Page 1

FCP

Single-phase Inverter for single or three-phase motor pump

Operation and maintenance handbook

Page 2

2

1. SPECIFICATIONS

The aim of this handbook, we would like to give you the most important information about the correct

use and maintenance of the inverter; the models of FCP, differents for the voltage output are:

FCP109: Single-phase Inverter for Single-phase motor-pump, max. 1100W (1.5 Hp) for a maximum

current of 9A.

FCP111: Single-phase Inverter for Single-phase motor-pump, max. 1500W (2 Hp) for a maximum

current of 11A.

FCP307: Single-phase Inverter for Three-phase motor-pump, max. 1500W (2 Hp) for a maximum

current of 7A.

This Inverter is designed specifically for motor-pumps operation, all types not depending from the flow

or the pressure, with a perfect feedback control of pressure (detected with a pressure transducer), a

substantial energy savings (up to 40% on respect to the standard on-off system) combined with

various security features for the pump that are not possible in common appliances using pressure or

flow switch.

The following instructions are about the standard model only.

If you require thecnical assistance regarding specific parts at Service Sales please do specify the

exact initials of the model, followed by the number of the model, on the upper-left part of the product.

2. WORKING CONDITIONS

Simbol

Value

Meas. Unit

Ambient working temperature

T

amb

0..+40

°c

Maximum relative humidity

50

%

(40°C)

Protection grade of the Inverter

IP65

Protection grade of the pressure transducer

IP67

Nominal single-phase pump power connected to FCP109

P2n1100

1.5WHp

Nominal single-phase pump power connected to FCP111

P2n15002W

Hp

Nominal three-phase pump power connected to FCP307

P2n15002W

Hp

Nominal voltage supply Inverter

V1n220-230

V

Range voltage supply Inverter

V1207..244

V

Frequency supply Inverter

f150-60

Hz

Voltage single-phase Output for FCP109 – FCP111

V2V1V

Voltage three-phase Output for FCP307

V23xV1V

Fequency Inverter Output

f20..55

Hz

Nominal input current to the Inverter FCP109 – FCP111

I1n10

A

Nominal input current to the Inverter FCP307

I1n12

A

Maximum output single-phase current for FCP109 (ED100%)

I29

A

Maximum output single-phase current for FCP111 (ED100%)

I211

A

Maximum output three-phase current for FCP307 (ED100%)

I27

A

Maximum output Inverter current for one second maximum

I2p3 x I2nA

Maximum pressure gauge

0 – 10

Bar

Resolution of pressure gauge

0.5

Bar

Storage temperature

T

stock

-20..+60

°C

Table 1: Working conditions

Vibrations and hits: they must be avoided by a correct assemblage;

For different environment conditions, please contact our Sales Department.

This Inverter can not be installed in explosive environments.

Page 3

3

3. WARNINGS AND RISKS

The following instructions give you important information for correct assembling and

use of the product. Please do read terms and conditions before installing the device,

these instructions should be read by people who assemble or use it; besides, these

instructions should be available to all person assigned to device setting and

maintenance

The inverter voltage supply is only possible with Inverter closed box, after carefully

following all instructions concerning installation and electrical connections of above

and after following step by step the connections described in Chapter 4 of this

handbook.

Installation workers

The installation, the starting and the maintenance of the product must be done by users that have

read this handbook, in order to avoid any danger of an incorrect use.

Risks due to missed respect of the safety laws

Failing to respect the safety regulations, could endangers others and damage the devices, which can

lead to the loss of warranty. The results of the non-observance of the security rules can be:

Malfunctioning of the system

Danger to others, to electrical and mechanical events

Security for the users

All the accident-prevention laws must be respected.

Security rules for assembling and control

Assembling, controlling and servicing procedures of the device must be read on this handbook. All

operations on this device must be done when the system is not in motion and with no voltage supply.

Alterations and spare parts

Every machine, equipment or system alteration must be authorized by the manufacturer. For your

safety, it is important to use only original spare parts. The use of non-original components may

endanger others and can lead to loss of warranty.

Misdirect working conditions

The working security is guaranteed only for the conditions described in chapter 2 of this handbook.

The values shown cannot be exceeded

4. ASSEMBLING AND INSTALLING

Installation operations must be performed only by whom have carefully read this

handbook and in particular as described in chapter 3 (Warnings and Risks). Please do

observe the health and safety on accident prevention.

If the product shows present any damage signs, do not install it, but contact the assistant service

immediately.

Install the device in a place for away from ice, water, rain et cetera. Do respect working limits and be

extremely careful with the motor and inverter’s cooling.

