Page 1

MANUAL

AS-I CC-LINK GATEWAY

FACTORY AUTOMATION

Page 2

AS-i CC-Link Gateway

With regard to the supply of products, the current issue of the following document is applicable: The

General Terms of Delivery for Products and Services of the Electrical Industry, published by the

Central Association of the Electrical Industry (Zentralverband Elektrotechnik und Elektroindustrie

(ZVEI) e.V.) in its most recent version as well as the supplementary clause: "Expanded reservation

of proprietorship"

Page 3

AS-i CC-Link Gateway

Table of contents

Table of contents

AS-i CC-Link Gateway

1 Introduction...........................................................................................6

2 Declaration of conformity ....................................................................7

2.1 Declaration of conformity................................................................................ 7

3 Safety.....................................................................................................8

3.1 Symbols relevant to safety.............................................................................. 8

3.2 General notes on safety ..................................................................................8

3.3 Disposal ............................................................................................................ 8

4 General ..................................................................................................9

4.1 Product information......................................................................................... 9

4.1.1 AS-i CC-Link Gateway ..................................................................................................... 9

4.2 AS-i 3.0 specification....................................................................................... 9

5 Specifications .....................................................................................10

5.1 Technical data ................................................................................................ 10

5.1.1 Data sheet....................................................................................................................... 10

6 Installation...........................................................................................11

6.1 Safety notes.................................................................................................... 11

6.2 Installing in the control cabinet .................................................................... 12

6.3 Removing........................................................................................................ 12

6.4 Dimensions [mm]........................................................................................... 13

7 Electrical connection..........................................................................14

7.1 AS-i bus connection ......................................................................................14

7.2 Connections ................................................................................................... 14

7.2.1 AS-i and power supply terminal assignments ............................................................15

7.3 Front view and connections.......................................................................... 16

7.3.1 Electrical connection: VBG-CCL-K20-D-BV ................................................................16

7.4 CC-Link interface .......................................................................................... 17

7.5 Chip card......................................................................................................... 17

14.4.2015

3

Page 4

AS-i CC-Link Gateway

Table of contents

7.6 Indicators and operating elements .............................................................. 18

7.6.1 LED indicators – master................................................................................................ 18

7.6.1.1 CC-Link status LED (green/red) flashing sample ......................................................... 19

7.6.2 Buttons ........................................................................................................................... 19

8 Commissioning...................................................................................20

8.1 Commissioning via the device ..................................................................... 20

8.1.1 Switching to advanced display mode .......................................................................... 20

8.1.2 Setting the CC-Link address 14................................................................................... 20

8.1.3 Connecting AS-i Slaves ................................................................................................21

8.1.4 Quick setup .................................................................................................................... 22

8.2 Error tracing................................................................................................... 23

8.2.1 Faulty slaves ..................................................................................................................23

8.2.2 Error display (last error)................................................................................................ 23

8.2.3 Addressing ..................................................................................................................... 24

8.2.3.1 Assigning address 6 to slave currently at address 2 .................................................... 24

8.2.4 Local parameter setting of Gateways .......................................................................... 25

8.2.5 Replacing the chip card ................................................................................................26

8.2.6 Using the chip card ....................................................................................................... 26

8.2.6.1 Card unformatted .......................................................................................................... 27

8.2.6.2 Data not compatible ......................................................................................................27

8.2.6.3 Card empty ...................................................................................................................27

8.2.6.4 Data compatible ............................................................................................................ 28

8.2.6.5 Data in the device and on the chip card identical .........................................................28

8.2.6.6 Data in the device and on the chip card not identical ...................................................28

9 Operation in display mode.................................................................29

10 Data transmission modes ..................................................................30

10.1 Selecting the data transmission mode ........................................................ 30

10.2 Summary of modes ....................................................................................... 31

10.3 Standard mode............................................................................................... 32

10.3.1 Remote IO Points........................................................................................................... 32

10.3.2 Buffer Memory Area ...................................................................................................... 33

10.3.3 Message Transmission ................................................................................................. 36

10.4 Compatibility mode for VBG-CCL-G4F ........................................................ 37

10.4.1 Remote IO Points........................................................................................................... 37

10.4.2 Buffer Memory Area ...................................................................................................... 38

10.5 CC-Link V1 Mode ........................................................................................... 41

10.5.1 Remote IO Points........................................................................................................... 41

10.5.2 Buffer Memory Area ...................................................................................................... 42

10.6 Compatibility Mode for FX2N-32ASI-M ........................................................ 46

10.6.1 Remote IO Points........................................................................................................... 46

10.6.2 Buffer Memory Area ...................................................................................................... 47

10.7 Compatibility Mode for HK-ASICC ............................................................... 49

10.7.1 Remote IO Points........................................................................................................... 49

10.7.2 Buffer Memory Area ...................................................................................................... 50

11 Advanced Diagnostics for AS-i Masters...........................................51

11.1 List of corrupted AS-i Slaves (LCS)51

4

14.4.2015

Page 5

AS-i CC-Link Gateway

Table of contents

11.2 Protocol analysis: Counters for corrupted data telegrams ....................... 51

11.3 Clear the diagnostic buffer............................................................................ 52

11.4 Offline Phase for Configuration Errors ........................................................52

11.5 Functions of the AS-i Fault Detector ............................................................ 52

11.5.1 Earth/Ground Fault Detector ........................................................................................52

11.5.2 Noise Detector ...............................................................................................................53

11.5.3 Over-voltage Detector ...................................................................................................53

11.6 Substitute values ........................................................................................... 54

12 Accessing command interface..........................................................55

12.1 Using BFM ...................................................................................................... 55

12.2 Using message transmission ....................................................................... 57

13 Codes indicated by the display.........................................................59

14 Glossary ..............................................................................................61

15 Reference List.....................................................................................66

15.1 Manual: “AS-i 3.0 Command Interface“ ....................................................... 66

14.4.2015

5

Page 6

AS-i CC-Link Gateway

Introduction

1. Introduction

Congratulations

You have chosen a device manufactured by Pepperl+Fuchs. Pepperl+Fuchs develops, produces and distributes electronic sensors and interface modules for the

market of automation technology on a worldwide scale.

Before installing this equipment and put into operation, read this manual carefully.

This manual containes instructions and notes to help you through the installation

and commissioning step by step. This makes sure bring such a trouble-free use of

this product. This is for your benefit, since this:

• ensures the safe operation of the device

• helps you to exploit the full functionality of the device

• avoids errors and related malfunctions

• avoids costs by disruptions and any repairs

• increases the effectiveness and efficiency of your plant

Keep this manual at hand for subsequent operations on the device.

After opening the packaging please check the integrity of the device and the number of pieces of supplied.

Symbols used

The following symbols are used in this manual:

Information!

This symbol indicates important information.

Attention!

This symbol warns of a potential failure. Non-compliance may lead to interruptions of

the device, the connected peripheral systems, or plant, potentially leading to total malfunctioning.

Warning!

This symbol warns of an imminent danger. Non-compliance may lead to personal injuries that could be fatal or result in material damages and destruction.

Contact

If you have any questions about the device, its functions, or accessories, please

contact us at:

Pepperl+Fuchs GmbH

Lilienthalstraße 200

68307 Mannheim

Telephone: +49 621 776-4411

Fax: +49 621 776-274411

E-Mail: fa-info@pepperl-fuchs.com

14.4.2015

6

Page 7

AS-i CC-Link Gateway

Declaration of conformity

2. Declaration of conformity

2.1 Declaration of conformity

This product was developed and manufactured under observance of the applicable European standards and guidelines.

Information!

A Declaration of Conformity can be requested from the manufacturer.

The product manufacturer, Pepperl+Fuchs GmbH, D-68307 Mannheim, has a

certified quality assurance system that conforms to ISO 9001.

14.4.2015

7

Page 8

AS-i CC-Link Gateway

Safety

3. Safety

3.1 Symbols relevant to safety

Information!

This symbol indicates important information.

Attention!

This symbol warns of a potential failure. Non-compliance may lead to interruptions of

the device, the connected peripheral systems, or plant, potentially leading to total malfunctioning.

Warning!

This symbol warns of an imminent danger. Non-compliance may lead to personal injuries that could be fatal or result in material damages and destruction.

3.2 General notes on safety

Only instructed specialist staff may operate the device in accordance with the operating manual.

User modification and or repair are dangerous and will void the warranty and exclude the manufacturer from any liability. If serious faults occur, stop using the device. Secure the device against inadvertent operation. In the event of repairs, return the device to your local Pepperl+Fuchs representative or sales office.

The connection of the device and maintenance work when live may only be carried out by a qualified electrical specialist.

The operating company bears responsibility for observing locally applicable safety regulations.

Store the not used device in the original packaging. This offers the device optimal

protection against impact and moisture.

Ensure that the ambient conditions comply with regulations.

3.3 Disposal

Information!

Electronic waste is hazardous waste. Please comply with all local ordinances when

disposing this product!

The device does not contain batteries that need to be removed before disposing it.

8

14.4.2015

Page 9

AS-i CC-Link Gateway

General

4. General

4.1 Product information

This system manual applies to the following Pepperl+Fuchs equipment:

4.1.1 AS-i CC-Link Gateway

Article no.

VBG-CCL-K20-D-BV

The AS-i CC-Link Gateways serve to connect AS-i systems to the superordinate

CC-Link. The gateways act as a master for AS-i and as a slave on CC-Link.

4.2 AS-i 3.0 specification

The AS-i CC-Link Gateway is designed according to the AS-i 3.0 specification.

field bus interface

number of AS-i Masters

RS 232 diagnostic interface

Recognition of duplicate addresses

CC-Link

Tab. 4-1. Function range of "AS-i CC-Link Gateway"

14.4.2015

9

Page 10

AS-i CC-Link Gateway

Connection

Connections AS-i: COMBICON

CC-Link: screw terminal blocks

Interface

CC-Link interface according to CC-Link specification

Baud rates 156 KBps up to 10 MBps

Type remote device

Occupied stations 2-4 (depending on operating mode)

CC-Link functions imaging of the AS-i slaves as RW data on CC-Link.

complete diagnosis and configuration via CC-Link

AS-i

Cycle time 150ȝs * (number of slaves + 2)

Operating current power supply A, approx. 200 mA out of AS-i

Operating voltage AS-i voltage 30V DC

Display

LCD menu, displaying AS-i slave addresses and error messages

LED power voltage ON

LED cc-link state of CC-Link

LED config error configuration error

LED U AS-i AS-i voltage o.k.

LED AS-i active AS-i in normal operation

LED prg enable automatic address programming enabled

LED prj mode configuration mode active

Environment

Applied standards EN 61 000-6-2

EN 61 000-6-4

Housing Stainless Steel

Operating temperature 0°C … +55°C

Storage temperature -25°C … +85°C

Protection category (EN 60 529) IP20

Allowable shock -and vibration stress according to EN 61 131-2

Voltage of insulation ≥ 500V

Dimensions (L / W / H in mm) 85 / 120 / 83

Weight 520 g

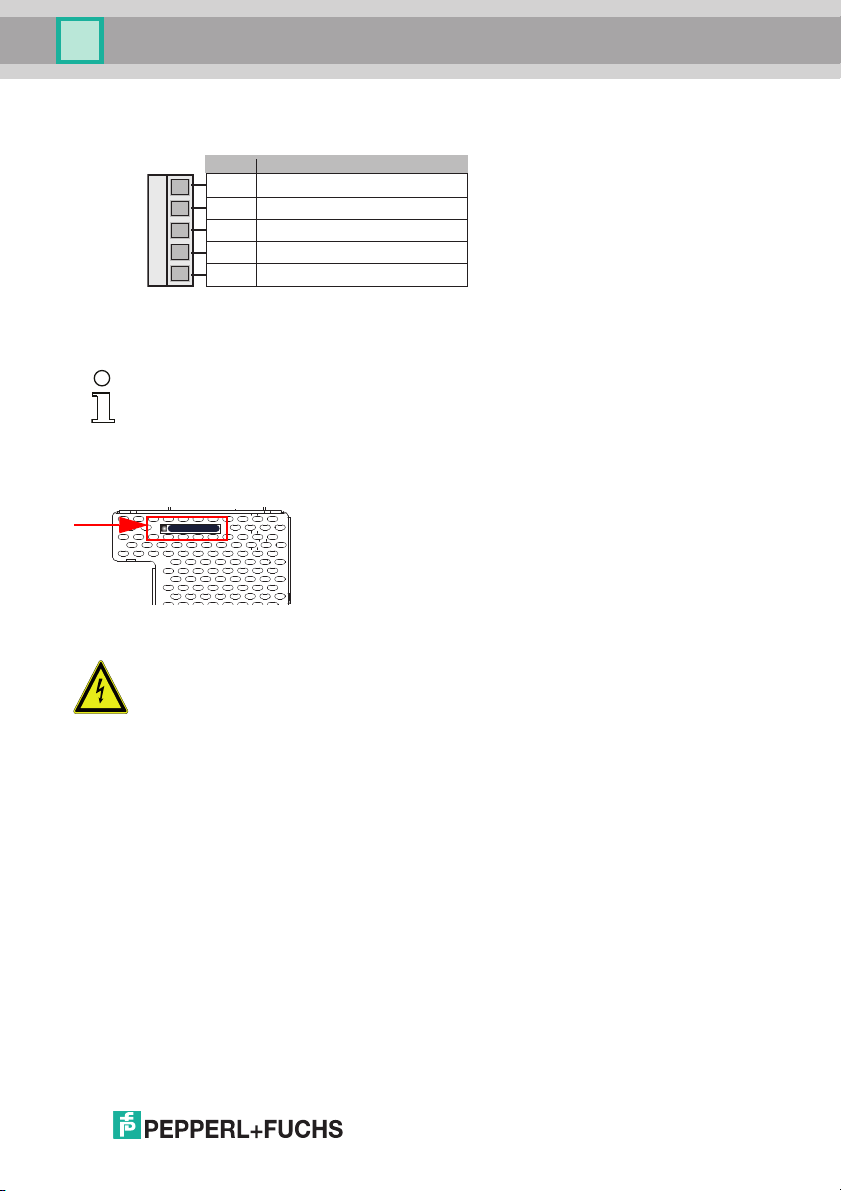

Pin assignment:

DA blue

DG yellow

SLD n/a

DB white

F G n/a

Signal Color

1

2

3

4

5

Specifications

5. Specifications

5.1 Technical data

The technical data are placed in the data sheet. Please view the current version

on the web page: http://www.pepperl-fuchs.com.

