Page 1

ISO9001

MANUAL

Trip Amplifier

2/209

PROCESS AUTOMATION

Page 2

Trip Amplifier 2/209

EN

Table of contents

1 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5 Safety applications/certificates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

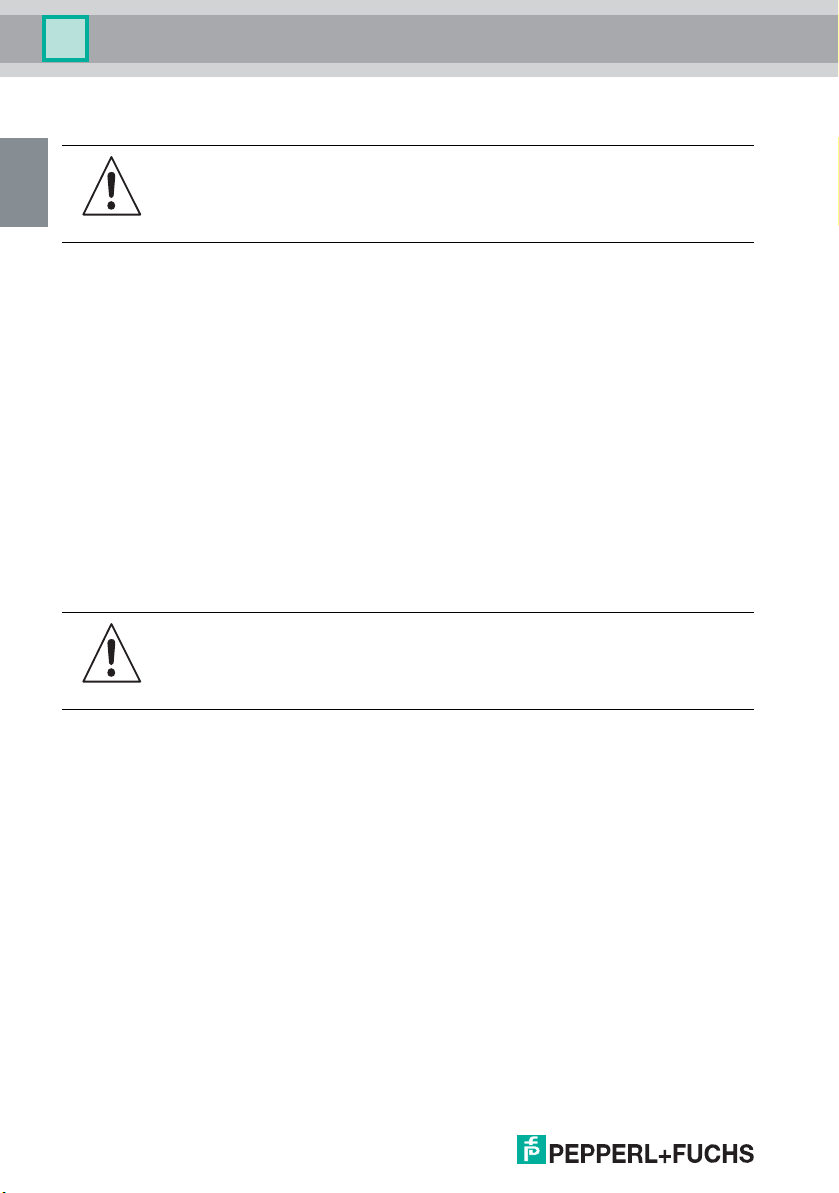

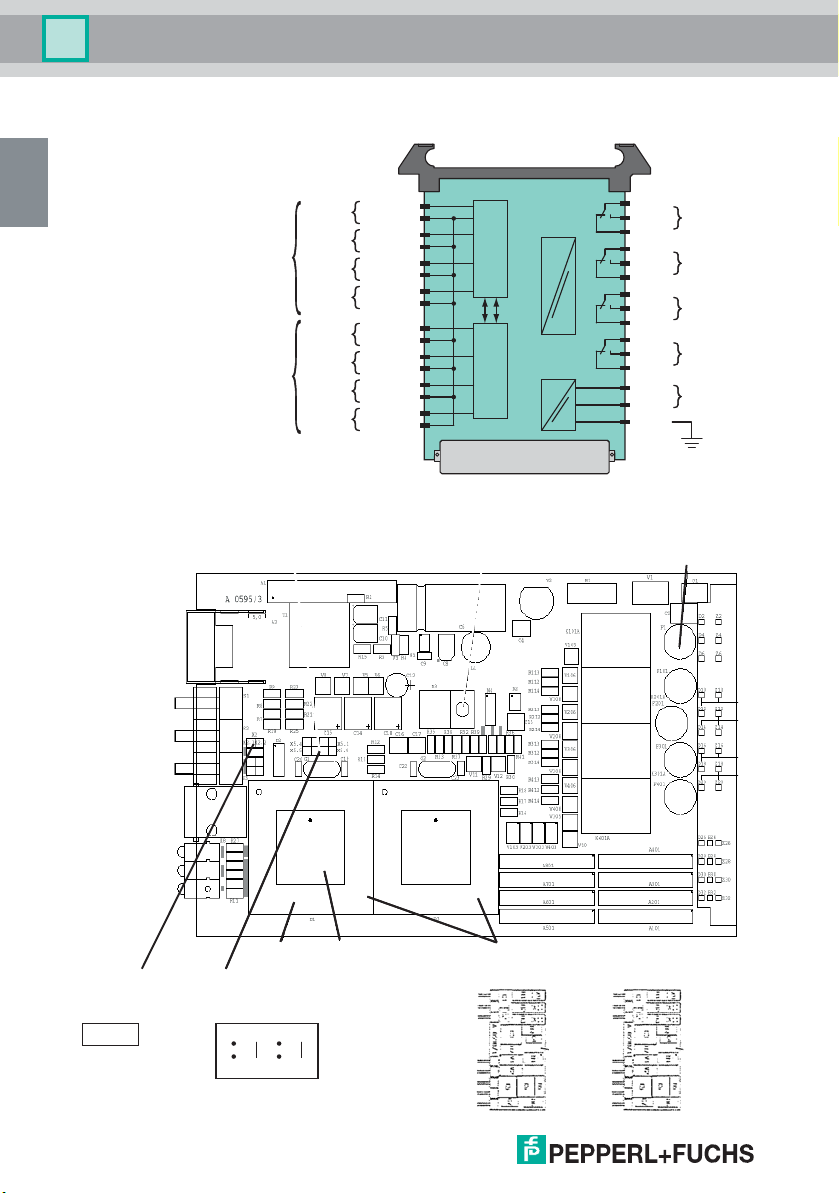

2.6 Front view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.7 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.8 Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.9 Device layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.10 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.11 Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

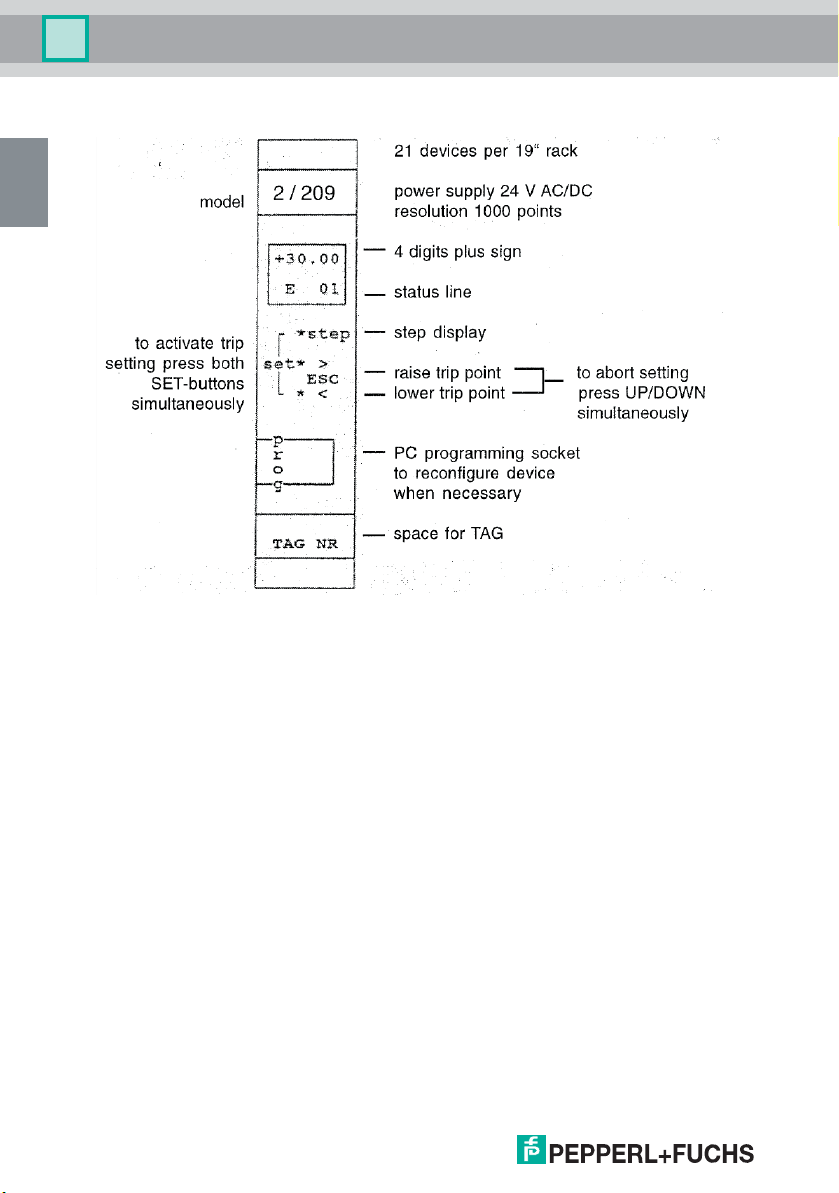

2.12 Front control elements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Mounting instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Cabinet design and heat dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.4 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.5 Functional test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.6 Changing current inputs/voltage inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.8 Service instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4 Software description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2 Numerical parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3 System parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.4 Programming example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.5 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.6 Installation of the PC program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

