SMART I/O User’s Manual

8 Channel AC Input Unit

Micro PLCs and Real-Time Computers

Manual ID 09901, Rev. Index 0500 of 08 Jan. 98

This page was intentionally left blank.

Preface

SMART I/O User’s Manual

Preface

Revision History ............................ 0-4

For Your Safety ............................. 0-5

Special Handling and Unpacking In-

structions ................................................. 0-6

08 Jan. 98

HV Safety Instructions............................. 0-6

Two Years Warranty...................... 0-7

Table of Contents.......................... 0-9

Page 0 - 3Manual ID 09901, Rev. Index 0500

Preface

Manual/Product Titl e:

SMART I/O User’s Manual

Manual ID Numb er:

09901

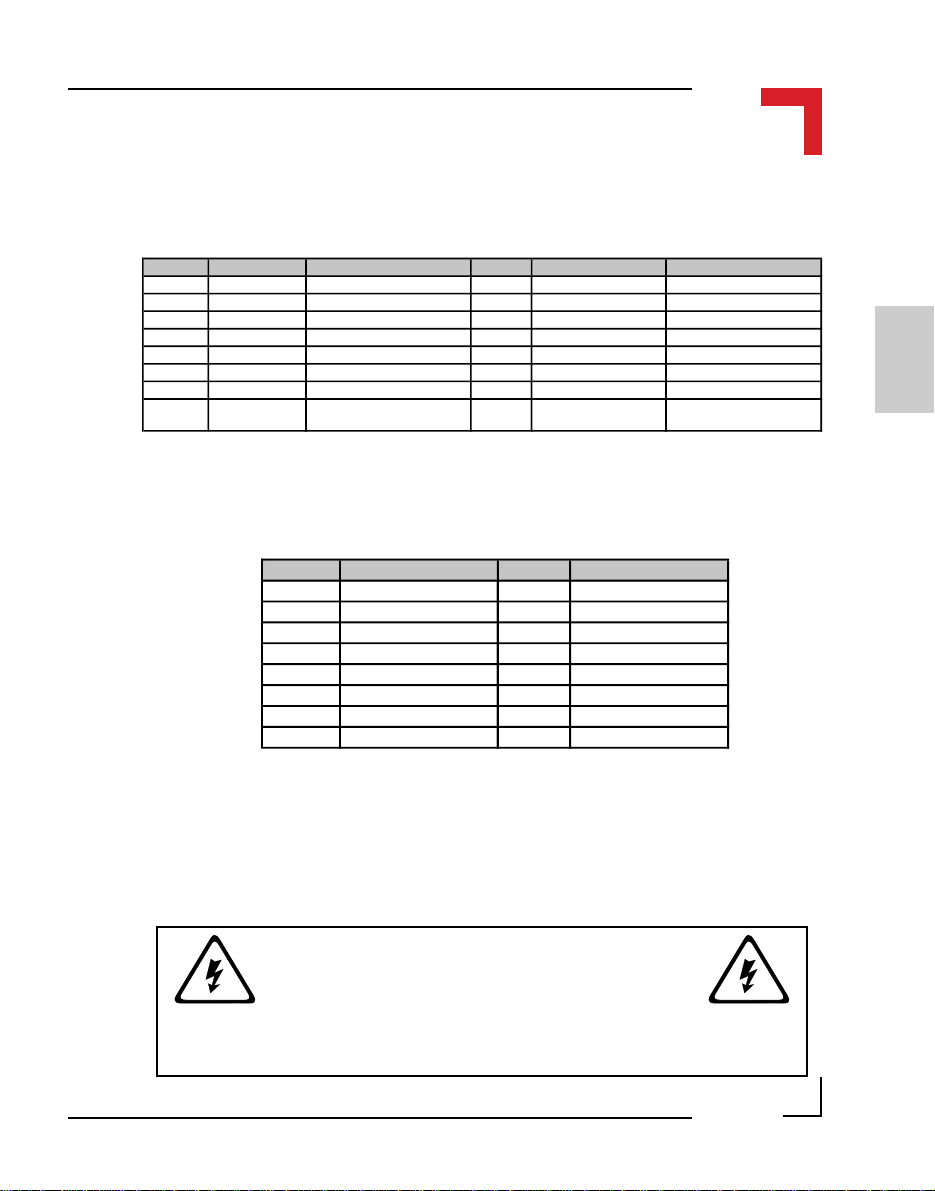

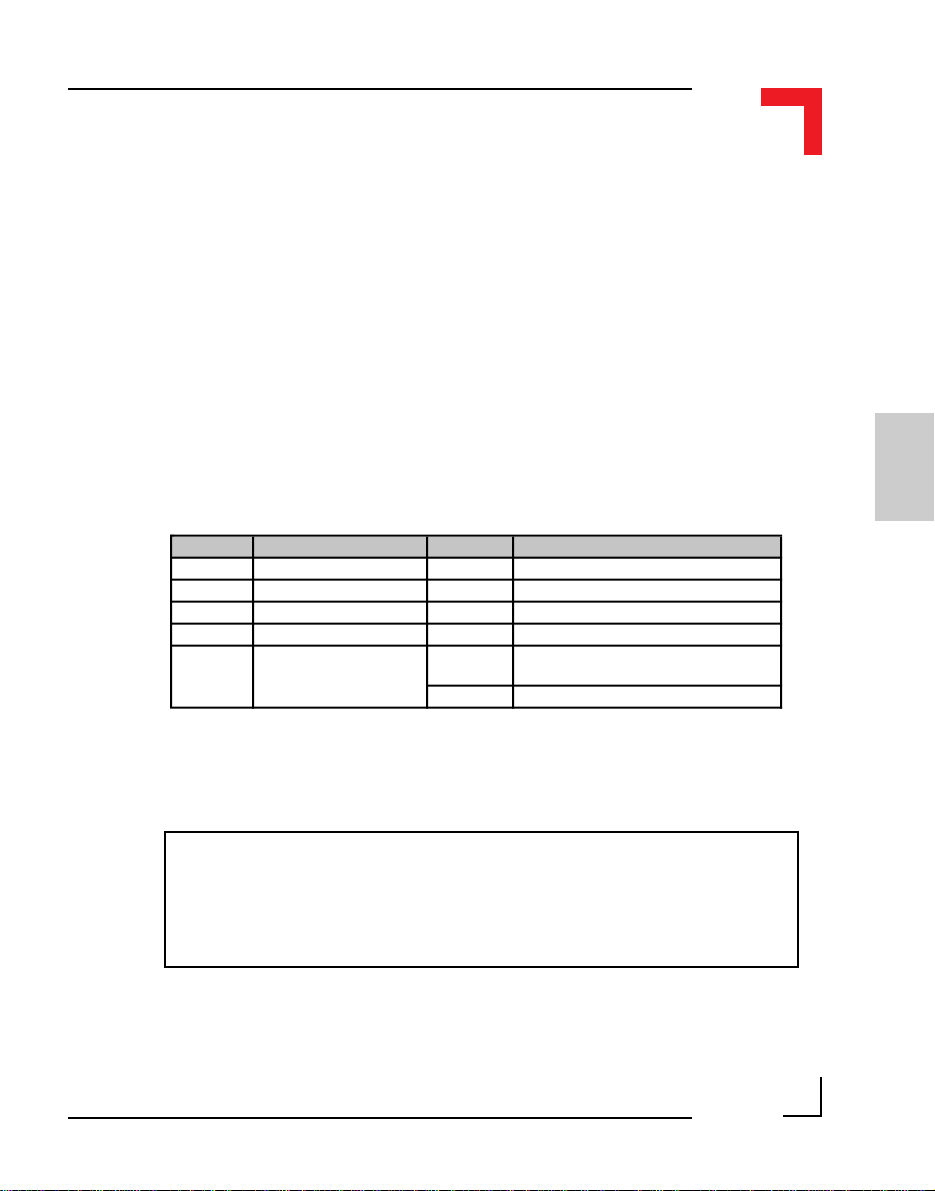

Rev.

Index

Brief Description of Changes

PCB Index

Date of

Issue

0100

Initial Issue

0202Dec. 94

0200

General Update, SM-DAD1 & Software

Library Added

0202Feb. 95

0300

New MS Modules A dded, D 5 For mat

0202Mar. 96

0400

New MS Modules A dded, C orrect ions

Including Update of SM-DAD1 ’C’ Pro-

gramming Section

0202Oct 96

0500

Standard Preface, ACI1 Module Added

0202Dec. 97

Revision History

SMART I/O User’s Manual

This document contains propri etary infor mation of PEP Modular Computers. It

may not be copied or transmitted by any means, passed to others, or stored in

any retrieval system or media, without the prior consen t of PEP Modul ar Com-

puters or its authorized agents.

The information in this document is, to the best of our knowledge , enti rely correct. However, PEP Modular Computers cannot a ccept liability for any inaccu-

racies, or the consequences thereof, nor for any liability arising from the use or

application of any circui t, pr oduct, or example shown in this document .

PEP Modular Computers reserve the right to change, modify, or improve this

document or the product descr ibed herein, as seen fit by PEP Modular Comput-

Page 0 - 4

08 Jan. 98Manual ID 09901, Rev. Index 0500

SMART I/O User’s Manual

Preface

For your safety

This PEP product is carefully designed for a long, fault-free life. However, its

life expectancy can be drastically reduced by improper treatment during

unpacking and installation. Therefore, in the interest of your own safety and of

correct operation of your new PEP product, please take care of the following

guidelines:

Before installing your new PEP product into a system, please, always

switch off your power mains. Thi s appl ie s al so t o installing piggybacks.

In order to maintain PEP’s p roduct warranty, pl ease, do not a lter or mod-

ify this product in any way. Changes or modifications to the device,

which are not explicitly approved by PEP Modular Computers and

described in this manual or received from PEP Technical Support as a

special handling instruct ion, wi ll void your warranty.

This device should only be installed in or connected to systems that ful-

fill all necessary technic al and specific envi ronmental requi rements. This

applies also to the operational temperature range of the specific board

version, which must not be exceeded. If batteries are present, their temperature restrictions mus t be take n int o account.

In performing all necessary installation and application operations, please,

follow only the instructions supplied by the present manual.

Keep all the original packaging material for future storage or warranty

shipments. If it is necessary to store or ship the board, warranty shipments. If it is necessary to stor e or ship the board, ple ase, re-pack it in the

original way.

08 Jan. 98

Page 0 - 5Manual ID 09901, Rev. Index 0500

Preface

SMART I/O User’s Manual

Special Handling and Unpacking Instructions

Electronic boards are sensitive to static electricity. Therefore, care must be

taken during all handling operations and inspections with this product, in order

to ensure product integri ty a t al l t imes.

Do not handle this product out of its protective enclosure while it is not

being worked with, or unless it i s ot her wise p rot ect ed.

Whenever possible, unpack or pack this product only at EOS/ESD safe

work stations.

Where safe work stations are not guaranteed, it is important for the user

to be electrically discharged before touching the product with his/her

hands or tools. This is most easily done by touching a metal part of your

system housing.

Particularly, observe standard ant i-sta tic prec autions when cha nging pig-

gybacks, ROM devices, jumper settings etc. If the product contains batteries for RTC or memory bac k-up, ensure that the board i s not place d on

conductive surfaces, including anti-static plastics or sponges. They can

cause short circuits and da ma ge t he bat teries or tracks on the board.

HV Safety Instructions

This chapter of the safety instructions applies to

(> 60 V)

Your new PEP product was developed and tested carefully to provide all features necessary to ensure the renown electrical safety requirements. However,

serious electrical shock hazards exist during all installation, repair and maintenance operations with this product. Therefore, always unplug the power cable

to avoid exposure to hazardous voltage.

All operations on this d evice have to be c arri ed ou t by su ffic ien tly sk ille d personnel only.

Page 0 - 6

only.

HIGH-VOLTAGE APPLIANCES

08 Jan. 98Manual ID 09901, Rev. Index 0500

SMART I/O User’s Manual

Two Years Warranty

Preface

PEP Modular Computers grants the original purchaser of PEP products a

YEARS LIMITED HARDWARE WARRANTY

as described in the following. How-

TWO

ever, no other warranties that may be granted or implied by anyone on behalf of

PEP are valid unless the consumer has the expressed written consent of PEP

Modular Computers.

PEP Modular Computers warrants their own products, excluding software, to

be exempt of manufacturing and materia l defect s for a perio d of 24 consecut ive

months from the date of purchase. Thi s warr ant y is not transferable nor extendible to cover any other users or long-term storage of the product. It does not

cover products which have been modified, altered or repaired by any other

party than PEP Modular Computers or their authorized agents. Furthermore,

any product which has been, or is suspected of being damaged as a result of

negligence, improper use, incorrect handling, servicing or maintenance, or

which has been damaged as a result of excessive current/voltage or temperature, or which has had its serial number(s), any other markings or parts thereof

altered, defaced or re mov ed will also be excluded fro m t his warranty.

If the customer’s eligibility for warranty has not been voided, in case of any

claim, he may return the product at the earliest possible convenience to the

original place of purchase, together with a copy of the original document of

purchase, a full description of the application the product is used on and a

description of the defect . Pack the product in such a way as to ens ure saf e tra nsportation (see our saf et y ins tructions).

PEP provides for repair or replacement of any part, assembly or sub-assembly

at their own discretio n, or to re fund the or iginal cost of purch ase, if ap propria te.

In the event of repair, refunding or replacement of any part, the ownership of

the removed or replaced parts reverts to PEP Modular Computers, and the

remaining part of the original guarantee, or any new guarantee to cover the

repaired or replaced items, will be transferred to cover the new or repaired

items. Any extensions to the o riginal guar antee ar e consid ered gest ure s of

08 Jan. 98

Page 0 - 7Manual ID 09901, Rev. Index 0500

Preface

SMART I/O User’s Manual

goodwill, and will be defined in the “Repair Report” issued by PEP with the

repaired or replaced it em.

PEP Modular Computers will not accept liability for any further claims resulting directly or indirectly from any warranty claim, other than the above specified repair, replacement or re funding. Particularly, all clai ms for damage to any

system or process in whi ch t he product was employed, or an y l oss incurred as a

result of the product not functioning at any given time, are exclude d. The extent

of PEP Modular Computers liability to the customer shall not exceed the origi-

nal purchase price of the i tem f or whi ch t he cl aim exist.

PEP Modular Computers issues no warranty or representation, either explicit

or implicit, with respect to its products, reliability, fitness, quality, marketability or ability to fulfil any pa rticular applicatio n or purpose. As a res ult, the products are sold “as is,” and the responsibility to ensure their suitability for any

given task remains of the purchaser. In no event will PEP be liable fo r direct,

indirect or consequential damages resulting from the use of our hardware or

software products, or documentation, even if PEP were advised of the possibility of such claims prior to the purchase of the product or during any period

since the date of its purc hase .

Please remember that no PEP Modul ar Computers employe e, dealer or agent is

authorized to make any modification or addition to the above specified terms,

either verbally or in any other form written or electronically transmitted, without the company’s consent.

Page 0 - 8

08 Jan. 98Manual ID 09901, Rev. Index 0500

SMART I/O User’s Manual

Table of Contents

Preface

Chapter

1. General Information............................... 1-3

1.1 Product Overview ............................................ 1-8

1.2 Ordering Information ....................................... 1-9

1.3 Product Information ................................... .... 1-10

1.4 Installation ..................................................... 1-13

1.5 ISaGRAF Installation ..................................... 1-18

Chapter

2. SMART-BASE ....................................... 2-3

2.1 Specifications .................................................. 2-4

2.2 Board Overview ............................................... 2-5

1

2

2.3 Functional Description ..................................... 2-6

2.4 Configuration ................................................... 2-8

08 Jan. 98

Page 0 - 9Manual ID 09901, Rev. Index 0500

Preface

2.5 Pinouts ............................................................. 2-9

2.6 ‘C’ Programming .. ............................ .... ..... ..... 2-17

2.7 ISaGRAF Programming ............................ ..... 2-32

2.8 Flash Utility .................................................... 2-37

SMART I/O User’s Manual

Chapter

3. SMART-EXT ......................................... 3-3

3.1 Specifications ................................................... 3-3

3.2 Board Overview ............................... .... ..... ....... 3-4

3.3 Functional Description ..................................... 3-5

3.4 Pinouts ............................................................. 3-6

Chapter

4. Digital Modules .....................................4-5

4.1 SM-DIN1........................................................... 4-5

4.2 SM-DOUT1..................................................... 4-19

3

4

Page 0 - 10

08 Jan. 98Manual ID 09901, Rev. Index 0500

SMART I/O User’s Manual

4.3 SM-REL1........................................... ..... .... .... 4-33

4.4 SM-ACI1............................................ ..... .... .... 4-51

Preface

Chapter

5. Analog Modules..................... ... .. ... .. ...... 5 -7

5.1 SM-DAD1......................................................... 5-7

5.2 SM-PT100 ..................................................... 5-29

5.3 SM-THERM ................................................... 5-59

5.4 SM-ADC1................... ............................ .... .... 5-89

5.5 SM-DAC1..................................................... 5-107

Chapter

6. Communications Modules .................... 6-5

6.1 SM-RS232........................................................ 6-5

5

6

6.2 SM-SSI......................................... ..... ..... ........ 6-17

08 Jan. 98

Page 0 - 11Manual ID 09901, Rev. Index 0500

This page was intentionally left blank.

Introduction

General Information.....................................1-3

SMART I/O User’s Manual

Table of Contents

1

Weights & Measures .................................................................... 1-4

1.1 Product Overview .................................................................. 1-8

1.2 Ordering Information ............................................................. 1-9

1.3 Product Information ............................................................. 1-10

1.4 Installation ........................................................................... 1-13

1.4.1 Overview ........................................................................................... 1-13

1.4.2 SMART I/O Module Installation....................................................... 1-15

1.4.3 RJ45 Telephone Connector Installation ............................................ 1-16

1.4.4 Screw Terminal Block Installation .................................................... 1-16

1.4.5 Battery Installation ............................................................................ 1-17

1.5 ISaGRAF-Installation .......................................................... 1-18

1.5.1 Before Installing ................................................................................1-18

1.5.2 Installation of the ISaGRAF for Windows Workbench..................... 1-19

1.5.3 Installation of PEP Library Functions ............................................... 1-21

1.5.4 Demo Application ............................................................................. 1-26

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 1 - 1

SMART I/O User’s Manual

This page has been left blank intentionally.

Introduction

Page 1 - 2

©1996 PEP Modular Computers GmbH

March 12, 1996

Introduction

General Information

SMART I/O User’s Manual

1

All PEP products are intended for use in industrial climates where extreme

environments exist. Dirt, temperature extremes, varying humidity levels,

vibration, noise, shock and electromagnetic signals must all be considered.

Only when certain precautions have been followed can PEP guarantee the

performance of the product stated in the data sheet.

In most cases, controllers are situated in close vicinity to electromechanical

devices like relays, transformers, motor controllers and high-frequency

switches etc. In such situations, a variety of disturbance sources are present

and effect the performance characteristics of the controller. However, by

observing the following precautions, many of the bad effects can be minimized.

• Earth protect the controller fixing

• Use screened/shielded cable connections

• Place cables according to relevant standards

• Observe the use of the correct cable diameter and type

• For unused module sockets, install a blank front-panel

• Leave enough room between a ‘hot body’ and the controller for air to

circulate freely

• Place the controller as far away as possible from ‘noisy’ components

• Separate digital and analog cabling

• Only replace/insert modules in the carrier unit with the power OFF

• Handle the controller components with care; Modules containing highly

integrated CMOS components are very sensitive to static discharges

• Try to separate analog modules from their digital cousins.

