Page 1

Operating instructions

S

DA6-IU-2K-V

DA6-IU-2K-C

Process Controllers

for analogue input signals with Totaliser

function

for analogue input signals

0…10 V

2…10 V

-10…+10 V

0…20 mA

4…20 mA

FACTORY AUTOMATION

SENSING YOU R NEED

Page 2

DA6-IU-2K-V

DA6-IU-2K-C

Table of Contents (German is the original version.)

1 Preface 3

2 Safety instructions and Warnings 3

2.1 Use according to the intended purpose 3

2.2 Mounting in a control panel 3

2.3 Electrical Installation 4

2.4 Cleaning and maintenance 4

3 Description 5

4 Display/Operating elements 5

5 Block diagram 6

6 Connections 6

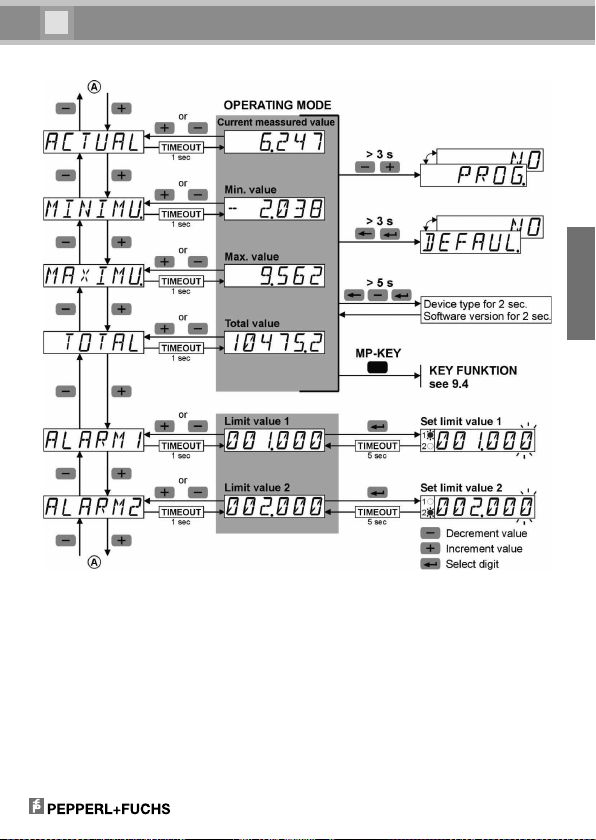

7 Operating concept (Operating mode) 7

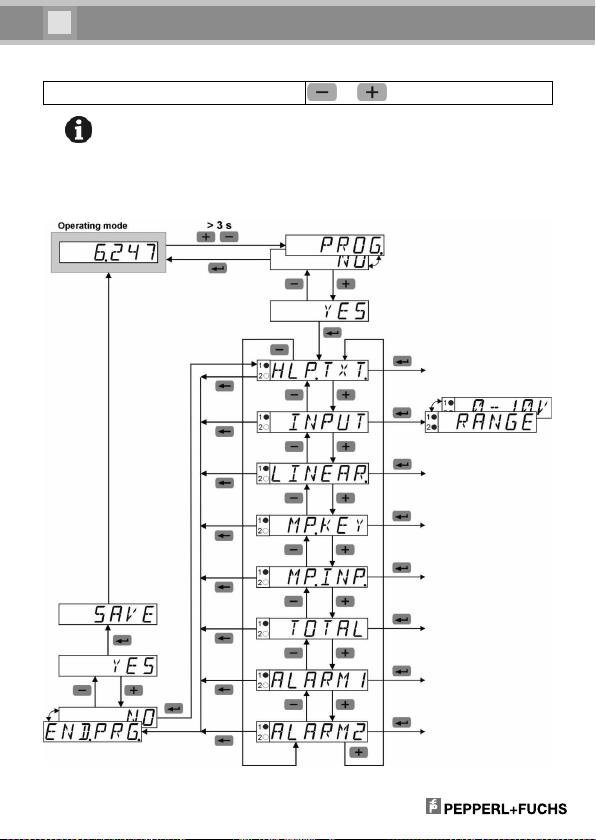

8 Programming 8

9 Function Groups 10

9.1 Help Texts (running text) 10

9.2 Signal inputs 10

9.3 User Linearisation 11

9.4 Function Multifunction Key (MP-Key) and Multifunction inputs (MP-INP) 13

9.4.1 Multifunction Key 14

9.4.2 Multifunction Inputs 14

9.5 Totaliser function 15

9.6 Limit Value (Alarm) Monitoring 16

10 Monitoring of Measuring Circuit 18

11 Technical Data 19

11.1 General Data 19

11.2 Measuring signal inputs 19

11.3 Control Inputs MPI 1 / MPI 2 19

11.4 Alarm outputs 19

11.5 Supply voltage 19

11.6 Sensor Supply voltage 19

11.7 Climatic Conditions 19

11.8 EMC 19

11.9 Device Safety 19

11.10 Mechanical Data 19

11.11 Connections 20

12 Dimensional Drawings 20

13 Help Texts 21

Page 2

Page 3

Please read this instruction manual

entirely and carefully before installation

and start

warnings and advice, both for your own

safety and for general plant safety. If

the device is not used in accordance

with this instruction manual, then the

intended protection can be impaired.