DOCT-1946C 2018-07 322903

1

Page 3

Trip Amplifier 2/209

EN

Table of contents

5 Handling without a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6 Handling with a PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.1 Action 1 – Preparing the hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.2 Action 2 – Preparing the software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.3 Action 3 – Preparing a back-up copy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.4 Action 4 – How to edit standard programs . . . . . . . . . . . . . . . . . . . . . . . . . . .41

6.5 Action 5 – How to save and send programs. . . . . . . . . . . . . . . . . . . . . . . . . 41

6.6 Action 6 – How to check edited programs . . . . . . . . . . . . . . . . . . . . . . . . . . .42

6.7 Action 7 - How to edit a program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.8 Action 8 - Ending a job. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7 Fault finding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8 Test programs using the EMULATOR . . . . . . . . . . . . . . . 43

9 Safety concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.1 CE marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.2 Safety related parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

DOCT-1946C 2018-07 322903

2

Page 4

Trip Amplifier 2/209

EN

Attention

Attention

Safety information

1Safety information

Target group: experiences skilled electricians.

The trip amplifier must not be converted or altered in any way.

Device must be mounted outside hazardous areas.

When working on the trip amplifier always comply with national safety and accident

prevention regulations and the safety information contained in this manual. Safety

information is printed in italics like this paragraph and marked accordingly.

Screened cables are recommended for all wiring which leaves the building.

According to IEC 801-5 application class 0 analog inputs must not be subjected to high

energy pulses. In all other respects the unit fulfils IEC 801 to the more stringent

applications class 3.

Redundant analog inputs A and B should be fed from separate sources. The signals

must not differ by more than 5 % since the sister channels are continuously compared

with each other.

In safety applications front push buttons should not be incorporated in those parts of the

program which are relevant to safety. Trip settings should not be changed during

operation. Front push buttons can be locked by placing the jumper KEY in the LOCK

position. The push buttons will then only be used to read values sequentially rather than

alter them (protection against unauthorized changes).

Programs for safety applications should try and avoid conditional branches because this

would simplify the final approval test considerably. This could then be restricted to a

functional test concentrating on the reaction of outputs to input changes.

For safety applications relay outputs must be configured to be normally energized. After

a power down the device will restart automatically. For safety applications it is therefore

necessary to establish suitable external means to resume production in an orderly

fashion.

The serial data link is not a safety related part of the circuitry.

DOCT-1946C 2018-07 322903

3

Page 5

Trip Amplifier 2/209

EN

Technical data

2 Technical data

2.1 Features

• 4-channel isolated barrier

• Input 0/4 mA ... 20 mA

• 4 relay contact outputs

•Programmable

• Simple operation via front buttons

• Lead monitoring

• Galvanic isolation between input, power supply and contact output

• With computational function SIL3

•LCD display

• Self-monitoring

2.2 Technical data

General specifications

Signal type analog input

Supply

Connection z2+, z4-, z6 (PE)

Rated voltage 18 ... 30 V DC, 18 ... 26.4 V AC 48 ... 62 Hz

Power consumption 2 W/2.5 VA

Input

Connection Input A I: d32+, z32-

Input resistance 50 (mA)

Current range 0/4 ... 20 mA (0/1 ... 5 V)

Input A II: d30+, z30Input A III: d28+, z28Input A IV: d26+, z26Input B I: b32+, z32Input B II:b30+, z30Input B III: b28+, z28Input B IV: b26+, z26-

10 k (V)

DOCT-1946C 2018-07 322903

4

Page 6

Trip Amplifier 2/209

EN

Technical data

Output

Connection Output I: z10, d12, d10

Output II: d14, z14, z12

Output III: z16, d18, d16

Output IV: d20, z20, z18

Relay

Switching voltage 50 V

Switching current 2 A AC/DC

Switch power 500 VA/60 W

Mechanical life 50 mio. cycles

Electrical lifetime 0.5 mio. cycles

Response time > 20 ms (variable)

Transfer characteristics

Temperature influence < 0.1 %/10 K

Indicators/settings

Display elements LED 1: trip value 1

LED 2: trip value 2

LED 3: trip value 3

LED 4: trip value 4

LED green: Power on

Configuration via RS 485 interface at the front side

Directive conformity

Electromagnetic compatibility

Directive 2004/108/EC EN 61326-1:2006

Conformity

Protection degree IEC 60529

Ambient conditions

Ambient temperature -10 ... 60 °C (14 ... 140 °F)

Storage temperature -25 ... 80 °C (-13 ... 176 °F)

Relative humidity < 75 % (annual mean)

Mechanical specifications

Protection degree IP20

Mass 300 g

Dimensions 22 x 143 x 193 mm (0.9 x 5.6 x 7.6 in)

Construction type Eurocard 100 x 160 mm (3.9 x 6.3 in) acc. to

< 95 % (30 d/year), no moisture condensation

DIN 41494, front panel 4TE, mountable in 19" rack

DOCT-1946C 2018-07 322903

5

Page 7

Trip Amplifier 2/209

EN

Attention

Attention

Technical data

2.3 Mounting

Devices must be mounted outside hazardous areas.

Fits 19" racks or DIN rail enclosures.

2.4 Options

Additional functions basic functions like mathematics and logical

operations are freely configurable.

Configuration via RS 232 serial data link via commercial PCs or

PC-like units such as SIEMENS PG 685, PG 730,

PG770, PG 790 or MS-DOS PC.

Handling Menu support to SAA standard.

Storage Non volatile EEPROM storage.

Function disable via jumpers.

2.5 Safety applications/certificates

SIL classification SIL3, TÜV Rheinland, 968/EL 292-03/08

acc. to IEC 61508

6

Device must be mounted outside hazardous areas.

DOCT-1946C 2018-07 322903

Page 8

Trip Amplifier 2/209

EN

2/209

ESC

STEP

4

3

2

1

SET

5

P

R

O

G

R

A

M

Front view

LED green:

Power supply

LED red:

Limit value

LC display

Technical data

2.6 Front view

2.7 Dimensions

DOCT-1946C 2018-07 322903

17.5 175.5

160

100

143

22

7

Page 9

Trip Amplifier 2/209

EN

2/209

z 10

d 12

d 10

d 26+

z 26-

d 28+

z 28-

d 30+

z 30-

d 32+

z 32-

b 26+

z 26-

b 28+

z 28-

b 30+

z 30-

b 32+

z 32-

z 2+

z 4z 6

24 V

IV

III

II

I

IV

A

B

III

II

I

IV

III

II

I

d 14

z 14

z 12

z 16

d 18

d 16

d 20

z 20

z 18

45312

62718

A B

(A) and (B)