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 1 - 3

SMART I/O User’s Manual

Weights & Measures

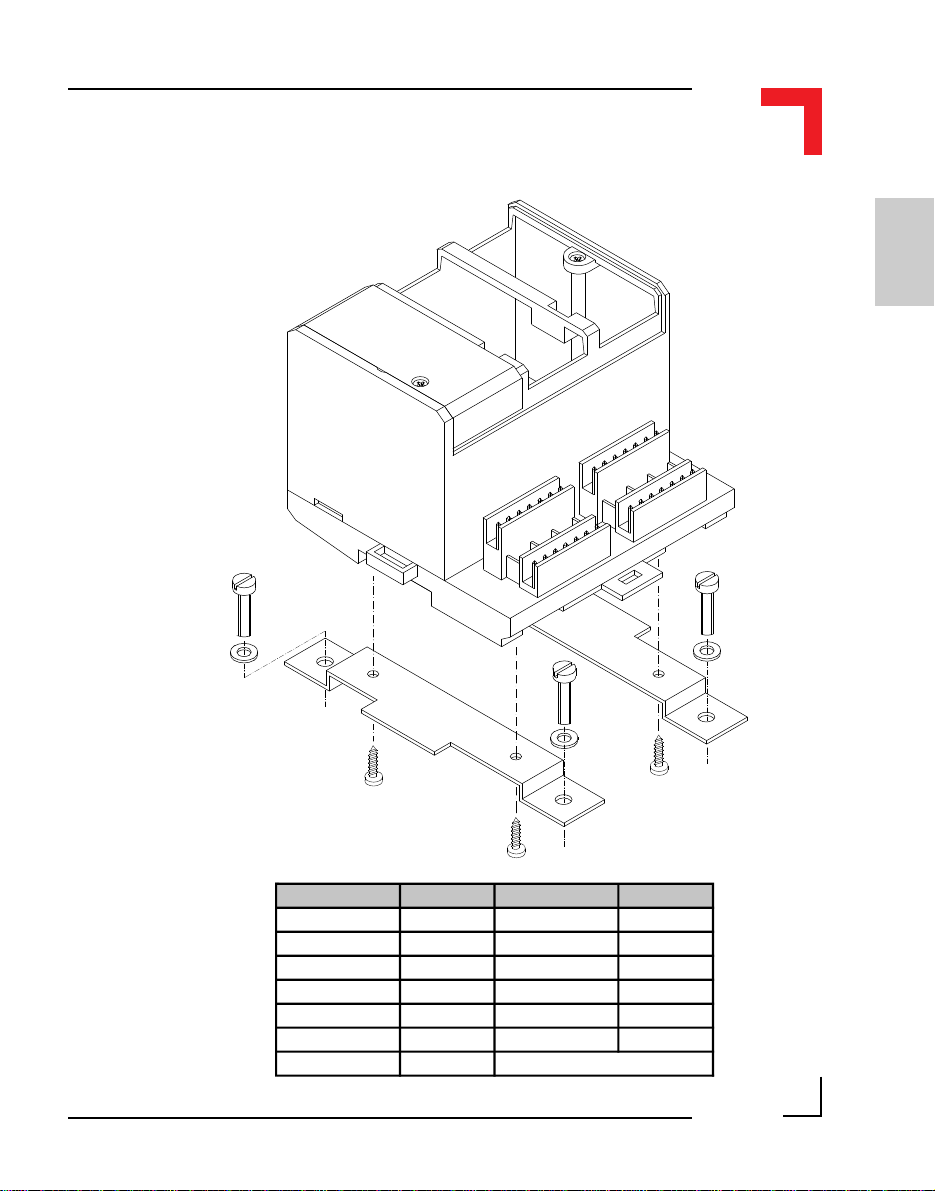

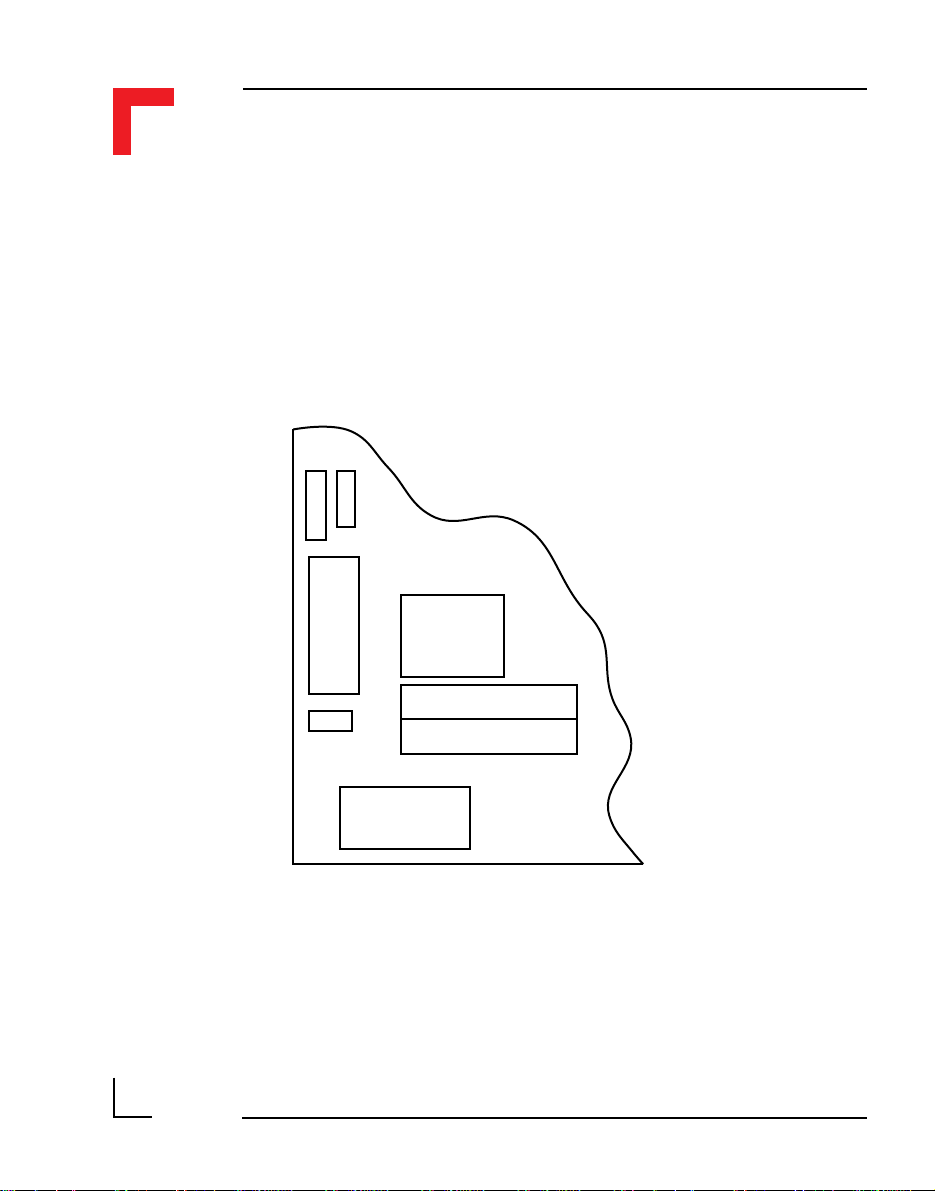

The following line drawings serve to illustrate the method of fixing the

controller to a DIN rail or brackets for wall/cabinet mounting. Note that all

measurements are in millimetres.

Introduction

Page 1 - 4

©1996 PEP Modular Computers GmbH

DIN Rail Mounting

March 12, 1996

Introduction

SMART I/O User’s Manual

1

Optional Bracket Mounting

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 1 - 5

SMART I/O User’s Manual

Introduction

Page 1 - 6

©1996 PEP Modular Computers GmbH

March 12, 1996

Introduction

SMART I/O User’s Manual

1

Unit Weight Unit Weight

SMART-BASE 650g SM-THERM 40g

SMART-EXT 250g SM-ADC1 70g

SM-DIN1 40g SM-DAC1 70g

SM-DOUT1 70g SM-SSI 70g

SM-REL1 61g SM-CNT1 N/A

SM-DAD1 70g SM-RS232 40g

SM-PT100 40g

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 1 - 7

SMART I/O User’s Manual

1.1 Product Overview

SMART I/O is based on a cost effective open system for industrial automation and industrial computing. By programming the SMART I/O using the

standard ISaGRAF workbench for IEC 1131-3 PLC programming languages

and the Ultra-C compiler (DOS, OS-9) for ANSI-C real-time programming,

the SMART I/O can be used as a micro PLC and as a real-time computer

system.

Equipped with the standard real-time fieldbus PROFIBUS, it allows the use

of the SMART I/O in a fully transparent real-time network architecture. This

architecture provides open communication between PEP systems and third

party I/O systems, as well as MMI. PROFIBUS not only allows I/O communication, but also file transfer, remote login and remote debugging facilities.

SMART I/O is designed around the MC68302 CPU from Motorola which

has two on-chip microprocessors. One is the industry standard 68HC000

running at 20MHz, and the second is a communication orientated RISC

processor. Fieldbus protocols use the power of this RISC CPU, freeing the

68HC000 for other tasks. Communication between the 68HC000 and the

communication processor is made using on-chip dual-ported RAM. Nonvolatile memory (battery backed SRAM and FLASH memory) allows a secure

and long-term backup of the application program and data.

Introduction

Well suited for machinery manufacturers and all OEMs, the SMART I/O is

an ideal companion for VME9000 and IUC9000 systems. Connected together with these high-end VME or IUC computers and PLCs, SMART I/O

allows the decentralization of I/O functions through the world wide accepted

PROFIBUS fieldbus.

SMART I/O systems provide more power than dumped remote I/O systems

since they support local intelligence: an IEC1131-3 programming environment as well as ANSI-C programming under real-time OS. All this power is

provided with excellent price/performance characteristics.

Page 1 - 8

©1996 PEP Modular Computers GmbH

March 12, 1996

Introduction

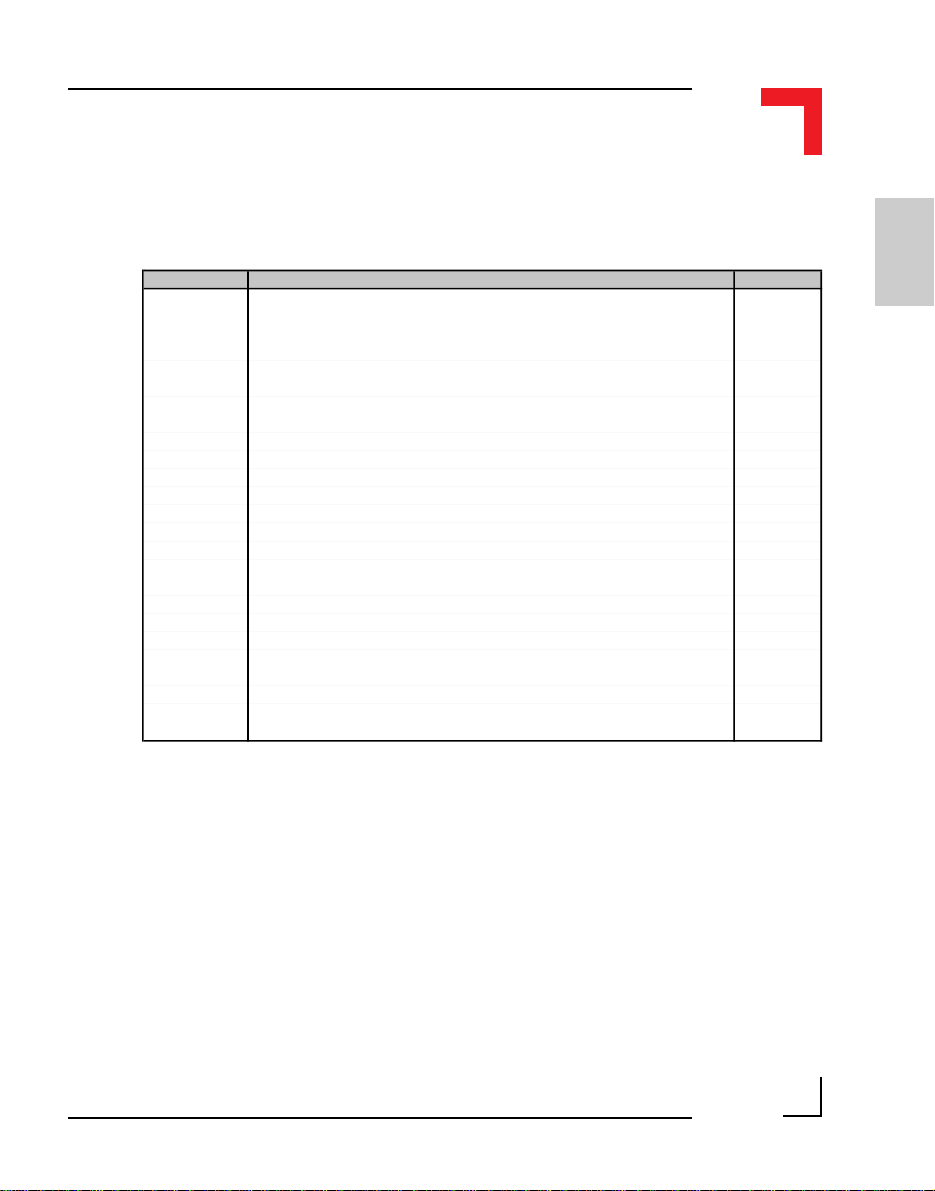

1.2 Ordering Information

SMART I/O User’s Manual

Product Description Order Nr.

SMART-BASE

SMART-BASE

SMART-EXT

SM-DIN1 SMART-Module with 8 optoisolated 24V DC digital inputs 4229

SM-DOUT1 SMART-Module with 8 optoisolated 24V DC/500mA digital outputs 4231

SM-DAD1 SMART-Module with 4 channel A/D (±10V), 2 channel D/A (±10V, 0..10V) 9868

SM-PT100 SMART-Module with 4 optoisolated 2, 3 or 4-wire PT100 inputs 12405

SM-THERM SMART-Module with 4 optoisolated thermocouple inputs 12426

SM-REL1 SMART-Module with 6 optoisolated normally open relay outputs 12238

SM-RS232 SMART-Module with RS232 (Rx & Tx) interface 12461

SM-SSI

SM-ADC1 SMART-Module with 6 12-bit, ±10V optoisolated analog inputs 13380

SM-ADC1 SMART-Module with 6 12-bit, 0..20mA optoisolated analog inputs 13868

SM-DAC1 SMART-Module with 2 12-bit, ±10V optoisolated analog outputs 13379

SM-DAC1

SM-DAC1 SMART-Module with 6 12-bit, ±10V optoisolated analog outputs 14019

SM-DAC1

Micro PLC & real-time computer, 1 MByte EPROM, 512 kByte DRAM,

64kByte SRAM, OS-9 v3.0, ISaGRAF v3.0x, PROFIBUS v3.12, Layer

2 & 7, RTC, full modem RS232 (8-pin RJ45 connector), 190 mAh

battery, housing and terminal block for the 24V DC power supply

As product 13843 but with additional 1 MByte Flash memory (TSOP) on

solder side

Expansion module for the SMART-BASE supporting 2 SMART-Modules

Delivered without terminal blocks, SMART-Modules or blank panels

SMART-Module with 1 SSI channel providing a 24V DC digital input and a

24V DC, 500mA digital output

SMART-Module with 2 12-bit, 0..20mA optoisolated analog outputs with

current sensing for broken sensor detection

SMART-Module with 6 12-bit, 0..20mA optoisolated analog outputs with

current sensing for broken sensor detection

13843

13844

4228

12825

14018

14020

1

All SM-Modules are delivered without screw terminals.

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 1 - 9

SMART I/O User’s Manual

Introduction

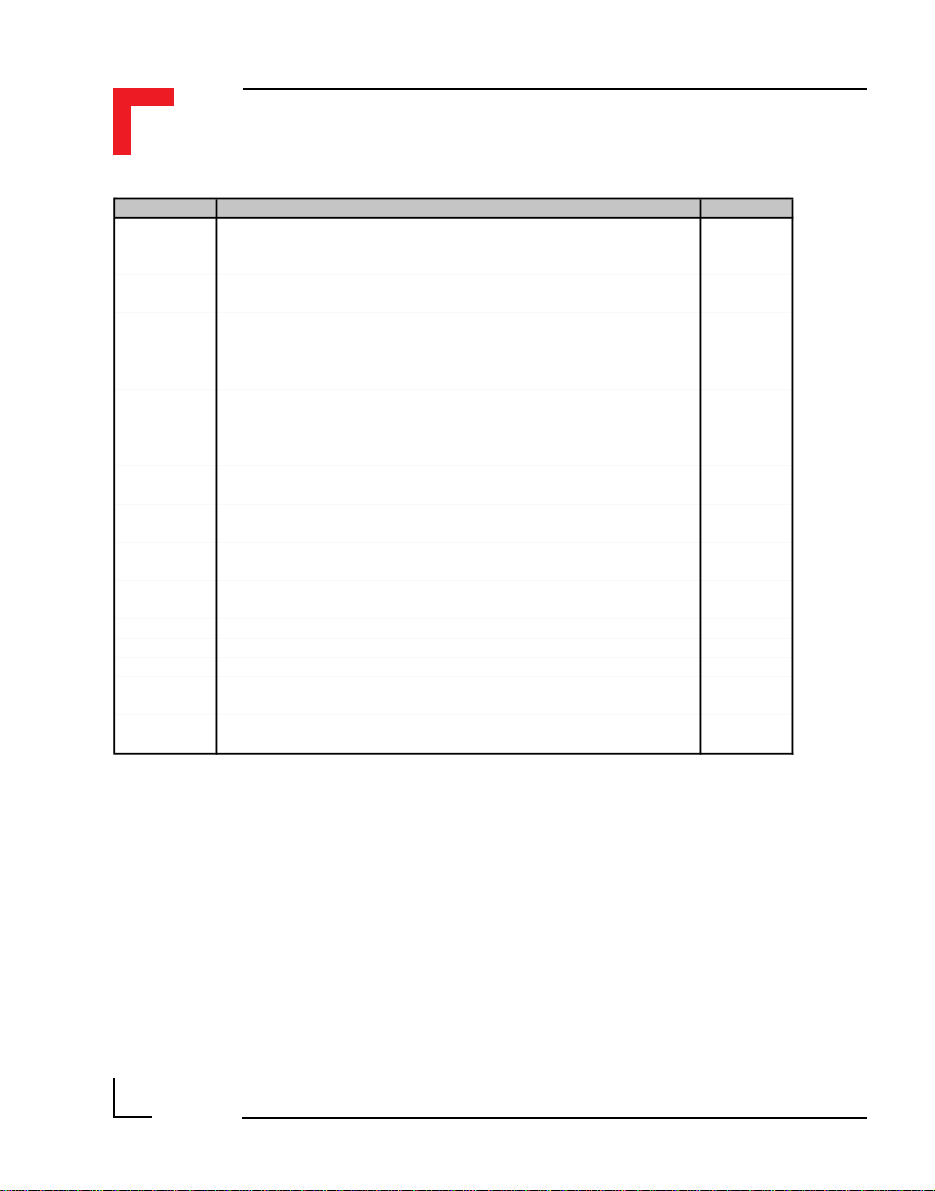

Product Description Order Nr.

ISaGRAFROM-START

OS9TRG-RGSMART

OS9DEVFTWIN-SMART

OS9DEVFTUNIX-SMART

OS9-PFBSMART

OS9-PFBSMART(FT)

Cable

Cable

Screw Term. For the SMART-BASE timer I/O. Pack of 5, 2x3 array 10892

SCR-2*7. For the SMART-Modules. Pack of 5, 2x7 array 10893

Dummy FP For unused SMART-Module slots. Available in packs of 20 10894

Battery

Battery

ROM kit v3.x for SMART I/O enables the generation of custom

firmware EPROMs. Platform can be a PC or OS-9 development

system

Target CPU kit for SMART I/O (OS-9 v3.x/Ix.x disks) 11299

OS-9/68000 FasTrak for Windows development pack for SMART I/O.

Contains extended OS-9 v3.x/Ix.x, PEP utilities and I/O drivers with

necessary makefiles for complete application and EPROM

generation.

OS-9/68000 FasTrak for UNIX development pack for SMART I/O.

Contains extended OS-9 v3.x/Ix.x, PEP utilities and I/O drivers with

necessary makefiles for complete application and EPROM

generation.

OS-9 PROFIBUS starter kit II for 1 node. Includes license, disk and

manual

OS-9 PROFIBUS starter kit II for 1 node operating under FasTrak for

Windows. Includes license, disk and manual

3 meters with 9-pin D-Sub (female) & RJ45 connectors for PC

operation

3 meters with 25-pin D-Sub (male) & RJ45 connectors for modem

operation

3V, 190mAh lithium batery (button) BR2032 for use in the standard

temperature range (0°C to +70°C)

3V, 850mAh lithium batery (cylinder) CR14250 for use in the

extendedtemperature range (-40°C to +85°C)

13829

13887

13926

1662

12666

10890

10891

11281

11282

1.3 Product Information

The SMART-BASE is a control module possessing an RS485 PROFIBUS

and serial RS232 interface as standard and provision for up to three SMARTModules. The modules currently available are discussed later. Normally, the

base unit is mounted on a DIN rail (see Weights & Measures section) which

in turn may be fixed in a cabinet. SMART-EXT units may be attached in a

similar manner.

