Page 1

Electronic

Theodolites

PENTAX Industrial Instruments Co.,Ltd.

2-5-2 Higashi-Oizumi / Nerima-ku, Tokyo 178-0063,Japan

Tel.+81-3-5905-1222 / Fax +81-3-5905-1225

E-mail:international@piic.pentax.co.jp

ETH-302

ETH-305

ETH-310

Instruction manual

Total Construction Solutions

10 sec.Angle Accuracy

Detachable Tribrach

5 sec.Angle Accuracy

Detachable Tribrach

2 sec.Angle Accuracy

Detachable Tribrach

ETH-320

20 sec.Angle Accuracy

Detachable Tribrach

Page 2

Page 3

3

Safety Precautions (must be followed)

The following items are intended to prevent possible injury to the user or

other people and/or damage to the instrument before it occurs.

These safety precautions are important to the safe operation of this

product and should be observed at all times.

•

Distinctive Displays

The following displays are used to distinguish precautions by the

degree of injury of damage that may result if the precaution is ignored.

WARNING

Items indicated by this display are precautions which if ignored could

result in death or serious injury.

CAUTION

Items indicated by this display are precautions which if ignored may

result injury or material damage.

• Here ”injury” refers to injuries such as cuts, burns or electric shock

the treatment of which will not likely require hospitalization or

long-term attention.

• ”Material damage”refers to the damage to facilities,buildings,

acquired data, etc.

WARNING

• Never look at the sun through the telescope as this may result in loss of

sight.

• Do not use at a place near flammable materials as there will be a risk of

fire or injury by explosion.

Page 4

4

CAUTION

• Secure the handle of main unit with the handle locking screws.

Failure to properly secure the handle could result in the main unit

detaching from the handle while being carried, causing injury.

• Do not use the carrying case as a footstool as it is slippery and

unstable and may cause you to fall, resulting in possible injury.

• When mounting the instrument to the tripod, tighten the center

screw securely.Failure to tighten the screw properly could result

in the instrument falling off the tripod causing injury.

• Securely tighten the leg fixing screws of the tripod. A person

could be injured by the tripod shoes on an extending leg due

to a loose screw.

• Do not carry a tripod with the metal shoe pointing toward another

person as the person may be injured if they strike them.

• Make sure that your hands and feet are not in the vicinity of

the tripod legs when setting up the tripod, or a hand or foot stab

would occur.

• Do not wield or throw the plumb bob. A person could be

injured if struck.

• If a battery box or a battery is gets wet by water, wipe off the

water and dry immediately.

• When a battery box is removed from the unit, power must be off.

If the battery box is removed with power on, it will cause trouble.

Electro-Magnetic Compatibility(EMC)

This instrument complies with the protection requirement for

residential and commercial areas.

If this instrument is used close to industrial areas or transmitters,

the equipment can be influenced by electromagnetic fields.

Page 5

5

CONTENTS

•1.General 7

1.1 Precautions

1.2 Standard equipment

1.3 Names of Parts

1.4 Preparation of power

•2.Key Operations and Display 14

2.1 Display

2.2 Keyboard

2.3 Function of each key

2.3.1 Power on-off key

2.3.2 V/% key

2.3.3 Hold key

2.3.4 0 set key

2.3.5 R/L key

2.3.6 Illumination key

2.4 Other functions

2.4.1 Remaining battery indicator

• 3. Special Key Operations 22

3.1 Setting of vertical angle

3.2 Setting of 90°buzzer

3.3 Setting of correction of vertical angle

3.4 Setting of angle measurement

3.5 Setting of automatic power-off function

3.6 Setting of Angle unit

•4.Preparation for Surveying 28

4.1 Setting up the instrument

4.2 Leveling with the circular vial

4.3 Leveling with the plate vial

4.4 Centering with the optical plummet

4.5 Eyepiece adjustment

4.6 Object sighting

Page 6

6

CONTENTS

•5.Measurement 34

5.1 Horizontal angle measurement (right)

5.2 Horizontal angle measurement (left)

5.3 Vertical angle measurement

•6. Inspection and Adjustment 37

6.1 Instructions on inspection and adjustment

6.2 Perpendicularity of plate vial to vertical axis

6.3 Perpendicularity of circular vial to vertical axis

6.4 Inclination of reticule graduations

6.5 Perpendicularity of line of sight to horizontal axis

6.6 Difference of the vertical angle

6.7 Optical plummet

•7. Optional Accessories 44

7.1 Diagonal eyepiece

•8.Specifications 45

Page 7

7

1. General

1.1 Precautions

Storing and environmental conditions

• Do not use the instrument until it has adjusted to

the ambient temperature.

