Page 1

COMPACT MANUAL

CC-LINK GATEWAYS

FACTORY AUTOMATION

Page 2

CC-Link Gateways

With regard to the supply of products, the current issue of the following document is applicable: The

General Terms of Delivery for Products and Services of the Electrical Industry, published by the

Central Association of the Electrical Industry (Zentralverband Elektrotechnik und Elektroindustrie

(ZVEI) e.V.) in its most recent version as well as the supplementary clause: "Expanded reservation

of proprietorship".

Page 3

CC-Link Gateways

Table of contents

Table of contents

CC-Link Gateways

1 Introduction...........................................................................................5

2 Declaration of conformity....................................................................6

2.1 Declaration of conformity ............................................................................... 6

3 Safety.....................................................................................................7

3.1 Symbols relevant to safety ............................................................................. 7

3.2 General notes on safety.................................................................................. 7

3.3 Disposal............................................................................................................ 7

4 Setting up the AS-i bus........................................................................8

5 Configuration and Start-up of the Safety Monitor.............................9

6 Data transmission modes of the CC-Link Gateways.......................10

6.1 Standard mode............................................................................................... 11

6.1.1 Remote IO Points .......................................................................................................... 11

6.1.2 Buffer memory area ...................................................................................................... 13

6.1.3 Safety Status ............................ ... .. ................................ .. ... ............................... ... ......... 15

6.1.4 Fieldbus Bits.................................................................................................................. 15

6.1.5 Message Transmission.................................................................................................16

6.2 Compatibility mode for VBG-CCL-G4F........................................................17

6.2.1 Remote IO Points .......................................................................................................... 17

6.2.2 Buffer Memory Area...................................................................................................... 18

6.3 CC-Link V1 Mode ........................................................................................... 22

6.3.1 Remote IO Points .......................................................................................................... 22

6.3.2 Buffer Memory Area...................................................................................................... 23

6.4 Compatibility Mode for FX2N-32ASI-M ........................................................ 27

6.4.1 Remote IO Points .......................................................................................................... 27

6.4.2 Buffer Memory Area...................................................................................................... 27

6.5 Compatibility Mode for HK-ASICC ............................................................... 30

6.5.1 Remote IO Points .......................................................................................................... 30

6.5.2 Buffer Memory Area...................................................................................................... 30

7 Accessing command interface..........................................................31

7.1 Using BFM........... ........................................................................................... 31

7.2 Using "Message Transmission"................................................................... 34

02.05.2016

3

Page 4

CC-Link Gateways

Table of contents

8 Diagnostics.........................................................................................36

8.1 System diagnostics on the PC......................................................................36

8.1.1 Software for diagnostics, service and release measurements.................................36

8.1.2 AS-i Control Tools .........................................................................................................36

8.1.3 ASIMON ..........................................................................................................................36

8.1.4 Web server .....................................................................................................................36

8.2 Diagnostics on the host controller...............................................................37

8.2.1 Diagnostics through process data ......................................... ... ... .. ... ..........................37

8.2.1.1 Diagnosing the AS-i circuits..........................................................................................37

8.2.1.2 Diagnosing the Safety Monitor......................................................................................37

8.2.2 Diagnosing the safety unit using the command interface.........................................40

8.2.3 LEDs ...............................................................................................................................40

8.2.4 LC-Display......................................................................................................................40

8.2.5 AS-i Monitor ...................................................................................................................40

8.2.5.1 Duplicate address detection .........................................................................................40

8.2.5.2 Earth fault monitor ........................................................................................................41

8.2.5.3 Noise voltage detection ............................................................................................ ....41

8.2.5.4 Overvoltage detection...................................................................................................41

Flags + Fault Detector (see chap. 6.1.1). ............ .......................................................37

Safety diagnostics in the Input Data Image ................................ ................................37

Fieldbus Bits and Safety Status .................................................................................37

Safety diagnostics in the Input Data Image (IDI) 38

Safety diagnostics of safe AS-i inputs ........................................................................38

Safety diagnostics of safe AS-i outputs ......................................................................39

Changing the base setting ............................................................................ ..............40

9 Appendix.............................................................................................42

4

02.05.2016

Page 5

CC-Link Gateways

Introduction

1. Introduction

Congratulations

You have chosen a device manufactured by Pepperl+Fuchs. Pepperl+Fuchs develops, produces and distributes electronic sensors and interface modules for the

market of automation technology on a worldwide scale.

Before installing this equipment and put into operation, read this manual carefully.

This manual containes instructions and notes to help you through the installation

and commissioning step by step. This makes sure bring such a trouble-free use

of this product. This is for your benefit, since this:

• ensures the safe operation of the device

• helps you to exploit the full functionality of the device

• avoids errors and related malfunctions

• avoids costs by disruptions and any repairs

• increases the effectiveness and efficiency of your plant

Keep this manual at hand for subsequent operations on the device.

After opening the packaging please check the integrity of the device and the num-

ber of pieces of supplied.

Symbols used

The following symbols are used in this manual:

Information!

This symbol indicates important information.

Attention!

This symbol warns of a potential failure. Non-compliance may lead to interruptions of

the device, the connected peripheral systems, or plant, potentially leading to total malfunctioning.

Warning!

This symbol warns of an imminent danger. Non-compliance may lead to personal injuries that could be fatal or result in material damage s and destruction.

Contact

If you have any questions about the device, its functions, or accessories, please

contact us at:

Pepperl+Fuchs GmbH

Lilienthalstraße 200

68307 Mannheim

Telephone: +49 621 776-4411

Fax: +49 621 776-274411

E-Mail: fa-info@pepperl-fuchs.com

02.05.2016

5

Page 6

CC-Link Gateways

Declaration of conformity

2. Declaration of conformity

2.1 Declaration of conformity

This product was developed and manufactured under observance of the applicable European standards and guidelines.

Information!

A Declaration of Conformity can be requested from the manufacturer.

The product manufacturer, Pepperl+Fuchs GmbH, D-68307 Mannheim, has a

certified quality assurance system that conforms to ISO 9001.

6

02.05.2016

Page 7

CC-Link Gateways

Safety

3. Safety

3.1 Symbols relevant to safety

Information!

This symbol indicates important information.

Attention!

This symbol warns of a potential failure. Non-compliance may lead to interruptions of

the device, the connected peripheral systems, or plant, potentially leading to total malfunctioning.

Warning!

This symbol warns of an imminent danger. Non-compliance may lead to personal injuries that could be fatal or result in material damage s and destruction.

3.2 General notes on safety

Only instructed specialist staff may operate the device in accordance with the operating manual.

User modification and or repair are dangerous and will void the warranty and exclude the manufacturer from any liability. If serious fault s occur, stop using the device. Secure the device against inadvertent operation. In the event of repairs, return the device to your local Pepperl+Fuchs representative or sales office.

The connection of the device and maintenance work when live may only be carried out by a qualified electrical specialist.

The operating company bears responsibility for observing locally applicable safety regulations.

Store the not used device in the original packaging. This offers the device optimal

protection against impact and moisture.

Ensure that the ambient conditions comply with regulations.

3.3 Disposal

Information!

Electronic waste is hazardous waste. Please comply with all local ordinances when

disposing this product!

The device does not contain batteries that need to be removed before disposing it.

02.05.2016

7

Page 8

CC-Link Gateways

Setting up the AS-i bus

4. Setting up the AS-i bus

1. Connect the unit to power.

2. Connect the AS-i cable to the unit.

3. One after the other connect the AS-i slaves to the AS-i cable and set the

slave addresses.

You may set the addresses directly on the slave using a portable addresser

or by using the option [SLAVE ADR TOOL] in the display menu of your

gateway.

4. In the display menu select [QUICK SETUP] to use the configuration of all

AS-i circuits connected to the unit.

Confirm with [STORE+RUN].

5. Set the CC-Link address and connect the gateway to the host fieldbus controller.

You can set the addresses directly using the option [CC-LINK] in the display menu of your gateway or through the PC using the ASIMON software

with integrated AS-i Control Tools.

For more detailed information pleas e refer to the installation guide for your g ateway

which is included with the unit.

8

02.05.2016

Page 9

CC-Link Gateways

Configuration and Start-up of the Safety Monitor

5. Configuration and Start-up of the Safety Monitor

Configuration and start-up of the AS-i Safety Monitor is accomplished using a PC/

notebook running the ASIMON configuration software.

Note!

For more detailed information please refer to the separate manual for the ASIMON

configuration software.

Configuration should be performed only by a safety specialist. All safety-related

commands are password protected.

The correct safety functioning of the unit must absolutely be verified in the system!

Note!

Quick Start Guides for commis sionin g and ser vice are p rovide d on the w ebsite av ailable for download.