5.1.1 Data sheet

10

14.4.2015

Page 11

AS-i CC-Link Gateway

Installation

6. Installation

Read instruction:

Before working with this unit: read these instructions carefully and completely. All notes on safety and

specifications of the device manual and the manual for the configuration software are to be considered!

6.1 Safety notes

Ensure appropiate installation:

Electrical installation is to be performed by trained expert personnel. During installation care must be

taken that supply and signal leads and also the AS-i bus cable are laid separately from power cables. In

the switchgear cabinet it must be ensured that appropriate spark-quenching equipment is used with contactors. Where drive motors and brakes are used, attention must be paid to the installation instructions in

the corresponding operating instructions. Please note that the maximum line length of the AS-i bus cable

is 100 m. Cables above that length require the use of a suitable circuit extension.

HAZARDOUS VOLTAGE:

Before any installation, maintenance or modification work: Disconnect your system from the supply network. Ensure that it cannot be reconnected inadvertently!

You are requested to make sure that the unit will be recycled by the end of its service life.

14.4.2015

11

Page 12

AS-i CC-Link Gateway

+-+

-

+

-

[1]

[2]

+-+

-

+

-

Installation

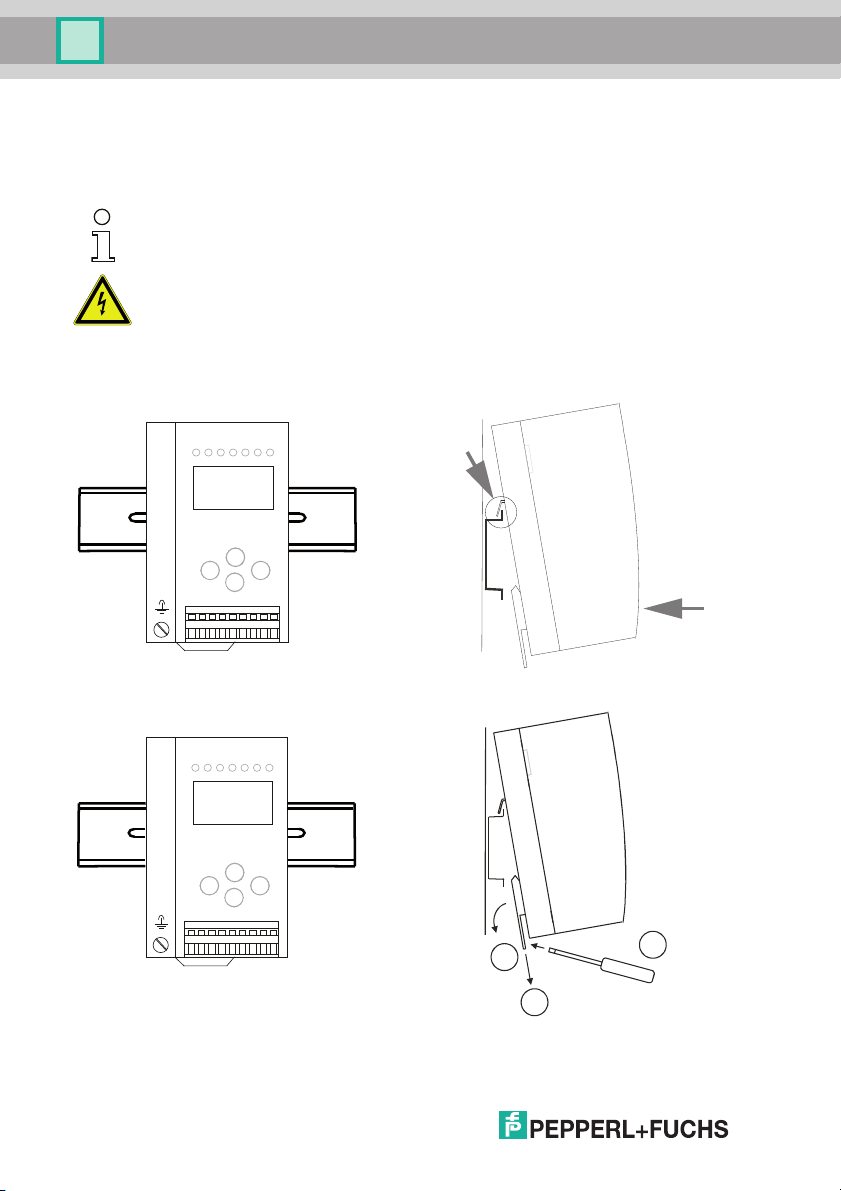

6.2 Installing in the control cabinet

The AS-i CC-Link Gateway is installed in the control cabinet on 35mm DIN rails

per DIN EN 50 022.

Information!

The enclosure of the AS-i/Gateway is made of stainless steel. The unit is also suitable

for exposed wall mounting.

Warning!

Cover the top of the gateway when doing any drilling work above the unit. No particles,

especially metal chips, should be allowed to enter the housing, since this could cause a

short circuit.

To install, place the unit on the upper edge of the DIN rail and then snap in the

lower edge.

6.3 Removing

To remove, press the holding clamps [2] down using a screwdriver [1], press the

unit firmly against the upper rail guide and lift out.

12

3

1

2

14.4.2015

Page 13

AS-i CC-Link Gateway

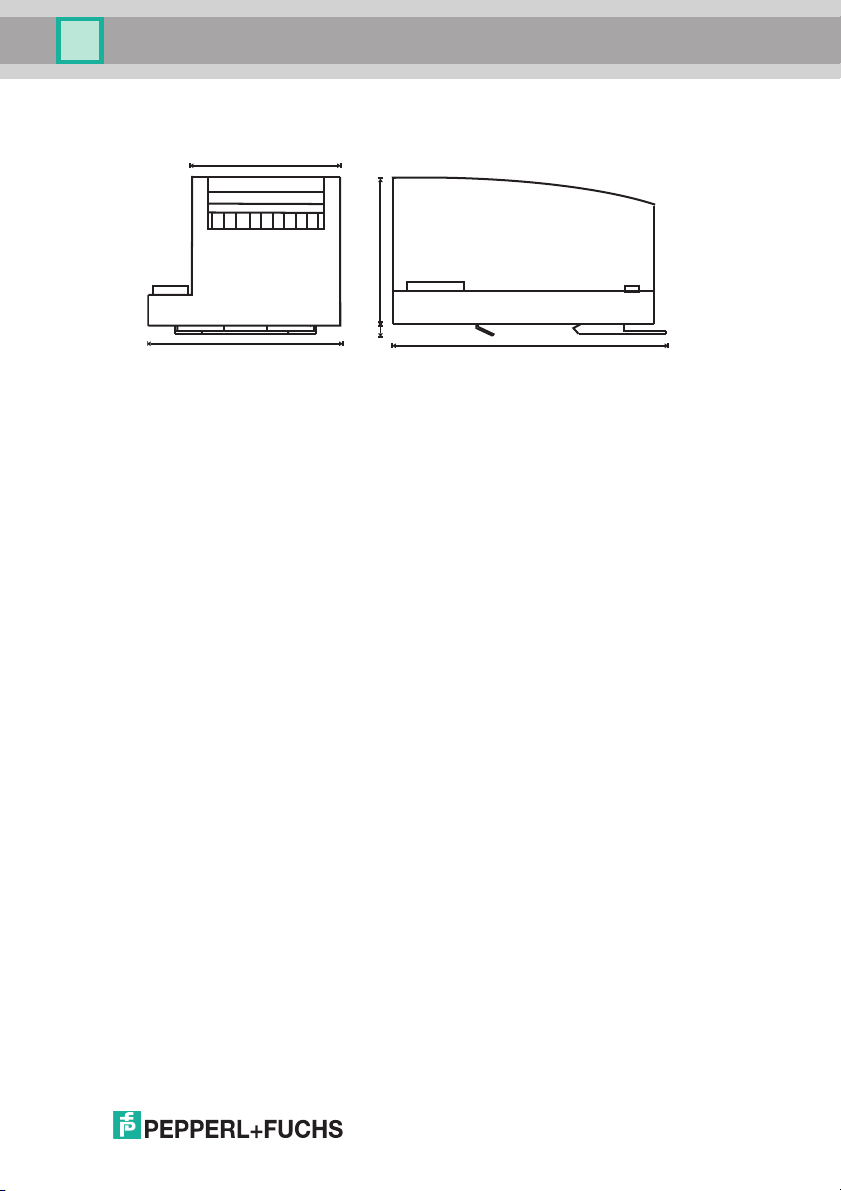

55

85

120

7

76

Installation

6.4 Dimensions [mm]

14.4.2015

13

Page 14

AS-i CC-Link Gateway

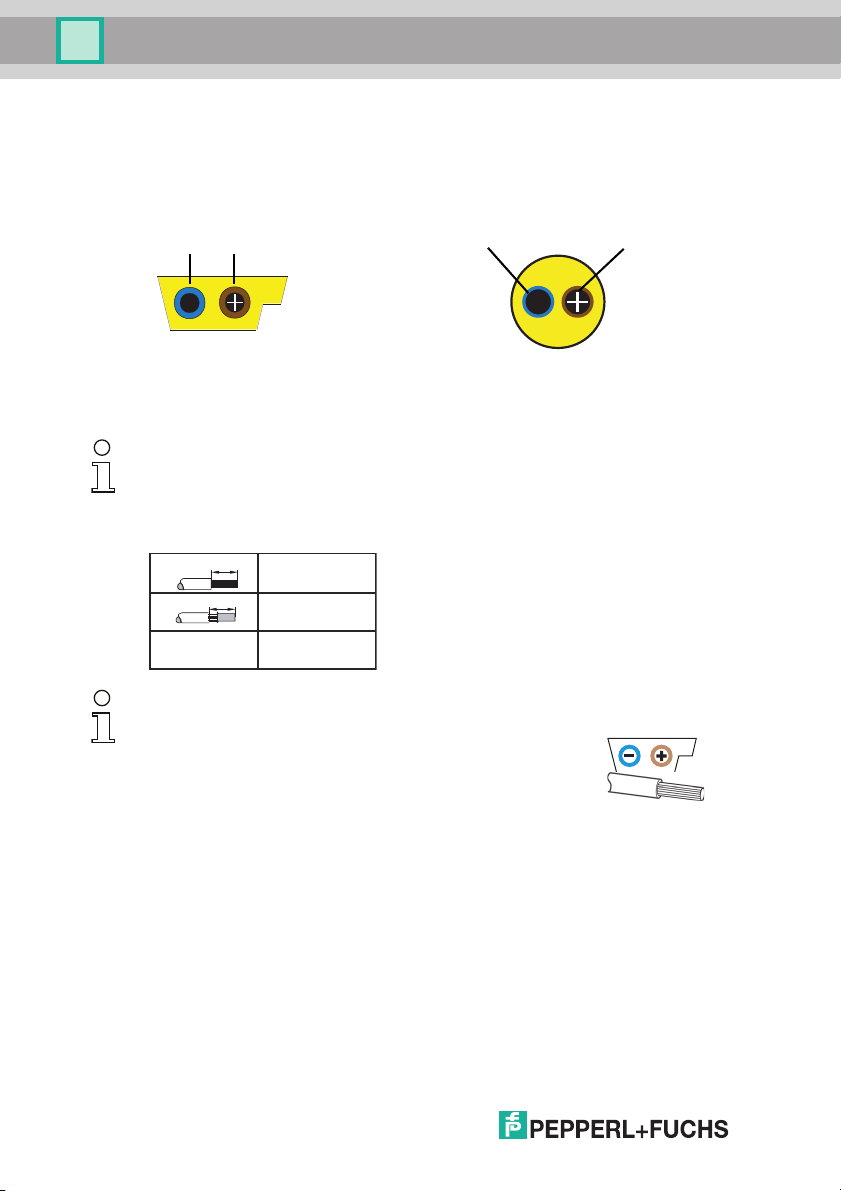

Yellow ASi ribbon cable

Blue

AS-i-

Brown

AS-i+

2-conductor AS-i round cable

(Recommended: flexible power cable

H05VV-F2x1,5 per DIN VDE 0281)

Blue

AS-i-

Brown

AS-i+

10

10

AWG 24 ... 12

0,2 ... 2,5 mm

2

0,2 ... 2,5 mm

2

Electrical connection

7. Electrical connection

7.1 AS-i bus connection

Information!