• Avoid using at a high or low temperature.

The instrument may not work normally at

temperatures exceeding –10 or +50˚C.

• When the instrument gets wet,

wipe off the water immediately and let it completely dry

outside of the case. Store in the case after completely dried.

• Be sure to store instrument in the case. Avoid storing in a place that is

subject to high temperature, high humidity, or dust.

• When not in use for extended periods, remove a battery from the

battery box. Also remove the instrument from the case and expose

to the air periodically.

Battery

• Batteries can naturally discharge due to shipment time.

Use new batteries for the first job.

• The four (4) batteries, in a battery box, should be of the same type.

• Do not use batteries, in a battery box, which have different remaining

capacities.

• Do not touch the liquid of leaking batteries.

Page 8

8

Transportation

• Do not subject to impact or vibration during

transportation.

• When transporting, handle the same as ”fragile” and

pack the shipping case with cushioning materials.

Inspection, Adjustment and Repair, Overhaul

• When not in use for extended periods of having been subjected to

impact or vibration, be sure to check the instrument adjustments

before using.

• If there is any problem in the instrument,

do not attempt to repair or you may make

the problem worse.

Contact your local dealer for proper repair or instructions.

Page 9

9

Others

• When cleaning the case or the instrument, do not use any organic

solvent.The surface of plastic parts may dissolve and deformation

and discoloration can occur.

Wipe off the dirt with a wet cloth of dilute household detergent

• Wipe off dirt on the optics with a cleaning cloth (or paper) specified

for optical surfaces.

• To realize full capability of the instrument, adhere to

cautions described in each chapter of this manual.

1.2 Standard Equipment

• Body (with objective cap)

• Battery box (One battery box is installed in the instrument)

• Batteries* (Contained in the carrying case)

• A set of tools (Adjusting pin, driver)

• A plumb bob

• Rain cover

• Carrying case

• Instruction manual

*The standard equipment AA batteries can naturally discharge due to

shipment time. Use new batteries for the first job.

When disposing used batteries, please follow your municipal

government rules.

Page 10

10

Unpacking and Storing

Unpacking

• Gently set down the carrying case so that its cover is upward.

• Unlatch and open the case while pushing the latch lock.

• Take the instrument out of the case.

Storing

• Set the telescope almost horizontal, and lightly tighten the telescope

clamp screw.

• Align the containing marks*, and lightly tighten the horizontal clamp

screw.

• Insert the instrument into the case with the containing marks*

facing upward.

• Close the case lid and lock the latches.

*Containing mark = Yellow dot sticker

Page 11

11

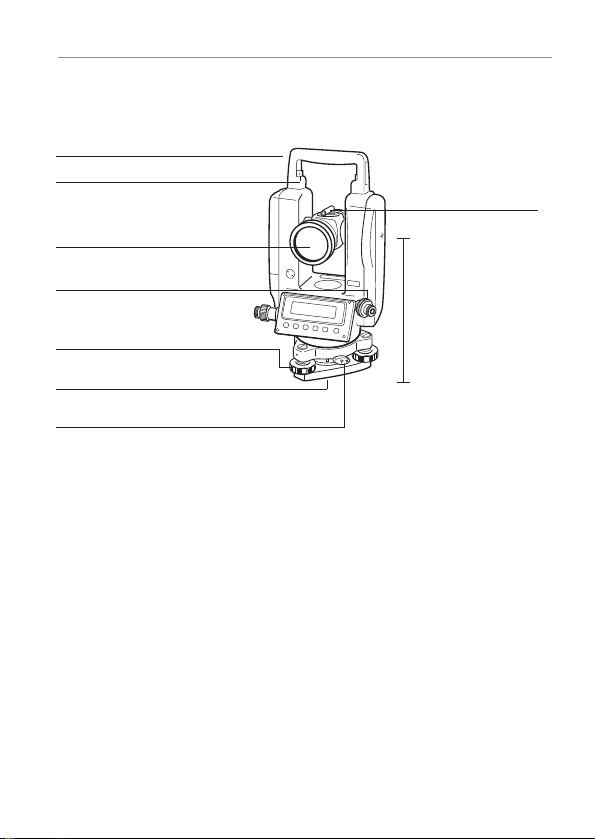

1.3 Names of Parts

Handle

Screw for handle

Objective lens

Optical plummet

Leveling screw

Bottom plate

Tribrach locking lever

Collimator

Instrument height mark

(215mm)