input modules with

jumper J

5 V, 10 V,

20 mA

RS 232 C

K1

K2

K3

display

Test X2

X5 - KEY, MODE

jumpers

X2 - TEST

jumpers

line fuse

mP socket space for label processors A + B

push buttons

jumper J

20 mA

5 V

10 V

jumper J

20 mA

5 V

10 V

Technical data

2.8 Connection

2.9 Device layout

8

DOCT-1946C 2018-07 322903

Page 10

Trip Amplifier 2/209

EN

Technical data

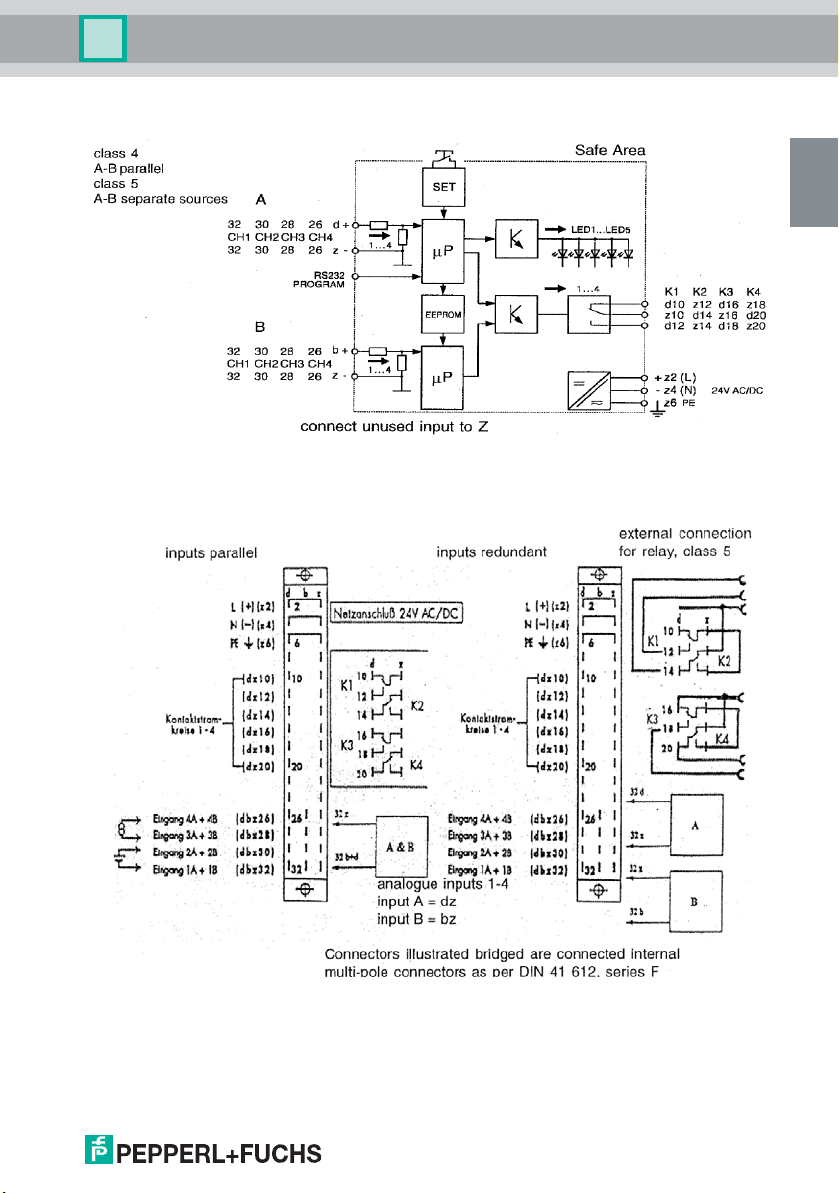

2.10 Block diagram

2.11 Connection diagram

DOCT-1946C 2018-07 322903

9

Page 11

Trip Amplifier 2/209

EN

Technical data

2.12 Front control elements

DOCT-1946C 2018-07 322903

10

Page 12

Trip Amplifier 2/209

EN

Attention

Hardware description

3 Hardware description

3.1 Mounting instructions

Devices must be mounted outside hazardous areas.

The devices are manufactured as narrow plug-in units for 19" racks. The exact

dimensions can be taken from the section "Technical data".

The racks should be mounted in easily accessible positions on walls, in panels, in

cabinets or protective enclosures so that the front panels of the devices take on a vertical

position. The mounting position should be dry and dust-free. Heavy vibrations,

mechanical stress, and strong heat sources are unacceptable. Maximum ambient

conditions must be observed.

The units are EMC-RFI tested to IEC 801.2-5 plus NAMUR AK EMV. Despite their

excellent RFI immunity, the mounting position should not be in the immediate vicinity of

strong electromagnetic fields and be low on RFI. To avoid radio frequency interference

shielded racks and screened cables are recommended. Please observe installation

code of practice. For advice on EMC - RFI see application notes EAN 1610. For best

EMC performance make sure to earth the assigned connector pin.

The units are pushed into the racks fitted with guide rails and female connectors until the

front panels are flush with the front frame of the rack. The units are then connected to the

external wiring via the female connectors. Screw or snap-in fasteners secure the units

against unintentional removal from the rack.

The following mounting recommendations should be observed. A maximum of

21 devices can be fitted in a rack. Power dissipation can be taken form the section

"Technical data". In order to disperse the heat sufficiently the racks should be mounted

in such a way as to ensure best ventilation. The following advice may be useful:

1. It is recommended in particular that permanent overvoltages should be avoided.

2. In particularly adverse operating conditions check the ambient temperature in the

vicinity of the devices (approx. 1 cm away from the front panels). The temperature

should not exceed 60 °C under worst case conditions.

3. Normally natural convection is sufficient for 19" racks in open frames. It has to be

noted however that the topmost rack should not be covered over unless by a cover

plate with sufficient air vents to avoid heat build-up.

DOCT-1946C 2018-07 322903

11

Page 13

Trip Amplifier 2/209

EN

V

Z = –––

G

Z = number of devices per cabinet

V = permissible power dissipation

G = power per device

Attention

Hardware description

3.2 Cabinet design and heat dissipation

Electronic devices will dissipate some of the energy applied to them in the form of heat.

The resulting cabinet temperature must not impair the device function. Therefore the

cabinets should be designed not to exceed the maximum permissible ambient

temperatures as given in the section "Technical data". The following table is based on

an over-temperature of 25 K.

The devices have been designed for 60 °C ambient. Further assuming that the control

room temperature does not exceed 40 °C, the permissible power dissipation in the

cabinet can be given as follows:

1. unforced draught convection 400 W

2. draught convection using vents and filters 800 W

3. draught convection using vents without filters 1600 W

4. unforced natural convection 160 W

5. forced convection ventilators per rack 320 W

6. forced convection using heat exchangers plus forced convection inside and out

1500 W

The number of devices per cabinet can then be computed as follows:

For mixed installations the individual power dissipation of devices can be used to

compute the total power loss to compare with the permissible values.

12

3.3 Connections

For all device types the rules and regulations for the installation of electrical equipment

and wiring (e. g. VDE 0100) of the user country must be observed.

Power and measuring cables have to be kept separate.

Devices are electrically connected using a male and female connector to DIN 41612,

type F. Connections see section "Technical data". The male connector is mounted on

the printed circuit board while the female connector is fitted at the back of the rack.

External connections are normally soldered to the connectors. The solder points are

covered by a heat shrunk sheath e. g. Drakavita Ray Quality H, manufacturer: Deutsche

Schrumpfschlauch Gesellschaft. Other wiring techniques are also acceptable (wirewrap, termipoint, crimp snap-in etc.).

DOCT-1946C 2018-07 322903

Page 14

Trip Amplifier 2/209

EN

4 digits plus sign, status line with one alpha

character plus 2 numerals

nn

T

Hardware description

3.4 Commissioning

The following checks are recommended prior to start-up.

1. Output relay: observe the voltage and current ratings of the relay or electronic

output.

2. Input

– Ensure that the measuring circuit is not subjected to overvoltages.

– Check the input connections and the corresponding jumper setting if the factory

setting is not required.

– For multiple analog inputs check that galvanic isolation is used where

appropriate (e. g. if several signals are also transmitted to another multiple input

device).

3. Power supply: check the supply voltage (see section "Technical data")

Most device settings will be carried out in Software. Check the setting using the

parameter list. This can be addressed via the PC menu

Example

PC menu (details see disk)

Place jumper X5 in position 4–5 for programming.

Connect the device to COM1 or COM2 RS 232 seria l dat a lin ks on your PC. Set your PC

MENU to COM1 or COM2 accordingly via <ALT><C>.

Use the command <ALT><U> to read all data from the device and then printing it

(1 A4 page)

1. LOAD DATA from the device (<ALT><L>).

2. Check constants (<F4> ... <ESC>).

3. Check the program (<F5> ... <ESC>).

Before attempting any changes the old parameters should be stored on disk using

<ALT><W> (see PC HELP TEXT). After effecting the changes these must be stored in

the device using <ALT><S>. Again a back-up copy on disk or WINCHESTER under a

suitable file name is recommended.

After these checks the unit can be plugged into its rack position. Devices are calibrated

ex works. Recalibration is therefore not normally required (see section "Calibration").

A simple functional test can be carried out as for conventional trip amplifiers by

connecting input signal sources to check the relays trip at the setpoint.

DOCT-1946C 2018-07 322903

13

Page 15

Trip Amplifier 2/209

EN

X5

X2

453

12

627

1

8

Hardware description

3.5 Functional test

3.5.1 General

The device will be calibrated ex works following the specifications given with orders. The

unit is operational and approximately 0.2 % accurate as soon as the power is turned on.

It has to be noted however that best performance is only achieved once temperature

balance is reached between the device and its ambient conditions. A device taken from

stock inserted in a warm rack may therefore take 1 ... 2 hours before it reaches its full

accuracy given that the ambient temperature is stable and within the boundaries

mentioned in the section "Technical data".

Factory calibration is carried out at 20 °C ... 25 °C after a 72 hour soak test. Due to the

excellent long term stability of the device no regular maintenance is needed. An annual

check of zero and span is regarded as being sufficient. The PCB carries a row of

jumpers:

Standard setting for row of jumpers X2, X5:

•MODE: X5

–jumper 4–5 PROGRAM

programming mode (program execution stops)

–jumper 3–6 RUN

run mode (device cannot be programmed)

•KEY: X5

– jumper 2–7 KEY LOCK

disable front push button changes

– jumper 1–8 KEY UNLOCK

enable front push button changes

•TEST: X2

–jumper 1–2 TEST

if this jumper is set during the programming mode X5 4–5 testing is enabled.

Device calibration is only possible in this mode of operation.

MODE jumper 4–5 is required for testing. The unit goes offline.

MODE jumper 3–6 for normal operation.

14

DOCT-1946C 2018-07 322903

Page 16

Trip Amplifier 2/209

EN

Hardware description

3.5.2 Testing analog inputs

Analog inputs are tested via the LCD-Display in the front of the device. Download a

program into the device which enables tests of analog inputs (e. g. program TESTE.EDT

in the DEMO directory). The program TESTE.EDT will allow you to display analog inputs

E01 ... E04 in percentage values in the display. Use the push button marked "STEP" to

advance the display to the next input.

The device connections are explained in the data sheet. Inputs A and B have to have the

same input signals applied to them because the program carries out a continuous cross

check between the two for safety reasons.

Use precision signal sources to apply to the inputs. Display readings will be in

engineering units or percentage values depending on the device software.

Use also PC MENUE "TERMINAL EMULATORS". There are the following parameter:

• P711 = input 1

• P712 = input 2

• P713 = input 3

• P714 = input 4

3.5.3 Testing push buttons

Front push buttons are used to set alarm points and to step the display to show

measured values, trip points or computed values. In safety applications changes via

push buttons are sometimes not permitted. Values may then only be read via push

button access.

Download a program into the device which allows several values to be displayed under

push button control (e. g. program TESTE.EDT in the DEMO directory). The program

TESTE.EDT will allow you to display analog inputs E01 ... E04 in percentage values in

the display. Use the push button marked "STEP" to advance the display to the next input.