02.05.2016

9

Page 10

CC-Link Gateways

Data transmission modes of the CC-Link Gateways

6. Data transmission modes of the CC-Link Gateways

There are several modes for the transmission of data in CC-Link:

1. Standard mode (see chap. 6.1)

2. Compatibility mode for VBG-CCL-G4F COMP (see chap. 6.2)

3. Compatibility mode for CC-Link V1 (see chap. 6.3)

4. Compatibility mode for FX2N-32ASI-M CP (see chap. 6.4)

5. Compatibility mode for HK-ASICC COMP (see chap. 6.5)

Information!

The selection of each data tr ansmi ss ion mod e take s plac e i n the me nu of t he g at ew ay

using the buttons and the display. Addi tional information ca n be foand in the description of the display menu of your gateway.

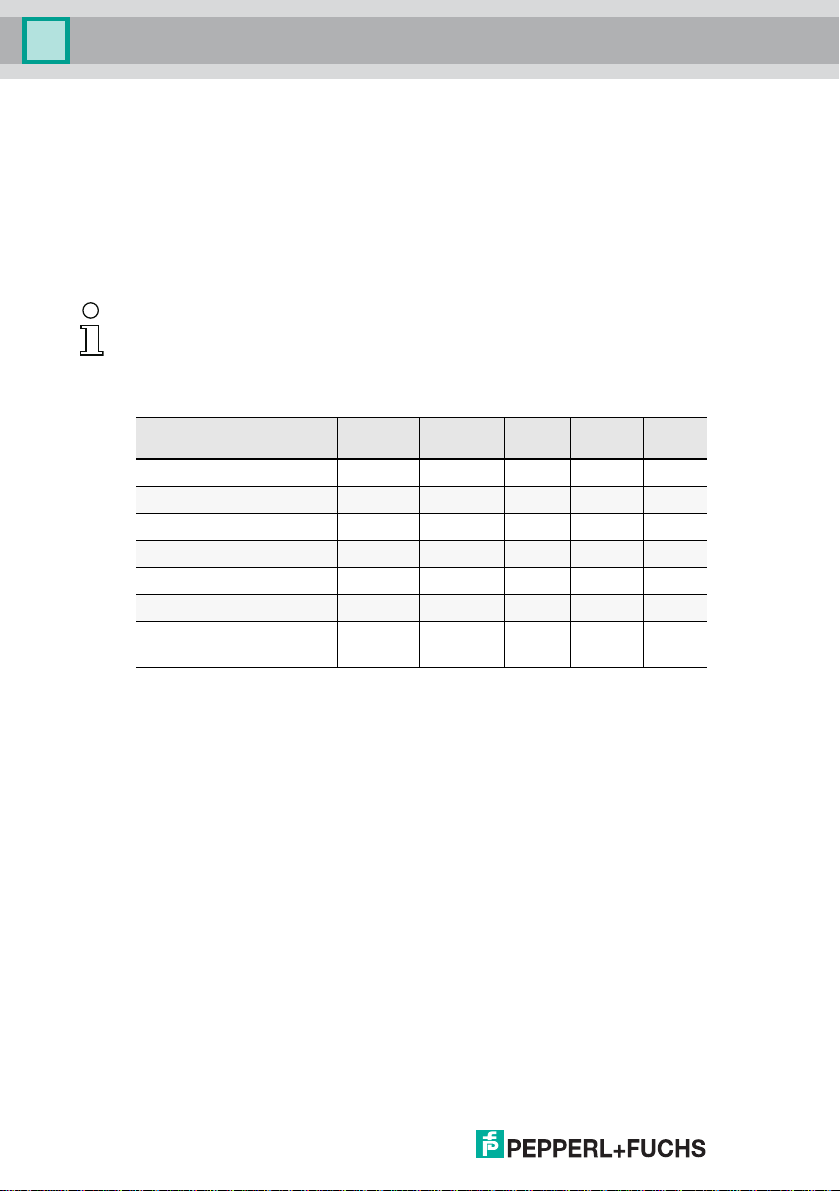

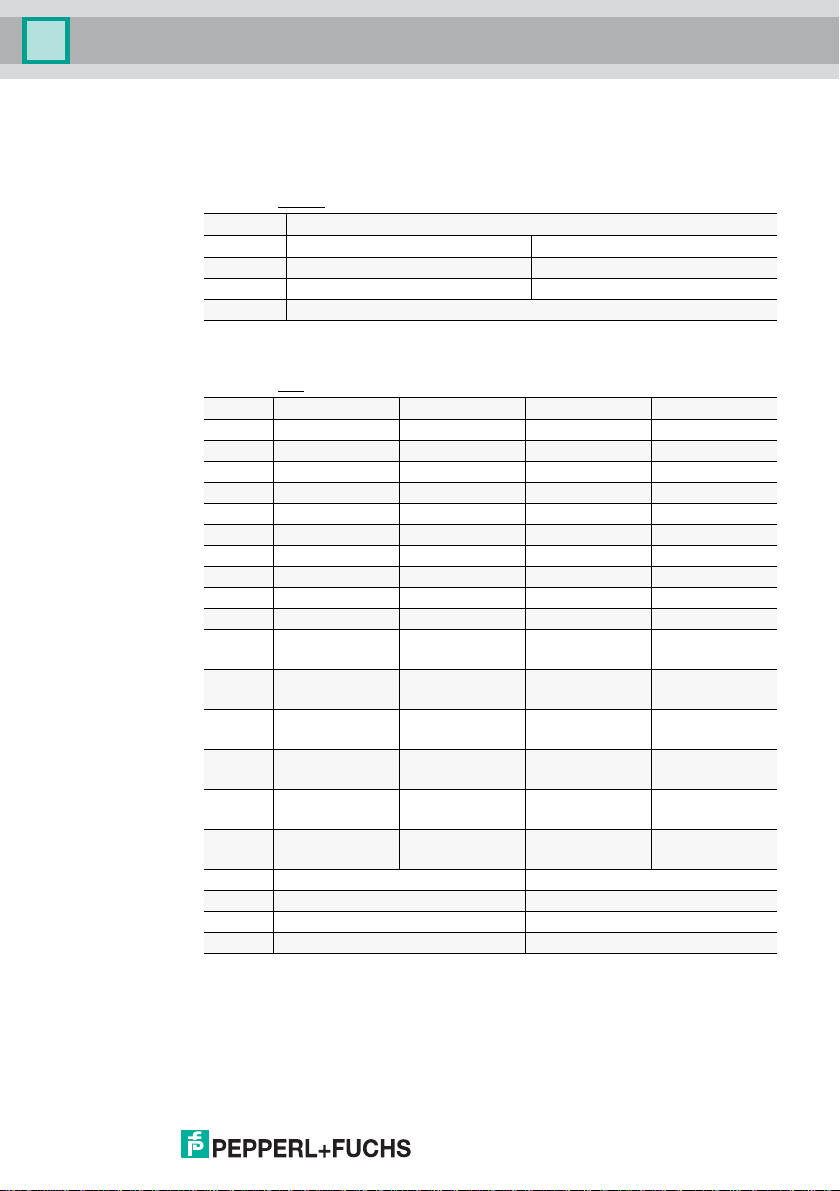

Summary of data transmission modes

Standard

occupied stations 3 3 4 4 2

cycle setting 2 1 1 1 1

required CC-Link master V2 V1 V1 V1 V1

support of 2 AS-i circuits no no no no no

support of B-slaves yes (yes) yes no no

support of analog slaves yes yes yes no no

support of AS-i configurati o n

via CC-Link

yes yes yes no no

VBG-CCL-

G4F

CC-Link V1FX2N-

32ASI-M

HK-

ASICC

Tab. 6-1.

10

02.05.2016

Page 11

CC-Link Gateways

Data transmission modes of the CC-Link Gateways

6.1 Standard mode

The Standard Mode has the following features:

• the gateway occupies 3 stations and has a double cycle setting.

• The last 2 words are reserved for "Message Transmission".

• The AS-i process data is mapped into the Buffer Memory Area (BFM).

• All acyclic requests are handled by "Message Transmission" using cyclic

data.