Page 1 - 10

©1996 PEP Modular Computers GmbH

March 12, 1996

Introduction

SMART I/O User’s Manual

The attachment of both units is achieved by sliding them over the DIN rail

with the clip assembly pulled out and then releasing it when correctly positioned.

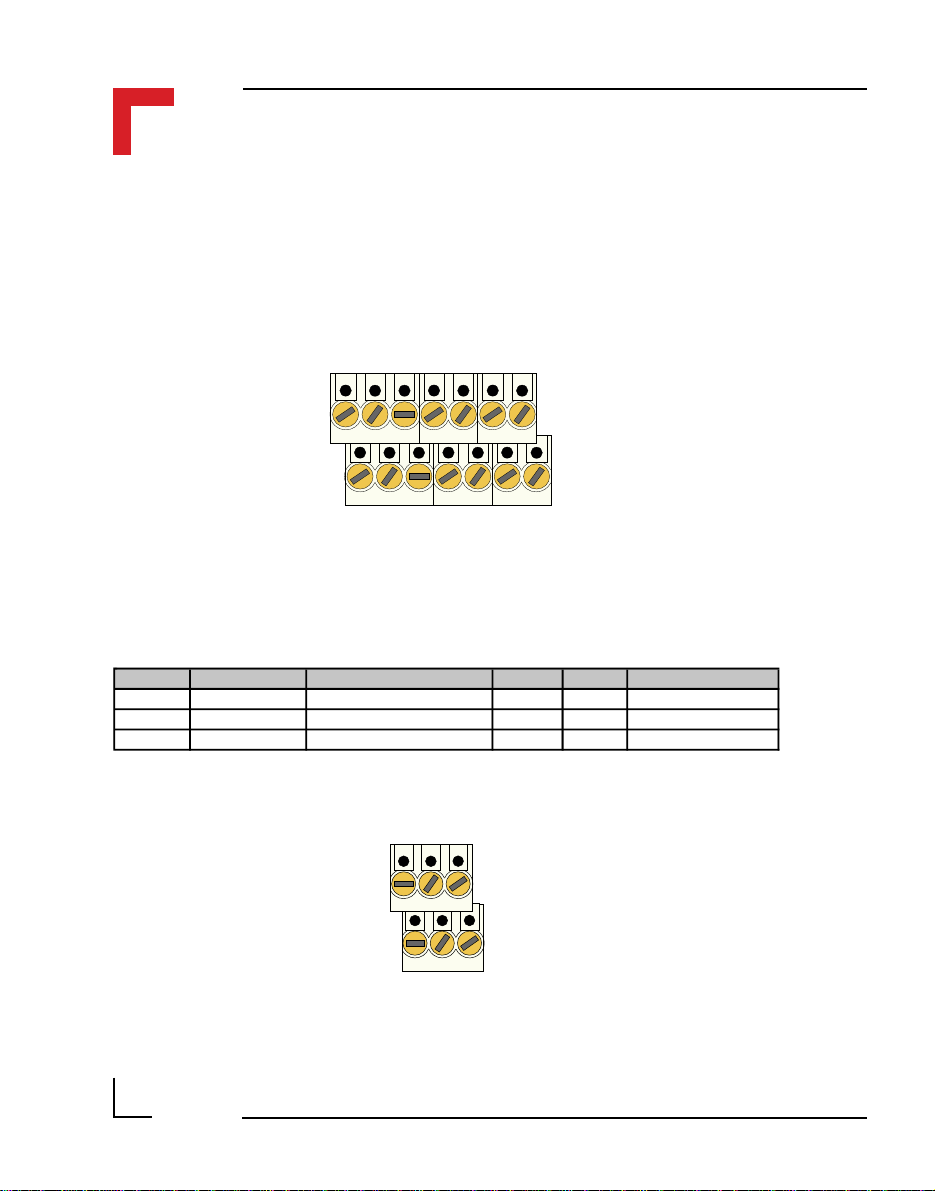

The 24V supply source should possess the following characteristics:

Voltage Current

min ma x Continuous Peak

18V 36V 400mA 1.5A (2ms)

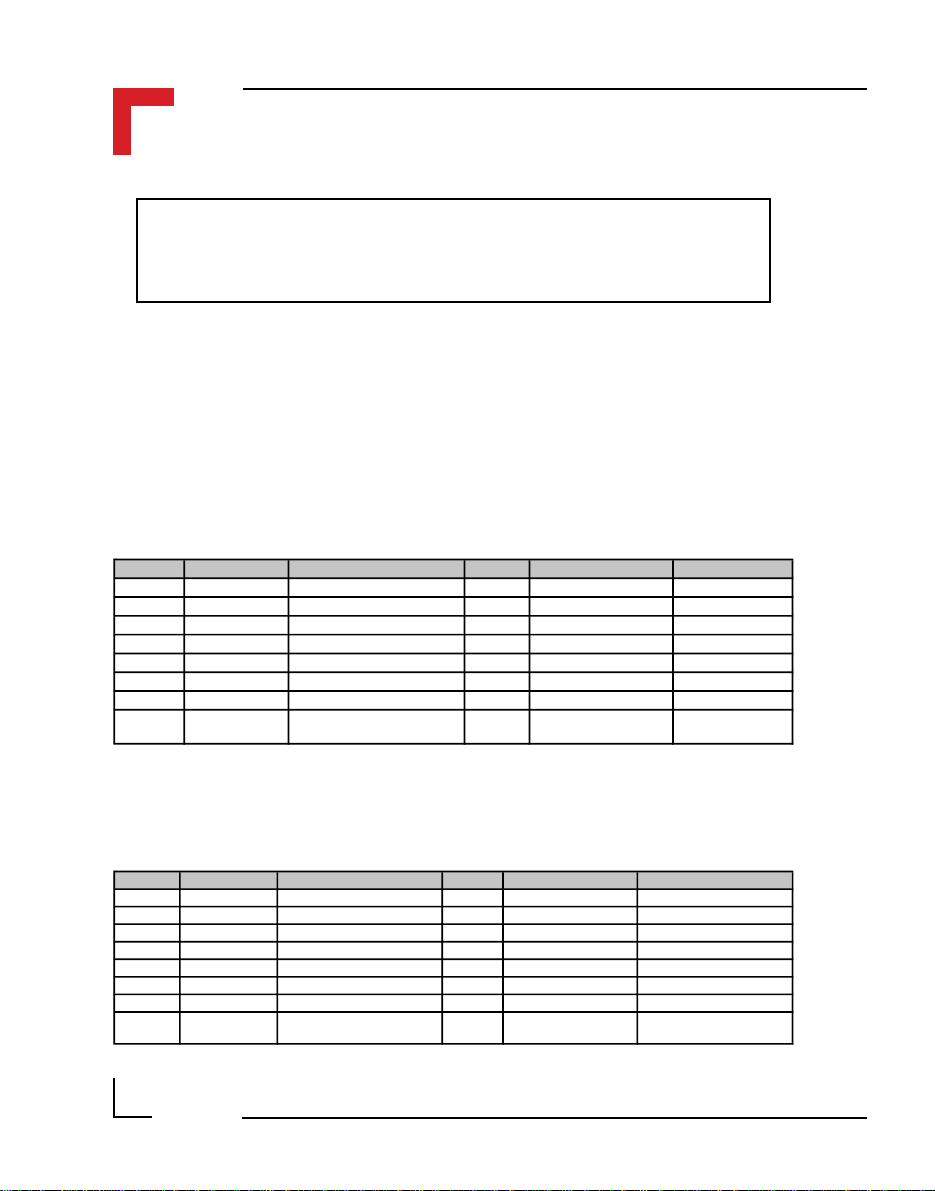

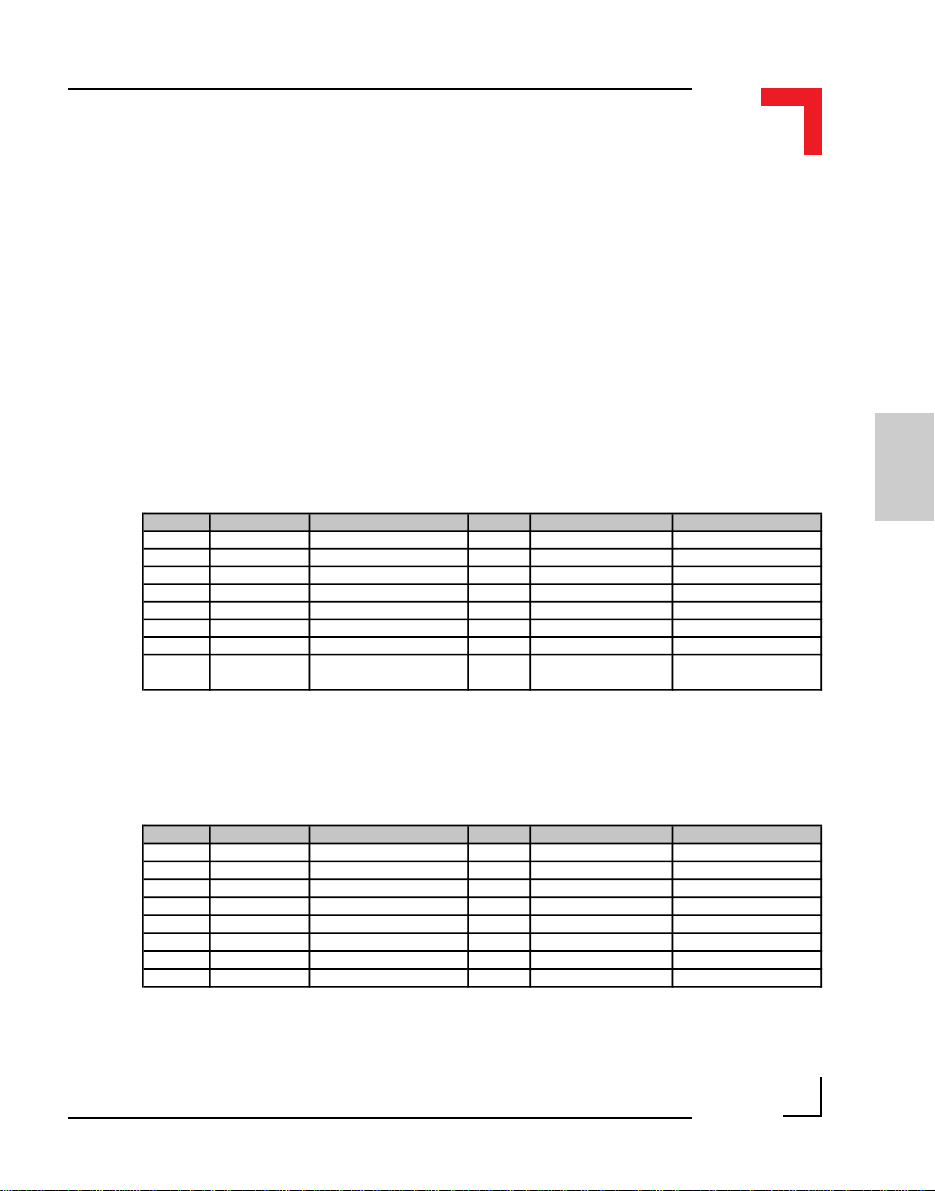

Because of power limitations, it should be noted that although up to 11

SMART-Modules are possible in a complete configuration, attention should

be paid to the following tables that show the individual component power

requirements. The maximum of 6750mW should not be exceeded as damage

to the on-board DC-DC converter may result due to overheating or entering a

reset status due to the thermal cutoff protection switching mechanism.

1

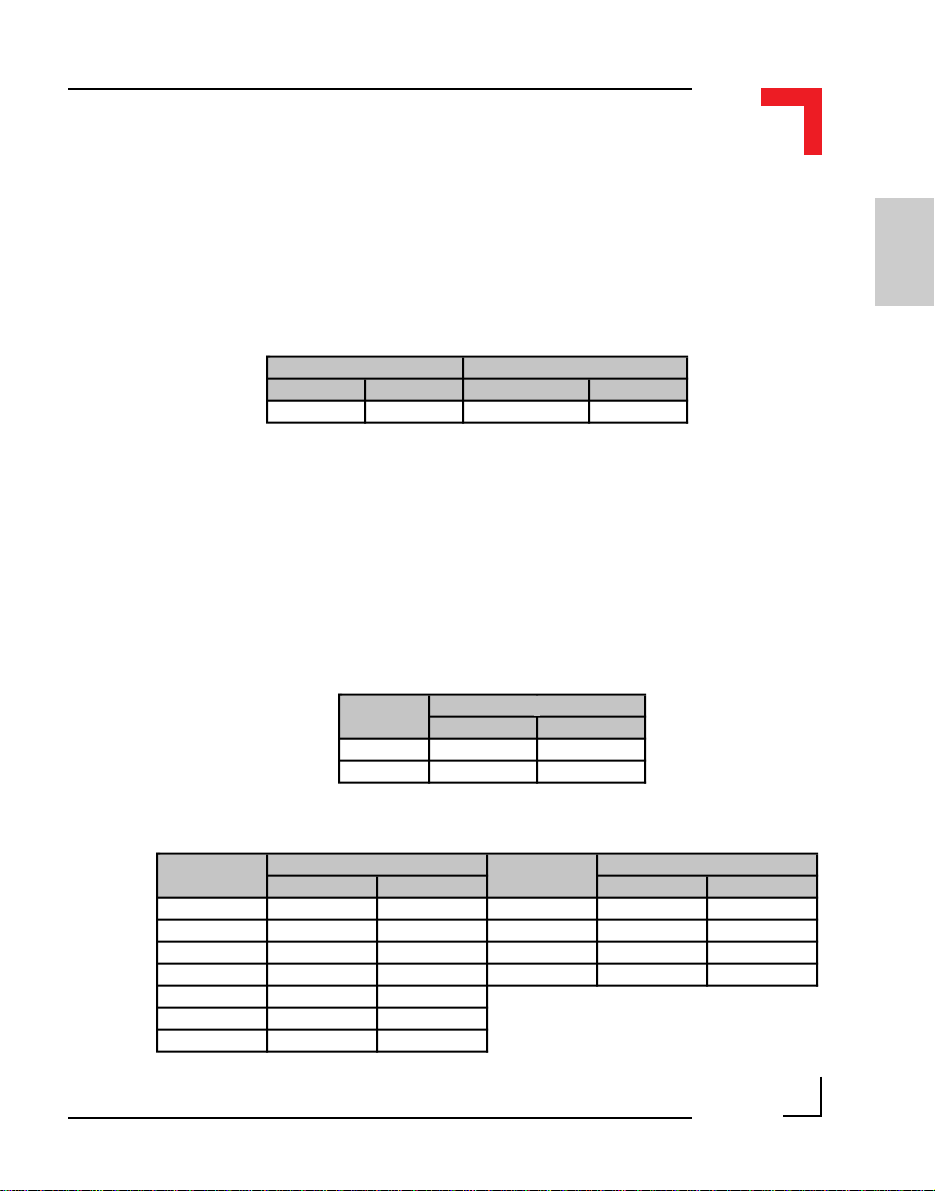

SM-BASEPower Consumption

min max

CPU Core 1500mW 1700mW

Profibus 250mW 750mW

Module Power Consumption Module Power Consumption

min m a x min ma x

SM-DIN1 5mW 100mW SM-ADC1 350mW 450mW

SM-DOUT1 5mW 270mW SM-DAC1 5mW 400mW

SM-DAD1 350mW 450mW SM-DAC1 350mW 660mW

SM-PT100 400mW 500mW SM-SSI unknown unknown

SM-THERM 400mW 500mW

SM-RS232 23mW 75mW

SM-REL1 23mW 160mW

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 1 - 11

SMART I/O User’s Manual

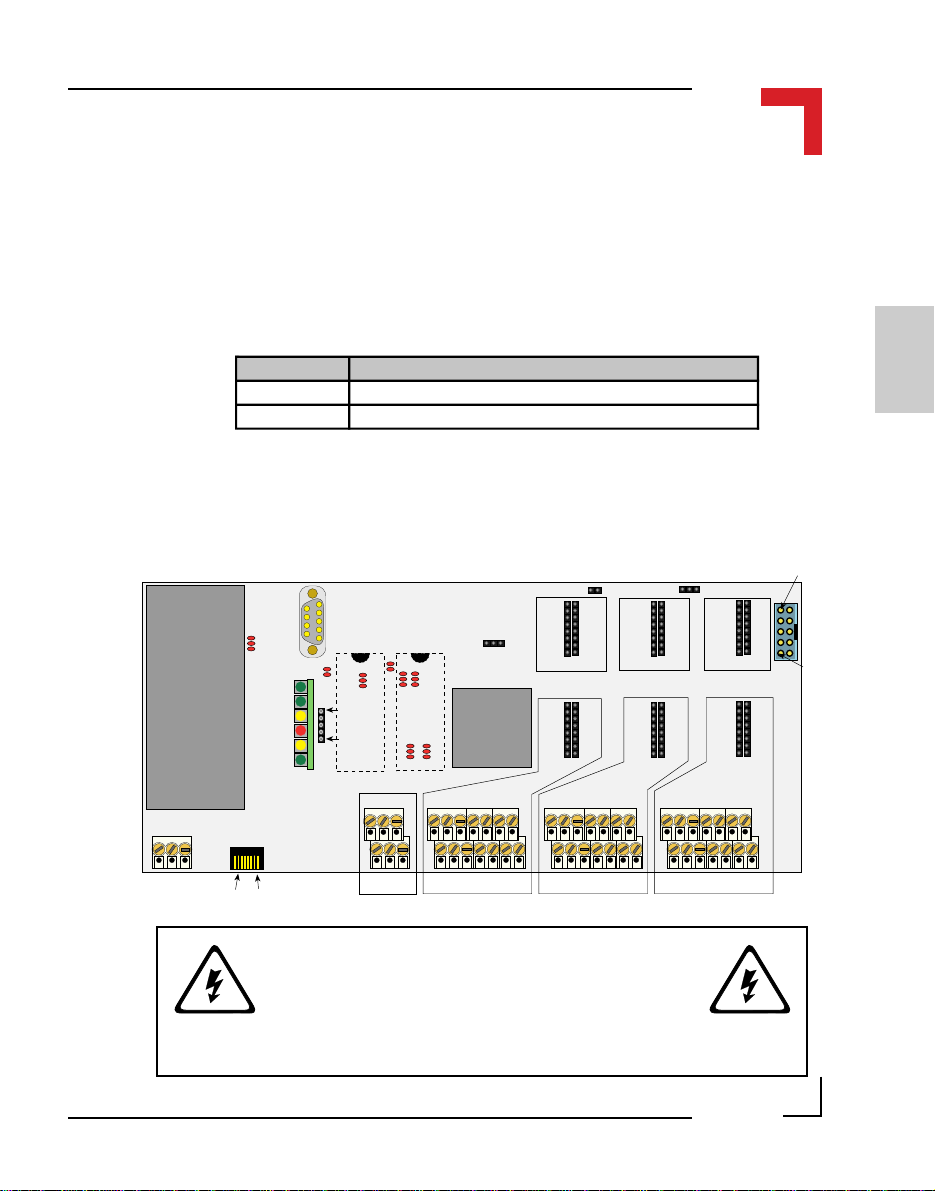

An on-board fuse protects the 24V DC input circuitry from damage through

higher voltages than those expected or AC voltages being inadvertently

applied to the system. This fuse, should it be assumed defect (the Power In

LED on the housing will not be illuminated), may be accessed by removing

the cover of the SMART-BASE and accessing the holder on the left-hand

side as shown in the illustration below.

D4

D3

C1

Introduction

F1 0.60A M

R77

SCR2

123

In the event of a blown fuse, replace it with the same size and type as the one

installed.

Page 1 - 12

©1996 PEP Modular Computers GmbH

C6

C7

March 12, 1996

Introduction

1.4 Installation

SMART I/O User’s Manual

1.4.1 Overview

The SMART-BASE and SMART-EXT units are supplied without screw

terminal blocks for the I/O slots, SMART Module piggybacks or blank

panels. These must be ordered separately to meet the requirements of individual specifications.

®

1

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 1 - 13

SMART I/O User’s Manual

Up to 4 SMART-EXT units can be cascaded depending on the power consumption of the individual SMART Modules.