Please use the device only if its

technical conditi

be used only for its intended purpose.

Please bear in mind safety aspects and

potential dangers and adhere to the

operating instructions at all times.

Defective or damaged devices should

be disc

immediately and taken out of operation.

The device shall not be opened. Use

the repair service of the manufacturer.

Only connect the device to the

electricity networks provided to that

purpose.

The safety of the system in which the

device is integrated is the responsibility

of the installer.

Disconnect all electricity networks prior

to any installation or maintenance

work.

Use exclusively cables approved in

your country and designed for your

temperature and power ranges.

Installation and service work shall be

carried out exclusively by qualified

personnel.

The device must compulsorily be

protected with approved external fuses.

The value of these fuses can be found

in the technical information.

This symbol is used on the device to

which are referred to in this manual.

Mount the device away from heat

sources and avoid direct contact with

corrosive liquids, hot steam or similar.

Provide a free space of 10mm all

aroun

T

that the terminals are out of the reach

of the operator and cannot be

touched by him. When mounting the

device, consider the fact that only the

front side is classified as accessible

for the operator.

1. Remove the mounting clip from the device.

2.

3.

Note:

reached on the front side.

DA6-IU-2K-V

DA6-IU-2K-C

1 Preface

-up. Please observe all

2 Safety instructions and

Warnings

on is perfect. It should

onnected from the mains

voltages at the terminals of the device must be kept

within the limits of Over-voltage Category II.

The device must only be operated when mounted

in a panel in the correct way and in accordance

with the section “Technical Data”.

The device is not suitable for use in hazardous

areas and for areas excluded in EN 61010 Part 1. If

the device is used to monitor machines or

processes in which, in the event of a failure of the

device or an error made by the operator, there

might be the risk of damaging the machine or

causing an accident to the operators, it is your

responsibility to take the appropriate safety

measures.

The device has been designed for indoor operation.

It may nevertheless be used outdoors, provided the

technical data is adhered to. In this case, take care

to provide suitable UV protection.

2.2 Mounting in a control panel

CAUTION

d the device for its ventilation.

he device should be mounted so

Mounting instructions

Insert the device from the front into the panel

cut-out, ensuring the front-panel gasket is

remind of the existence of dangers,

2.1 Use according to the intended

purpose

The purpose of the Process Control devices is to

display measured values, as well as to monitor limit

values (alarms). The application areas for this

device lie in industrial processes and controls.

The application area for this device lies in industrial

processes and controls, in the fields of

manufacturing lines for the metal, wood, plastics,

paper, glass, textile and other like industries. Over-

correctly seated.

Slide the fixing clip from the rear onto the

housing, until the spring clamps are under

tension and the upper and lower latching lugs

have snapped into place.

In case of proper installation, IP65 can be

english

Page 3

Page 4

The device must be disconnected

from any power sup

installation or mai

Make sure that no more voltages

LIABLE TO CAUSE AN ELECTROCUTION

are present.

AC

connected to the low-voltage network

via a switch or circuit breaker installed

close to the d

their disconnect

Installation or maintenance work must

only be carried out by qualified

personnel and in compliance with the

applicable national and international

standards.

Take care to separate all extra

voltages entering or exiting the device

from haz

by means of a double or reinforced

insulation (SELV circuits).

The device must be protected

externally for its proper operation.

Information about the prescribed

fuses can be found

information.

The

internally in the device. Without

suitable protection of the relay

outputs, undesired heat development

or even fire may occur. The relay

outputs must be protected externally

by the manufac

must also be

case of a malfunction, the values

stated in the technical data are under

no circumstances exceeded.

DA6-IU-2K-V

DA6-IU-2K-C

2.3 Electrical Installation

ply prior to any

DANGER

DANGER

-powered devices must only be

relay outputs are not protected

ntenance work.

evice and marked as

ing device.

ardous electrical conductors

in the technical

-low

• Before starting the device, check the cables for

proper wiring and tightening. The screws of

unused screw terminals must be screwed to the

stop, so that they cannot loosen and get lost.

• The device has been designed for overvoltage

category II. If higher transient voltages cannot

be excluded, additional protection measures

must be taken in order to limit the overvoltage

to the values of CAT II.

Advice on noise immunity

All connections are protected against external

sources of interference. The installation location

should be chosen so that inductive or capacitive

interference does not affect the device or its

connecting lines! Interference (e.g. from switchmode power supplies, motors, clocked controllers

or contactors) can be reduced by means of

appropriate cable routing and wiring.

Measures to be taken:

• Use only shielded cable and control lines.

Connect shield at both ends. The conductor

cross-section of the cables should be a

minimum of 0.14 mm².

• The shield connection to the equipotential

bonding should be as short as possible and

with a contact area as large as possible (lowimpedance).

• Only connect the shields to the control panel, if

the latter is also earthed.

• Install the device as far away as possible from

noise-containing cables.

• Avoid routing signal or control cables parallel to

power lines.

2.4 Cleaning and maintenance

turer of the plant. It

• During installation, make sure that the supply

voltage and the wiring of the output contacts

are both fed from the same mains phase, in

order not to exceed the maximum permitted

voltage of 250V.