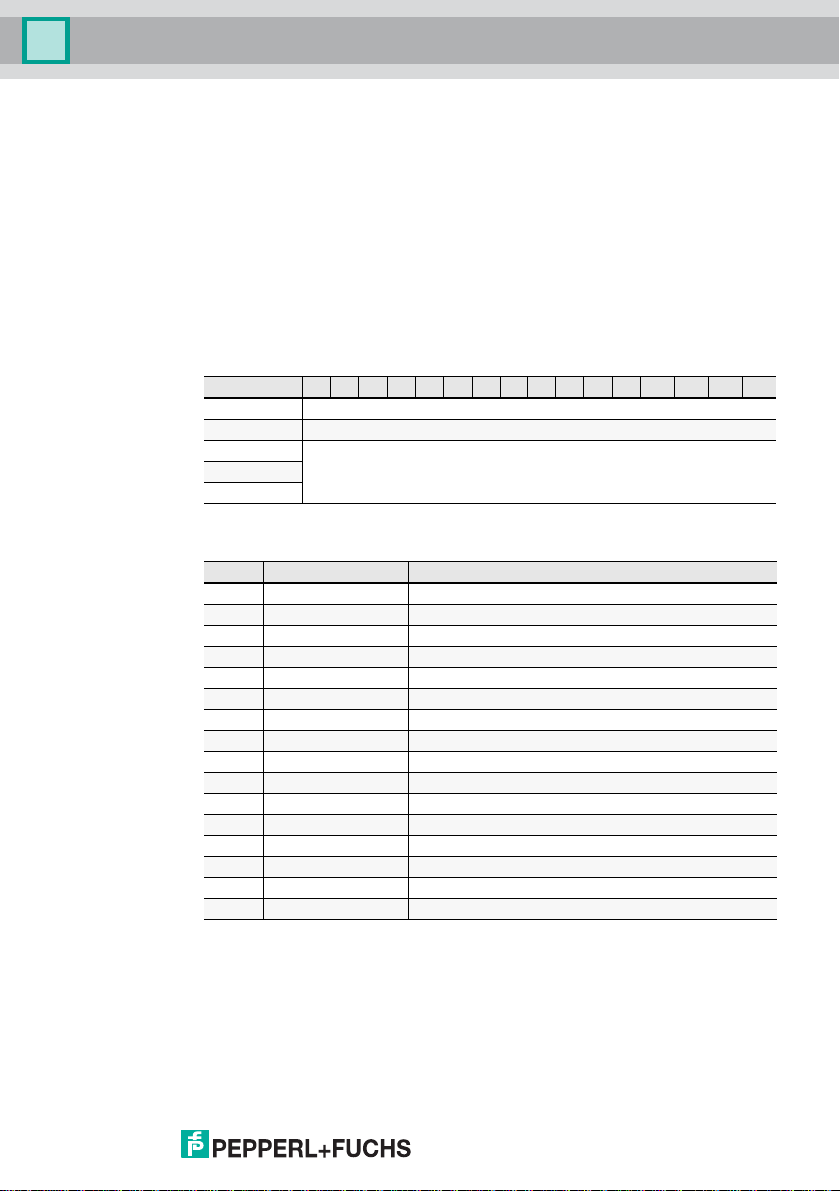

6.1.1 Remote IO Points

Remote to Host

Address 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

RXm reserved

RXm+1 AS-i circuit 1: EC-Flags and Fault Detector

RXm+2

RXm+9

EC-Flags and Fault Detector

Bit Short Cut Name

0 Cfg. OK Configuration OK

1 S0 Slave Address 0 detected

2 Aaasn Auto Address Assign

3 Aaavail Auto Address Available

4 CM Configuration Mode active

5 NA Normal Operation active

6 APF AS-i Power Fail (AS-i voltage below 19 V)

7 Offl Off-line

8 NPF No Peripheral Fault

9 reserved reserved

10 PWRw Power Warning (AS-i voltage below 22.5 V)

11 reserved reserved

12 EF Earth Fault

13 OV Over-voltage on AS-i

14 Noise Noise

15 reserved reserved

reserved…

Tab. 6-2.

Tab. 6-3.

02.05.2016

11

Page 12

CC-Link Gateways

Data transmission modes of the CC-Link Gateways

Host to Remote

Address 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

RYm PM CM AAE OFL

RYm+1 reserved

…

RYm+9

Tab. 6-4.

Flags in RYm

Bit Short Cut Name

0 OFL Offline

1 AAE Auto Address Enable

2 CM Enter Configuration Mode on rising edge

3 PM Enter Protected Mode on rising edge

4 … 15 reserved

Tab. 6-5.

12

02.05.2016

Page 13

CC-Link Gateways

Data transmission modes of the CC-Link Gateways

6.1.2 Buffer memory area

Buffer memory

for master without integr. safety monitor

Address 1 Master

0 … 7 AS-i 1, input A + single slaves AS-i 1, output A + single slaves

8 … 15 AS-i 1, input B slaves AS-i 1, output B slaves

16 … 23 reserved

Buffer memory (read)

for master with integr. safety monitor

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWrm0 AS-i 1: Inp. Slv3 AS-i 1: Inp. Slv2 AS-i 1: Inp. Slv1 flags AS-i 1

RWrm1 AS-i 1: Inp. Slv7 AS-i 1: Inp. Slv6 AS-i 1: Inp. Slv5 AS-i 1: Inp. Slv4

RWrm2 AS-i 1: Inp. Slv11 AS-i 1: Inp. Slv10 AS-i 1: Inp. Slv9 AS-i 1: Inp. Slv8

RWrm3 AS-i 1: Inp. Slv15 AS-i 1: Inp. Slv14 AS-i 1: Inp. Slv13 AS-i 1: Inp. Slv12

RWrm4 AS-i 1: Inp. Slv19 AS-i 1: Inp. Slv18 AS-i 1: Inp. Slv17 AS-i 1: Inp. Slv16

RWrm5 AS-i 1: Inp. Slv23 AS-i 1: Inp. Slv22 AS-i 1: Inp. Slv21 AS-i 1: Inp. Slv20

RWrm6 AS-i 1: Inp. Slv27 AS-i 1: Inp. Slv26 AS-i 1: Inp. Slv25 AS-i 1: Inp. Slv24

RWrm7 AS-i 1: Inp. Slv31 AS-i 1: Inp. Slv30 AS-i 1: Inp. Slv29 AS-i 1: Inp. Slv28

RWrm8 AS-i 1: Inp. Slv3B AS-i 1: Inp. Slv2B AS-i 1: Inp. Slv1B

RWrm9 AS-i 1: Inp. Slv7B AS-i 1: Inp. Sl v6B AS-i 1: Inp. Slv5B AS-i 1: Inp. Slv4B

RWrm10 AS-i 1:

Inp. Slv11B

RWrm11 AS-i 1:

Inp. Slv15B

RWrm12 AS-i 1:

Inp. Slv19B

RWrm13 AS-i 1:

Inp. Slv23B

RWrm14 AS-i 1: Inp.

Slv27B

RWrm15 AS-i 1:

Inp. Slv31B

RWrm16 fieldbus bits 15 … 8 fieldbus bits 7 … 0

RWrm17 Safety Status OSSD2 Safety Status OSSD1

RWrm18 Safety Status OSSD4 Safety Status OSSD3

RWrm19 Safety Status OSSD6 Safety Status OSSD5

read write

AS-i 1:

Inp. Slv10B

AS-i 1:

Inp. Slv14B

AS-i 1:

Inp. Slv18B

AS-i 1:

Inp. Slv22B

AS-i 1: Inp.

Slv26B

AS-i 1:

Inp. Slv30B

AS-i 1:

Inp. Slv9B

AS-i 1:

Inp. Slv13B

AS-i 1:

Inp. Slv17B

AS-i 1:

Inp. Slv21B

AS-i 1: Inp.

Slv25B

AS-i 1:

Inp. Slv29B

Tab. 6-6.

AS-i 1:

Inp. Slv8B

AS-i 1:

Inp. Slv12B

AS-i 1:

Inp. Slv16B

AS-i 1:

Inp. Slv20B

AS-i 1: Inp.

Slv24B

AS-i 1:

Inp. Slv28B

Tab. 6-7.

02.05.2016

13

Page 14

CC-Link Gateways

Data transmission modes of the CC-Link Gateways

Bits in flags

Bit Name

0 0: No C onfig Error

1 0: AS-i Power OK

2 0: Normal Operation active

3 0: Protected Mode active

Tab. 6-8.

Buffer memory (write)

for master with integr. safety monitor

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWwm0 AS-i 1: Outp. Slv3 AS-i 1: Outp. Slv2 AS-i 1: Outp. Slv1

RWwm1 AS-i 1: Outp. Slv7 AS-i 1: Outp. Slv6 AS-i 1: Outp. Slv5 AS-i 1: Outp. Slv4

RWwm2 AS-i 1: Outp.