Electrical work is to be performed only by electrical technicians.

7.2 Connections

14

Ambient air temperature

Temperature rating for cable

Use copper conductors only

0°C +55 °C

60/75oC

14.4.2015

Page 15

AS-i CC-Link Gateway

Electrical connection

7.2.1 AS-i and power supply terminal assignments

Caution!

At the black cable for power supply no slaves or repeaters may be attached. At the

yellow cable for AS-i circuit no power supplies or further masters may be attached.

Even in case of a fault, the output voltage of the power supply shall be 42 V or less.

Information!

The function ground can be connected either to the grounding screw or to the terminal.

The function ground should be made with as short a cable as possible to ensure good

EMC characteristics.

Therefore function grounding using the grounding screw is preferred.

14.4.2015

15

Page 16

AS-i CC-Link Gateway

+-+

-

+

-

+ASI- +ASI-

n.c. n.c.

ASI

+PWR

-

ASI

ASI +PWR– (max. 8 A)

+ASI 1–

+ASI 1–

[2]

[3]

[4]

[5]

[1]

[6]

Electrical connection

7.3 Front view and connections

7.3.1 Electrical connection: VBG-CCL-K20-D-BV

+ASI–

Connection AS-i circuit

ASI +PWR– (max. 8 A)

Supply voltage AS-i circuit

[1] Chip card

[2] LED status display

[3] Fieldbus interface

[4] LC display

[5] Buttons for hand operation

[6] Power supply

16

Information!

For additional information, please refer to the sections: <AS-i and power supply terminal assignments>.

14.4.2015

Page 17

AS-i CC-Link Gateway

1

2

3

4

5

Signal color

DA blau/ blue/ bleu/ blu/ azul

DB weiss/ white/ blanc/ bianco/ blanco

DG gelb/ yellow/ jaune/ giallo/ amarillo

SLD n/a

FG n/a

Electrical connection

7.4 CC-Link interface

The CC-Link interface connector is designed as a 5-pin COMBICON connector. It

is located on the left hand side of the front panel (see section <Overview of terminals, indicators and operating elements>).

Information!

For better noise performance, SLD (cable shield) should be grounded separately in

10 cm distance to the COMBICON connector.

7.5 Chip card

The configuration is stored in a fixed installed EEPROM and can be overwritten

by the chip card. The chip card does not have to be inserted in operation.

Warning!

Power must always be turned off when removing or inserting the chip card!

14.4.2015

17

Page 18

AS-i CC-Link Gateway

CC-Link

Electrical connection

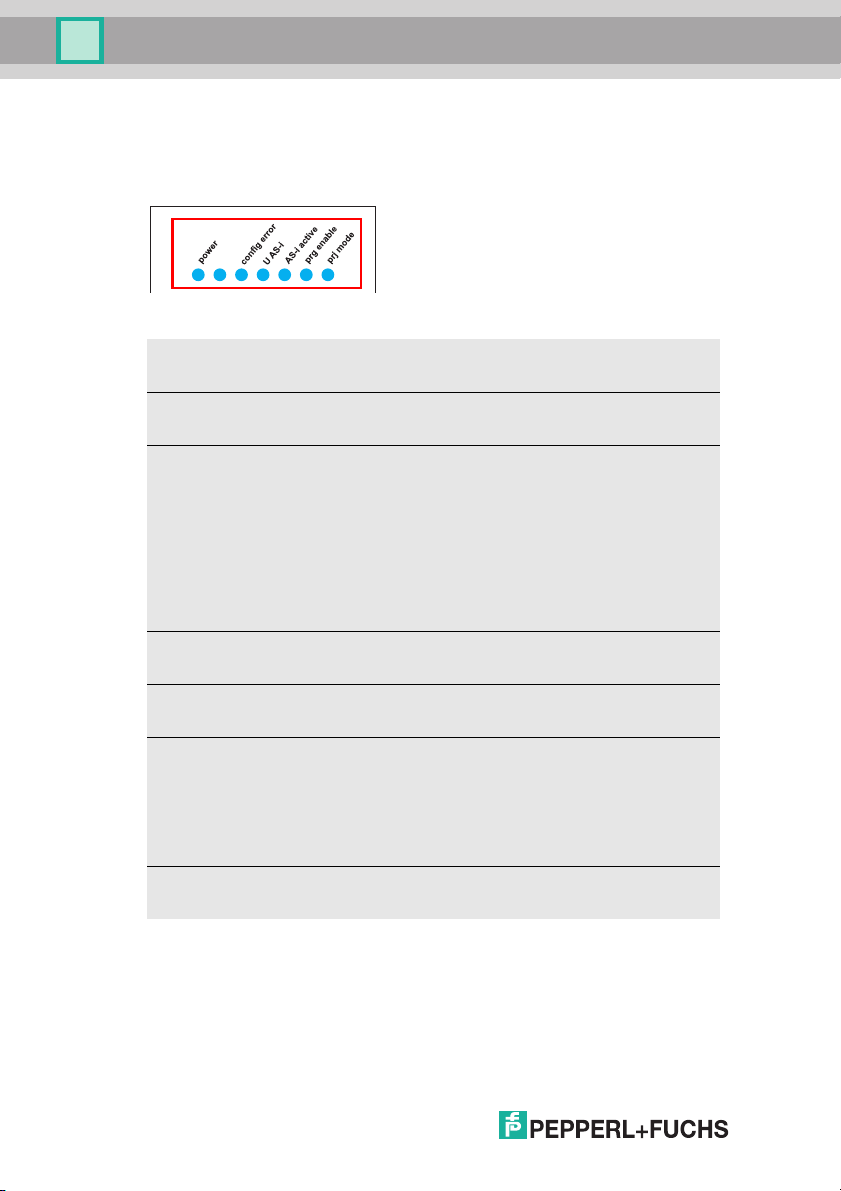

7.6 Indicators and operating elements

7.6.1 LED indicators – master

The LED’s on the front panel of the device indicate:

Power

The AS-i master is receiving sufficient power.

CC-Link (CC-Link status LED)

Flashing sample see chap. <CC-Link status LED (green/red) flashing sample>.

config error

Configuration error.

At least one configured slave is missing, or at least one detected slave is not configured, or for at least one configured and detected slave the actual configuration data

does not match the nominal configuration data, or the master is in the startup process.

This LED flashes if a peripheral fault has been detected for at least one AS-i slave

on the AS-i network. If there are configuration errors as well as periphery faults, only

the configuration error is displayed.

U AS-i

The AS-i network is sufficiently powered.

AS-i active

Normal operation is active

prg enable

Automatic single node replacement is enabled.

Exactly one slave is missing in the protected operating mode. The slave can be

replaced by another slave of the same type with address zero. The master automatically addresses the new slave to the faulty address and thus corrects the configuration error

prj mode

The AS-i master is in configuration mode.

18

14.4.2015

Page 19

AS-i CC-Link Gateway

Electrical connection

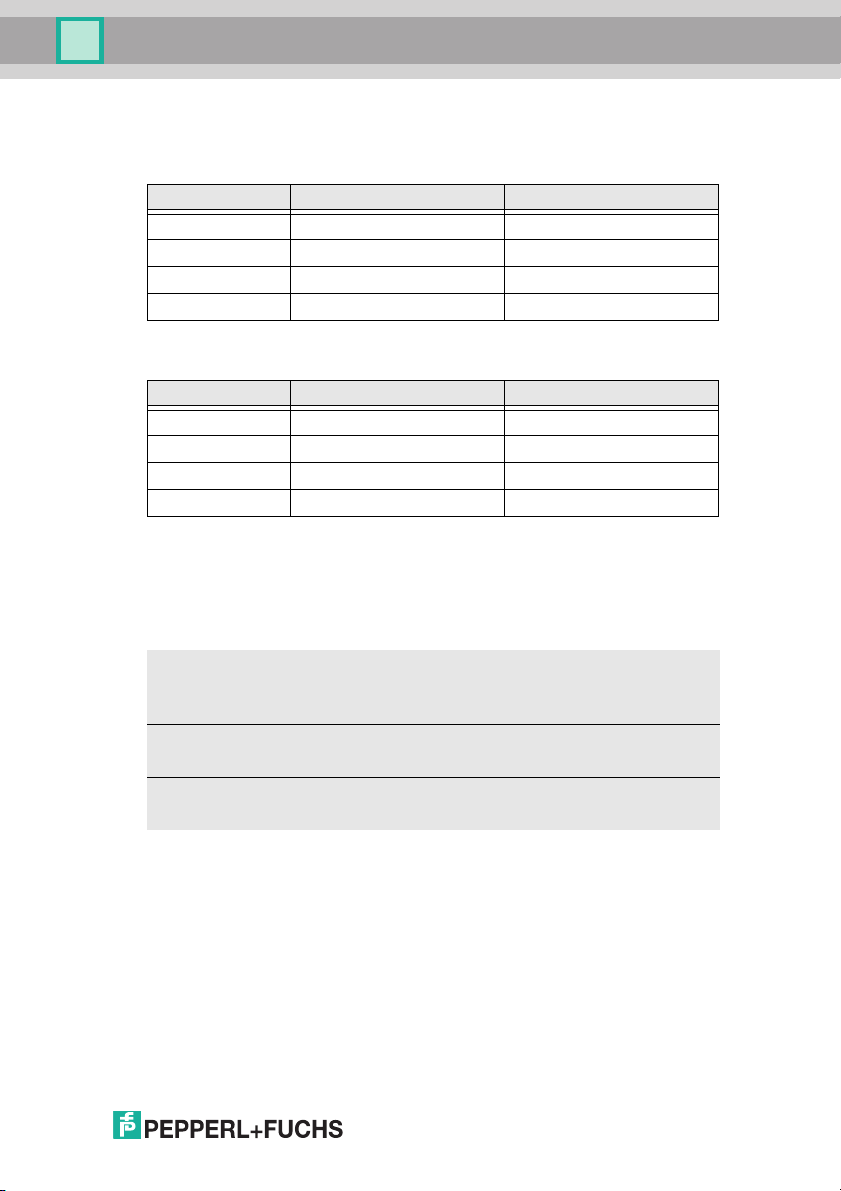

7.6.1.1 CC-Link status LED (green/red) flashing sample

C-Control mode (C-Control active)

CC-Link LED CC-Link Error CC-Link Run

flashing green off off

flashing green/red on or flashing off

green off on

flashing green/red on or flashing on

Standard mode (C-Control inactive)

CC-Link LED CC-Link Error CC-Link Run

off off off

red on or flashing off

green off on

red on or flashing on

7.6.2 Buttons

The buttons are used for the following:

Tab. 7-2.

Tab. 7-3.

Mode/

Switching between configuration mode and protected operating mode, and saving

the current AS-i configuration as the nominal configuration.

Set

Selecting the address of and assigning an address to a slave.

OK, ESC

Changing to the advanced display mode.

For additional information see section <Operation in advanced display mode>.