• The cables and their insulation must be

designed for the planned temperature and

voltage ranges. Regarding the type of the

cables, adhere to the applicable standards of

the country and of the plant. The cross sections

allowed for the screw terminals can be found in

the technical data.

Page 4

made sure that, even in

The front side of the unit should only be cleaned

using a soft damp (water!) cloth. Cleaning of the

embedded rear side is not planned and is the

responsibility of the service personnel or of the

installer.

In normal operation, this device is maintenancefree. Should the device nevertheless not operate

properly, it must be sent back to the manufacturer

or to the supplier. Opening and repairing the device

by the user is not allowed and can adversely affect

the original protection level.

Page 5

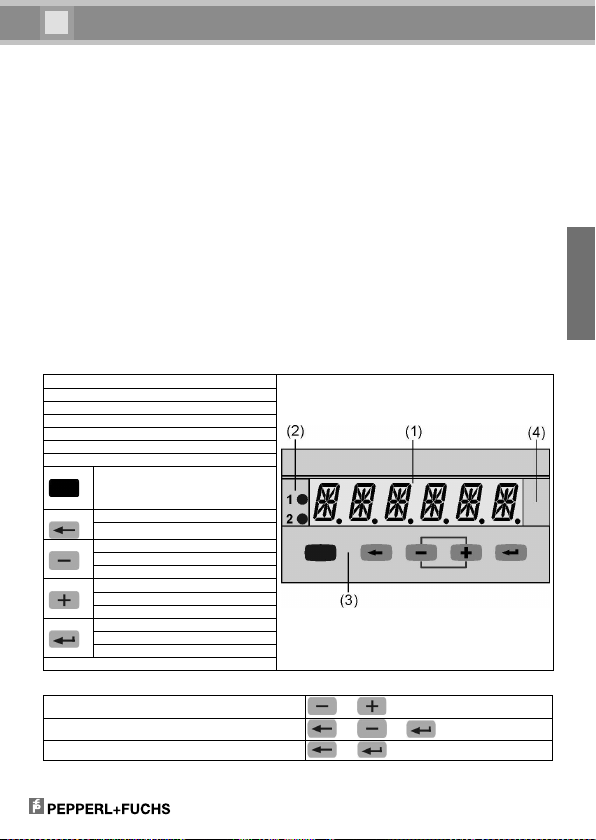

(1) Display

- 14 segment display, 6-digit, red

- Height of figures 14 mm

(2) Status display, 2 LED annunciators, red

- Switching status of Alarm 1 and Alarm 2

- Indication Function Group or Function

(3) MP-Key and Programming Keys

- Return from Function Group

- Return from Function

- Select previous Function Group

- Select previous Function

- Decrement parameter value

- Select next Function Group

- Select next Function

- Increment parameter value

- Enter a Function Group

- Enter a Function

- Accept the new setting

(4) Space for unit overlay

+ > 3 sec

+ + > 5 sec

To restore factory default settings

+ > 3 sec

DA6-IU-2K-V

DA6-IU-2K-C

3 Description

Digital panel meter for displaying measured values, as well as monitoring limit values in industrial

applications.

• 6-digit 14-segment LED display, 14 mm, for displaying measured values and dialogs

• Running text can be switched on as Help Text

• Language for the Help Text selectable as English or German

• Signal input for 0 – 10 V, 2 – 10 V, ±10 V, 0 – 20 mA and 4 – 20 mA

• Sampling rate 10 readings per second

• Digital filter (1st order) for smoothing display fluctuations with unstable input signals

• Customised linearisation

• MIN/MAX memory function

• Totaliser function

• 2 Relay outputs (changeover contacts) for limit monitoring

• Start delay for relay outputs after Power ON

• Versions for supply voltage 10 ... 30 V DC and 100 … 240 V AC ± 10%

• Auxiliary power supply 15 V DC / 25 mA

• Additional aux. power output 24 V / 30 mA with AC supply

• Programmable via the front keys

• Multifunction key and two multifunction inputs, function programmable

4 Display/Operating elements

- Multifunction key (MP-Key)

english

To enter the Programming Menu

To display Device Type and Software Version

Page 5

Page 6

DA6-IU-2K-V

DA6-IU-2K-C

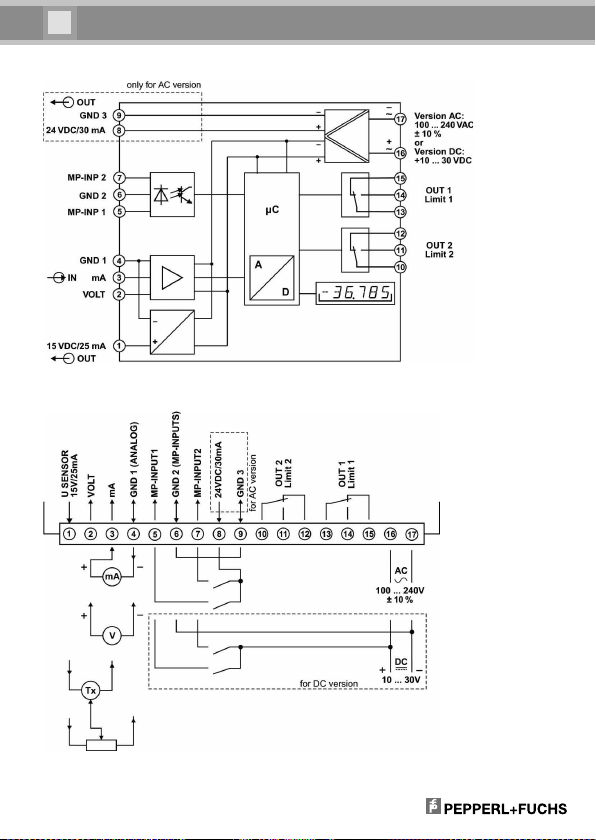

5 Block diagram

6 Connections

Page 6

Page 7

DA6-IU-2K-V

DA6-IU-2K-C

7 Operating concept (Operating mode)

english

Page 7

Page 8

+ > 3 sec

• During programming the relays are inactive (not energised).

the totaliser value are all cleared.