Slv11

RWwm3 AS-i 1:

Outp. Slv15

RWwm4 AS-i 1:

Outp. Slv19

RWwm5 AS-i 1:

Outp. Slv23

RWwm6 AS-i 1:

Outp. Slv27

RWwm7 AS-i 1:

Outp. Slv31

RWwm8 AS-i 1:

Outp. Slv3B

RWwm9 AS-i 1:

Outp. Slv7B

RWwm10 AS-i 1:

Outp. Slv11B

RWwm11 AS-i 1:

Outp. Slv15B

RWwm12 AS-i 1:

Outp. Slv19B

RWwm13 AS-i 1:

Outp. Slv23B

RWwm14 AS-i 1:

Outp. Slv27B

RWwm15 AS-i 1:

Outp. Slv31B

AS-i 1:

Outp. Slv10

AS-i 1:

Outp. Slv14

AS-i 1:

Outp. Slv18

AS-i 1:

Outp. Slv22

AS-i 1:

Outp. Slv26

AS-i 1:

Outp. Slv30

AS-i 1:

Outp. Slv2B

AS-i 1:

Outp. Slv6B

AS-i 1:

Outp. Slv10B

AS-i 1:

Outp. Slv14B

AS-i 1:

Outp. Slv18B

AS-i 1:

Outp. Slv22B

AS-i 1:

Outp. Slv26B

AS-i 1:

Outp. Slv30B

AS-i 1:

Outp. Slv9

AS-i 1:

Outp. Slv13

AS-i 1:

Outp. Slv17

AS-i 1:

Outp. Slv21

AS-i 1:

Outp. Slv25

AS-i 1:

Outp. Slv29

AS-i 1:

Outp. Slv1B

AS-i 1:

Outp. Slv5B

AS-i 1:

Outp. Slv9B

AS-i 1:

Outp. Slv13B

AS-i 1:

Outp. Slv17B

AS-i 1:

Outp. Slv21B

AS-i 1:

Outp. Slv25B

AS-i 1:

Outp. Slv29B

AS-i 1:

Outp. Slv8

AS-i 1:

Outp. Slv12

AS-i 1:

Outp. Slv16

AS-i 1:

Outp. Slv20

AS-i 1:

Outp. Slv24

AS-i 1:

Outp. Slv28

AS-i 1:

Outp. Slv4B

AS-i 1:

Outp. Slv8B

AS-i 1:

Outp. Slv12B

AS-i 1:

Outp. Slv16B

AS-i 1:

Outp. Slv20B

AS-i 1:

Outp. Slv24B

AS-i 1:

Outp. Slv28B

RWwm16 fieldbus bits 15 … 8 fieldbus bits 7 … 0

…

RWwm19

reserved

Tab. 6-9.

14

02.05.2016

Page 15

CC-Link Gateways

Data transmission modes of the CC-Link Gateways

Bits in flags

Bit Name

0 0: No C onfig Error

1 0: AS-i Power OK

2 0. Normal Operation active

3 0: Protected Mode active

6.1.3 Safety Status

Tab. 6-10.

Bits in Safety Status

Bit

7

2

one or more

devices are red

flashing

6

2

one or more

devices are yellow

flashing

6.1.4 Fieldbus Bits

Information!

This functionality is only available in devices in t he safety ve rsion ’SV 4.3’ (see latera l

label)!

The fieldbus bits enable communication between the controller and the safety

program. The fieldbus bits can be used to pass any acknowledgment signals or

similar to the safety program and provide status information to the controller.

The states of the AS-i Safety in- and outputs are sent to the controller via the input data image (see par. <Safety diagnostics in the Input Data Image (IDI)>).

Output data (device fieldbus bit in ASIMON)

2152142132122112102928272625242322212

FB15FB14FB13FB12FB11FB10FB09FB08FB07FB06FB05FB04SI 4SI 3SI 2SI 1

Input data (output assignment fieldbus bit in ASIMON)

2152142132122112102928272625242322212

FB15FB14FB13FB12FB11FB10FB09FB08FB07FB06FB05FB04FB03FB02FB01FB

FB: fieldbus bit

SI1 … SI4: monitor inputs

02.05.2016

25242322212

OSSD Color

0: green

1: flashing green

2: yellow

reserved

3: yellow flashing

4: red

5: flashing red

6: grey

7: reserved

Tab. 6-11. Bits in Safety Status

Tab. 6-12.

Tab. 6-13.

0

0

0

00

15

Page 16

CC-Link Gateways

Data transmission modes of the CC-Link Gateways

Information!

More detailed information can b e found in the manual "ASIMON configuration software", sections: "Monitoring devices -> Fieldbus bit" and "Output assignment"..

6.1.5 Message Transmission

"Message Transmission" provides only command interface commands (see separate manual "AS-i 3.0 Command Interface").

Information!

For details on the Message Tran smiss io n pr ot oc ol, plea se re fer to the CC- Link sp ec ifi cation. For more informat ion or PLC program examples, how to u se Message Transmission, please refer to the documentatio n of your CC-Link master in use.

16

02.05.2016

Page 17

CC-Link Gateways

Data transmission modes of the CC-Link Gateways

6.2 Compatibility mode for VBG-CCL-G4F

The Compatibility Mode for VBG-CCL-G4F has the following features:

• 3 stations are occupied using a single cycle setting.

• All functions of VBG-CCL-G4F are implemented.

• The AS-i process data or the command interface is mapped into the buffer

memory area (BFM) (as done in the VBG-CCL-G4F).

• "Message Transmission" is not supported

(since VBG-CCL-G4F also does not use it).

6.2.1 Remote IO Points

Remote to Host

Address 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

RXm reserved BfEAck MbAck reserved

RXm+1

…

RXm+5

Flags in RXm

Bit Short Cut Name

0 … 3 reserved

4 MbAck Acknowledge bit for Y4

5 BfEAck Acknowledge bit for Y5

6 … 15 reserved

Host to Remote

Address 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

RYm reserved BfE Mb PM CM AAE OFL

RYm+1

…

RYm+5

reserved

Tab. 6-14.

Tab. 6-15.

reserved

Tab. 6-16.

02.05.2016

17

Page 18

CC-Link Gateways

Data transmission modes of the CC-Link Gateways

Flags in RYm

Bit Short Cut Name

0 OFL Offline

1 AAE Auto Address Enable

2 CM Enter Configuration Mode on rising edge

3 PM Enter Protected Mode on rising edge

4 Mb 0: BFM used for IO data onl y

5 BfE 0: Enable use of BFM

6 … 15 reserved

6.2.2 Buffer Memory Area

Buffer memory (read) when using ’IO data only mode’

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWrm0

RWrm1

RWrm2

RWrm3

RWrm4

RWrm5

RWrm6

RWrm7

RWrm8

RWrm9

RWrm10

RWrm11

AS-i 1: Inp. Slv3 AS-i 1: Inp. Slv2 AS-i 1: Inp. Slv1 flags

AS-i 1: Inp. Slv7 AS-i 1: Inp. Slv6 AS-i 1: Inp. Sl v5 AS-i 1: Inp. Slv4

AS-i 1:

Inp. Slv11

AS-i 1:

Inp. Slv15

AS-i 1:

Inp. Slv19

AS-i 1:

Inp. Slv23

AS-i 1:

Inp. Slv27

AS-i 1:

Inp. Slv31

AS-i 1:

Inp. Slv3B

AS-i 1:

Inp. Slv7B

AS-i 1:

Inp. Slv11B

AS-i 1:

Inp. Slv15B

1: BFM used for command interface

Tab. 6-17.

AS-i 1:

Inp. Slv10

AS-i 1:

Inp. Slv14

AS-i 1:

Inp. Slv9

AS-i 1:

Inp. Slv13

AS-i 1:

Inp. Slv8

AS-i 1:

Inp. Slv12

AS-i 1: Inp. Slv18 AS-i 1: Inp. Slv17 AS-i 1: Inp. Slv16

AS-i 1:

Inp. Slv22

AS-i 1:

Inp. Slv26

AS-i 1:

Inp. Slv30

AS-i 1:

Inp. Slv2B

AS-i 1:

Inp. Slv6B

AS-i 1:

Inp. Slv10B

AS-i 1:

Inp. Slv14B

AS-i 1:

Inp. Slv21

AS-i 1:

Inp. Slv25

AS-i 1:

Inp. Slv29

AS-i 1:

Inp. Slv1B

AS-i 1:

Inp. Slv5B

AS-i 1:

Inp. Slv9B

AS-i 1:

Inp. Slv13B

AS-i 1:

Inp. Slv20

AS-i 1:

Inp. Slv24

AS-i 1:

Inp. Slv28

AS-i 1:

Inp. Slv4B

AS-i 1:

Inp. Slv8B

AS-i 1:

Inp. Slv12B

Tab. 6-18.

Bits in Flags

Bit Name

0 0: No C onfig Error

1 0: AS-i Power OK

2 0. Normal Operation active

3 0: Protected Mode active

18

Tab. 6-19.

02.05.2016

Page 19

CC-Link Gateways

Data transmission modes of the CC-Link Gateways

Buffer memory (read) when using ’command interface mode’

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWrm0

RWrm1

RWrm2

RWrm3

RWrm4

RWrm5

RWrm6

RWrm7

RWrm8

RWrm9

RWrm10

RWrm11

command interface:

circuit

command interface:

response byte 2

command interface:

response byte 4

command interface:

response byte 6

command interface:

response byte 8

command interface:

response byte 10

command interface:

response byte 12

command interface:

response byte 14

command interface:

response byte 16

command interface:

response byte 18

command interface:

response byte 20

command interface:

response byte 22

command interface:

command

command interface:

response byte 1

command interface:

response byte 3

command interface:

response byte 5

command interface:

response byte 7

command interface:

response byte 9

command interface:

response byte 11

command interface:

response byte 13

command interface:

response byte 15

command interface:

response byte 17

command interface:

response byte 19

command interface:

response byte 21

Tab. 6-20.