Page 4

4

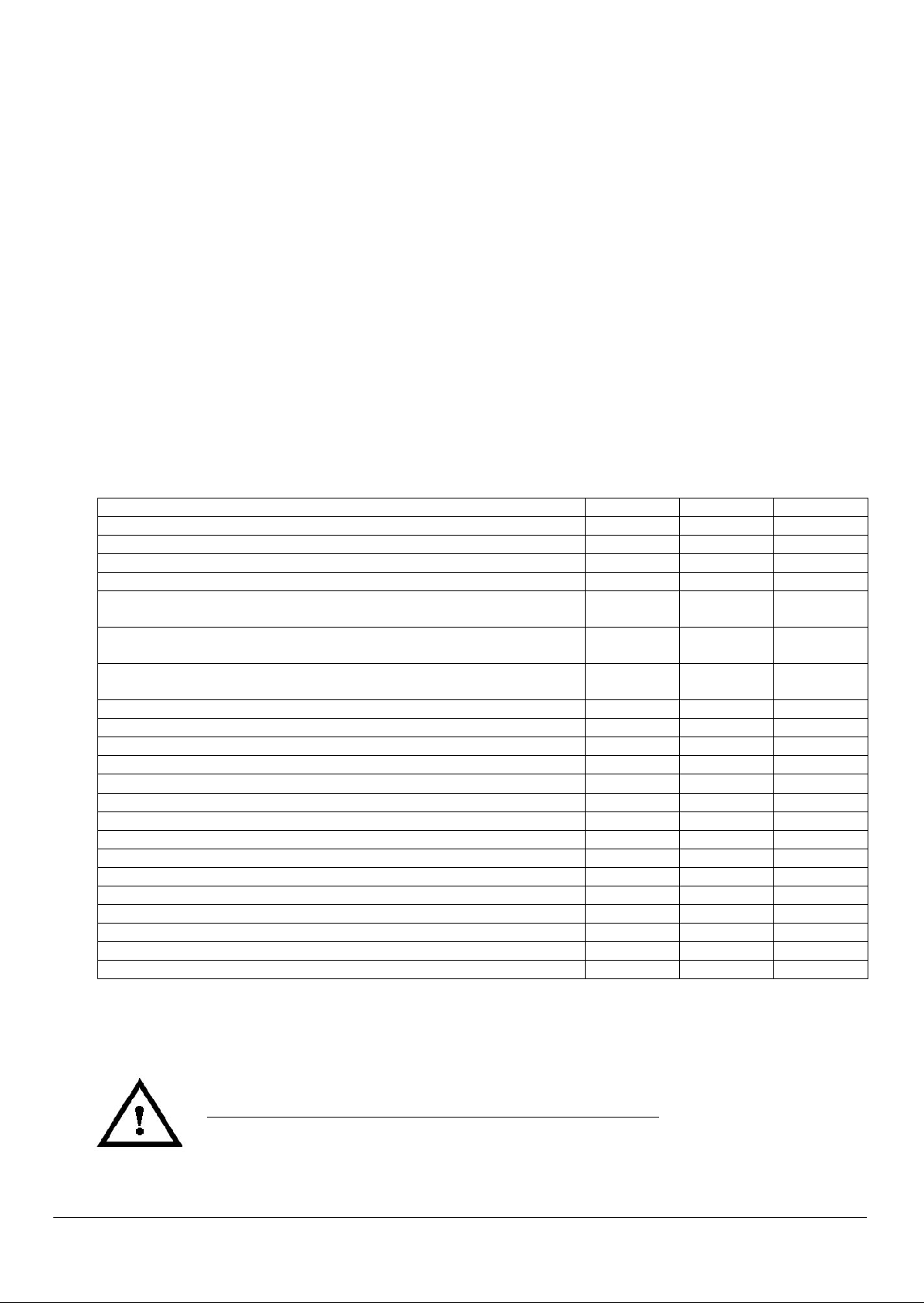

4.1 Wall Inverter fixing in vertical position

Install the product in place away from frost and

weather conditions, mounting the unit on a wall in a

vertical position only, leaving at least 200mm of

space above and below the same so as to ensure

sufficient cooling of the heat sink on the back of the

inverter. The wall may also be of metal type as long

as it is not a heat source and be not directly exposed

to the sun.

For wall mounting the inverter using the N° 4 holes

7mm diameter arranged in the pattern of holes in

Figure 1.

