Pepperl Fuchs DVS58 Data Sheet

Singleturn absolute encoder DVS58

Technical data

General specifications

Detection type photoelectric sampling

Device type Singleturn absolute encoder

Functional safety related parameters

MTTFd 80 a

Mission Time (TM) 20 a

L

1.9 E+11 at 6000 rpm and 20/40 N axial/radial shaft load

10

Diagnostic Coverage (DC) 0 %

Electrical specifications

Model Number

DVS58

Features

• Industrial standard

housing Ø58 mm

•16 Bit singleturn

• Galvanically isolated DeviceNet

interface

•Servo or clamping flange

Description

In addition to the CANopen, PROFIBUS and ASInterface rotary encoders, we have broadened our

product line of bus-capable absolute encoders with

the DVS58 for DeviceNet.

Absolute encoders deliver an absolute step value

for each angle setting. All these values are

represented by code samples of one or more code

disks. The code disks are screened by an infrared

LED and the bit obtained sample is detected by

means of an optical array. Its signals are

electronically amplified and are forwarded on to the

interface for processing.

The absolute encoder has a maximum basic

resolution of 65536 steps per revolution (16 Bits).

The integrated CAN bus interface of the absolute

encoder supports all DeviceNet functions. The

following operating modes can be programmed,

and can selectively be turned on or off:

• Polled mode

•Cyclic Mode

• Change of state mode

The device is designed for shaft mounting and is

available in servo flange or clamping flange design.

Operating voltage U

No-load supply current I

Time delay before availability t

Linearity ± 2 LSB at 16 Bit, ± 1 LSB at 13 Bit, ± 0,5 LSB at 12 Bit

Output code binary code

Code course (counting direction) cw ascending (clockwise rotation, code course ascending)

Interface

Interface type DeviceNet

Resolution

Single turn up to 16 Bit

Overall resolution up to 16 Bit

Transfer rate max. 0.5 MBit/s

Connection

Terminal compartment in removable housing cover

Standard conformity

Degree of protection DIN EN 60529, IP65

Climatic testing DIN EN 60068-2-30 , no moisture condensation

Emitted interference DIN EN 61000-6-4

Noise immunity DIN EN 61000-6-2

Shock resistance DIN EN 60068-2-27, 100 g, 6 ms

Vibration resistance DIN EN 60068-2-6, 20 g, 10 ... 2000 Hz

Ambient conditions

Operating temperature -40 ... 85 °C (-40 ... 185 °F)

Storage temperature -40 ... 85 °C (-40 ... 185 °F)

Mechanical specifications

Material

Combination 1 housing: powder coated aluminum

Combination 2 (Inox) housing: stainless steel

Mass approx. 550 g (combination 1)

Rotational speed max. 12000 min

Moment of inertia 30 gcm

Starting torque ≤ 3 Ncm (version without shaft seal)

Shaft load

Axial 40 N

Radial 110 N

Approvals and certificates

UL approval cULus Listed, General Purpose, Class 2 Power Source

B

0

v

10 ... 30 V DC

max. 230 mA at 10 V DC

max. 100 mA at 24 V DC

< 250 ms

cw descending (clockwise rotation, code course

descending)

IP66 (with shaft seal)

flange: aluminum

shaft: stainless steel

flange: stainless steel

shaft: stainless steel

approx. 1000 g (combination 2)

-1

2

Release date: 2017-07-06 13:09 Date of issue: 2017-07-06 t49156_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