Page 12

12

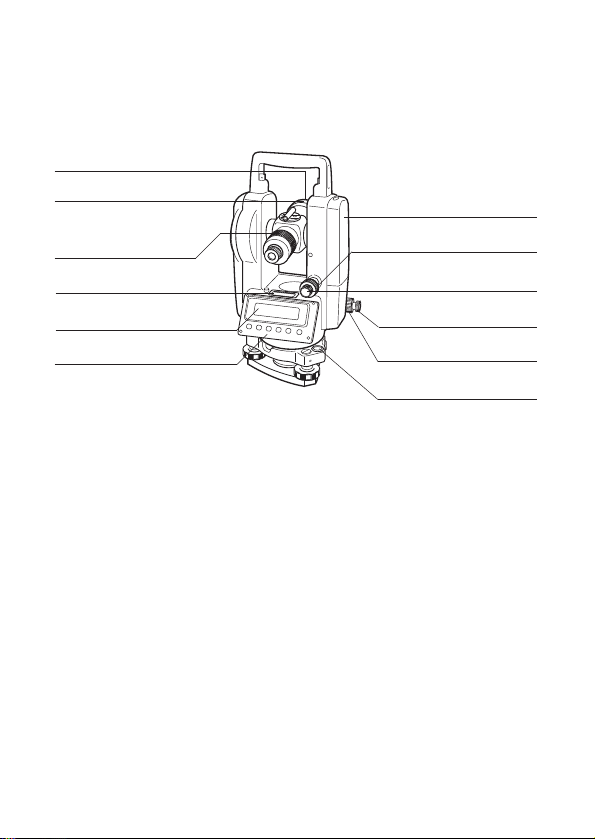

Eyepiece cap

Eyepiece lens

Focusing knob

Plate vial

LCD panel

Keyboard

Battery box

Telescope tangent screw

Telescope clamp screw

Horizontal clamp screw

Horizontal tangent screw

Circular vial

Page 13

13

1.4 Preparation of Power

• Remove battery box from the unit by pushing the release button on

the top of the battery box. Remove the battery box cover.

• Insert four AA batteries into the battery box according to (+) and (-).

• Press the battery box to the leg by inserting the guide pin

to the guide groove.

• Confirm the correct work by pressing the power switch.

This instrument can operate using 1.2V AA rechargeable batteries.

• The four (4) batteries, in a battery box, should be of the same type.

Do not use batteries, in a battery box, which have different remaining

capacities.

• When a battery box or batteries are wet, wipe off the moisture

immediately and dry completely.

• When a battery box is removed from the unit, power must be off.

If the battery box is removed with power on, it will cause trouble.

Page 14

14

2. Key Operations and Display

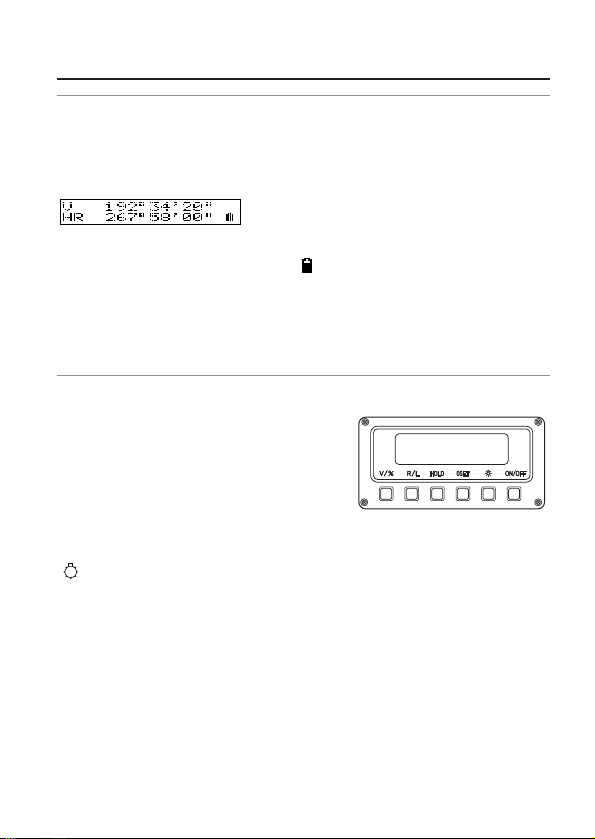

2.1 Display

Ver tical angle

V=Zenith 0°, V%=Slope(VH=Horizontal 0°, Vc=Compass)

Horizontal angle Battery indicator:

(HR=right rotation horizontal angle, HL=left rotation horizontal angle)