Setpoints can be altered after placing jumper "KEY" in position 1–8. Press the upper and

lower push buttons "SET" simultaneously. The display will start to flash. Adjust trip points

by using the UP ">" and DOWN "<" push buttons. Store the setting by using the "STEP"

button. Return to normal operation by pressing the two lower push buttons "<" and ">"

simultaneously (ESC). The flashing stops. All three push buttons have now been tested.

Download your operating program and replace the jumpers as shown in

section "Functional test – Generals".

DOCT-1946C 2018-07 322903

15

Page 17

Trip Amplifier 2/209

EN

Hardware description

3.5.4 Testing relay outputs

Relay outputs are used to generate alarms or to identify trip conditions. Download a

program into the device which allows setpoints to be checked by applying input signals

(e. g. program TESTE.EDT in the DEMO directory).

The program offers two lower trips at 20 % and at 40 % plus two high trips at 60 % and

at 80 % with a deadband (hysteresis) of 1 % (pulse stream normally active). A red LED

is assigned to each output to light up on alarm.

After finalizing the output test download your operating program and replace the jumpers

as shown in section "Functional test – Generals".

3.5.5 Testing LEDs

Front LEDs are used to indicate the relay status (red). A green LED can be employed to

indicate the status of the self monitoring feature.

The LEDs can also be used to fulfil other tasks e. g. all LEDs flash: device fault. The

display will then show the error code (see section "Calibration").

LEDs can be tested together with the relays or by placing the MODE jumper in position

4–5 and the TEST jumper X2 to 1–2. The 4 LEDs will then light up in sequence.

3.5.6 Testing the display

The front panel display is used to read measured values, device parameters or trip

settings (top line 4 digits plus sign).

The bottom line offers status indication. An alpha character and 2 digits show which

value is being displayed in the upper line.

Example

T01 = temperature in input 1

L01 = low trip for input 1

The display can be tested together with the push buttons as shown in section "Testing

Push Buttons" or by placing the MODE jumper in position 4–5 and the TEST jumper X2

to 1–2. The display segments will then be turned on.

DOCT-1946C 2018-07 322903

16

Page 18

Trip Amplifier 2/209

EN

Hardware description

3.6 Changing current inputs/voltage inputs

These changes should only be carried out in the laboratory.

Remove and replace jumpers as shown in the following table. Desoldering should only

be carried out using a desoldering wick. Do not use a pump as this may damage the

solder pads. The device does not have to be recalibrated once the changes have been

completed because the components are accurate to within 0.1 %.

In class 4 (DIN V 19250) applications inputs A and B may be driven from the same

source. In this case A and B are to be connected in parallel as shown in figure inputs in

parallel in section "Layout". Open all the jumpers on module B and connect the positive

end of the sister channels together.

Input 0/4 mA ... 20 mA

1 A101 A501 A101 A501 A101 A501

2 A201 A601 A201 A601 A201 A601

3 A301 A701 A301 A701 A301 A701

4 A401 A801 A401 A801 A401 A801

channel/module A B A B A B

jumper X9

0/1 V ... 5 V

jumper X10

For jumper locations see device layout in section "Layout".

3.7 Maintenance

The devices do not employ mechanical components which are exposed to wear and tear

other than the front push buttons and relays. The circuits are well selected only

incorporating high quality parts.

Therefore no regular maintenance is required as long as the maximum operating

conditions are observed. Due to the excellent long-term stability calibration of zero and

span need only be checked once a year. The relay life is given in technical data in

section "Technical data".

0/2 V ... 10 V

jumper X11

DOCT-1946C 2018-07 322903

17

Page 19

Trip Amplifier 2/209

EN

Hardware description

3.8 Service instructions

In case of dubious measuring results please check all external connections carefully. It

is also good practice to check that the desired program has actually been stored in

EPROM. A TAG number can be stored for identification purposes (also see

section "Commissioning"). If there is no doubt about the fault lying with the device, it is

seldom possible to repair the unit on site. Local analysis should be restricted to a check

of the fuses.

Each fuse is tagged with its nominal value. Fuses must always be replaced by their

equivalents. Fuse positions may be taken from section "Technical data" figure device

layout.

Fuse Value Function

F1 0.630 A Power supply

F101 3.15 A Relay 1

F201 3.15 A Relay 2

F301 3.15 A Relay 3

F401 3.15 A Relay 4

Other faults require laboratory tests. Circuit diagrams can be made available at request.

Repairs can be carried out by our service department quickly and efficiently if units are

returned to the factory. Spares help to maintain production in such cases.

DOCT-1946C 2018-07 322903

18

Page 20

Trip Amplifier 2/209

EN

Attention

Software description

4Software description

4.1 General

The device is freely programmable like a PLC.

Make sure to use the dedicated 2/209 - PC connector cable.

The following sections explain the software features of the unit. They are of interest

mainly to those users who intend to write their own software. For standard applications

skip reading sections "Programm and commands" to "System parameters".

Devices can be programmed using a personal computer. A MENU supported software

package is available for PC users (see PC MENU disk).

Programming or reconfiguring is not required for standard applications. Therefore the

following sections will mainly be used for writing new software.

In the normal way trip settings are accomplished via front panel push buttons. Additional

options are explained in the following sections. A personal computer will allow for

maximum user friendliness since all device functions are MENU supported via context

sensitive HELPs.

numerical range:

+ /-1.18E-38 ... +/-3.39E+38

accuracy:

7 decimals

The trip amplifier is designed around a 16 Bit microprocessor.

Hardware and Software have been developed to safety standards (see section

"Safety concept").

4.2 Numerical parameter list

All device parameters are listed in numerical order.

4.2.1 Program and commands P100 ... P299

Program changes can only be undertaken with jumper <MODE> in the <ENABLE>

position.

Trips are only monitored with jumper MODE disabled (RUN).

Parameters P100 to P299 contain up to 200 programming steps. User programs can be

entered to adapt the device to various applications. A powerful EDITOR is available for

PC users. Once edited using (F2) programs must be compiled using compiler (F3).

Available commands and operands can be taken from the following list.

DOCT-1946C 2018-07 322903

19

Page 21

Trip Amplifier 2/209

EN

Software description

4.2.2 Operands

AE1 ... AE4 analog inputs 1 ... 4 return up-to-date values (0 ... 1) of analog inputs (read only)

DE1 ... DE4 digital inputs 1 ... 4 derived from analog inputs

TE1 ... TE3

TR2 ... TR3

X01 ... X20 variables 1 .. 20 read and write

K01 ... K20 constants 1 .. 20 stored in EEPROM (read only)

Fixed values (program) and corresponding figures

Z00 Z01 Z02 Z03 Z04 Z05 Z10 ZM1 Z1H Z1T

0 1 2 3 4 5 10 -1 100 1000

CRP

CRC

4.2.3 Mathematical operations

Command Call Formula

Add ADD,op1,op2,op3 op3 = op1 + op2

Subtract SUB,op1,op2,op3 op3 = op1 - op2

Multiply MUL,op1,op2,op3 op3 = op1 x op2

Divide DIV,op1,op2,op3 op3 = op1/op2

Square root SQR,op1,op2 op2 = SQR(op1)

Absolute ABS,op1,op2 op2 = ABS(op1)

Logarithm (nat. LOG) LOG,op1,op2 op2 = LOG(op1)

Exponential function EXP,op1,op2 op2 = e^op1

Sine SIN,op1,op2 op2 = SIN(op1)

Cosine COS,op1,op2 op2 = COS(op1)

Tangent TAN,op1,op2 op2 = TAN(op1)

Arc-tangent ATN,op1,op2 op2 = ATN(op1)

Move MOV,op1,op2 op2 = op1

Clear CLR,op1 op1 = -1

Clear all var. CLA X01 ... X20 = -1

Logical AND AND,op1,op2,op3 op3 = op1 and op2

Logical OR ORA,op1,op2,op3 op3 = op1 and op2

DEx = -1 when AEx < 33 %

DEx = 0 when AEx >= 33 % and <= 66 %

DEx = 1 when lAEx > 66 %

(read only)

push button inputs (1 when pressed)

push button inputs (0 when pressed)

checksum of the user program

checksum of user constants and calibration

op3 = 1 when op1 and op2 = 1

op3 = -1 when op1 or op2 = -1

op3 = 1 when op1 or op2 = 1

op3 = -1 when op1 and op2 = -1

DOCT-1946C 2018-07 322903

20

Page 22

Trip Amplifier 2/209

EN

Software description

4.2.4 Conditional branches

Branch on equal

Call: IEQ,op1,op2,op3

Formula: if op1 = op2 branch to op3

Branch on not equal

Call: INE,op1,op2,op3

Formula: if op1 <> op2 branch to op3

Branch on greater or equal

Call: IGE,op1,op2,op3

Formula: if op1 >= op2 branch to op3

Branch on lower

Call: ILO,op1,op2,op3

Formula: if op1 < op2 branch to op3

Unconditional branch

Call: GTO,op1

Formula: branch to op3

4.2.5 Timers and other operations

Command Call Formula

End of program END end of program

No operation NOP no operation

Timer TIM,op1 read timer and delete (time in ms)

Timer TIN,op1 read timer (time in ms)

Wait WAI,op1 wait so many ms (max. 10,000 ms)

Filter analog in FIL,op1 number of averaged input values

Watchdog WDT,op1 starts the watchdog (max 10,000 ms)

(max. 100) program waits for

execution

4.2.6 Output operations

Command Call Formula

De-energize relay RD1...RD4, op1 relay de-energized within limits

Energize relay RE1...RE4,op1 relay energized within limits

Set LEDs SL1...SL5,op1 set LEDs

Set LEDs reverse logic RL1...RL5,op1 set LEDs

LED flash FL5,op1 flashing LED 5 (green)

The following commands must be placed at the beginning of a program

On delay ND1...ND4, op1 ON-Delay

Off delay FD1...FD4, op1 OFF-Delay

DOCT-1946C 2018-07 322903

op1 = -1 relay off

op1 = 0 previous status

op1 = 1 relay energized

op1 = -1 relay off

op1 = 0 previous status

op1 = 1 relay energized

op1 = -1 off

op1 = 0 previous status

op1 = 1 on

op1 = 1 off

op1 = 0 previous status

op1 = -1 on

op1 = -1 off

op1 = 0 previous status

op1 = 1 on

op1 = delay (max 10,000ms)

op1 = delay (max 10,000ms)

21

Page 23

Trip Amplifier 2/209

EN

Software description

4.2.7 Special Operations

Display menu:

The DSP command has to be placed at the beginning of a program. DISPLAY

commands must be in sequence. Other commands follow.