02.05.2016

19

Page 20

CC-Link Gateways

Data transmission modes of the CC-Link Gateways

Buffer memory (write) when using ’IO data only mode’

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWwm0

RWwm1

RWwm2

RWwm3

RWwm4

RWwm5

RWwm6

RWwm7

RWwm8

RWwm9

RWwm10

RWwm11

AS-i 1:

Outp. Slv3

AS-i 1:

Outp. Slv7

AS-i 1:

Outp. Slv11

AS-i 1:

Outp. Slv15

AS-i 1:

Outp. Slv19

AS-i 1:

Outp. Slv23

AS-i 1:

Outp. Slv27

AS-i 1:

Outp. Slv31

AS-i 1:

Outp. Slv3B

AS-i 1:

Outp. Slv7B

AS-i 1:

Outp. Slv11B

AS-i 1:

Outp. Slv15B

AS-i 1:

Outp. Slv2

AS-i 1:

Outp. Slv6

AS-i 1:

Outp. Slv10

AS-i 1:

Outp. Slv14

AS-i 1:

Outp. Slv18

AS-i 1:

Outp. Slv22

AS-i 1:

Outp. Slv26

AS-i 1:

Outp. Slv30

AS-i 1:

Outp. Slv2B

AS-i 1:

Outp. Slv6B

AS-i 1: Outp.

Slv10B

AS-i 1:

Outp. Slv14B

AS-i 1:

Outp. Slv1

AS-i 1:

Outp. Slv5

AS-i 1:

Outp. Slv9

AS-i 1:

Outp. Slv13

AS-i 1:

Outp. Slv17

AS-i 1:

Outp. Slv21

AS-i 1:

Outp. Slv25

AS-i 1:

Outp. Slv29

AS-i 1:

Outp. Slv1B

AS-i 1:

Outp. Slv5B

AS-i 1: Outp.

Slv9B

AS-i 1:

Outp. Slv13B

flags

AS-i 1:

Outp. Slv4

AS-i 1:

Outp. Slv8

AS-i 1:

Outp. Slv12

AS-i 1:

Outp. Slv16

AS-i 1:

Outp. Slv20

AS-i 1:

Outp. Slv24

AS-i 1:

Outp. Slv28

AS-i 1:

Outp. Slv4B

AS-i 1: Outp.

Slv8B

AS-i 1:

Outp. Slv12B

Tab. 6-21.

20

02.05.2016

Page 21

CC-Link Gateways

Data transmission modes of the CC-Link Gateways

Buffer memory (write) when using ’command interface mode’

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWwm0

RWwm1

RWwm2

RWwm3

RWwm4

RWwm5

RWwm6

RWwm7

RWwm8

RWWm9

RWwm10

RWwm11

command interface:

circuit

command interface:

request byte 2

command interface:

request byte 4

command interface:

request byte 6

command interface:

request byte 8

command interface:

request byte 10

command interface:

request byte 12

command interface:

request byte 14

command interface:

request byte 16

command interface:

request byte 18

command interface:

request byte 20

command interface:

request byte 22

command interface:

command

command interface:

request byte 1

command interface:

request byte 3

command interface:

request byte 5

command interface:

request byte 7

command interface:

request byte 9

command interface:

request byte 11

command interface:

request byte 13

command interface:

request byte 15

command interface:

request byte 17

command interface:

request byte 19

command interface:

request byte 21

Tab. 6-22.

02.05.2016

21

Page 22

CC-Link Gateways

Data transmission modes of the CC-Link Gateways

6.3 CC-Link V1 Mode

CC-Link V1 Mode is an enxanced version of the compatibility mode for VBG-

CCL-G4F.

Features:

• 4 stations are occupied using a single cycle setting.

• The AS-i process data or the mailbox is mapped into the buffer memory area

(BFM) (as done in the VBG-CCL-G4F).

• "Message Transmission" is not supported.

6.3.1 Remote IO Points

Remote to Host

Address 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

RXm reserved BfEAck MbAck reserved

RXm+1

…

RXm+7

Flags in RXm

Bit Short Cut Name

0 … 3 reserved

4 MbAck Acknowledge bit for Y4

5 BfEAck Acknowledge bit for Y5

6 … 15 reserved

Host to Remote

Address 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

RYm reserved BfE Mb PM CM AAE OFL

RYm+1

…

RYm+7

reserved

Tab. 6-23.

Tab. 6-24.

reserved

Tab. 6-25.

Flags in RYm

Bit Short Cut Name

0 OFL Offline

1 AAE Auto Address Enable

2 CM Enter Configuration Mode on rising edge

3 PM Enter Protected Mode on rising edge

4 Mb 0: BFM used for IO Data only

5 BfE 0: Enable use of BFM

6 … 15 reserved

22

1: BFM used for command interface

Tab. 6-26.

02.05.2016

Page 23

CC-Link Gateways

Data transmission modes of the CC-Link Gateways

6.3.2 Buffer Memory Area

Buffer memory (read) when using ’IO data only mode’

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWrm0 AS-i 1: Inp. Slv3 AS-i 1: Inp. Slv2 AS-i 1: Inp. Slv1 flags

RWrm1 AS-i 1: Inp. Slv7 AS-i 1: Inp. Slv6 AS-i 1: Inp. Slv5 AS-i 1: Inp. Slv4

RWrm2

RWrm3

RWrm4

RWrm5

RWrm6

RWrm7

RWrm8

RWrm9

RWrm10

RWrm11

RWrm12

RWrm13

RWrm14

RWrm15

Inp. Slv11B

Inp. Slv15B

Inp. Slv19B

Inp. Slv23B

Inp. Slv27B

Inp. Slv31B

AS-i 1:

Inp. Slv11

AS-i 1:

Inp. Slv15

AS-i 1:

Inp. Slv19

AS-i 1:

Inp. Slv23

AS-i 1:

Inp. Slv27

AS-i 1:

Inp. Slv31

AS-i 1:

Inp. Slv3B

AS-i 1:

Inp. Slv7B

AS-i 1:

AS-i 1:

AS-i 1:

AS-i 1:

AS-i 1:

AS-i 1:

AS-i 1:

Inp. Slv10

AS-i 1:

Inp. Slv14

AS-i 1:

Inp. Slv18

AS-i 1:

Inp. Slv22

AS-i 1:

Inp. Slv26

AS-i 1:

Inp. Slv30

AS-i 1:

Inp. Slv2B

AS-i 1:

Inp. Slv6B

AS-i 1:

Inp. Slv10B

AS-i 1:

Inp. Slv14B

AS-i 1:

Inp. Slv18B

AS-i 1:

Inp. Slv22B

AS-i 1:

Inp. Slv26B

AS-i 1:

Inp. Slv30B

AS-i 1:

Inp. Slv9

AS-i 1:

Inp. Slv13

AS-i 1:

Inp. Slv17

AS-i 1:

Inp. Slv21

AS-i 1:

Inp. Slv25

AS-i 1:

Inp. Slv29

AS-i 1:

Inp. Slv1B

AS-i 1:

Inp. Slv5B

AS-i 1:

Inp. Slv9B

AS-i 1:

Inp. Slv13B

AS-i 1:

Inp. Slv17B

AS-i 1:

Inp. Slv21B

AS-i 1:

Inp. Slv25B

AS-i 1:

Inp. Slv29B

AS-i 1:

Inp. Slv8

AS-i 1:

Inp. Slv12

AS-i 1:

Inp. Slv16

AS-i 1:

Inp. Slv20

AS-i 1:

Inp. Slv24

AS-i 1:

Inp. Slv28

AS-i 1:

Inp. Slv4B

AS-i 1:

Inp. Slv8B

AS-i 1:

Inp. Slv12B

AS-i 1:

Inp. Slv16B

AS-i 1:

Inp. Slv20B

AS-i 1:

Inp. Slv24B

AS-i 1:

Inp. Slv28B

Tab. 6-27.

Bits in Flags

Bit Name

0 0: No C onfig Error

1 0: AS-i Power OK

2 0. Normal Operation active

3 0: Protected Mode active

02.05.2016

Tab. 6-28.

23

Page 24

CC-Link Gateways

Data transmission modes of the CC-Link Gateways

’

Buffer memory (read) when using ’command interface mode’

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWrm0

RWrm1

RWrm2

RWrm3

RWrm4

RWrm5

RWrm6

RWrm7

RWrm8

RWrm9

RWrm10

RWrm11

RWrm12

RWrm13

RWrm14

RWrm15

command interface:

circuit

command interface:

response byte 2

command interface:

response byte 4

command interface:

response byte 6

command interface:

response byte 8

command interface:

response byte 10

command interface:

response byte 12

command interface:

response byte 14

command interface:

response byte 16

command interface:

response byte 18

command interface:

response byte 20

command interface:

response byte 22

command interface:

response byte 24

command interface:

response byte 26

command interface:

response byte 28

command interface:

response byte 30

command interface:

command

command interface:

response byte 1

command interface:

response byte 3

command interface:

response byte 5

command interface:

response byte 7

command interface:

response byte 9

command interface:

response byte 11

command interface:

response byte 13

command interface:

response byte 15

command interface:

response byte 17

command interface:

response byte 19

command interface:

response byte 21

command interface:

response byte 23

command interface:

response byte 25

command interface:

response byte 27

command interface:

response byte 29

Tab. 6-29.