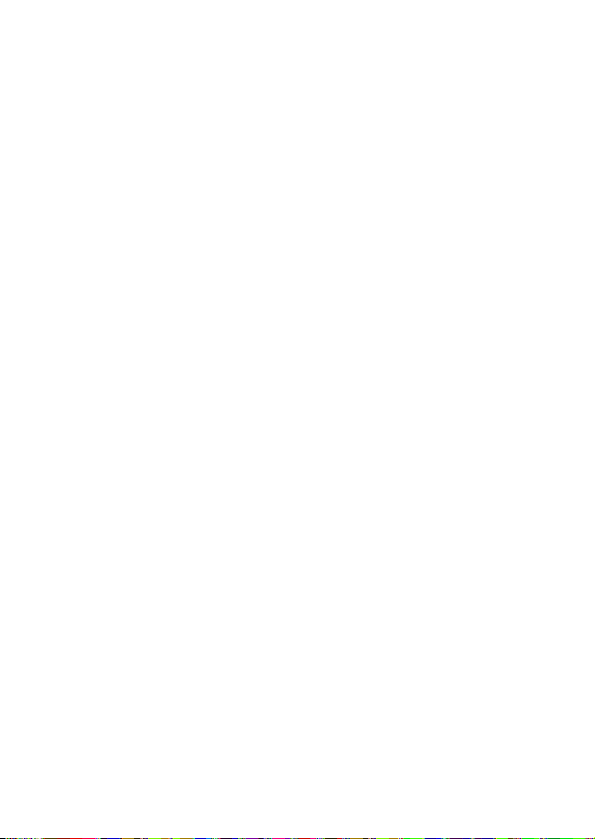

2.2 Keyboard

[V/%] key

(Switches the display of vertical angle)

[R/L] key (Set the horizontal angle right

and left rotation alternately)

[HOLD] key (Pressing twice holds the horizontal

angle shown on the display)

[0SET] key (Pressing twice resets the horizontal angle to 0°,00’,00”)

[ ]Illumination key (Illuminate LCD panel and the telescope reticle)

[ON/OFF] key

(Turns the power on and off alternately)

Page 15

15

2.3 Function of each key

2.3.1 Power [ON/OFF] key

<Power ON and set the vertical angle 0 point>

Pressing the ON/OFF key turns on the power supply and the message

”0 SET” is displayed. After the ”0 SET” of vertical angle is performed,

the Horizontal and Vertical angle are displayed and the instrument

enters into the angle measurement mode.

<Setting vertical angle 0 point>

Set the vertical angle 0 point by turning the telescope upward or

downward when the instrument is at the ”normal” position

(Vertical circle at left.)

<Power OFF>

To turn the power supply off,press the ON/OFF key for more than

1 second (”OFF” will display) and then release it. Power turns OFF.

1

2

3

Page 16

16

2.3.2 [V/%] key

Pressing the V/% key will change the Vertical angle display to

V%(slope). (At the shipping, it is set at Zenith 0°)

By special key operation, horizontal 0° (VH) and Compass (Vc)

can be set.

(Factory default is Zenith 0°)

(Refer to 3.1 Setting of vertical angle.)

Page 17

17

The error ”OVER RANGE” is displayed when the telescope

exceeds 45°(100%) in the V% display mode.

Page 18

18

2.3.3 [HOLD] key

Press the [HOLD] key twice in succession to hold the displayed

horizontal angle and retain it. (Press once, the key buzzer will sound,

then press again during the sound.)

Press the key once more to release.

To prevent operation error, the buzzer sounds for three seconds

when the [HOLD] key is pressed.

HOLD is not initiated unless the key is pressed during

the buzzer sound.