Introduction

SMART I/O Modules or blank panels must be ordered separately to the

SMART-BASE or SMART-EXT units. Blank panels come in packs of 20.

Two RS232 cables are available. One terminates with a female 9-pin D-Sub

connector for PC use and the other terminates in a male 25-pin D-Sub

connector for Modem operation.

Page 1 - 14

©1996 PEP Modular Computers GmbH

March 12, 1996

Introduction

SMART I/O User’s Manual

Screw terminal connectors are available in packs of 5.

1

1.4.2 SMART I/O Module Installation

The SMART I/O Modules are fitted into the relevant sockets (ST1 - ST6; 3

slots) on the SMART-BASE or in sockets on the SMART-EXT unit. It is

important that the Modules are inserted the correct way. The Figure

below illustrates this procedure.

Figure 1.4.2.1 : SMART I/O Module Installation

SMART-Module

Socket

WARNING!

Once fitted on the board, the Module sockets and components should be on

the right hand side of the Module.

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 1 - 15

SMART-Module

SMART I/O User’s Manual

1.4.3 RJ45 Telephone Connector Installation

The RJ45 connector is fitted into the RS232 Telephone connector (BU1) on

the SMART-BASE. This is illustrated in the Figure below.

Figure 1.4.3.1 : RJ45 Telephone Connector Installation

SMART-BASE

Introduction

SCR2

BU1

RJ45 Connector

1.4.4 Screw Terminal Block Installation

The Screw Terminal Blocks are easily fitted to the SMART-BASE or

SMART-EXT by pushing them onto the relevant Screw Terminal, as shown

in the figure below.

Figure 1.4.4.1 : Screw Terminal Block Installation

Page 1 - 16

©1996 PEP Modular Computers GmbH

March 12, 1996

Introduction

SMART I/O User’s Manual

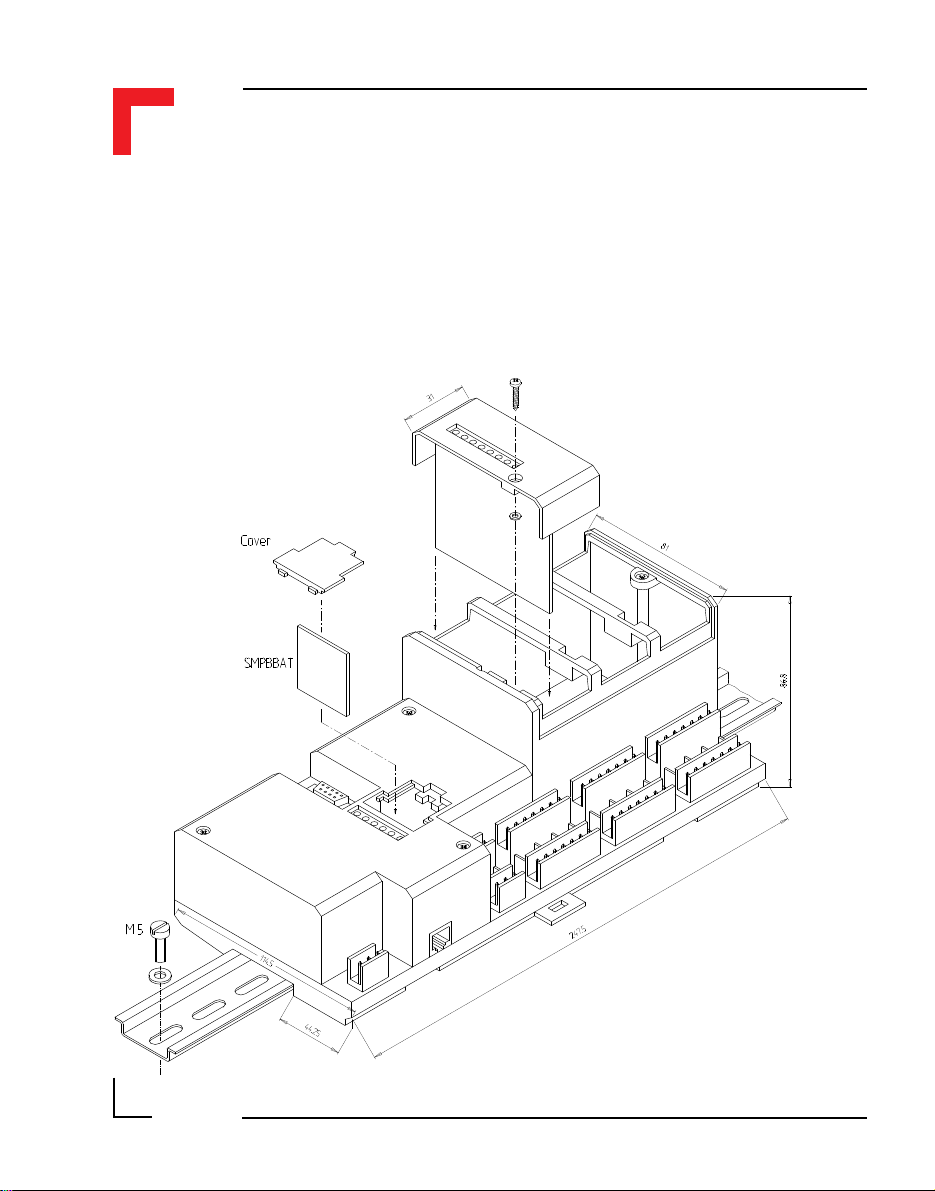

1.4.5 Battery Installation

The battery piggyback SMPBBAT is fitted into the socket BU3 on the

SMART-BASE. It is important that the piggyback is inserted in the correct

way. The figure below illustrates this procedure.

Figure 1.4.5.1: Battery Piggyback Installation

Pin 5

BU3

Pin 1

SMPBLED

SMPBBAT

Battery

Battery Type 3V Lithium BR2032 3V Lithium CR14250

Battery Capacity 190mAh 850mAh

Typical Data Retention Time *140 Days 590 Days

* this is the time without the main power being applied

WARNING!

1

Once fitted on the board, the battery should be on the right hand side of the

SMPBBAT piggyback. If the battery needs to be replaced, it must only be

done with a replacement SMPBBAT piggyback, the order number of which

is shown in the Ordering Information section of this manual.

The temperature on the battery must not exceed +70°C, due to the risk of

battery damage! For SMART I/O modules with extended temperature ranges

of up to 85°C, a special lithium battery must be fitted to the SMPBBAT.

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 1 - 17

SMART I/O User’s Manual

1.5 ISaGRAF-Installation

1.5.1 Before Installing

ISaGRAF is a Windows™ 3.xx based software development tool requiring a

minimum of 10 MB of hard disk space and 4 MB of available memory.

Before installing ISaGRAF, make a backup copy of each DOS disk in the

package and write-protect them to prevent accidental overwriting of files.

Note : The backup disks must have the same volume labels as the original

ISaGRAF disks. Use the Windows Copy Disk... command on the Disk menu

in the File Manager to create backup disks with the original volume labels

and disk contents.

If it is intended to install ISaGRAF in a directory other than the default

(C:\ISAWIN) then remember to provide the full path of the new directory

when prompted during installation.

Introduction

Altogether, 10 DOS disks and 2 OS-9 disks are supplied for ISaGRAF

installation; four for the Workbench, two composite and four for the

ISaGRAF Target and are labelled:

“Workbench Disk 1/4”

“Workbench Disk 2/4”

“Workbench Disk 3/4”

“Workbench Disk 4/4”

“Lib/Appli/Help Disk 1/2”

“Lib/Appli/Help Disk 2/2”

“Samples for OS-9 1/1”

“Target Disk 1/2” for DOS

“Target Disk 2/2” for DOS

“Profibus FMS for ISaGRAF, Documentation, Disk 1/1”

“Target Disk 1/2” for OS-9

“Target Disk 2/2” for OS-9

Page 1 - 18

©1996 PEP Modular Computers GmbH

March 12, 1996

Introduction

SMART I/O User’s Manual

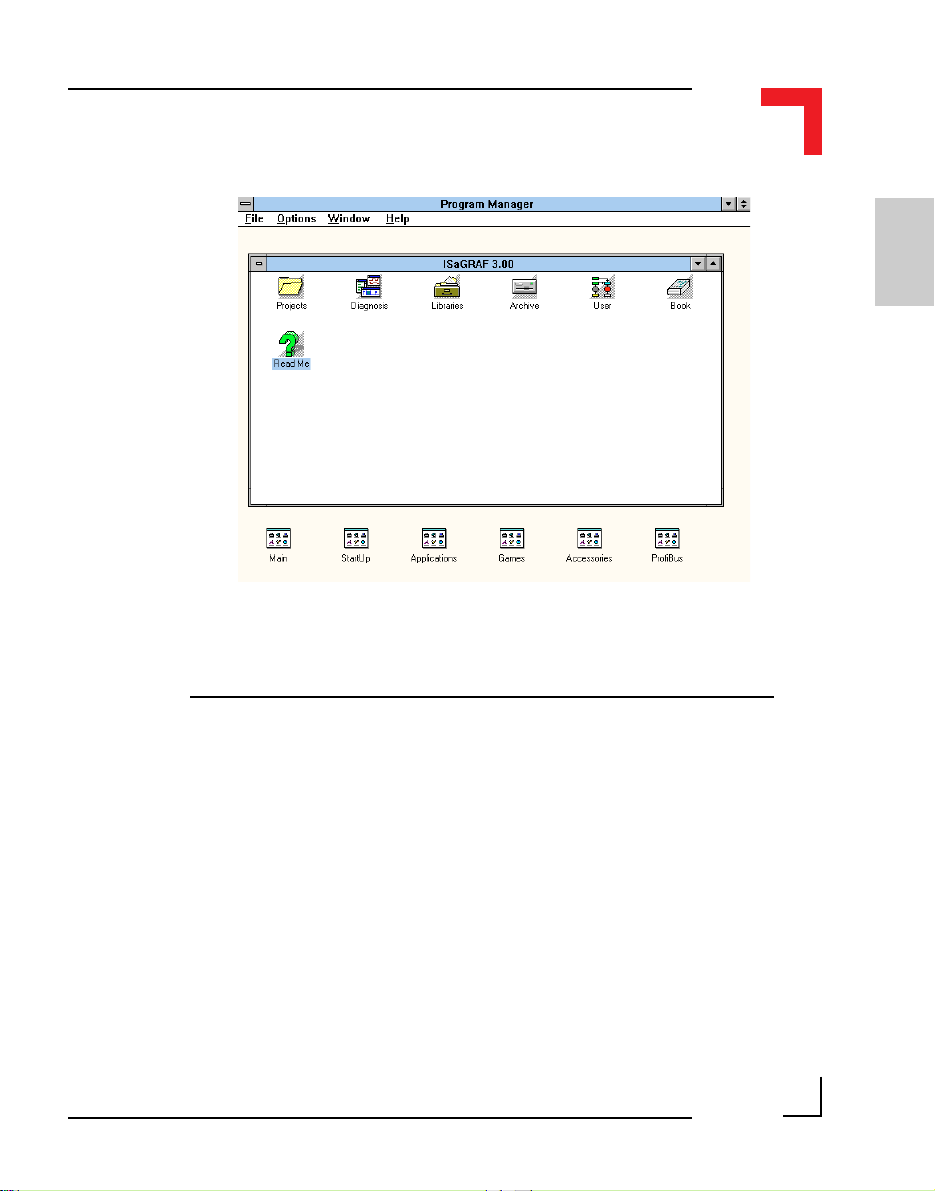

1.5.2 Installation of the ISaGRAF for Windows Workbench

The following steps should be followed to ensure successful installation of

the ISaGRAF software. Initially the disk labelled Workbench Disk 1/4 will

be required.

• Start Windows

• Insert diskette Workbench Disk 1/4 into the floppy drive (usually A:)

• Select File from the Windows Program Manager and select Run ...

• Type A:\INSTALL in the command field and select OK

The ISaGRAF installation will start automatically. Figure 1.5.2.1 illustrates a

typical opening screen.

1

Figure 1.5.2.1 Typical Opening Screen

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 1 - 19

SMART I/O User’s Manual

Having checked the installation directory (default is C:\ISAWIN) and

selected Install, the program progresses by asking whether the complete

system should be installed or just certain sections. The selection possibilities

are shown in figure 1.5.2.2.

Introduction

Figure 1.5.2.2 Installation Selection

The default is for a complete installation, i.e. all files. Once confirmed, the

installation copies the required files to the installation directory and unpacks

their contents. This procedure will take a few minutes. Upon completion, the

windows desktop will show a new program group containing the files shown

in figure 1.5.2.3.

Page 1 - 20

©1996 PEP Modular Computers GmbH

March 12, 1996

Introduction

SMART I/O User’s Manual

1

Figure 1.5.2.3 ISaGRAF Program Group

1.5.3 Installation of PEP Library Functions

The library functions are adapted to suit the SMART I/O and other PEP

products and should be installed using the two diskettes labelled LIB/

APPLI/HELP.

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 1 - 21

SMART I/O User’s Manual

These libraries for projects, I/O boards, ’C’ functions and common data are

extracted by following the described procedure:

• Start Windows if not already started

• Insert diskette Lib/Appli/Help Disk 1/2 into the floppy drive

• Select File from the Windows Program Manager and select Run ...

• Type A:\INSTALL in the command field and select OK

Figure 1.5.3.1 illustrates the Installation Start-up screen.

Introduction

Page 1 - 22

Figure 1.5.3.1 The Installation Start-up Screen

©1996 PEP Modular Computers GmbH

March 12, 1996

Introduction

SMART I/O User’s Manual

It should be noted that the standard ISA-Terminal is configured for COM2. If

another port is required then the switch to the new one is made by firstly

starting the ISA-Terminal program and then selecting the Settings from the

Communication pull-down menu. Here the possibility exists to select the

desired communications port. When leaving the ISA-Terminal environment,

remember to save the configuration if changes have been made.

The installation of the ISaGRAF development tool is now complete and

access is provided to a full IEC1131-3 programming platform.

The following sections deal with the application of this tool with the SMART

I/O and other PEP PLCs. Note that ‘C’ programming is not an option for the

SMART I/O Starter Kit and if required must be ordered separately through

one of the PEP offices or agents.

1

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 1 - 23

SMART I/O User’s Manual

In order to verify that the hardware and software have been correctly setup,

the following procedure should be followed.

• Connect the D-Sub connector end of the terminal cable to the chosen

COM port of the computer. The other end, with the telephone type

connector should be pushed into place in the RS232-port of the

SMART I/O base (see figure 1.4.3.1)

• With the power supply turned OFF, connect the power plug to SCR-2

on the SMART base.

• Start the ISA-Terminal program.

• Switch on the power supply to the SMART I/O; three green LEDs

should illuminate on the control panel (not the SMART Modules!). The

terminal should display the messages shown in figure 1.5.3.2.

Introduction

Page 1 - 24

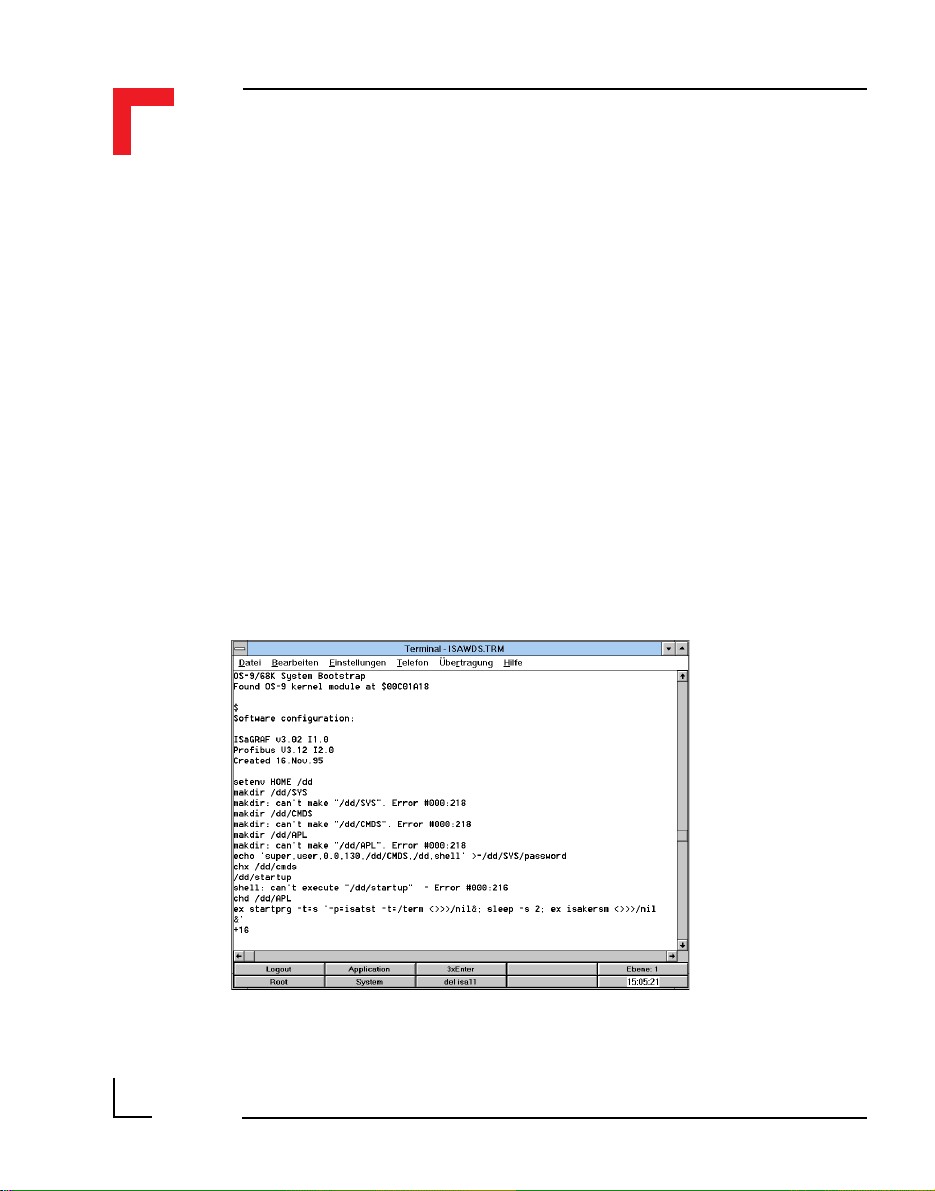

Figure 1.5.3.2 Power Up Messages

©1996 PEP Modular Computers GmbH

March 12, 1996

Introduction

SMART I/O User’s Manual

The error messages that are shown in figure 1.5.3.2 are normal as the system

is trying to create files or directories in the RAM disk that are already

present.

If no further messages appear, then the installation is complete. Should the

terminal result in anything different than shown then check through the

installation steps again before contacting PEP for help.

The three green LEDs mentioned earlier show the state of

• PROFIBUS 5V

• System 5V and

• Power ON

1

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 1 - 25

SMART I/O User’s Manual

1.5.4 Demo Application

Several demonstration applications are delivered with the ISaGRAF set of

disks and are installed automatically. The applications suitable for use with

the SMART I/O are prefixed SM- and serve to show how the SMART I/O

can be used through practical examples. Two such programs, the SM-

DEMO1 and 2 are discussed here :

SM_DEMO1 should be used if the SMART I/O has the SM_DOUT1

module in the first of the SMART Module slots and has SM_DIN1 in slot 2

(the last) on the SMART-BASE.

SM_DEMO2 should be used if the modules are reversed.