DA6-IU-2K-V

DA6-IU-2K-C

8 Programming

To enter the Programming menu

• When quitting the programming menu via SAVE, the minimum and maximum values and

Entering the Programming Menu / Selecting Function Group / Quitting the Programming

menu

Page 8

Page 9

Function Groups

Function

Parameter

DA6-IU-2K-V

DA6-IU-2K-C

Selecting Function / Setting Parameters / Accepting Parameters

english

Page 9

Page 10

Help Text menu

ON

any programming key

Deutsch (German)

Menu Input Signal

Meas. range 2 … 10 V

Select lower measuring range

limit

Input range depends on meas.

range [V / mA]

Select upper measuring range

limit

Input range depends on meas.

range [V / mA]

Select decimal point

(optical function only)

0

0.0000

Input range depends on meas.

range [V / mA]

Select display low value for

INP.LO.

Input range

Select input high value

Input range depends on meas.

Select display high value for

INP.HI.

Input range

-199999 … +999999 and DP

Select Input Filter

average.

Input range 1 … 99 [cycles]

function is switched off

Select Start Delay after Power

time has expired)

Select local mains frequency

Mains frequency 50 Hz

Input range depends on measuring range:

greater than the value for LO.LIM.

Factory settings are highlighted grey.

DA6-IU-2K-V

DA6-IU-2K-C

9 Function Groups

9.1 Help Texts (running text)

Select Help Text

- a running text that has

started can be aborted with

OFF

Select language for Help Text

English

9.2 Signal inputs

Select measuring range

Meas. range 0 … 10 V

Meas. range -10 … +10 V

Meas. range 0 … 20 mA

Meas. range 4 … 20 mA

0.0

0.00

0.000

Select input low value

-199999 … +999999 and DP

range [V / mA]

The Filter function shows how

many measurement cycles are

used to determine the moving

- with a value of 1 the filter

On

(limit monitoring is processed

only after the programmed

Input range 0.0 ... 99.9 [sec]

Mains frequency 60 Hz

0 … 10 V = -0.500 … 10.500 [V]

2 … 10 V = 1.500 … 10.500 [V]

-10 … +10 V = -10.500 ... +10.500 [V]

0 … 20 mA = -0.500 … 21.000 [mA]

4 … 20 mA = 3.000 … 21.000 [mA]

The functions LO.LIM and HI.LIM limit the

editable range.

The value for HI.LIM must always be

Page 10

Page 11

Select User Linearisation

Linearisation OFF

Select number of linearisation

(control) points

Input range depends on

measuring range [V / mA]

Select display low value for

INP.LO.

Input range

-199999 … +999999 and DP

Select input value 1

Input range depends on

measuring range [V / mA]

Select display value for

INP.01.

Input range

-199999 … +999999 and DP

Input range depends on

measuring range [V / mA]

Select display value for

INP.10.

Input range

-199999 … +999999 and DP

Input range depends on

measuring range [V / mA]

Select display high value for

INP.HI.

Input range

-199999 … +999999 and DP

Input range depends on measuring range:

greater than the value for LO.LIM.

DA6-IU-2K-V

DA6-IU-2K-C

9.3 User Linearisation

Menu User Linearisation

Linearisation ON

Input range 3 … 12

Select input low value

A maximum of 12 linearisation points is possible.

An input value INP must be entered for each

linearisation point (LP) - input of the sensor

value from the analogue input in physical units as well as the corresponding display value DISP

for this sensor value. The linearisation points

(LP) may be entered in any order. They are then

sorted in the firmware in ascending order for the

linearisation function. Linearisation based on a

negative slope is possible.

Select input value 10

Select input high value

0 … 10 V = -0.500 … 10.500 [V]

2 … 10 V = 1.500 … 10.500 [V]

-10 … +10 V = -10.500 ... +10.500 [V]

0 … 20 mA = -0.500 … 21.000 [mA]

4 … 20 mA = 3.000 … 21.000 [mA]

The functions LO.LIM and HI.LIM limit the

editable range.

The value for HI.LIM must always be

english

Page 11

Page 12

DA6-IU-2K-V

DA6-IU-2K-C

Example for linear scaling

Example 1: 0 … 10 V = 0 … 600

Example 2: 4 … 20 mA = 300 … 900

Example 3: 1.0 … 9.0 V = 750 … 400

Example for non-linear scaling

Page 12

Page 13

DA6-IU-2K-V

DA6-IU-2K-C

9.4 Function Multifunction Key

(MP-Key) and Multifunction

inputs (MP-INP)

Tare

• In the function group MP.KEY, programme the

function TARA to ON. In the operating mode

select the current measured value (ACTUAL)

and briefly press the MP Key.

