be implemented when the area surrounding the pressurized enclosure is known to be

non-hazardous!

ing ‘Y’, the system will go into bypass and will turn on K1. In the

‘Y’ mode, K1 can be energized before the system goes through a

successful purge. This mode can be useful in commissioning the

enclosure during start up. This mode is on when it is selected and

the menu stays in the purge settings mode. If the user exits from

the purge settings mode, then the Y’ is automatically changed to

‘N’ and K1 will de-energize.

Bypass LED is on.

6.14 Units

The units can be changed from ‘M’ metric to ‘I’ imperial. This affects the pressure readings. "M" reads in

mbar, and "I" reads in inches of water column. The temperature settings are always in Celcius.

48

Page 49

6.15 Change Password

To change the existing password, use the UP and DOWN buttons for each digit.

Enter 4 digits.

To cancel without saving a new password, press RESET. The existing password will still be valid.

Note!

There is no confirmation of key strokes when changing the password. Note what the new password is when

changing it.

7500 Series Manual

49

Page 50

7500 Series Manual

7 Determining Purging Time

To make sure the enclosure is safe from the hazardous atmosphere, the inside of the enclosure has to be

free of the hazardous atmosphere and pressurized before the equipment inside can be powered.

The first step in this process is to get rid of the hazardous atmosphere within the enclosure.

For a dust atmosphere, the inside of the enclosure must be cleaned out and then pressurized. Because most

vents on a pressurized enclosure have a spark arrestor, purging is not the method used. The dust must be

cleaned out manually or with a vacuum that is rated for the area. Alternatively, it must be cleaned out in a

non-hazardous area.

For gas atmospheres, the enclosure is purged by introducing a flow of protective gas (compressed air, or

Inert gas) through the enclosure to make it safe. Depending on the standards that are being used to evaluate

the effectiveness of the purging operation, the volume of protective gas through the enclosure determines

the amount of time for purging. The exchange of protective gas is related to the volume of the enclosure, the

number of exchanges, and the flow rate through the enclosure.

Below is an equation for determining the purging time:

(number of volume exchange) x (volume of the enclosure) / flow rate = purging time

The number of volume exchange depends on the item being purged and the standard it is being evaluated:

Number of exchanged Class/Division (NFPA 496) Zone (60079-2)

4 X n/a

5 n/a X

10 (motors) X X

Example:

P3 = 2.6 inch H2O 6.5 mbar

Vent = EPV-7500-...-02

table for P3: EPV-7500-...-02,

see chapter 4.2.2

Enclosure volume = 10 ft3 282 liters

Flow Rate from P3 (see table) 11.3 scfm 320 liters/min

NEC (class/division) 4 volume exch. 4 volume exch.

Zone (ATEX, IECEx) 5 volume exch. 5 volume exch.

NFPA: 4 x 10 ft3 / 11.3 scfm = 3.6 min 4 x 282 liters / 320 l/min = 3.6 min

Zone: 5 x 10 ft³ / 11.3 scfm = 4.5 min 5 x 282 liters / 320 l/min = 4.5 min

Motors: 10 x 10 ft³ / 11.3 scfm = 8.9 min 10 x 282 liters / 320 l/min = 8.9 min

The 7500 control unit has a purge timer and is user-selectable through the menu.

The purge timer is activated when the enclosure pressure goes above P3. The pressure must always be

above P3 for the timer to continue until it counts down to 000:00. If the enclosure pressure drops below P3 for

any amount of time, then the timer is reset to its starting value and will not start counting down until pressure

is above P3.