To install the demonstrations correctly, observe the following procedure and

make sure the correct diskette is in place :

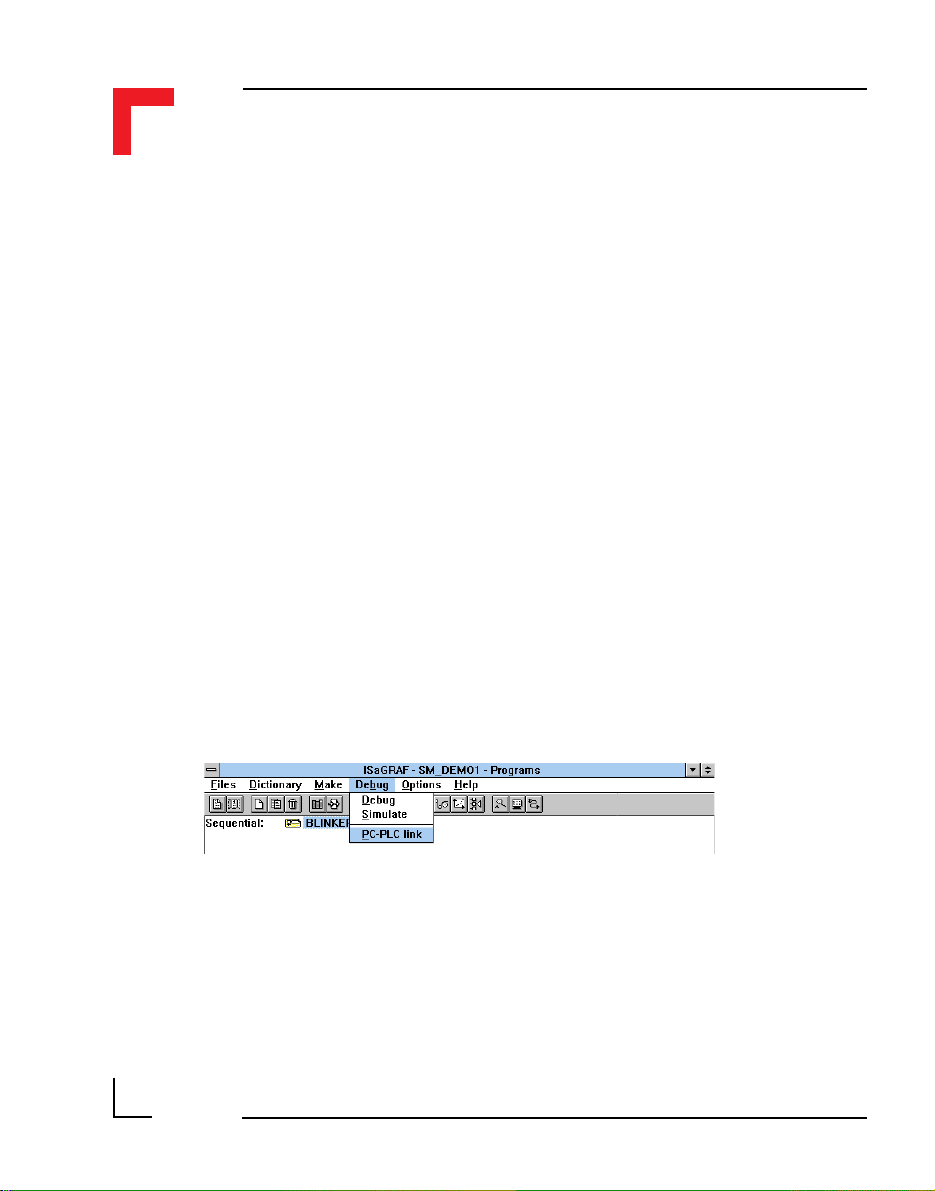

•Run the Projects Program and select SM_DEMO1 or SM_DEMO2 by

double clicking on the icon;

Introduction

•Go to the Debug/PC-PLC Link Menu to ensure that the correct COM

port is selected for communication to the SMART I/O;

•When confirmed, select Debug/Debug;

•From the Debugger Window, select File from the pull-down

menu if an application is already executing (indicated by Run in the

status line);

Page 1 - 26

©1996 PEP Modular Computers GmbH

March 12, 1996

Introduction

SMART I/O User’s Manual

• Finally, from the Files/Download pull-down menu, select

Motorola Target Code.

The chosen SM_DEMO will be downloaded to the SMART I/O (target

system) and the application will begin automatically.

1

This is a simple SFC-program which will activate channel 7 of the SMDOUT1 when the first SFC-step (init) is encountered thereby illuminating

the diode. During the next cycle, step 2 is encountered and activates channel

2 and at the same time deactivates channel 3. The program will wait for 1

second in this state before reversing the action. The effect is that the second

and third LED illuminate alternately with a pause of 1 second between.

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 1 - 27

SMART I/O User’s Manual

This page has been left blank intentionally.

Introduction

Page 1 - 28

©1996 PEP Modular Computers GmbH

March 12, 1996

Chapter 2 SMART-BASE

2. SMART-BASE.........................................2-3

2.1 Specifications ......................................................................... 2-4

2.2 Board Overview ..................................................................... 2-5

2.3 Functional Description........................................................... 2-6

2.4 Configuration ......................................................................... 2-8

2.4.1 Jumper J1: Boot Selection (Pin Connector) ........................................ 2-8

2.4.2 Jumper J6: LED Function (Pin Connector) ......................................... 2-9

2.5 Pinouts ................................................................................... 2-9

2.5.1 SMART Module Piggyback Connectors........................................... 2-10

2.5.2 Screw Terminal Pinouts .................................................................... 2-12

2.5.3 Timer I/O Screw Terminal (SCR1) ...................................................2-12

2.5.4 Supply Screw Terminals (SCR2) ...................................................... 2-14

2.5.5 RS232 Telephone Connector (BU1) .................................................2-15

2.5.6 RS485 D-Sub Connector for Half-Duplex Operation (Profibus) ...... 2-15

2.5.7 SPI Connector (ST7) ......................................................................... 2-16

2.6 ‘C’ Programming ................................................................. 2-17

2.6.1 SMART-BASE Library ..................................................................... 2-17

2.6.2 SMTselIn ...........................................................................................2-18

2.6.3 SMTsettout ........................................................................................2-20

2.6.4 SMTpre .............................................................................................2-21

2.6.5 SMTstasto.......................................................................................... 2-23

2.6.6 SMTrd ............................................................................................... 2-24

2.6.7 SMTtin .............................................................................................. 2-25

2.6.8 SMTstat ............................................................................................. 2-26

2.6.9 SMTout.............................................................................................. 2-27

2.6.10 SMLed .............................................................................................2-28

2.6.11 SMwdon .......................................................................................... 2-29

2.6.12 SMwdtrig ......................................................................................... 2-30

2.6.13 SMwdoff .........................................................................................2-31

SMART I/O User’s Manual

Table of Contents

2

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 2 - 1

SMART I/O User’s Manual

Chapter 2 SMART-BASE

2.7 ISaGRAF Programming ...................................................... 2-32

2.7.1 The ISaGRAF Board Parameters ...................................................... 2-32

2.7.2 The ISaGRAF Operate Calls............................................................. 2-33

2.8 Flash Utility ......................................................................... 2-37

Page 2 - 2

©1996 PEP Modular Computers GmbH

March 12, 1996

Chapter 2 SMART-BASE

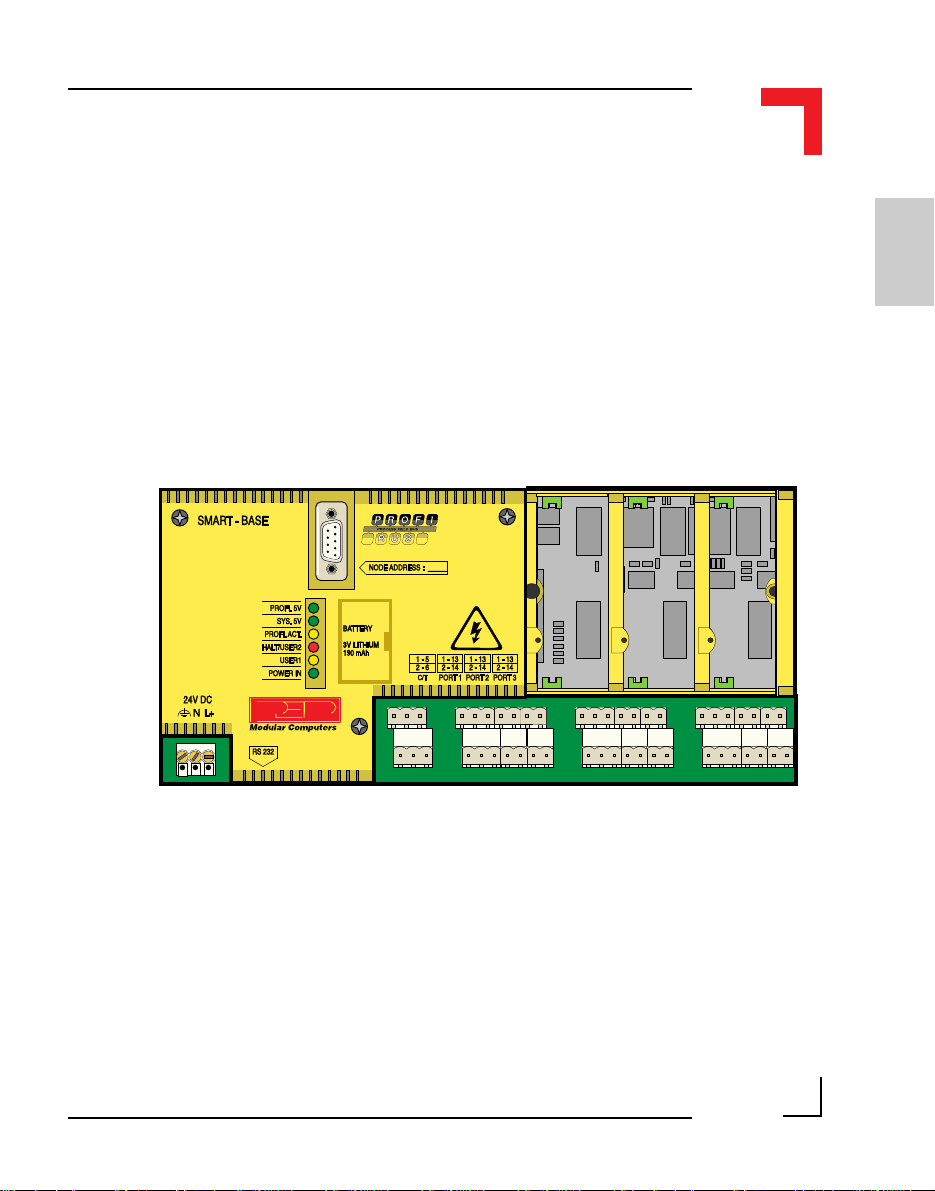

2. SMART-BASE

The SMART-BASE is the main unit to which up to three SMART-Modules

may be connected to fulfil a given I/O task with I/O enhancement being

provided through the connection of a SMART-EXT unit which itself may

accommodate up to 2 SMART-Modules. A counter/timer is also a standard

feature providing direct access to IRQ4 of the I/O controller. The driving

force behind the SMART-BASE is the MC68302 microprocessor from

Motorola operating at 20MHz.

The SMART-BASE, complete with built-in RS232 and RS485 (PROFIBUS)

interfaces is connected to the outside world by RJ45 and 9-pin D-Sub

connectors respectively. Connected SMART-Modules use industrial standard, plug-in screw terminals.

Program code is stored in EPROM or FLASH memory thereby doing away

with disk accesses and ensuring data security in harsh industrial environments. A SMART-BASE unit with additional 1MByte FLASH memory may

be ordered as an option in which to extend the standard code and supply

user-specific functionality.

SMART I/O User’s Manual

2

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 2 - 3

SMART I/O User’s Manual

2.1 Specifications

Nominal Input Voltage 24V DC

Input Voltage Range 18V - 36V DC

Input Current

Main Output Voltage 5V DC / 1.2A ± 2.5%

Auxiliary Output Voltage 5V DC / 150mA (PROFIBUS/RS485) ± 5%

Switching Frequency 100kHz

Main Output Ripple ± 10mV typ.

Max. Efficiency 68% typ. (between 74% and 100% load)

Galvanic Isolation 500V DC max. to/from supply source

CPU MC68302 @ 20MHz

EPROM or FLASH*

FLASH*

DRAM 512 kByte, byte/word access (16-bit)

SRAM 64 kByte, byte/word access (16-bit)

EEPROM 93C46, 32-byte system data

Galvanic Isolation 2.5kV DC to/from process I/O

Temperature Range

- Storage

- Operating

- Extended

Operating Humidity 0 to 95% non-condensing

Weight 640g typ. without SMART-Modules, blank

Chapter 2 SMART-BASE

DC/DC

140mA typ. @ 24V (static)

400mA typ. @ 24V (full load)

Controlling Unit

1 MByte or 256 kByte on Jedec 32-pin

sockets (16-bit access)

1 MByte or 256 kByte additionally soldered

on rear side of the board (16-bit access)

Common

-40°C to + 85°C (without battery)

0°C to +70°C

-40°C to +85°C

panels or screw terminals

* Option

Page 2 - 4

©1996 PEP Modular Computers GmbH

March 12, 1996

Chapter 2 SMART-BASE

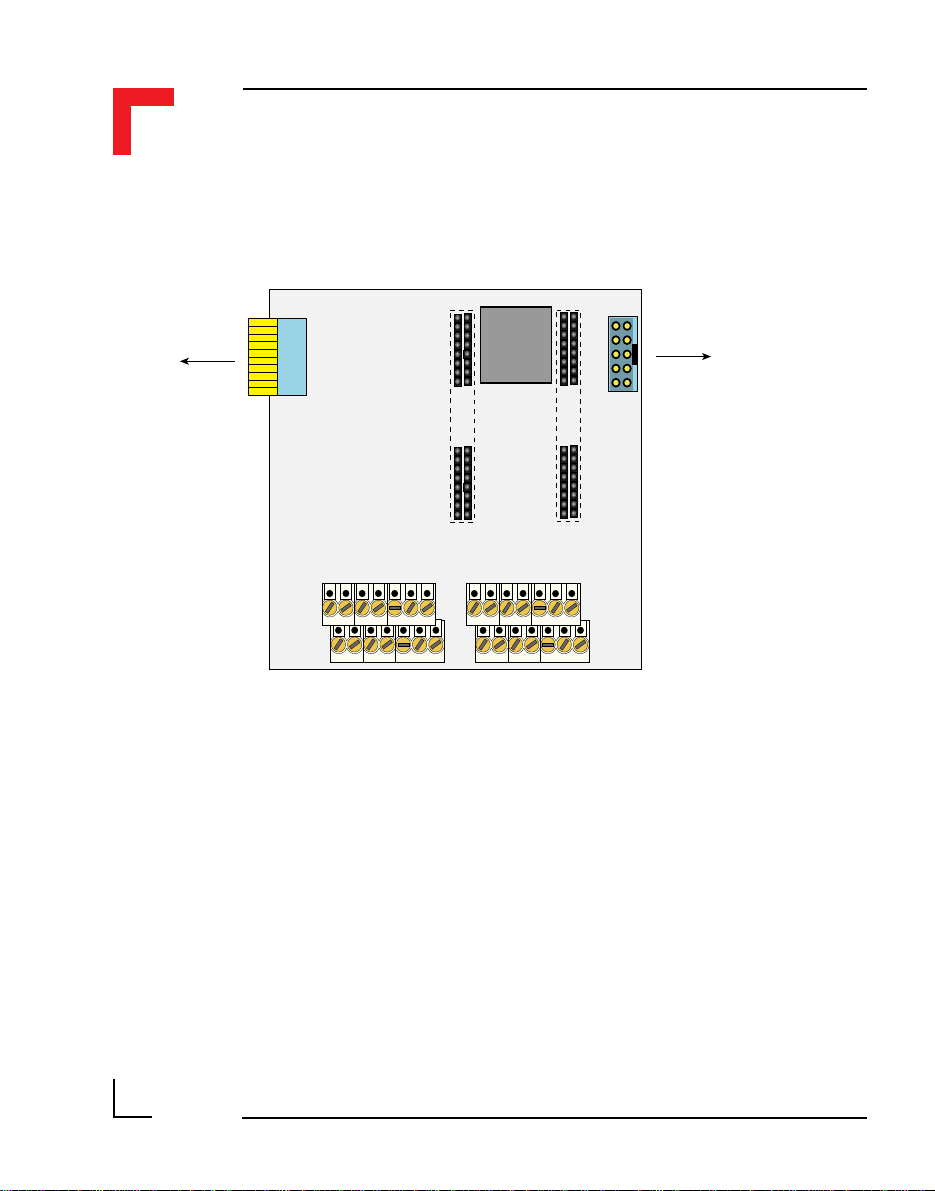

2.2 Board Overview

Front view

RS485 Isolated

(PROFIBUS)

SMART I/O User’s Manual

J13 J1

ST5 ST3 ST1 ST7

SPI

DC/DC

24V DC

Rear View

BU2

Status

Piggyback

SMPBLED

Battery

Piggyback

SMPBBAT

RS232

BU1SCR2 SCR1 SCR5 SCR4 SCR3

DRAM

UD LD

EPROM/FLASH

BU3

EPROM/FLASH

Timer

I/O

(SRAM)

RTC Quartz

J6

68302FC20

RTC

I/O Controller

ST6 ST4 ST2

SMART Modules

I/O Slot #2I/O Slot #1I/O Slot #0

2

1

J15

3

Full DUPLEX RS485

(Option)