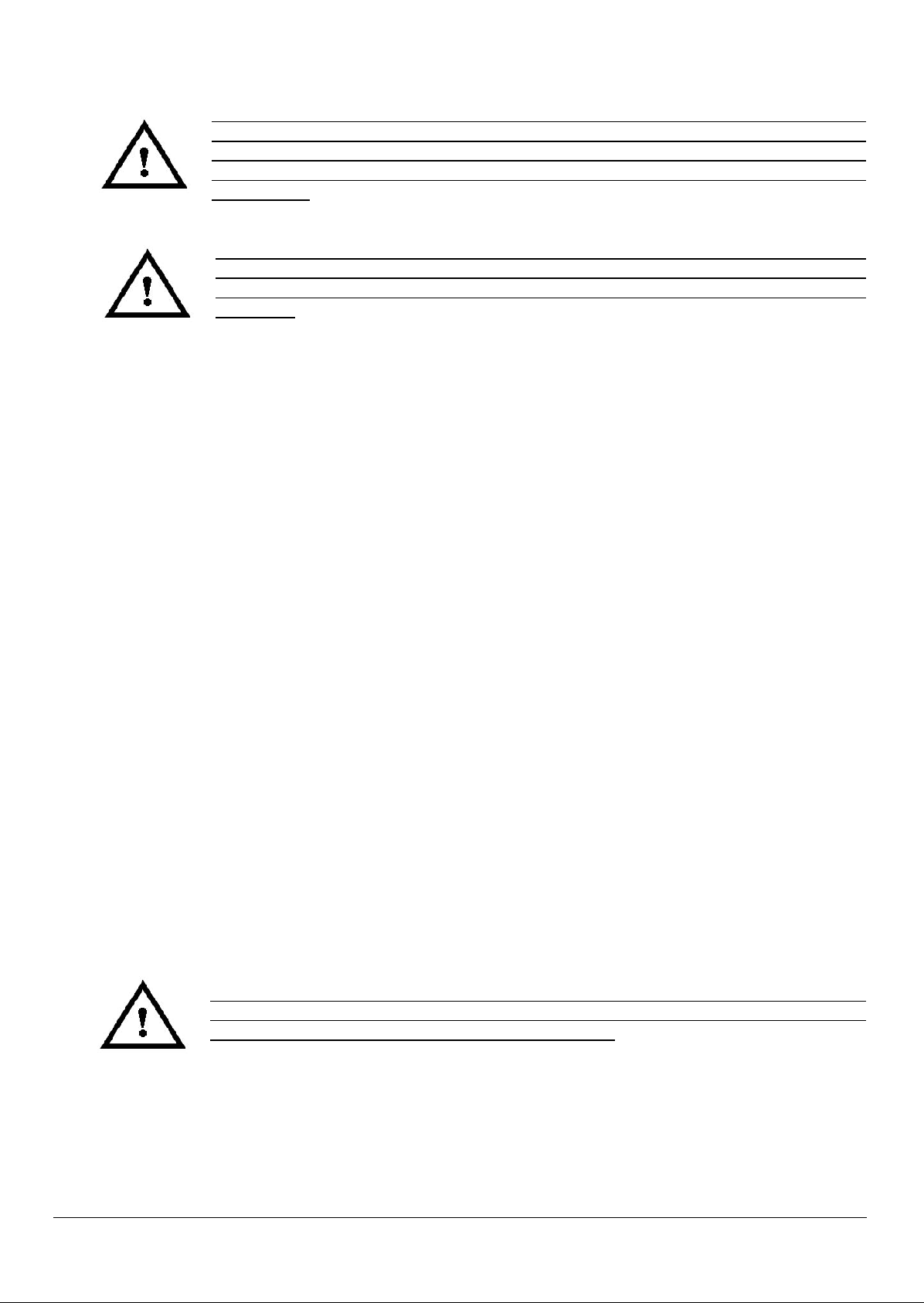

4.2 Connecting the hydraulic pressure transducer at the pump

Proceed to the hydraulic installing in

accordance with current laws. To control

pressure in feedback you need to connect to

the pump outlet, the pressure transducer

supplied (No. 1 fig 2), ¼ "M, coming from the

central to the inverter.

The type of transducer supplied may be a

different one presented in this handbook, but

maintaining the same connection and

functioning.

Fig. 1: Fixing holes distances (millimetres)

3) 220-230 Vac

Inverter voltage

supply plug

2) Motor pump

voltage supply plug;

Red color for threephase plug

1) Pressure

transducer

Page 5

5

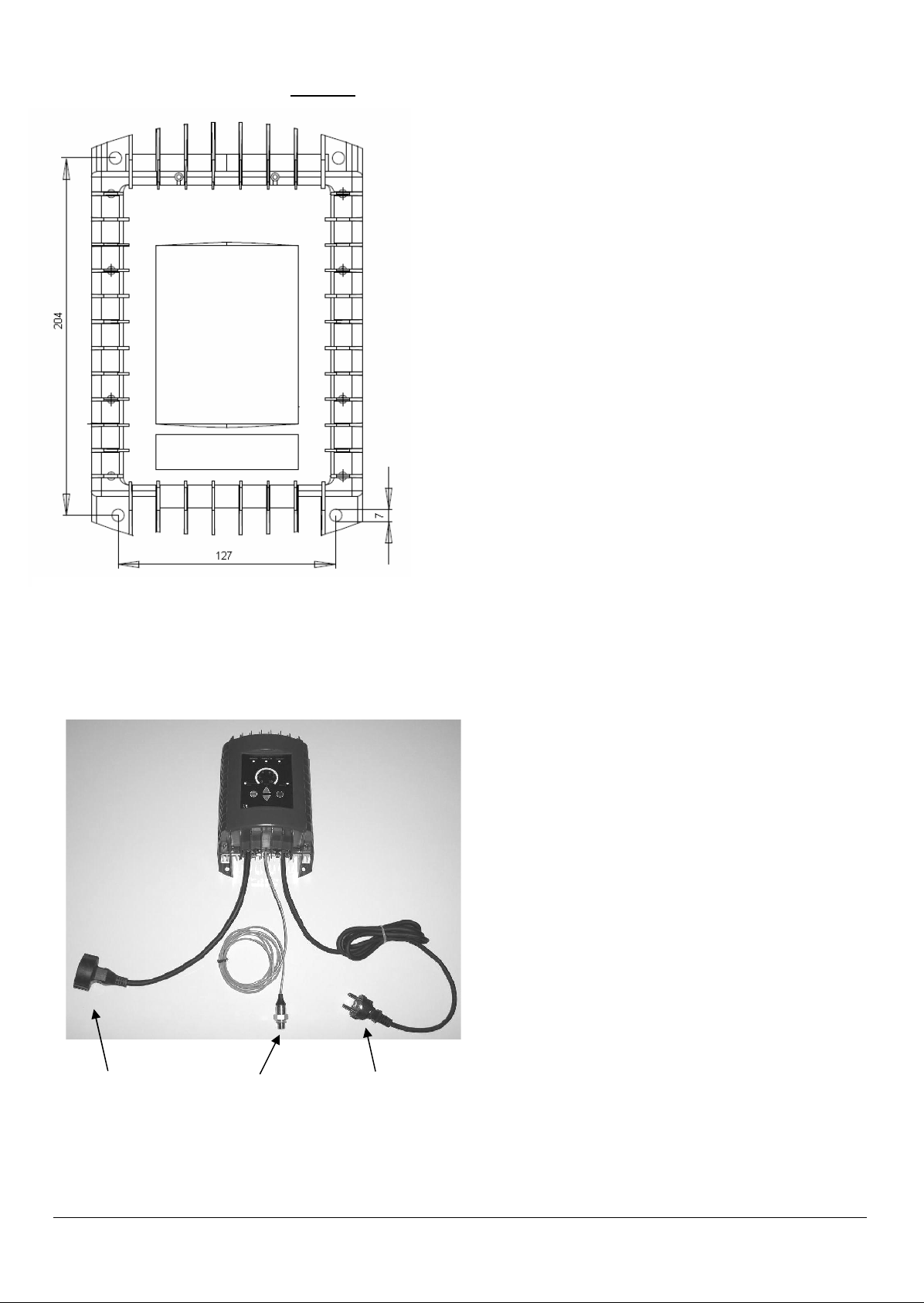

4.2.1 Connecting the pressure transducer to New waterworks system

Connect the pressure transducer in the hole of the filling cap

¼ "F of the pump provided to the output pressure

(depending on the type of pump);

