Page 1

Brief Instructions

ENG

Adapters, Metal

AD.*

Pepperl-Fuchs GmbH

Lilienthalstrasse 200

69307 Mannheim, Germany

Tel. +49 621 776-0

Fax +49 621 776-1000

Copyright Pepperl+Fuchs

www.pepperl-fuchs.com

Validity

Specifi c processes and instructions in this instruction manual require special

provisions to guarantee the safety of the operating personnel.

Tar get Group, P erson nel

Responsibility for planning, assembly, commissioning, operation,

maintenance, and dismounting lies with the plant operator.

The personnel must be appropriately trained and qualifi ed in order to carry

out mounting, installation, commissioning, operation, maintenance, and

dismounting of the device. The trained and qualifi ed personnel must have

read and understood the instruction manual.

Reference to Further Documentation

Observe laws, standards, and directives applicable to the intended use

and the operating location. Observe Directive 1999/92/EC in relation to

hazardous areas.

The corresponding datasheets, manuals, declarations of conformity, ECtype-examination certifi cates, certifi cates, and control drawings if applicable

support this document. You can fi nd this information under www.pepperl-

fuchs.com.

Intended Use

The metal adapters type AD.* are suitable to adjust diff erent thread types and

sizes for connections to enclosures certifi ed according to type of protection

Ex d, Ex e or Ex tb.

Remarks on Assembly

For non-threaded enclosures it is recommended to use fl at washer gaskets

(e.g. fi ber washer of Klingersil type C-4400 or similar, or chloroprene or

silicone washer gaskets) between screw-in component and the enclosure.

For threaded enclosures both fi ber washers or O-rings can be used.

Metric metal screw-in components when supplied as individual packaging

units are equipped with washer gasket and O-ring. Variants for ambient

temperatures below -50 °C are available. Please refer to the individual

datasheets for details.

Mounting and Installation

Observe the installation instructions according to IEC/EN 60079-14.

If you intend to install the device or enclosure in areas that may be exposed

to aggressive substances, ensure that the stated surface materials are

compatible with these substances. If required, contact Pepperl+Fuchs for

further information.

Install the adapter (3) in the entry of the enclosure.

Use washer gasket (1) and O-Ring (2) when appropriate.

Screw the second installation component into the adapter (3).

Tighten all screw threads with the specifi ed torque.

Document No.: DOCT-5516c

Edition: 02/2020

IP Protection Method Mode for Ex d / Ex e

Ex d enclosures and tapered NPT threads:

Assemble through a threaded hole. The enclosure wall has to be thick enough

to engage at least 5 full threads.

Ex d enclosures and metric threads:

Assemble through a threaded hole with O-ring on the thread outside of the

enclosure. The enclosure wall has to be thick enough to engage at least 5 full

threads.

Ex e enclosures and metric threads:

Tighten with locknut inside and fi ber washer gasket on the thread outside of

the enclosure. In case of O-ring it has to be positioned between fi ber washer

and screw head. An enclosure wall thickness of minimum 1.5 mm has to

respected.

Operation, Maintenance, Repair

Observe IEC/EN 60079-17 for maintenance and inspection.

If there is a defect, always replace the device with an original device.

Do not modify or manipulate the device.

Delivery, Transport, Disposal

Disposing of device and packaging must be in compliance with the applicable

laws and guidelines of the respective country.