14.4.2015

19

Page 20

AS-i CC-Link Gateway

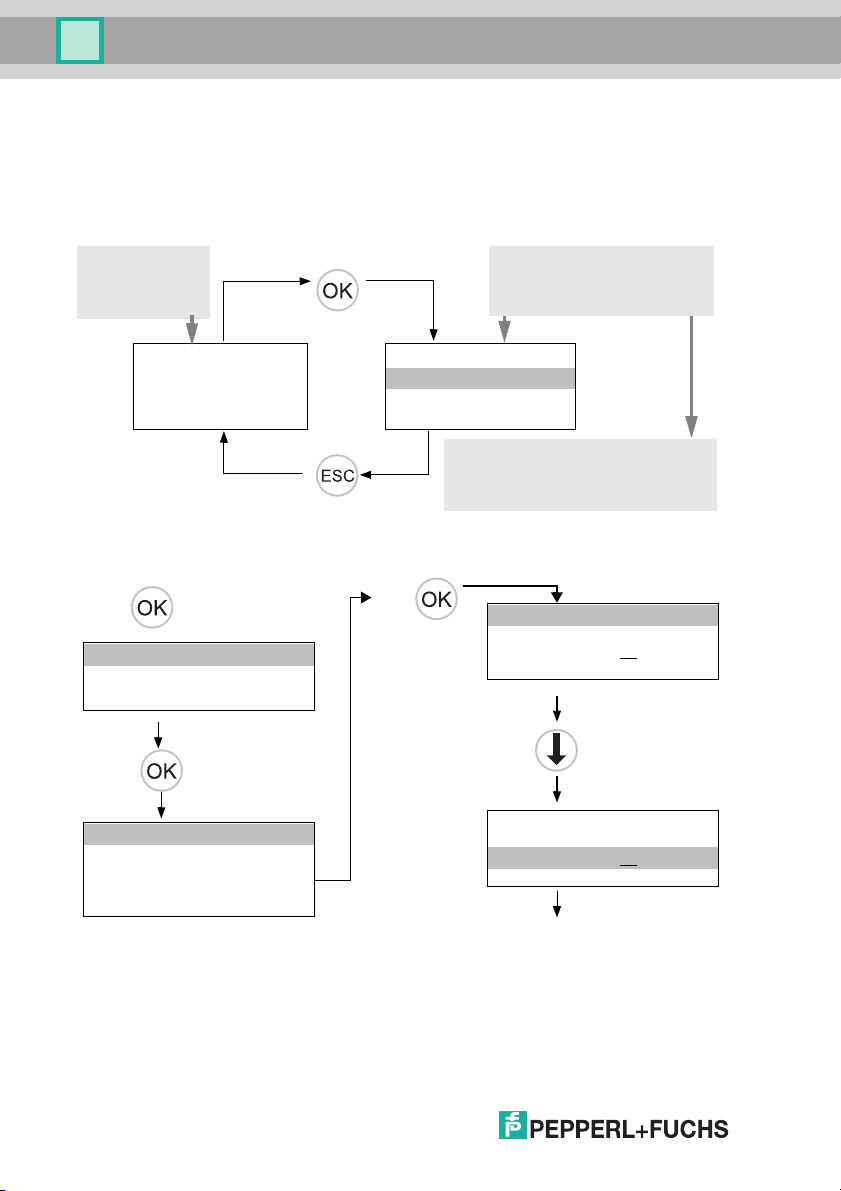

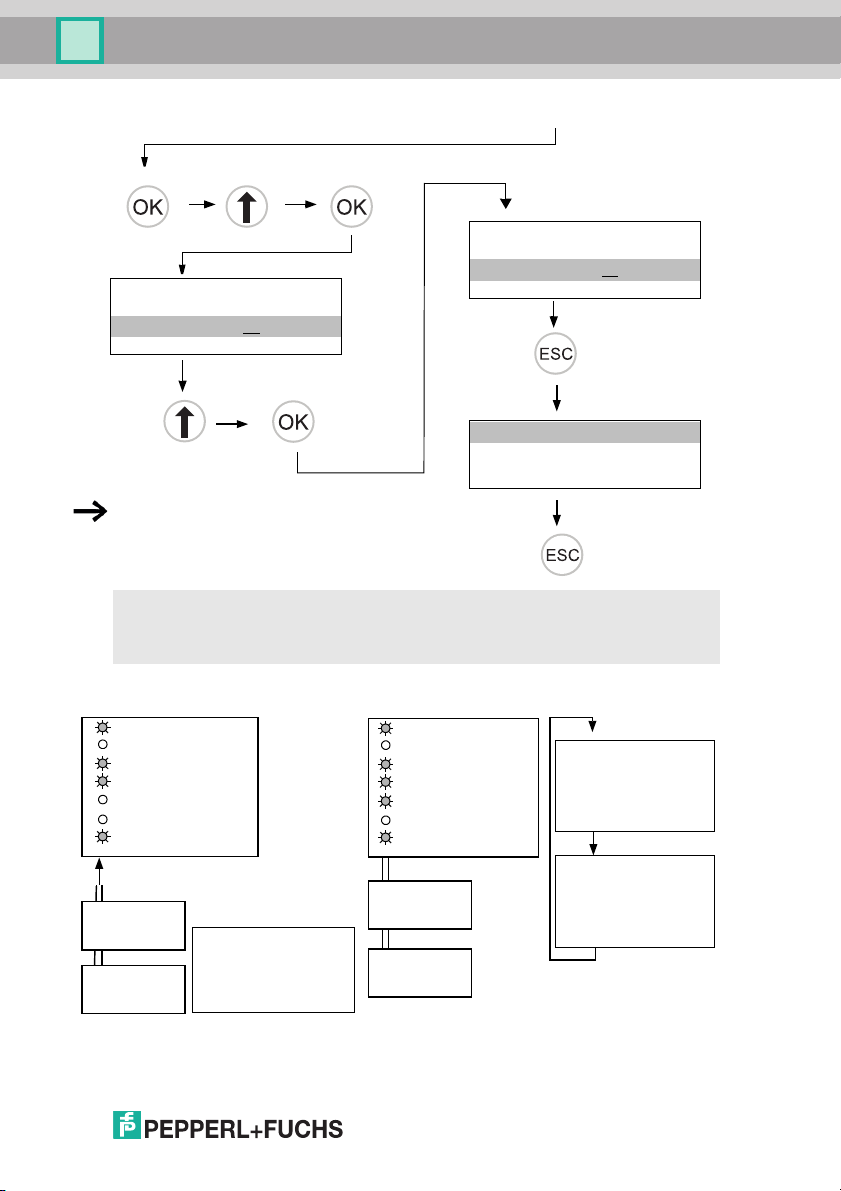

Menu structure see additional page

Classical display

LCD

.12A

UNKNOWN SLAVE

LCD

CC LINK

QUICK SETUP

SETUP

SLAVE ADR TOOL

Advanced display mode

LCD

CC LINK ADDRESS

CC LINK STATUS

MODE

CC BAUD RATE

INFO

CC LINK ADDRESS

OLD ADDRESS 1

NEW ADDRESS 01

CC LINK ADDRESS

OLD ADDRESS 1

NEW ADDRESS 01

CC LINK

QUICK SETUP

DIAGNOSIS

1x

1x

1x

2x

Commissioning

8. Commissioning

8.1 Commissioning via the device

8.1.1 Switching to advanced display mode

8.1.2 Setting the CC-Link address 14

20

14.4.2015

Page 21

AS-i CC-Link Gateway

The device is set to address 1 at the factory.

CC LINK ADDRESS

OLD ADDRESS 1

NEW ADDRESS 10

CC LINK ADDRESS

OLD ADDRESS 1

NEW ADDRESS 14

CC LINK

QUICK SETUP

DIAGNOSIS

New address/baud rate will be used after rebooting the Gateway

2x

1x 1x

4x

1x

2x

2x

Slave 1

AS-i

Slave 5

AS-i

LCD

0.5s

0.5s

Slave 1

AS-i

Slave 5

AS-i

AS-i

prj mode

config error

prg enable

AS-i active

U AS-i

CC-Link

power

AS-i

prj mode

config error

prg enable

AS-i active

U AS-i

CC-Link

power

. 5

. 1

AS-i Master

AS-i Master

LCD

. 41

SEARCHING SLAVES

Commissioning

8.1.3 Connecting AS-i Slaves

14.4.2015

21

Page 22

AS-i CC-Link Gateway

config error

CONFIGURATION OK

...

QUICK SETUP

SETUP

SLAVE ADR TOOL

WARNING:

OUTPUTS MAY BE

RESET

STORE AS-I

CONFIGURATION

STORE + RUN

STORE AS-I

CONFIGURATION

OK

LCD

. 5

STORE + PRJ MODE

STORE +PRJ MODE

config error

Host Error

No connection

10 sec

5sec 5sec

CONFIGURATION OK

config error

Commissioning

8.1.4 Quick setup

The function [QUICK SETUP] enables simple and quick configuration of all

AS-i circuits connected to the AS-i gateway:

[STORE+RUN]

Saves the current configuration of the connected AS-i slaves as a target configuration and moves the gateway to the protected operating mode.

[STORE+PRJ MODE]

Saves the current configuration of the connected AS-i slaves as a target configuration and moves the gateway to the configuration mode.

22

Hotkey

[STORE+RUN]

14.4.2015

Page 23

AS-i CC-Link Gateway

Slave 1

AS-i

Slave 5

AS-i

Slave 24

AS-i

.1

AS-i

prj mode

Config error

prg enable

AS-i active

U AS-i

CC-Link

Power

.24

MISSING SLAVE

MISSING SLAVE

2s

2s

LCD

LCD

AS-i Master

Slave 1

AS-i

Slave 5

AS-i

Slave 24

AS-i

AS-i

24

Slave 1

AS-i

Slave 5

AS-i

Slave 24

AS-i

AS-i

prj mode

Config error

prg enable

AS-i active

U AS-i

CC LINK

Power

prj mode

Config error

prg enable

AS-i active

U AS-i

CC LINK

Power

AS-i Master

AS-i Master

CC LINK error

No connection

LCD

Commissioning

8.2 Error tracing

8.2.1 Faulty slaves

8.2.2 Error display (last error)

14.4.2015

23

Page 24

AS-i CC-Link Gateway

LCD

1. 41

SEARCHING SLAVE

SETUP

SLAVE ADR TOOL

AS-I CIRCUIT 1

AS-I CIRCUIT 2

SLAVE ADR TOOL

OLD ADDRESS 2

NEW ADDRESS 0

PRG

SLAVE ADR TOOL

OLD ADDRESS 2

NEW ADDRESS 6

1. 6

UNKNOWN SLAVE

SLAVE ADR TOOL

OK

PRG

SLAVE ADR TOOL

OLD ADDRESS 2

NEW ADDRESS 6

PRG

Master Slave

Connect module

4x

1x

1x

1x

1x

6x

2x

1x

QUICK SETUP

SLAVE ADR TOOL

CONNECT NEW SLAVE

OLD ADDRESS

NEW ADDRESS

1x

1x

1x

Disconnect field bus!