2

Optional

FLASH

RS232 Driver

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 2 - 5

SMART I/O User’s Manual

2.3 Functional Description

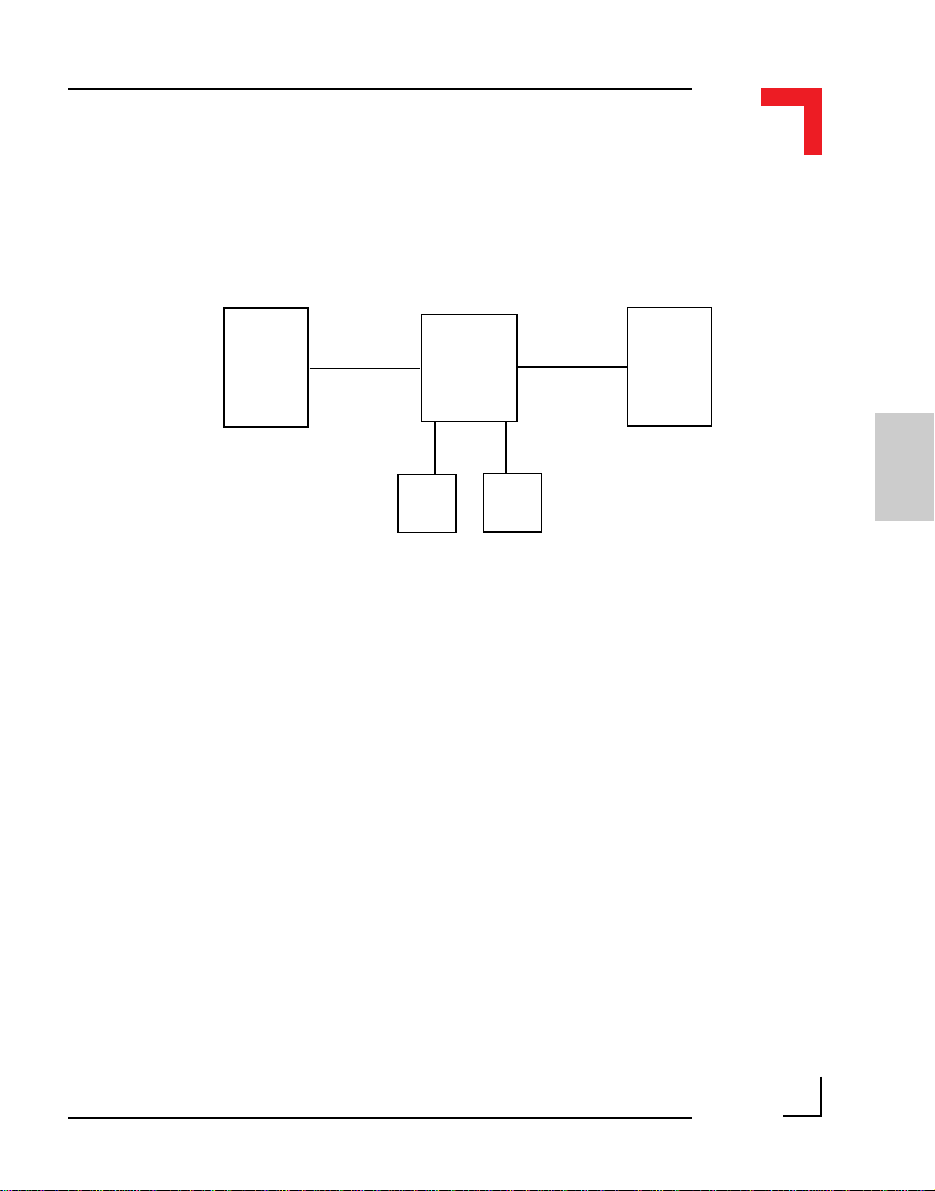

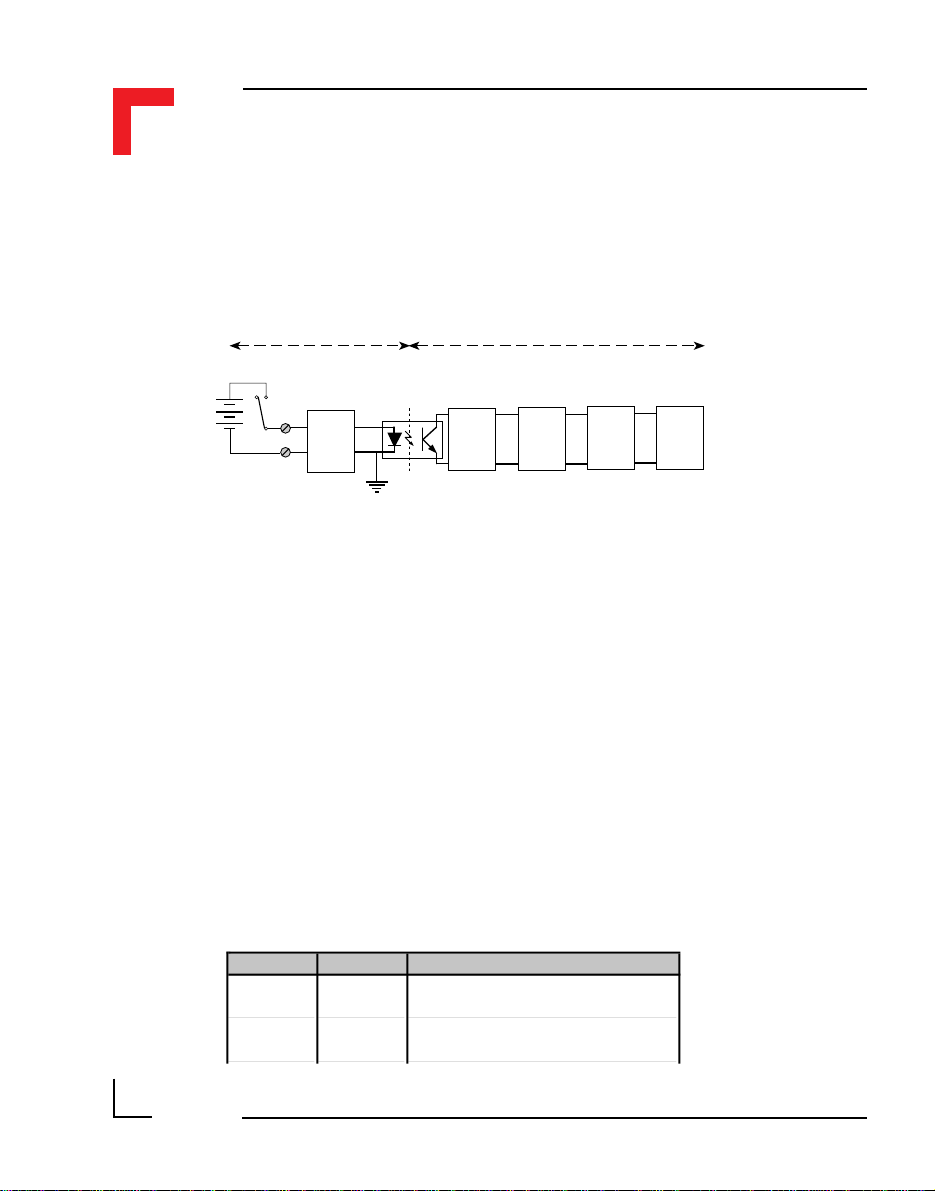

Figure 2.3.0.1: SMART I/O Block Diagram

Chapter 2 SMART-BASE

Clock

Generators

Serial Interfaces

RS485

RS232

DC/DC

I/O Controller

Timer/Counter

Interface

MCU

MC68302

@ 20 MHz

SMART-Module

Interface

The MCU, an MC68302 microprocessor operating at 20 MHz is responsible

for handling all communication between the various interfaces and on-board

memory.

An RS485 highspeed PROFIBUS 2-wire interface is optically isolated from

the system and may be configured for full duplex operation (a 4-wire interface available on request for OEM volume). Likewise, a fully configured

RS232 modem interface is available for program downloading for example

on SMART I/O systems supporting FLASH memory for this task or to the

RAM disk etc.

Memory

FLASH

EPROM

SRAM

SPI

Interface

Page 2 - 6

©1996 PEP Modular Computers GmbH

March 12, 1996

Chapter 2 SMART-BASE

The isolated DC/DC converter is based on a switched mode regulating

system operating at 100 kHz and supplies power to both the system and the

isolated RS485 (PROFIBUS) interface.

The SPI interface, a 3-wire communication protocol providing SCLK, RxD

and TxD is embedded within a larger 10-wire interface for handling communication between the base unit and SMART-Modules attached either directly

or on extension units.

Up to three SMART-Modules are supported on the SMART-BASE unit with

connection to the outside world being provided by industrial standard screw

terminals. The same calibre of terminal is used for the counter/timer, which

is directly coupled to the system I/O controller. A more detailed description

of the counter/timer appears in the pinout section of this chapter.

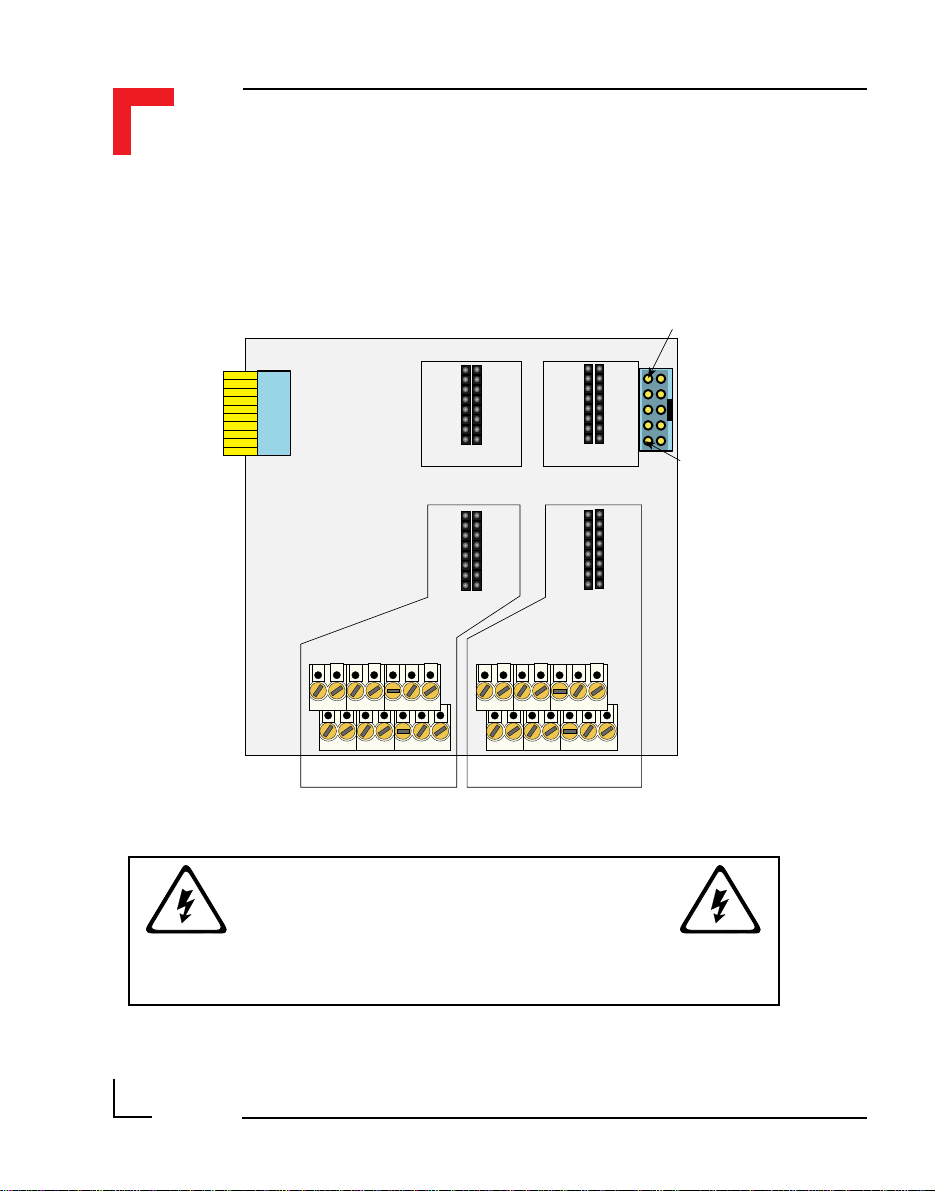

Figure 2.3.0.2 shows the interrupt handling capability of the I/O controller. It

should be noted that the controller can only be programmed with the use of a

PEP defined software protocol that ensures compatibility in case of hardware

changes.

SMART I/O User’s Manual

2

Figure 2.3.0.2 IRQ Capabilities

Smart Base

Smart

Smart

Module

Module

IRQ

IRQ

Int 1

Int 2

Interrupt

I/O

Timer

Logic

IRQ 4

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 2 - 7

Smart

Module

IRQ

Int 3

IRQ 1

1st Smart Ext

Smart

Module

IRQ

Int 4

Smart

Module

Programmable

SMART I/O User’s Manual

Chapter 2 SMART-BASE

2.4 Configuration

The SMART BASE has 2 configurable jumpers which are explained in the

following sections. The jumper settings marked in italics in the tables are

default.

Figure 2.4.0.1: SMART BASE Jumper Layout (Front View)

RS485 Isolated

(PROFIBUS)

J13 J1

ST5 ST3 ST1 ST7

SPI

DC/DC

24V DC

BU2

Status

Piggyback

SMPBLED

Battery

Piggyback

SMPBBAT

RS232

BU1SCR2 SCR1 SCR5 SCR4 SCR3

DRAM

UD LD

EPROM/FLASH

BU3

EPROM/FLASH

Timer

I/O

(SRAM)

J6

68302FC20

I/O Controller

ST6 ST4 ST2

SMART Modules

I/O Slot #2I/O Slot #1I/O Slot #0

2.4.1 Jumper J1: Boot Selection (Pin Connector)

The jumper J1 selects whether the SMART I/O boots directly from OS-9 or

from ISaGRAF.

Jumper J1 Description

1-3 Application Boot (ISaGRAF)

1-2 OS-9 Shell Boot

Page 2 - 8

©1996 PEP Modular Computers GmbH

March 12, 1996

Chapter 2 SMART-BASE

2.4.2 Jumper J6: LED Function (Pin Connector)

This jumper selects the function of the red LED; halt or user defined. The

user defined function that is supported in software will only take effect if this

jumper is set accordingly.

SMART I/O User’s Manual

Jumper J6 Description

1-3 Processor HALT function monitor

1-2 User defined function

2.5 Pinouts

Figure 2.5.0.1: SMART-BASE Connector Overview

Pin 5

Pin 9

DC/DC

SCR2

Pin 1 Pin 2 Pin 3

BU2

Pin 6

B17

SMPBLED

BU1

Pin 1

Pin 8

B8

Pin 1

UD LD

B10

Pin 5

BU3

Pin 1

EPROM/FLASH

B7

B11

B16 B1

Pin 1

Pin 5

Pin 2

Pin 6

SCR1

B9

68302FC20

Pin 1

Pin 2

Slot #0 Slot #1 Slot #2

SCR5 SCR4 SCR3

ST5

J6

Slot #0 Slot #1 Slot #2

ST6

Pin 1

Pin 13

Pin 2

Pin 14

2

J13

Pin 15Pin 16

ST3

Pin 1Pin 2

Digital Side

Process SIde

Pin 15Pin 16

ST4

Pin 1Pin 2

Pin 13

Pin 14

J1

Pin 15Pin 16

ST1

Pin 1Pin 2

Pin 15Pin 16

ST2

Pin 1Pin 2

Pin 1

Pin 2

Pin 1

Pin 15Pin 16

Pin 2

ST7

Pin 1Pin 2

Pin 10

Pin 9

Pin 15Pin 16

Pin 1Pin 2

Pin 13

Pin 14

WARNING !

Dangerous voltages may be present at the terminals.

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 2 - 9

SMART I/O User’s Manual

Chapter 2 SMART-BASE

Note

Slot# numbers are counted from #0 up to #10 while the ISaGRAF logic

counts from #1 to #11!

2.5.1 SMART Module Piggyback Connectors

There are three sets of SMART Module piggyback connectors available on

the SMART-BASE, each divided into two sets of 2x8 standard pin rows.

Pinouts digital side (ST1, ST3 and ST5)

SMART-Module location #0 (ST5) pinouts

Pin Nr. Signal Description Pin Nr. Signal Description

1 PA8 68302 Port A8 2 PA9 68302 Port A9

3 PA10 68302 Port A10 4 PA11 68302 Port A11

5 PA12 68302 Port A12 6 PA13 68302 Port A13

7 PA14 68302 Port A14 8 PA15 68302 Port A15

9 System GND GND 10 Serial RxD RxD

11 System VCC 5V VCC 12 Serial TxD TxD

13 CS-SM1 Port Select (Module 0) 14 Serial CLK CLK

15 Reset Reset (Power ON/OFF) 16 SM1 Interrupt PI/T

INT3 to the

I/O Controller

SMART-Module location #1 (ST3) pinouts

Pin Nr. Signal Description Pin Nr. Signal Description

1 PITB0 I/O Controller Port B0 2 PITB1 I/O Controller Port B1

3 PITB2 I/O Controller Port B2 4 PITB3 I/O Controller Port B3

5 PITB4 I/O Controller Port B4 6 PITB5 I/O Controller Port B5

7 PITB6 I/O Controller Port B6 8 PITB7 I/O Controller Port B7

9 System GND GND 10 Serial RxD RxD

11 System VCC 5V VC C 12 Serial TxD TxD

13 CS-SM2 Port Select (Module 1) 14 Serial CLK CLK

15 Reset Reset (Power ON/OFF) 16 SM2 Interrupt PI/T

Page 2 - 10

©1996 PEP Modular Computers GmbH

INT2 to the

I/O Controller

March 12, 1996

Chapter 2 SMART-BASE

SMART-Module location #2 (ST1) pinouts

Pin Nr. Signal Description Pin Nr. Signal Description

1 PITA0 I/O Controller Port A0 2 PITA1 I/O Controller Port A1

3 PITA2 I/O Controller Port A2 4 PITA3 I/O Controller Port A3

5 PITA4 I/O Controller Port A4 6 PITA5 I/O Controller Port A5

7 PITA6 I/O Controller Port A6 8 PITA7 I/O Controller Port A7

9 System GND GND 10 Serial RxD RxD

11 System VCC 5V VC C 12 Serial TxD TxD

13 CS-SM3 Port Select (Module 2) 14 Serial CLK CLK

15 Reset Reset (Power ON/OFF) 16 SM3 Interrupt PI/T

Pinouts process side (ST6, ST4 and ST2) for Modules #0 to #2

Pin Nr. Signal Pin Nr. Signal

1 Screw Terminal 13 2 Screw Terminal 13

3 Screw Terminal 1 4 Screw Terminal 2

5 Screw Terminal 3 6 Screw Terminal 4

7 Screw Terminal 5 8 Screw Terminal 6

9 Screw Terminal 7 10 Screw Terminal 8

11 Screw Terminal 9 12 Screw Terminal 10

13 Screw Terminal 11 14 Screw Terminal 12

15 Screw Terminal 14 16 Screw Terminal 14

SMART I/O User’s Manual

INT1 to the

I/O Controller

2

The PC board connections to the screw terminals are capable of absorbing a

continuous current of up to 3A each. However, pins 13 and 14 can support

up to 6 Amps.

WARNING !

Dangerous voltages may be present at the terminals.

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 2 - 11

SMART I/O User’s Manual

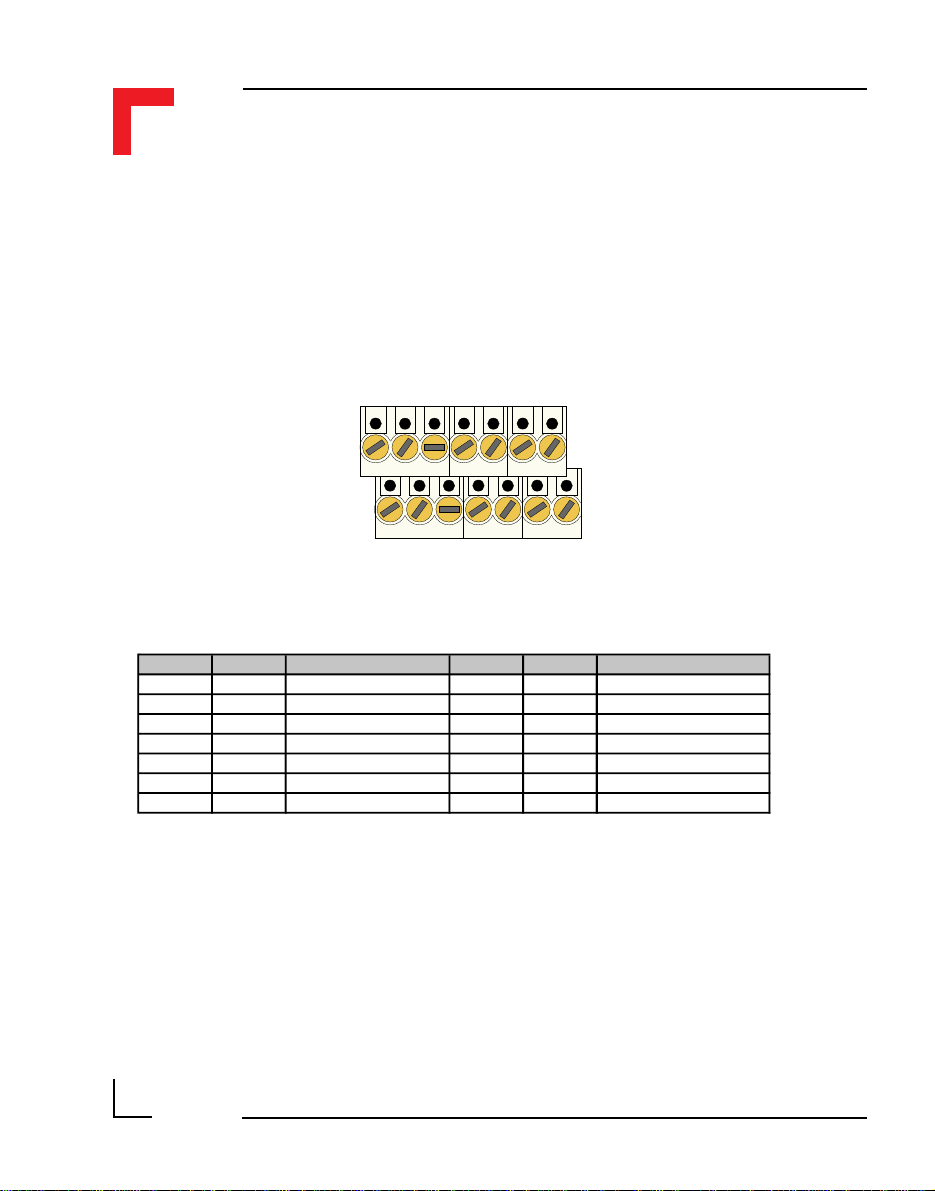

Chapter 2 SMART-BASE

2.5.2 Screw Terminal Pinouts

The following shows the pinout for a screw terminal block suited for use

with SMART-Modules. The pinouts of these blocks depends on the SMART

Modules that are fitted.