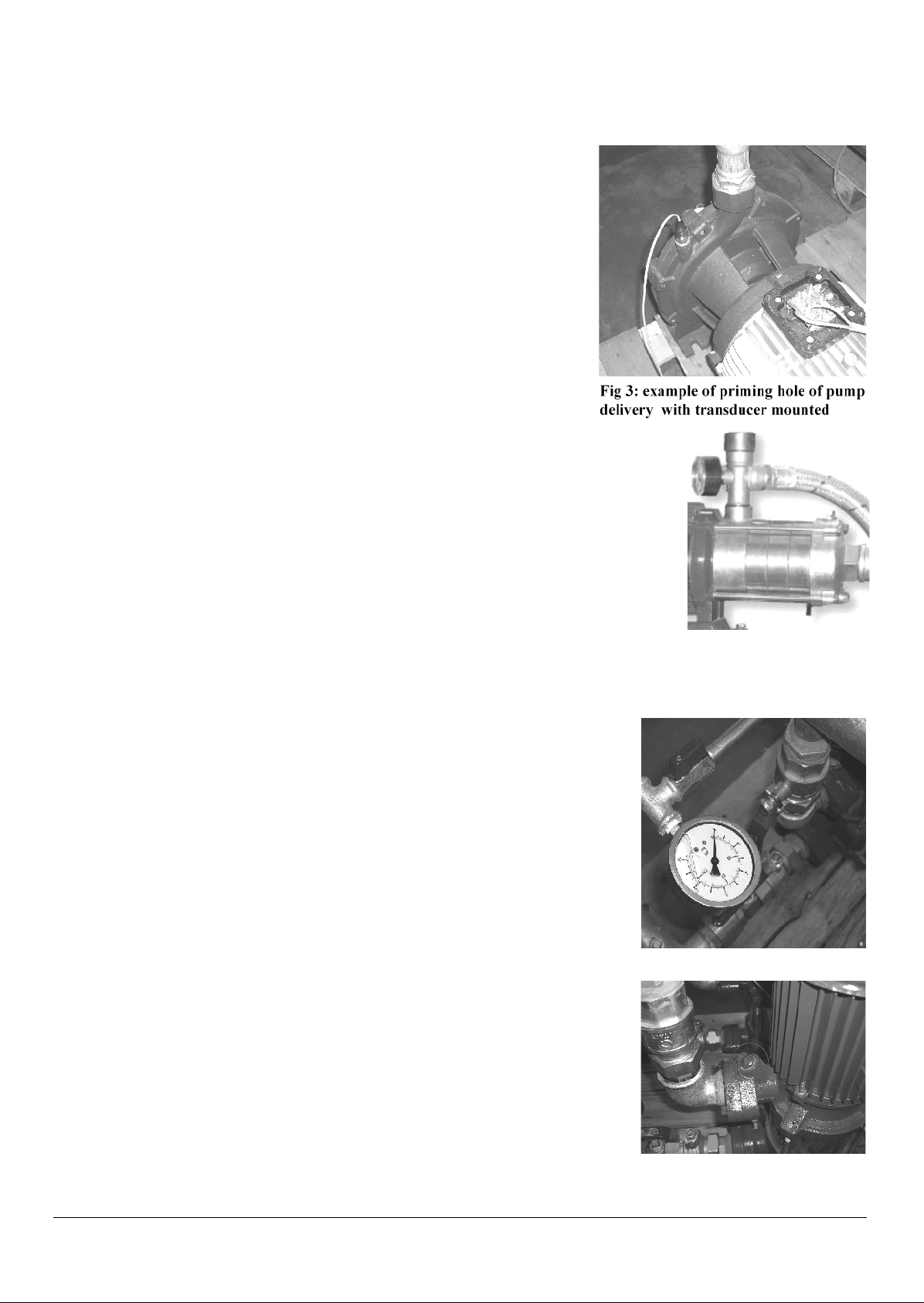

On the delivery of a multistage pump, assembled with a T-fitting is

possible to mount the pressure transducer in place of the pressure

gauge.

Be aware that: in multi-stage pumps with the hole filling near aspiration it

is not possible to mount the pressure transducer at that hole because it

will not do the correct output pressure.

Use ¼” F hole for the pressure gauge, which can be – in case –

removed for connecting the pressure transducer;

Use any other ¼ "F hole on the pump hydraulics connections,

possibly removing the cap (such as a hole for venting air);

Fig. 5: Pressure gauge to replace

Fig. 6: mounting transducer to

venting air hole on the delivery

pump

Fig 4: multistage pump outlet

with manometer to replace

with the transducer

Fig 3: example of priming hole of pump

delivery with transducer mounted

Page 6

6

4.2.2 Connecting the pressure transducer to Old waterworks system

Pump comes with PRESSURE-SWITCH with tank or with

galvanized steel tank: mount the pressure transducer in place at

the pressure switch, using reduction to ¼ "M. In case you need to

maintain the switch for maximum pressure additional security,

connect the N.C. output of the switch to ENABLE and 0V contacts

(poles 2 and 5 of J5 electronic board, fig. 10)

Pump comes with flow switch device: replace the flow switch with

a T-fitting flow and in the central hole screwing the pressure

transducer. This allows you to eliminate the problem of any

blocking of the valve flow and to eliminate pressure drop, does

mean eliminate all the problems inherent the flow switch

systems.

It is possible to use a valve or other type of output provided at the delivery of the pump.

In case of installation of the check valve on the outlet of the pump, place the pressure transducer after

the valve.

4.2.3 Membrane Tank

For an optimal pressure control is recommended to mount a small

diaphragm tank (12L are usually good for a pump up to 2Hp).

For a perfect operation of the control of pressure, make sure that the tank is

capable of withstanding the pressure and set the correct pressure to preload before connecting it to (normally 0.5-1 Bar less than the working

pressure) .

Fig. 9: Membrane Tank

Fig 7: pressure switch system

with pressure switch to

replace with transducer

flow switch system

Fig 8: Replace

Page 7

7

4.3 Inverter – Pump connection

Do connect the female schuko cable of the Inverter (No. 2 of fig. 2nd) to the power plug of the pump.

Make sure the pump is in accordance with the operating conditions listed in Chapter 2 of this

handbook. The pump to function with this Inverter must have the appropriate capacitor for the

auxiliary winding and connected to power cable properly dimensioned, with a plug (schuko

recommended).