Commissioning

8.2.3 Addressing

8.2.3.1 Assigning address 6 to slave currently at address 2

24

14.4.2015

Page 25

AS-i CC-Link Gateway

Commissioning

8.2.4 Local parameter setting of Gateways

Konfiguration auf Karte +

Gerät ungleich

(Werkskonfigration

geändert) // Confiugration on

chip card + device not

identical (factory settings

changed) // Configuration sur

carte à puce + dispositif pas

identiques (configuration

d'usine modifié) //

Configurazione sulla scheda

chip + sul dispositivo non

identici (configurazione di

fabbrica modificate) //

Configuración en el tarjeta

chip + dispositivo no idénticos

(configuración de fabrica

modificado)

Konfiguration auf Karte +

Gerät gleich // Configuration

on chip card + device

identical // Configuration sur

carte à puce + dispositif

identiques // Configurazione

sulla scheda chip + sul

dispositivo identici //

Configuración en el tarjeta

Karte leer + formatiert //

Chip card empty + formatted //

Carte à puce vide +

CHIPCARD FOUND

formatée // Scheda chip vuota

+ formattata // Tarjeta chip

vacía + formateada

chip + dispositivo idénticos

Keine Meldung // No

message // Aucun

message // Nessun

DATA WILL

BE SYNCHRONIZED

Keine Aktion erforderlich //

messaggio // Ningún

mensaje

Daten werden vom Gerät auf

Karte übertragen // Data

transferred from device to

chip card // Données

transférées du dispositif à la

CHIPCARD AND DATA

DIFFERENT

CARD->MASTER

MASTER->CARD

Daten kopieren

No action required //

Aucune action requise //

Nessuna azione richiesta //

Ninguna acción requrida

Keine Aktion erforderlich //

carte à puce // Dati trasferiti

dal dispositivo al chip card //

Datos transferidos desde

No action required //

dispositivo de chip card

Karte -> Master oder

Master -> Karte //

Copy data

Card -> Master or

Master -> Card //

Copiez données

Aucune action requise //

Nessuna azione richiesta //

Ninguna acción requrida

Carte -> Maître ou

Maître -> Carte //

Copiare dati

Chipcard -> Master o

Master -> Chipcard //

Copiar datos

TarjetaChip -> Maestro o

Maestro -> TarjetaChip

DATA F ROM

Konfiguration kompatibel

(Werkskonfiguration) //

Configuration compatible

(factory settings) //

Configuration compatible

(configuration d'usine) //

Configurazione compatibile

(configurazione di fabbrica) //

Konfiguration auf Karte nicht

kompatibel mit Gerät //

Configuration on chip card not

compatible with device //

Configuration sur carte à puce

non compatible avec

dispositif // Configurazione

sulla scheda chip non

NEW CHIPCARD

chip non formattata // Tarjeta

chip no formateada

WILL BE FORMATTED

Karte nicht formatiert // Chip

card not formatted // Carte à

puce pas formatée // Scheda

14.4.2015

CHIPCARD TAKEN

Configuración compatible

(configuración de fábrica)

compatibile con il dispositivo //

DATA WILL BE

CHIPCARD NOT

Configuración en la tarjeta

chip no compatible con el

dispositivo

SYNCHRONIZED

Karte wird formatiert // Chip

Daten von Karte auf Gerät

übertragen // Data transferred

from chip card to device //

Données transférées de la

carte à puce au dispositif //

COMPATIBLE

card will be formatted // Carte

à puce sera formatée //

Karte löschen // Clear the

Scheda chip verrà

formattata // Tarjeta chip se

formateará

Keine Aktion erforderlich //

card // Supprimer carte //

Cancellare scheda chip //

No action required //

Dati trasferiti dal chip card al

dispositivo // Datos

transferidos desde chip card

de dispositivo

Keine Aktion erforderlich //

No action required //

Borrar tarjeta chip

Aucune action requise //

Nessuna azione richiesta //

Ninguna acción requrida

Aucune action requise //

Nessuna azione richiesta //

Ninguna acción requrida

25

Page 26

AS-i CC-Link Gateway

[1]

[2]

old

new

[3]

Commissioning

8.2.5 Replacing the chip card

Caution!

Always turn off power before inserting or removing the card!

Power

Supply

8.2.6 Using the chip card

The chip card integrated in the AS-i master is used to read-out and to store configuration data.

26

Power

Supply

14.4.2015

Page 27

AS-i CC-Link Gateway

Commissioning

8.2.6.1 Card unformatted

If an unformatted card is found when the device is started, the following is displayed:

The chip card is formatted and then the data copied to the chip card.

8.2.6.2 Data not compatible

If a card is found whose data are incompatible with the device, the following error

message is displayed:

8.2.6.3 Card empty

The following message is displayed for an empty card:

NEW CHIPCARD

WILL BE FORMATED

AS-I DATA WILL

BE SYNCHRONIZED

CHIPCARD NOT

COMPATIBLE

CHIPCARD FOUND

AS-I DATA WILL

BE SYNCHRONIZED

From this time on all changes are made both in the device and on the chip card.

14.4.2015

27

Page 28

AS-i CC-Link Gateway

Commissioning

8.2.6.4 Data compatible

When starting with an empty device (e.g. after a factory reset) a non-empty card

is found whose data are compatible with the device, the following message is displayed:

AS-I DATA FROM

CHIPCARD TAKEN

The card configuration is written to the device. From this time on all changes are

made both in the device and on the chip card.

8.2.6.5 Data in the device and on the chip card identical

If the card and device are not empty at start and the data are identical, no message is displayed.

8.2.6.6 Data in the device and on the chip card not identical

If the card and device are not empty at start and the data are not identical, an error message is displayed and the card is not synchronized with the device. The

following menu is then automatically opened:

28

CHIPCARD AND

AS-I DATA

DIFFERENT

CARD->MASTER

MASTER->CARD

CONTINUE

Description

CHIP CARD>MASTER: Chip card data are copied to the master

MASTER->CHIPCARD: Master data are copied to the chip card

NEXT: No change to the data

The menu can be exited by pressing the ESC/Service key without changing the

data.

14.4.2015

Page 29

AS-i CC-Link Gateway

Operation in display mode

9. Operation in display mode

Information!

You will find a description of the display menu in the separate document

play_Menue".

"Dis-

14.4.2015

29

Page 30

AS-i CC-Link Gateway

Data transmission modes

10. Data transmission modes

10.1 Selecting the data transmission mode

The selection of the respective data transmission mode takes place in the menu

of the AS-i CC-Link Gateway using the buttons and the display.

Main menu || CC-LINK || MODE ||

CC LINK ADDRESS

CC LINK STATUS

MODE

CC BAUD RATE

INFO

STANDARD

VBG-CCL-G4F COMP

CC-Link V1

FX2N-32ASI-M CP

HK-ASICC COMP

30

Following modes are supported:

• Standard

• Compatibility modes for:

• VBG-CCL-G4F COMP

• CC-Link V1

• FX2N-32ASI-M CP

• HK-ASICC COMP

14.4.2015

Page 31

AS-i CC-Link Gateway

Data transmission modes

10.2 Summary of modes

Standard VBG-

CCL-G4F

Occupied Stations 3 3 4 4 2

Cycle Setting 2 1 1 1 1

Required CC-Link Master V2 V1 V1 V1 V1

Support of 2 AS-i Circuits No No No No No

Support of B-Slaves Yes (Yes) Yes No No

Support of AS-i Safety No No No No No

Support of Analog Slaves Yes Yes Yes No No

Support of AS-i Configuration

via CC-Link

Yes Yes Yes No No

CCLink V1

FX2N32ASI-M

Tab. 10-4. Summary of modes

HKASICC

14.4.2015

31

Page 32

AS-i CC-Link Gateway

Data transmission modes

10.3 Standard mode

• In standard mode, the Gateway occupies 3 stations and has a double cycle

setting.

• The last 2 words are reserved for "Message Transmission".

• The AS-i process data is mapped into the Buffer Memory Area (BFM).

• All acyclic requests are handled by "Message Transmission" using cyclic

data.

10.3.1 Remote IO Points

Address 1514131211109876543210

RXm reserved

RXm+1 AS-i Circuit 1: EC-Flags and Fault Detector

RXm+2 reserved

…

RXm+9

Bit Short Name Name

0 Cfg. OK Configuration OK

1 S0 Slave Address 0 Detected

2 Aaasn Auto Address Assign

3 Aaavail Auto Address Available

4 CM Configuration Mode active

5 NA Normal Operation active

6 APF AS-i Power fail (AS-i Voltage below 19V)

7 Offl Offline

8 NPF No Peripheral Fault

9 reserved reserved

10 PWRw Power Warning (AS-i Voltage below 22.5V)

11 reserved reserved

12 EF Earth Fault

13 OV Over-voltage on AS-i

14 Noise Noise

15 reserved reserved

Tab. 10-5. Remote IO Points

Tab. 10-6. EC-Flags and Fault Detector

32

14.4.2015

Page 33

AS-i CC-Link Gateway

Data transmission modes

Address1514131211109876543 2 1 0

RYm PM CM AAE OFL

RYm+1 reserved

…

RYm+9

Bit Short Name Name

0 OFL Offline

1 AAE Auto Address Enable

2 CM Enter Configuration Mode on rising edge

3 PM Enter Protected Mode on rising edge

4 … 15 reserved

10.3.2 Buffer Memory Area

Address 1 Master

Read Write

0 … 7 AS-i 1, Input A+Single Slaves AS-i 1, Output A+Single Slaves

8 … 15 AS-i 1, Input B Slaves AS-i 1, Output B Slaves

16 … 23 reserved

Tab. 10-7. Remote IO Points

Tab. 10-8. Flags in RYm

Tab. 10-9. Overview Memory Mapping

14.4.2015

33

Page 34

AS-i CC-Link Gateway

Data transmission modes

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWrm0 AS-i 1: Inp. Slv3 AS-i 1: Inp. Slv2 AS-i 1: Inp. Slv1 Flags AS-i 1

RWrm1 AS-i 1: Inp. Slv7 AS-i 1: Inp. Slv6 AS-i 1: Inp. Slv5 AS-i 1: Inp. Slv4

RWrm2 AS-i 1: Inp. Slv11 AS-i 1: Inp. Slv10 AS-i 1: Inp. Slv9 AS-i 1: Inp. Slv8

RWrm3 AS-i 1: Inp. Slv15 AS-i 1: Inp. Slv14 AS-i 1: Inp. Slv13 AS-i 1: Inp. Slv12

RWrm4 AS-i 1: Inp. Slv19 AS-i 1: Inp. Slv18 AS-i 1: Inp. Slv17 AS-i 1: Inp. Slv16

RWrm5 AS-i 1: Inp. Slv23 AS-i 1: Inp. Slv22 AS-i 1: Inp. Slv21 AS-i 1: Inp. Slv20

RWrm6 AS-i 1: Inp. Slv27 AS-i 1: Inp. Slv26 AS-i 1: Inp. Slv25 AS-i 1: Inp. Slv24

RWrm7 AS-i 1: Inp. Slv31 AS-i 1: Inp. Slv30 AS-i 1: Inp. Slv29 AS-i 1: Inp. Slv28

RWrm8 AS-i 1: Inp. Slv3B AS-i 1: Inp. Slv2B AS-i 1: Inp. Slv1B

RWrm9 AS-i 1: Inp. Slv7B AS-i 1: Inp. Slv6B AS-i 1: Inp. Slv5B AS-i 1: Inp. Slv4B

RWrm10 AS-i 1: Inp.

Slv11B

RWrm11 AS-i 1: Inp.

Slv15B

RWrm12 AS-i 1: Inp.

Slv19B

RWrm13 AS-i 1: Inp.

Slv23B

RWrm14 AS-i 1: Inp.

Slv27B

RWrm15 AS-i 1: Inp.

Slv31B

RWrm16 reserved

…

RWrm23

Bit Name

0 0: No Config Error

1 0: AS-i Power OK

2 0. Normal Operation active

3 0: Protected Mode active

AS-i 1: Inp.

Slv10B

AS-i 1: Inp.

Slv14B

AS-i 1: Inp.

Slv18B

AS-i 1: Inp.

Slv22B

AS-i 1: Inp.

Slv26B

AS-i 1: Inp.

Slv30B

AS-i 1: Inp. Slv9B AS-i 1: Inp. Slv8B

AS-i 1: Inp.

Slv13B

AS-i 1: Inp.

Slv17B

AS-i 1: Inp.

Slv21B

AS-i 1: Inp.

Slv25B

AS-i 1: Inp.

Slv29B

AS-i 1: Inp.

Slv12B

AS-i 1: Inp.

Slv16B

AS-i 1: Inp.

Slv20B

AS-i 1: Inp.

Slv24B

AS-i 1: Inp.

Slv28B

Tab. 10-10. Buffer Memory (Read)

Tab. 10-11. Bits in Flags

34

14.4.2015

Page 35

AS-i CC-Link Gateway

Data transmission modes

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWwm0 AS-i 1: Outp. Slv3 AS-i 1: Outp. Slv2 AS-i 1: Outp. Slv1

RWwm1 AS-i 1: Outp. Slv7 AS-i 1: Outp. Slv6 AS-i 1: Outp. Slv5 AS-i 1: Outp. Slv4

RWwm2 AS-i 1: Outp.

Slv11

RWwm3 AS-i 1: Outp.

Slv15

RWwm4 AS-i 1: Outp.

Slv19

RWwm5 AS-i 1: Outp.

Slv23

RWwm6 AS-i 1: Outp.

Slv27

RWwm7 AS-i 1: Outp.

Slv31

RWwm8 AS-i 1: Outp.

Slv3B

RWwm9 AS-i 1: Outp.

Slv7B

RWwm10 AS-i 1: Outp.

Slv11B

RWwm11 AS-i 1: Outp.

Slv15B

RWwm12 AS-i 1: Outp.

Slv19B

RWwm13 AS-i 1: Outp.

Slv23B

RWwm14 AS-i 1: Outp.

Slv27B

RWwm15 AS-i 1: Outp.

Slv31B

RWwm16 reserved

…

RWwm23

AS-i 1: Outp.

Slv10

AS-i 1: Outp.

Slv14

AS-i 1: Outp.

Slv18

AS-i 1: Outp.

Slv22

AS-i 1: Outp.

Slv26

AS-i 1: Outp.

Slv30

AS-i 1: Outp.

Slv2B

AS-i 1: Outp.

Slv6B

AS-i 1: Outp.

Slv10B

AS-i 1: Outp.