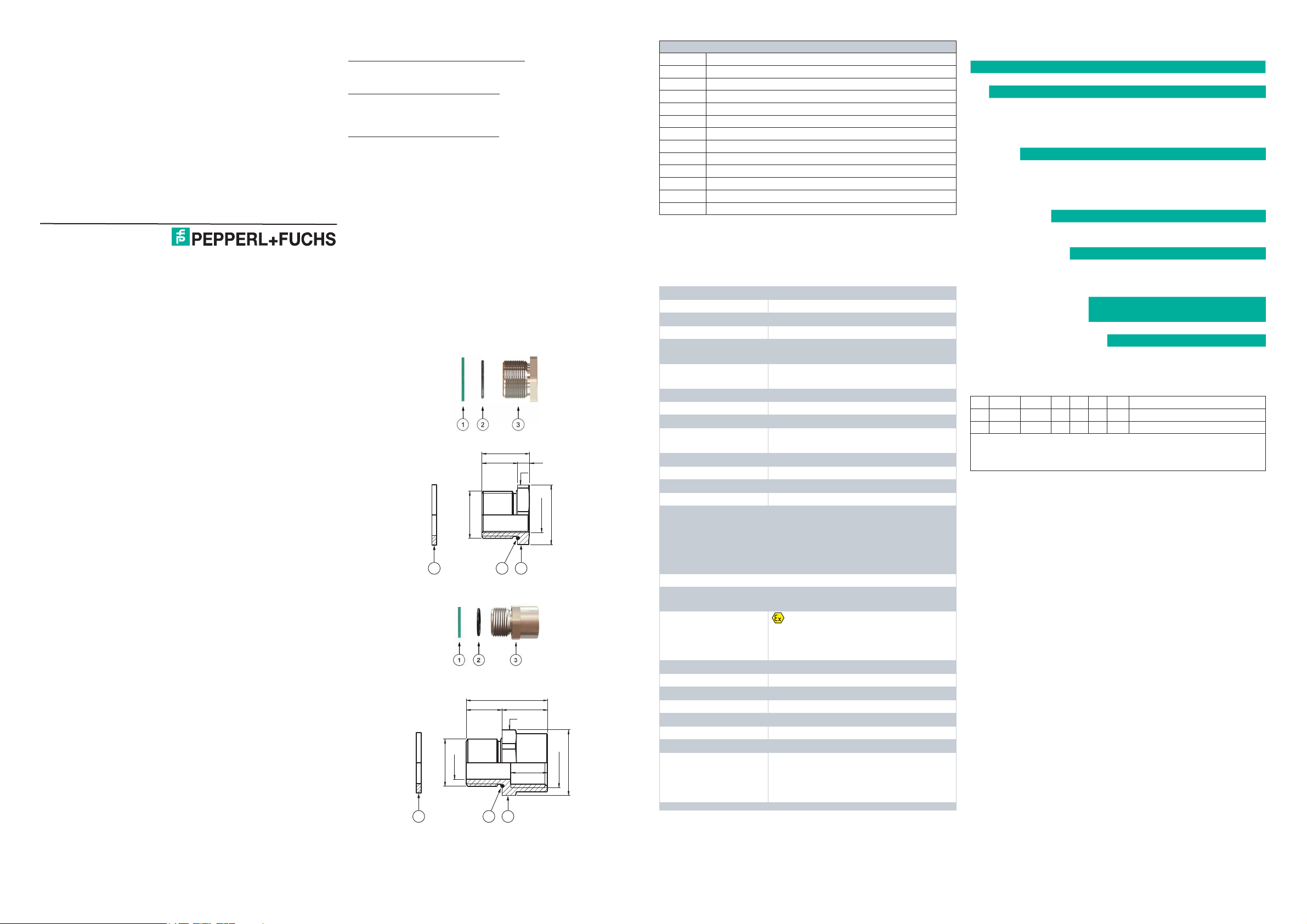

Dimensions and Assembly

TD

1 32

DI

TD

1 32

L

HTL

SW

TF

D2

L

HTL

SW

TF

TLF

D2

Legend - details and values see data table

1 Washer gasket (accessory)

2 O-Ring

3 Adapter

DI Diameter thru-hole

D2 Width across corners

H Length outside enclosure

SW Width across fl ats

TD Thread size

TF Thread size female

TL Thread length

TLF Thread length female

L Total length

Tech nic al S pec ifi cations

General

Types and variants AD* - see type code table

Mechanical specifications

Dimensions see data tables

Thread type

Thread type female

Degree of protection IP66 / IP68

Mass see individual datasheets

Material

Adapter

Finish inherent color silver

O-Ring chloroprene / neoprene or silicone

Washer gasket aramid fibers bonded with NBR

Ambient conditions

Ambient temperature

Data for application in connection with hazardous areas

EU-Type Examination

Certificate

Marking

International approvals

IECEx approval IECEx CES 15.0006X

EAC approval TC RU C-TR.GB05.B.00918

CCOE approval PESO A/P/HQ/KA/104/5579 (P420366)

Conformity

Degree of protection EN 60529

CE marking 0102

Standards

metric ISO pitch 1.5 mm or NPT ANSI ASME

B1.20.1

metric ISO pitch 1.5 mm or NPT ANSI ASME

B1.20.1

brass nickel-plated or AISI 316 (1.4401)

stainless steel

chloroprene O-ring:

-40 ... 100 °C (-40 ... 212 °F)

silicone O-ring: -60 ... 130 °C (-76 ... 266 °F)

washer gasket: -40 ... 80 °C (-40 ... 176 °F)

Service temperature might be limited by the

use of O-rings or washer gaskets.

