Singleturn absolute encoder BVS58

Technical data

General specifications

Detection type photoelectric sampling

Device type Singleturn absolute encoder

Electrical specifications

Model Number

BVS58

Features

• Industrial standard

housing Ø58 mm

• 13 Bit singleturn

• Output code: gray and binary

• Transfer of position data with 4 ASInterface slaves

• Parameterization and addressing

via AS-Interface

• Servo or clamping flange

Description

In modern machines and systems, binary sensors

and actuators are connected together via AS-Interface.

Until now it was necessary to go back to the use of

costly conventional wiring when wanting to use absolute encoders. The reason for this was that the

handshake mode with the control module of the

analogue profile proved to be too slow for positioning tasks.

In order to meet the real-time demands of many applications, a multi-slave solution using the BVS58

AS-Interface rotary encoders was created. The position value of 13 Bits in length is transferred within

a single cycle via the 4 integrated AS-Interface

chips to the master and made available to the PLC.

This singleturn absolute encoder is available either

in clamping flange design with a shaft 10 mm in diameter x 20 mm or in servo flange design with a

shaft 6 mm in diameter x 10 mm.

Operating voltage U

No-load supply current I

Linearity ± 1 LSB

Output code programmable, Gray code, binary code

Code course (counting direction) programmable,

Interface

Interface type AS-Interface

Resolution

Single turn 13 Bit

Overall resolution 13 Bit

Transfer rate max. 0.167 MBit/s

Standard conformity AS-Interface

Connection

Connector type V1, M12, 4-pin

Standard conformity

Degree of protection DIN EN 60529, IP65

Climatic testing DIN EN 60068-2-3, no moisture condensation

Emitted interference EN 61000-6-4:2007

Noise immunity EN 61000-6-2:2005

Shock resistance DIN EN 60068-2-27, 100 g, 11 ms

Vibration resistance DIN EN 60068-2-6, 10 g, 10 ... 2000 Hz

Ambient conditions

Operating temperature -20 ... 70 °C (-4 ... 158 °F)

Storage temperature -25 ... 85 °C (-13 ... 185 °F)

Mechanical specifications

Material housing: powder coated aluminum

Mass approx. 330 g

Rotational speed max. 10000 min

Moment of inertia 30 gcm

Starting torque ≤ 2 Ncm

Shaft load

Axial 40 N at max. 6000 min

Radial 60 N at max. 6000 min

B

0

29.5 ... 31.6 V DC

max. starting current 155 mA , operating current max. 85 mA

cw ascending (clockwise rotation, code course ascending)

cw descending (clockwise rotation, code course

descending)

flange: aluminum

shaft: stainless steel

-1

2

-1

10 N at max. 12000 min

20 N at max. 12000 min

-1

-1

-1

Release date: 2014-04-14 15:31 Date of issue: 2016-01-26 t37283_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