Pin 1

Pin 2

Pin 13

Pin 14

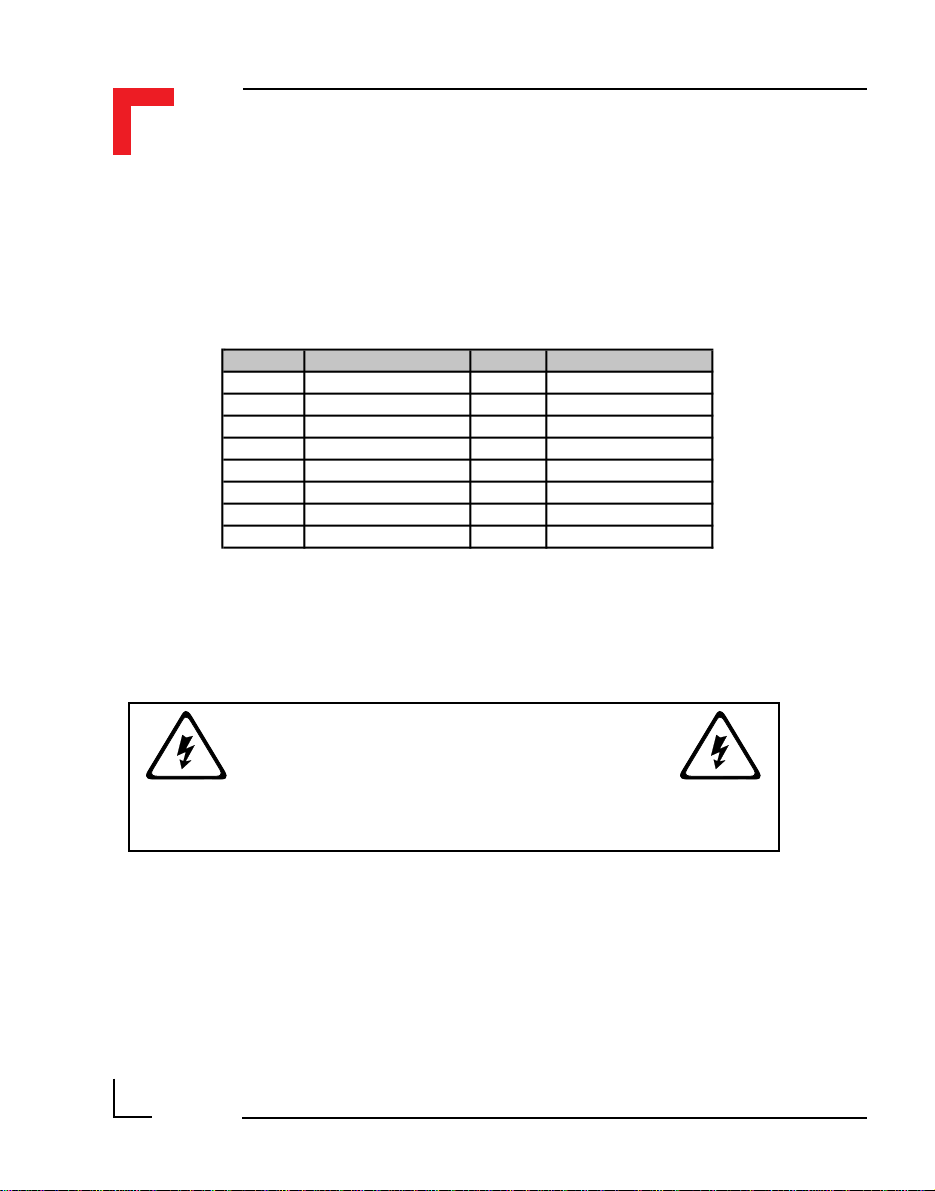

2.5.3 Timer I/O Screw Terminal (SCR1)

Pin Nr. Signal Description Pin Nr. Signal Description

1 External VCC 5V VCC 2 TOUT Timer OUT

3 External GND Ground for TIN, TOUT 4 TIN Timer IN

5 External GND Ground for TGATE 6 GATE GATE Connection

Pin 1

Pin 5

Page 2 - 12

Pin 2

Pin 6

©1996 PEP Modular Computers GmbH

March 12, 1996

Chapter 2 SMART-BASE

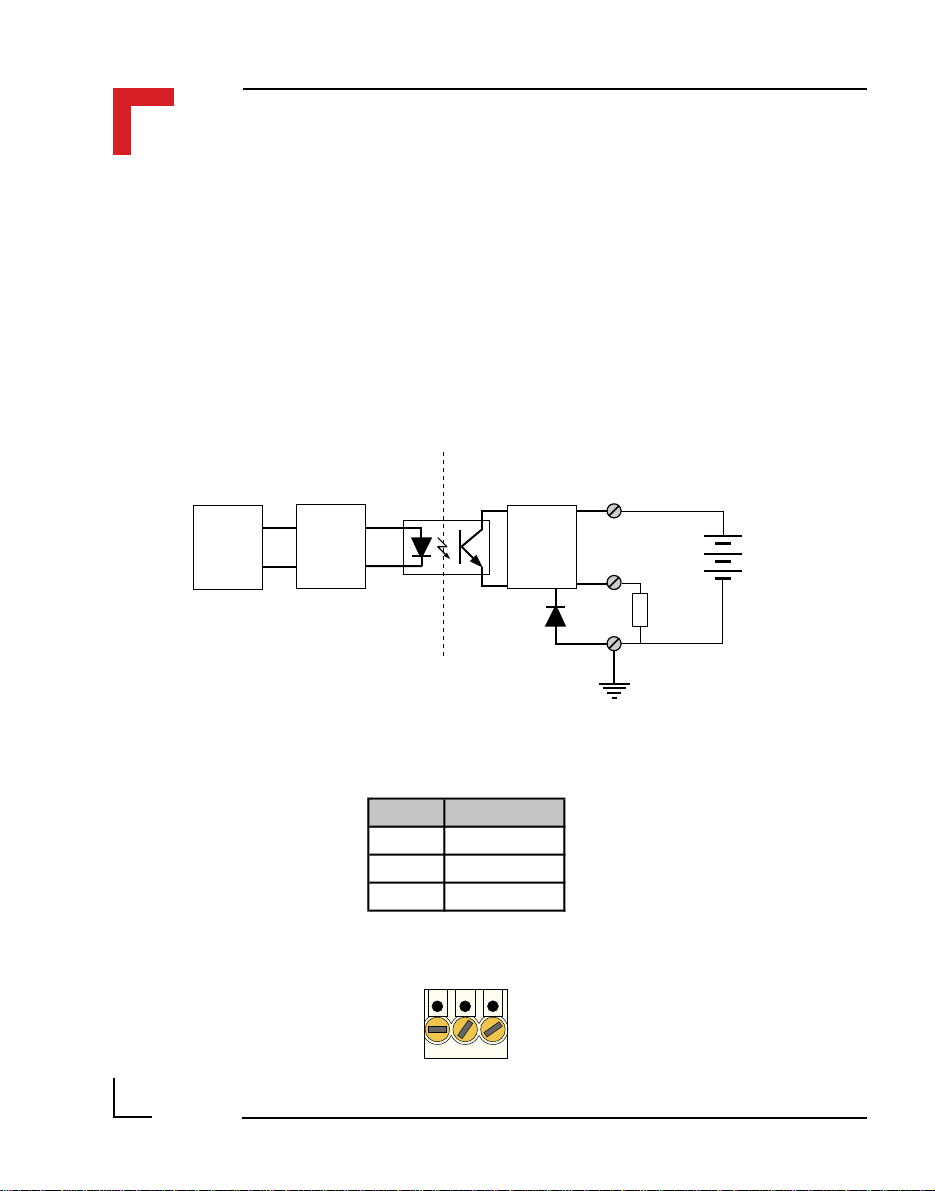

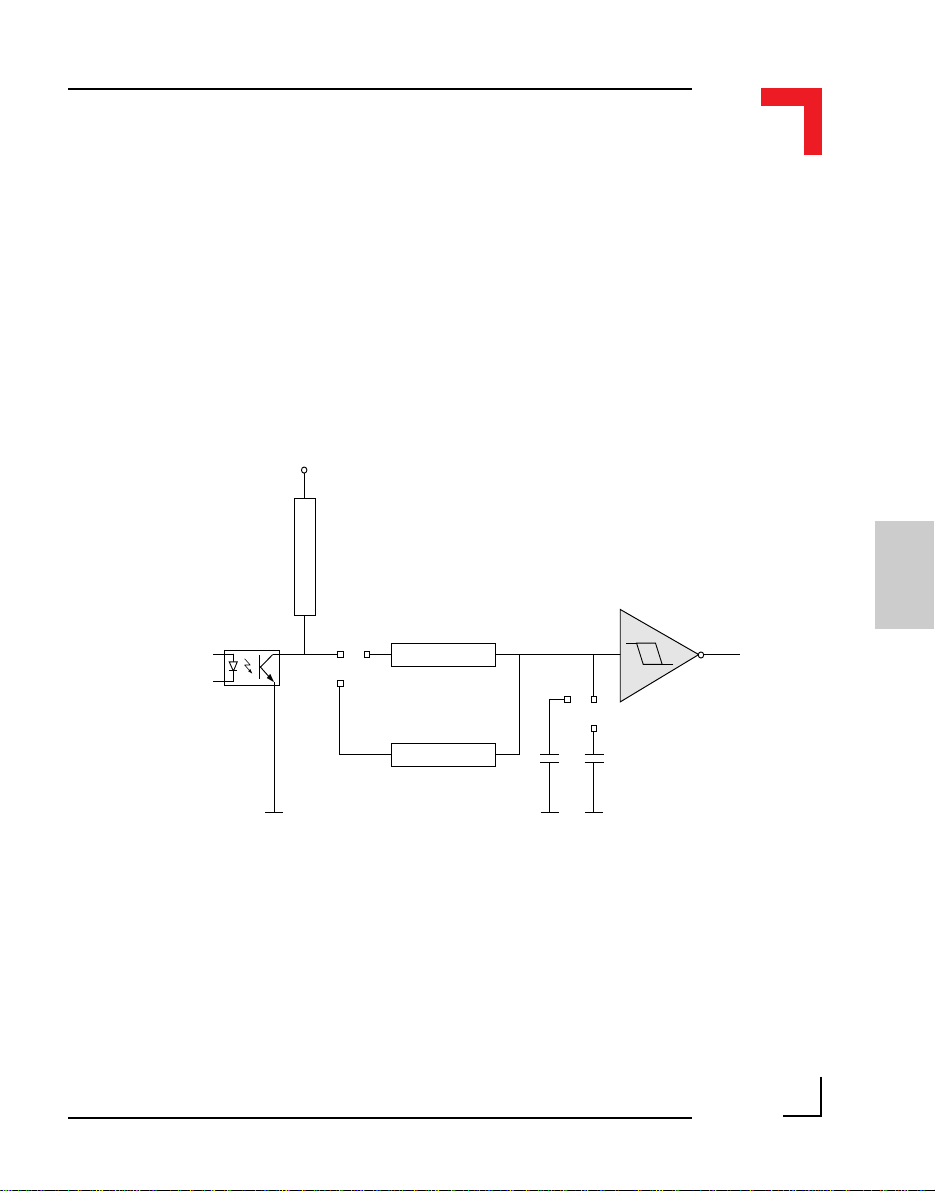

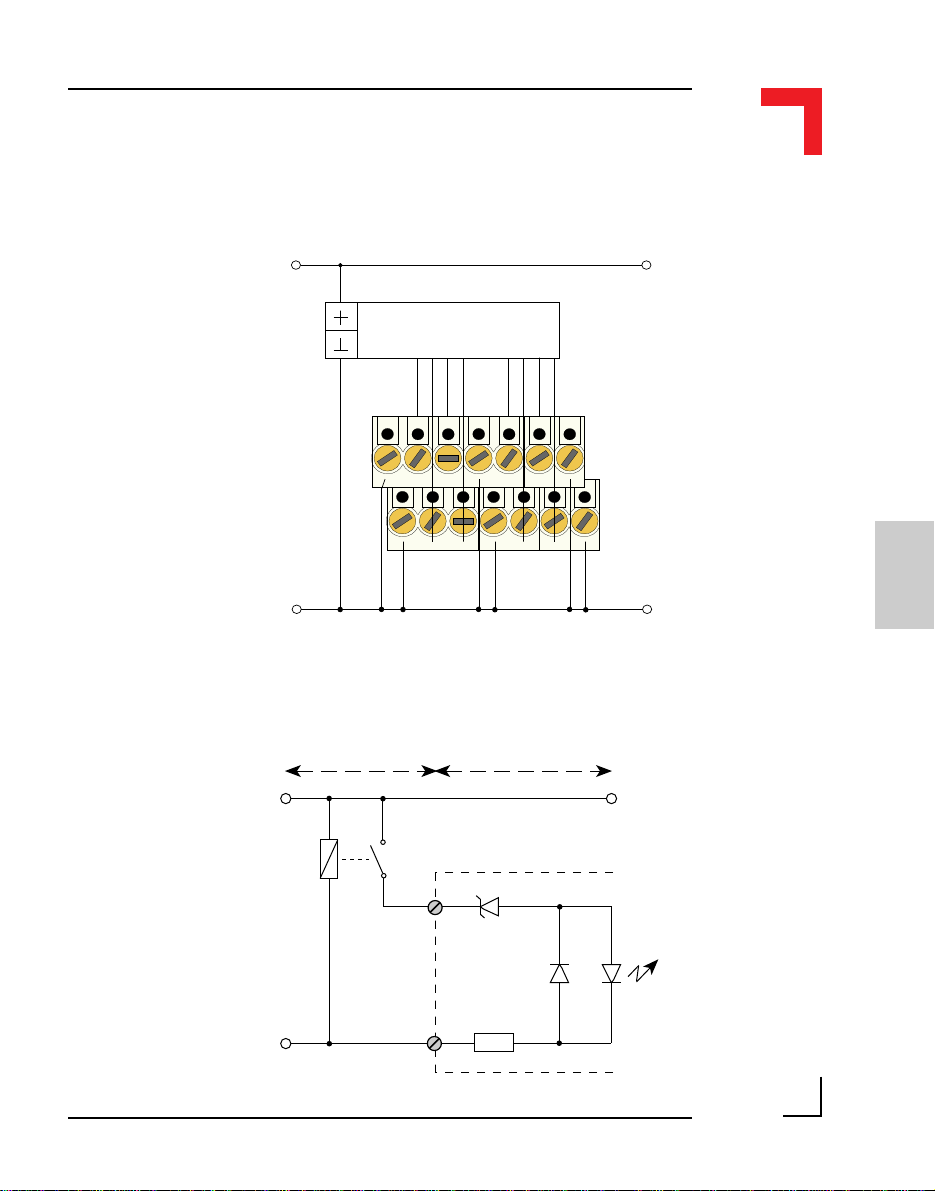

To understand the functionality of the counter/timer, it is necessary to

understand the purpose of TIN, TOUT and TGATE. Figure 2.5.3.1 shows

the block diagram of TIN.

Figure: 2.5.3.1 Timer I/O (TIN) Schematic

SMART I/O User’s Manual

+Vcc (24V)

1

TINGATE

Gnd (common)

+Vcc (24V)

Gnd (common)

4

3

1

6

5

Input

Circuit

Input

Circuit

Low

Pass

Filter

Low

Pass

Filter

Digital

Input

Timer I/O

TIN

GATE

The I/O Controller timer is used for the generation of the TOUT and TIN

functions with the three timer I/O lines being fully isolated from the system.

The internal clock of the timer/counter is 6MHz and can be prescaled to

enable lower frequencies as necessary.

With the GATE permanently active (relay closed), every pulse detected on

the TIN line will be acknowledged up to a frequency of 20kHz. Otherwise,

TIN will only be recognized for the duration that the GATE is active.

2

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 2 - 13

SMART I/O User’s Manual

Chapter 2 SMART-BASE

Figure 2.5.3.2 shows the TOUT block diagram. Here, the output is only

active when an interrupt on level 4 has been acknowledged by the I/O

controller or a previously set timer has decremented to 0. The driving stage

of the output consists of a Darlington connected transistor pair protected

from inductive loads by a clamp diode. This TOUT line can generate squarewave pulses from 0.2ms to 178ms and can deliver 500mA continuously at

24V DC. The maximum frequency of TOUT is 5kHz.

Figure 2.5.3.2: Timer I/O (TOUT) Schematic

+Vcc (common)

Timer I/O

TOUT

Digital

Output

2.5.4 Supply Screw Terminals (SCR2)

Pin Nr. Signal

1 SHIELD

2 GND

3 +24V

Pin 1

Pin 3

Output

Stage

1

2

Load

3

Gnd

Page 2 - 14

©1996 PEP Modular Computers GmbH

March 12, 1996

Chapter 2 SMART-BASE

2.5.5 RS232 Telephone Connector (BU1)

In order to meet the needs of widespread standards, the RS232 connector is

selected as a telephone connector, an 8-pin RJ12 telephone jack with full

MODEM support.

SMART I/O User’s Manual

Pin Nr. Signal Description

1 DSR Data Set Ready

2 RTS Ready to Send

3 System GND System GND

4 TxD Transmit Line

5 RxD Receive Line

6 DCD Data Carrier Detect

7 CTS Clear to Send

8 DTR Data Terminal Ready

2.5.6 RS485 D-Sub Connector (BU2) for Half-Duplex Operation (Profibus)

Pin Nr. Signal Description Pin Nr. Signal Description

1 SHIELD Shield Isolation 6 Aux. +5V Auxiliary +5V

2 N/C Not Connected 7 N/C Not Connected

3 T/RxD + Transmit / Receive Line 8 T/RxD - Transmit / Receive Line

4 CNTR +* Control Line 9 CNTR -* Control Line

5 Aux. GND Auxiliary Ground

* optional, for full-duplex operation

12 8

2

9

6

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 2 - 15

5

1

SMART I/O User’s Manual

Chapter 2 SMART-BASE

The full-duplex description may be found in the SMART-I/O Advanced

User’s Guide.

Note

There is no internal line termination as laid down in DIN 19245 Part 1

and must be performed externally.

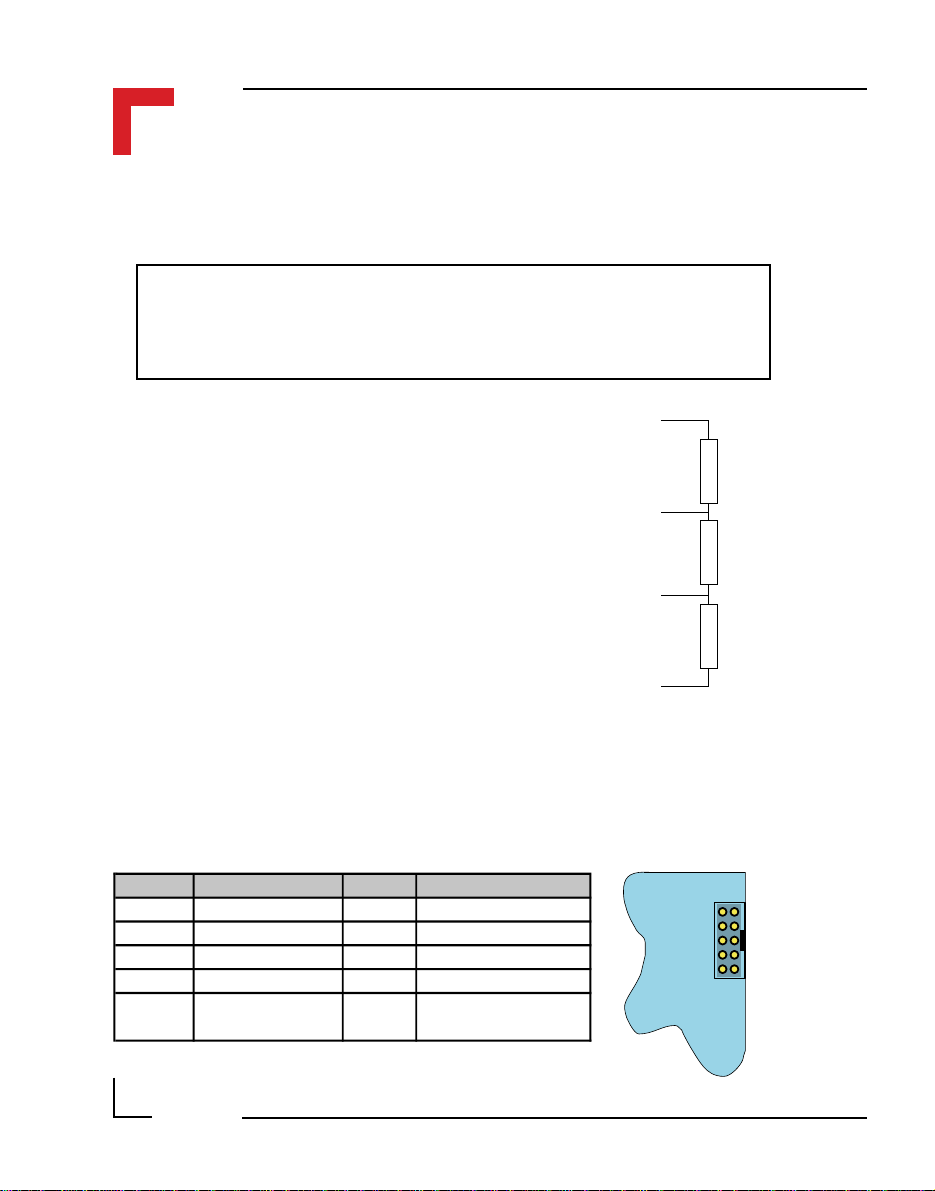

Aux. +5V, 90mA

The line termination is achieved as shown in

the figure. Assuming a power supply voltage

of +5V emanating from the PROFIBUS

connector (pin 6), the following resistor

T/RxD +

values are recommended.