24

02.05.2016

Page 25

CC-Link Gateways

Data transmission modes of the CC-Link Gateways

Buffer memory (write) when using ’IO data only mode’

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWwm0

RWwm1

RWwm2

RWwm3

RWwm4

RWwm5

RWwm6

RWwm7

RWwm8

RWwm9

RWwm10

RWwm11

RWwm12

RWwm13

RWwm14

RWwm15

AS-i 1:

Outp. Slv3

AS-i 1:

Outp. Slv7

AS-i 1:

Outp. Slv11

AS-i 1:

Outp. Slv15

AS-i 1:

Outp. Slv19

AS-i 1:

Outp. Slv23

AS-i 1:

Outp. Slv27

AS-i 1:

Outp. Slv31

AS-i 1:

Outp. Slv3B

AS-i 1:

Outp. Slv7B

AS-i 1:

Outp. Slv11B

AS-i 1:

Outp. Slv15B

AS-i 1:

Outp. Slv19B

AS-i 1:

Outp. Slv23B

AS-i 1:

Outp. Slv27B

AS-i 1:

Outp. Slv31B

AS-i 1:

Outp. Slv2

AS-i 1:

Outp. Slv6

AS-i 1:

Outp. Slv10

AS-i 1:

Outp. Slv14

AS-i 1:

Outp. Slv18

AS-i 1:

Outp. Slv22

AS-i 1:

Outp. Slv26

AS-i 1:

Outp. Slv30

AS-i 1:

Outp. Slv2B

AS-i 1:

Outp. Slv6B

AS-i 1:

Outp. Slv10B

AS-i 1:

Outp. Slv14B

AS-i 1:

Outp. Slv18B

AS-i 1:

Outp. Slv22B

AS-i 1:

Outp. Slv26B

AS-i 1:

Outp. Slv30B

AS-i 1:

Outp. Slv1

AS-i 1:

Outp. Slv5

AS-i 1:

Outp. Slv9

AS-i 1:

Outp. Slv13

AS-i 1:

Outp. Slv17

AS-i 1:

Outp. Slv21

AS-i 1:

Outp. Slv25

AS-i 1:

Outp. Slv29

AS-i 1:

Outp. Slv1B

AS-i 1:

Outp. Slv5B

AS-i 1:

Outp. Slv9B

AS-i 1:

Outp. Slv13B

AS-i 1:

Outp. Slv17B

AS-i 1:

Outp. Slv21B

AS-i 1:

Outp. Slv25B

AS-i 1:

Outp. Slv29B

flags

AS-i 1:

Outp. Slv4

AS-i 1:

Outp. Slv8

AS-i 1:

Outp. Slv12

AS-i 1:

Outp. Slv16

AS-i 1:

Outp. Slv20

AS-i 1:

Outp. Slv24

AS-i 1:

Outp. Slv28

AS-i 1:

Outp. Slv4B

AS-i 1:

Outp. Slv8B

AS-i 1:

Outp. Slv12B

AS-i 1:

Outp. Slv16B

AS-i 1:

Outp. Slv20B

AS-i 1:

Outp. Slv24B

AS-i 1:

Outp. Slv28B

Tab. 6-30.

02.05.2016

25

Page 26

CC-Link Gateways

Data transmission modes of the CC-Link Gateways

Buffer memory (write) when using ’command interface mode’

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWwm0 command interface: circuit command interface: command

RWwm1 command interface: request byte 2 command interface: request byte 1

RWwm2 command interface: request byte 4 command interface: request byte 3

RWwm3 command interface: request byte 6 command interface: request byte 5

RWwm4 command interface: request byte 8 command interface: request byte 7

RWwm5 command interface: request byte 10 command interface: request byte 9

RWwm6 co mmand interface: request byte 12 command interface: request byte 11

RWwm7 command interface: request byte 14 command interface: request byte 13

RWwm8 co mmand interface: request byte 16 command interface: request byte 15

RWwm9 command interface: request byte 18 command interface: request byte 17

RWwm10 command interface: request byte 20 command interface: request byte 19

RWwm11 command interface: request byte 22 command interface: request byte 21

RWwm12 command interface: request byte 24 command interface: request byte 23

RWwm13 command interface: request byte 26 command interface: request byte 25

RWwm14 command interface: request byte 28 command interface: request byte 27

RWwm15 command interface: request byte 30 command interface: request byte 29

Tab. 6-31.

26

02.05.2016

Page 27

CC-Link Gateways

Data transmission modes of the CC-Link Gateways

6.4 Compatibility Mode for FX2N-32ASI-M

The Compatibility Mode for FX2N-32ASI-M is used to facilitate the migration of

applications using the obsolete Mitsubishi FX2N-32ASI-M-Module (AS-i Master

2.04) for FX2N SPS.

Features:

• 4 stations are occupied using a single cycle setting (CC-Link V1).

• ’Message Transmission’ is not supported.

Not all functions of FX2N-32ASI-M are implemented:

• no command buffer.

• no list of slaves with differences in the configuration.

• no module ’Error Status’, no module ’Identifier’

(specific for the FX2N series).

6.4.1 Remote IO Points

not used

6.4.2 Buffer Memory Area

Buffer memory (read)

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWrm0 AS-i 1: Inp. Slv3 AS-i 1: Inp. Slv2 AS-i 1: Inp. Slv1 flags

RWrm1 AS-i 1: Inp. Slv7 AS-i 1: Inp. Slv6 AS-i 1: Inp. Slv5 AS-i 1: Inp. Slv4

RWrm2 AS-i 1: Inp. Slv11 AS-i 1: Inp. Slv10 AS-i 1: Inp. Slv9 AS-i 1: Inp. Slv8

RWrm3 AS-i 1: Inp. Slv15 AS-i 1: Inp. Slv14 AS-i 1: Inp. Slv13 AS-i 1: Inp. Slv12

RWrm4 AS-i 1: Inp. Slv19 AS-i 1: Inp. Slv18 AS-i 1: In p. Slv17 AS-i 1: Inp. Slv16

RWrm5 AS-i 1: Inp. Slv23 AS-i 1: Inp. Slv22 AS-i 1: Inp. Slv21 AS-i 1: Inp. Slv20

RWrm6 AS-i 1: Inp. Slv27 AS-i 1: Inp. Slv26 AS-i 1: In p. Slv25 AS-i 1: Inp. Slv24

RWrm7 AS-i 1: Inp. Slv31 AS-i 1: Inp. Slv30 AS-i 1: Inp. Slv29 AS-i 1: Inp. Slv28

RWrm8 EC-Flags

RWrm9 reserved

RWrm10

RWrm11

RWrm12

RWrm13

RWrm14

RWrm15

LDS

Slave 15 … 12

LDS

Slave 31 … 28

LAS

Slave 15 … 12

LAS

Slave 31 … 28

LPS

Slave 15 … 12

LPS

Slave 31 … 28

LDS

Slave 11 … 8

LDS

Slave 27 … 24

LAS

Slave 11 … 8

LAS

Slave 27 … 24

LPS

Slave 11 … 8

LPS

Slave 27 … 24

LDS

Slave 7 … 4

LDS

Slave 23 … 20

LAS

Slave 7 … 4

LAS

Slave 23 … 20

LPS

Slave 7 … 4

LPS

Slave 23 … 20

LDS

Slave 3 … 0

LDS

Slave 19 … 16

LAS

Slave 3 … 0

LAS

Slave 19 … 16

LPS

Slave 3 … 0

LPS

Slave 19 … 16

Tab. 6-32.

02.05.2016

27

Page 28

CC-Link Gateways

Data transmission modes of the CC-Link Gateways

Bits in Flags

Bit Name

0 0: No C onfig Error

1 0: AS-i Power OK

2 0. Normal Operation active

3 0: Protected Mode active

EC-Flags

Bit Short Cut Name

0 Cfg. Err Configuration Error

1 S0 Slave Address 0 detected

2 Aaasn Auto Address Assign

3 Aaavail Auto Address Available

4 CM Configuration Mode active

5 !NA Normal Operation not active

6 APF AS-i Power fail (AS-i voltage below 19V)

7 Offl Offline

8 NPF No Peripheral Fault

9 … 15 reserved

Tab. 6-33.

Tab. 6-34.

28

02.05.2016

Page 29

CC-Link Gateways

Data transmission modes of the CC-Link Gateways

Buffer memory (write)

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWwm0 AS-i 1: Outp. Slv3 AS-i 1: Outp. Slv2 AS-i 1: Outp. Slv1 flags

RWwm1 AS-i 1: Outp. Slv7 AS-i 1: Outp. Slv6 AS-i 1: Outp. Slv5 AS-i 1: Outp. Slv4

RWwm2

RWwm3

RWwm4

RWwm5

RWwm6

RWwm7

…

RWwm15

AS-i 1:

Outp. Slv11

AS-i 1: Outp.