1

Singleturn absolute encoder DVS58

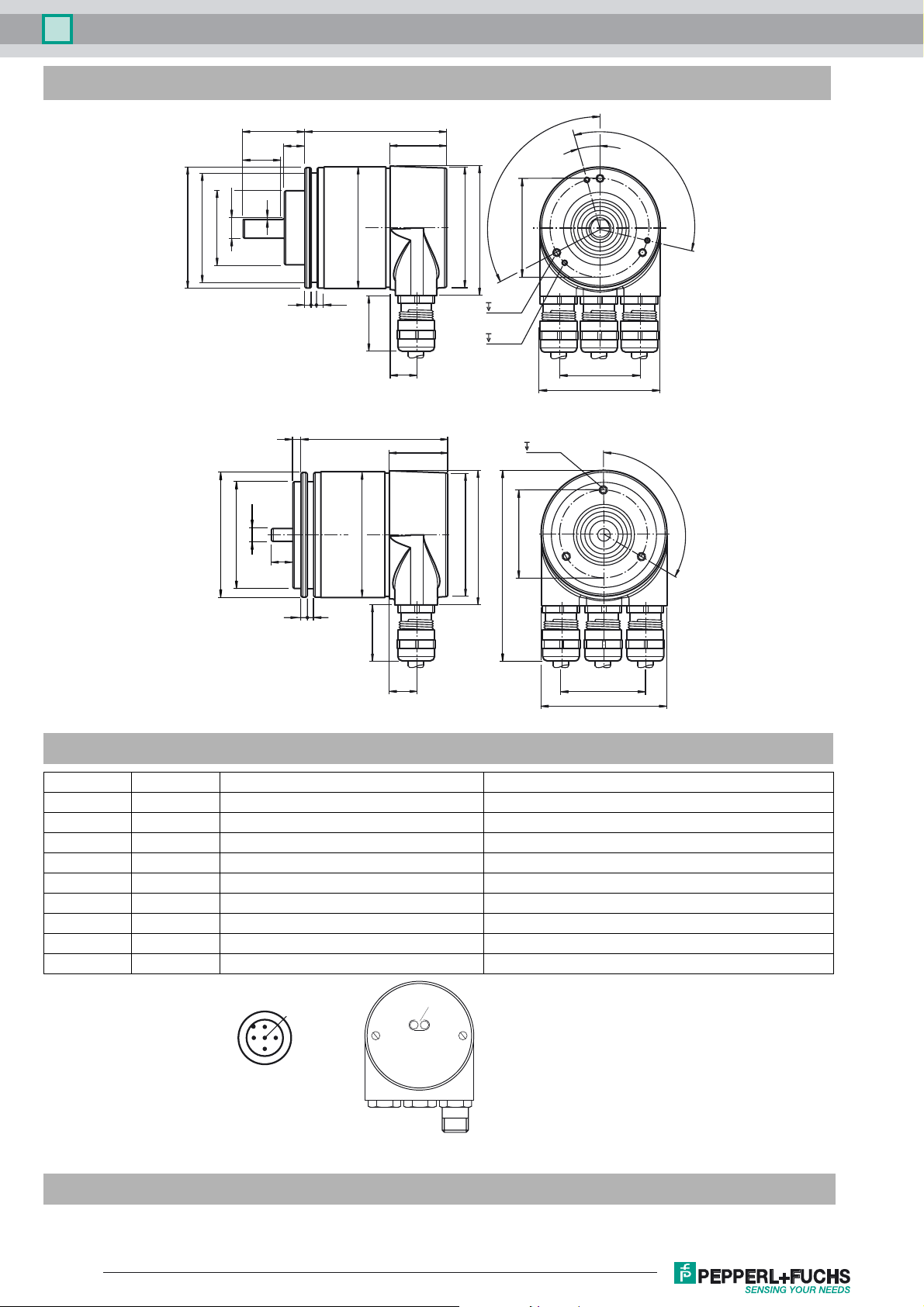

Dimensions

30 L

10

18

1

10h8

ø 58

ø 53

36f7

3 3.5

* Singleturn: L = 69, Multiturn : L = 80

** Aluminum: d = 59, stainless steel: d = 61

4

6f6

ø 58

ø 50f7

10

d**

3

25

L

d**

12.7

27.5

27.5

ø 58

ø 58

3 x 120°

63

M4 x 0.7

6

M3 x 0.5

6

63

88

TK ø 48

M4 x 0.7

6

TK ø 42

15°

3 x 120°

40

60

3 x 120°

3

3

25

* Singleturn: L = 69, Multiturn : L = 80

** Aluminum: d = 59, stainless steel: d = 61

-

12.7

40

60

Electrical connection

Terminal Cable M12 x 1 Connector Explanation

⊥ - - Ground connection for power supply

(+) Red 2 Power supply

(-) Black 3 Power supply

CG - 1 CAN ground

CL Blue 5 CAN low

CH White 4 CAN high

CG - - CAN ground

CL Blue - CAN low

CH White - CAN high

1

5

2

4

LEDs

3

Indicating and operating elements

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Release date: 2017-07-06 13:09 Date of issue: 2017-07-06 t49156_eng.xml

Loading...

Loading...