R

150Ω ± 2%, min 0.25W

t

R

390Ω ± 2%, min 0.25W

U

R

390Ω ± 2%, min 0.25W

d

T/RxD -

Ru = 390Ω

t

= 150Ω

R

d

= 390Ω

R

Aux. GND

2.5.7 SPI Connector (ST7)

The SPI connector is a 2x5 standard pinrow connector, located on the righthand side of the SMART-BASE to enable easy connection of the SMARTEXT module using a flat ribbon cable connection.

Pin Nr. Signal Pin Nr. Signal

1 System VCC 2 Serial RxD

Pin 1 Pin 2

3 System VCC 4 Serial TxD

5 Serial Ext. Select 6 Serial CLK

7 System GND 8 Reset

9 System GND 10

Page 2 - 16

©1996 PEP Modular Computers GmbH

Serial Ext. Interrupt

(Controller I/O IRQ4)

Pin 9 Pin 10

SMART-BASE

ST7

March 12, 1996

Chapter 2 SMART-BASE

2.6 ‘C’ Programming

2.6.1 SMART-BASE Library

The SMART-BASE library of functions smartio.l provide a convenient way

of accessing various features of the SMART-BASE.

• All functions are written in ANSI C;

• Prototypes are to be found in the file BSP/SMART/DEFS/SMAC.h.

Hardware Requirements

• SMART I/O Base Module.

Software Requirements

The compiler from one of the following:

SMART I/O User’s Manual

2

• Ultra C Version 1.1.2 or higher;

• FasTrak 2.0.2 or higher.

The examples provided here are primarily concerned with the timer/counter.

Other aspects of SMART BASE programming may be found in the Advanced User’s guide.

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 2 - 17

SMART I/O User’s Manual

2.6.2 SMTselIn

Syntax

error_code SMTselIn(u_int8 mode);

Description

This function selects one of four possible counter/timer input (TIN) configurations utilizing the 6MHz internal counter/timer clock.

Input

Chapter 2 SMART-BASE

u_int8 mode

This represents the four input configurations. They

are:

MODE00

the Simple I/O and the CLK and prescaler are used.

The prescaler is decremented on the falling transition

of the clock pin; the 24-bit counter is decremented,

rolls over or is loaded from the counter preload

registers when the prescaler rolls over from $00 to

$1F.

MODE01

input and the CLK and prescaler are used. The

prescaler and counter are decremented as in

MODE00.

MODE10

timer input and the prescaler is used. The prescaler is

decremented following the rising transition of the

TIN pin after being synchronized with the internal

clock. The 24-bit counter is decremented, rolls over

or is loaded from the counter preload registers when

the prescaler rolls over from $00 to $1F.

The Simple I/O/TIN input pin carries

The Simple I/O/TIN serves as a timer

The Simple I/O/TIN pin serves as a

Page 2 - 18

©1996 PEP Modular Computers GmbH

March 12, 1996

Chapter 2 SMART-BASE

SMART I/O User’s Manual

MODE11

timer input and the prescaler is not used. The 24-bit

counter is decremented, rolls over or is loaded from

the counter preload registers following the rising

edge of the TIN pin after being synchronized with

the internal clock.

Output

error_code SUCCESS

E_BMODE

or standard OS-9 error code (refer to the OS-9

Technical Manual Error Codes Section).

Example

RetVal = SMTselIn(MODE00);

The counter/timer contains a 24-bit synchronous down counter that is loaded

from three 8-bit counter preload registers. The 24-bit counter may be

clocked by the output of a 5-bit (divide by 32) prescaler or by an external

timer input (TIN). If the prescaler is used, it may be clocked by the system

clock (6 MHz CLK pin) or by the TIN external input. The counter signals

the occurrence of an event primarily through zero detection. (A zero is when

the counter of the 24-bit timer is equal to zero). This sets the zero detect

status (ZDS) bit in the timer status register. It may be checked by the processor or may be used to generate a timer interrupt. The ZDS bit can be reset by

writing a one to the timer status register in that bit position independent of

timer operation.

The Simple I/O/TIN pin serves as a

Unsupported mode

2

The general operation of the timer is flexible and easily programmable. The

timer is fully configured and controlled by programming the 8-bit timer

control register. It controls 1) the choice between Simple I/O operation and

the timer operation of the three timer pins, 2) whether the counter is loaded

from the counter preload registers or rolls over when zero detect is reached,

3) the clock input, 4) whether the prescaler is used and 5) whether the timer

is enabled.

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 2 - 19

SMART I/O User’s Manual

2.6.3 SMTsettout

Syntax

error_code SMTsettout(u_int8 mode);

Description

This function sets the timer output (TOUT) control.

Input

u_int8 mode

Output

error_code SUCCESS

Two modes of TOUT control are available. They are:

MODE_PORTC

MODE_SQUARE

When the timer is stopped, tout is high (see diagram).

E_BMODE

or standard OS-9 error code (refer to the OS-9

Technical Manual Error Codes Section).

Chapter 2 SMART-BASE

tout has the Simple I/O function.

tout toggles on counter zero.

Unsupported mode

Example

RetVal = SMTsettout(MODE_SQUARE);

T

OUT

OFF

ON

Timer

Stop

The high state of TOUT illustrated in the above diagram shows that the

output is deactivated i.e. OFF. Only when TOUT is in the low state can a

load be driven.

Page 2 - 20

©1996 PEP Modular Computers GmbH

t

March 12, 1996

Chapter 2 SMART-BASE

2.6.4 SMTpre

Syntax

error_code SMTpre(u_int32 *value);

SMART I/O User’s Manual

Description

This function reads / sets the timer preload register.

Input

u_int32 *value

Output

error_code SUCCESS

Example

RetVal = SMTpre(0);

Pointer to a variable that holds the value to set.

The previous value is returned to the variable.

If value is 0, only the read is performed.

E_BMODE

or standard OS-9 error code (refer to the OS-9

Technical Manual Error Codes Section).

Requested value is out of range

2

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 2 - 21

SMART I/O User’s Manual

Chapter 2 SMART-BASE

Example for a Square Wave Generator

The Timer Control Register

76543210

TOUT/TIAC

Control

0 1 x 0 0 00 or 1x Changed

Z.D.

Control

•

Clock

Control

Timer

Enable

In this configuration, the timer produces a square wave at the TOUT pin

which is connected to the user’s circuitry. The TIN pin may be used as a

clock input. The processor loads the counter preload registers and the timer

control register and then enables the timer. When the 24-bit counter passes

from $000001 to $000000, the ZDS status bit is set and the TOUT is

toggled. At the next clock to the 24-bit counter it is again loaded with the

contents of the CPRs and thereafter decrements.

Page 2 - 22

©1996 PEP Modular Computers GmbH

March 12, 1996

Chapter 2 SMART-BASE

2.6.5 SMTstasto

Syntax

error_code SMTstasto(u_int8 mode);

SMART I/O User’s Manual

Description

This function starts / stops the timer; the zero-detect control bit is set at the

start; the counter rolls over on reaching zero or is loaded with the value set

in the preload register and continues counting down.

Input

u_int8 mod

Output

error_code SUCCESS

Example

RetVal = SMTstasto(TMR_STRT);

e Two modes are available. They are:

TMR_STRT

TMR_STOP

E_BMODE

or standard OS-9 error code (refer to the OS-9

Technical Manual Error Codes Section).

Start timer

Stop timer

Unsupported mode

2

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 2 - 23

SMART I/O User’s Manual

2.6.6 SMTrd

Syntax

error_code SMTrd(u_int32 *value);

Description

This function reads the actual timer count value.

Chapter 2 SMART-BASE

NOTE !

A stable read value can only be achieved if the timer is not running. Therefore, a read request to the running timer terminates with

E_DEVBSY.

Input

u_int32 *value

Output

error_code SUCCESS

E_DEVBSY

or standard OS-9 error code (refer to the OS-9

Technical Manual Error Codes Section).

Example

RetVal = SMTrd(buffer);

Page 2 - 24

©1996 PEP Modular Computers GmbH

Pointer to a variable in which to place the read

value.

Timer is currently running

March 12, 1996

Chapter 2 SMART-BASE

2.6.7 SMTtin

Syntax

error_code SMTtin(u_int8 *value);

SMART I/O User’s Manual

Description

This function reads the current level present on TIN/PC2.

Input

u_int8 *value

Output

error_code SUCCESS

Example

RetVal = SMTin(buffer);

Pointer to a variable in which to place the read

value. 0 represents low, 1 represents high

or standard OS-9 error code (refer to the OS-9

Technical Manual Error Codes Section).

2

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 2 - 25

SMART I/O User’s Manual

2.6.8 SMTstat

Syntax

error_code SMTstat(u_int8 *value);

Description

This function reads the timer status register and clears it if set.

Input

u_int8 *value

Output

error_code SUCCESS

Pointer to a variable in which to place the read

value. 0 represents not set, 1 represents set

or standard OS-9 error code (refer to the OS-9

Technical Manual Error Codes Section).

Chapter 2 SMART-BASE

Example

RetVal = SMTstat(buffer);

Description of the Timer Status Register (TSR)

76543210

•••••••ZDS

The timer status register contains one bit from which the zero detect status

can be determined. The ZDS status bit (bit 0) is an edge-sensitive flip-flop

that is set to one when the 24-bit counter decrements from $000001 to

$000000. The ZDS status bit is cleared to zero following the direct reset

operation or when the timer is halted. This register is always readable

without consequence. A write access performs a direct reset operation if bit

0 in the written data is one!

Page 2 - 26

©1996 PEP Modular Computers GmbH

March 12, 1996

Chapter 2 SMART-BASE

2.6.9 SMTout

Syntax

error_code SMTout(u_int8 *value);

SMART I/O User’s Manual

Description

This function reads the actual status of the TOUT pin.

Input

u_int8 *value

Output

error_code SUCCESS

Example

RetVal = SMTout(buffer);

Pointer to a variable in which to place the read

value. 0 represents a low level while a 1

represents a high level.

or standard OS-9 error code (refer to the OS-9

Technical Manual Error Codes Section).

2

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 2 - 27

SMART I/O User’s Manual

2.6.10 SMLed

Syntax

error_code SMLed(u_int8 led, u_int8 value);

Description

This function switches on / off user LED’s.

Input

u_int8 led

Two options are available. They are:

USERL1

USERL2

if the LED is not jumpered as 68302 HALT.

Yellow LED on piggyback

Red LED on piggyback (only

Chapter 2 SMART-BASE

u_int8 value

Output

error_code SUCCESS

E_BMODE

or standard OS-9 error code (refer to the OS-9

Technical Manual Error Codes Section).

Example

RetVal = SMLed(USERL1, 0);

Page 2 - 28

©1996 PEP Modular Computers GmbH

Indicates the status of the LED.

0 Switch LED off

Not 0 Switch LED on

LED does not exist

March 12, 1996

Chapter 2 SMART-BASE

2.6.11 SMwdon

Syntax

error_code SMwdon(u_int32 *time);

SMART I/O User’s Manual

Description

This function activates the watchdog timer of the 68302. If timeout is

reached, the system is reset; in normal operating mode, this must be avoided

by periodically triggering the watchdog using the function SMwdtrig.

Input

u_int32 *time

Output

error_code SUCCESS

Example

RetVal = SMwdon(time);

Time in ms. The range is from 1ms to approx.

13 seconds. The function returns the real set

time in *time.

E_BMODE

or standard OS-9 error code (refer to the OS-9

Technical Manual Error Codes Section).

Time is out of range or subsequent error

2

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 2 - 29

SMART I/O User’s Manual

2.6.12 SMwdtrig

Syntax

error_code SMwdtrig(void);

Description

This function re-triggers the watchdog of the 68302 preventing a timeout

and subsequent system reset.

Output

error_code SUCCESS

or standard OS-9 error code (refer to the OS-9

Technical Manual Error Codes Section).

Example

RetVar = SMwdtrig();

Chapter 2 SMART-BASE

Page 2 - 30

©1996 PEP Modular Computers GmbH

March 12, 1996

Chapter 2 SMART-BASE

2.6.13 SMwdoff

Syntax

error_code SMwdoff(void);

SMART I/O User’s Manual

Description

This function deactivates the watchdog timer.

Output

error_code SUCCESS

or standard OS-9 error code (refer to the OS-9

Technical Manual Error Codes Section).

Example

RetVar = SMwdoff();

2

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 2 - 31

SMART I/O User’s Manual

Chapter 2 SMART-BASE

2.7 ISaGRAF Programming

2.7.1 The ISaGRAF Board Parameters

Information on board parameters may be found in the PEP online help and

ISaGRAF online help or user’s manual.

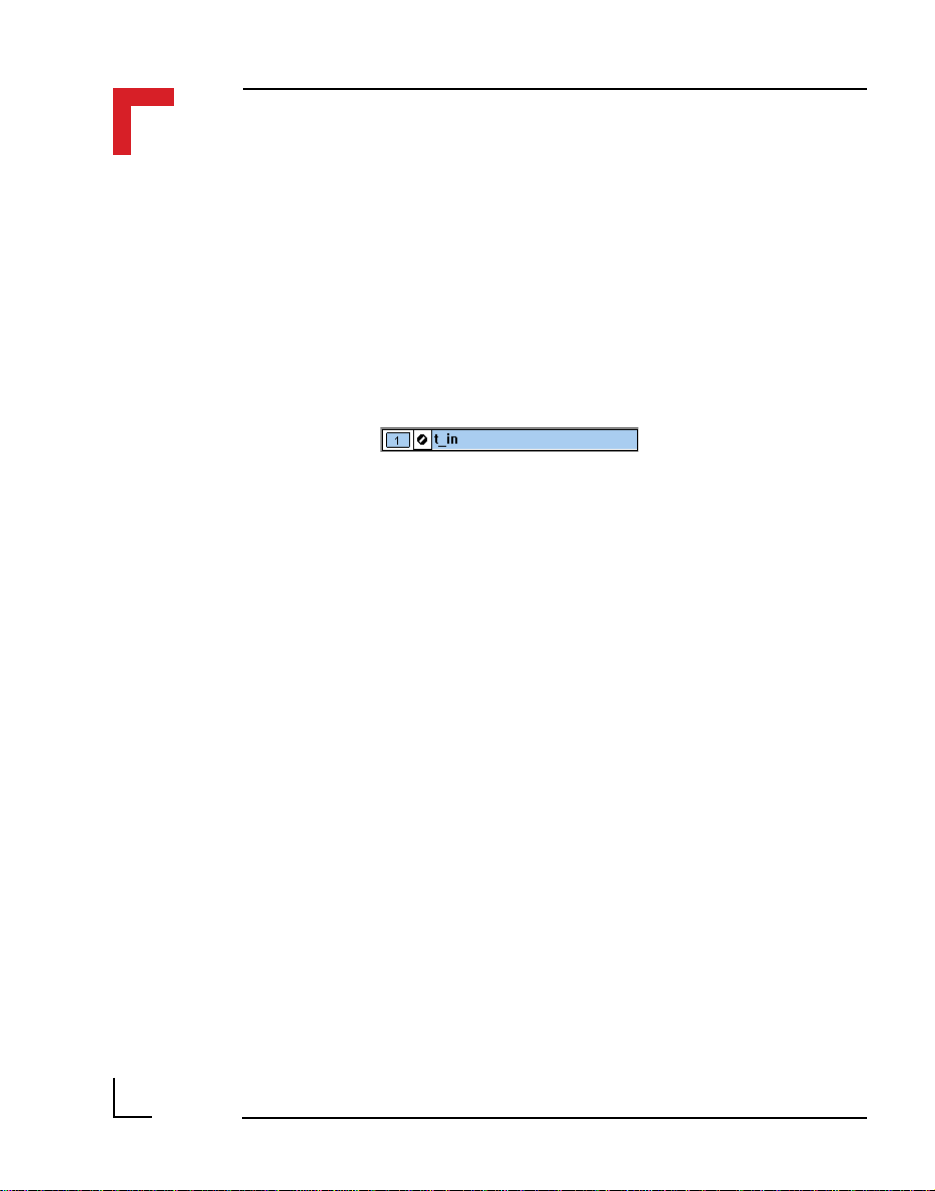

Figure 2.7.1.1 Typical Screen Section for the SMART-BASE

Because the communication to the timer/counter is performed using Operate

Calls, there is no need for manual selection of such things as a logical

address etc.

the operate call to decide which port to access.

t_in

represents a variable for the counter timer and is used for

Page 2 - 32

©1996 PEP Modular Computers GmbH

March 12, 1996

Chapter 2 SMART-BASE

2.7.2 The ISaGRAF Operate Calls

Operate calls are built into a program using ST or FBD languages when

defining the project. A typical use could be at the initialization stage to

check that the SMART-Modules are in fact located where they have been

programmed to be. The syntax of the operate call is as follows:

SMART I/O User’s Manual

Syntax:

<return variable> := OPERATE(<source var>, COMMAND,

<source data>);

Here the return variable is assigned a value associated with the

selected COMMAND parameter. A number of these COMMANDS exist for the

SMART-BASE.

Example:

<error.code>:= OPERATE(<channel>, O_INIT_CODE, 0);

O_INIT_CODE is one of a number of distinct commands recognized by the

PEP Modular Computers’ implementation of board drivers and checks for

example that a SMART-Module is located where the program expects it to

be.

channel provides channel specific information and in the example shown

here, any of the input channels may be used. The last parameter is not

usually used by PEP implementations and is set to 0 (zero).

The error.code returns a value of zero if no error was detected, otherwise it returns a non-zero value depending on the error encountered. A list of

these error codes may be found in the PEP online help.

2

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 2 - 33

SMART I/O User’s Manual

Chapter 2 SMART-BASE

A complete list of the operate COMMANDS may be obtained by selecting a

project from the ISaGRAF projects group, opening an application and

observing the Common defines in the Dictionary pull-down menu. Note that

not all calls in the list may be used within the SMART I/O environment

however, the calls applicable to this module are :

O_INIT_CODE : The syntax and usage have already been explained.

O_POWERFAIL_SET : The purpose of this operate call is to detect when

(if) the power to the PLC (SMART I/O) has failed.

The function is normally built into the initialization

stage of an application and has the following

syntax :

RetVar := OPERATE(s_time, O_POWERFAIL_SET, 0);

When the application is initialized, the start time is

recorded in battery backed ram (1) at the given

address (

s_time

). If the power to the PLC fails (2)

and recovers at a later stage (3), the software makes

a comparison with the actual clock time (via the

RTC) and the time stored in this memory location.

If a discrepancy exists then the RetVar will record

this fact. Refer to the PEP online help for more

information pertaining to the implementation of this

operate call.

Voltage

Page 2 - 34

123

Time

©1996 PEP Modular Computers GmbH

March 12, 1996

Chapter 2 SMART-BASE

O_START_COUNTER : This call starts the counter; it’s syntax is as follows :

<RetVar> := OPERATE(<iovar>, O_START_COUNTER, <null>);

SMART I/O User’s Manual

where the

O_READ_COUNTER : With this call the contents of the counter register

may be read. When this call is issued, the counter is

stopped, it’s register read and then restarted. If a

high-frequency input exists then pulses may be lost

(not counted). The same effect may also be true due

to timeslicing during timer stop and start operations.

Therefore it is recommended that this call be only

used for low frequency inputs (<1kHz). There is no

detection for counter overflow and the call should

not be used for count down operations or square

wave generation. It’s syntax is as follows :

<RetVar> := OPERATE(<iovar>, O_READ_COUNTER, <null>);

where the

O_STOP_COUNTER : This call stops the counter counting up or down and

square-wave generation and has the following

syntax :

<RetVar> := OPERATE(<iovar>, O_STOP_COUNTER, <null>);

where the

<iovar>

<iovar>

<iovar>

is typically t_in.

is typically t_in.

is typically t_in.

2

The counter/timer is configured automatically as MODE10 (refer to the ‘C’

Programming section) and from within ISaGRAF there is no ability to alter

this configuration.

©1996 PEP Modular Computers GmbHMarch 12, 1996 Page 2 - 35