Slv15

AS-i 1:

Outp. Slv19

AS-i 1:

Outp. Slv23

AS-i 1:

Outp. Slv27

AS-i 1:

Outp. Slv31

AS-i 1:

Outp. Slv10

AS-i 1: Outp.

Slv14

AS-i 1:

Outp. Slv18

AS-i 1:

Outp. Slv22

AS-i 1:

Outp. Slv26

AS-i 1:

Outp. Slv30

reserved

AS-i 1:

Outp. Slv9

AS-i 1: Outp.

Slv13

AS-i 1:

Outp. Slv17

AS-i 1:

Outp. Slv21

AS-i 1:

Outp. Slv25

AS-i 1:

Outp. Slv29

AS-i 1:

Outp. Slv8

AS-i 1:

Outp. Slv12

AS-i 1:

Outp. Slv16

AS-i 1:

Outp. Slv20

AS-i 1:

Outp. Slv24

AS-i 1:

Outp. Slv28

Tab. 6-35.

02.05.2016

29

Page 30

CC-Link Gateways

Data transmission modes of the CC-Link Gateways

6.5 Compatibility Mode for HK-ASICC

The Compatibility Mode for HK-ASICC uses compatible EA data for easy transfer of existing HK-ASICC applications.

Features:

• 2 stations are occupied using a single cycle setting (CC-Link V1).

• "Message Transmission" is not supported.

Not all functions of HK-ASICC are implemented:

• no ’Status Command Area’

• AS-i input / output area is supported in compatibility mode.

6.5.1 Remote IO Points

not used

6.5.2 Buffer Memory Area

Buffer memory (read)

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWrm0 AS-i 1: Inp. Slv3 AS-i 1: Inp. Slv2 AS-i 1: Inp. Slv1 reserve d

RWrm1 AS-i 1: Inp. Slv7 AS-i 1: Inp. Slv6 AS-i 1: Inp. Slv5 AS-i 1: Inp. Slv4

RWrm2 A S-i 1: Inp. Slv11 AS-i 1: Inp. Slv10 AS-i 1: Inp. Slv9 AS-i 1: Inp. Slv8

RWrm3 AS-i 1: Inp. Slv1 5 AS-i 1: Inp. Slv14 AS-i 1: Inp. Slv13 AS-i 1: Inp. Slv12

RWrm4 AS-i 1: Inp. Slv19 AS-i 1: Inp. Slv18 AS-i 1: Inp. Slv17 AS-i 1: Inp. Slv16

RWrm5 AS-i 1: Inp. Slv2 3 AS-i 1: Inp. Slv22 AS-i 1: Inp. Slv21 AS-i 1: Inp. Slv20

RWrm6 AS-i 1: Inp. Slv27 AS-i 1: Inp. Slv26 AS-i 1: Inp. Slv25 AS-i 1: Inp. Slv24

RWrm7 AS-i 1: Inp. Slv3 1 AS-i 1: Inp. Slv30 AS-i 1: Inp. Slv29 AS-i 1: Inp. Slv28

Tab. 6-36.

Buffer memory (write)

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWwm0 AS-i 1: Outp. Slv3 AS-i 1: Outp. Slv2 AS-i 1: Outp. Slv1 reserved

RWwm1 AS-i 1: Outp. Slv7 AS-i 1: Outp. Slv6 AS-i 1: Outp. Slv5 AS-i 1: Outp. Slv4

RWwm2

RWwm3

RWwm4

RWwm5

RWwm6

RWwm7

30

AS-i 1:

Outp. Slv11

AS-i 1:

Outp. Slv15

AS-i 1:

Outp. Slv19

AS-i 1:

Outp. Slv23

AS-i 1:

Outp. Slv27

AS-i 1:

Outp. Slv31

AS-i 1:

Outp. Slv10

AS-i 1:

Outp. Slv14

AS-i 1:

Outp. Slv18

AS-i 1:

Outp. Slv22

AS-i 1:

Outp. Slv26

AS-i 1:

Outp. Slv30

AS-i 1:

Outp. Slv9

AS-i 1:

Outp. Slv13

AS-i 1:

Outp. Slv17

AS-i 1:

Outp. Slv21

AS-i 1:

Outp. Slv25

AS-i 1:

Outp. Slv29

AS-i 1:

Outp. Slv8

AS-i 1:

Outp. Slv12

AS-i 1:

Outp. Slv16

AS-i 1:

Outp. Slv20

AS-i 1:

Outp. Slv24

AS-i 1:

Outp. Slv28

Tab. 6-37.

02.05.2016

Page 31

CC-Link Gateways

Accessing command interface

7. Accessing command interface

BFM used for I/O data

(RY4 = 0)

Disable BFM

(set RY5 = 1)

Wait for BFM disable

acknowledge (RX5 = 1)

Switch to mailbox mode

(set RY4 = 1)

Wait for mailbox mode

acknowledge (RX4 = 1)

Write command interface request data

(including command and changed

toggle bit) to RWw area

1

Enable BFM

(set RY5 = 0)

Wait for BFM enable

acknowledge (RX5 = 0)

7.1 Using BFM

This example describes one method of accessing a command interface when it is

mapped into the cyclic buffer memory area (when using VBG-CCL-G4F Mode, or

CC-Link V1 Mode)

02.05.2016

31

Page 32

CC-Link Gateways

Accessing command interface

Wait for response data in RWr

area (indicated by response toggle

bit and mirrored command)

Read command interface result and res-

ponse from RWr area

Disable BFM

(set RY5 = 1)

Wait for BFM disable

acknowledge (RX5 = 1)

Switch to I/O data mode

(set RY4 = 0)

Wait for I/O data mode

acknowledge (RX4 = 0)

Write new output data to RWw area

Enable BFM

(set RY5 = 0)

Wait for BFM enable

acknowledge (RX5 = 0)

32

02.05.2016

Page 33

CC-Link Gateways

Accessing command interface

1.)

Example:

For example, when the first command used is reading the list of detected

slaves (command 0x46), write the following to the RWw area:

Adresse Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWwm0 0x80

(command interface: toggle bit and circuit)

(command interface: command)

0x46

Tab. 7-38.

The rest of RWw area is not used by this command, because other request bytes

are not needed.

If there is no error during command execution and there are slaves 1A, 2A and

3A detected, the response data in the RWr area will be:

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWrm0 0x80

(command interface: mirrored toggle bit and

result)

RWrm1 0x00

(command interface: response byte 2)

RWrm2 0x00

(command interface: response byte 4)

RWrm3 0x00

(command interface: response byte 6)

RWrm4 0x00

(command interface: response byte 8)

(command interface: response byte 1)

(command interface: response byte 3)

(command interface: response byte 5)

(command interface: response byte 7)

0x46

(command interface:

mirrored command)

0x0E

0x00

0x00

0x00

Tab. 7-39.

The rest of the RWr area is not used by this command, because the response

data does not require the complete RWw area.

Information!

For a list of all command interface commands and the request/response data structures, please refer to the separate manual "AS-i 3.0 Command interface".

In standard mode, "Message Transmission" is used to access the command interface.

02.05.2016

33

Page 34

CC-Link Gateways

Accessing command interface

7.2 Using "Message Transmission"

"Message Transmission" is a method to map acyclic requests in the cyclical CC-

Link Process data. All data transfers are initiated by the CC-Link Master module.

Information if telegram transmission is supported or not by the master, see the

documentation of your CC-Link Master.

Example:

The Mitsubishi CC-Link master module QJ61BT11N for the Mitsubishi Q-Serie

supports the command G(P).RDMSG for telegram transmission. A detailed description of this instruction can be found in the user's manual of the QJ61BT11N.

This instruction requires various parameters, such as the CC-Link station number

of the target remote device and a buffer to hold the response data. These are described in the QJ61BT11N user's manual.

Information!

The structure of the transmission and response data of the command interface command is independent of the used CC-Li nk master and it is described in the separate

manual "AS-i 3.0 command interface".

34

02.05.2016

Page 35

CC-Link Gateways

Accessing command interface

Example:

For example, when reading the list of detected slaves (command 0x46) and the

register D1 of the Mitsubishi QCPU is assigned as a parameter to G(P).RDMSG

as start number of the device that stores the data to be sent. The following data

must be stored in D1:

Address Bit 15..12 Bit 11..8 Bit 7..4 Bit 3..0

D1 0x00

(command interface: toggle bit and circuit)

(command interface: command)

0x46

Tab. 7-40.

Note that the toggle bit does not have to be changed for each new request.

The send data size in bytes must be set to 2 and given as parameter to G(P).RD-

MSG.