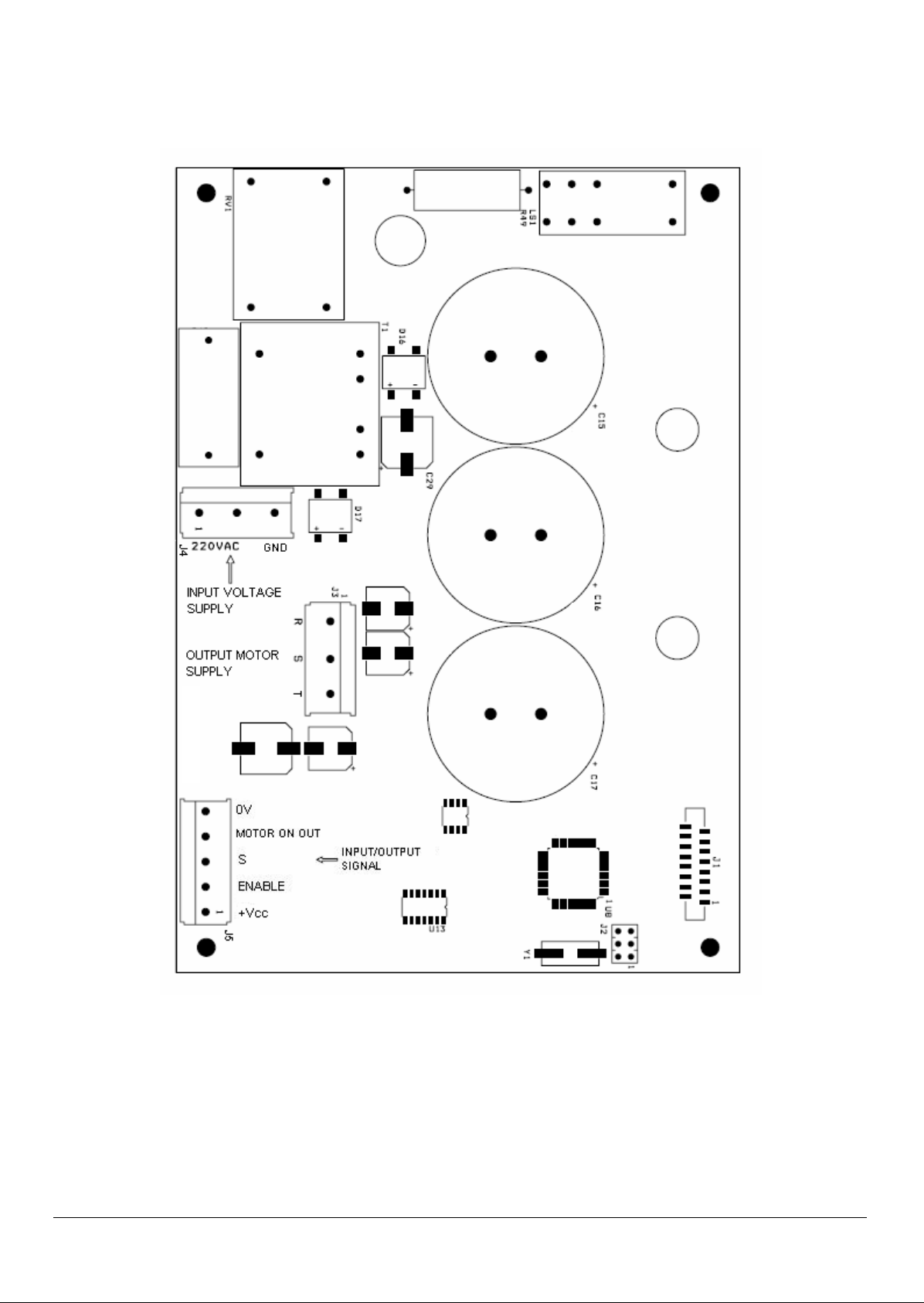

Please do attention to following cable length table if you connect the inverter to a sommersible singlephase motor-pump:

In case of submersed motor pump with a cable

length more than 20 meters be sure that the motorpump is designed to works with inverter (may have

a good phase-phase electrical insulation and not

conductive rolling bearings) otherwise you need to

use the specific output filter (optional – ask our sales

service) connecting it between the inverter output

and the motor pump voltage supply cable.

4.4 Inverter electric connection to line

The line voltage supply must match with the Inverter limits, described on chapter 3 –

WORKING CONDITIONS. Do ensure proper protection from general electrical short

circuit on the line.

The connection to the voltage supply is made by inserting the schuko plug ( No. 3 of Fig. 3) into the

socket power

The plant to which the inverter is connected must be conforms to safety regulations in use:

• Differential automatic switch: IΔn = 30mA

• Magnetic-thermal automatic switch with intervention current proportionate to the power of the

pump installed (see Table 1)

• Ground connection with total resistance less than 100 Ω

• If required by local electrical regulations in force, the installation of a differential circuit breaker,

make sure it is of a type suitable for installation (see table below). The switches are suitable for those

with the characteristic curve for alternating-current fault (type A).

Pump power Kw

Magneto-thermal protection (A)

0.5 (0.75 Hp)

8

0.75 (1 Hp)

12

1.1 (1.5 Hp)

16

1.5 (2 Hp)

25

Table 3: Magneto-Thermal protections

Before reopening of the inverter box to possible change cable or other components,

after functioning, remove voltage and wait at least two minutes, then you can open the

box (danger: contact with electric high voltage parts).

Table 2: cable lengths admitted

Page 8

8

The unit is equipped with all those technical arrangements required to ensure a good functioning

under normal situations installation.

The control system has a entry-filter, also have a current overload protection which guarantees

absolute protection when the Inverter is combined with motors that not exceed the maximum power.

For EMC is good that the power wires of control panel and motor power wires (when the motor are

separated from the inverter) are shielded type (or armoured) with individual conductors of appropriate

section (current density <= 5 A/mm2). These cables must be the minimum length necessary. The

screen conductor must be connected to the ground by both sides. On motor use the metal case for

connection to the ground of the screen.

To avoid loops that can create mass disturbances radiated (antenna effect), the motor operated by

the frequency converter must be connected on the ground individually, always with a low-impedance

using the metallic box of the machine.

The wires from power supply to frequency converter and wires from frequency converter – motor (if

the motor is separated to the Inverter) must be spaced as much as possible, not to create loops, not

make them run parallel less than 50 cm.