1

2

Page 19

19

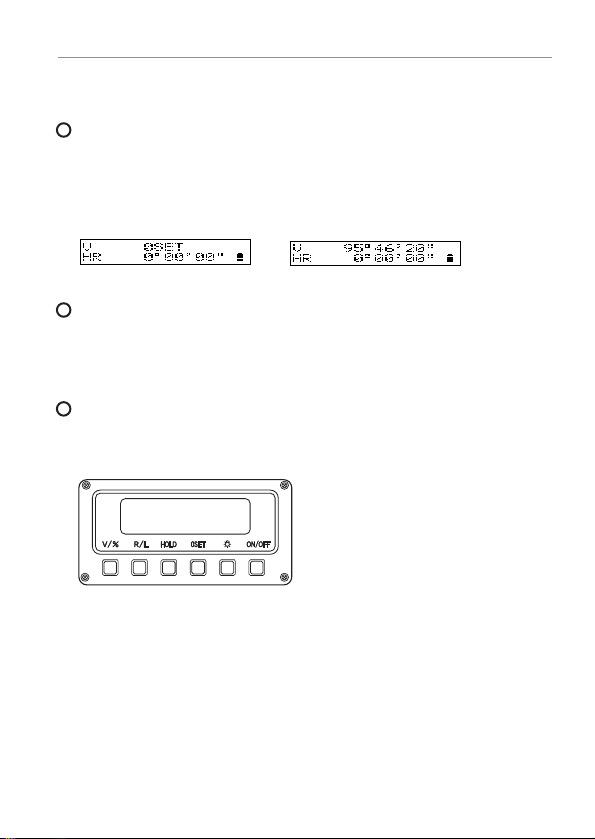

2.3.4 [0SET] key

Press the [0SET] key twice in succession to reset the displayed

horizontal angle 0°,00’,00”.(Press once, the key buzzer will sound,

then press again during the sound.)

Press the key once more to release.

To prevent operation error, the buzzer sounds for three seconds when

the [OSET] key is pressed.

[OSET] is not initiated unless the key is pressed during the buzzer

sound.

1

2

Page 20

20

2.3.5 [R/L] key

Press the [R/L] key to change from clockwise to counterclockwise

rotation. A clockwise or counterclockwise reading is alternately

displayed each time the key is pressed.

Clockwise horizontal angle Count horizontal angle in a right

rotation direction (HR)

Counterclockwise horizontal angle Count horizontal angle in a left

rotation direction (HL)

If the power turns off during the counterclockwise mode, the display

returns to a clockwise horizontal angle display when power is turned on.

2.3.6 [Illumination key ]

Pressing the key, illuminates the LCD panel and telescope reticule.

The illumination is automatically turned off after five minutes.

Pressing the key, with illumination on, turns off the illumination.

1

2

Page 21

21

2.4 Other Functions

2.4.1 Remaining battery indicator

The status of the remaining battery capacity is displayed with

””symbolizing the battery capacity.

Battery full - operating possible

Operation possible

Operation still possible

Get the battery ready for a stand by

Replace batteries

Automatic Power-off function

If there is no key operation for about 30 minutes, the power supply is

turned off automatically.

This function can be set to NIL by special key operation. (Refer to 3.5

Setting of automatic power off function.)

Page 22

22

3. Special key operations

Special key operation enables selection of angle unit and

other such items.

Press [HOLD] key and [0SET] key at the same time

Press [ON/OFF] key

Release [ON/OFF] key

(No display or buzzer)

Release [HOLD] key and [0SET] key,

Following display appears:

1

2

3

4

5

Page 23

23

Flow of setting display

Setting of vertical angle

Press [R/L] key

Setting of 90°buzzer

Press [R/L] key

Setting of correction of vertical angle

Press [R/L] key

Setting of angle display

Press [R/L] key

Setting of automatic power off function

Press [R/L] key

Setting of Angle unit

Previous items can be displayed by pressing the [HOLD] key.

Page 24

24

3.1 Setting of Vertical Angle

Ver tical angle setting display by special key operation

Zenith 0° (V)

Setting is switched by pressing [0SET] key

Horizontal angle 0°(VH)

Compass (Vc)

Store with [V/%] key when the setting is decided.

Page 25

3.2 Setting of 90°buzzer

90°buzzer setting display by special key operation

No 90°buzzer

Setting is switched by pressing [0SET] key

With 90°buzzer

Store with [V/%] key when the setting decided.

3.3 Setting of correction of vertical angle

Correction of vertical angle setting display by special key operation

Setting is switched by pressing [0SET] key

Store with [V/%] key when the setting decided.

25

Page 26

26

3.4 Setting of angle measurement

Angle setting display by special key operation

For models ETH-302/305

Setting is switched by pressing [0SET] key

Store with [V/%] key when the setting decided.

For models ETH-310

Setting is switched by pressing [0SET] key

Store with [V/%] key when the setting decided.

For ETH-320

Setting is switched by pressing [0SET] key

Store with [V/%] key when the setting decided.

1

2

3

Page 27

27

3.5 Setting of automatic power off function

Automatic power off function setting display by special key operation

Automatic power off active

Setting is switched by pressing [0SET] key

Automatic power off inactive

Store with [V/%] key when the setting decided.

3.6 Setting of Angle unit

Setting is switched by pressing [0SET] key

You can Select DEG or DEC or GRD or MIL as the unit for angle.

Store with [V/%] key when the setting decide.

Page 28

28

4. Preparation for Surveying

4.1 Setting up the instrument

Adjust the tripod legs so that a height suitable for surveying is

obtained when the instrument is set on the tripod.