CESI 15ATEX029X

II 2 GD

Ex db IIC Gb

Ex eb IIC Gb

Ex tb IIIC Db

IEC/EN 60079-0: 2012

IEC/EN 60079-1: 2007

IEC/EN 60079-7: 2007

IEC/EN 60079-31: 2009

Type Code / Model Number

Series

AD adapters

|

Thread, male

| M*

| NPT*

||

|| M*

||NPT*

|| |

|| |BN brass nickel-plated

|| |SS stainless steel

|| ||

|| ||C chloroprene / neoprene

|| ||S silicone

|| ||X no seal

|| |||

|| |||** length in mm

|| ||||

|| ||||

|| ||||K** units quantity per package

AD .xx .xx .xx .x .nn .Knn

AD .M50 .NPT2 .BN .C .18 .K01 Example

Example: Adapter, male thread size M50, female thread size NPT 2", body

brass nickel-plated, O-Ring chloroprene, installation thread length 18 mm,

one piece

male thread metric ISO pitch 1.5; sizes see dimensions data

table

male thread NPT ANSI ASME B1.20.1; sizes see dimensions

data table

Thread, female

male thread metric ISO pitch 1.5; sizes see dimensions

data table

NPT ANSI ASME B1.20.1; sizes see dimensions data

table

Material

Material Seals / O-Ring

Thread length for installation in

enclosure

Packaging unit

units not packaged, for use

in Pepperl+Fuchs Solution

Engineering Centers

Page 2

Variant-Specifi c Data Metric-Metric

Thread Male Thread Female Dimensions [mm]

Type

AD.M20.M16.*.*.15.* M20 15 M16 19 4 19 27.5 25 6

AD.M25.M20.*.*.15.* M25 15 M20 19 4 19 33 30 8.5

AD.M32.M20.*.*.15.* M32 15 M20 19 4 19 39.5 36 9

AD.M32.M25.*.*.15.* M32 15 M25 19 4 19 39.5 36 9

AD.M40.M32.*.*.18.* M40 18 M32 22 4 22 50 45 9.5

AD.M50.M40.*.*.18.* M50 18 M40 23 5 23 61 55 10

AD.M63.M50.*.*.18.* M63 18 M50 23 5 23 77 70 10.5

TD

TL

[mm]

TF

TLF

[mm]

H L D2 SW SW

Nut torques

[Nm]

Variant-Specifi c Data NPT-Metric

TL

Thread

Female

TF

TLF

[mm]

Dimensions [mm]

H L DI D2 SW SW

Thread Male

Type

TD

AD.NPT1/2.M20.*.*.15.* NPT 1/2'' 15 M20 15 19 34 14.5 27.5 25 8

AD.NPT3/4.M20.*.*.15.* NPT 3/4'' 15 M20 19 4 19 - 33 30 9

AD.NPT3/4.M25.*.*.15.* NPT 3/4'' 15 M25 15 19 34 19 33 30 9

AD.NPT3/4.M32.*.*.15.* NPT 3/4'' 15 M32 15 19 34 19 39.5 36 9

AD.NPT1.M32.*.*.15.* NPT 1'' 15 M32 15 19 34 26 39.5 36 11

AD.NPT1.M40.*.*.15.* NPT 1'' 15 M40 18 22 37 26 50 45 11

AD.NPT1-1/4.M40.*.*.18.* NPT 1-1/4'' 18 M40 18 22 40 35 50 45 13

AD.NPT1-1/2.M50.*.*.18.* NPT 1-1/2'' 18 M50 18 22 40 40 61 55 15

AD.NPT2.M75.*.*.18.* NPT 2'' 18 M75 18 22.5 40.5 51 88.5 80 18

[mm]

Nut torques

[Nm]

Variant-Specifi c Data Metric-NPT

Thread Male Thread Female Dimensions [mm]

Type

AD.M20.NPT1/2.*.*.15.* M20 15 NPT 1/2'' 15 19 34 14 27.5 25 6

AD.M20.NPT3/4.*.*.15.* M20 15 NPT 3/4'' 15 19 34 14 33 30 6

AD.M25.NPT1/2.*.*.15.* M25 15 NPT 1/2'' 19 4 19 - 33 30 8.5

AD.M25.NPT3/4.*.*.15.* M25 15 NPT 3/4'' 15 19 34 19 33 30 8.5

AD.M25.NPT1.*.*.15.* M25 15 NPT 1'' 15 19 34 19 39.5 36 8.5

AD.M32.NPT3/4.*.*.15.* M32 15 NPT 3/4'' 19 4 19 - 39.5 36 9

AD.M32.NPT1.*.*.15.* M32 15 NPT 1'' 15 19 34 26 39.5 36 9

AD.M40.NPT1-1/4.*.*.18.* M40 18 NPT 1-1/4'' 18 22 40 34 50 45 9.5

AD.M40.NPT1-1/2.*.*.18.* M40 18 NPT 1-1/2'' 18 22 40 34 61 55 9.5

AD.M50.NPT1-1/2.*.*.18.* M50 18 NPT 1-1/2'' 18 22 40 40 61 55 10

AD.M50.NPT2.*.*.18.* M50 18 NPT 2'' 18 22.5 40.5 44 72 65 10

AD.M63.NPT2.*.*.18.* M63 18 NPT 2'' 18 22.5 40.5 51 75 68 10.5

TD

TL

[mm]

TF

TLF

[mm]

H L DI D2 SW SW

Nut torques

[Nm]

Loading...

Loading...