1

Singleturn absolute encoder BVS58

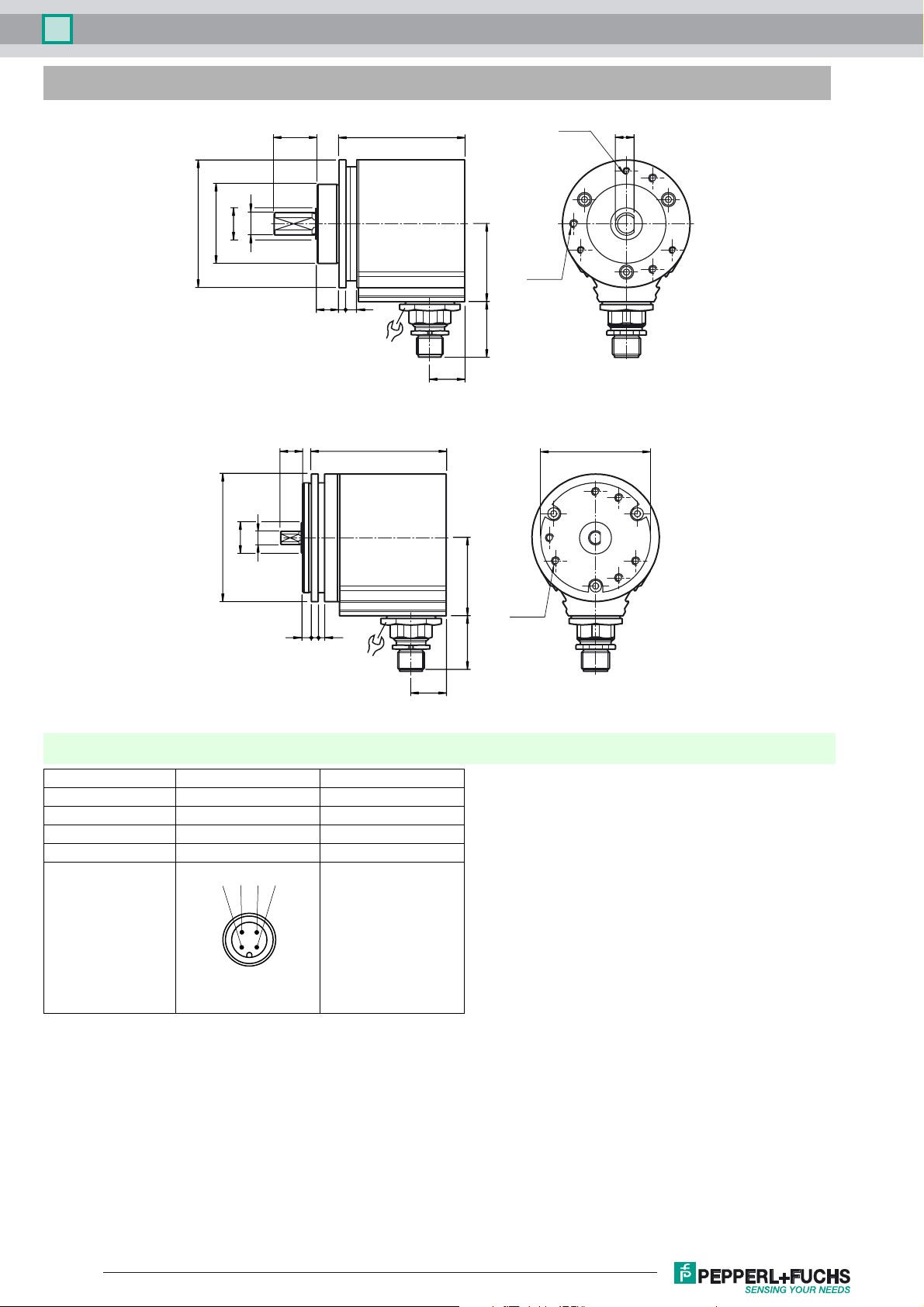

Dimensions

ø 58

ø 14

ø 36f8

Camping flange

ø 58

ø 10h7

ø 14

6h7

19.5+1

10+1

10 3 5

24

61.3

57,3

3 x M3

5 deep

35,5

3 x M4

5 deep

25.2

16

9

50h7

433

24

Servo flange

Electrical connection

Signal V1 connector, 4-pin Explanation

AS-Interface + 1

Reserved 2 Not wired

AS-Interface - 3

Reserved 4 Not wired

143

2

35.525.2

6 x M4

6 deep

16

Release date: 2014-04-14 15:31 Date of issue: 2016-01-26 t37283_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Singleturn absolute encoder BVS58

Addresses

Slave A Slave B Slave C Slave D

Preset address 1 2 3 4

IO code 7000

ID code FFFF

When readdressing by means of a bus master or a programming device, it is absolutely essential to assign different addresses to the four integrated AS-Interface chips.

Parameter bits

The four parameter bits of slave A are used to set the parameters of the rotary encoder.

The parameter bits of slave B, C and D are not used.

Status of

parameter bit

0 Gray code Transfer with flag bits Descending counting direction for clockwise rotation Not used

1 Binary code Transfer without flag bits Ascending counting direction for clockwise rotation Not used

P0 P1 P2 P3

Data bits

From the AS-Interface master to the rotary encoder

Data from the AS-Interface master are transferred to the rotary encoder via slave A, which works bidirectionally. Slaves B, C and D work unidirectionally,

i.e. they are incapable of receiving data.

Status of

D0/D1 or D2/D3

00 Normal mode Position data are not saved!

01 Rotary encoder is set to ¼ of the singleturn resolution. Position data are saved!

10 Rotary encoder is set to 0. Position data are saved!

11 Normal mode Position data are not saved!

When a change is made in data bits D2 and D3 from 01 to 10 or vice-versa, position data are resaved in the rotary encoder.