Slv14B

AS-i 1: Outp.

Slv18B

AS-i 1: Outp.

Slv22B

AS-i 1: Outp.

Slv26B

AS-i 1: Outp.

Slv30B

AS-i 1: Outp. Slv9 AS-i 1: Outp. Slv8

AS-i 1: Outp.

Slv13

AS-i 1: Outp.

Slv17

AS-i 1: Outp.

Slv21

AS-i 1: Outp.

Slv25

AS-i 1: Outp.

Slv29

AS-i 1: Outp.

Slv1B

AS-i 1: Outp.

Slv5B

AS-i 1: Outp.

Slv9B

AS-i 1: Outp.

Slv13B

AS-i 1: Outp.

Slv17B

AS-i 1: Outp.

Slv21B

AS-i 1: Outp.

Slv25B

AS-i 1: Outp.

Slv29B

AS-i 1: Outp.

Slv12

AS-i 1: Outp.

Slv16

AS-i 1: Outp.

Slv20

AS-i 1: Outp.

Slv24

AS-i 1: Outp.

Slv28

AS-i 1: Outp.

Slv4B

AS-i 1: Outp.

Slv8B

AS-i 1: Outp.

Slv12B

AS-i 1: Outp.

Slv16B

AS-i 1: Outp.

Slv20B

AS-i 1: Outp.

Slv24B

AS-i 1: Outp.

Slv28B

Tab. 10-12. Buffer Memory (Write)

14.4.2015

35

Page 36

AS-i CC-Link Gateway

Data transmission modes

Bit Name

0 0: No Config Error

1 0: AS-i Power OK

2 0. Normal Operation active

3 0: Protected Mode active

10.3.3 Message Transmission

By "Message Transmission", all command interface commands are available (see

the separate manual „AS-i 3.0 Command interface“). No commands other than

Mailbox commands are supported.

Information!

For details on the Message Transmission protocol, please refer to the CC-Link specification. For more information or PLC program examples, how to use Message Transmission, please refer to the documentation of your CC-Link master in use.

Tab. 10-13. Bits in Flags

36

14.4.2015

Page 37

AS-i CC-Link Gateway

Data transmission modes

10.4 Compatibility mode for VBG-CCL-G4F

In this mode, 3 stations are occupied using a single cycle setting.

No "Message Transmission" is supported.

All functions of VBG-CCL-G4F are implemented

The AS-i process data or the mailbox is mapped into the Buffer Memory Area

(BFM) as done in the VBG-CCL-G4F.

"Message Transmission" is not supported, since VBG-CCL-G4F does not use it.

10.4.1 Remote IO Points

Remote to Host

Address 1514131211109 8 7 6 5 4 3 2 1 0

RXm reserved BfEAck MbAck reserved

RXm+1

…

RXm+5

Bit Short Name Name

0 … 3 reserved

4 MbAck Acknowledge Bit for Y4

5 BfEAck Acknowledge Bit for Y5

4 … 15 reserved

Address 1514131211109 8 7 6 5 4 3 2 1 0

RYm reserved BfE Mb PM CM AAE OFL

RYm+1

…

RYm+5

Bit Short Name Name

0 OFL Offline

1 AAE Auto Address Enable

2 CM Enter Configuration Mode on rising edge

3 PM Enter Protected Mode on rising edge

4 Mb 0: BFM used for IO Data only

5 BfE 0: Enable Use of BFM

4 … 15 reserved

14.4.2015

reserved

Host to Remote

reserved

1: BFM used for Mailbox

Tab. 10-14. Remote IO Points Remote to Host

Tab. 10-15. Flags in RXm

Tab. 10-16. Remote IO Points Host to Remote

Tab. 10-17. Flags in RYm

37

Page 38

AS-i CC-Link Gateway

Data transmission modes

10.4.2 Buffer Memory Area

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWrm0 AS-i 1: Inp. Slv3 AS-i 1: Inp. Slv2 AS-i 1: Inp. Slv1 Flags

RWrm1 AS-i 1: Inp. Slv7 AS-i 1: Inp. Slv6 AS-i 1: Inp. Slv5 AS-i 1: Inp. Slv4

RWrm2 AS-i 1: Inp.

Slv11

RWrm3 AS-i 1: Inp.

Slv15

RWrm4 AS-i 1: Inp.

Slv19

RWrm5 AS-i 1: Inp.

Slv23

RWrm6 AS-i 1: Inp.

Slv27

RWrm7 AS-i 1: Inp.

Slv31

RWrm8 AS-i 1: Inp.

Slv3B

RWrm9 AS-i 1: Inp.

Slv7B

RWrm10 AS-i 1: Inp.

Slv11B

RWrm11 AS-i 1: Inp.

Slv15B

Bit Name

0 0: No Config Error

1 0: AS-i Power OK

2 0. Normal Operation active

3 0: Protected Mode active

AS-i 1: Inp.

AS-i 1: Inp. Slv9 AS-i 1: Inp. Slv8

Slv10

AS-i 1: Inp.

Slv14

AS-i 1: Inp.

Slv18

AS-i 1: Inp.

Slv22

AS-i 1: Inp.

Slv26

AS-i 1: Inp.

Slv30

AS-i 1: Inp.

Slv2B

AS-i 1: Inp.

Slv6B

AS-i 1: Inp.

Slv10B

AS-i 1: Inp.

Slv14B

Tab. 10-18. Buffer Memory (Read) when using IO Data on ly Mode

AS-i 1: Inp.

Slv13

AS-i 1: Inp.

Slv17

AS-i 1: Inp.

Slv21

AS-i 1: Inp.

Slv25

AS-i 1: Inp.

Slv29

AS-i 1: Inp.

Slv1B

AS-i 1: Inp.

Slv5B

AS-i 1: Inp.

Slv9B

AS-i 1: Inp.

Slv13B

AS-i 1: Inp.

Slv12

AS-i 1: Inp.

Slv16

AS-i 1: Inp.

Slv20

AS-i 1: Inp.

Slv24

AS-i 1: Inp.

Slv28

AS-i 1: Inp.

Slv4B

AS-i 1: Inp.

Slv8B

AS-i 1: Inp.

Slv12B

Tab. 10-19. Bits in Flags

38

14.4.2015

Page 39

AS-i CC-Link Gateway

Data transmission modes

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4

Bit 3 … 0

RWrm0 Mailbox: Circuit Mailbox: Command

RWrm1 Mailbox: Response Byte 2 Mailbox: Response Byte 1

RWrm2 Mailbox: Response Byte 4 Mailbox: Response Byte 3

RWrm3 Mailbox: Response Byte 6 Mailbox: Response Byte 5

RWrm4 Mailbox: Response Byte 8 Mailbox: Response Byte 7

RWrm5 Mailbox: Response Byte 10 Mailbox: Response Byte 9

RWrm6 Mailbox: Response Byte 12 Mailbox: Response Byte 11

RWrm7 Mailbox: Response Byte 14 Mailbox: Response Byte 13

RWrm8 Mailbox: Response Byte 16 Mailbox: Response Byte 15

RWrm9 Mailbox: Response Byte 18 Mailbox: Response Byte 17

RWrm10 Mailbox: Response Byte 20 Mailbox: Response Byte 19

RWrm11 Mailbox: Response Byte 22 Mailbox: Response Byte 21

Tab. 10-20. Buffer Memory (Read) when using Mail box Mode

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWwm0 AS-i 1: Outp.

Slv3

RWwm1 AS-i 1: Outp.

Slv7

RWwm2 AS-i 1: Outp.

Slv11

RWwm3 AS-i 1: Outp.

Slv15

RWwm4 AS-i 1: Outp.

Slv19

RWwm5 AS-i 1: Outp.

Slv23

RWwm6 AS-i 1: Outp.

Slv27

RWwm7 AS-i 1: Outp.

Slv31

RWwm8 AS-i 1: Outp.

Slv3B

RWwm9 AS-i 1: Outp.

Slv7B

RWwm10 AS-i 1: Outp.

Slv11B

RWwm11 AS-i 1: Outp.

Slv15B

14.4.2015

AS-i 1: Outp.

Slv2

AS-i 1: Outp.

Slv6

AS-i 1: Outp.

Slv10

AS-i 1: Outp.

Slv14

AS-i 1: Outp.

Slv18

AS-i 1: Outp.

Slv22

AS-i 1: Outp.

Slv26

AS-i 1: Outp.

Slv30

AS-i 1: Outp.

Slv2B

AS-i 1: Outp.

Slv6B

AS-i 1: Outp.

Slv10B

AS-i 1: Outp.

Slv14B

Tab. 10-21. Buffer Memory (Write) when using IO Da ta only Mode

AS-i 1: Outp.

Slv1

AS-i 1: Outp.

Slv5

AS-i 1: Outp.

Slv9

AS-i 1: Outp.

Slv13

AS-i 1: Outp.

Slv17

AS-i 1: Outp.

Slv21

AS-i 1: Outp.

Slv25

AS-i 1: Outp.

Slv29

AS-i 1: Outp.

Slv1B

AS-i 1: Outp.

Slv5B

AS-i 1: Outp.

Slv9B

AS-i 1: Outp.

Slv13B

Flags

AS-i 1: Outp.

Slv4

AS-i 1: Outp.

Slv8

AS-i 1: Outp.

Slv12

AS-i 1: Outp.

Slv16

AS-i 1: Outp.

Slv20

AS-i 1: Outp.

Slv24

AS-i 1: Outp.

Slv28

AS-i 1: Outp.

Slv4B

AS-i 1: Outp.

Slv8B

AS-i 1: Outp.

Slv12B

39

Page 40

AS-i CC-Link Gateway

Data transmission modes

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWwm0 Mailbox: Circuit Mailbox: Command

RWwm1 Mailbox: Request Byte 2 Mailbox: Request Byte 1

RWwm2 Mailbox: Request Byte 4 Mailbox: Request Byte 3

RWwm3 Mailbox: Request Byte 6 Mailbox: Request Byte 5

RWwm4 Mailbox: Request Byte 8 Mailbox: Request Byte 7

RWwm5 Mailbox: Request Byte 10 Mailbox: Request Byte 9

RWwm6 Mailbox: Request Byte 12 Mailbox: Request Byte 11

RWwm7 Mailbox: Request Byte 14 Mailbox: Request Byte 13

RWwm8 Mailbox: Request Byte 16 Mailbox: Request Byte 15

RWWm9 Mailbox: Request Byte 18 Mailbox: Request Byte 17

RWwm10 Mailbox: Request Byte 20 Mailbox: Request Byte 19

RWwm11 Mailbox: Request Byte 22 Mailbox: Request Byte 21

Tab. 10-22. Buffer Memory (Write) when using Mailbox Mod e

40

14.4.2015

Page 41

AS-i CC-Link Gateway

Data transmission modes

10.5 CC-Link V1 Mode

In this mode, 4 stations are occupied using a single cycle setting.

No "Message Transmission" is supported.

This mode is an extended version of the Compatibility Mode for VBG-CCL-G4F.

The AS-i process data or the mailbox is mapped into the Buffer Memory Area

(BFM) as done in the VBG-CCL-G4F.

"Message Transmission" is not supported.

10.5.1 Remote IO Points

Remote to Host

Address 1514131211109 8 7 6 5 4 3 2 1 0

RXm reserved BfEAck MbAck reserved

RXm+1

…

RXm+7

Bit Short Name Name

0 … 3 reserved

4 MbAck Acknowledge Bit for Y4

5 BfEAck Acknowledge Bit for Y5

4 … 15 reserved

Address 1514131211109 8 7 6 5 4 3 2 1 0

RYm reserved BfE Mb PM CM AAE OFL

RYm+1

…

RYm+7

Bit Short Name Name

0 OFL Offline

1 AAE Auto Address Enable

2 CM Enter Configuration Mode on rising edge

3 PM Enter Protected Mode on rising edge

4 Mb 0: BFM used for IO Data only

5 BfE 0: Enable Use of BFM

4 … 15 reserved

14.4.2015

reserved

Host to Remote

reserved

Tab. 10-23. Remote IO Points Remote to Host

Tab. 10-24. Flags in RXm

Tab. 10-25. Remote IO Points Host to Remote

1: BFM used for Mailbox

Tab. 10-26. Flags in RYm

41

Page 42

AS-i CC-Link Gateway

Data transmission modes

10.5.2 Buffer Memory Area

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4

Bit 3 … 0

RWrm0 AS-i 1: Inp. Slv3 AS-i 1: Inp. Slv2 AS-i 1: Inp. Slv1 Flags

RWrm1 AS-i 1: Inp. Slv7 AS-i 1: Inp. Slv6 AS-i 1: Inp. Slv5 AS-i 1: Inp. Slv4

RWrm2 AS-i 1: Inp.