If register D10 of the Mitsubishi QCPU is given as parameter to G(P).RDMSG as

start number of the device to store the received data, the receivable data size in

bytes for G(P).RDMSG is set to at least 10, there is no error during command

execution and there are slaves 1A, 2A and 3A detected the following will be stored starting from register D10:

Address Bit 15..12 Bit 11..8 Bit 7..4 Bit 3..0

D10 0x00

(command interface: toggle bit and result)

D11 0x00

(command interface: response byte 2)

D12 0x00

(command interface: response byte 4)

D13 0x00

(command interface: response byte 6)

D14 0x00

(command interface: response byte 8)

(command interface: mirrored command)

(command interface: response byte 1)

(command interface: response byte 3)

(command interface: response byte 5)

(command interface: response byte* 7)

0x46

0x0E

0x00

0x00

0x00

Tab. 7-41.

The device given as parameter to G(P).RDMSG to store the received data size in

bytes will be set to 10 by the system.

Information!

For a list of all command interface commands and the request/response data structures, please refer to the separate manual "AS-i 3.0 command interface".

02.05.2016

35

Page 36

CC-Link Gateways

Diagnostics

8. Diagnostics

8.1 System diagnostics on the PC

8.1.1 Software for diagnostics, service and release measurements

The intuitively constructed software for diagnostics, service and release measurements enables PC-assisted measurement using the high-level measuring technology built into the masters.

This specially developed software assists both machine and systems builders in

release measurements and preventive troubleshooting as well as end users in

preventive maintenance and fast, self-performed error elimination. As an option

the analysis data can also be sent to our technical support group and used as the

basis for fast, reliable help with problem handling.

8.1.2 AS-i Control Tools

The Software AS-i Control Tools provide you with all the key testing and configuration possibilities of your AS-i circuit in organized fashion on your PC.

A graphic representation of your AS-i network provides you with a quick overview

of the system status, showing for example any missing or unprojected slaves. In

addition, peripheral errors and the status of the "AS-i Monitors" integrated into the

Masters. The diagnostic buffer (not available with all devices!) stores with a time

stamp in a ring buffer up to 1024 events. The AS-i Control Tools software also

provides a simple and convenient way to configure new AS-i circuits or modify already existing configurations. This software is also a component of the ASIMON

software.

8.1.3 ASIMON

The ASIMON software is used to configure the safety unit. Already configured

systems can be diagnosed live using the software. The status of all in- and outputs is graphically represented as are the results of the preparatory processing.

When projecting the user has the ability to assign unique identifiers to the individual devices. These also appear in the device displays in connection with error

messages. To prevent errors in the projecting stage the ASIMON software provides advance warning at the relevant points.

The AS-i Control Tools software is also part of the ASIMON.

8.1.4 Web server

Units having an Ethernet port provide all the diagnostics data through a web server. If necessary this also allws the system information to be viewed from any PC

connected to the network without any additional software, simply using a standard internet browser and Java.

To be able to take advantage of the full scope of diagnostics functions and configuration possibilities of the AS-i Masters, you will however need the ASIMON

software with integrated AS-i Control Tools and ideally also the software for diagnostics, service and release measurement.

36

02.05.2016

Page 37

CC-Link Gateways

Diagnostics

8.2 Diagnostics on the host controller

All the diagnostics information is also provided on the host controller.

8.2.1 Diagnostics through process data

Diagnostics through the process data provides a very simple means of incorporating diagnostics information into the controller program and displaying it on a control panel.

For useful diagnostics we recommend use of the following options:

8.2.1.1 Diagnosing the AS-i circuits

Flags + Fault Detector (see chap. 6.1.1).

When a configuration error is reported, e.g. because an AS-i slave has failed, the

AS-i master continues to communicate with the remaining slaves. In many cases

however a good and simple solution is to terminate running of the PLC program in

case of a configuration error.

8.2.1.2 Diagnosing the Safety Monitor

Safety diagnostics in the Input Data Image

Diagnostics for the states of the safety AS-i in- and outputs. To obtain diagnostics information for a safety AS-i output the associated diagnostics slave

address must be incorporated (see paragraph <A>).

Fieldbus Bits and Safety Status

User-specific diagnosing and diagnosing the states of the release circuits

(see chap. 6.1.4 and chap. 6.1.3)

02.05.2016

37

Page 38

CC-Link Gateways

Diagnostics

Paragraph A:

Safety diagnostics in the Input Data Image (IDI)

Safety diagnostics of safe AS-i inputs

Diagnostics in the IDI is a way of sending the key diagnostics functions to the

controller without a command interface (Mailbox) or any additional effort. The diagnostics information is sent in the input data image, coded for the input bits of the

address of the safety input slave.

The switching state of Channels 1 and 2 of the safety input is shown with negligible time lag in bits 0 and 1 and can be directly read:

Bit3 Bit2 Bit1 Bit0 Description

X X 0 0 Both channels open

XX 0 1

XX 1 0

X X 1 1 Both channel closed

2nd channel open, 1st channel closed

2nd channel closed, 1st channel open

Tab. 8-42.

Bits 2 and 3 are used to send the status of the safety input (the device color of the

ASIMON):

Bit3 Bit2 Bit1 Bit0 Description

0 0 X X Device color: red, green o r gray

0 1 X X Device color: yellow ("waiting")

1 0 X X Device color: yellow flashing ("te s ting")

1 1 X X Device color: red flashing ("Error")

Tab. 8-43. Stae of safety input

38

02.05.2016

Page 39

CC-Link Gateways

Diagnostics

Safety diagnostics of safe AS-i outputs

The diagnostic informations are transfered via the Input Data Image, coded to the

input bits of the diagnostic address (diagnostic slave) of an AS-i safety slave.

The diagnostics information for the safety output is encoded to the input data of

the diagnostics slave of the respective safety output.

Bit value of the input bits of the diagnostic slaves

Bit AS-i input

E0

diagnostics (see table device colors)E1

E2

E3 reserved for EDM input

Tab. 8-44. Bit value of input bits of the diagnostic slaves

Device colors

The colors refer to the diagnostics in the ASIMON.

Value Color Description state change LED "OUT"

0 green output on – on

green

1

flashing

–––

2 yellow restart inhibit auxiliary signal 2 1 Hz

yellow

3

flashing

–––

4 red output off – off

5 red flashing

6gray

7 green/yellow

1. See documentation of the AS-i slave.

waiting for reset of error

condition

connection or

internal error

output released,

but not switched on

auxiliary signal 1 8 Hz

only via Power On

on device

switched on by setting

the output bit

1

all LEDs

flashing

off

Tab. 8-45. Device colors

1

02.05.2016

39

Page 40

CC-Link Gateways

Diagnostics

Important!

The following points must be noted for processing:

• The information for switching state and error status are not processed timesynchronous.

• When there is a configuration error all bits having value 0 are sent; this must

be noted when processing the data.

• When the Monitor is stopped the device color is "gray".

• When regularly switching, the status "yellow flashing" can be recognized as a

transition status. This depends on the component model set. This status cannot be understood as a testing request until it is stably reported (see Monitor

Info and Safety Control/Status Byte). This is not the case until bit ’6’ is set in

the Monitor Info and Safety Control/Status Byte ("At least one module in Test

status"). This means the diagnostics information in the input data image does

not serve as a trigger for the testing request, but rather only as detailed information after the Monitor Info and Safety Control/Status byte have indicated

that at least one component has reported a testing request.

Changing the base setting

Setting and changing the diagnostics type is done using the device display ([SAFETY]->[AS-I SAFETY]->[SAFE SUBST VAL])

8.2.2 Diagnosing the safety unit using the command interface

All the diagnostics data can also be queried individually and acyclic using the

command interface commands. This method does however involve greater programming effort.

8.2.3 LEDs

The LEDs located on the device allow you to quickly see the status of the main

function parameters, such as power, communication with the host controller, communication on the AS-i circuit and state of the safety in- and outputs.

8.2.4 LC-Display

In the display of the Gateways plain text messages are shown spontaneously for

any detected errors (e.g. missing slaves, earth fault, duplicate address…).

8.2.5 AS-i Monitor

Comprehensive, standard measuring technology built into the AS-i Masters make

it possible to simply localize even sporadically occurring configuration errors and

interference sources affecting AS-i communication.

8.2.5.1 Duplicate address detection

The Master detects when two slaves having the same address are present in the

AS-i circuit.

40

02.05.2016

Page 41

CC-Link Gateways

Diagnostics

8.2.5.2 Earth fault monitor

The earth fault monitor checks the symmetry of the AS-i voltage. If the voltage is

no longer sufficiently symmetrical, the noise immunity of data transmission is

compromised.

8.2.5.3 Noise voltage detection

Noise voltages on the AS-i cable can cause telegram errors. The noise voltage

detector monitors the AS-i circuit for AC voltages which have been generated by

neither the AS-i Master nor the slaves.

8.2.5.4 Overvoltage detection

Normally UASi+ and UASi- are in symmetry with system ground. If this potential

rises significantly, the overvoltage detector reports this anomaly.

02.05.2016

41

Page 42

CC-Link Gateways

Appendix

9. Appendix

Quick Start Guides for commissioning and service are provided on the website

available for download.

42

02.05.2016

Page 43

Loading...

Loading...