D0/D1 D2/D3

From the rotary encoder to the AS-Interface master

Depending on the value of parameter bit P1 of slave A, data transfer to the AS-Interface master takes place with or without flag bits.

P1 = 1: Transfer without flag bits

Slave A Slave B Slave C Slave D

D0 D1 D2 D3 D0 D1 D2 D3 D0 D1 D2 D3 D0 D1 D2 D3

Bit 0 Bit 1 Bit 2 Bit 3 Bit 4 Bit 5 Bit 6 Bit 7 Bit 8 Bit 9 Bit 10 Bit 11 Bit 12 Not used!

P1 = 0: Transfer with flag bits MA, MB, MC, MD

Slave A Slave B Slave C Slave D

D0 D1 D2 D3 D0 D1 D2 D3 D0 D1 D2 D3 D0 D1 D2 D3

Bit 0 Bit 1 Bit 2 MA Bit 3 Bit 4 Bit 5 MB Bit 6 Bit 7 Bit 8 MC Bit 9 Bit 10 Bit 11 MD

Slave A

Slave A

Operating modes

Address assignments for the four slaves

The AS-Interface master accesses all slaves one after the other within an AS-Interface cycle in order to transfer output data to slave A or to read in input

data from the slaves. The singleturn absolute encoder uses only four AS-Interface chips to transfer the position data that are 13 bits wide, i. e. four slave

addresses are assigned.

Since these four slaves are queried one after the other, the data may originate from any one of four different sampling times. To minimise the influence of

this effect, sequential addresses (n, n+1, n+2 and n+3) should be assigned to slaves A, B, C and D.

Furthermore, it should be noted that slave A is responsible for controlling the functions of the absolute encoder. If the order of the slaves is changed (D = n,

C = n+1, B = n+2, A = n+3), the output word, which is supposed to be transmitted by the function control module of the absolute encoder, will not be transmitted until slaves D, C and B have been read in.

Release date: 2014-04-14 15:31 Date of issue: 2016-01-26 t37283_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

3

Singleturn absolute encoder BVS58

A memory command would thus only take effect for slave A. The command would not take effect for slaves that were already read until the next read cycle.

Data consistency would be lost because of the change of order.

Temporary storage and transfer with flag bits

If individual telegrams of the four slaves to the AS-Interface master suffer interference, it may happen in spite of temporary storage in the rotary encoder that

the data that are transferred to the control module do not all originate from the same position data set.

Transferring one flag bit for each slave makes it possible for the control module to check which position data set an individual data set belongs to by comparing the four flag bits. Data bit D2 is used for this purpose.

Example:

Slave A

Cycle Slave A Slave B Slave C Slave D

1 0 XXX0 XXX0 XXX0 XXX0

2 1 XXX1 XXX1 XXX1 XXX1

3 0 XXX0 XXX0 XXX0 XXX0

4 1 XXX1 XXX1 XXX1 XXX1

etc.

Bit D2 is influenced by the control module. Bit 4 of the input data corresponds to the value of this bit for each slave.

D2 is set to 0 in cycle 1. If the value of bit 4 of a slave were "1", that value would be derived from another cycle. This is a simple way to recognise data

consistency.

Transferring the flag bits, however, reduces the usable position data from 13 bits to 12. Masking out the fourth bit of each slave increases slightly the effort

of putting together the position data set in the control module.

Data bit D2

Order code

Position data

BV 5 8N– AVR0NN–

Option 2

N Not expanded

Output code

N Selectable, binary/Gray

Option 1

0 No option

Exit position

R Radial

Connection type

AV Plug connector M12 x 1, 4-pin

Shaft dimension/flange version

011 Shaft Ø10 mm x 20 mm with clamping flange

032 Shaft Ø6 mm x 10 mm with servo flange

Housing material

N Aluminium, powder coated

Principle of operation

M Multiturn

S Singleturn

Shaft version

V Solid shaft

Data format

B AS-Interface

Bit combinations (resolution)

Multiturn encoder (see table)

Singleturn encoder

0016

(16 bit = 65536)

Release date: 2014-04-14 15:31 Date of issue: 2016-01-26 t37283_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

4

Loading...

Loading...