Slv11

RWrm3 AS-i 1: Inp.

Slv15

RWrm4 AS-i 1: Inp.

Slv19

RWrm5 AS-i 1: Inp.

Slv23

RWrm6 AS-i 1: Inp.

Slv27

RWrm7 AS-i 1: Inp.

Slv31

RWrm8 AS-i 1: Inp.

Slv3B

RWrm9 AS-i 1: Inp.

Slv7B

RWrm10 AS-i 1: Inp.

Slv11B

RWrm11 AS-i 1: Inp.

Slv15B

RWrm12 AS-i 1: Inp.

Slv19B

RWrm13 AS-i 1: Inp.

Slv23B

RWrm14 AS-i 1: Inp.

Slv27B

RWrm15 AS-i 1: Inp.

Slv31B

AS-i 1: Inp.

AS-i 1: Inp. Slv9 AS-i 1: Inp. Slv8

Slv10

AS-i 1: Inp.

Slv14

AS-i 1: Inp.

Slv18

AS-i 1: Inp.

Slv22

AS-i 1: Inp.

Slv26

AS-i 1: Inp.

Slv30

AS-i 1: Inp.

Slv2B

AS-i 1: Inp.

Slv6B

AS-i 1: Inp.

Slv10B

AS-i 1: Inp.

Slv14B

AS-i 1: Inp.

Slv18B

AS-i 1: Inp.

Slv22B

AS-i 1: Inp.

Slv26B

AS-i 1: Inp.

Slv30B

Tab. 10-27. Buffer Memory (Read) when using IO Data on ly Mode

AS-i 1: Inp.

Slv13

AS-i 1: Inp.

Slv17

AS-i 1: Inp.

Slv21

AS-i 1: Inp.

Slv25

AS-i 1: Inp.

Slv29

AS-i 1: Inp.

Slv1B

AS-i 1: Inp.

Slv5B

AS-i 1: Inp.

Slv9B

AS-i 1: Inp.

Slv13B

AS-i 1: Inp.

Slv17B

AS-i 1: Inp.

Slv21B

AS-i 1: Inp.

Slv25B

AS-i 1: Inp.

Slv29B

AS-i 1: Inp.

Slv12

AS-i 1: Inp.

Slv16

AS-i 1: Inp.

Slv20

AS-i 1: Inp.

Slv24

AS-i 1: Inp.

Slv28

AS-i 1: Inp.

Slv4B

AS-i 1: Inp.

Slv8B

AS-i 1: Inp.

Slv12B

AS-i 1: Inp.

Slv16B

AS-i 1: Inp.

Slv20B

AS-i 1: Inp.

Slv24B

AS-i 1: Inp.

Slv28B

Bit Name

0 0: No Config Error

1 0: AS-i Power OK

2 0. Normal Operation active

3 0: Protected Mode active

Tab. 10-28. Bits in Flags

42

14.4.2015

Page 43

AS-i CC-Link Gateway

Data transmission modes

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWrm0 Mailbox: Circuit Mailbox: Command

RWrm1 Mailbox: Response Byte 2 Mailbox: Response Byte 1

RWrm2 Mailbox: Response Byte 4 Mailbox: Response Byte 3

RWrm3 Mailbox: Response Byte 6 Mailbox: Response Byte 5

RWrm4 Mailbox: Response Byte 8 Mailbox: Response Byte 7

RWrm5 Mailbox: Response Byte 10 Mailbox: Response Byte 9

RWrm6 Mailbox: Response Byte 12 Mailbox: Response Byte 11

RWrm7 Mailbox: Response Byte 14 Mailbox: Response Byte 13

RWrm8 Mailbox: Response Byte 16 Mailbox: Response Byte 15

RWrm9 Mailbox: Response Byte 18 Mailbox: Response Byte 17

RWrm10 Mailbox: Response Byte 20 Mailbox: Response Byte 19

RWrm11 Mailbox: Response Byte 22 Mailbox: Response Byte 21

RWrm12 Mailbox: Response Byte 24 Mailbox: Response Byte 23

RWrm13 Mailbox: Response Byte 26 Mailbox: Response Byte 25

RWrm14 Mailbox: Response Byte 28 Mailbox: Response Byte 27

RWrm15 Mailbox: Response Byte 30 Mailbox: Response Byte 29

Tab. 10-29. Buffer Memory (Read) when using Mail box Mode

14.4.2015

43

Page 44

AS-i CC-Link Gateway

Data transmission modes

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWwm0 AS-i 1: Outp.

Slv3

RWwm1 AS-i 1: Outp.

Slv7

RWwm2 AS-i 1: Outp.

Slv11

RWwm3 AS-i 1: Outp.

Slv15

RWwm4 AS-i 1: Outp.

Slv19

RWwm5 AS-i 1: Outp.

Slv23

RWwm6 AS-i 1: Outp.

Slv27

RWwm7 AS-i 1: Outp.

Slv31

RWwm8 AS-i 1: Outp.

Slv3B

RWwm9 AS-i 1: Outp.

Slv7B

RWwm10 AS-i 1: Outp.

Slv11B

RWwm11 AS-i 1: Outp.

Slv15B

RWwm12 AS-i 1: Outp.

Slv19B

RWwm13 AS-i 1: Outp.

Slv23B

RWwm14 AS-i 1: Outp.

Slv27B

RWwm15 AS-i 1: Outp.

Slv31B

AS-i 1: Outp.

Slv2

AS-i 1: Outp.

Slv6

AS-i 1: Outp.

Slv10

AS-i 1: Outp.

Slv14

AS-i 1: Outp.

Slv18

AS-i 1: Outp.

Slv22

AS-i 1: Outp.

Slv26

AS-i 1: Outp.

Slv30

AS-i 1: Outp.

Slv2B

AS-i 1: Outp.

Slv6B

AS-i 1: Outp.

Slv10B

AS-i 1: Outp.

Slv14B

AS-i 1: Outp.

Slv18B

AS-i 1: Outp.

Slv22B

AS-i 1: Outp.

Slv26B

AS-i 1: Outp.

Slv30B

Tab. 10-30. Buffer Memory (Write) when using IO Da ta only Mode

AS-i 1: Outp.

Slv1

AS-i 1: Outp.

Slv5

AS-i 1: Outp.

Slv9

AS-i 1: Outp.

Slv13

AS-i 1: Outp.

Slv17

AS-i 1: Outp.

Slv21

AS-i 1: Outp.

Slv25

AS-i 1: Outp.

Slv29

AS-i 1: Outp.

Slv1B

AS-i 1: Outp.

Slv5B

AS-i 1: Outp.

Slv9B

AS-i 1: Outp.

Slv13B

AS-i 1: Outp.

Slv17B

AS-i 1: Outp.

Slv21B

AS-i 1: Outp.

Slv25B

AS-i 1: Outp.

Slv29B

Flags

AS-i 1: Outp.

Slv4

AS-i 1: Outp.

Slv8

AS-i 1: Outp.

Slv12

AS-i 1: Outp.

Slv16

AS-i 1: Outp.

Slv20

AS-i 1: Outp.

Slv24

AS-i 1: Outp.

Slv28

AS-i 1: Outp.

Slv4B

AS-i 1: Outp.

Slv8B

AS-i 1: Outp.

Slv12B

AS-i 1: Outp.

Slv16B

AS-i 1: Outp.

Slv20B

AS-i 1: Outp.

Slv24B

AS-i 1: Outp.

Slv28B

44

14.4.2015

Page 45

AS-i CC-Link Gateway

Data transmission modes

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWwm0 Mailbox: Circuit Mailbox: Command

RWwm1 Mailbox: Request Byte 2 Mailbox: Request Byte 1

RWwm2 Mailbox: Request Byte 4 Mailbox: Request Byte 3

RWwm3 Mailbox: Request Byte 6 Mailbox: Request Byte 5

RWwm4 Mailbox: Request Byte 8 Mailbox: Request Byte 7

RWwm5 Mailbox: Request Byte 10 Mailbox: Request Byte 9

RWwm6 Mailbox: Request Byte 12 Mailbox: Request Byte 11

RWwm7 Mailbox: Request Byte 14 Mailbox: Request Byte 13

RWwm8 Mailbox: Request Byte 16 Mailbox: Request Byte 15

RWwm9 Mailbox: Request Byte 18 Mailbox: Request Byte 17

RWwm10 Mailbox: Request Byte 20 Mailbox: Request Byte 19

RWwm11 Mailbox: Request Byte 22 Mailbox: Request Byte 21

RWwm12 Mailbox: Request Byte 24 Mailbox: Request Byte 23

RWwm13 Mailbox: Request Byte 26 Mailbox: Request Byte 25

RWwm14 Mailbox: Request Byte 28 Mailbox: Request Byte 27

RWwm15 Mailbox: Request Byte 30 Mailbox: Request Byte 29

Tab. 10-31. Buffer Memory (Write) when using Mailbox Mod e

14.4.2015

45

Page 46

AS-i CC-Link Gateway

Data transmission modes

10.6 Compatibility Mode for FX2N-32ASI-M

To ease the migration of applications using the obsolete Mitsubishi FX2N-32ASIM Module (AS-i Master 2.04) for FX2N PLCs, a compatibility mode is implemented.

In this mode, 4 stations are occupied using a single cycle setting (CC-Link V1).

No "Message Transmission" is supported.

Not all functions of FX2N-32ASI-M are implemented:

• No Command Buffer

• No List of Slaves with Configuration Differences

• No Module Error Status, no Module Identifier (Specific to FX2N Series)

10.6.1 Remote IO Points

not used

46

14.4.2015

Page 47

AS-i CC-Link Gateway

Data transmission modes

10.6.2 Buffer Memory Area

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWrm0 AS-i 1: Inp. Slv3 AS-i 1: Inp. Slv2 AS-i 1: Inp. Slv1 Flags

RWrm1 AS-i 1: Inp. Slv7 AS-i 1: Inp. Slv6 AS-i 1: Inp. Slv5 AS-i 1: Inp. Slv4

RWrm2 AS-i 1: Inp.

Slv11

RWrm3 AS-i 1: Inp.

Slv15

RWrm4 AS-i 1: Inp.

Slv19

RWrm5 AS-i 1: Inp.

Slv23

RWrm6 AS-i 1: Inp.

Slv27

RWrm7 AS-i 1: Inp.

Slv31

RWrm8 EC-Flags

RWrm9 reserved

RWrm10 LDS Slave 15

… 12

RWrm11 LDS Slave 31

… 28

RWrm12 LAS Slave 15

… 12

RWrm13 LAS Slave 31

… 28

RWrm14 LPS

Slave 15 … 12

RWrm15 LPS

Slave 31 … 28

AS-i 1: Inp.

Slv10

AS-i 1: Inp.

Slv14

AS-i 1: Inp.

Slv18

AS-i 1: Inp.

Slv22

AS-i 1: Inp.

Slv26

AS-i 1: Inp.

Slv30

LDS Slave 11

… 8

LDS Slave 27

… 24

LAS Slave 11

… 8

LAS Slave 27

… 24

LPS

Slave 11 … 8

LPS

Slave 27 … 24

AS-i 1: Inp. Slv9 AS-i 1: Inp. Slv8

AS-i 1: Inp.

Slv13

AS-i 1: Inp.

Slv17

AS-i 1: Inp.

Slv21

AS-i 1: Inp.

Slv25

AS-i 1: Inp.

Slv29

AS-i 1: Inp.

Slv12

AS-i 1: Inp.

Slv16

AS-i 1: Inp.

Slv20

AS-i 1: Inp.

Slv24

AS-i 1: Inp.

Slv28

LDS Slave 7 … 4LDS Slave 3 …

0

LDS Slave 23

… 20

LDS Slave 19

… 16

LAS Slave 7 … 4LAS Slave 3 …

0

LAS Slave 23

… 20

LPS

Slave 7 … 4

LPS

Slave 23 … 20

LAS Slave 19

… 16

LPS

Slave 3 … 0

LPS

Slave 19 … 16

Tab. 10-32. Buffer Memory (Read)

Bit Name

0 0: No Config Error

1 0: AS-i Power OK

2 0. Normal Operation active

3 0: Protected Mode active

Tab. 10-33. Bits in Flags

14.4.2015

47

Page 48

AS-i CC-Link Gateway

Data transmission modes

Bit Short Name Name

0 Cfg. Err Configuration Error

1 S0 Slave Address 0 detected

2 Aaasn Auto Address Assign

3 Aaavail Auto Address Available

4 CM Configuration Mode active

5 !NA Normal Operation not active

6 APF AS-i Power fail (AS-i Voltage below 19V)

7 Offl Offline

8 NPF No Peripheral Fault

9 … 15 reserved

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWwm0 AS-i 1: Outp.