The order in which display commands are used determines the sequence of parameters

displayed when pushing the STEP key on the device front.

Example

• input 1, trip point 1,

input 2, trip point 2

or

• input 1, input 2,

trip point 1, trip point 2

Front push buttons will operate ONLINE, i. e. trip points continue to be monitored while

the buttons are pushed. The program will read the push buttons once every cycle. It may

therefore be necessary to press a push buttons several times before the unit responds.

Push buttons can be used to chang e co nstan ts. Th is i s used to set trip points. Press SET

to initiate changes (two keys simultaneously to protect against unintentional changes).

The STATUS line will flash.

Use UP/DOWN ">" "<" push buttons to adjust the value.

Store the result in non-volatile EEPROM by pressing STEP key. Prior to storing the value

in EEPROM you can restore the previous setting by pressing the UP/DOWN buttons

simultaneously "ESC". The keys terminate the programming mode (display stops

flashing). If keys are not pressed for 30 seconds the SET mode is terminated

automatically.

Action:

Display operand op1 in mode op2.

The lower line will carry the alpha character a and the numerals nn. DSP commands

have to be placed at the beginning of a program. The front push buttons are used to step

DSP commands or change constants.

Call DSP,op1,op2,op3,op4

In the EDITOR operands op3 ... op5 are grouped together.

Example

DSP,X01,Z00,E01 (see example programs in DEMO directory)

DSP = display

op1 = variable or constant upper line

op2 = mode: (0 = float, 1 ... 4 = (no - 1)decimals)

op3 = ASCII: (A ... Z e. g. "#E")

op4 = num. (0 ... 9 e. g. "#1") lower line

op5 = num. (0 ... 9 e. g. "#0")

DOCT-1946C 2018-07 322903

22

Page 24

Trip Amplifier 2/209

EN

Software description

4.2.8 Live zero conversion

Call CLI, op1, op2, op3, op4 (convert live input)

Formula op4 = (op1-0.2) / 0.8 x (op3-op2) + op2

This command serves to convert live zero input signals into engineering units. That way

measured values and trip points can be displayed as °C, m

units. The user does not have to establish conversion formula for himself.

Example

• Begin = 180 at 4 mA

• Full scale = 380 at 20 mA

• Display = 280 at 12 mA

The device front offers space for entering TAG numbers and engineering units. Enter

•0 = beginning

• 100 = full scale

in order to display percentage values.

Live zero signals: 4 mA ... 20 mA, 1 V ... 5 V, 2 V ... 10 V

4.2.9 Dead zero conversion

Convert dead zero input signals into engineering units.

Call CDI, op1, op2, op3, op4 (convert dead input)

Formula op4 = op1 x (op3-op2) + op2

The function is equivalent to the live zero conversion.

Dead zero signals: 0 mA ... 20 mA, 0 V ... 5V, 0 V ... 10 V

CLI = live zero - measuring range

op1 = input (AE1 ... AE4)

op2 = beginning of range

op3 = full scale

op4 = result

CDI = dead zero - measuring range

op1 = input (AE1 ... AE4)

op2 = beginning of range

op3 = full scale

op4 = result

3

/h, % or other engineering

DOCT-1946C 2018-07 322903

23

Page 25

Trip Amplifier 2/209

EN

Software description

4.2.10 Trip high on mid – hysteresis

This command is used to monitor a high alarm. You can monitor inputs or computed

values.

Call AHM,op1,op2, op3, op4 (alarm high mid hysteresis)

Formula op4 = 1 for alarms or if op4 was 1 before

Example

ADD, AE1, AE2, op1

Monitors the average of input 1 and input 2 etc.

Use Operand op4 to energize or de-energize relays.

Trip points are in engineering units as determined by the beginning and end of range (full

scale) values. This relieves the user from tedious conversion tasks. This command sets

the trip point in the centre of the deadband (hysteresis op3 as with conventional trip

amplifiers).

Example

• high contact = 60 %

• hysteresis = 6 %

• alarm > 63 %

• no alarm < 57 %

The hysteresis is also set in engineering units (0.1 % to 100 %).

AHM = alarm high contact on centre hysteresis

op1 = value to be monitored (e. g. AE1 ... AE4)

op2 = trip point

op3 = hysteresis

op4 = result

op4 = 0 while inside deadband or if op4 was 0 before

op4 = -1 when there is no alarm

4.2.11 Trip low on mid – hysteresis

This command is used to monitor a low alarm. You can monitor inputs or computed

values.

Call ALM,op1,op2, op3, op4 (alarm low mid hysteresis)

Formula op4 = 1 for alarms or if op4 was 1 before

ALM = alarm low contact on centre hysteresis

op1 = value to be monitored (e. g. AE1 ... AE4)

op2 = trip point

op3 = hysteresis

op4 = result

op4 = 0 while inside deadband or if op4 was 0 before

op4 = -1 when there is no alarm

Example

• high contact = 60 %

• hysteresis = 6 %

• alarm > 57 %

• no alarm < 63 %

24

DOCT-1946C 2018-07 322903

Page 26

Trip Amplifier 2/209

EN

Software description

4.2.12 Trip high on set-point

This command is used to monitor a low alarm. You can monitor inputs or computed

values. In contrast to previous alarms this one triggers exactly on the preset trip point.

The hysteresis or deadband will then be to one side of the set-point.

Call AHS,op1,op2,op3,op4 (alarm high on set-point)

Formula op4 = 1 for alarms or if op4 was 1 before

Example

• high contact = 60 %

• hysteresis = 3 %

• alarm > 60 %

• no alarm < 57 %

The hysteresis is also set in engineering units (0.1 % to 100 %).

4.2.13 Trip low on set-point

This command is used to monitor a low alarm. You can monitor inputs or computed

values.

Call ALS,op1,op2,op3,op4 (alarm low on set-point)

Formula op4 = 1 for alarms or if op4 was 1 before

Example

• high contact = 60 %

• hysteresis = 3 %

• alarm < 60 %

• no alarm > 63 %

The hysteresis is also set in engineering units (0.1 % to 100 %).

AHS = alarm high contact exactly on set-point

op1 = value to be monitored (e. g. AE1 ... AE4)

op2 = trip point

op3 = hysteresis

op4 = result

op4 = 0 while inside deadband or if op4 was 0 before

op4 = -1 when there is no alarm

ALS = alarm low contact exactly on set-point

op1 = value to be monitored (e. g. AE1 ... AE4)

op2 = trip point

op3 = hysteresis

op4 = result

op4 = 0 while inside deadband or if op4 was 0 before

op4 = -1when there is no alarm

DOCT-1946C 2018-07 322903

25

Page 27

Trip Amplifier 2/209

EN

Software description

4.2.14 Trip 2 of 3 selector

Call SEL,op1,op2,op3,op4,op5,op6,op7,op8,op9

Formula op5 and op6 show:

SEL = select the deviating channel

op1 = input 1

op2 = input 2

op3 = input 3

op4 = tolerance band

op5 = tolerance band hysteresis

op6 = signal alarm -1, 0, 1 (channels are deviates)

op7 = channel alarm -1, 0, 1(channels are different)

op8 = average of acceptable inputs

op9 = faulty channel (0, 1, 2, 3, 123)

op4= 1 for alarms or if op. was 1 before

op4 = 0 while inside deadband or if op. was 0 before

op4 = -1 when there is no alarm

Example

SEL,E01,E02,E03,K01,K02,X01,X02,X03,X04

Normal operation

• signal alarm = -1

• channel alarm = -1

• average = (E1 + E2 + E3) / 3

• faulty channel = 0

Single fault

• signal alarm = 1

• channel alarm = -1

• average = (Ex + Ey) / 2

• faulty channel = E1 or E2 or E3

Multiple fault

• signal alarm = 1

• channel alarm = 1

• average = previous value

• faulty channel = 123

Three input signals op1, op2, op3 are monitored for equality. If one input leaves the

tolerance band op4 around the average of the signals, the signal alarm op6 will be

activated. If all inputs are different, the channel alarm op7 will be activated.

The faulty channel can be read in op9. Use the DISPLAY command to read the value in

the display in the front panel. The average op8 of those values which are within the

tolerance band can also be displayed. Variables op6, op7, op8, op9 must not be

overwritten during the remaining user program.

DOCT-1946C 2018-07 322903

26

Page 28

Trip Amplifier 2/209

EN

Software description

4.2.15 Trip rate of change alarm

Prior to calling this rate of change alarm use the timer command TIM,op5 to enter the

time since the last call in memory cell op5.

An input or a computed value op1 is monitored for change op3 per time interval op2. The

up-to-date value of op1 will be compared with the old value in op6 (op3 = op1 - op6)

when the time integral op7 > op2. If the change per time interval op3 is above 0 the

gradient is positive. If the change per time interval op3 is less 0 the gradient is negative.