Don’t observe these conditions could cancel completely or partially the effect of the filter integrated.

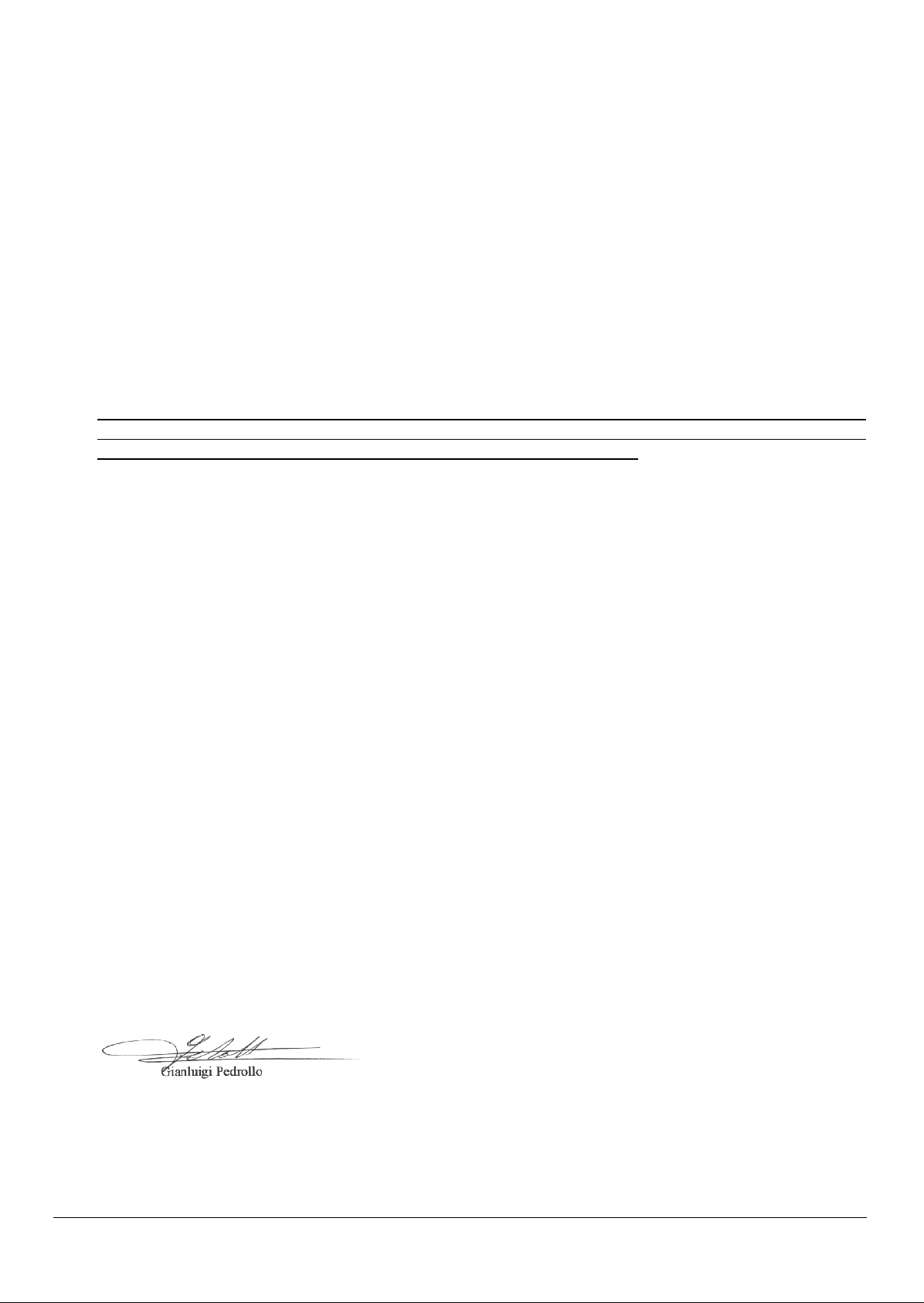

4.5 Access to the electronic board

In case is necessary to change damaged cables, pressure transducer or to add the float switch

contact, you need to open the Inverter case.

The operations of a component for the inverter must be performed only by experienced

personnel qualified by the manufacturer, using only original spare parts supplied by the

manufacturer.

Any action with open box of the Inverter must be made after at least 2 minutes after

open line with appropriate switch or the physical separation from the power supply

cable;

In case of failure to one of the cables or the pressure transducer, for the replacement of that should

be opened by unscrewing the inverter cover the N° 12 screws in the back on the heat sink. For the

extraction of a cable, unscrew the three screws that close the cable triangular plate. Remember to

always replace the O-ring seal on the cable under the plate. To connect the cables in the appropriate

terminals follow the pattern of connections in the electronic board below (fig. 10):

Inverter Power supply cable: contact 220Vac + GND (J4)

Pressure transducer with 4-20 mA output: contact +Vcc, S;

Float switch enable: contact ENABLE, 0V (J5);

Motor ON output signal: Contact MOTOR ON, 0V (J5 - closed when the motor is ON, max. 30V,

3mA)

4.6 Connecting the float contact or other NC contact

To connect an enable Normally Closed contact use the poles 2 (Enable) and 5 (common) of J5 (fig.

10). When the contact open, the Inverter stop the pump; when the contact close, the pump may restart at previous working condition.

For the connection of the float switch contact you need to change the three poles cable of the sensor

with a four poles cable, passing on the same central exit of the transducer cable.

The new connections of pressure transducer and float switch contact must be done

out of the Inverter box, protecting them to humidity, water and dust. Do not practice

others holes to the Inverter case to avoid damages or decrease of the protection and

insulation grade and interruption in anticipation of the guarantee.