• In the function group MP.INP, programme the

function MP.INP1 or MP.INP2 to TARA. In the

operating mode briefly activate the

multifunction input 1 or multifunction input 2.

Reset Tare Value

• In the function group MP.KEY, programme the

function TARA to ON. In the operating mode

select the current measured value (ACTUAL)

and press the MP Key >5 sec.

• In the function group MP.INP, programme the

function MP.INP1 or MP.INP2 to R.TARA. In

the operating mode briefly activate the

multifunction input 1 or multifunction input 2.

Reset MIN value memory

• In the function group MP.KEY, programme the

function RES.MIN to ON. In the operating mode

select the minimum value memory (MINIMU)

and briefly press the MP Key.

• In the function group MP.INP, programme the

function MP.INP1 or MP.INP2 to RES.MIN or

R.PEAKS. In the operating mode briefly

activate the multifunction input 1 or

multifunction input 2.

Reset MAX value memory

• In the function group MP.KEY, programme the

function RES.MAX to ON. In the operating

mode select the maximum value memory

(MAXIMU) and briefly press the MP Key.

• In the function group MP.INP, programme the

function MP.INP1 or MP.INP2 to RES.MAX or

R.PEAKS. In the operating mode briefly

activate the multifunction input 1 or

multifunction input 2.

Reset of relay outputs in Latch mode

• In the function group MP.KEY, programme the

function RES.REL to ON. In the operating mode

briefly press the MP Key.

• In the function group MP.INP, programme the

function MP.INP1 or MP.INP2 to RES.REL. In

the operating mode briefly activate the

multifunction input 1 or multifunction input 2.

Reset Totaliser

• In the function group MP.KEY, programme the

function RES.TOT to ON. In the operating

mode, select the totaliser (TOTAL) and briefly

press the MP Key.

• In the function group MP.INP, programme the

function MP.INP1 or MP.INP2 to RES.TOT. In

the operating mode briefly activate the

multifunction input 1 or multifunction input 2.

Display Hold

• In the function group MP.INP, programme the

function MP.INP1 or MP.INP2 to DISP.HD. In

the operating mode, select either the current

measured value (ACTUAL) or the totaliser

(TOTAL) and activate multifunction input 1 or

multifunction input 2.

Lock-out Limit Value (Alarm) setting

• In the function group MP.INP, programme the

function MP.INP1 or MP.INP2 to LOC.ALR. In

the operating mode, activate multifunction input

1 or multifunction input 2.

Lock-out Programming and Default

setting

• In the function group MP.INP, programme the

function MP.INP1 or MP.INP2 to LOC.PRG. In

the operating mode, activate multifunction input

1 or multifunction input 2.

Lock-out Keypad

• In the function group MP.INP, programme the

function MP.INP1 or MP.INP2 to LOC.KEY. In

the operating mode, activate multifunction input

1 or multifunction input 2.

english

Page 13

Page 14

Menu Function MP-Key

Select function:

display

Select function:

appears in the display

Select function:

in the display

OFF

ON

Select function Output-Latch

mode (ALARMx = LATCH)

ON

OFF

Select function

display

Menu Function MP-Inputs

Reset MAX value

Reset Output-Latch

mode (ALARMx = LATCH)

Lock-out programming and

default setting

Lock-out limit value setting,

and MP-Key

Reset tare value

Select function MP-Input 2

Reset MIN value

Reset Output-Latch

mode (ALARMx = LATCH)

Lock-out limit value setting

Lock-out programming and

default setting

Lock-out limit value setting,

and MP-Key

Tare Reset tare value

Reset totaliser

DA6-IU-2K-V

DA6-IU-2K-C

9.4.1 Multifunction Key

9.4.2 Multifunction Inputs

Reset tare (TARA) value with

MP-Key – only when current

measured value appears in the

OFF

ON

Reset MIN value with MP-Key

– only when MIN value

OFF

ON

Reset MAX with MP-Key –

only when MAX value appears

Reset with MP-Key

- only if output is in memory

OFF

- this setting is possible only if

all other settings are set to

Reset Totaliser with MP-Key

- only if totaliser is in the

OFF

ON

Select function MP-Input 1

No function

Reset MIN value

Reset MIN and MAX values

- only if output is in memory

Hold (‘freeze’) display

Lock-out limit value setting

programming, default setting

Tare

Reset totaliser

No function

Reset MAX value

Reset MIN and MAX values

- only if output is in memory

Hold (‘freeze’) display

programming, default setting

Page 14

Page 15

Select value for low threshold

cut-off

Input value range

-199999 … +999999 and DP

Select value for multiplication

factor

Input value range

0.00001 … 9.99999

Select scale factor

Scale factor x 1

Select decimal point for

totaliser (optical function only)

0

0.00000

DA6-IU-2K-V

DA6-IU-2K-C

9.5 Totaliser function

Menu Totaliser

Scale factor x 0.1

Scale factor x 0.01

Scale factor x 0.001

Scale factor x 0.0001

0.0

0.00

0.000

0.0000

The totaliser function captures the current

(instantaneous) measured value every 100 msec.