Memory cells op6 to op9 must not be overwritten during the remaining user program.

Call GRD,op1,op2,op3,op4,op5,op6,op7,op8,op9

Formula op9 = 1 for alarms or if op9 was 1 before

Example

GRD,E01,K01,K02,K03,X01,X02,X03,X04,X05

GRD = (gradient) monitor rate of change

op1 = input value to be monitored

op2 = time interval in ms

op3 = max change per time interval

op4 = hysteresis

op5 = time since last call

op6 = input memory (start value)

op7 = time memory (integral of op5 in ms)

op8 = alarm memory

op9 = alarm -1, 0, 1

op9 = 0 while inside deadband or if op9 was 0 before

op9 = -1 when there is no alarm

DOCT-1946C 2018-07 322903

27

Page 29

Trip Amplifier 2/209

EN

Software description

4.2.16 Trip stuck sensor alarm

Prior to calling this rate of change alarm use the timer command TIM,op5 to enter the

time since the last call in memory cell op5.

An input signal or a computed value op1 is monitored to see if the value has changed by

more than the required minimum value op3 during the sample time (time interval op2). If

the minimum change has not been achieved, an alarm is generated because it must now

be assumed that there is a fault in the circuit which is under observation.

Memory cells op6 to op9 must not be overwritten during the remaining user program.

Call STS,op1,op2,op3,op4,op5,op6,op7,op8,op9,op10

Formula op10 = 1 for alarms or if op10 was 1 before

Example

STS,E01,K01,K02,K03,X01,X02,X03,X04,X05,X06

STS = stuck sensor

op1 = input

op2 = time interval in ms

op3 = min change per time interval

op4 = hysteresis

op5 = time since last call in ms

op6 = min input memory

op7 = max input memory

op8 = time memory (integral of op5)

op9 = alarm memory

op10 = alarm -1,0,1

op10 = 0 while inside deadband or if op10 was 0 before

op10 = -1 when there is no alarm

DOCT-1946C 2018-07 322903

28

Page 30

Trip Amplifier 2/209

EN

Software description

4.2.17 Trip Analog Monitor (setpoint and line monitor)

An input signal op2 (op1 = live or dead zero) in converted into engineering units using

op3 = beginning o.r. and op4 = full scale.

The result is stored in op12. The signal will then be monitored for line interrupts and

overrange (Fault) plus a setpoint (op5) depending on op6 = low limit or high limit.

Call ANA,op1,op2,op3,op4,op5,op6,op7,op8,op9,op10,op11,op12

Formula op10 = 1 for alarms or if op10 was 1 before

Example

ANA,Z01,AE1,K01,K02,K03,Z00,X01,K04,X03,X04,X05,X06

Comment

op1 = input mode 0 = dead zero (21 mA)

ANA = analog input monitor

op1 = input mode

op2 = input

op3 = beginning of range

op4 = full scale

op5 = trip point

op6 = trip mode (0=low limit; 1=high limit)

op7 = Reset (> 0 then reset)

op8 = delay (delay = op8 x program cycle)

op9 = delay counter

op10 = alarm memory

op11 = line interrupt/overrange (fault)

op12 = analog output

op10 = -1 while inside deadband

op11 = 1 for fault or if op11 was 1 before

op11 = -1 while inside deadband

Line monitor trips at

1 = live zero (3.6 mA and 21 mA)

2 = live zero (0.5 mA and 21.5 mA)

The reset variable op7 is used to clear alarm or fault conditions. This allows you to HOLD

the Alarm and RESET it via a variable value (op7) under software control. The variable

may be governed by an analog input or the front push buttons.

The alarm will be delayed by op8. The delay will reach 1 second, if op8 = 25 and the

average program execution time is estimated to be 40 ms.

If an alarm or fault are detected this information will be stored. If both fault and alarm are

detected, fault will be predominant.

Memory cells op9 to op11 may only be read during the remaining program. They must

not be overwritten.

DOCT-1946C 2018-07 322903

29

Page 31

Trip Amplifier 2/209

EN

Software description

4.3 System parameters

System parameters help to analyse problems and locate faults.

4.3.1 Software version P700 (read only)

This parameter gives access to the number of the current software version.

Example

2/209 V 1.18

4.3.2 Device ID P701 (read and write)

This parameter contains a device identification or TAG No. of up to 12 characters. It

does not have any influence on program execution. It can be employed to advantage

when storing data of several devices on a personal computer.

Example

2/209

4.3.3 Jumper KEY P704

Displays the status of the jumper KEY.

Example

Enter: P704 <Enter>

Display: P704 = 1 (1 = KEY ENABLE)

1 = push button changes unlocked

0 = push button changes locked

4.3.4 Jumper MODE P705

Displays the status of the jumper MODE.

Example

Enter: P705 <Enter>

Display: P705 = 0 (0 = MODE DISABLE)

0 = programming disabled

1 = programming enabled. Trips are NOT monitored

4.3.5 Jumper TEST P706

Displays the status of the TEST jumper.

Example

Enter: P706 <Enter>

Display: P706 = 0 (0 = TEST DISABLE)

1 = TEST Mode (calibration enabled)

0 = normal mode (calibration disabled)

DOCT-1946C 2018-07 322903

30

Page 32

Trip Amplifier 2/209

EN

Software description

4.3.6 Device Programming P707 (PC menu only)

Entering parameter P707 = 1 will delete all data in EEPROM. The device will then expect

to receive a new identification ID, 20 constants, 200 programming steps and a CRC

(checksum) following data transmission.

Once data transmission has been completed successfully data are copied to EEPROM

followed by an echo of 0. Otherwise 1 is echoed. The PC program will control data

transmission and the generation of the CRC.

4.3.7 Test parameters

Test parameters are used for electrical device checks.

Check analog inputs and push buttons (ONLINE)

P711 analog input 1 corresponding to 0 ... 1 (read)

P712 analog input 2 corresponding to 0 ... 1 (read)

P713 analog input 3 corresponding to 0 ... 1 (read)

P714 analog input 4 corresponding to 0 ... 1 (read)

Check calibration data (ONLINE). Both microprocessors contain calibration data about

the redundant analog inputs assigned to them.

CPU A

P781 read calibrate analog input 1A

P782 read calibrate analog input 2A

P783 read calibrate analog input 3A

P784 read calibrate analog input 4A

P785 read calibrate analog input 1B

P786 read calibrate analog input 2B

P787 read calibrate analog input 3B

P788 read calibrate analog input 4B

CPU B

4.3.8 Calibration

Devices are calibrated ex works. Therefore recalibration is not normally required after

commissioning. An annual check is regarded as being sufficient. Range changes or live/

dead zero changes do not involve recalibration.

Recalibration is also not required after changing from current to voltage inputs or vice

versa (also 5V ... 10V) because precision resistors have been used.

Set the MODE jumper to PROG (4–5) and the TEST jumper to X2. Connect the device

to the PC using the TERMINAL EMULATOR <ALT><E> (see section "Numerical

parameter list").

1. Set all analog inputs to 100 %

2. Enter P790=1 (calibrate analog inputs)

3. Display P790 = n n = 0 o.k.

n = 1...8 error in channel n

n = 9 jumper TEST disabled

DOCT-1946C 2018-07 322903

31

Page 33

Trip Amplifier 2/209

EN

Software description

After calibration has been completed the jumpers have to be changed back to the

operating mode. MODE = RUN (X5 3–6) and TEST jumper removed.

The calibration procedure eliminates tolerances of the precision resistors in the input

channels of the device. Conventional potentiometers have been replaced by nonvolatile EEPROM memory.

4.3.9 Constants

P801 ... P820 contain constants K01 ... K20.

Constants are stored in EEPROM and can be altered ONLINE using the front push

buttons (see special commands). External access is often not permitted in safety

applications.

Data will be retained upon loss of power.

4.3.10 Variables

P901 ... P920 contain variables X01 ... X20.

Variables are stored in RAM and will be used for computed or interim values.

RAM contents will be lost upon loss of power.

4.4 Programming example

Install your PC software for the 2/209 trip amplifier (see section "How to install your

program").

Power the trip amplifier (24 V DC) and connect it to the personal computer (COM1 or

COM2). Analog inputs should be connected to signal sources.

Set the MODE jumper (X5) to programming X5.4 - X5.5 (see section "Functions –

General").

Start the PC program by entering START/1 (device connected at COM1 of the PC) or

enter START/2 (device connected at COM2). The screen will now show the main

MENU.

Open communication by entering keys <ALT><E> simultaneously. The selected serial

data link COM1 or COM2 should be echoed in the display window. Now enter the

command P700 followed by RETURN (ENTER).

The communication window will display as follows:

P700

P700=2/209-V3.0 (device version)

In case there is no reply from the device, please check your connection:

a) use the correct cable

b) use the correct serial data link COM1 or COM2

c) check the jumper positions

of the device (see above).

DOCT-1946C 2018-07 322903

32

Page 34

Trip Amplifier 2/209

EN

Software description

Once communication has been established between the PC and the device close the

communication window using <ESC>.

Now activate the EDITOR using key <F2>. Press RETURN <ENTER>, to enter the

selection box.

Move to the DEMO directory using arrow keys and acknowledging with <ENTER>.

Select the file TEST_E.EDT and acknowledge with RETURN. The test program will now

be displayed.

Colons are used to introduce comments. You can step through the program using the

arrow keys. A program always consists of constants K01 ... K20 and statements.

The software example is used to monitor 4 inputs.