Slv3

RWwm1 AS-i 1: Outp.

Slv7

RWwm2 AS-i 1: Outp.

Slv11

RWwm3 AS-i 1: Outp.

Slv15

RWwm4 AS-i 1: Outp.

Slv19

RWwm5 AS-i 1: Outp.

Slv23

RWwm6 AS-i 1: Outp.

Slv27

RWwm7 AS-i 1: Outp.

Slv31

RWwm8 reserved

RWwm9 reserved

RWwm10 reserved

RWwm11 reserved

RWwm12 reserved

RWwm13 reserved

RWwm14 reserved

RWwm15 reserved

AS-i 1: Outp.

Slv2

AS-i 1: Outp.

Slv6

AS-i 1: Outp.

Slv10

AS-i 1: Outp.

Slv14

AS-i 1: Outp.

Slv18

AS-i 1: Outp.

Slv22

AS-i 1: Outp.

Slv26

AS-i 1: Outp.

Slv30

AS-i 1: Outp.

Slv1

AS-i 1: Outp.

Slv5

AS-i 1: Outp.

Slv9

AS-i 1: Outp.

Slv13

AS-i 1: Outp.

Slv17

AS-i 1: Outp.

Slv21

AS-i 1: Outp.

Slv25

AS-i 1: Outp.

Slv29

Tab. 10-35. Buffer Memory (Write)

Tab. 10-34. EC-Flags

Flags

AS-i 1: Outp.

Slv4

AS-i 1: Outp.

Slv8

AS-i 1: Outp.

Slv12

AS-i 1: Outp.

Slv16

AS-i 1: Outp.

Slv20

AS-i 1: Outp.

Slv24

AS-i 1: Outp.

Slv28

14.4.2015

48

Page 49

AS-i CC-Link Gateway

Data transmission modes

10.7 Compatibility Mode for HK-ASICC

To ease the migration of existing Applications with HK-ASICC a Mode with compatible IO-Data mapping is integrated.

In this mode, 2 stations are occupied using a single cycle setting (CC-Link V1).

No "Message Transmission" is supported.

Not all functions of HK-ASICC are implemented

• No Status Command Area

AS-i input/output area is supported in compatibility mode.

10.7.1 Remote IO Points

not used

14.4.2015

49

Page 50

AS-i CC-Link Gateway

Data transmission modes

10.7.2 Buffer Memory Area

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWrm0 AS-i 1: Inp. Slv3 AS-i 1: Inp. Slv2 AS-i 1: Inp. Slv1 reserved

RWrm1 AS-i 1: Inp. Slv7 AS-i 1: Inp. Slv6 AS-i 1: Inp. Slv5 AS-i 1: Inp. Slv4

RWrm2 AS-i 1: Inp.

Slv11

RWrm3 AS-i 1: Inp.

Slv15

RWrm4 AS-i 1: Inp.

Slv19

RWrm5 AS-i 1: Inp.

Slv23

RWrm6 AS-i 1: Inp.

Slv27

RWrm7 AS-i 1: Inp.

Slv31

Address Bit 15 … 12 Bit 11 … 8 Bit 7 … 4 Bit 3 … 0

RWwm0 AS-i 1: Outp.

Slv3

RWwm1 AS-i 1: Outp.

Slv7

RWwm2 AS-i 1: Outp.

Slv11

RWwm3 AS-i 1: Outp.

Slv15

RWwm4 AS-i 1: Outp.

Slv19

RWwm5 AS-i 1: Outp.

Slv23

RWwm6 AS-i 1: Outp.

Slv27

RWwm7 AS-i 1: Outp.

Slv31

AS-i 1: Inp.

Slv10

AS-i 1: Inp.

Slv14

AS-i 1: Inp.

Slv18

AS-i 1: Inp.

Slv22

AS-i 1: Inp.

Slv26

AS-i 1: Inp.

Slv30

AS-i 1: Outp.

Slv2

AS-i 1: Outp.

Slv6

AS-i 1: Outp.

Slv10

AS-i 1: Outp.

Slv14

AS-i 1: Outp.

Slv18

AS-i 1: Outp.

Slv22

AS-i 1: Outp.

Slv26

AS-i 1: Outp.

Slv30

AS-i 1: Inp. Slv9 AS-i 1: Inp. Slv8

AS-i 1: Inp.

Slv13

AS-i 1: Inp.

Slv17

AS-i 1: Inp.

Slv21

AS-i 1: Inp.

Slv25

AS-i 1: Inp.

Slv29

AS-i 1: Outp.

AS-i 1: Inp.

Slv12

AS-i 1: Inp.

Slv16

AS-i 1: Inp.

Slv20

AS-i 1: Inp.

Slv24

AS-i 1: Inp.

Slv28

Tab. 10-36. Buffer Memory (Read)

reserved

Slv1

AS-i 1: Outp.

Slv5

AS-i 1: Outp.

Slv9

AS-i 1: Outp.

Slv13

AS-i 1: Outp.

Slv17

AS-i 1: Outp.

Slv21

AS-i 1: Outp.

Slv25

AS-i 1: Outp.

Slv29

AS-i 1: Outp.

Slv4

AS-i 1: Outp.

Slv8

AS-i 1: Outp.

Slv12

AS-i 1: Outp.

Slv16

AS-i 1: Outp.

Slv20

AS-i 1: Outp.

Slv24

AS-i 1: Outp.

Slv28

Tab. 10-37. Buffer Memory (Write)

50

14.4.2015

Page 51

AS-i CC-Link Gateway

Advanced Diagnostics for AS-i Masters

11. Advanced Diagnostics for AS-i Masters

The advanced AS-i diagnostics is intended to localize occasionally occurring configuration errors and to determine the quality of data transmission on AS-i without

using additional diagnostics tools.

AS-i Control Tools, a MS-Windows software designed to simplify AS-i installation

and used to program AS-i Control, enables operation of the advanced diagnostics

functions (LCS, error counters, and LOS).

11.1 List of corrupted AS-i Slaves (LCS)

The LCS contains the information from the list of slaves with configuration error

(Delta list). In addition to the list of configured slaves (LPS), the list of detected

slaves (LDS), and the list of activated slaves (LAS), the AS-i master creates a

fourth list, the list of corrupted slaves (LCS) containing advanced diagnostics

data used to diagnose the causes for intermittently occurring configuration errors

on AS-i. This list contains entries for all AS-i slaves that were responsible for at

least one intermittent configuration error since the list was last read or since the

AS-i master was turned on. Furthermore, intermittent AS-i power failures are listed in the LCS at the position of AS-i slave with address ’0’.

Information!

Whenever the LCS is read it is deleted from memory.

Information!

The last intermittent configuration error can also be displayed on the AS-i master:

Pressing the "Set" button on the AS-i master initiates the display of the AS-i slave

responsible for the last intermittent configuration error. If a intermittent AS-i power failure occurred, the display shows 39 after pressing the "Set" button.

This function is only available if the device is in normal operating mode of the protected

mode (display empty) or in the off-line phase (Display: "40").

11.2 Protocol analysis: Counters for corrupted data telegrams

The AS-i master with advanced diagnostics provides a counter for telegram repetitions for each AS-i slave. The counter counts up every time a corrupted data telegram has been found, making it possible to determine the quality of the transmission if only a few telegrams are corrupt and the AS-i slave never caused a

configuration error.

Information!

The counter values are read via the host interface and will be deleted after they were

read.

Displaying the protocol analysis is possible through the AS-i Control Tools software by using the command "Master | AS-i Diagnostics".

14.4.2015

51

Page 52

AS-i CC-Link Gateway

Advanced Diagnostics for AS-i Masters

11.3 Clear the diagnostic buffer

The diagnostic buffer in the device can only be deleted when there is no field bus

connection to the higher-level controller. If in an existing bus connection yet the

'clear diagnostic buffer' is pressed, the diagnosis can only be deleted in the web

interface and not on the device.

11.4 Offline Phase for Configuration Errors

The AS-i masters with advanced diagnostics offer the possibility to set themselves into the offline phase when a configuration error occurs and thus are able

to transition the AS-i network into a safe operational state. This ensures a quick

reaction to a configuration error and the host can be relieved from this task. If any

problems occur on the AS-i network, the AS-i masters can independently switch

the AS-interface into a safe state.

There are two different ways to parameterize the AS-i master for this feature:

• Any configuration error occurring on AS-i switches the master from regular

operation in protected mode into the offline phase.

• o . A list with the addresses of slaves that can potential initiate the off-line

phase is defined (list of offline slaves LOS).

The user can decide how the system should react to a configuration error on

AS-i. Thus, the AS-i master can be set to the offline phase for critical AS-i slaves,

whereas for less critical slaves only the error message is sent to the host, but ASi is still running.

Like the advanced diagnostics, the parameterization "offline phase on configuration error" is also supported by "AS-i-Control-Tools"

(Command | Characteristics | Offline because of configuration error).

There are two options to reset the error message "OFFLINE BY LOS:

1. Deleting the complete LOS list on the affected AS-i network ("CLEAR ALL").

2. Power reset on the affected AS-i network.

11.5 Functions of the AS-i Fault Detector

11.5.1 Earth/Ground Fault Detector

An Earth/Ground Fault exists when the voltage

U

GND

=0,5 U

10% U

.) is outside of the following range:

AS-i

U

GND

90%U

AS-i

This error substantially limits the noise immunity of the AS-i communication.

Ground faults are indicated on the master´s display as well as in AS-i Control

Tools.

Information!

To recognize ground faults the master must be grounded with its machine ground connection.

52

AS-i

U

(Nominal value of

GND

14.4.2015

Page 53

AS-i CC-Link Gateway

Advanced Diagnostics for AS-i Masters

11.5.2 Noise Detector

The noise detector detects AC voltages on AS-i, that are not initiated by an AS-i

master or AS-i slaves. These interference voltages can cause telegram disturbances.

A frequent cause are insufficiently shielded frequency inverters or improperly

routed cables.

Noises is indicated on the master´s display as well as in AS-i Control Tools.

11.5.3 Over-voltage Detector

Over-voltages are present if the conductors of an AS-i network that normally are

routed electrically symmetrical with respect to machine ground, are strongly electrically raised. A cause can for example be startup procedures of large consumers.

However, over-voltages do generally not interfere with the AS-i communication,

but can under certain circumstances cause incorrect sensor signals.

Over-voltages are indicated on the master´s display as well as in the AS-i Control

Tools.

14.4.2015

53

Page 54

AS-i CC-Link Gateway

Advanced Diagnostics for AS-i Masters

11.6 Substitute values

SAFE SUBST VAL (Substitute values for input data from safe slaves)

…

1.12A

Quick Setup

Diagnosis

Slave Adr Tool

…

Safety Slaves

Safe Subst Val

Ext Monitor

…

Safe Subst Val

Substitute

Change

54

No Substitute

This function enables activation/deactivation of the code substitute function for

safe slaves.

The status can be changed by selecting Change.

SUBSTITUTE (values)

The safety code sequences are replaced by the following values:

Both channels are in the safe state: 0000bin

Channel 1 is in the safe state: 0011bin

Channel 2 is in the safe state: 1100bin

No channel is in the safe state: 1111bin

NO SUBSTITUTE

The safety code sequences are transmitted via the input data.

14.4.2015

Page 55

AS-i CC-Link Gateway

BFM used for I/O data

(RY4 = 0)

Disable BFM

(set RY5 = 1)

Wait for BFM disable

acknowledge (RX5 = 1)

Switch to mailbox mode

(set RY4 = 1)

Wait for mailbox mode

acknowledge (RX4 = 1)

Write command interface request data

(including command and changed

toggle bit) to RWw area

1

Enable BFM

(set RY5 = 0)

Wait for BFM enable

acknowledge (RX5 = 0)

Accessing command interface

12. Accessing command interface

12.1 Using BFM

This example shows one method to access command interface when it is

mapped into the cyclic Buffer Memory Area (when using VBG-CCL-G4F mode or

CC-Link V1 mode):

14.4.2015

55

Page 56

AS-i CC-Link Gateway

Wait for response data in RWr

area (indicated by response toggle

bit and mirrored command)

Read command interface result and

response from RWr area

Disable BFM

(set RY5 = 1)

Wait for BFM disable

acknowledge (RX5 = 1)

Switch to I/O data mode

(set RY4 = 0)

Wait for I/O data mode

acknowledge (RX4 = 0)

Write new output data to RWw area

Enable BFM

(set RY5 = 0)

Wait for BFM enable

acknowledge (RX5 = 0)

Accessing command interface

56

14.4.2015

Page 57

AS-i CC-Link Gateway

Accessing command interface