From these values the throughput rate per second

is calculated. To convert the throughput rate into

other units FACTOR and SCALE are available.

Negative measured values are also taken into

consideration. A decimal point that is programmed

with a current measured value is not taken into

consideration. The throughput rate is added into

the totaliser memory every second. A dummy

decimal point (optical indication only) can be

programmed into the totaliser as required.

english

Page 15

Page 16

Select operating mode

OFF

Memory latch operation

- not with band limitation

Select source value for Alarm

output 1

Select Output triggering

With incrementing measuring

signal

With decrementing measuring

signal

Band limitation

Select on-hysteresis

Input range

0 … +9999 and DP

Select off-hysteresis

- only with auto operation

Input range

0 … +9999 and DP

Select off-delay

- only with auto operation

Menu Alarm Output 2

Memory latch operation

Select source value for Alarm

output 2

Select Output triggering

With incrementing measuring

signal

With decrementing measuring

signal

Select on-hysteresis

Input range

0 … +9999 and DP

Select off-hysteresis

- only with auto operation

Input range

0 … +9999 and DP

Select off-delay

- only with auto operation

DA6-IU-2K-V

DA6-IU-2K-C

9.6 Limit Value (Alarm) Monitoring

Menu Alarm Output 1

Automatic operation

Band limitation

Select Alarm status

With alarm: output active

With alarm: output inactive

Current measured value

Totaliser

Select Alarm status

With alarm: output active

With alarm: output inactive

Select on-delay

Input range 0.0 ... 99.9 [sec]

Input range 0.0 ... 99.9 [sec]

Select on-delay

Input range 0.0 ... 99.9 [sec]

Input range 0.0 ... 99.9 [sec]

Select operating mode

OFF

Automatic operation

Current measured value

Totaliser

Page 16

ON switching point = limit value + ON hysteresis

OFF switching point = limit value – OFF hysteresis

ON switching point = limit value – ON hysteresis

OFF switching point = limit value + OFF hysteresis

An alarm is triggered, if the measured value falls

outside a defined range (Band).

Upper switching point = limit value + ON hysteresis

Lower switching point = limit value – OFF

hysteresis

An alarm causes the output to become active

(Relay energised, LED ON)

An alarm causes the output to become inactive

(Relay not energised, LED OFF)

In memory latch operation the status of the outputs

is stored in the event of a Power OFF condition

and then immediately restored at the next Power

ON.

In auto operation the status of the outputs is not

saved in the event of a Power OFF condition. At

the next Power ON the limit values are not

processed until after the expiration of the start

delay (PW.DELY).

Page 17

DA6-IU-2K-V

DA6-IU-2K-C

Control with incrementing measuring signal

english

Control with decrementing measuring signal

Page 17

Page 18

Meas. range

Lower Display

Upper Display

Lower Meas.

Upper Meas.

Probe or wire

0 … 10 V

■ ■ ■

■

–

2 … 10 V

■ ■ ■

■

■ (< 1 V)

-10 V/+10 V

■ ■ ■

■

–

0 ... 20 mA

■ ■ ■

■

–

4 ... 20 mA

■ ■ ■

■

■ (< 2 mA)

blinking

DA6-IU-2K-V

DA6-IU-2K-C

Control with Band Limitation

10 Monitoring of Measuring Circuit

Range limit

Indication

(■ = is detected)

Page 18

blinking

Range limit

blinking

Range limit

blinking

Range limit

blinking

short-circuit

Probe or wire

break

Page 19

The maximum values shall in no case

be exceeded!

Only the front side is classified as

accessible for the operator.

DA6-IU-2K-V

DA6-IU-2K-C

11 Technical Data

11.1 General Data

Display: 6-digit, 14 segment LED

Digit height: 14 mm

Data retention: > 10 years, EEPROM

Operation: 5 keys

11.2 Measuring signal inputs

Sampling rate: 10 readings/sec

SELV circuits, reinforced / double insulation

Voltage input

Progr. ranges: 0 … 10 V, 2 … 10 V, ± 10 V

Meas. range: -10.5 ... +10.5 V

Resolution: < 0.4 mV (±15Bit)

Meas. accuracy typ. 0.02 % of range

@ 23°C: max. ≤0.05 % of range

Temperature drift: < 100 ppm/K

Input resistance: 1 MΩ

Max. voltage: ± 30 V

Current input

Progr. ranges: 0 ... 20 mA, 4 … 20 mA

Measuring range: -0.5 ... 21 mA

Resolution: 1 µA (> 14 Bit)

Measuring accuracy typ. 0.02 % of range

@ 23°C: max. ≤0.05 % of range

Temperature drift: < 100 ppm/K

Input resistance: 22 Ω + PTC 25 Ω

Voltage drop: ca. 1,8 V @ 20 mA

Max. current: 60 mA

11.3 Control Inputs MPI 1 / MPI 2

SELV circuits, reinforced / double insulation

Quantity: 2, optocouplers

Function: programmable

Switching levels: Low: < 2 V

High: > 4 V (max. 30 V)