E01 low limit

20 % normally energized

1% hysteresis

LED 1 On for alarm

E02 low limit

40 % normally energized

1% hysteresis

LED 2 On for alarm

E03 high limit

60 % normally energized

1% hysteresis

LED 3 On for alarm

E04 high limit

80 % normally energized

1% hysteresis

LED 4 On for alarm

The WDT,K08 statement starts a watchdog which will halt the system after 1,000 ms

should the program fail to pass this statement.

The following values can be addressed on the front LCD display:

E01 analog input 1 in %

E02 analog input 2 in %

E03 analog input 3 in %

E04 analog input 4 in %

L01 low limit for E01 in %

L02 low limit for E02 in %

H01 high limit for E03 in %

H02 high limit for E04 in %

C00 checksum of device (program, constants, calibration)

P00 checksum of the program

T00 program execution time in ms.

DOCT-1946C 2018-07 322903

33

Page 35

Trip Amplifier 2/209

EN

Software description

Leave the EDITOR using ESC. At the top of the screen the question "SAVE Y/N" will

appear. Reply "N" unless you want save changes.

If you have made changes in the source code and you want to safe it, please reply

with "Y".

The program now has to pass the COMPILER to become executable. Activate the

COMPILER using key <F3>. Any program which has just passed the EDITOR will

automatically be addressed by the COMPILER. Acknowledge using RETURN. The

screen will show "data loaded from compiler". Acknowledge using ESC.

Send the translated program to the trip amplifier using <ALT><S> (press <ALT> and

<S> simultaneously). Acknowledge the question "are you sure" with RETURN. A new

windo w will appear on the screen and you will be able to watch data being transferred to

the trip amplifier. After about 2 minutes data transfer will be completed and a checksum

is formed to be stored as an unmistakable value in EEPROM (P00).

Set jumper MODE to RUN X5.3 - X5.6 (see section "Functions – General"). The trip

amplifier will now perform the desired function.

DOCT-1946C 2018-07 322903

34

Page 36

Trip Amplifier 2/209

EN

100

F54

Software description

4.5 Error messages

When an error is detected while a program is being executed, the processor will halt and

all LEDs will flash. Relay outputs will be de-energized. The error code will be shown on

the display.

Example

Error 54 in line 100 will lead to the following display.

PC screen: F54 in 100

Display:

Fault Meaning Action

11 analog input 1 difference in CPU A and B Check input signals.

12 analog input 2 difference in CPU A and B

13 analog input 3 difference in CPU A and B

14 analog input 4 difference in CPU A and B

15 difference in the program monitor of CPU A and B

20 wrong length of start bits for communication

21 time-out in the parallel CPU (no data from parallel CPU)

22 time-out on main program (user programs are interrupted)

23 unused interrupt

24 time-out through watchdog WDT command Check program execution time.

39 program runtime error in the operating system

38 program runtime error in the user program

40 CRC error in RAM (retransmit program and constants) Briefly switch off power to generate

41 ERROR unable to switch off relay output 1 Briefly switch off power to generate

42 ERROR unable to switch off relay output 2

43 ERROR unable to switch off relay output 3

44 ERROR unable to switch off relay output 4

45 power monitor (internal 5V-supply < 4.5V or > 5.5V)

46 CPU not functioning properly

49 AD converter, MUX, reference input faulty

51 RAM fault Inverter and cross talk check failed.

52 CRC error in EPROM Briefly switch off power to generate

53 faulty statement e. g. ADD,Z00,Z01,Z00

The result of an operation cannot be stored in a fixed value (Z00).

54 faulty statement e. g. ADD,X01,X02,X03,X04,...

The ADD statement should only be followed by 3 operands.

These are to be followed by the next statement (X04 is wrong).

55 program counter less than 100 or greater 299 Check your program and its

a RESET.

a RESET. Repair if necessary.

a RESET.

statements.

DOCT-1946C 2018-07 322903

35

Page 37

Trip Amplifier 2/209

EN

Software description

Errors lead to a program interrupt. All the LEDs will be turned on and the output relays

are de-energized.

• Error Axx: the error has been recognized by CPU A.

• Error Bxx: the error has been recognized by CPU B.

As a first action briefly switch off the power supply to the device. The card will be RESET

and all functions will be tested.

You may be able to correct faults in the execution of a program by setting the MODE

jumper to PROG and then back again to RUN. If necessary reload the program from the

PC.

Should the device indicate an error during programming due to strong electromagnetic

bursts briefly switch off power before resuming your task.

DOCT-1946C 2018-07 322903

36

Page 38

Trip Amplifier 2/209

EN

Software description

4.6 Installation of the PC program

The 2/209 software will operate on any IBM compatible PC with 512 kB memory and an

MS-DOS or PC-DOS operating system Version 3.0 or higher.

For maximum user friendliness install a Mouse and an EGA or VGA monitor. However,

the program will also run without a Mouse and with a monochrome monitor. If you want

to use a Mouse, make sure the corresponding driver is loaded. It is best to incorporate

the driver in the start batch using an editor to do so (file: START.BAT).

If a WINCHESTER drive is available, a new directory should be generated. Afterwards

all the files should be copied from the floppy disk to the new directory.

Example

•c:

• md PC2209

• cd PC2209

• xcopy a:*.* /s

•dir

Now the following files should be listed:

START BAT Start batch

MAIN_209 EXE Menu support

COMP_209 EXE Compiler

SIMU_209 EXE Emulator

EDIT_209 EXE Editor

SYNATAX OPL Syntax for the compiler

TXT_209G TXT German menu

TXT_209E TXT English menu

HLP_209G HLP German help

HLP_209E HLP English help

EDT_209G HLP German help for editor functions

EDT_209E HLP English help for editor functions

DEMO DIR Subdirectory with sample programs

STD DIR Subdirectory with standard programs

While in DOS type TYPE START.BAT to display the START file.

REM MOUSE here you may want to add the MOUSE driver; in

that case please remove the REM statement.

MAIN_209 %1 %2 this program starts the menu support.

Activate the english version by entering START /e /2. The menu will then appear on the

screen.

DOCT-1946C 2018-07 322903

37

Page 39

Trip Amplifier 2/209

EN

Software description

The following START-up parameters are possible:

/g German help *

/e English help

/0 DEMO mode active *

/1 Serial link via COM1

/2 Serial link via COM2

Start options marked by a star * will be assumed unless other parameters are used.

Connect the trip amplifier via a serial data link (RS 232) to the personal computer. The

desired PC port "COM" is assigned during start-up (/2 = COM2) as shown above. The

port may be changed under MENU support using (<ALT><C>). Only lines GND (7), TXD

(2) and RXD (3) of the PC need to be connected with the trip amplifier. A suitable cable

is available as an accessory.

Menu items are explained via HELP text. Use key F1 for HELP. Context sensitive HELP

texts simplify matters when working with the program. Every line of the menu can thus

be explained in detail. HELP is also accessible using alphabetical search.

DOCT-1946C 2018-07 322903

38

Page 40

Trip Amplifier 2/209

EN

Handling without a PC

5 Handling without a PC

In the normal way front panel push buttons can be used to adjust set points read on the

digital display. Set points are secured against unintentional adjustments (jumper X5 2–

7). Enable push button adjustments by setting jumper X5 to 1–8.

In order to activate the UP/DOWN push buttons both SET buttons must be pressed

simultaneously. The display will start to flash. Set points can now be raised using > or

lowered using < push buttons. Keep the push button down to accelerate.

Use the STEP button to save the new setting. The new value will not be accepted until

STEP is pressed and the next value is displayed. If you want to restore the previous

setting and erase the new one you can do so by pressing both > and < simultaneously

(ESC) prior to pressing the STEP button.

The status line indicated which value is being displayed at present e. g.

• E01 = input 1

• T01 = temp. 1

• F01 = flow 1

• L01 = low alarm 1,

• H01 = high alarm 1

Front push buttons can be disabled via an internal jumper (see section "Functional test

– Generals").

In that case measured values and trip setting can be displayed online, but alterations will

not be possible. The basic device function is outlined on the TAG covering the

microprocessor. You can replace the label yourself after changing the factory setting.

Carefully use your thumb and digit finger to lever the cover off the socket. The position

of the TAG can be taken from the device layout drawing in section "Layout".

• The disk contains a print program TYPENG.TXT with some examples. These can be

altered using the EDITOR. Use the PRINT command in your DOS operating system

to print the label in IBM compatible printers. Proceed as follows:

Call the EDITOR in the main MENU using key <F2>. Select file TYPENG.TXT using

the tabulator key <TAB> and the arrow keys. Activate the file using <ENTER>.

Make sure only to overwrite lines in this file. Do not alter the line length. Do not go

beyond the markers. Do not enter new lines.

• After saving file TYPENG.TXT using <ESC> leave the menu and return to the

DOS operating system pressing keys <ALT><X>.

• Now enter the command PRINT TYPENG.TXT. Your IBM compatible printer will

now print a label of just the right size.

DOCT-1946C 2018-07 322903

39

Page 41

Trip Amplifier 2/209

EN

Handling with a PC

6 Handling with a PC

The trip amplifier can be reconfigured under menu support using a PC or LAPTOP with

the enclosed disk. Every item on the MENU is supported by HELP functions which are

accessible via key F1. The following section explains a simple example:

Device handling

• Action 1 – preparing the hardware

• Action 2 – preparing the software

• Action 3 – preparing a back-up copy

• Action 4 – how to edit standard programs

• Action 5 – how to save and send programs

• Action 6 – how to check edited programs

• Action 7 – how to EDIT a program

• Action 8 – ending a job

6.1 Action 1 – Preparing the hardware

2/209 Device to be connected to 24 V DC power supply.

2/209 Device to be connected to a PC via an RS 232 link.

2/209 Set jumper MODE to 4–5 (programming mode, trip monitor

Insert a copy of the disk supplied with this manual. Remove WRITE protection.