A Set the tripod and fix the metal shoe firmly into the ground so that

the tripod head is as level as possible and centered above the station

point. If the tripod head is disturbed by the action of fixing the metal

shoe into the ground, correct the level by extending or retracting each

leg of the tripod.

Set the instrument on the tripod head; insert the tripod center screw

into the instrument bottom plate and tighten firmly.

1

2

3

Tripod head

Center screw

Trip od

Bottom plate

Page 29

29

4.2 Leveling with the Circular level

After [4.1 Setting up the instrument] is completed, instrument must be

leveled using the circular vial.

By rotating any two leveling screws,position the bubble in the center

of the vial (See A.) (To adjust the screws at the same time, turn them in

opposite directions.)

Adjust the remaining leveling screw,and position the bubble in the

center of the circle (See B)

For the relation between the screw adjusting direction and bubble

moving direction, refer to the arrows of the following figures. Bubble will

move to the right in figure A, while in figure B it moves upward.

1

2

(A) (B)

Page 30

30

4.3 Leveling with the Plate level

After [4.2 Leveling with the circular vial] is completed,instrument must be

leveled with plate vial.

Place the plate vial in parallel with a line joining any two of the leveling

screws. By rotating two leveling screws in the opposite direction of

each other,position the bubble in the center of the vial (See A)

Rotate the plate vial through 90°, position the bubble in the center of

the vial by operating the remaining one leveling screw (See B)

Confirm if the bubble stays in the center by rotating the

instrument 180°.

If the bubble moves, repeat procedure and .

For the relationship between the screw adjusting direction and bubble

moving direction, refer to the arrows of following figures. Bubble will

move to the left in figure A, while in figure B moves upward.

When the bubble is not positioned in the center by repeating procedure

and in procedure 4.2 , adjustment is required.

(Refer to [6.Inspection and Adjustment.])

1

2

3

1

2

1

2

(A) (B)

Plate vial

Page 31

31

4.4 Centering with the optical plummet

After [4.3 Leveling with the plate vials] is completed,the instrument must

be centered above the station point.

Focus the optical plummet reticule by rotating the optical plummet

eyepiece knob.

Focus the station point by rotating the optical plummet focusing knob.

Loosen the tripod center screw.Look through the optical plummet

eyepiece, and move the instrument bottom plate until the reticule

center coincides with the station point. (Take care not to rotate

the instrument)

Tighten the tripod center screw.Ascertain that the bubble stays

positioned in the center when rotating the plate vial position in steps

of 90°. If the bubble is not positioned in the center, adjust with the

leveling screws. (Refer to [4.3 Leveling with the plate vial]).

Even if the bubble is shifted by one graduation in , deviation of

centering is just 0.3mm, at the instrument height of 1.4m,giving little

effect on the survey result.

1

2

3

4

Center mark

4

Page 32

32

4.5 Eyepiece adjustment

After [4.4 Centering with the optical plummet] completed, focus the

telescope eyepiece on the telescope reticule.

Remove the telescope lens cap.

Point the telescope at a bright object.

Rotate the eyepiece completely counterclockwise.

Look through the eyepiece, and rotate the eyepiece clockwise until the

reticule appears at its maximum sharpness.

At procedure , keep your eye relaxed to prevent parallax and eye

fatigue. Parallax causes problems with object sighting.

(Refer to [4.6 Object sighting])

1

2

3

4

Horizontal graduation

(double)

Ver tical graduation

(single)

Ver tical graduation

(double)

Optical axis

Reticule pattern

4

Page 33

33

4.6 Object sighting

After [4.5 Eyepiece adjustment] is completed, sight the object.

Loosen the telescope clamp screw and horizontal clamp screw.

Point the telescope at the object using the collimator sight.

Tighten the telescope clamp screw and horizontal clamp screw.

Focus on the object by rotating the focusing ring, while looking

through the telescope.

Accurately align the reticule with the object, using each tangent

screw.

• In procedure , focus on the object correctly so that the reticule

will not move in relationship to the object when you move your eye

slightly left and right, while looking through the eyepiece.

• Turn the focusing ring clockwise to focus on a near object.

Turn the focusing ring counterclockwise to focus on a far object.

• Two screws of the collimator are fixed and adjusted at the distributor

or the manufacturer.Do not move them arbitrarily.

1

2

4

5

3

Horizontal clamp screw

Horizontal tangent screw

object

Focusing ring

Telescope eyepiece

Collimator

4

Page 34

34

5. Measurement

5.1 Horizontal angle measurement (right)

Level the instrument, and after power on set the vertical angle 0 point.