Single-phase Motor Power supply cable on FCP109

Three-phase Motor Power supply cable on FCP307: contact R, S,T (J3);

a

nd

FCP111

: contact S, T (J3);

Page 9

9

4.7 Electronic Board connections:

Fig. 10: Electronic Board connections

Page 10

10

5. STARTING AND PROGRAMMING

LED

Description

Power:

Green fixed: Inverter voltage supply is ON

Pump On

Green fixed: Motor ON

Green flashing: Enable OFF condition

Alarm:

Red fixed: Motor stop for a problem that need manual re-start (STOP then START)

Red flashing: Motor stop for a problem with auto re-start

Minimum Flow:

Yellow fixed: Motor stop for minimum output flow

Yellow flashing: Motor is stopping for minimum flow

Dry Working:

Red flashing: Motor stop for dry working condition of the pump, during one of four re-start of

this problem, separated from 15 minuts

Red fixed: final stop after 5th consecutive stop for this problem

Circular Led Bar:

Like a manometer shape of 20 Leds to indicate the instant pressure in BAR. On advanced

regulation to each group of led correspound a function (see table Advanced regulations). In

ALARM condition to each led correspound a different type of alarm (see Alarm table).

Table 5: Led description

Button

Description

Allow to increase the reference pressure; it

allow to go up on the advanced regulation

functions also

Allow to reduce the reference pressure; it

allow to go down on the advanced

regulation functions also

Starting pump; start Self-Regulation Test

on the first installation or after a RESET

Instant Stop of the motor pump

Fig. 11: Control panel

Table 4: Buttons description

Page 11

11

5.1 Programming

A) Make sure the pump is charged (full of water); in case the pump is not charged provide it a

direct voltage supply (without Inverter) until the complete filling of water, then re-connect the

pump to the Inverter;

B) In case the pressure of the system is more than 3 BAR open the delivery to reduce it under this

value, then completely close the delivery or all of the valves on the output of the pump (very

important condition);

C) Press START to start the self-regulation check. Wait roughly one minute for a completed cycle,

and once the flashing Led bar is completed indicate the data saving and the pump stop for null

flow condition (Minimum flow);

D) At this point the Inverter is running; It is now possible to open the delivery of the pump and work;

the reference default pressure, modifiable, is 3 BAR;

E) If necessary, adjust the working pressure acting on keys and on panel; during the

reference pressure setting the led bar is flashing up to one second of data saving; the measured

pressure is indicated by fixed led bar;

F) For a correct over-current motor-pump protecion set the maximum current with F2 on advanced

functions (chap. 5.2) reading the nominal motor data value.

The inverters generally comes to the user with the constructor data (default); if for any reason i.e.

(such as inverters had been previously tested and configured for another pump) the inverter is preregulated, in order to RESET before self-regulation test, is necessary to perform this following:

Command

Procedure

RESET (to restore constructor data)

& press them simultaneously for 5 seconds

Starting SELF-REGOLATION CHECK

After RESET, press

Table 6: Reset and Self-Regulation Check starting

During self-regulation check the velocity and pressure of the pump arrive to maximum

values; if is necessary, limit the maximum pressure before (F7).

We suggest to repeat the self-regulation check after any variation of parameters, in particular for

variation of Maximum Velocity (F4) or Maximum pressure (F7), or in case of variations of the

electrical/mechanical pump conditions, that may appear after long time of working.

5.1.1 Checking the pump stop for delivery closed

At the end of the self-regulation check, done with the delivery of the pump completely closed (all of

the output valves closed) the pump shall be automatically stopping and the Inverter could show the

message "MINIMUM FLOW" by the corresponding Yellow LED. The stop is preceded by a phase of

flashing LED “MINIMUM FLOW”. Verify that the pump stopped and after that the pump re-start

working when opening any valve on pump delivery.

5.1.2 Checking the arrest of the pump dry running

After installing, if is possible, close the water input of the pump and check that, after approximately 40

seconds, the pump stop and show the message “DRY WORKING” with corresponding Red Led.

Page 12

12

5.2 Advanced regulations and control panel visualization

Command

Procedure

Enter on Advanced Regulations

& press them simultaneously for 3 seconds

Press and go up with to enter on the advanced function request, as show on table 7

regulating the value of the selected function on a variation range indicated, on a scale from 0 to 10.

N°

Visualization

Advanced Function

Description

Range

Default

F1

Minimum flow stop

Adjustment of the minimum flow

before pump stop, from the selfregulation value setted.

-10..+10

Step: 1

0

F2

Maximum motor

current

Maximum RMS current setting

– limit value for over-current

thermal protection (A5)

3..9 (11) A for

1..7 A for FCP307

Step: 0.5 A

9 (11)A

7 A

F3

Minimum Motor

Minimum motor velocity

adjustment.

30..70%

Step: 2%

50%

F4

Maximum Motor

Maximum value of the motor

velocity on respect to the

nominal velocity.

90..110%

Step: 1%

105%

(100% for

FCP109)

F5

FCP109 – FCP111:

Starting velocity

FCP307: Rotation

Starting velocity of the motor,

before pressure control

regulation.

Rotation direction on FCP307

40..100%

Step: 3%

0/1

79%

0

F6

Starting maximum

Current

FCP307: Rump

Starting Current – RMS limit

value

Velocity ramp acceleration/deceler.

18..28 A

Step: 0.5 A

1000-10000 RPM/s

Step: 500

26 A

(28 A for

FCP111)

3000 RPM/s

F7

Maximum pressure

Maximum security pressure of

the system.

2..10 Bar

Step: 0.5 Bar

10 Bar

F8

Pressure

Hysteresis

Adjustment of the control

pressure hysteresis.

0.15 ..1 Bar

Step: 0.05 Bar

0.3 Bar

F9

Pressure ramp

Adjustment of the control

pressure ramp on increasingdecreasing.

0.1 .. 2 Bar/s

Step: 0.1 Bar/s

1 Bar/s

F10

Minimum output

value of the

pressure

transducer

Adjustment of the minimum

output value of the pressure

transducer

1..5 mA

Step: 0.2 mA

4 Ma

Velocit

FCP109 and FCP111

y

Veloci

ty

Page 13

13

F11

Maximum output

value of the

pressure

transducer

Adjustment of the maximum

output value of the pressure

transducer

10.. 20 mA

Step: 0.5 mA

20 Ma

F12

Pressure

transducer

measure range

Adjustment of the pressure

transducer range.