Alternatively use hard disk.

disabled).

6.2 Action 2 – Preparing the software

A: <ENTER> Select drive A, A> displayed on screen.

START <ENTER> Start program in English, the main MENU will appear on the

screen.

<ALT><C> Select PC communications link.

1 Enter figure 1 or 2, select COM1 or COM 2.

6.3 Action 3 – Preparing a back-up copy

<ALT><L> Load data from the trip amplifier.

<ALT><W> Save data in a file

This is to produce a back-up copy of the factory or original

setting.

NAME.209 Enter NAME and save with <ENTER>. If you want to save

data from several devices, repeat above action from

<ALT><L> and issue a file name per device (TAG No).

DOCT-1946C 2018-07 322903

40

Page 42

Trip Amplifier 2/209

EN

Handling with a PC

6.4 Action 4 – How to edit standard programs

<F6> Call a standard program.

1 <ENTER> Select the desired program number 1 (example 1). A window will

be opened for user entries (<F1> HELP).

zero 0 Use <TAB> key to move forward.

full scale 100 Towards entry fields.

display E01 Use <SHIFT-TAB> to move backwards.

display mode 2

input zero ( ) live Change using arrow keys.

( ) dead Change using arrow keys.

trip point 50

hysteresis 1

display L01

display mode 2

relay action ( ) OFF Change using arrow keys.

( ) ON Change using arrow keys.

switch at ( ) set Change using arrow keys.

( ) hyst Change using arrow keys.

contact ( ) LOW Change using arrow keys.

( ) HIGH Change using arrow keys.

( ) Line - toggle using space key (X = active).

Ch ang es be come vali d on ce yo u hav e ac ce pte d en tri es by pre ssin g 0 = O K or s ele ct OK

via the <TAB> key (will be highlighted) followed by <ENTER>. Abort using <ESC>.

6.5 Action 5 – How to save and send programs

<ALT><W> Save data on file. This is to establish a back-up copy of a

standard copy after effecting changes. The copy can later be

used to configure spares or new devices (see <ALT><S>).

However the changes cannot be displayed in the same menu

supported way as the original standard setting.

NAME.209 Type the desired name and press <ENTER>. If you want to

create several identical devices, repeat above action from

<ALT><W> and issue a file name per device (TAG No).

<ALT><S> Save data in the trip amplifier. If you want to create several

identical devices, connect them to your personal computer one

by one and save data with <ALT><S>.

DOCT-1946C 2018-07 322903

41

Page 43

Trip Amplifier 2/209

EN

Handling with a PC

6.6 Action 6 – How to check edited programs

<ALT><R> Load parameters from file.

NAME.209 Enter the desired file name or

<ALT><L> load parameters from the trip amplifier.

Data are now accessible.

<F5> Check the program. Changes can now be made immediately.

<F4> Check constants. Changes can now be made immediately. Use

Alterations should be saved as explained in action 5.

Use the tabulator <TAB> key to move to the programming step

which is to be altered and overwrite with the new command.

the tabulator <TAB> key to move to the constant which is to be

altered and overwrite with the new value.

6.7 Action 7 - How to edit a program

This task will not have to be undertaken very often. You should have prior programming

experience before attempting it.

<F2> Call the editor.

NAME.EDT Enter the name of the FILE to be edited. Existing programs can

be altered using the editor or new programs can be established.

<F1> offers extensive HELP during an EDIT session. Program

examples are to be found in the DEMO directory under

DEMOE.EDT ... or in directory STD under STD_1.EDT ...

STD_8.EDT.

Comments must be preceded by ";".

Once a program has been established it must pass the

compiler. Only then will you have an executable program which

can be transferred to the trip amp using action 5.

6.8 Action 8 - Ending a job

2/209 Remove the connector cable from the PCs serial data link.

2/209 Place jumper MODE in position 3-6 (run mode).

DOCT-1946C 2018-07 322903

42

Page 44

Trip Amplifier 2/209

EN

Fault finding

7 Fault finding

Error Solution

No communication

between PC and the

device 2/209

Device doesn’t work.

Display shows P.

Trip points cannot be

set.

High alarm instead of

low alarm or vice

versa.

Check the cable.

Check that the correct COM link is being used typing

<ALT><C>. Check that the jumper MODE is in position 4–5.

Check that the jumper MODE in position 3–6.

Jumper KEY must be in position 1–8.

Use action 6 to load parameters from the trip amplifier with

<ALT><L>. Modify the program with <F5>. Use the

<TAB> key to move to the command which determines the

MIN or MAX-contact. Overwrite the line in question. e. g.

AHS MAX-contact which switches exactly on the set point.

Change to:

ALS MIN-contact which switches exactly on the set point.

End action by saving the program in the trip amplifier

following action 5 <ALT><S>.

The display can be altered in the same way, e. g. overwrite

H01 with L01.

8 Test programs using the EMULATOR

The EMULATOR allows you to check programs which have been written for the trip

amplifier 2/209. Once the program has been tested successfully it can be stored in the

trip amplifier (see <ALT><S>).

This tool replaces the hardware during program development. This effectively speeds

up the process of writing applications software. The program simulates the device 2/209

in all its functions. You can generate input signals on screen to check the relay and LED

action as well as that of the front display.

Call a program which you have written with the aid of the EDITOR. Run the program

through the COMPILER. Load this program into the EMULATOR by entering its

NAME.209 (NAME the program of your choice).

The EMULATOR offers:

• single stepping (F7)

• a monitor for variables (F8)

• a monitor for constants (F9)

• a monitor for the system (F10)

The basic EMULATOR input setting is for 0 % ... 100 % signals. However it is also

possible to apply hardware equivalents of 0 mA ... 20 mA, 0 V ...10 V, 0 V ... 5 V.

Reconfigure the EMULATOR dialling <F9>.

DOCT-1946C 2018-07 322903

43

Page 45

Trip Amplifier 2/209

EN

Safety concept

9 Safety concept

The fault detection calculations and measures meet the requirements of SIL3. From a

safety-related point of view, the configuration program is suitable for programming and

configuring the devices.

Conditions

1. The devices must only be operated in housings/control cabinets meeting at least

IP54.

2. Two functionally diverse selector relays must be connected in series (NO/NC series

connection).

3. The analog input circuits must be checked regularly and recurrently (e.g. annually)

in the context of calibration.

4. It must not be possible to modify the programmed switching thresholds (trip values)

via the function buttons on the front plate during operation. This must be ensured

through organizational measures.

5. The user program must be checked during factory/on-site acceptance testing:

– Correct implementation of the specified function in the instruction list must be

verified, e. g. by means of a function check.

– The printout of the read-back instruction list must be compared with the

compiled instruction list for this purpose.

– The user programs must be written such that the application-dependent

response times relating to the process requirements and fault tolerance times,

including in conjunction with the overall control system, are not exceeded (e. g.

1 s for plants complying with DIN VDE 0116).

6. If branch commands are used, it must be demonstrated that the cyclic processing of

the commands for activation of the relay/dynamic pulse outputs is maintained under

all branch conditions. If necessary, the output commands must be protected by

means of a watchdog function (the WTD command must be programmed

immediately before the output commands).

7. The installation conditions for the trip amplifier inputs and outputs must comply with

the IEC 801-5 [7] standard in terms of immunity against transient voltages (well

protected electrical environment, no transient voltages exceeding 25 V) or

protected via external measures.

8. The application notes in the manufacturer’s operating instructions must be

observed.

Additional conditions for SIL2 or SIL3 applications

1. For SIL3 applications, the use of paired output contacts in a safety chain is

mandatory.

2. For SIL2 applications, it must be ensured that a safe status has been achieved and

is maintained upon detection of a potentially hazardous fault during the repeat check

(proof test).

Single-channel use of an output for a safety function is only permissible if “one fault”

safety is not required and the application does not require an equivalent according

to category 3, EN 954-1. Otherwise, configurations according to SIL3 must be used.

3. When determining the checks to be performed at regular intervals, the determined

proof-test intervals must be observed.

DOCT-1946C 2018-07 322903

44

Page 46

Trip Amplifier 2/209

EN

Safety concept

The following basic principles have been applied:

1. Manipulations are excluded during operation,

2. 2 lines of a digital display give access to important data without disturbing the plant

operation,

3. 4 pairs of analog inputs ensure that single errors on these circuits will be detected.

4. 2 processors monitor each other, a self monitoring feature will generate error codes

in case of faults,

5. a dynamic watch dog circuit together with other safety functions will ensure that

relays.

6. the user program is stored in non-volatile EEPROM,

7. the relay position is monitored continuously,

8. relays are de-energized if program execution is disrupted,

9. single faults will drive the unit to a safe position,

10. each contact circuit is fused are de-energized in case of faults,

11. free programming of the device functions on the basis of safety-tested software via

a PC menu with help texts,

12. approved structure of commands and operating system,

13. safe state after restart,

14. monitoring of the operation and data transfer,

15. structured programming and

16. detailed documentation.

9.1 CE marking

• The unit 2/209 is designed to be used in an industrial environment.

• Noise immunity acc. to EN 61000-6-2:2005 and EN 61326-3-2

DOCT-1946C 2018-07 322903

45

Page 47

Trip Amplifier 2/209

EN

Safety concept

9.2 Safety related parameters

9.2.1 Safety parameters for SIL2

In consultation with TÜV Rheinland, the PFH value for this device can be calculated as

follows:

PFH = PFD

Configuration: 8 inputs (use in pairs for a physical value)

Device SSF

2/209 90.4 % 94.6 % SIL2

2/209 90.4 % 94.6 % SIL2

2/209 90.4 % 94.6 % SIL2