Sight the first object using the horizontal clamp and tangent screw as

well as the telescope clamp and tangent screw.

Press [0SET] twice to set the horizontal angle to 0°,00’,00”

Sight the second object using the horizontal clamp and tangent screw

as well as the telescope clamp and tangent screw.

Read the displayed value (α).

First Object: Zero Setting (0 °00’ 00”)

Second Object (34 °47’ 20”)

Horizontal Angle (α) = 34 °47’ 20”

1

2

4

5

3

First object

Second object

Page 35

35

5.2 Horizontal angle measurement (left)

Level the instrument, and after the power on set

the vertical angle 0 point.

Sight the first object using the horizontal clamp and tangent screw as

well as screw as well as the telescope clamp and tangent screw.

Press the [R/L] key to switch the horizontal angle display to

counterclockwise reading (HL).

Subsequent operation will be done as in [5.1 Horizontal angle

measurement (right), but the order of collimation is reversed.

To switch the mode back to ”right”,press the [R/L] key again.

• If the power turns off during the counterclockwise mode, the display

returns to a clockwise horizontal angle display when power is

turned on.

2

1

3

Page 36

36

5.3 Vertical angle measurement

Level the instrument, turn the power on and set

the vertical angle 0 point.

Sight the object A using the horizontal clamp and tangent screws as well

as the telescope clamp and tangent screws.

Read the displayed value ( ).

• The vertical angle mode can be changed to slope percent display

(V%) by pressing [V%] key.

Also, horizontal 0°(VH) and compass (Vc) can be set using special

key operation.

(Factory setting is Zenith 0°)

(Refer to 3.1 Setting of vertical angle)

Ver tical angle (θ) = 86 °24’40”

Press the [V/%] key to view the Vv and V%.

Ver tical angle 0 point

Object

Horizontal angle

Page 37

37

6. Inspection and Adjustment

6.1 Instructions on inspection and adjustment

• Inspection and adjustment should be done after setting the

instrument on a tripod or on an adjustment stand.

• Inspection should be done sequentially from [6.2 Plate vial] to

[6.5 Perpendicularity of line of sight to horizontal axis]

• Adjustments should be finished with adjustment screws having been

tightened and with firm torque. Do not finish by loosening an

adjustment screw.

• Repeat inspection after adjustment and confirm if the adjustment is

performed correctly.

• It is recommended that a trained professional perform adjustments,

if possible.

6.2 Perpendicularity of plate vial to vertical axis

Inspection

Perform [4.3 Leveling with the horizontal vial]

Rotate the instrument through 90° and confirm if the bubble is

always in the center.

When the bubble is in the center,no adjustment is necessary.

If the bubble moves from the center, following adjustment is required.

1

2

3

Leveling screw

Plate vial

Page 38

38

Adjustment

Center the plate vial bubble.

Rotate the instrument 180°, move the bubble half way back to

the center by operating a leveling screw which is located parallel

with the plate vial.

Rotate the vial adjusting screw with the adjusting pin and position

the bubble in the center.

Repeat procedure again to confirm.

1

2

3

4

Page 39

39

6.3 Perpendicularity of circular vial to vertical axis

Inspection

Confirm if the bubble of the circular vial is in the center after

the inspection and adjustment of [6.2 Plate vial].

No adjustment is necessary if the bubble of the circular vial is

in the center but if not, the following adjustment is required.

Adjustment

Move bubble to the center by rotating the bubble adjusting

screws, using the adjusting pin.

Inspect again.

1

2

1

2

Circular vial

Bubble adjusting screws

Page 40

40

6.4 Inclination of reticule graduations

Inspection

Set an object point A on the line of sight through the telescope.

Move point A to the edge of the field of view by adjusting the

telescope tangent screw (point A’).

No adjustment is necessary if point A moves along the vertical line of

the reticule. If the point A does not move along the vertical line of the

reticule, it needs adjustment - Consult with your dealer.

1

2

3

A'

Ver tical line

Line of sight axis

Page 41

41

6.5 Perpendicularity of line of sight to horizontal axis

Inspection

Set an object (point A) at a distance of 30 to 50m away from the

instrument and sight it through the telescope.

Loosen the telescope clamp screw and reverse the telescope around

the horizontal axis. Mark a point set on the line of sight at about the

same distance to the object point A, and call it point B.

Loosen the horizontal clamp screw, and rotate the instrument around

the vertical axis. Sight point A again.

Loosen the telescope clamp screw,and reverse the telescope around

the horizontal axis. Mark a point on the line of sight at about the same

distance as point B, and call it point C.