Pulse length: >100 ms

11.4 Alarm outputs

Relays: changeover contacts

Prescribed fuse: 5A

Switching voltage: max. 250 V AC / 125 V DC

min. 5 V AC / V DC

Switching current: max. 5 A AC / A DC

min. 10 mA

Switching capacity: max. 1250 VA / 150 W

Mechanical service life (switching cycles) 1x10

N° of switching cycles at 5 A / 250 V AC 5x10

N° of switching cycles at 5 A /30 V DC 5x10

11.5 Supply voltage

AC supply: 100 ... 240 V AC / max. 9 VA

50 / 60 Hz, Tolerance ± 10%

ext. fuse protection: T 0.1 A

DC supply: 10 ... 30 VDC / max. 3.5 W

with galvanic isolation and,

reverse polarity protection

SELV, CLASS II (Limited

ext. fuse protection: T 0.4 A

Mains hum 50 Hz or 60 Hz,

suppression: programmable

11.6 Sensor Supply voltage

(Voltage output for external sensors)

SELV circuits, reinforced / double insulation

at AC supply: 24 VDC 15 %, 30 mA

at DC supply: 15 VDC 1 %, 25 mA

11.7 Climatic Conditions

Operating temperature: -20°C ... +65°C

Storage temperature: -25°C ... +75°C

Relative humidity: R.H. 93 % at +40°C,

non-condensing

Altitude: up to 2000 m

11.8 EMC

Noise immunity: EN 61000-6-2

Noise emission: EN 55011 Class B

11.9 Device Safety

Design to: EN 61010 Part 1

Protection Class: Protection Class 2 (front side)

Application area: Pollution level 2

over-voltage Category II

Insulation: Front: double insulation,

Rear side: basic insulati on,

Signal inputs and und sensor power supply: SELV

11.10 Mechanical Data

Housing: Panel mount housing

to DIN 43 700, RAL 7021

Dimensions: 96 x 48 x 102 mm

Panel cut-out: 92

Installation depth: approx. 92 mm incl. terminals

7

Weight: approx. 180 g

4

Protection: IP65 (front, device only)

4

Housing material: Polycarbonate UL94 V-2

Vibration resistance: 10 - 55 Hz / 1 mm / XYZ

EN 60068-2-6 30 min in each direction

Power Source)

15 VDC 1 %, 25 mA

with shielded signal and

control cables

+0.8

x 45

+0.6

english

mm

Page 19

Page 20

DA6-IU-2K-V

DA6-IU-2K-C

Shock resistance:

EN 60068-2-27 100G / XYZ

3 times in each direction

EN 60068-2-29 10G / 6 ms / XYZ

2000 times in each direction

11.11 Connections

Supply voltage and outputs:

Plug-in screw terminal, 8-pin, RM5.00

Core cross-section, max. 2.5 mm²

Signal and control inputs:

Plug-in screw terminal, 9-pin, RM 3.50

Core cross section, max. 1.5 mm²

12 Dimensional Drawings

Dimensions in mm [inch]

Page 20

Page 21

PROG.

NO

NO PROGRAMMING

PROG.

YES

START PROGRAMMING

HLP.TXT.

MAIN MENU SELECT HELPTEXT

HLP.TXT.

ON

HELPTEXTS ON

HLP.TXT

OFF

HELPTEXTS OFF

SL.LANG.

DE

SPRACHE DEUTSCH

SL.LANG.

EN

LANGUAGE ENGLISH

INPUT. MAIN MENU SIGNAL INPUT

RANGE

0-10V

VOLTAGE INPUT RANGE 0-10V

RANGE

2-10V

VOLTAGE INPUT RANGE 2-10V

RANGE

-10.10V

VOLTAGE INPUT RANGE -10V/+10V

RANGE

0-20MA

CURRENT INPUT RANGE 0-20MA

RANGE

4-20MA

CURRENT INPUT RANGE 4-20MA

LO.LIM.

LOWER INPUT RANGE LIMIT

HI.LIM.

UPPER INPUT RANGE LIMIT

DP.

0

NO DECIMAL POINT

DP.

0.0

DECIMAL POINT 0.0

DP.

0.00

DECIMAL POINT 0.00

DP.

0.000

DECIMAL POINT 0.000

DP.

0.0000

DECIMAL POINT 0.0000

DP.

0.00000

DECIMAL POINT 0.00000

INP.LO.

INPUT START VALUE

DISP.LO.

DISPLAY START VALUE

INP.HI.

INPUT END VALUE

DISP.HI.

DISPLAY END VALUE

FILTER

INPUT FILTER

PW.DELY.

POWER-ON DELAY FOR OUTPUTS [SEC]

PW.FREQ.

50HZ

POWER LINE FREQUENCY 50HZ

PW.FREQ.

60HZ

POWER LINE FREQUENCY 60HZ

LINEAR.

MAIN MENU LINEARIZATION

LINEAR.

NO

LINEARIZATION OFF

LINEAR.

YES

LINEARIZATION ON

NUM.PNT.

NUMBER OF LINEARIZATION POINTS

INP.01 INPUT VALUE NO.1

DISP.01 DISPLAY VALUE NO.1

to

INP.10 INPUT VALUE NO.10

DISP.10

DISPLAY VALUE NO.10

MP.KEY

MAIN MENU MP-BUTTON

TARA

OFF

FUNCTION TARA OFF

TARA

ON

FUNCTION TARA ON

RES.MIN.

OFF

FUNCTION RESET MIN VALUE OFF

RES.MIN.

ON

FUNCTION RESET MIN VALUE ON

RES.MAX.