10..20 Bar

Step: 0.5 Bar

16 Bar

F13

Proportional P.I.D.

Factor

Proportional factor on the P.I.D.

pressure control

0..6000

Step: 300

3000

F14

Integral P.I.D.

Factor

Integral factor on the P.I.D.

pressure control

0..4000

Step: 200

1000

F15

Minimum flow stop

delay

Delay time on the minimum flow

condition before stopping pump

2..20 sec

Step: 1 sec

10 sec

F16

Dry working stop

delay

Delay time on the dry working

condition before stopping pump

10..100 sec

Step: 5 sec

40 sec

F17

Noiseless working

mode

It is possible change of the

working mode type

0: Normal working

1: Noiseless working

0

F18

Check suspension

It is possible to suspend the self

regulation check using a

theoretical pump curve or to

repeat the check on next START

0: Theoretical curve

1: Start new check

2: Checked curve

1

F19

Phisical quantity

Measures

Measures of different phisical

quantity on respect the

pressure

0: Pressure (0..10)

1: Frequency (15..55)

2: Current (0..10)

3: Voltage (200..240)

4: T [°C] (70..90)

5: Last alarm

6: Motor ΔT[°C](0..100)

0

Table 7: Advanced Functions

WARNING: setting an high Maximum Velocity (function F4) increase the performance

of the pump but can also reduce the endurance of the same for the stress of electrical

and mechanical parts.

NOTES:

Check suspension function (F18-0) eliminate the Self regulation check and regulate the pump working

using a theoretical approximated curve (minimum flow stop is modifiable with F1);

Noiseless working function (F17-1) provide a more silent working power of the motor-pump (low

electromagnetic acoustic noise caused by iron-core vibrations) but increase the power loss and

consequently increases the Inverter temperature;

If the high value of the starting current cause problems on the magneto-thermal switch protection try

reduce this current with F6 and verify that the torque remains sufficient.

Page 14

14

6. PROTECTIONS AND ALARMS

N°

Alarm type with

ALARM led ON

Protection

Description

A1

Current pick

The logic switches off the power instantaneously if this

value exceeds a peak that can damage the power

electronic components. Possible high starting current or

short-circuit on motor.

A2

Over-voltage

The logic switches off the current if the voltage exceeds a

maximum instantaneous limit beyond that can damage

some electronic components of the inverter.

A3

Minimum-voltage

If the voltage goes below the minimum value of 207 Vac

the power supply may provide a under-voltage to some

electronic components; for this the logic switches off the

current.

A4

Over-temperature

IGBT

If the temperature of the power electronic components

(IGBT) exceeds 85°C the inverter provide a thermal

protection and stops the current.

Before this stop protection the Inverter limit the current to

90% of the value imposed (F2)

A5

Motor Over-Current

Thermal protection

To over-current beyond a certain time defined by an I2t

algorithm, the inverter limit the current to protect the

motor from damage to the insulation. For the correct

functioning of this protection regulate the nominal motor

current (F2).

A6

Pressure

transducer problem

In case of a problem or failure of the pressure transducer,

the Inverter switches off the motor current. Re-start must

be manually, pressing STOP followed by START.

A7

Minimum flow

This protection stop the pump when all output are closed

and the flow of water is null. Do not appear “Alarm” led

signalising

A8

Dry working

This protection stop the pump in absence of input flow of

water. After five consecutive re-start, the stop is

permanent and switch on also the “Alarm” led

Table 8: Protections and Alarms

All Alarms are showed with the corresponding Led on the circular Led bar and the red Alarm Led, that

is flashing if the protection have automatic re-start otherwise is fixed if the protection need a manually

re-start doing STOP then START.

Protections and Alarm details:

CURRENT PICK PROTECTION (A1): The Inverter stop immediately the current in case this value

exceed a maximum value limit for the electronic components

CLOSED DELIVERY WORKING PROTECTION (A7): to prevent a closed delivery working, the

control logic read the motor’s working point condition; if this point is under a setting value, the system

switches off the pump, and appears advise “Minimum Flow”. At the end of this condition, the system

restarts its normal operation. The pump curve is detected by the initial self-regulation check.

Page 15

15

DRY WORKING PROTECTION (A8): To avoid that the pump can continue to operate after a problem

in absence of input water, the system read some information of the electric motor, in a time of 30

seconds, and when they go below a minimum, turn off the pump and show the relative signal of alarm

“Dry Working”. The inverter tries N°5 consecutive re-start in this condition, one spaced 15 minutes of

each other. After the fifth consecutive fault, switch on the led Alarm and the re-start must be manually

do, pressing STOP followed by START.

ENABLE OFF: the enable contact (float contact) is open and the led MOTOR ON is flashing.

7. GUARANTEE

Under the current European low: guarantee of 2 years calculated from the date of delivery of

prejudice further provisions of law or contract.

To have service in guarantee, it must submit to the company providing the guarantee certificate

completed.

The guarantee is excluded or interrupted in anticipation if the damage is caused to the following:

External influences, non-professional installation, non-compliance with instructions, interventions by

unauthorized locations, use of not original spare parts and normal wear.

8. DECLARATION OF CONFORMITY

PENTAX SPA - declare that the products :

FCP109

FCP111

FCP307

are conforms to the following European directives and to national law and at following technical

standards:

Machines 98/37/CE

Low Voltage 73/23/CE and subsequent amendments

EMC 89/336/CE

EN60034, EN60335-1, EN 60335-2-41, EN 55014-1, EN 55014-2, EN 61000-3-2,

EN 61000-3-3, EN 61000-3-4, EN 61000-3-12, EN292-1, EN292-2, EN50-178

Manufacturer and depositary of tecnical documentation:

PENTAX S.p.A.

Viale dell’industria, 1

37040 Veronella (VR) - Italia

Gianluigi Pedrollo (President)

Veronella (Vr), 01/01/2008

Page 16

16

Loading...

Loading...