No adjustment is necessary if point B and C coincide,

but if it does not - Consult with your dealer.

1

2

4

5

3

Page 42

42

6.6 Difference of the vertical angle

Inspection

Set the vertical angle in Zenith 0° mode

Sight an object (Point P) with the telescope and read the vertical

angle (V correct).

Reverse the telescope and rotate the alidade.

Sight point P again in the reverse position and

read the vertical angle (V reverse).

At this time, when (V correct + V reverse - 360°)/2 is less than 15”,

it is within tolerance. If it shows a larger value,

it needs adjustment - Consult your dealer.

1

2

4

5

3

Page 43

43

6.7 Optical plummet

Inspection

Place a piece of white paper,with a cross drawn on it,directly under

the instrument.

Look through the optical plummet, and move the paper so that the

intersecting point of the cross comes to the center of the field of view.

Adjust the leveling screws so that the center mark of the optical

plummet coincides with the intersection point of the cross.

Rotate the instrument around the vertical axis. Look through the

optical plummet each step of 90° rotation, and observe the center

mark position against the intersection point of the cross.

If the center mark always coincides with the intersection point, no

adjustment is necessary.When it does not coincide,the following

adjustments are required.

Adjustment

Remove the cover of the optical plummet.

Mark the point set on the line of sight at each step of 90° on the

white paper and call them A,B, C and D.

Join the opposed points (A, C and B, D) with a straight line,and set

intersecting point 0.

Turn four optical plummet adjusting screws with the adjusting pin so

that the center mark coincides with the intersection point 0.

Repeat procedure again to confirm.

Optical plummet adjusting screw

5

1

2

3

4

5

1

2

3

4

Center mark

Point

Cap of optical plummet

Adjusting pin for the center mark

Page 44

44

7. Optional Accessories

7.1 Diagonal Eyepiece (SB14)

The Diagonal eyepiece can be attached to the telescope for convenience

in observing the zenith or when in confined spaces.

<Installation>

Turn the telescope eyepiece ring counterclockwise to remove

the eyepiece.

Be sure to hold the eyepiece, securely,so that you do not drop it.

Attach the diagonal eyepiece to the telescope by reversing

the procedure.

The diagonal eyepiece can be rotated through 360°.

When sighting through the telescope with the diagonal eyepiece

attached, the reticule may be seen deflected vertically or horizontally,

but this has no influence upon accuracy.

1

Page 45

45

8. Specifications

Telescope

Magnification 30 X

Effective aperture 45 mm

Resolving power 3”

Field of view 1° 30’

Minimum focus distance 1.35 m

Stadia ratio 100

Stadia constant 0

Angle Measurement

Type Incremental rotary encoder

Detection mode V. angle: Single

H. angle: Dual

Minimum Display (Selectable)

ETH-302 1”/5”

ETH-305 1”/5”

ETH-310 5”/10”

ETH-320 10”/20”

Accuracy (DIN18723, Standard deviation)

ETH-302 2”

ETH-305 5”

ETH-310 10”

ETH-320 20”

Ver tical Angle Compensation

Method Automatic compensation

Stadia Ratio 100

Stadia Constant 0

Display

Type Dot matrix LCD/Two lines

Display panel Dual display

Page 46

46

Ver tical axis

Single

Sensitivity of vials

Plate vial

ETH-302 30”/2 mm

ETH-305 30”/2 mm

ETH-310 40”/2 mm

ETH-320 40”/2 mm

Circular vial 8’

Tribrach type

Detachable

Optical plummet

Magnification 3 x

Focusing range 0.5 m to Infinity

Power source

Type 4 x AA dry battery

Operation time (Alkaline) 25 to 28 hrs.

(NiMH2300mAh) 25 to 28 hrs.

Water resistant

IP x4

Ambient temperature

- 10 °C to + 50 °C

Height

215 mm

Dimensions

Instrument (including batteries) W168 x H330 x L158mm/4.6kg

Page 47

Page 48

certified

Printed in Belgium

Member s ym bol of the Japan Surveying

Instruments Manufacturers’ Association

representing the high quality surveying

products.

2-5-2 Higashi-Oizumi

Nerima-ku, Tokyo 178-0063,Japan

Tel.:+81-3-5905-1222

Fax: + 81-3-5905-1225

E-mail:international@piic.pentax.co.jp

PENT

PENT

X Industr

ial Instr

umen

ts C

Lt

AX Industr

ial Instr

umen

The CE marking assures that

this product complies with

the requirements of the EC

directive for safety.

ts C

o., Lt

d.

Loading...

Loading...