OFF

FUNCTION RESET MAX VALUE OFF

RES.MAX.

ON

FUNCTION RESET MAX VALUE ON

RES.REL.

OFF

FUNCTION RESET OUTPUT-LATCH OFF

RES.REL.

ON

FUNCTION RESET OUTPUT-LATCH ON

RES.TOT.

OFF

FUNCTION RESET TOTALIZER VALUE OFF

RES.TOT.

ON

FUNCTION RESET TOTALIZER VALUE ON

DA6-IU-2K-V

DA6-IU-2K-C

13 Help Texts

english

Page 21

Page 22

MP.INP.

MAIN MENU MP-INPUTS

MP.INP.x

NO.FUNC.

NO FUNCTION

MP.INP.x

RES.MIN.

FUNCTION RESET MIN VALUE

MP.INP.x

RES.MAX.

FUNCTION RESET MAX VALUE

MP.INP.x

R.PEAKS

FUNCTION RESET MIN/MAX VALUE

MP.INP.x

RES.REL.

FUNCTION RESET OUTPUT-LATCH

MP.INP.x

DISP.HD.

FUNCTION DISPLAY HOLD

MP.INP.x

LOC.ALR.

FUNCTION LOCK EDITING ALARM VALUES

MP.INP.x

LOC.PRG.

FUNCTION LOCK PROGRAMMING

MP.INP.x

LOC.KEY

FUNCTION LOCK KEYS

MP.INP.x

TARA

FUNCTION TARA

MP.INP.x

R.TARA

FUNCTION RESET TARA VALUE

MP.INP.x

RES.TOT

FUNCTION RESET TOTALIZER VALUE

TOTAL MAIN MENU TOTALIZER

CUT.OFF

CUT OFF VALUE

FACTOR

MULTIPLICATION FACTOR TOTALISER

SCALE

x1

SCALING FACTOR TOTALIZER X1

SCALE

x0.1

SCALING FACTOR TOTALIZER X0.1

SCALE

x0.01

SCALING FACTOR TOTALIZER X0.01

SCALE

x0.001

SCALING FACTOR TOTALIZER X0.001

SCALE

x0.0001

SCALING FACTOR TOTALIZER X0.0001

DP.TOT.

0

NO DECIMAL POINT

DP.TOT.

0.0

DECIMAL POINT TOTALISER 0.0

DP.TOT.

0.00

DECIMAL POINT TOTALISER 0.00

DP.TOT.

0.000

DECIMAL POINT TOTALISER 0.000

DP.TOT.

0.0000

DECIMAL POINT TOTALISER 0.0000

DP.TOT

0.00000

DECIMAL POINT TOTALISER 0.00000

ALARMx

MAIN MENU ALARM x

AL.OUTx

OFF

ALARM x OFF

AL.OUTx

AUTO

AUTOMATIC MODE OF ALARM OUTPUT x

AL.OUTx

LATCH

LATCH MODE OF ALARM OUTPUT x

ALLOC.x

ACTUAL

ACTUAL VALUE TO ALARM

ALLOC.x

TOTAL

TOTALIZER TO ALARM

MD.OUTx

INCR

ALARM x ACTIVE AT INCREASING INPUT SIGNAL

MD.OUTx

DECR

ALARM x ACTIVE AT DECREASING INPUT SIGNAL

MD.OUTx

BAND

ALARM x BAND LIMITATION

FM.OUTx

OUTPUT ACTIVE AT ALARM

FM.OUTx

ON.HYS.x

SWITCH ON HYSTERESIS ALARM x

OF.HYS.x

SWITCH OFF HYSTERESIS ALARM x

ON.DLY.x

ON DELAY ALARM x [SEC]

OF.DLY.x

OFF DELAY ALARM x [SEC]

END.PRG.

NO

REPEAT PROGRAMMING

END.PRG.

YES

EXIT PROGRAMMING AND STORE DATA

-1.9.9.9.9.9

DISPLAYRANGE UNDERFLOW

9.9.9.9.9.9.

DISPLAYRANGE OVERFLOW

OVERFL.

OVERFLOW UPPER INPUT RANGE LIMIT

UNDERF.

UNDERFLOW LOWER INPUT RANGE LIMIT

SENSOR

SENSOR ERROR

DA6-IU-2K-V

DA6-IU-2K-C

OUTPUT INACTIVE AT ALARM

Page 22

Page 23

Page 24

FACTORY AUTOMATION –

SENSING YOUR NEEDS

Worldwide Headquarters

Pepperl+Fuchs GmbH

68307 Mannheim · Germany

Tel. +49 621 776-0

E-mail: info@de.pepperl-fuchs.com

USA Headquarters

Pepperl+Fuchs Inc.

Twinsburg, Ohio

Tel. +1 330 4253555

E-mail: sales@us.pepperl-fuchs.com

Asia Pacific Headquarters

Pepperl+Fuchs Pte Ltd.

Company Registration

Singapore 139942

Tel. +65 67799091

E-mail: sales@sg.pepperl-fuchs.com

44087 · USA

No. 199003130E

www.pepperl-fuchs.com

Subject to modifications

Copyright PEPPERL+FUCHS • Printed in Germany

R60361.9465 - Index 4, 10/ 2020

Loading...

Loading...